Preparation method of curtain cloth with mosquito repellent effect

A technology of efficacy and curtains, applied in the field of textile fabrics, can solve the problems of difficulty in enjoying the refreshing feeling of natural wind, low strength of screen windows and screen doors, rampant mosquitoes, etc., to achieve good mosquito repellent effect, outstanding practical performance, and process Arrange for a reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

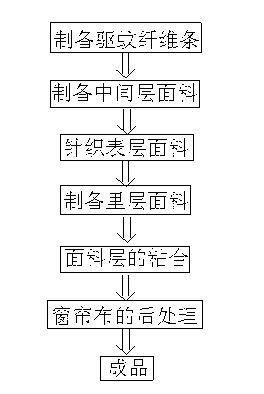

Image

Examples

Embodiment 1

[0018] Concrete preparation process is as follows:

[0019] a) Prepare mosquito repellent fiber strips. The base material of mosquito repellent fiber strips is natural cotton sliver, and the preparation process is dipping treatment; the preparation process of mosquito repellent fiber strips is as follows: first, the natural cotton sliver is immersed in the reaction of holding mosquito repellent liquid Heating in the kettle, the temperature is controlled at about 50°C; then, the soaking time is controlled to 22 hours, and the fiber strips are turned and squeezed every 6 hours to fully integrate the mosquito repellent liquid with the fiber strips; then, take out the fiber strips, Wash in clean water at 30°C for 15 minutes, and dehydrate in a centrifugal dehydrator; finally, put the fiber strips into an oven for drying treatment, the temperature of the oven is controlled at 60°C, and the time is 25 minutes to remove excess additives , stabilize the performance of fiber strips; th...

Embodiment 2

[0026] Concrete preparation process is as follows:

[0027] a) Prepare mosquito repellent fiber strips, the base material of mosquito repellent fiber strips is natural cotton sliver, and the preparation process is dipping treatment; the preparation process of mosquito repellent fiber strips is as follows: first, immerse the natural cotton sliver in a container containing mosquito repellent liquid Heating in the reaction kettle, the temperature is controlled at about 55°C; then, the soaking time is controlled to 22 hours, and the fiber strips are turned and squeezed every 6 hours to fully integrate the mosquito repellent liquid with the fiber strips; then, take out the fiber strips , washed in clean water at 30°C for 20 minutes, and dehydrated in a centrifugal dehydrator; finally, put the fiber strips into an oven for drying treatment. The temperature of the oven is controlled at 65°C for 20 minutes to remove excess auxiliary agent to stabilize the performance of fiber strips; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com