Composite conductive elastic fiber

An elastic fiber and composite conductive technology, applied in the direction of conductive/antistatic filament manufacturing, conjugated synthetic polymer artificial filament, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

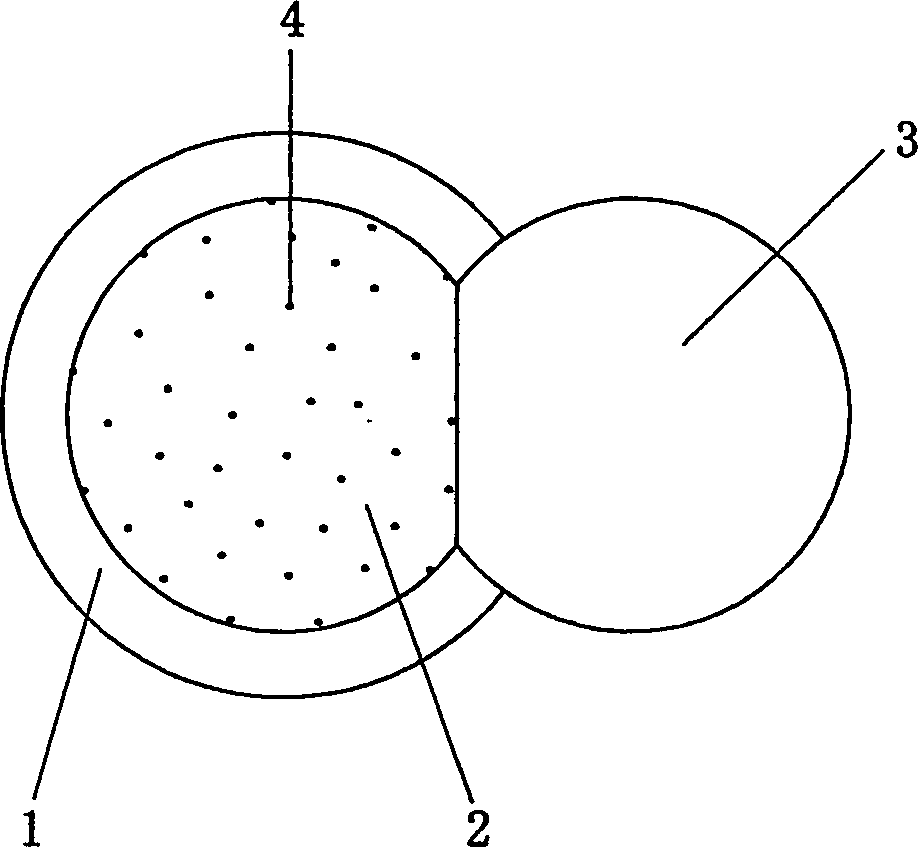

[0022] Water-soluble polyester is input into the skin layer screw extruder as component one, carbon black masterbatch and PET are blended as component two into the core layer screw extruder, PTT is component three input into the parallel partial screw extruder, and the Three-component composite melt spinning. Wherein the weight ratio of component one: component two: component three is 5:50:45, and the weight ratio of carbon black fine powder to component two is 4096. The metering pumps are respectively metered and input into the spinning box, extruded by the composite spinneret assembly with a specific structure, and the filaments of the three-component composite fiber are obtained through post-spinning treatment.

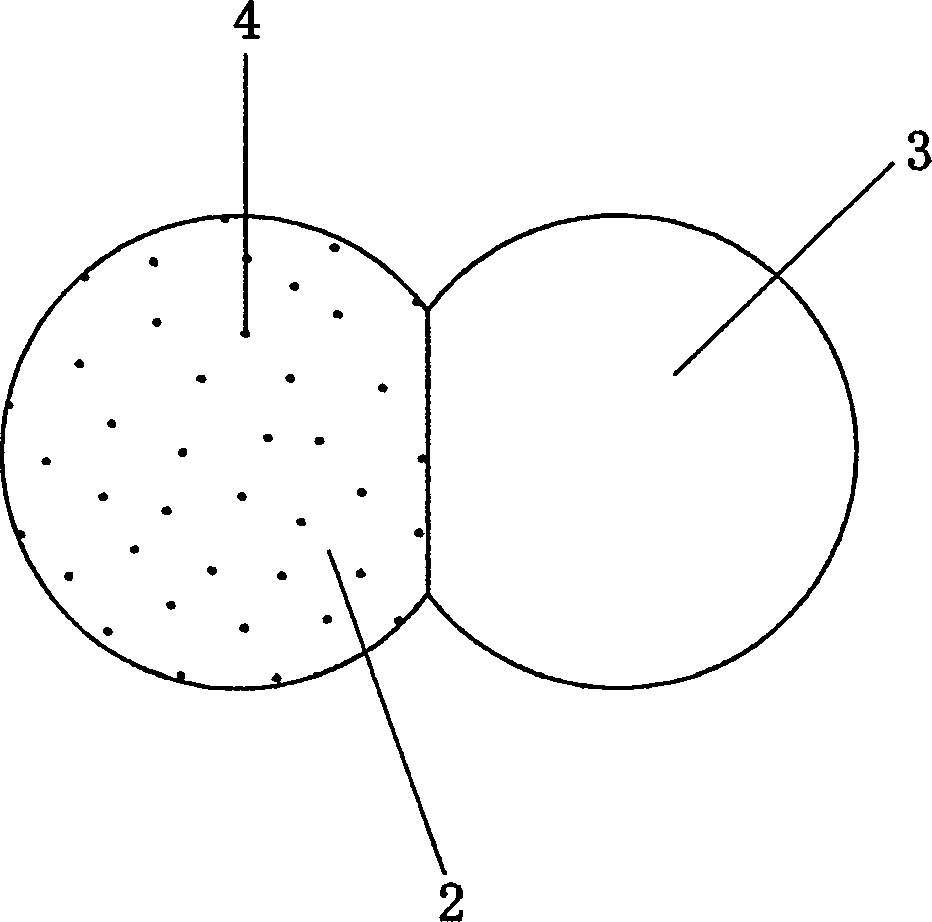

[0023] The fiber is applied to the fabric, and the water-soluble polyester is removed after being treated with an alkali solution of appropriate concentration and temperature for a certain period of time to form a conductive elastic fiber filament with a parallel c...

Embodiment 2

[0025] Water-soluble polyester is input into the skin layer screw extruder as component one, metal compound masterbatch and PET are blended as component two into the core layer screw extruder, and PBT is input into the parallel partial screw extruder as component three, and the Three-component composite melt spinning. The weight ratio of component one:component two:component three is 10:60:30, and the weight ratio of conductive powder to component two is 3096. The metering pumps are respectively metered and then input into the spinning box, extruded by the composite spinneret assembly with a specific structure, and the staple fiber of the three-component composite fiber is obtained after spinning.

[0026] The fiber is applied to the fabric, and after being treated with an alkali solution of appropriate concentration and temperature for a certain period of time, the water-soluble polyester component is removed to form a conductive elastic fiber staple with a PBT / PET side-by-si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com