Patents

Literature

121results about How to "Avoid backlash" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

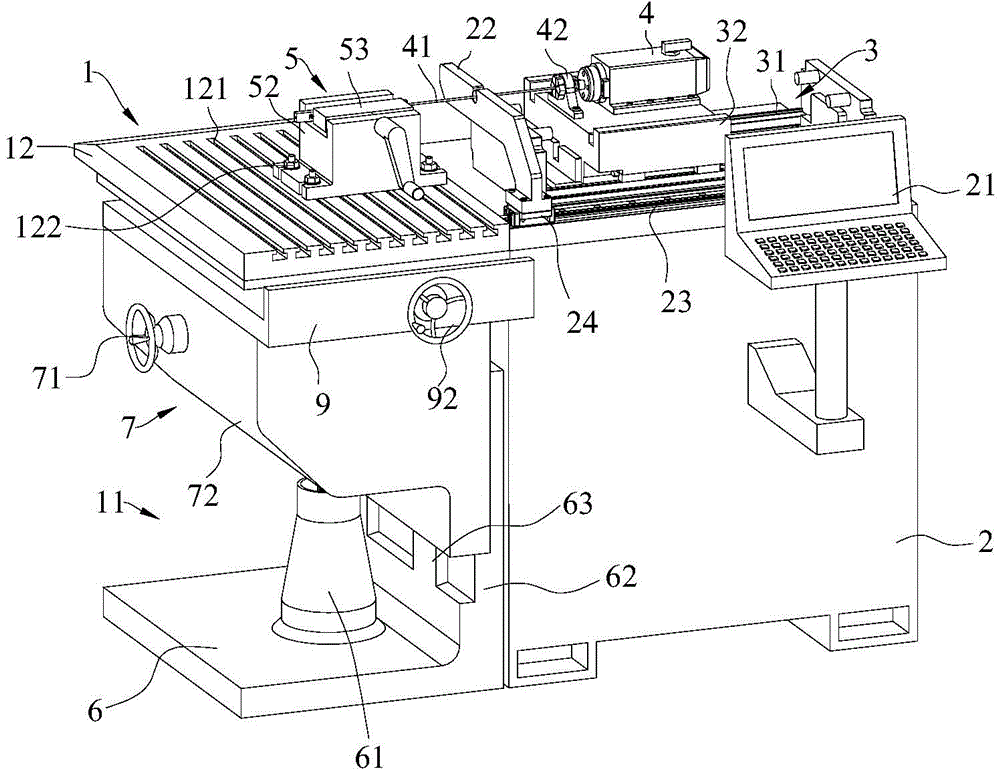

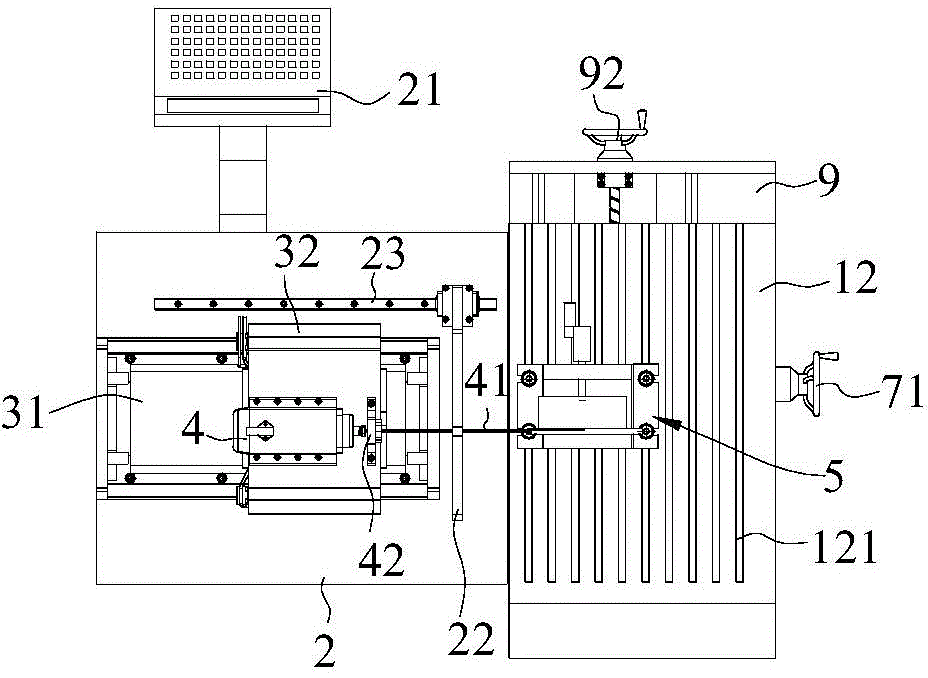

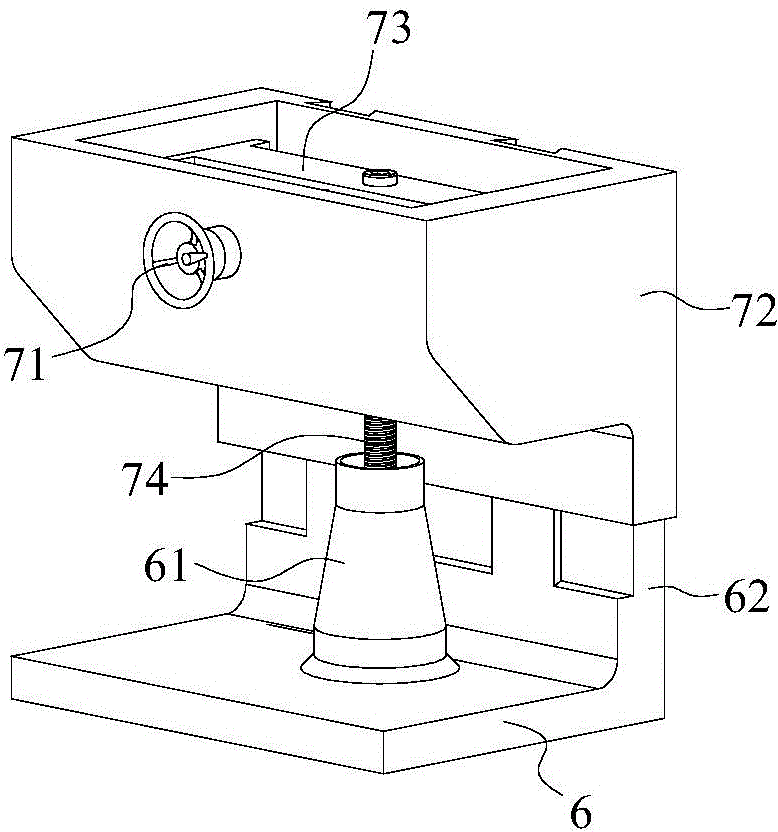

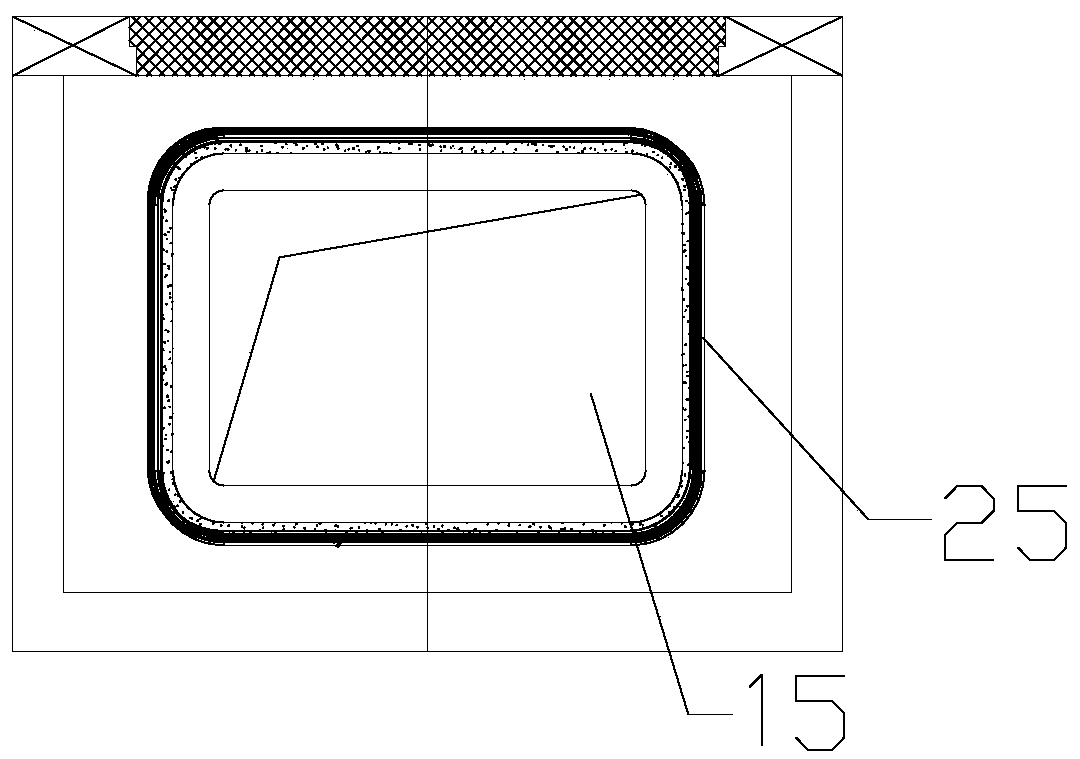

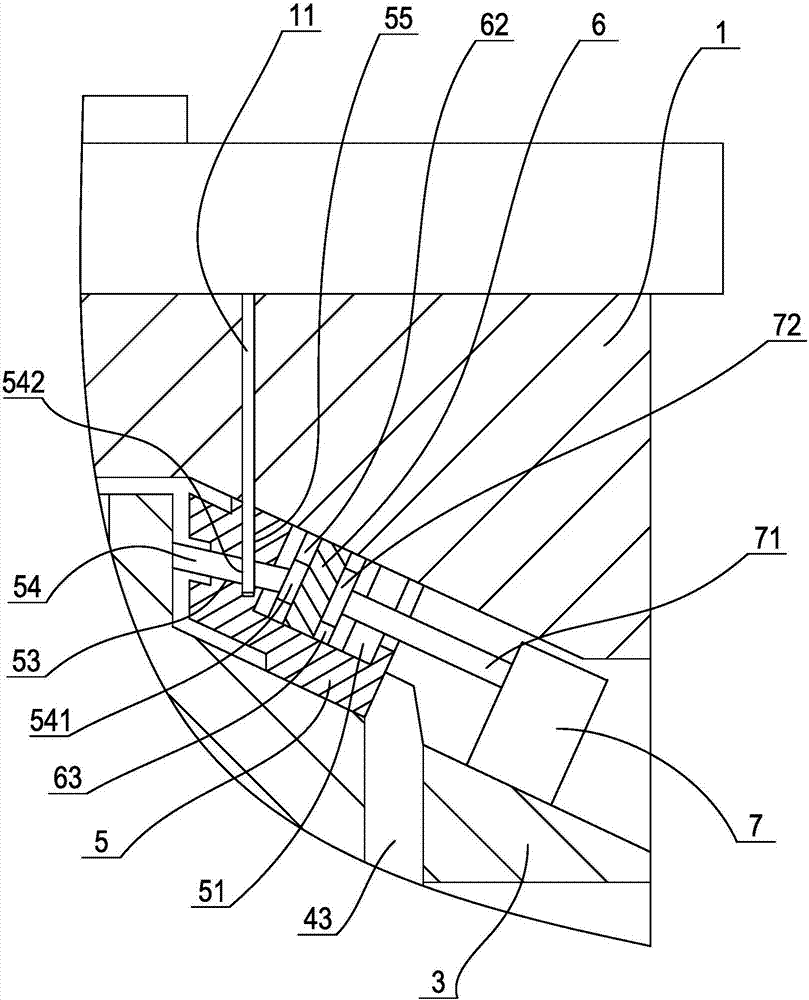

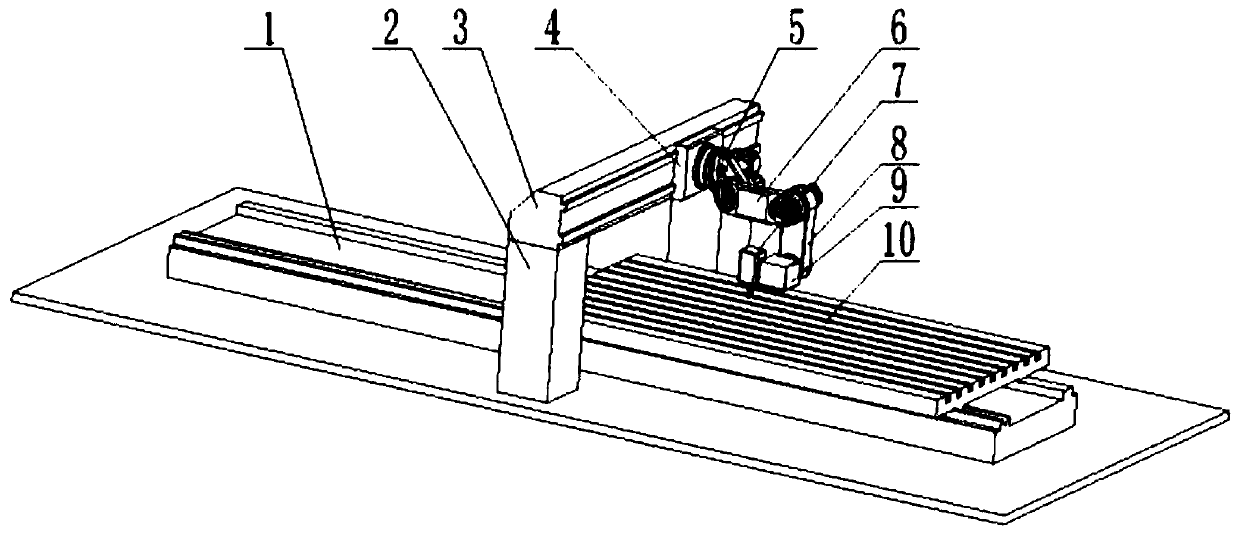

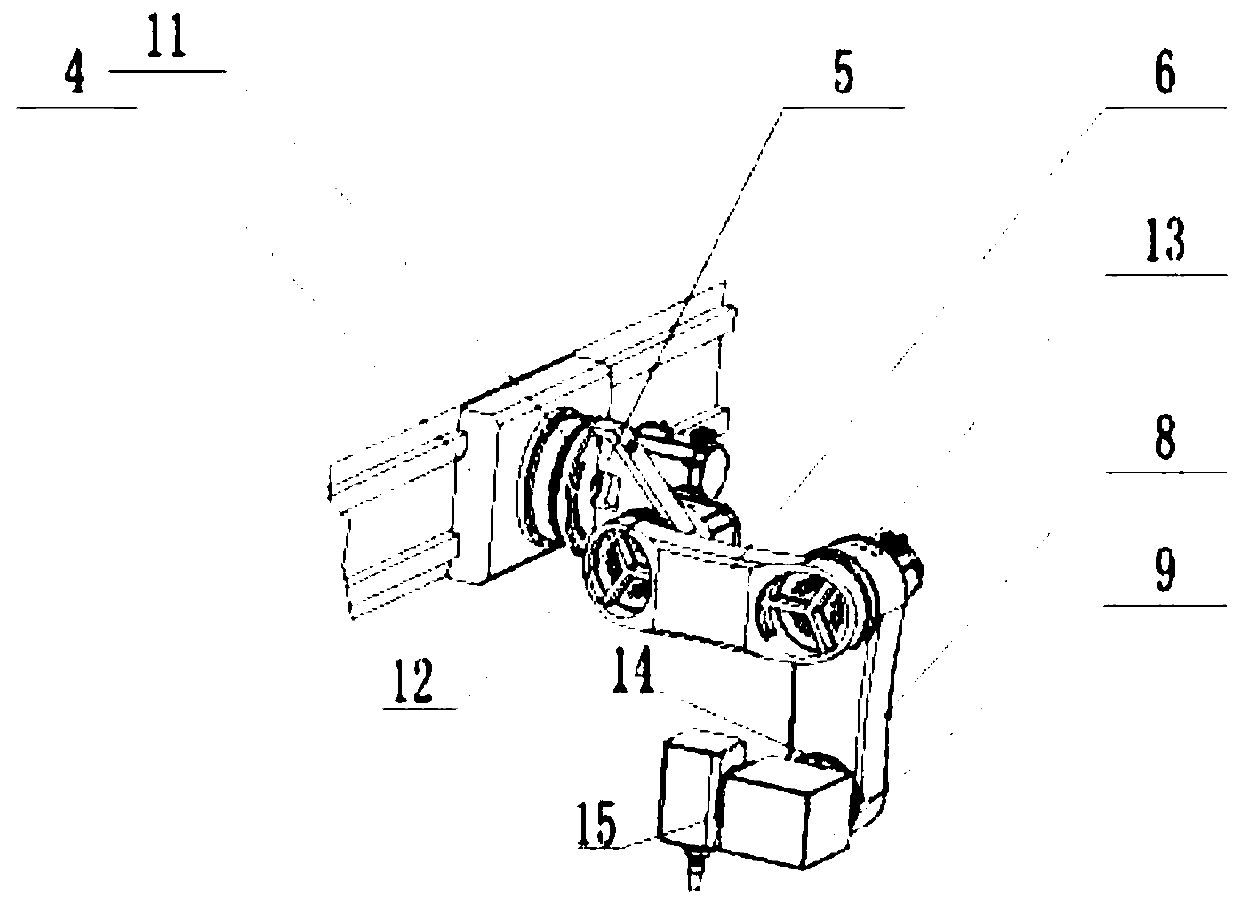

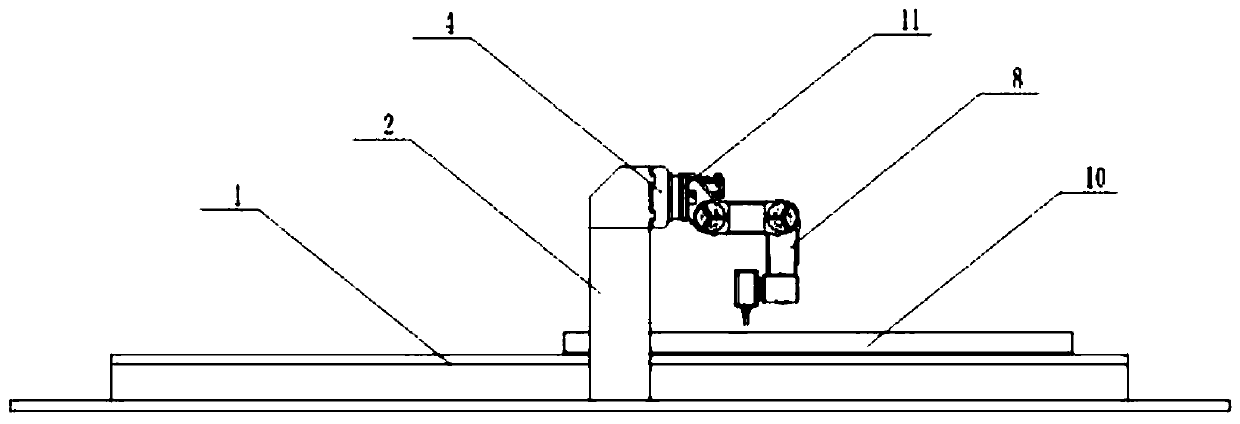

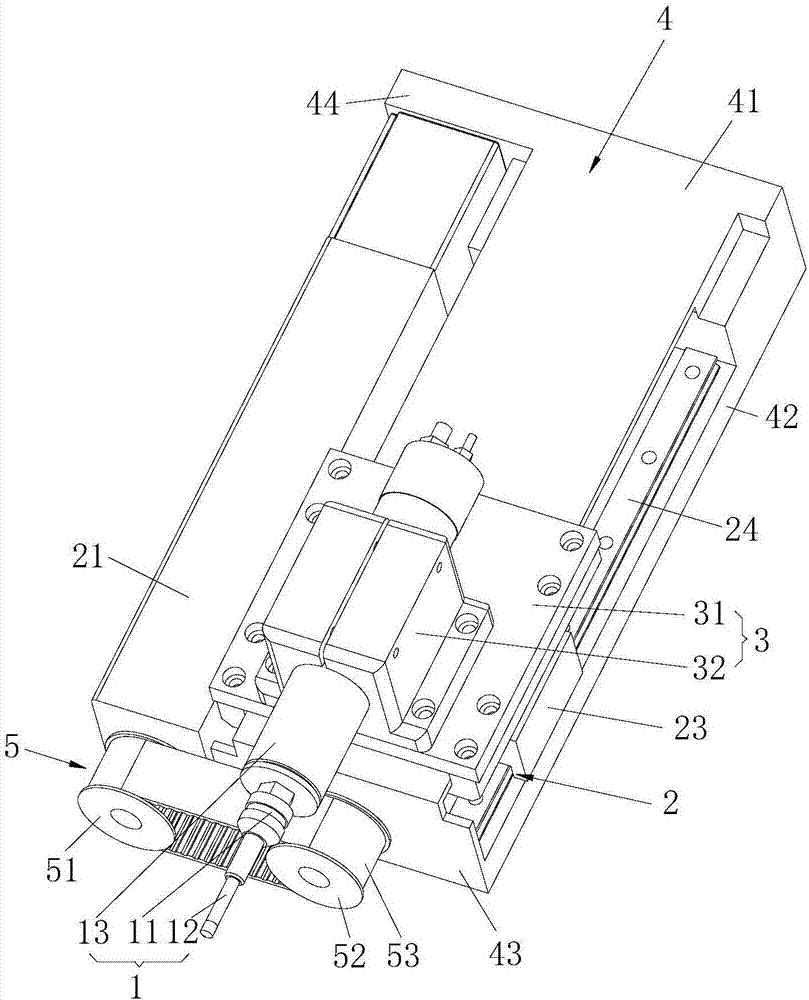

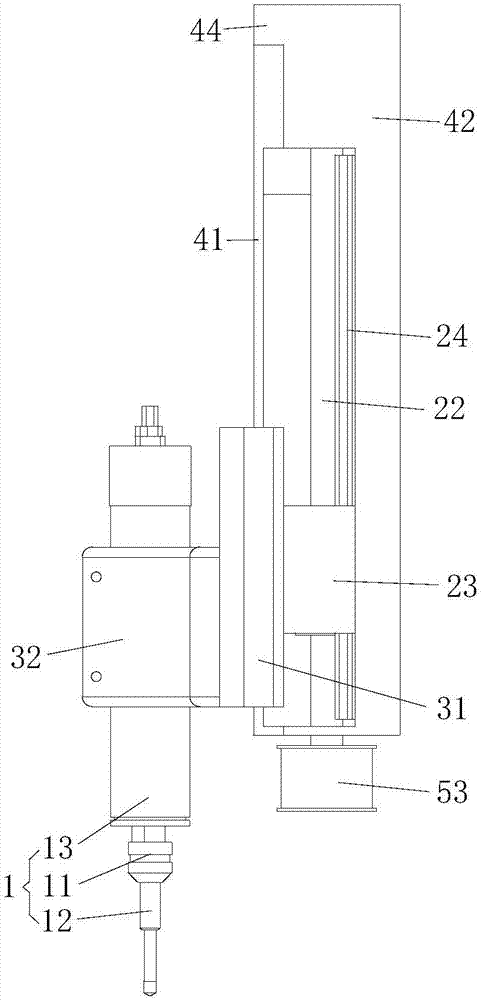

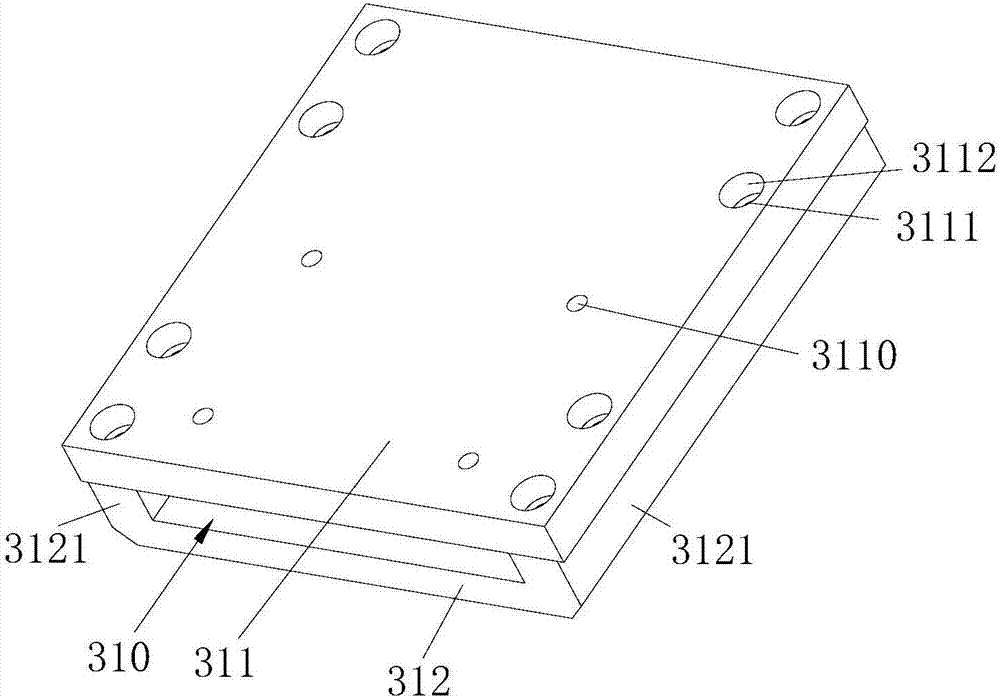

Numerical control precision micro-fine super-long deep hole drilling machine

InactiveCN104001967AAvoid noiseAvoid wear and tearFeeding apparatusLarge fixed membersHysteresisNumerical control

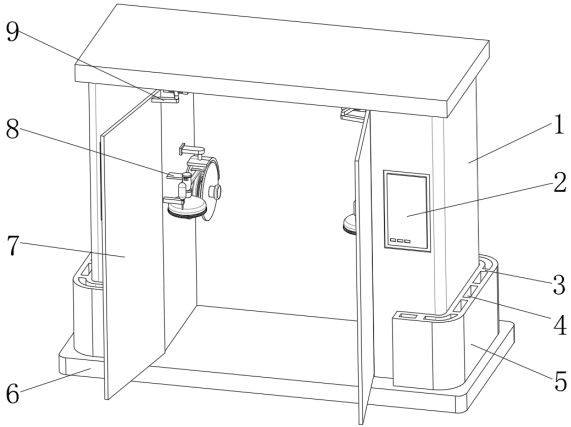

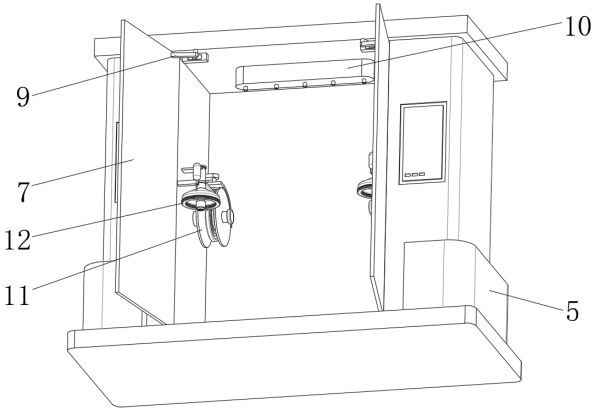

The invention discloses a numerical control precision micro-fine super-long deep hole drilling machine which comprises a workbench, a master control cabinet, a linear motor and a servo motor. An output shaft of the servo motor is provided with a drilling bit. The linear motor comprises a primary part installed on the master control cabinet and a secondary part where the servo motor is installed. The secondary part drives the servo motor to move so as to enable the drilling bit to stretch out or retract back above the workbench. The workbench comprises a lifting base and a workbench top arranged on the lifting base. A clamp for fixing a workpiece is installed on the workbench top. According to the numerical control precision micro-fine super-long deep hole drilling machine, the linear motor is used as a feeding power source of the drilling bit, intermediate transmission links such as a gear, a worm gear pair, a belt, a lead screw pair, a coupler and a clutch which are needed in an existing transmission chain from a motor used as a power source to a working component are abandoned, and rotational inertia, elastic deformation, a backlash, motion hysteresis, friction, vibration, noise and abrasion of the intermediate transmission links are avoided; the numerical control precision micro-fine super-long deep hole drilling machine is high in degree of automation, easy to operate, high in control precision, stable in motion, low in noise, long in service life, safe and reliable.

Owner:GUANGZHOU INST OF ADVANCED TECH CHINESE ACAD OF SCI

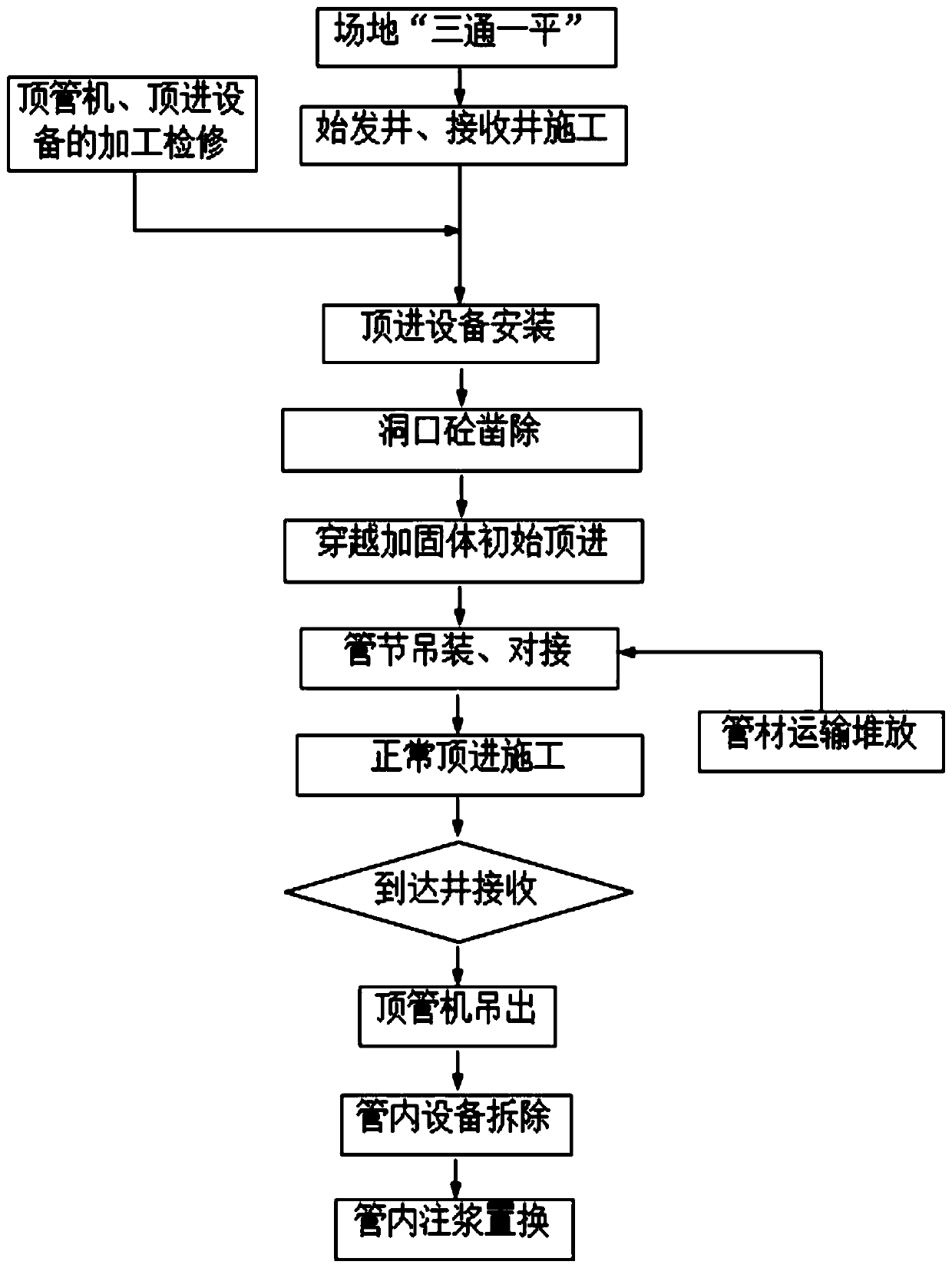

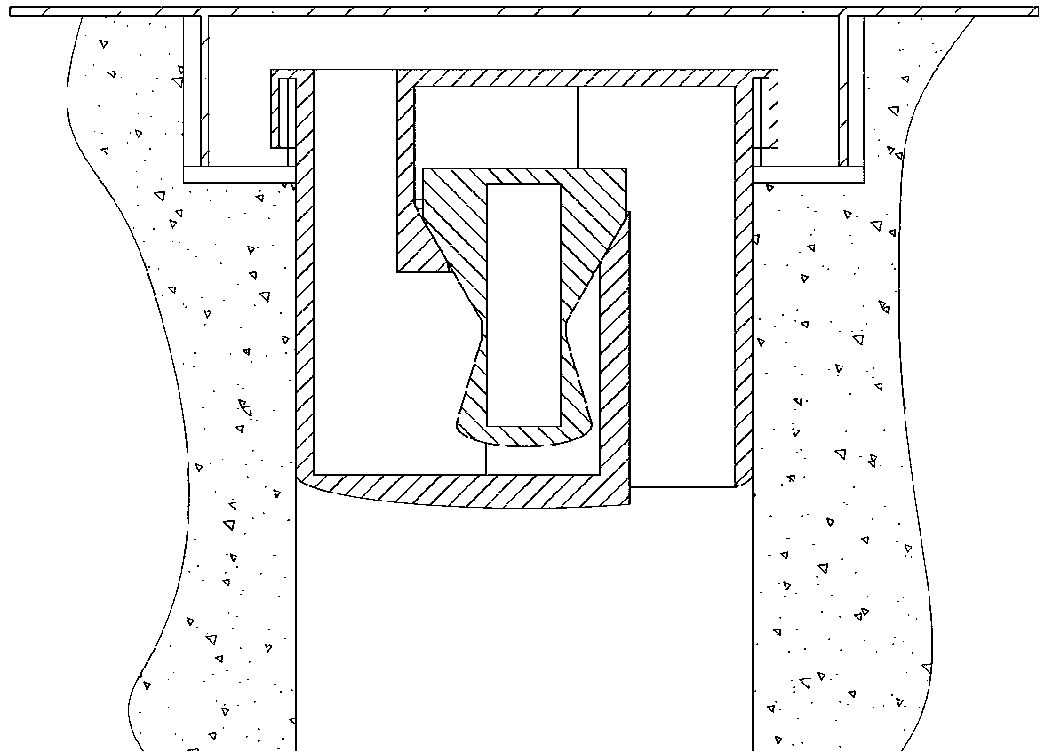

Rectangular pipe jacking construction method for outlet and inlet channel of subway station

ActiveCN111075474AReduce coefficient of frictionReduce frictional resistanceUnderground chambersTunnel liningLine tubingArchitectural engineering

The invention provides a rectangular pipe jacking construction method for an outlet and inlet channel of a subway station. The construction method specifically comprises the steps of constructing an initial well and a receiving well, calculating and determining jacking parameters, smearing wax on the outer wall of a pipe before jacking, connecting a head of a pipe jacking machine and three adjacent pipe sections into a whole during jacking, simultaneously injecting pressure injection thixotropic slurry into the back of the pipe sections in the jacking process, and arranging a stopping device to prevent the pipe jacking machine from retreating; erecting a receiving platform to receive the pipe jacking machine, after the jacking construction is finished, plugging pipe section gaps and the gaps between the pipe sections and two end openings, and finally adding cement slurry to replace the thixotropic slurry to consolidate a pipe jacking channel. It is ensured that the underground pipelinedoes not settle, crack, leak or the like, and compared with construction of a traditional open excavation method, the construction method has the advantages of small environmental impact, safe construction, simple operation, single procedure, low manufacturing cost, cost saving and good popularization significance.

Owner:URBAN MASS TRANSIT ENG CO LTD OF CHINA RAILWAY 11TH BUREAU GRP +1

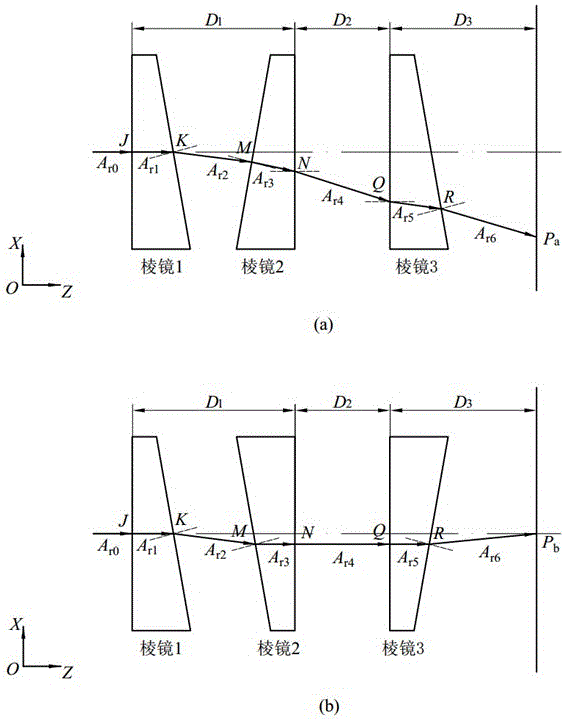

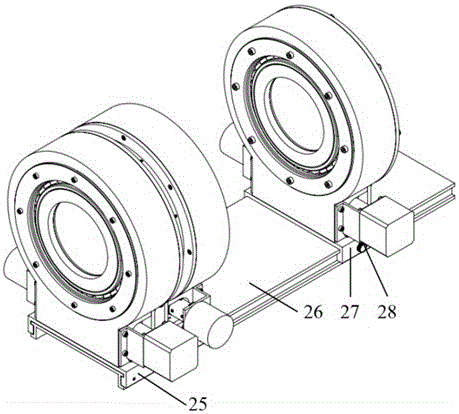

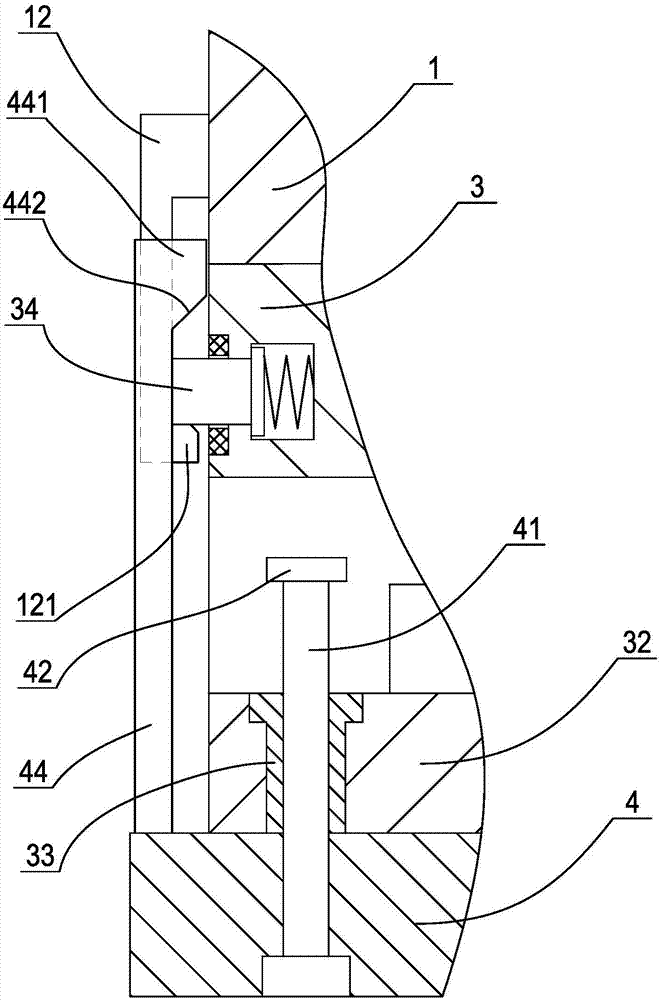

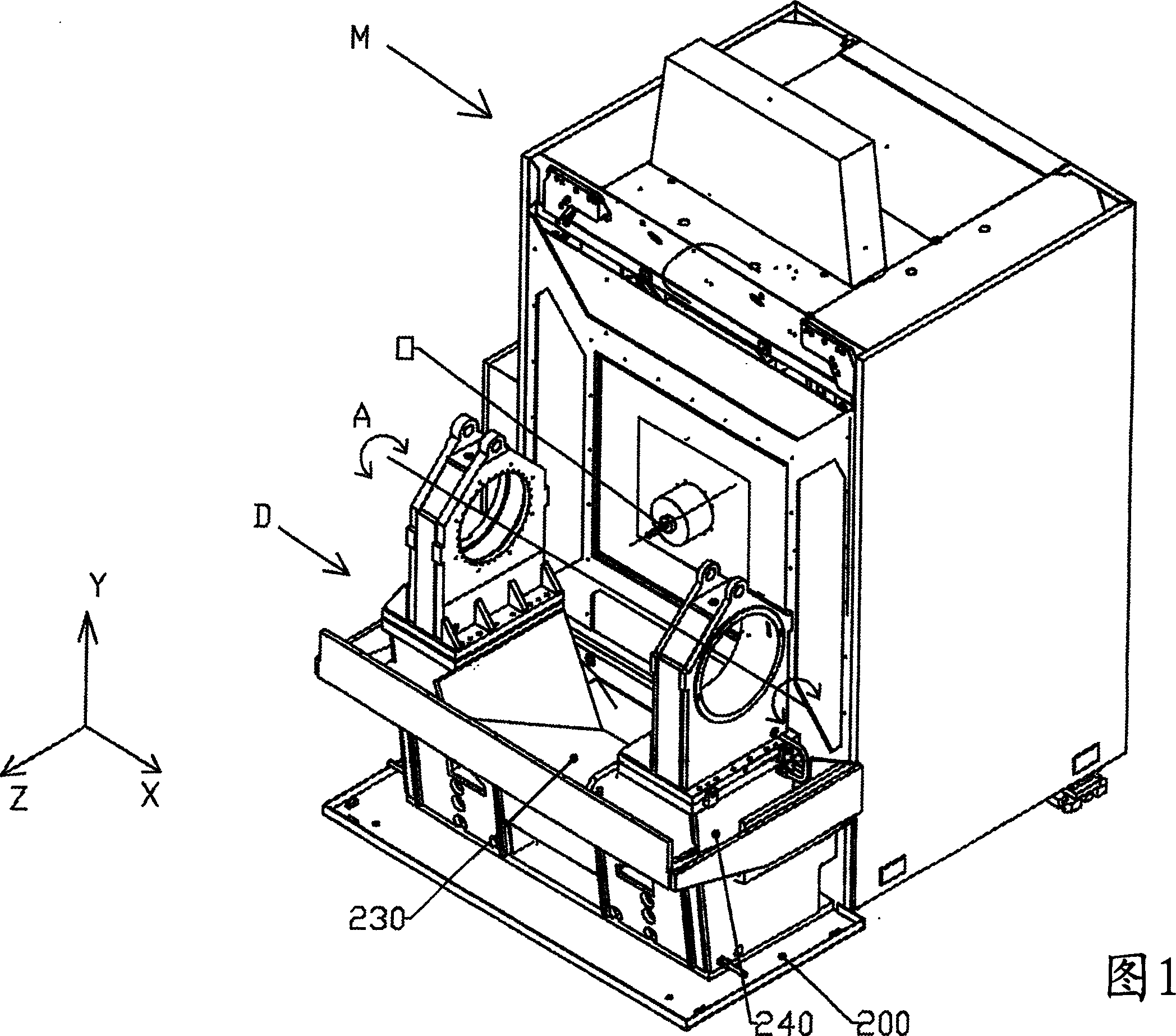

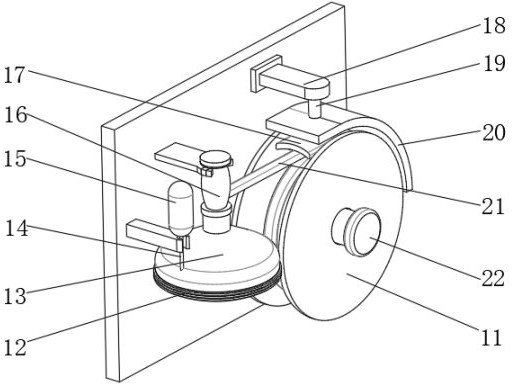

Rotating triple-prism beam scanning device

InactiveCN106249405AControl rotation angleAvoid empty backOptical elementsCouplingRolling-element bearing

The invention relates to a rotating triple-prism beam scanning device comprising a rotating double-prism system, a rotating single-prism system, a guide rail, an adjustable support, and a fixed support. The rotating single-prism system comprises a base component, a prism and frame assembly, and a worm-and-gear mechanism. The prism and frame assembly comprises a flat washer, a wedge prism, a rubber pad, a wedge retainer ring, a threaded retainer ring, and a frame. The base component comprises a base, a base baffle, and a base insert. The worm-and-gear mechanism comprises a rotary motor, a motor stand, a coupling, a worm, a bearing support, a rolling bearing, a worm gear, an encoder support, and a rotary encoder. The rotating double-prism system is formed by assembling two rotating single-prism systems together. In the invention, the three wedge prisms are driven by the worm-and-gear mechanisms to do full-circumferential rotation, transmission is stable and accurate, and the scanning precision and stability of dynamic beams can be ensured; the prisms are independent of one another in rotation control, and diversified scanning modes can be achieved; and by introducing the third prism to the double-prism system, the scanning field of beams is enlarged significantly, and the problem that a double-prism system has scanning blind areas and control singular points is solved effectively.

Owner:TONGJI UNIV

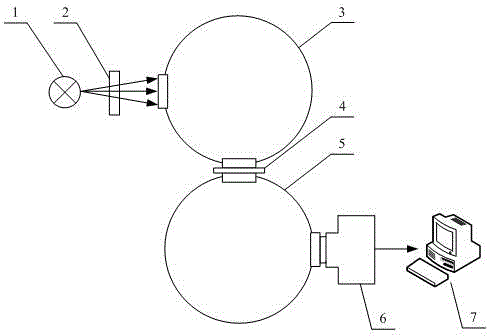

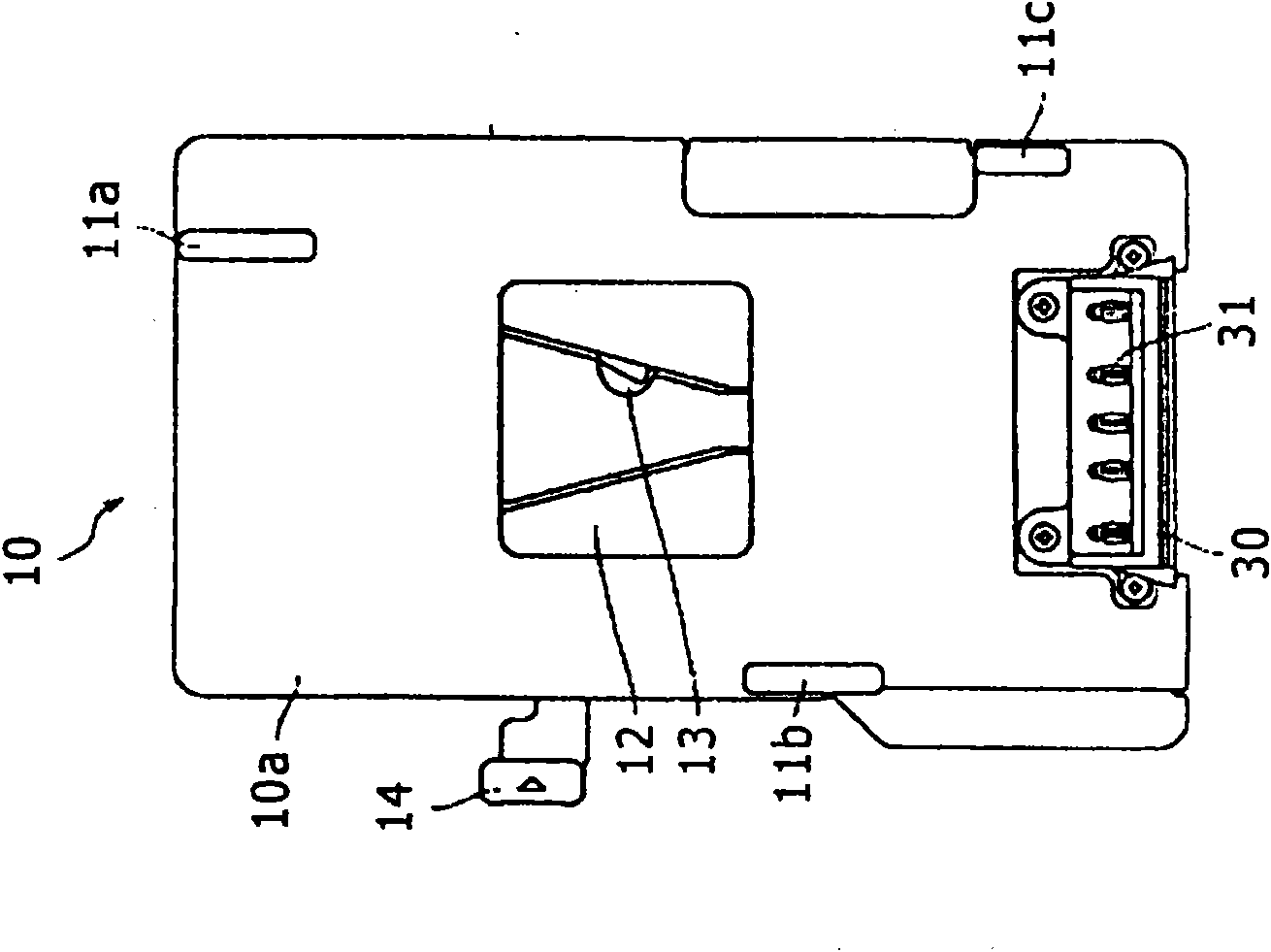

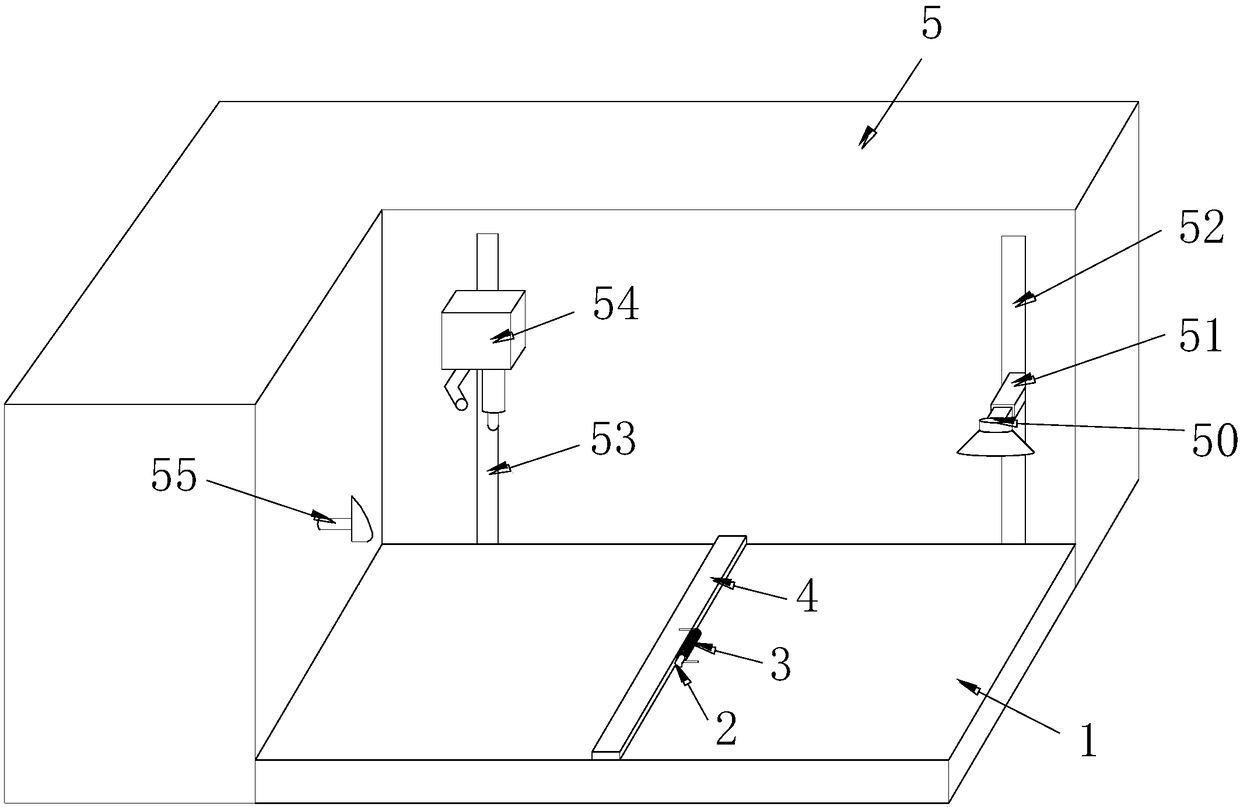

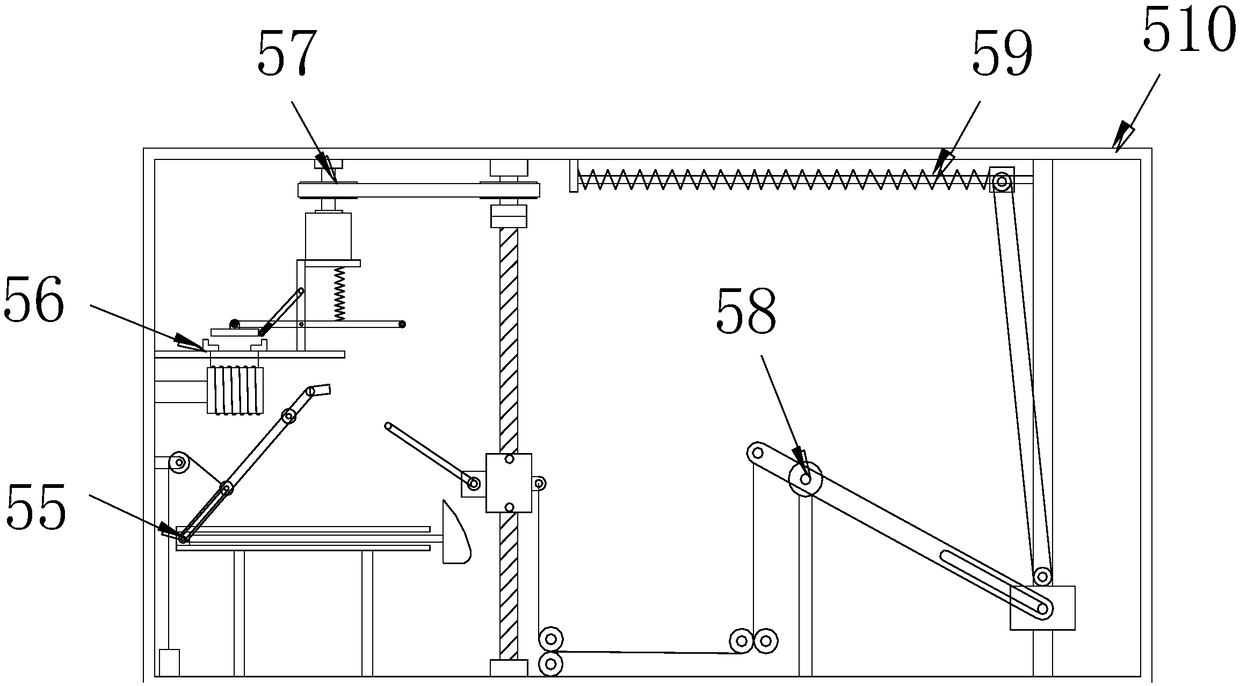

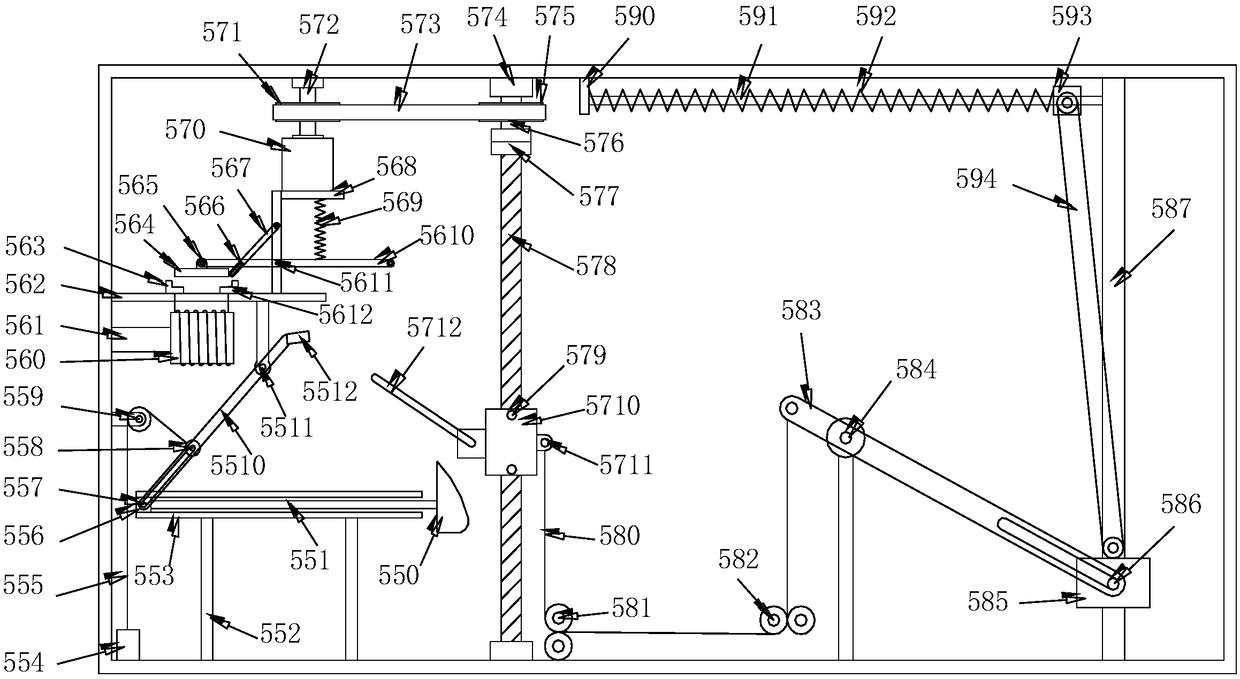

Test system and test method for signal-noise ratio of low-light ICCD (Intensified Charge Coupled Device)

ActiveCN104634449AAvoid backlashImprove stabilityPhotometry electrical circuitsSpecific testEngineering

The invention discloses a test system and a test method for a signal-noise ratio of a low-light ICCD (Intensified Charge Coupled Device) and relates to the test system and the specific test method for the signal-noise ratio. The test method comprises the following steps of putting ICCD in a dark box, irradiating ICCD by using uniform light, applying working voltage to the ICCD and enabling the ICCD to work normally; adjusting a gradient wedge diaphragm and an aperture-variable diaphragm to change intensity of illumination, and collecting image signals of ICCD to obtain an average signal value and a noise root-mean-square value; calculating the signal-noise ratio value of ICCD through data processing. The test method can scientifically evaluate the noise characteristic of ICCD and can be widely applied to development and production of low-light devices.

Owner:NANJING UNIV OF SCI & TECH

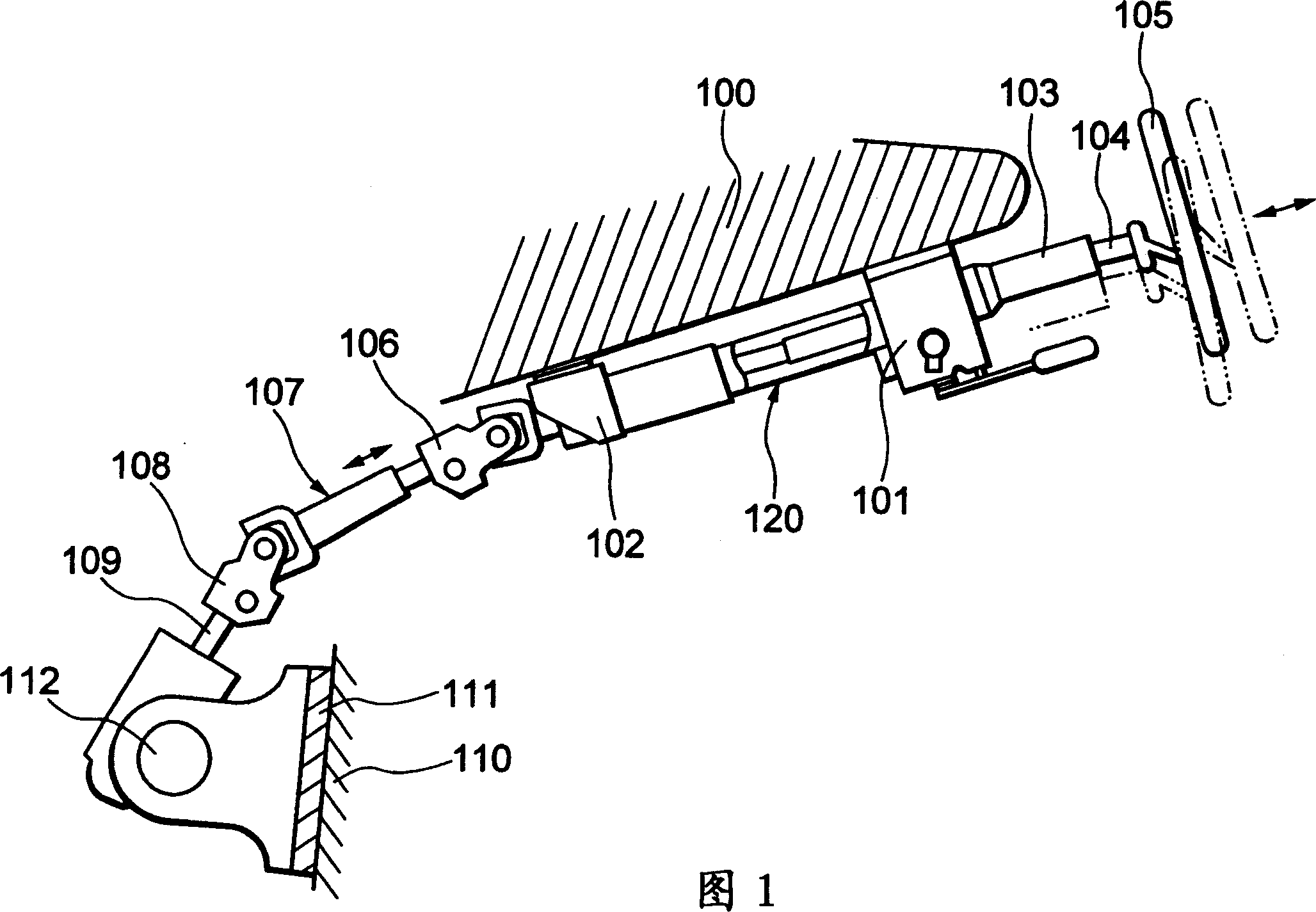

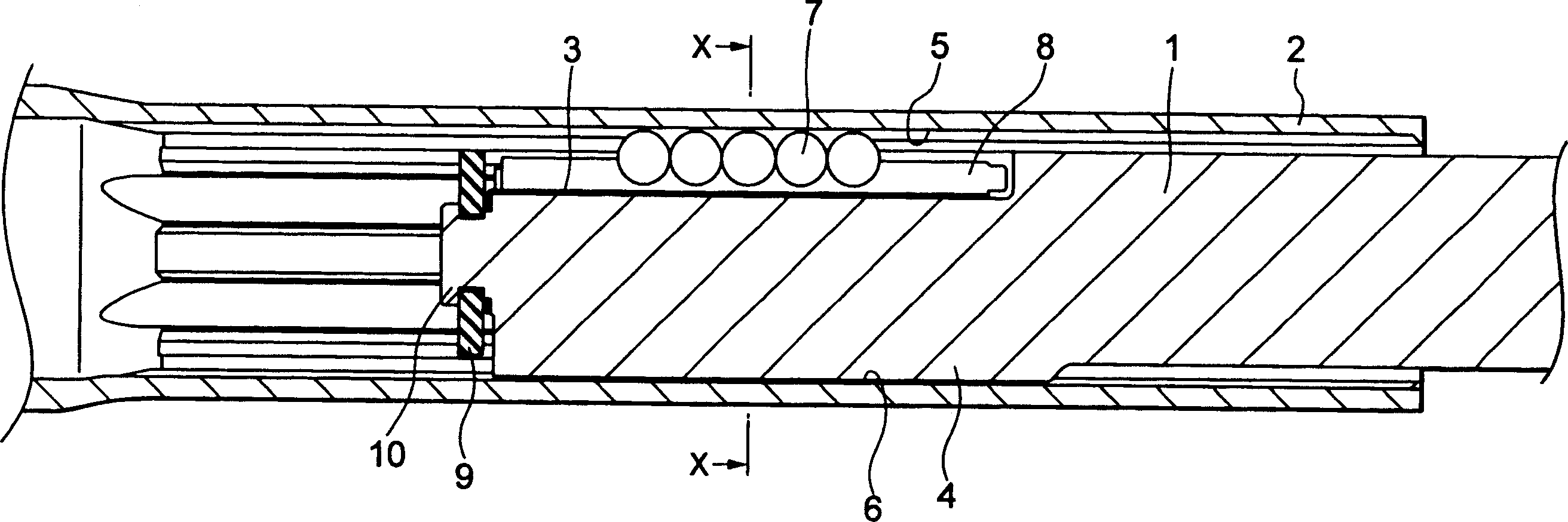

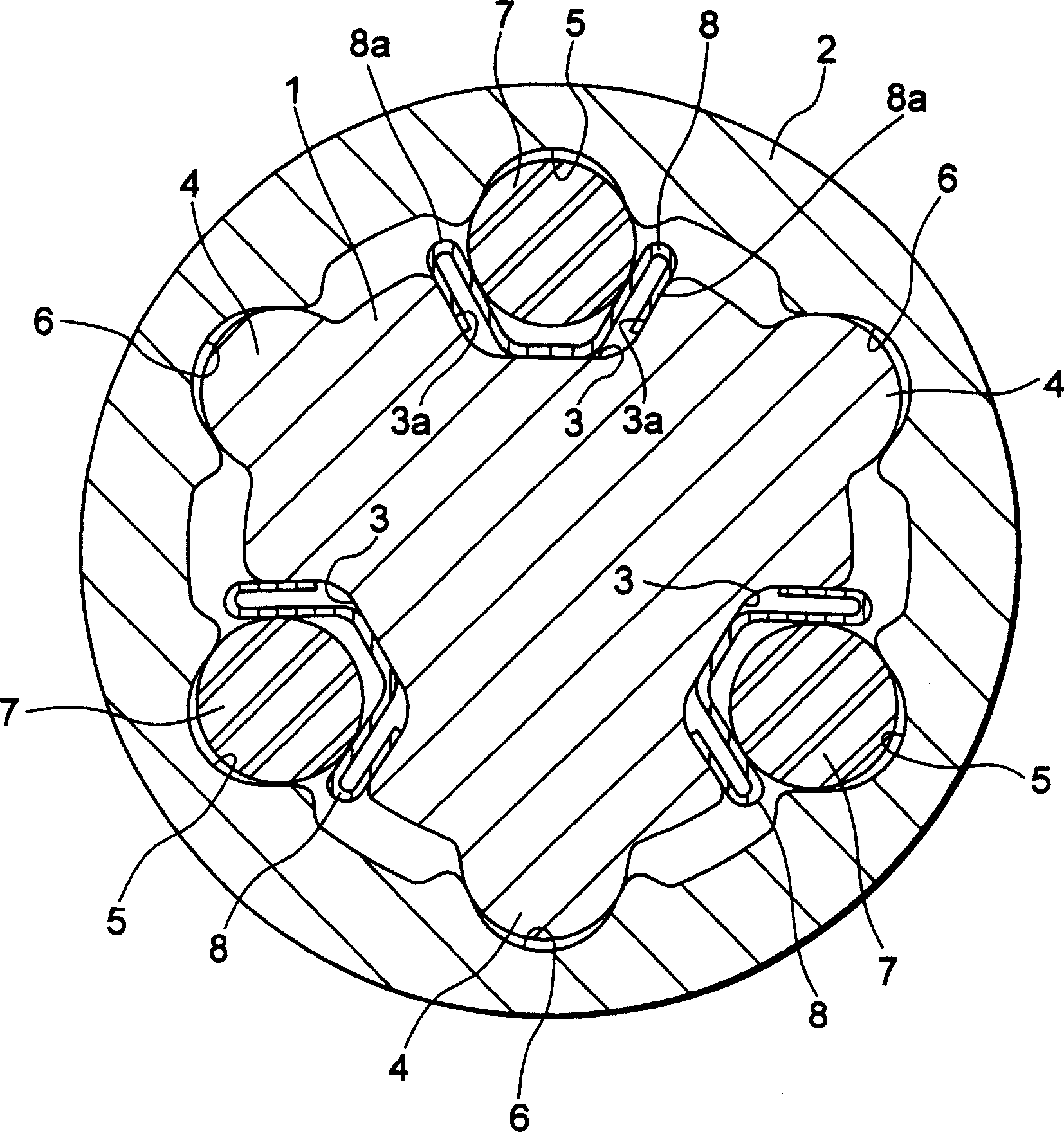

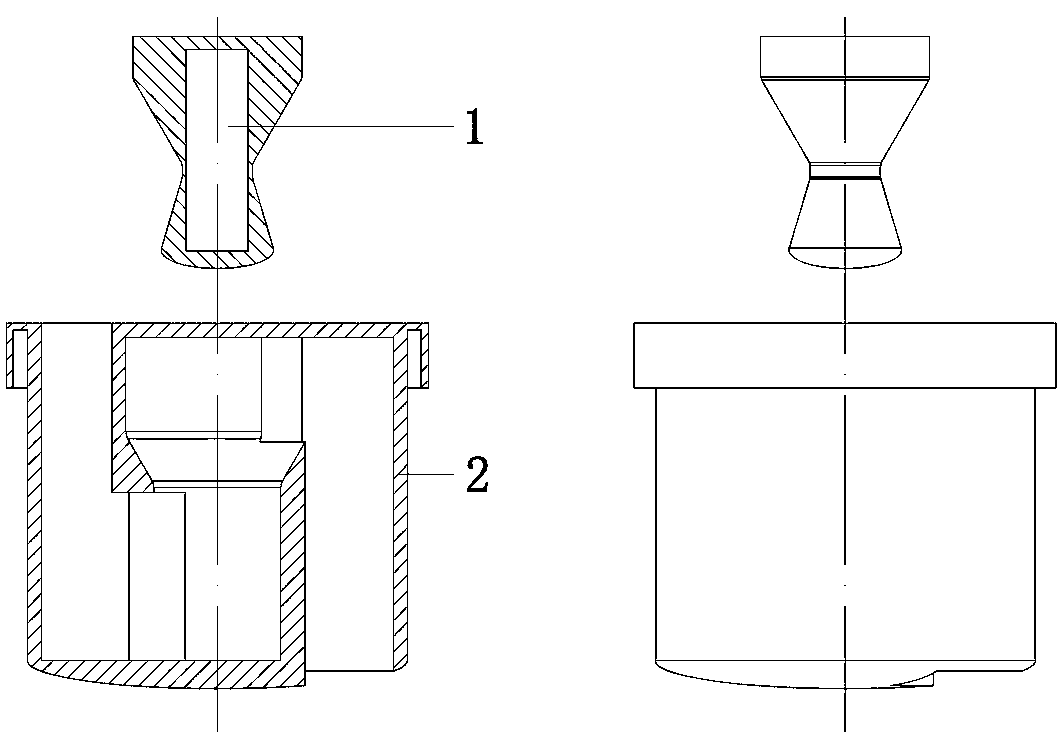

Vehicle steering telescopic shaft

InactiveCN1681697ASteady sliding loadAvoid backlashRoller bearingsYielding couplingControl theoryEngineering

A telescopic shaft for vehicle steering which is assembled in a steering shaft of a vehicle and in which a male shaft 1 and a female shat 2 are fitted to each other to be unrotatable and slidable, comprises torque transmitting portions respectively provided in an outer peripheral portion of the male shaft 1 and in an inner peripheral portion of the female shaft 2 for transmitting torque when they are mutually in contact to rotate; and preloading portions each consisting of a rolling member 7 provided between the outer peripheral portion of the male shaft 1 and the inner peripheral portion of the female shaft 2 at a position different from that of the torque transmitting portion for rotating when the male shaft and the female shaft are relatively moved in the axial direction and an elastic member 8 provided adjacently to the rolling member 7 in the radial direction for applying preload on the male shaft 1 and the female shaft 2 through the rolling member 7.

Owner:NSK LTD

Injection-molded part forming method requiring two stages of core pulling

Owner:SHENTONG TECH GRP CO LTD

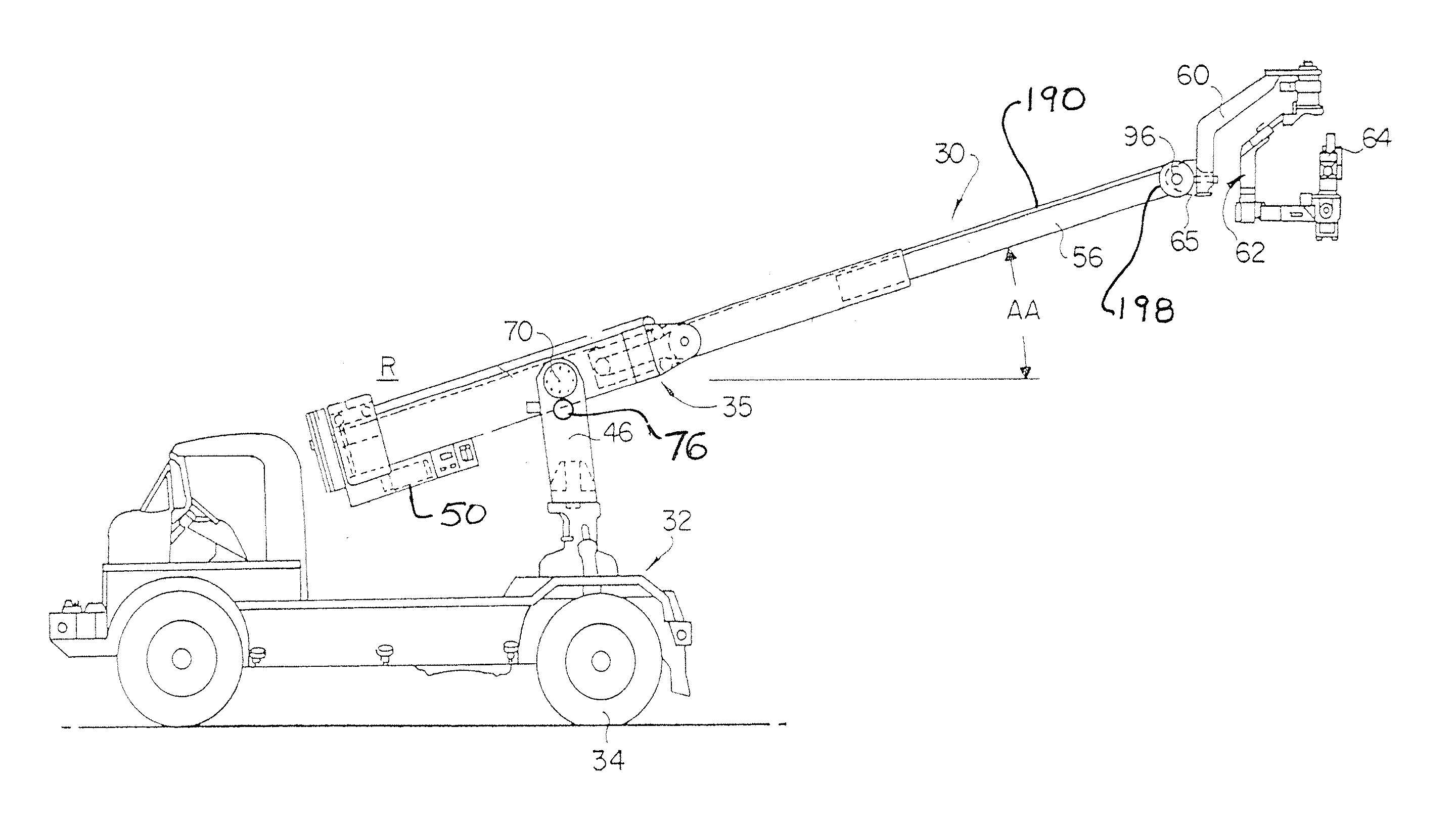

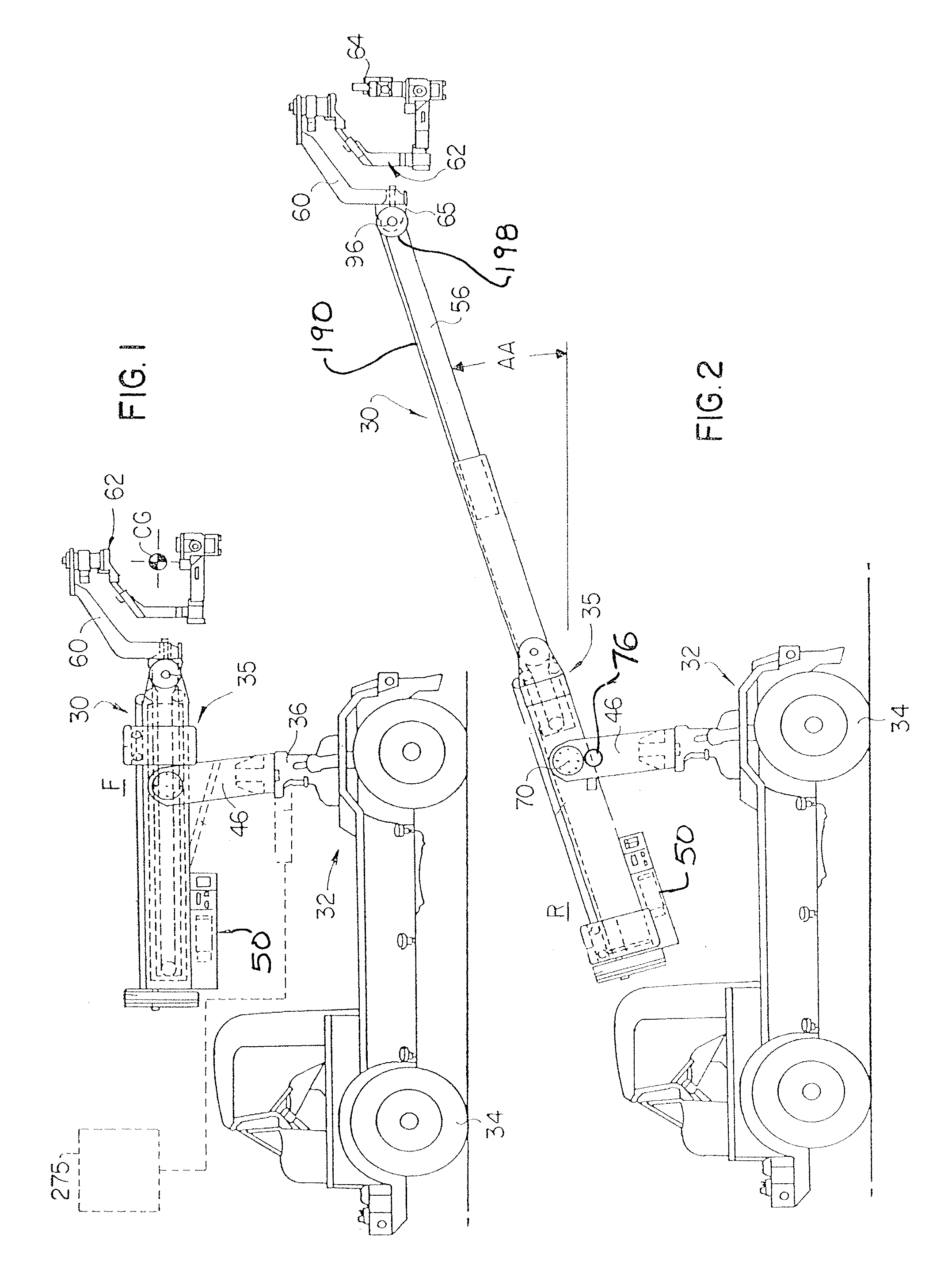

Camera platform stabilizing systems

ActiveUS20080002967A1Avoid backlashPrevent reboundLifting devicesStands/trestlesArm movingPositive direction

Owner:CHAPMANLEONARD STUDIO EQUIP

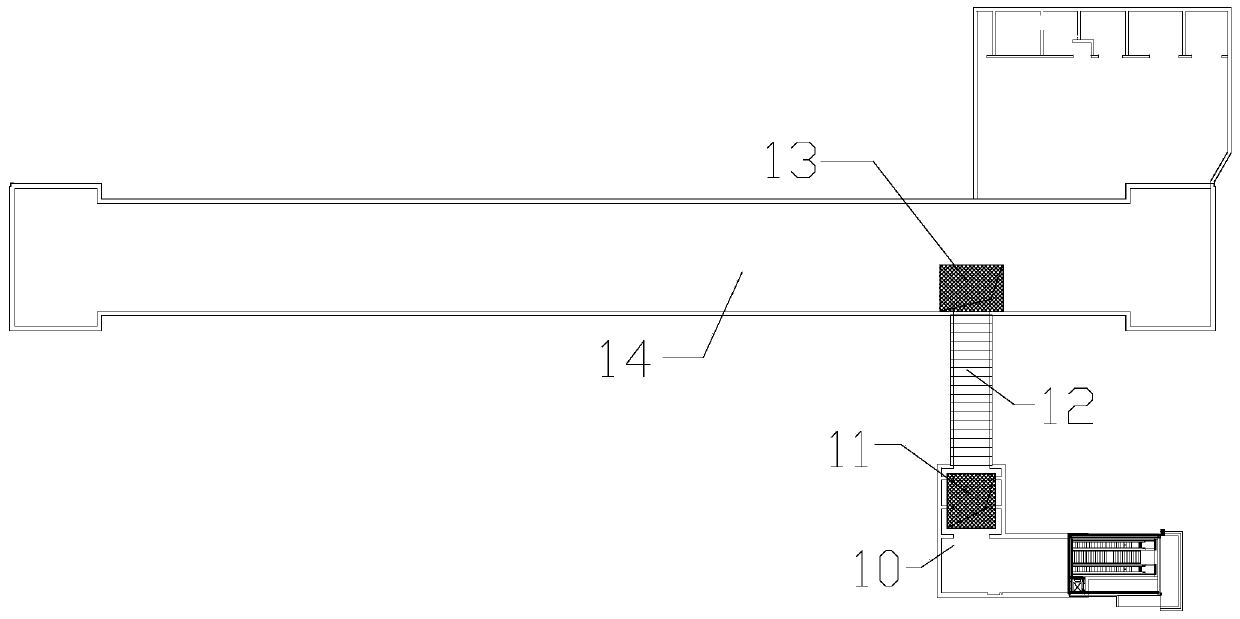

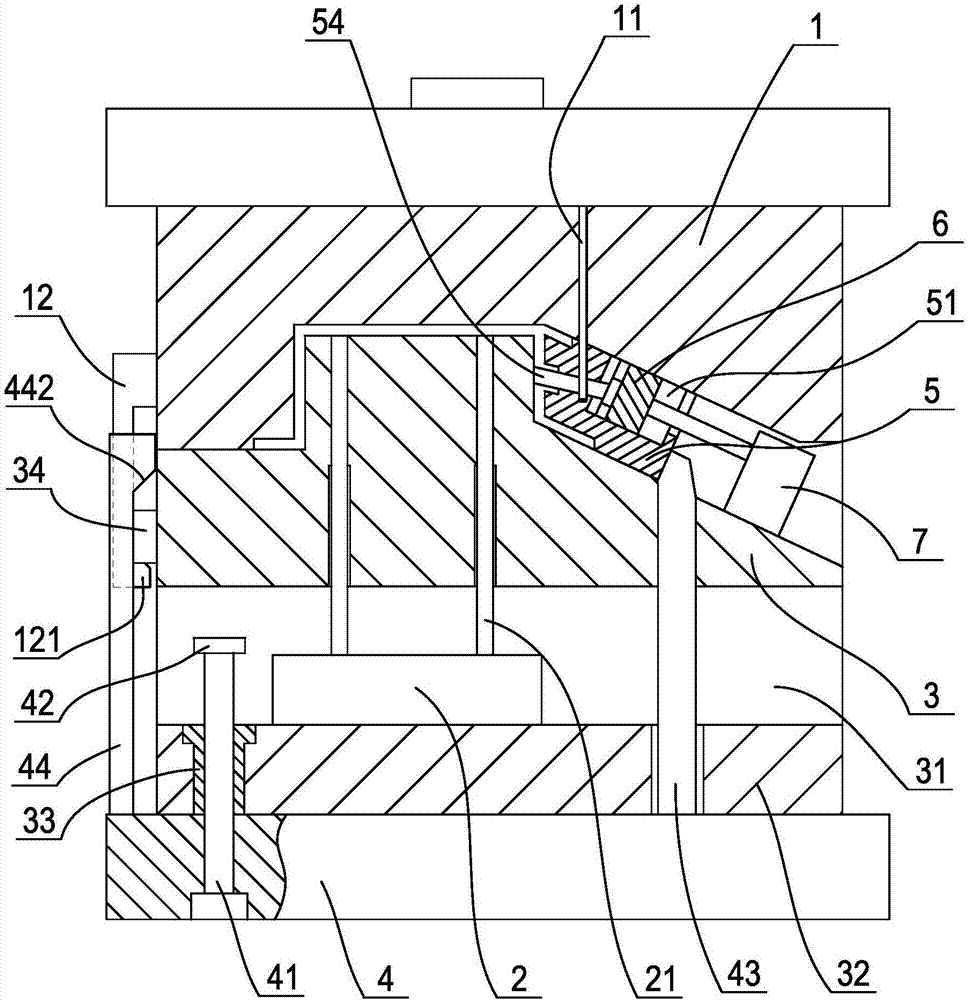

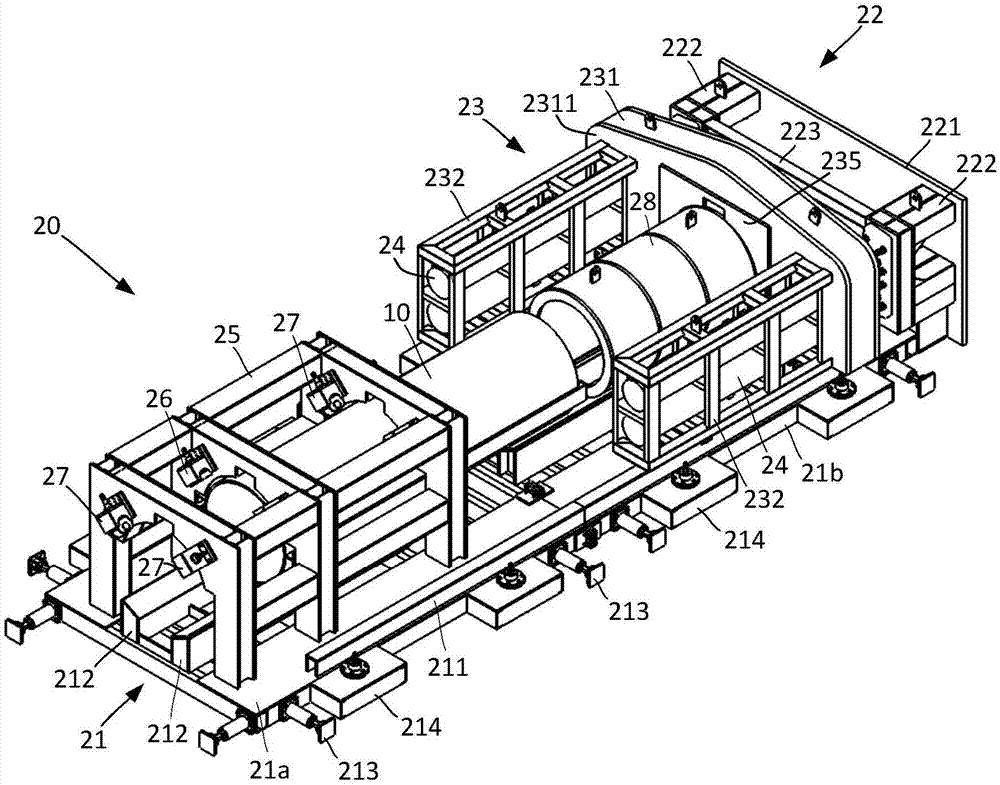

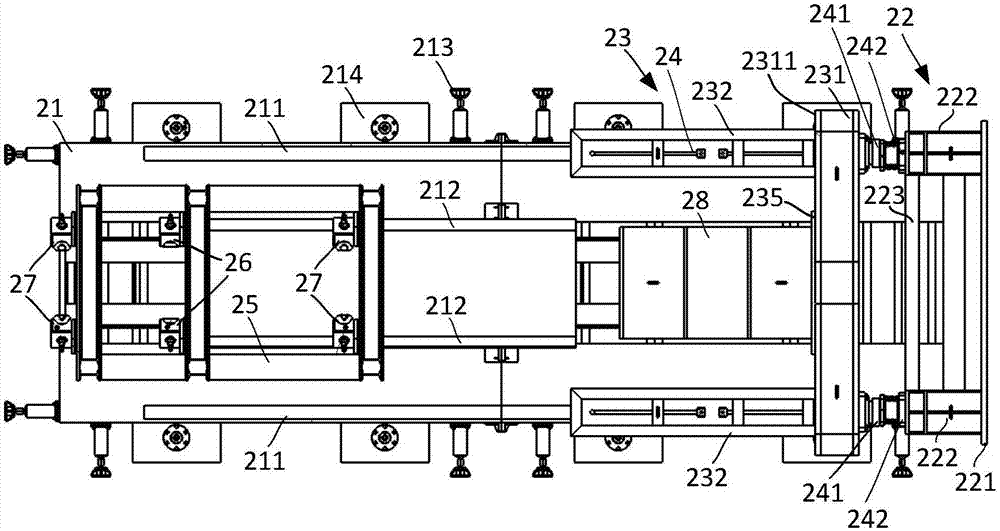

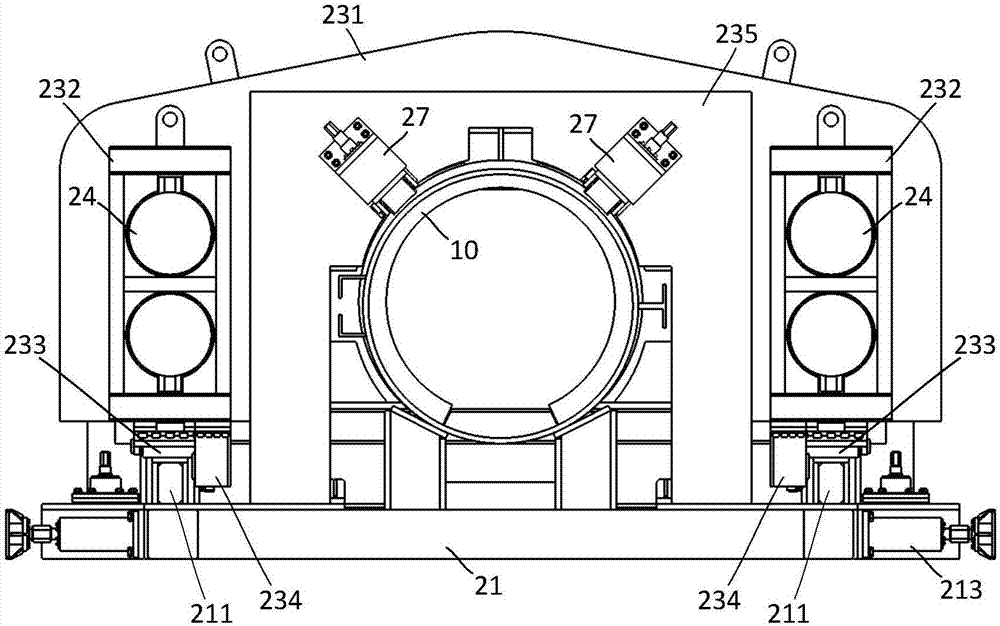

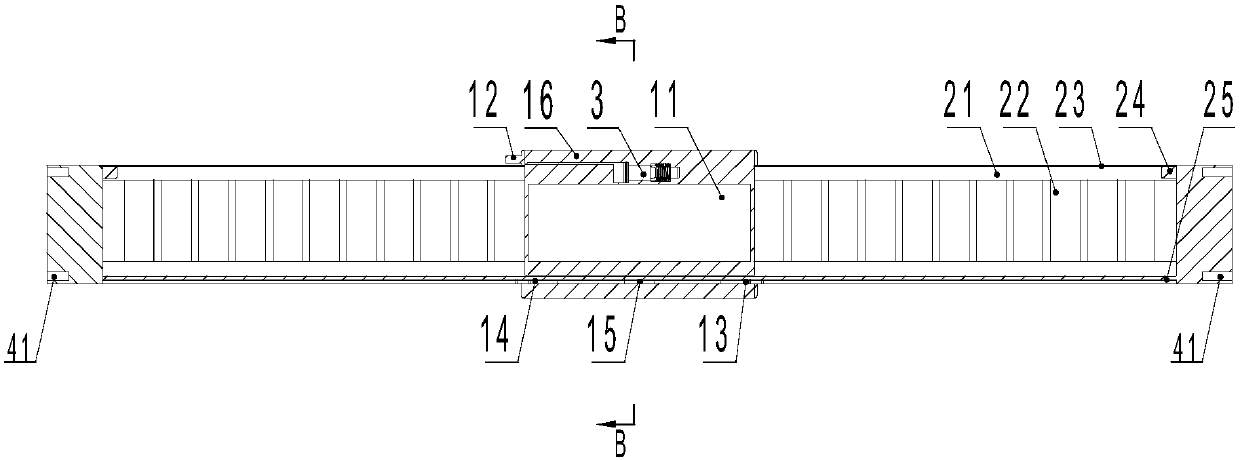

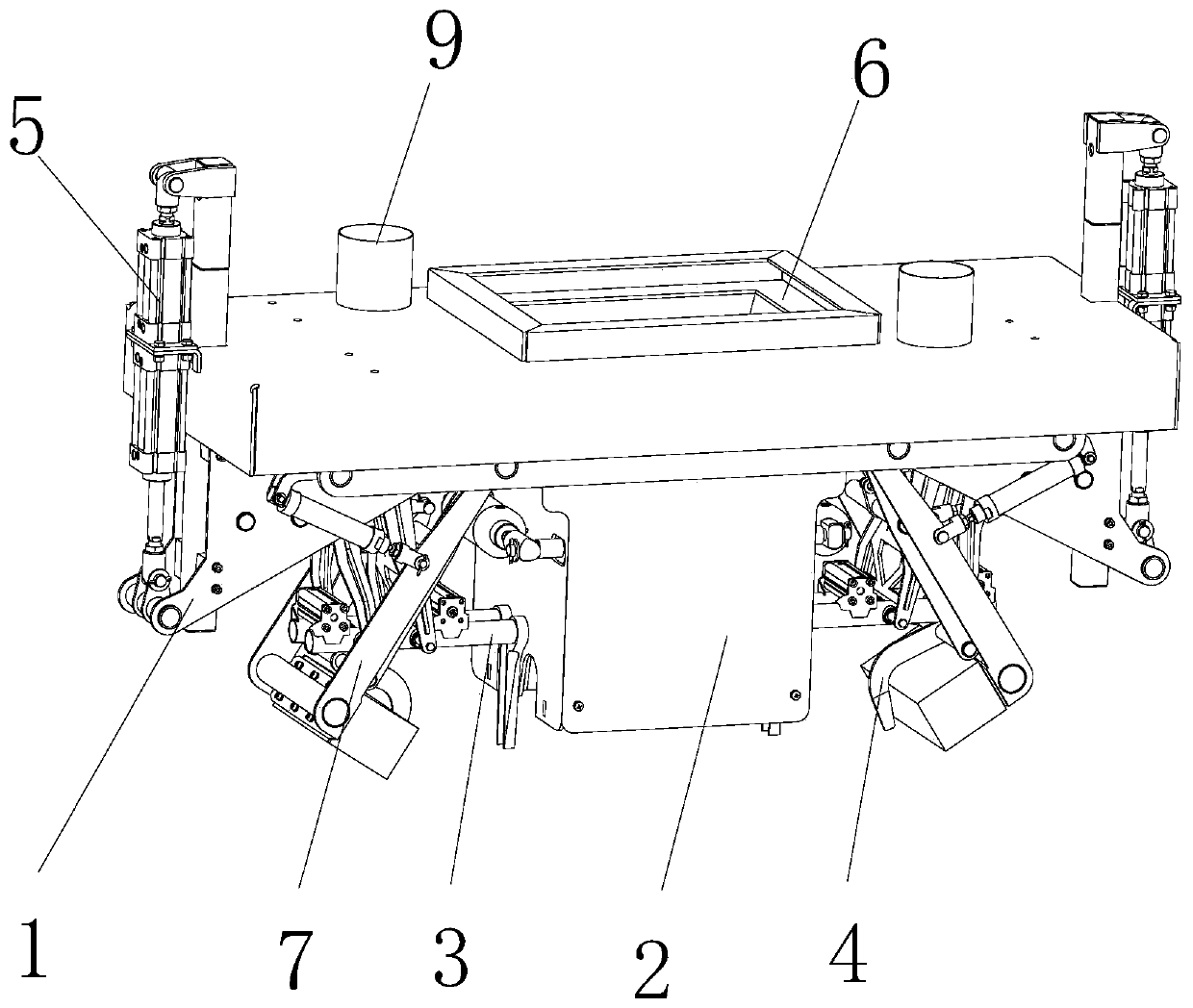

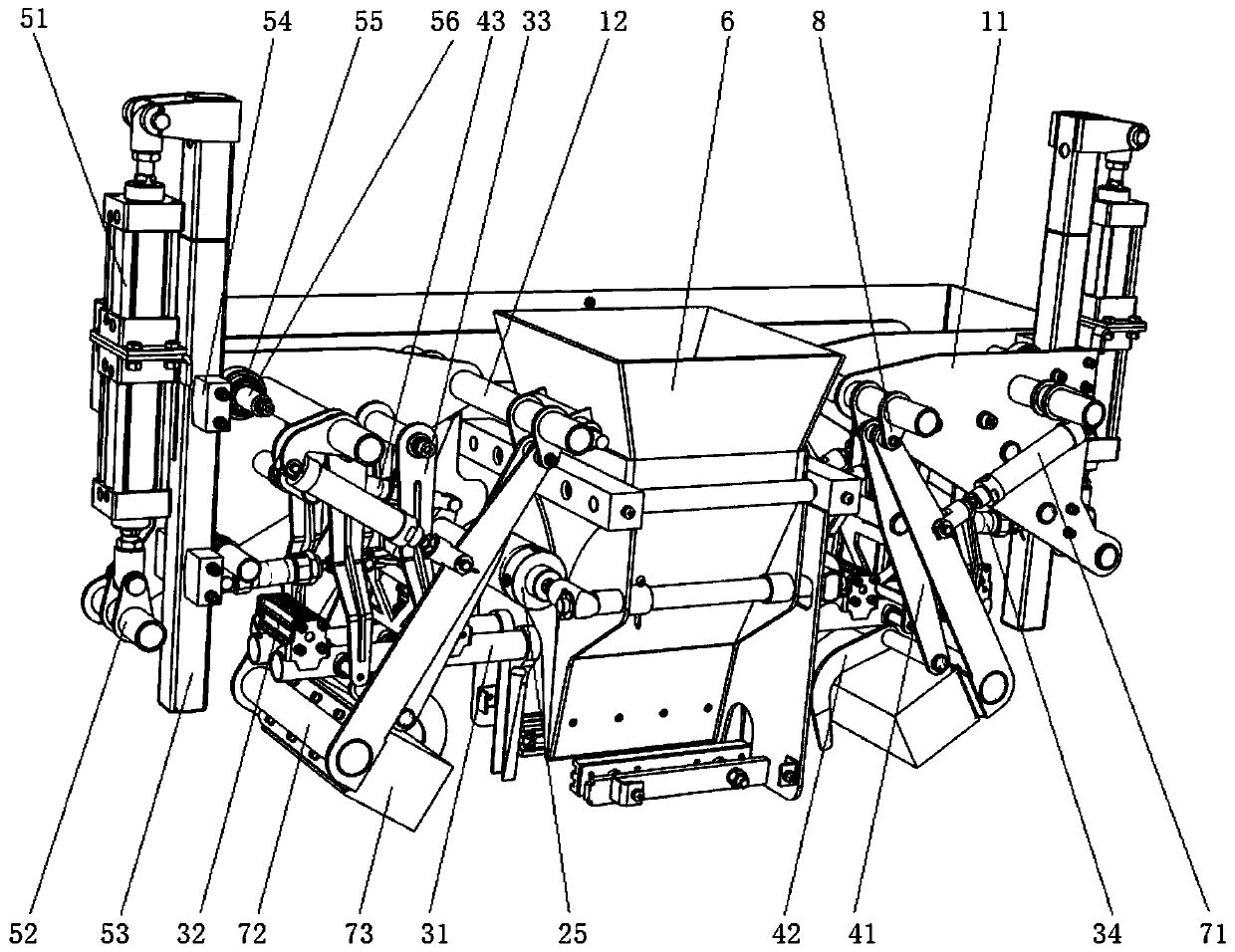

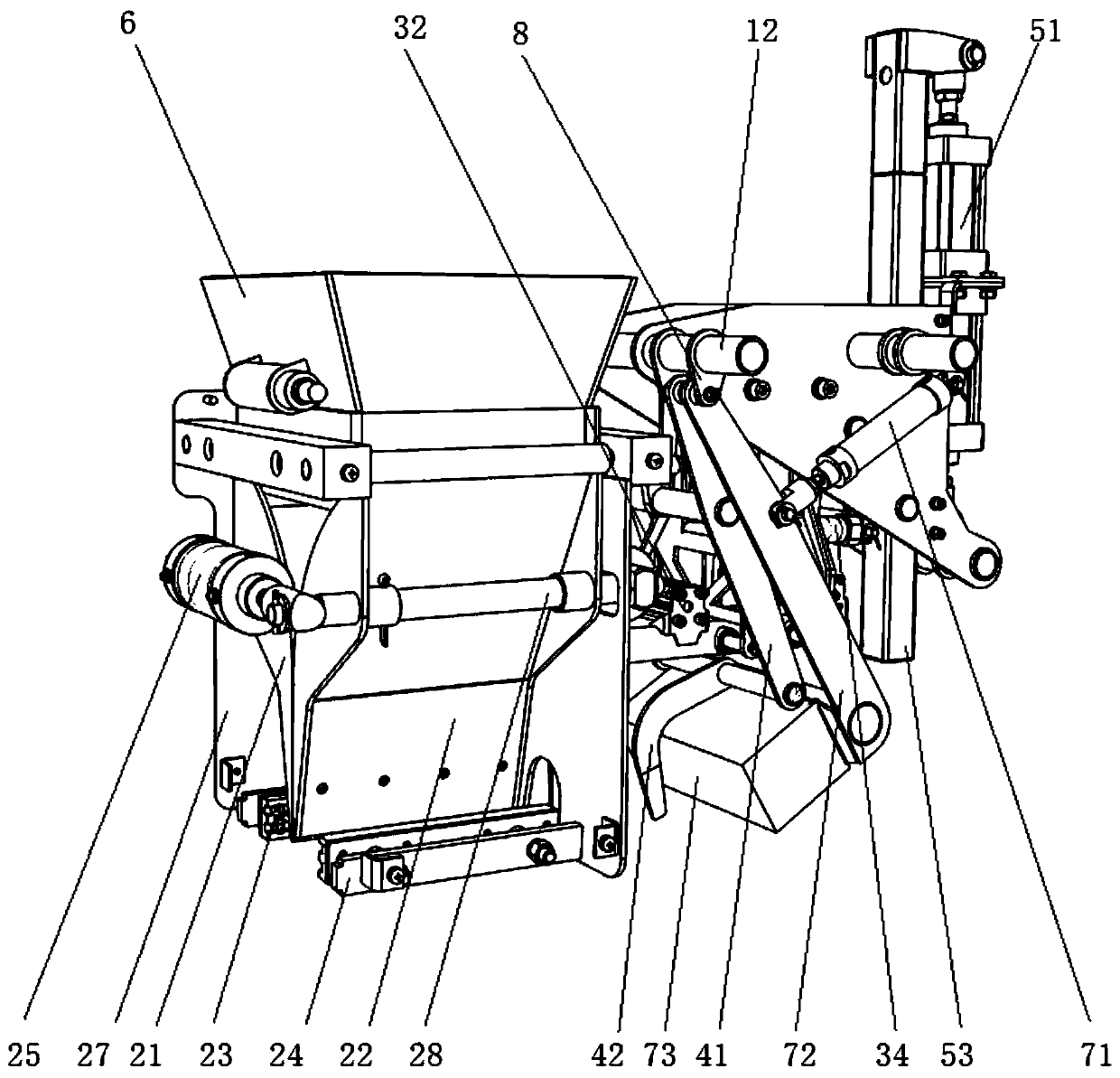

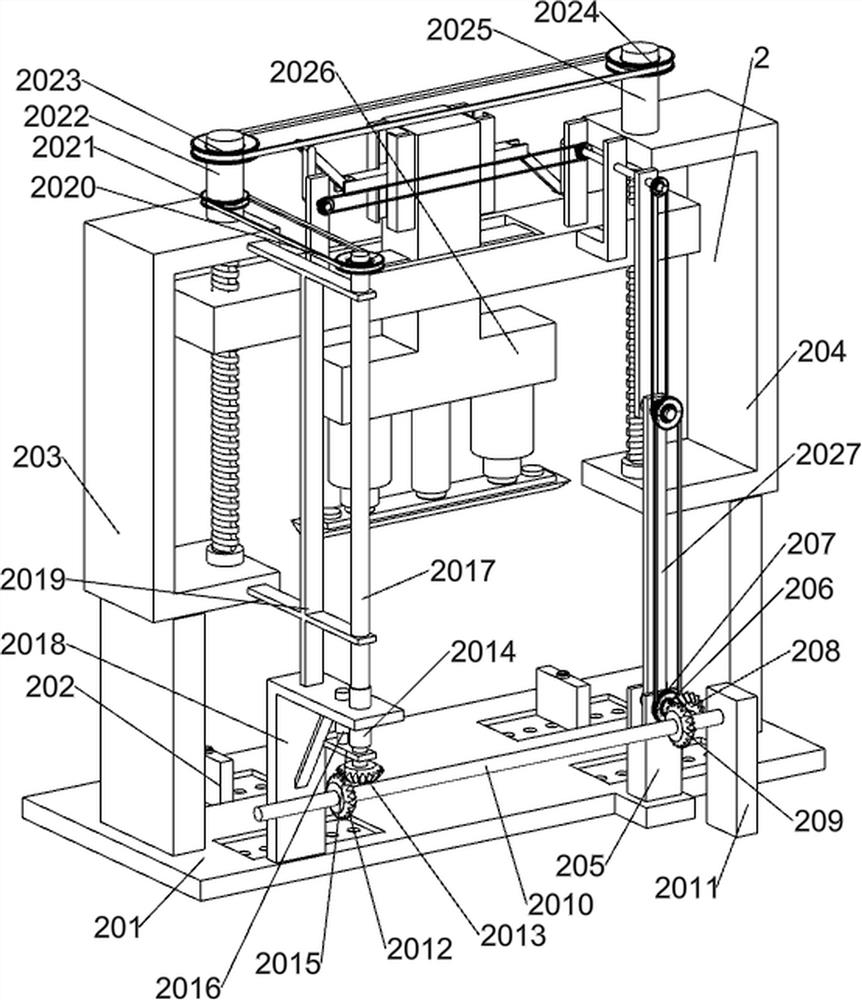

Main jacking device for pipe jacking construction through pipe-roofing underground excavation method

The invention relates to a main jacking device for pipe jacking construction through a pipe-roofing underground excavation method. The main jacking device comprises a base, a fixed back part connectedwith the base, a propelling assembly movably and slidably arranged on the base, power mechanisms fixedly arranged on the propelling assembly, a portal frame fixedly arranged on the base and located in front of the propelling assembly, and stopping mechanisms mounted on the portal frame and capable of conducting extending-retracting adjustment. The power mechanisms are connected with the fixed back part, and the propelling assembly is pushed through the power mechanisms to move forwards along the base; and sawtoothed faces matched with pipe sections are arranged on the stopping mechanisms, andthe sawtoothed faces are closely attached to the outer side faces of the pipe sections through extending-retracting adjustment of the stopping mechanisms. The phenomenon that the jacked pipe sectionsrecede when the pipe sections are additionally arranged during pipe jacking construction through the pipe-roofing underground excavation method can be well avoided, downward-inclining of the whole pipe sections due to sinking of a machine head in the propelling process can slow down, and stable propelling of the pipe sections can be ensured, and the construction efficiency is high.

Owner:SHANGHAI TUNNEL ENG CO LTD

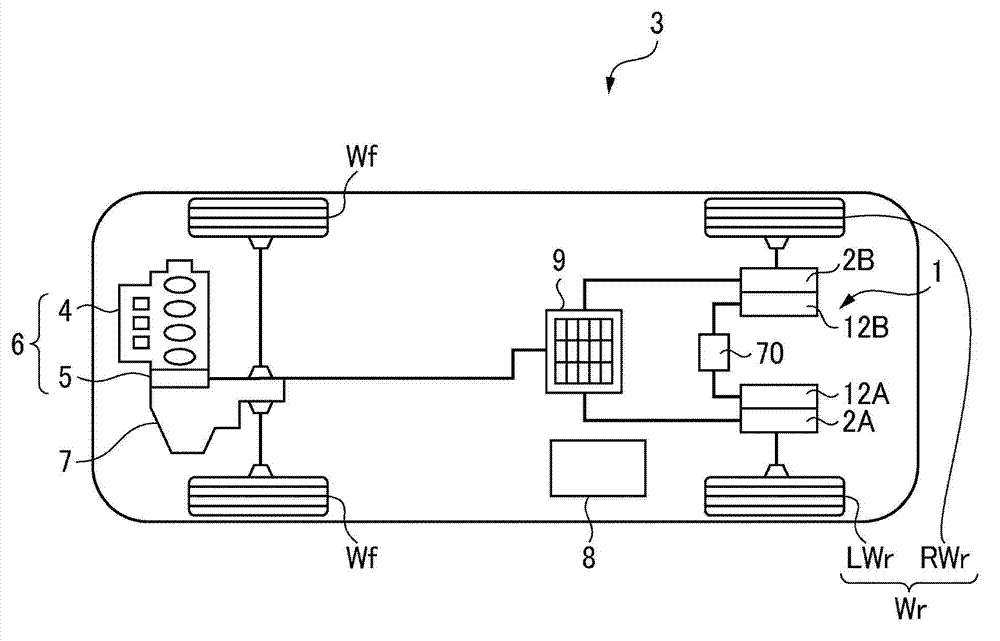

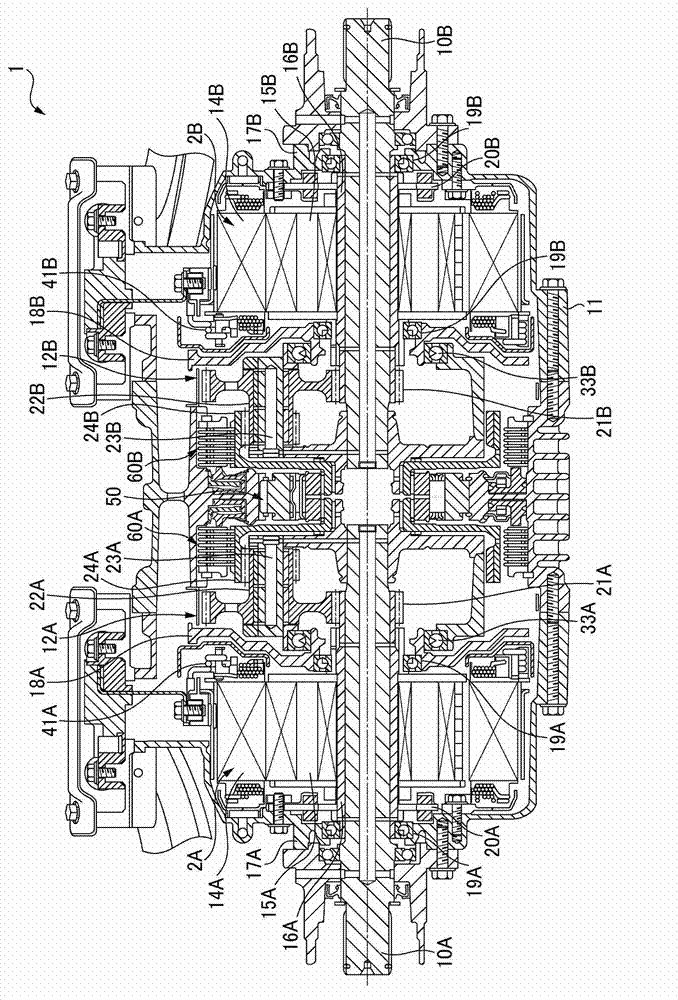

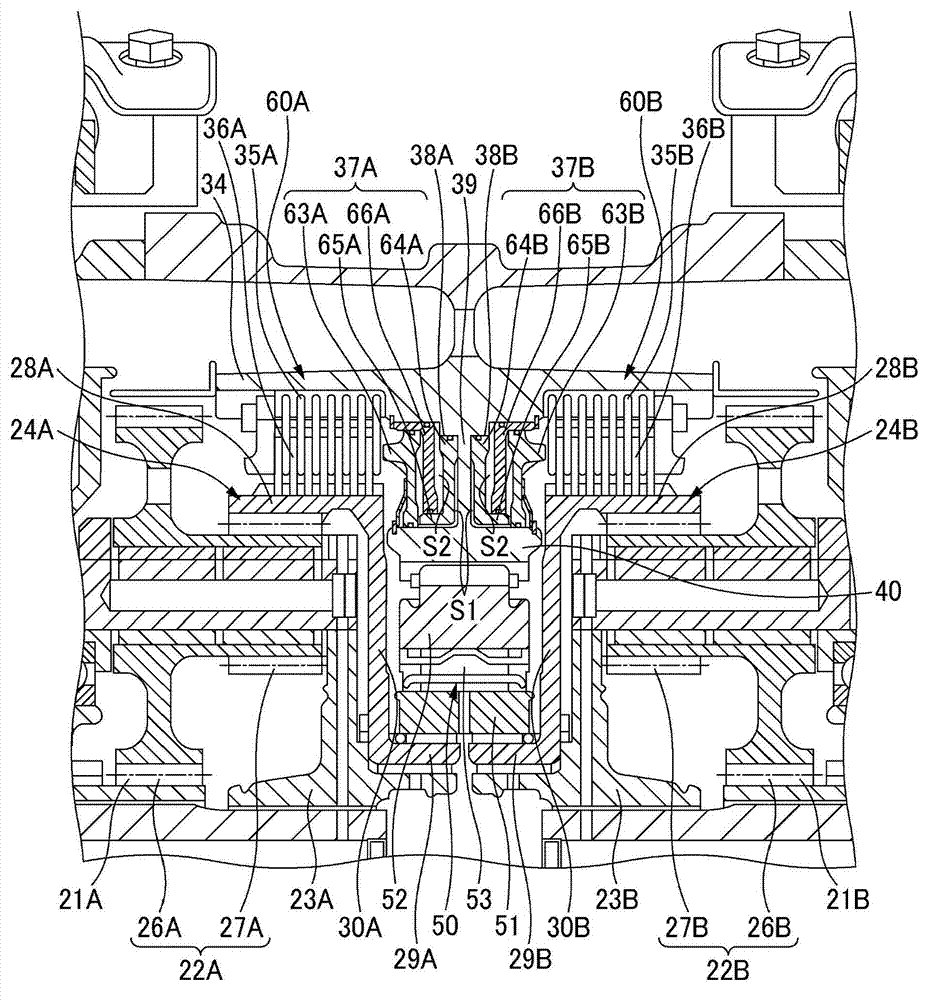

Vehicle drive device

ActiveCN103171430AIncrease profitReduce power consumptionHybrid vehiclesVehicle sub-unit featuresWheel driveSpur gear

The present invention provides a vehicle drive device which can generate a desired yawing moment when left and right reverse torque control is carried out and control first and second motors to be at any target rotating speed simultaneously. A back-wheel drive device is equipped with a left-wheel drive unit possessing a first motor and a first planetary gear reducer arranged on the transmission paths of the first motor and a left back-wheel; a right-wheel drive unit possessing a second motor and a second planetary gear reducer arranged on the transmission paths of the second motor and a right back-wheel; and a control unit. The first motor is connected with a sun gear of the first planetary gear reducer, and the second motor is connected with a sun gear of the second planetary gear reducer; the left back-wheel is connected on a planetary gear carrier of the first planetary gear reducer, the right back-wheel is connected on a planetary gear carrier of the second planetary gear reducer, and inner gears are connected with each other.

Owner:HONDA MOTOR CO LTD

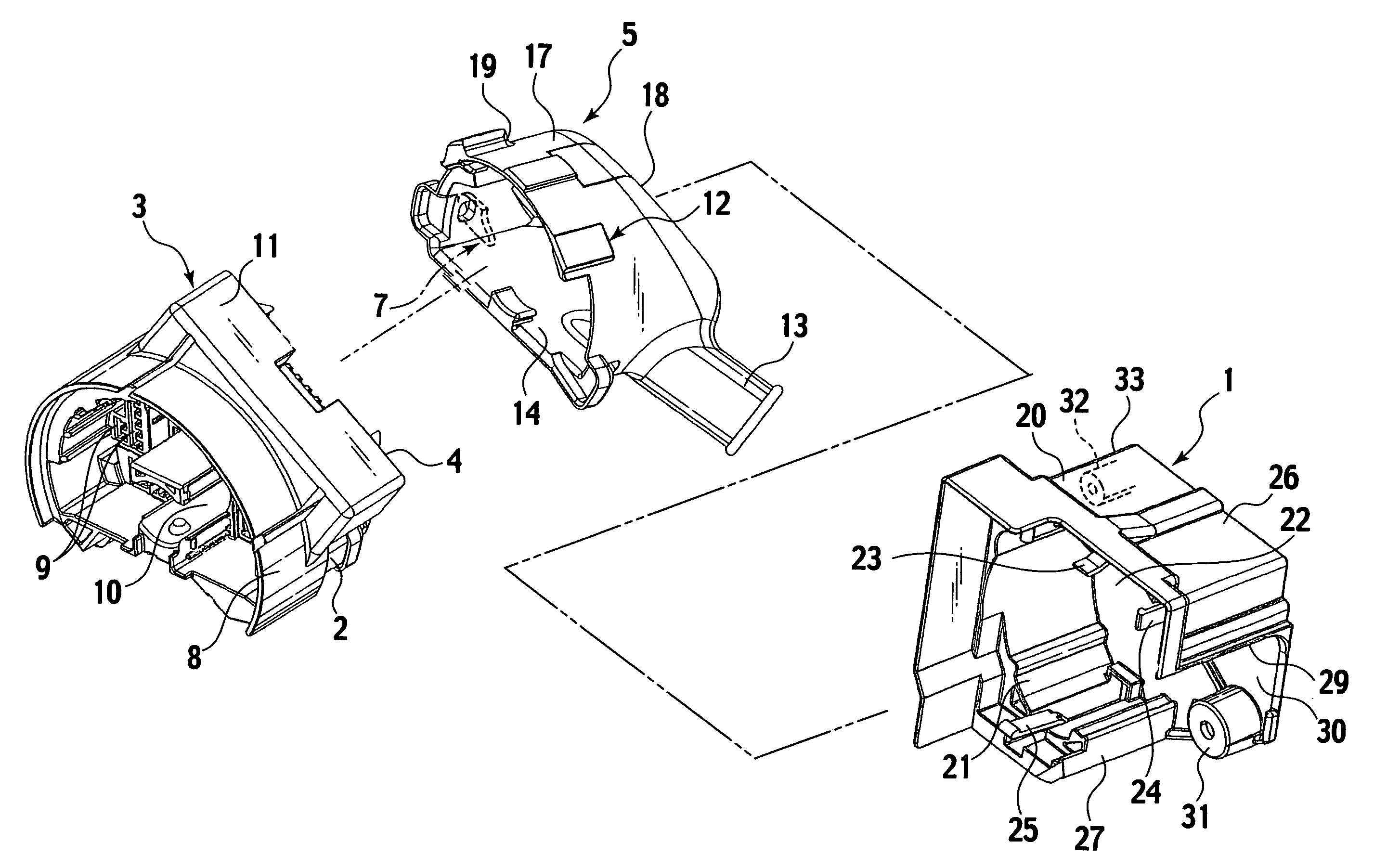

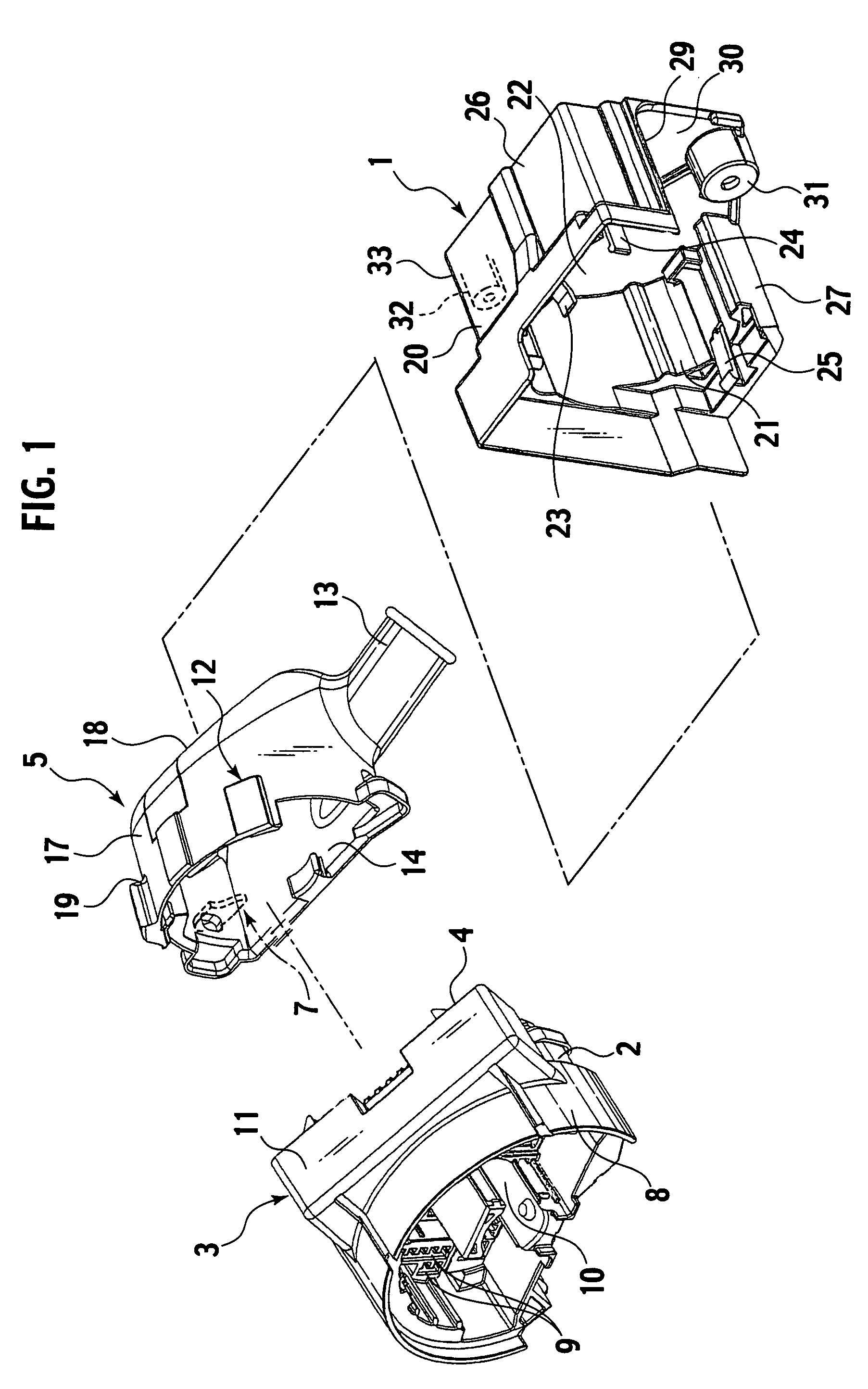

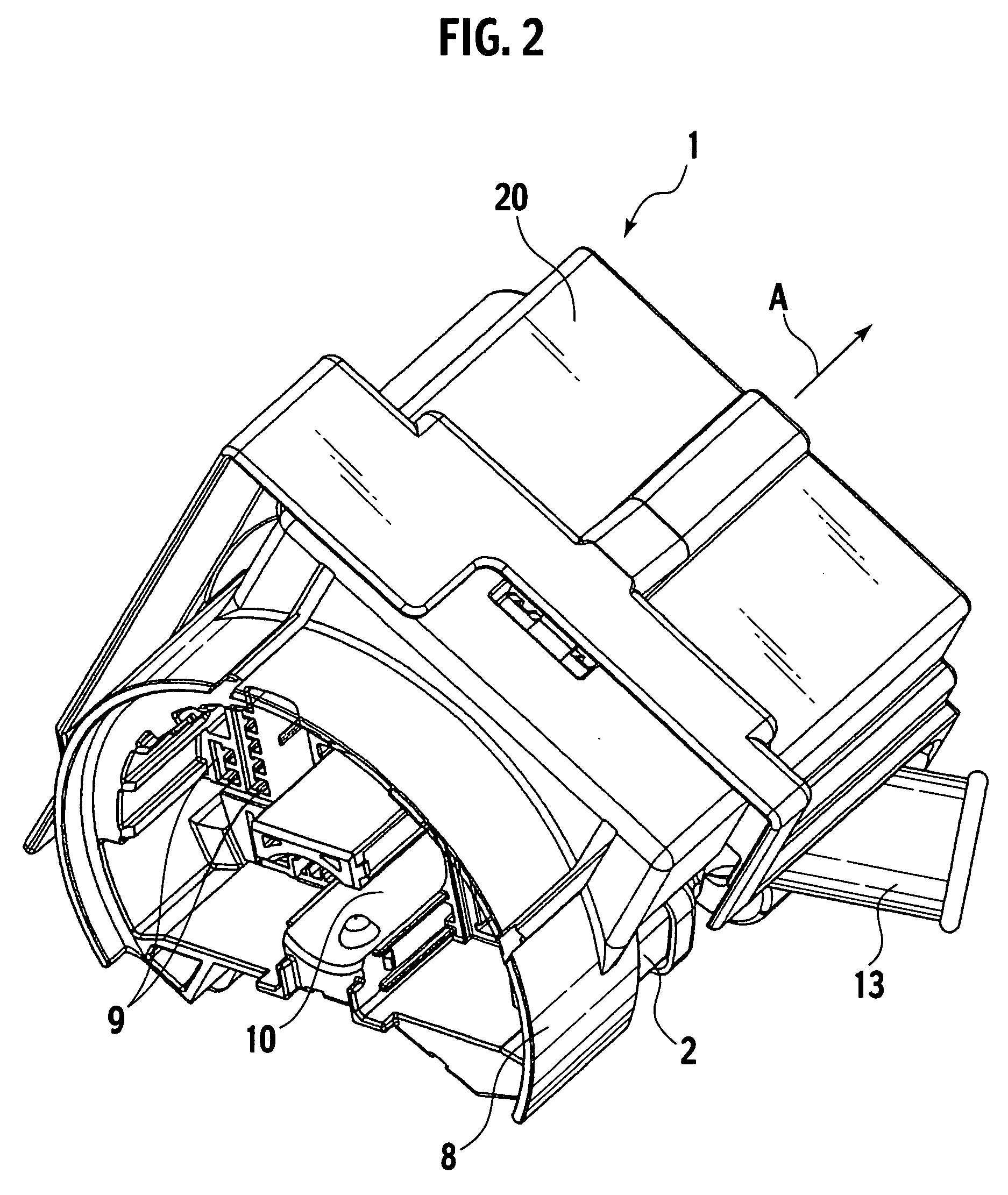

Rear-Cover Attachment Structure

InactiveUS20080220659A1Low operating forceEasy to assembleSecuring/insulating coupling contact membersEngineeringGrommet

A fixation structure for a rear cover (1) in which a waterproofing grommet (5) is fixed to the wire lead-out side (4), from which a wire from a connector housing (2) is led out, of a connector (3) and which is assembled to the wire lead-out side (4) of the connector for (3) with the waterproofing grommet (5) in between. The grommet (5) is provided with a rib (7) that is in contact with the inner wall (protrusion (34)) (6) to hold the attitude of the grommet (5) relative to the rear cover (1).

Owner:YAZAKI CORP +1

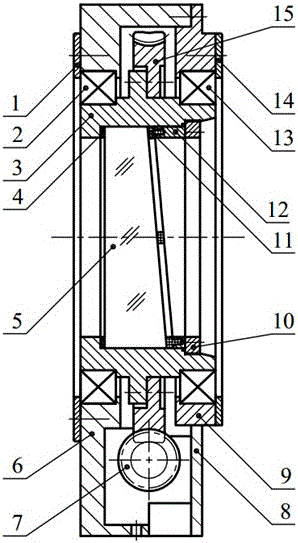

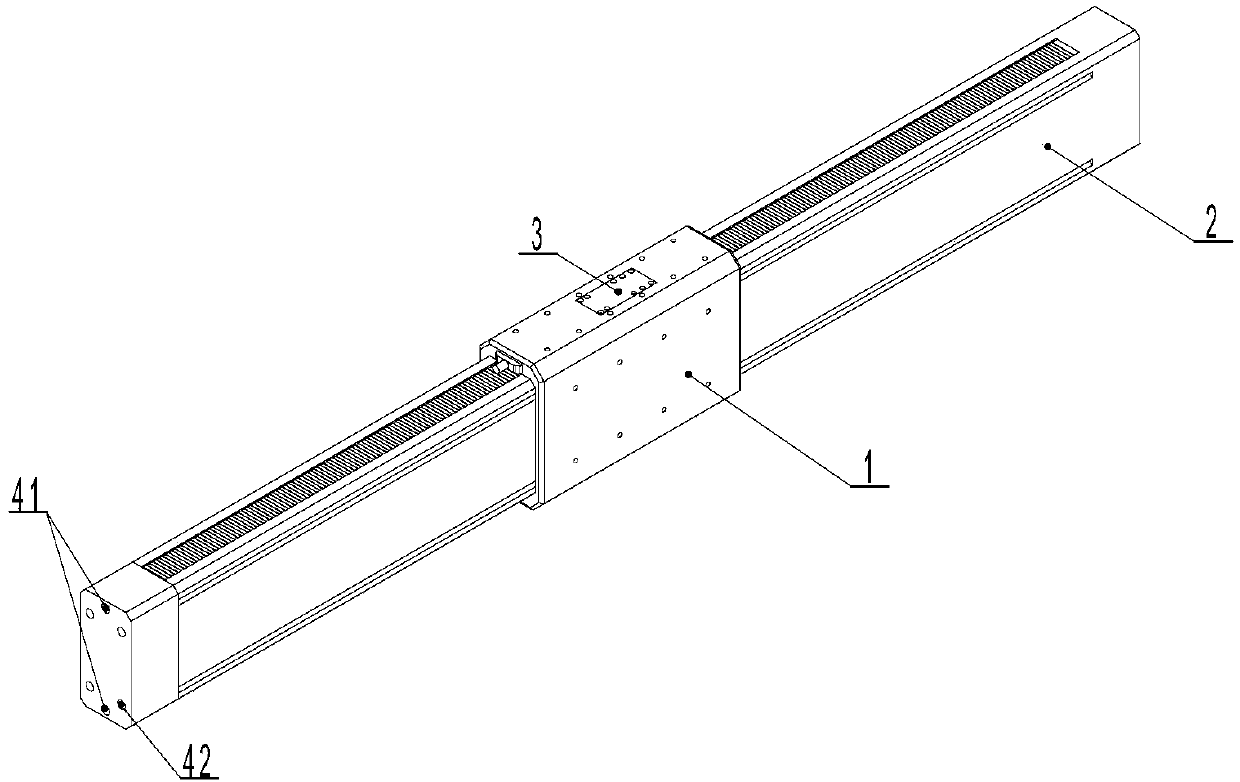

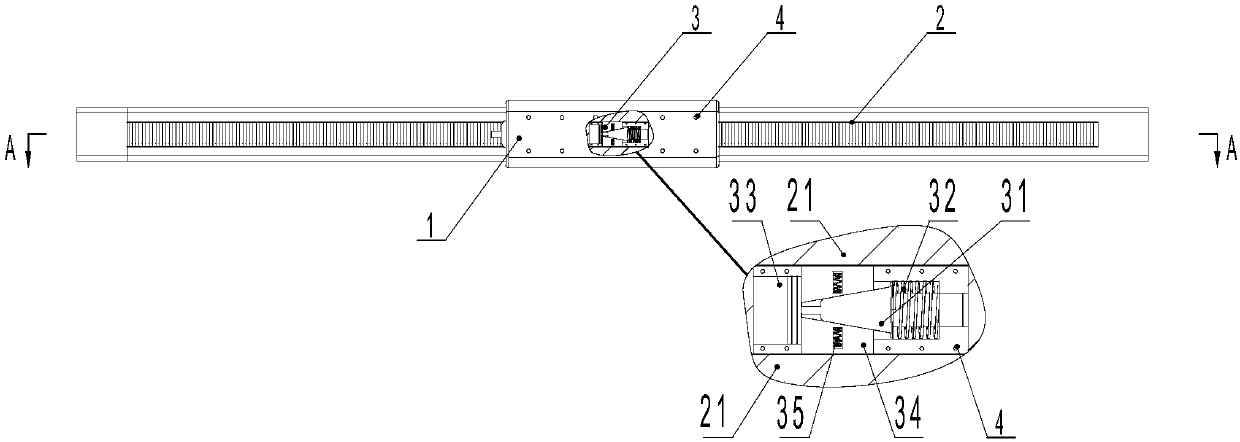

Linear motor module for robot splicing

PendingCN107733204ACompact structureReduce power lossProgramme-controlled manipulatorMechanical energy handlingElectric machineControl engineering

The invention relates to a linear motor module for robot splicing. The linear motor module comprises a rotor assembly, a stator assembly, a brake and a controller, wherein the brake is connected to the rotor assembly, the rotor assembly sleeves the stator assembly, connection holes are formed in both of the rotor assembly and the stator assembly, the rotor assembly comprises a shell, a coil, a connector, a grating reading head, a first limit switch and a second limit switch, the stator assembly comprises a stator body, a permanent magnet and a grating, the brake comprises a wedge-shaped block,a braking spring, a piston, a braking block and an extrusion spring, and the grating reading head, the first limit switch, the second limit switch and the piston all are electrically connected with the controller.

Owner:GSK CNC EQUIP

M-type bag forming clamping device

PendingCN109850270AHighly integratedCompact structureSolid materialEngineeringMechanical engineering

The invention provides an M-type bag forming clamping device. The M-type bag forming clamping device solves the problems of complex and large structure, low matching degree and low packaging efficiency of an existing M-type bag clamping device. The M-type bag forming clamping device comprises a mounting frame, a bag clamping assembly, two bag supporting rod assemblies, two M-type bag forming assemblies and two lifting assemblies, wherein the mounting frame is connected with the lifting assemblies; the lifting assemblies are fixedly arranged on a discharging device and used for driving the mounting frame to move up and down; the bag clamping assembly is arranged at a discharging opening of the discharging device; the two bag supporting rod assemblies are arranged on the mounting frame, corresponding to two sides of the discharging device, and used for performing bag supporting action on an M-type bag; each bag supporting rod assembly comprises two bag supporting rods, two bag supportingcylinders, two swing frames and a swing cylinder; the two M-type bag forming assemblies are arranged on the mounting frame, correspondingly arranged on two sides of the discharging device, and used for performing M-type forming recovery action on the M-type bag; each M-type bag forming assembly comprises a forming frame, a forming sheet and a forming cylinder; and the movement area of the formingsheet is in the middle of the bag supporting rod assemblies.

Owner:XIAN MAGNETIC FOREST ELECTROMATIC

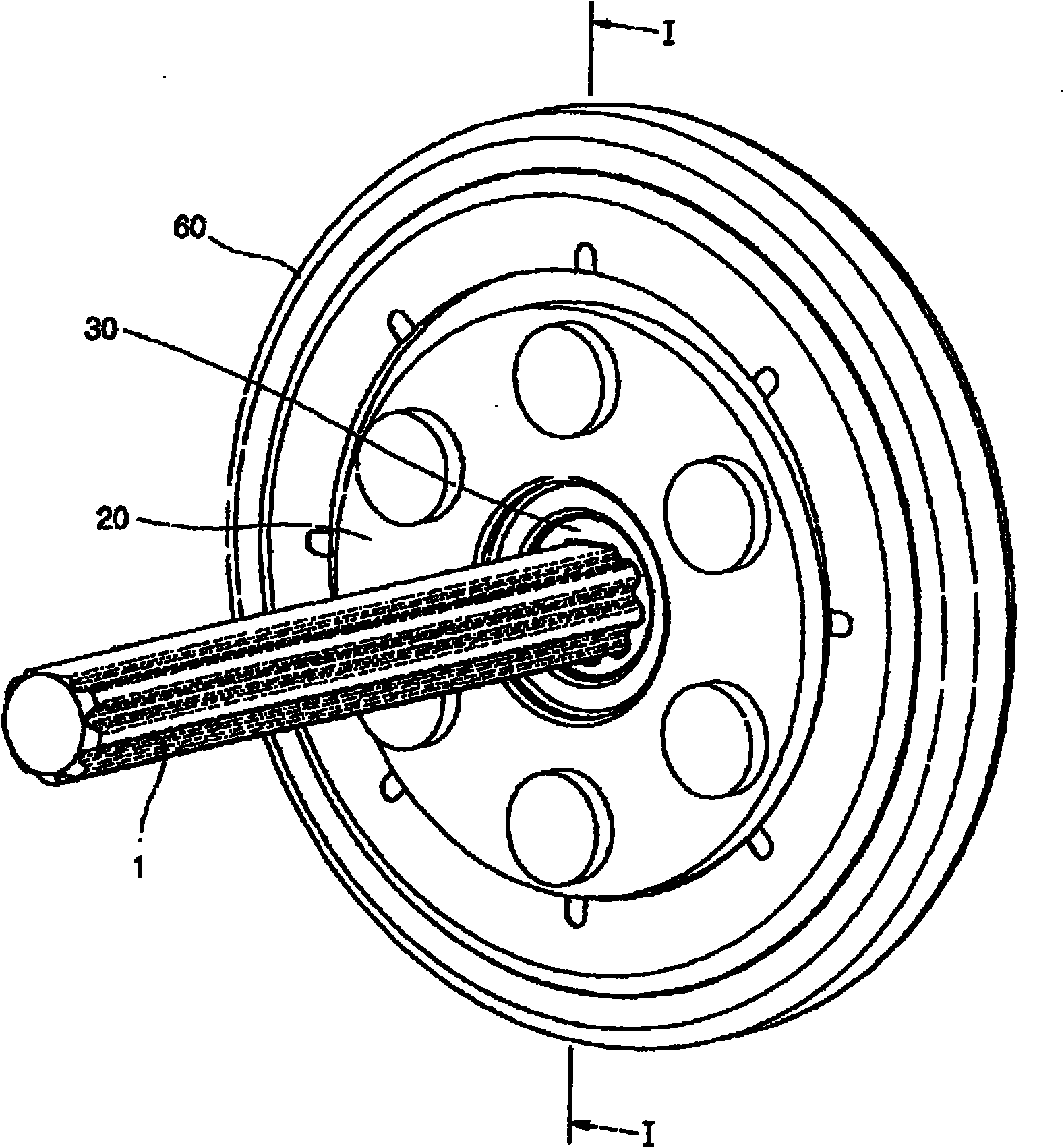

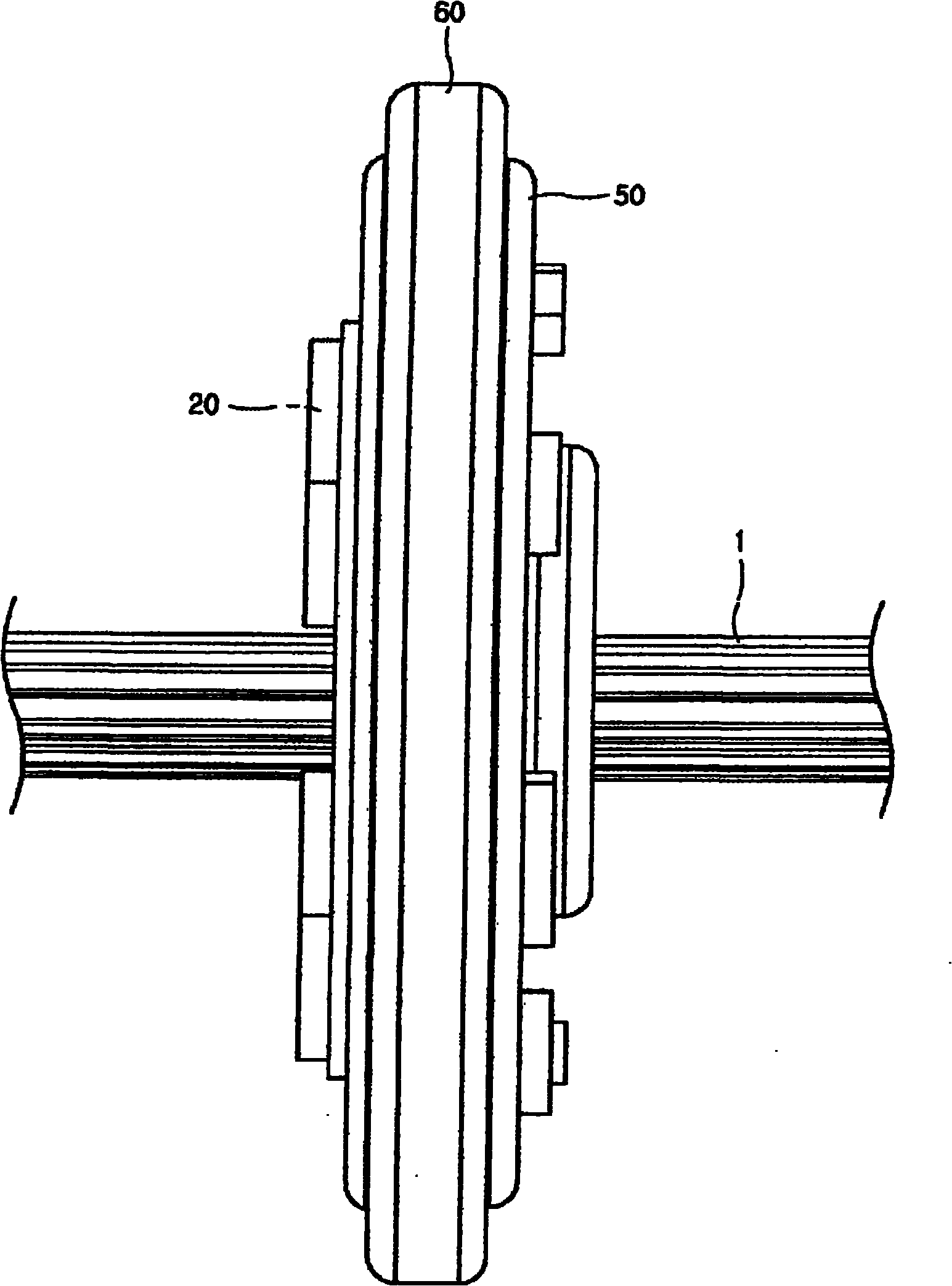

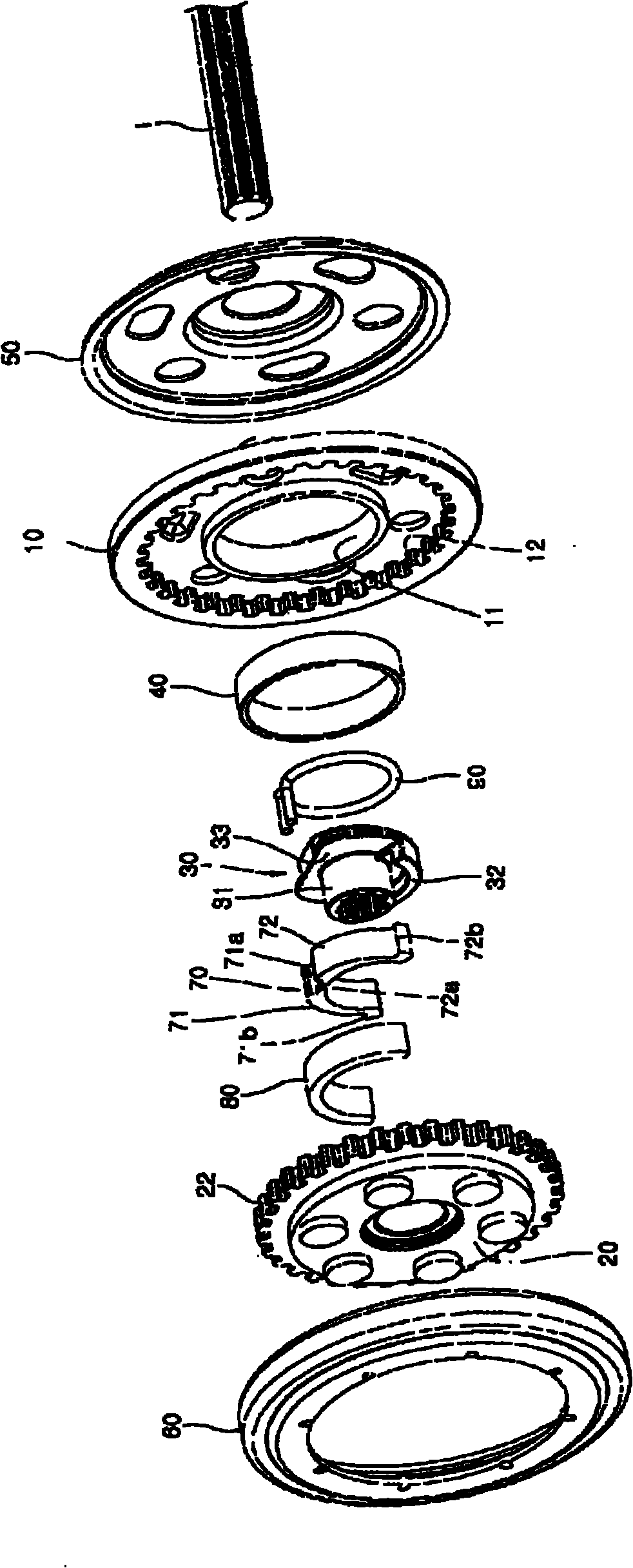

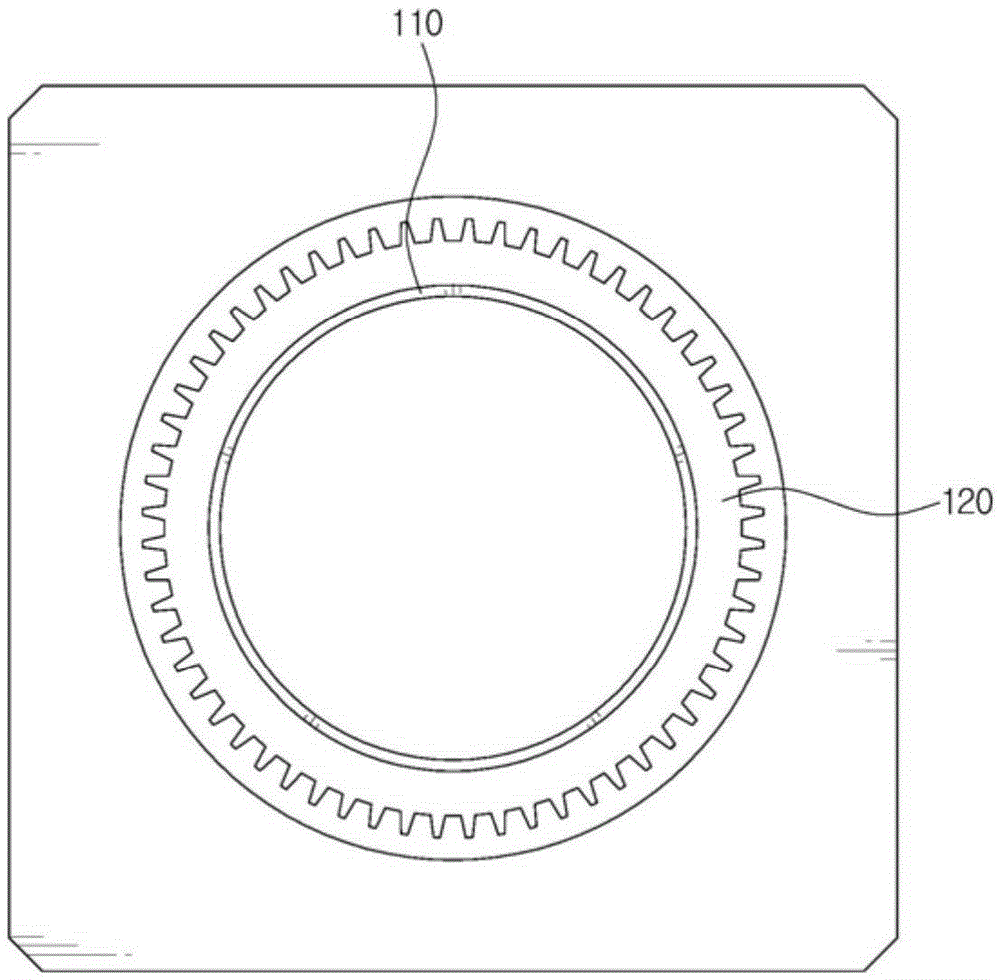

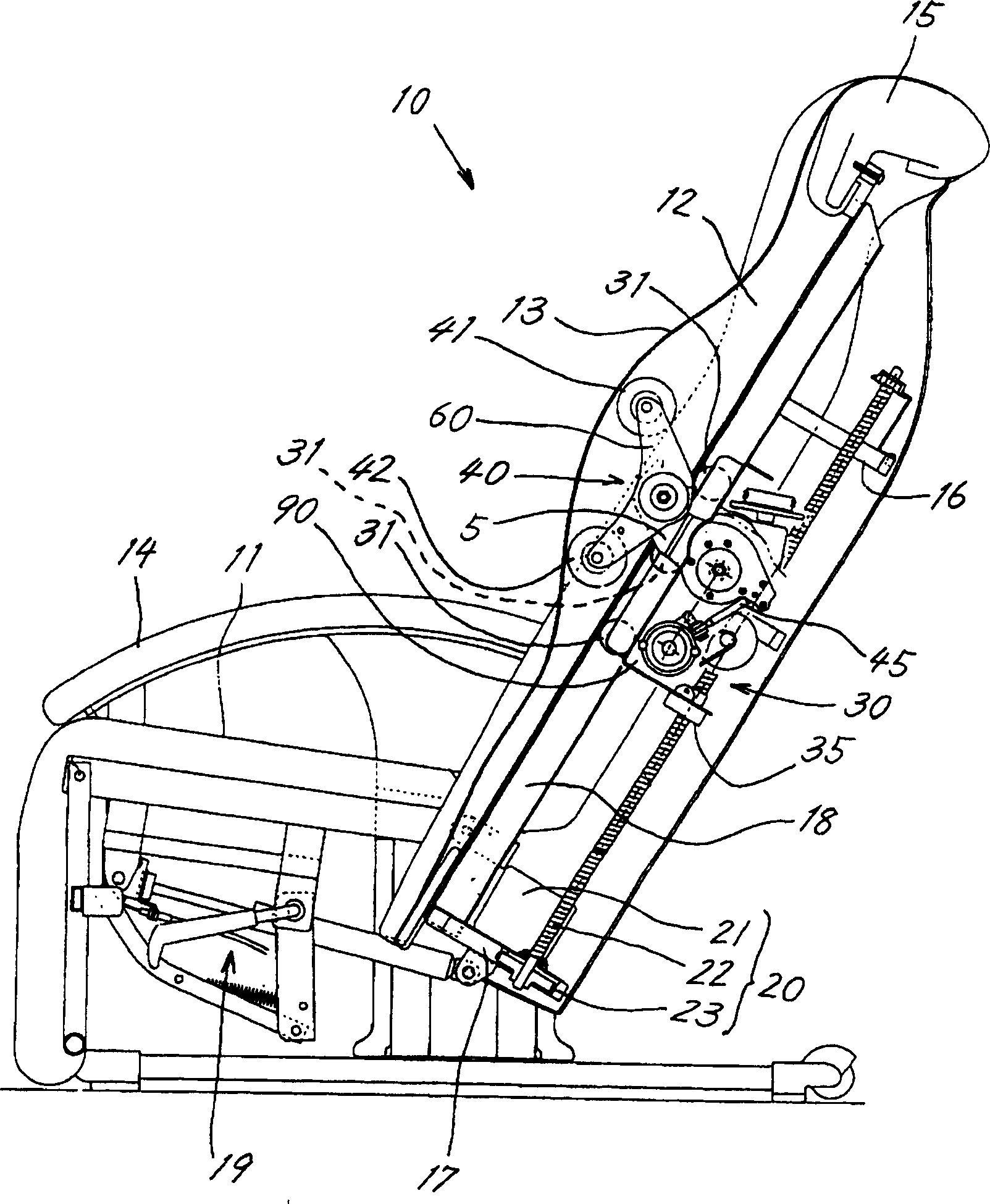

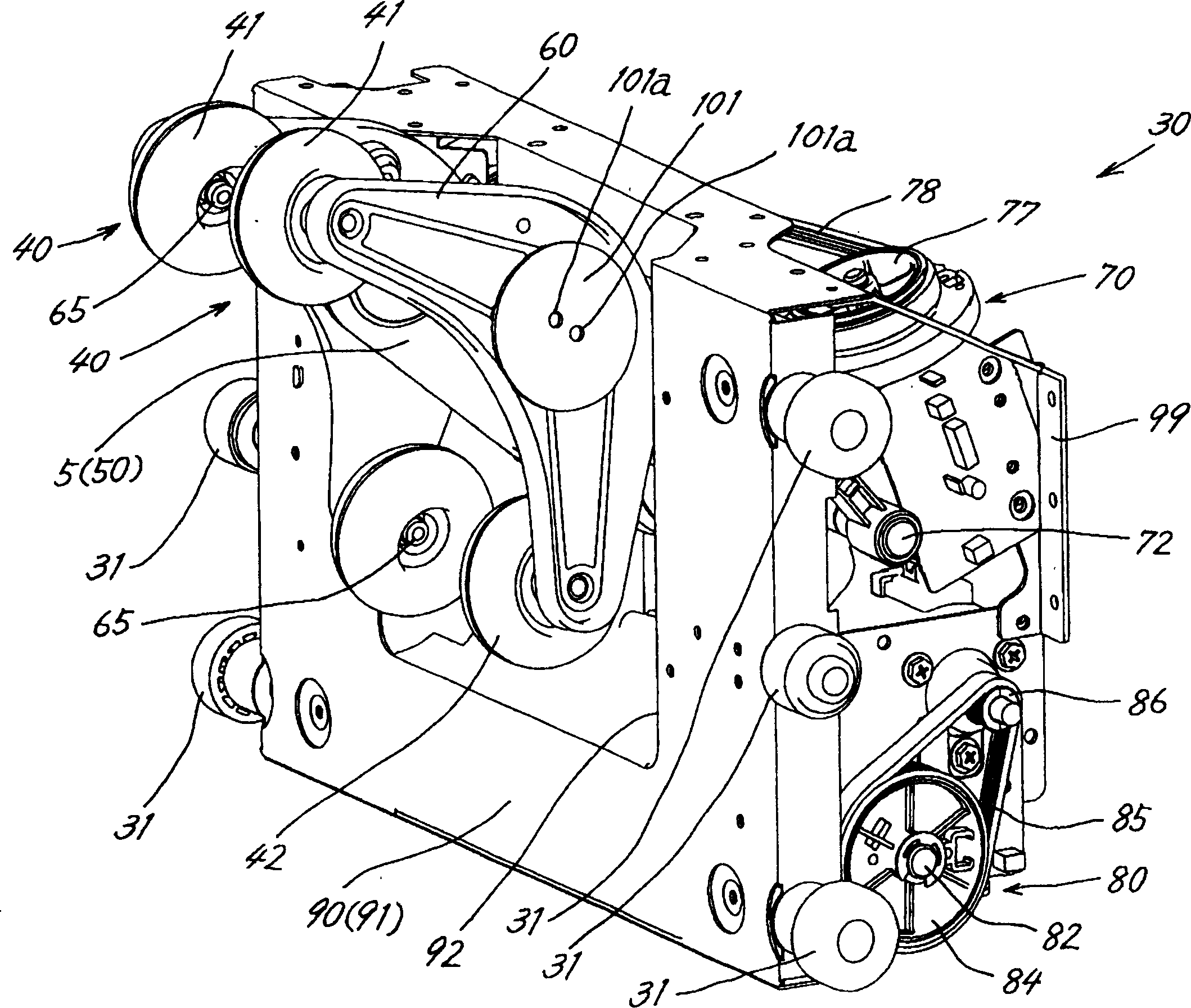

Reclining device of seat for vehicle

ActiveCN101778734AAvoid backlashAdjustable angleMovable seatsManufacturing cost reductionEngineering

The present invention relates to a reclining device of a seat for a vehicle, which makes it possible to prevent backlash between an external gear 12 and an internal gear 22 in stop, resulting in preventing a vibration noise due to movement of the seatback. Further, it is possible to obtain sufficient power from even a small-output motor in operation, by minimizing the gear press angle to increase the operational efficiency. In addition, it is possible to design a compact reclining device by simplifying the shape and reduce the size of assemblies of wedge blocks 70, 120 and cams 80, 110, resulting in reducing the weight and the manufacturing cost and making it possible to freely designing the reclining device, depending on a disposing space.

Owner:DAS CO LTD

Female connector structure, male connector structure, battery, adapter and electric device

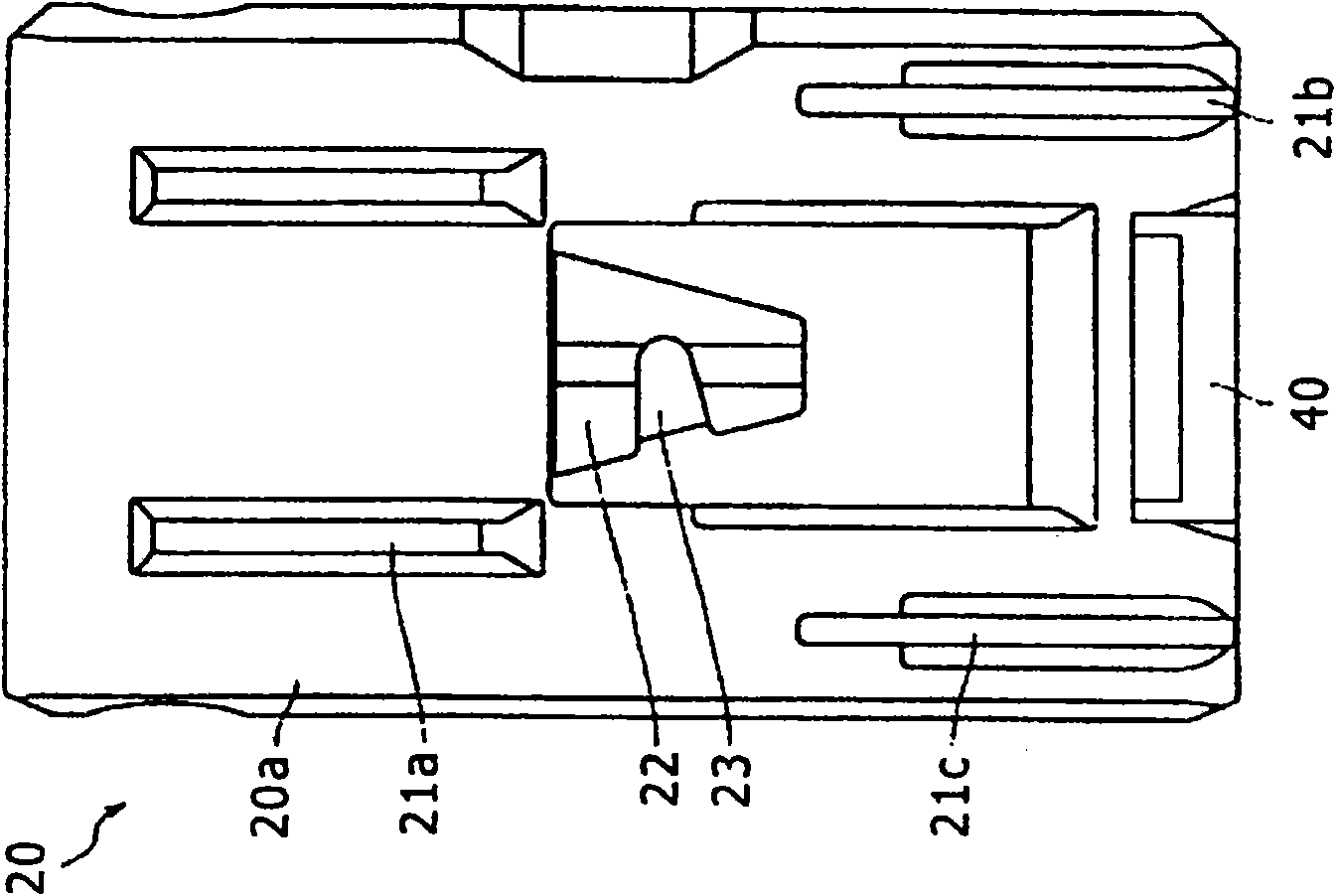

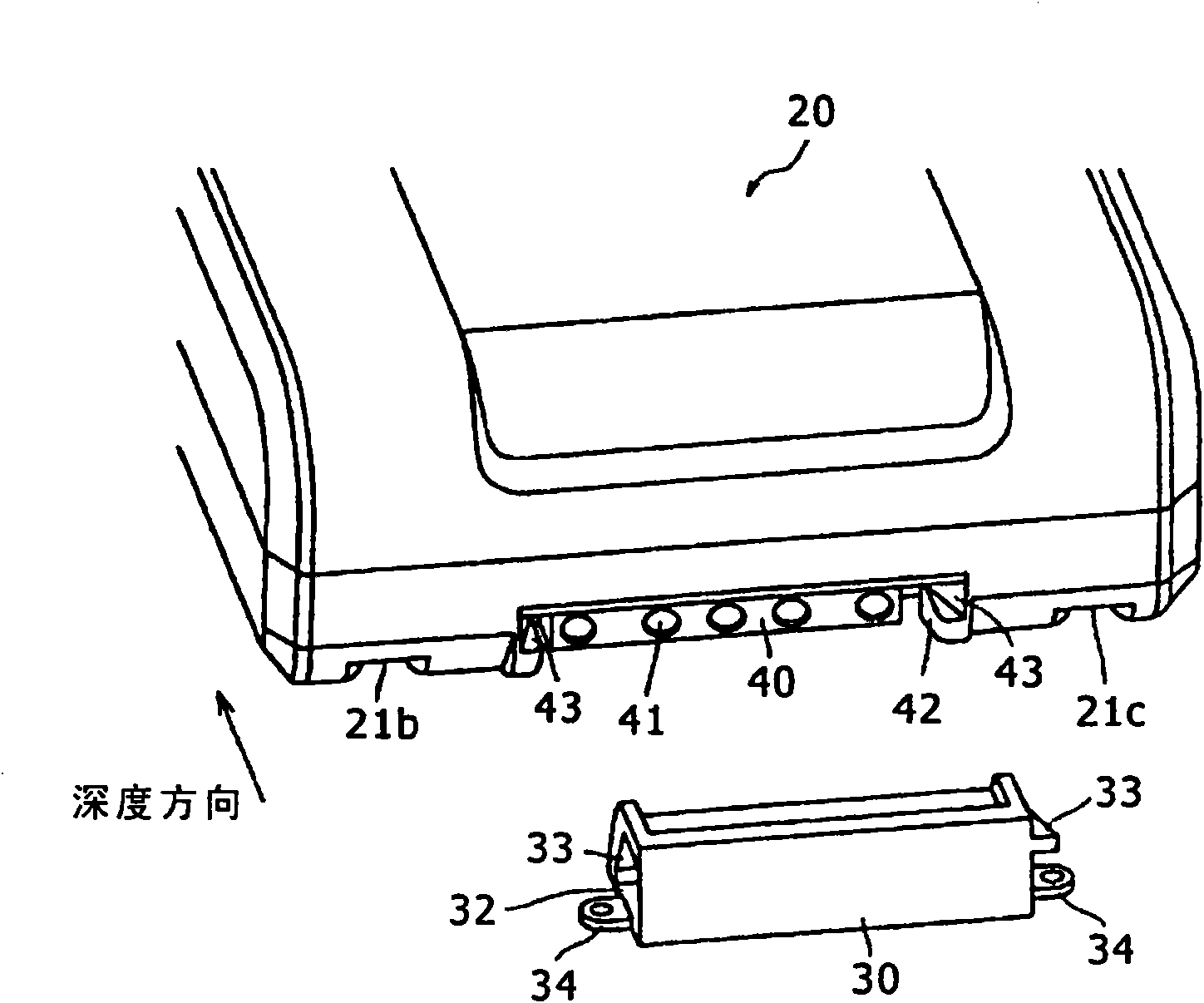

InactiveCN101615745AGap does not increaseAvoid backlashEngagement/disengagement of coupling partsTelevision system detailsDepth directionElectrical and Electronics engineering

The invention relates to a female connector structure, a male connector structure, a battery, an adapter and an electric device. The female connector structure including a plurality of pin insertion holes arranged in a row to correspond to a plurality of columnar connector pins arranged in a male connector section and adapted to receive the respective connector pins individually inserted thereinto; a pair of connector inner walls formed externally of the pin insertion holes of opposite ends so as to extend in a depth direction of the pin insertion holes; and a pair of grooves each formed on an inner surface of the connector inner wall so as to be gradually shallower as the groove goes from an opening side of the pin insertion hole toward a deepest side thereof in such a manner as to receive a projection, fitted thereinto, provided on the male connector section.

Owner:SONY GRP CORP

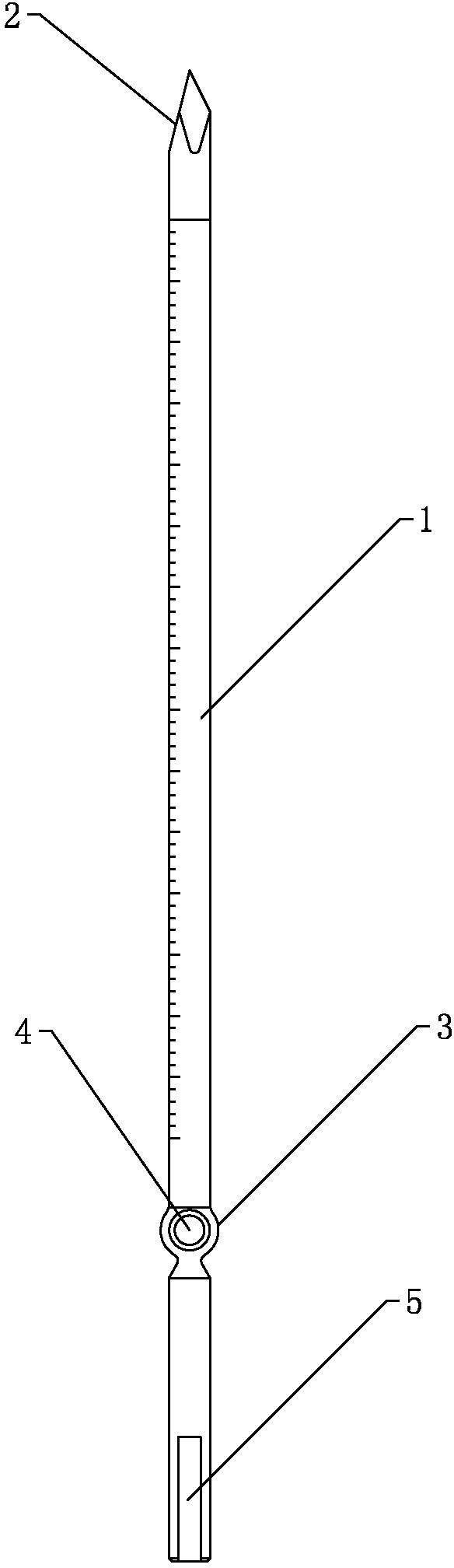

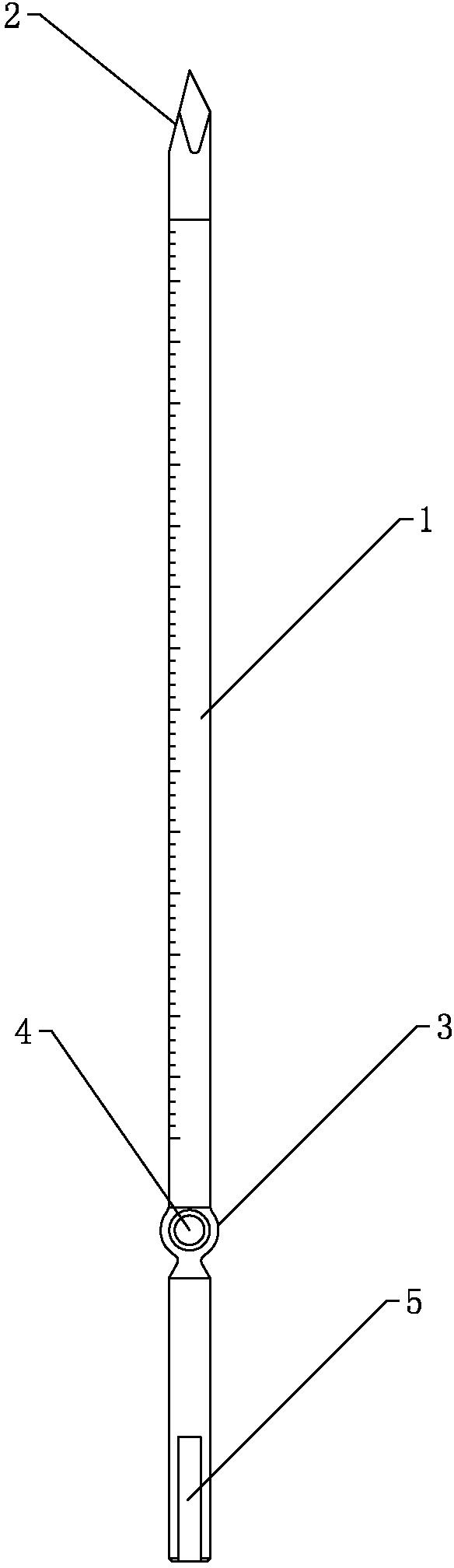

Internal fixing Kirschner wire for fracture

The invention discloses an internal fixing Kirschner wire for fracture. The Kirschner wire can prevent the rear shaft of the Kirschner wire from retreating, and can also prevent the Kirschner wire from excessively inserting into human body tissues in an axial direction. The internal fixing Kirschner wire for fracture comprises a needle bar and a needle point arranged at the head part of the needle bar, wherein the needle point is in self-tapping needle head design, the needle bar is provided with a limiting part with a threading hole, the lateral size of the limiting part is larger than the diameter of the needle bar, and the tail end of the needle bar is in a triangular prism shape.

Owner:SUZHOU KANGLI ORTHOPEDICS INSTR

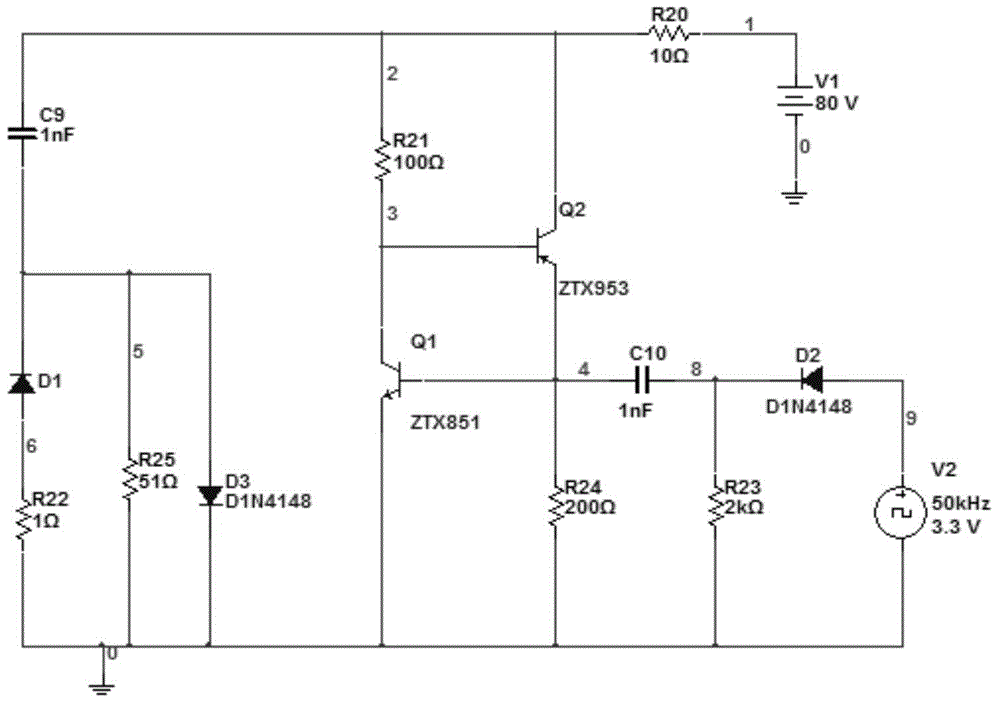

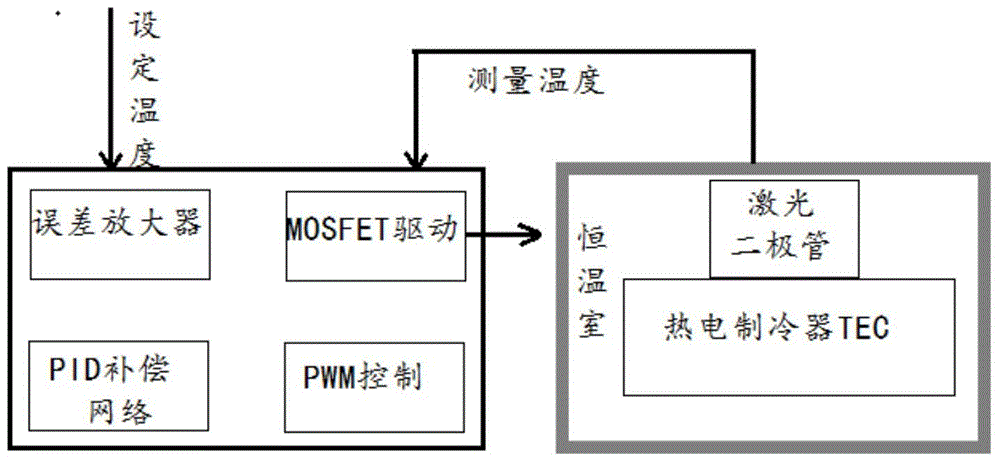

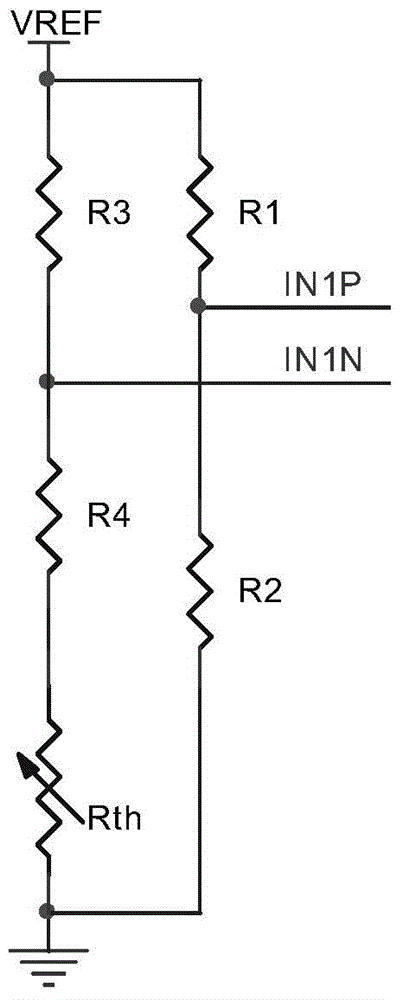

High repetition frequency narrow pulse laser emission circuit

InactiveCN105807269AIncreased range and dynamic stabilitySimple circuitWave based measurement systemsLaser rangingPeripheral

The invention proposes a high repetition frequency narrow pulse laser emitting circuit. It includes a driving circuit and a temperature control circuit of the laser diode; the driving circuit includes a trigger signal source, a charging and discharging circuit and a switching circuit; the driving circuit controls the closing of the switching circuit through the triggering signal, and then controls the frequency and frequency of the laser diode emitting laser through the charging and discharging circuit. pulse width to realize high repetition frequency and narrow pulse laser emission; the temperature control circuit includes a thermoelectric cooler and a peripheral circuit based on a control chip; the thermoelectric cooler is attached to a laser diode for temperature sensing, and the obtained temperature value is input to the The peripheral circuit of the chip, the peripheral circuit realizes the cooling control of the thermoelectric cooler by controlling the chip, thereby reducing the temperature of the laser diode and making it work at a constant temperature. The invention realizes the emission of pulsed laser and effectively improves the working distance and precision of laser ranging.

Owner:NANJING UNIV OF SCI & TECH

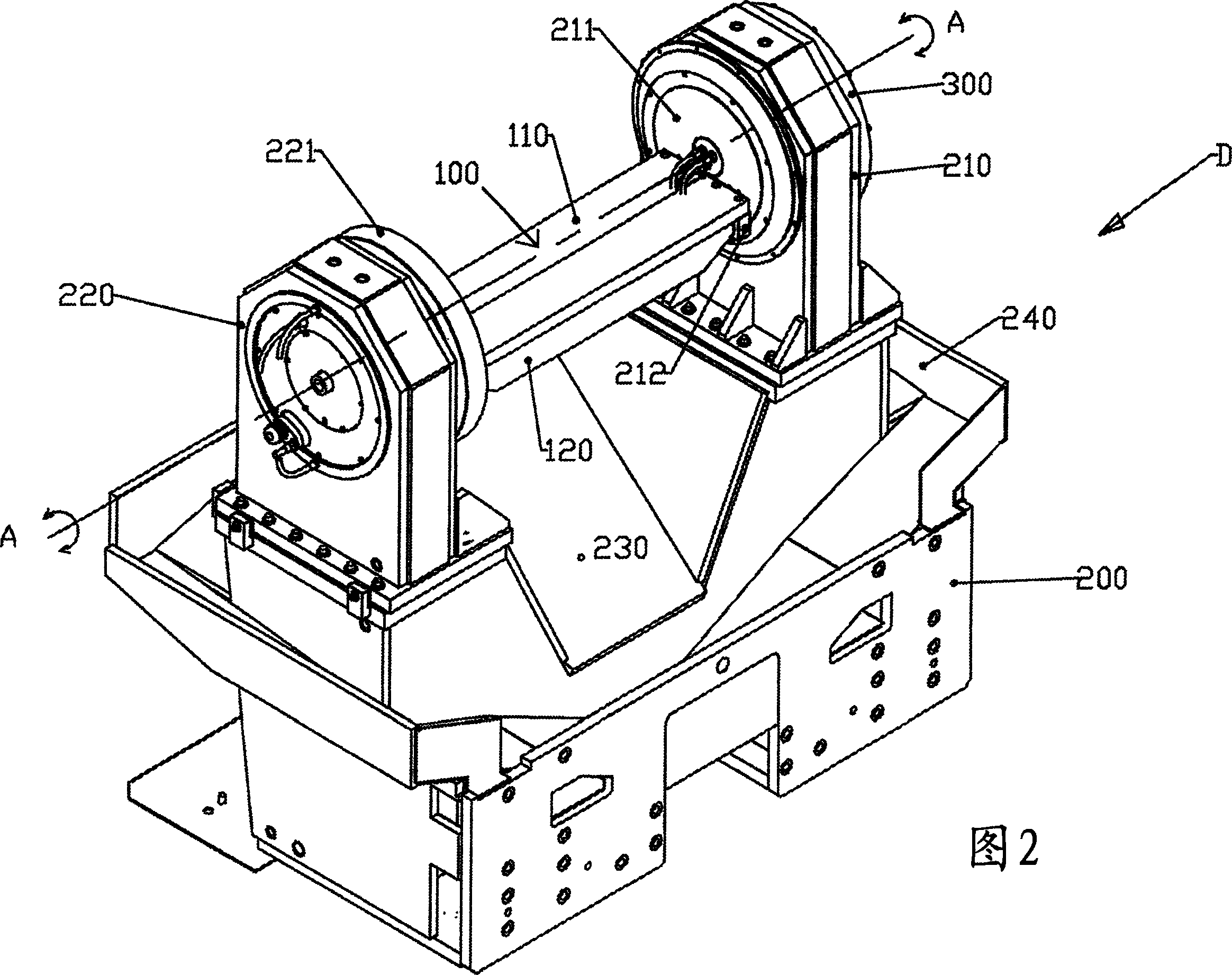

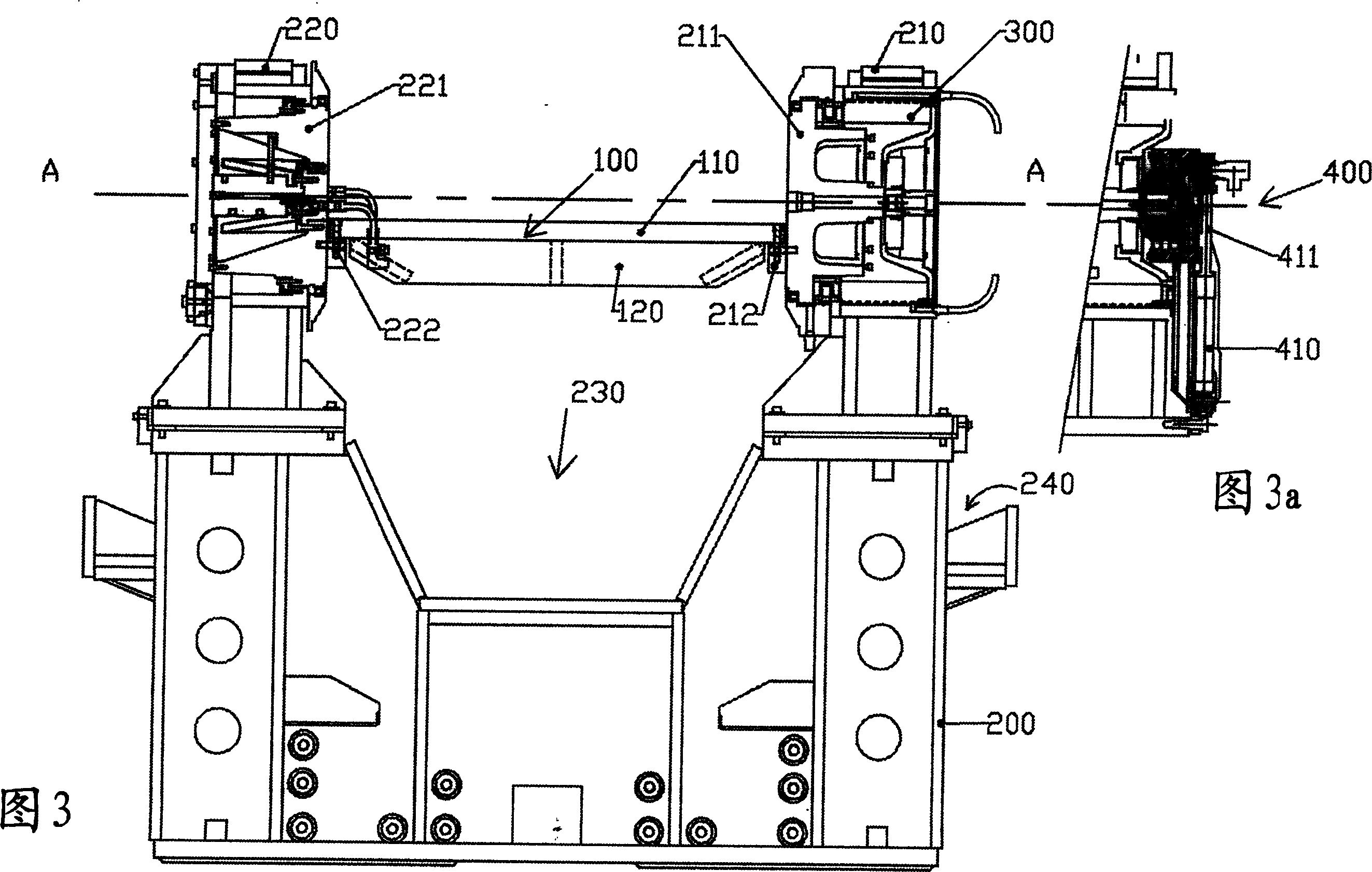

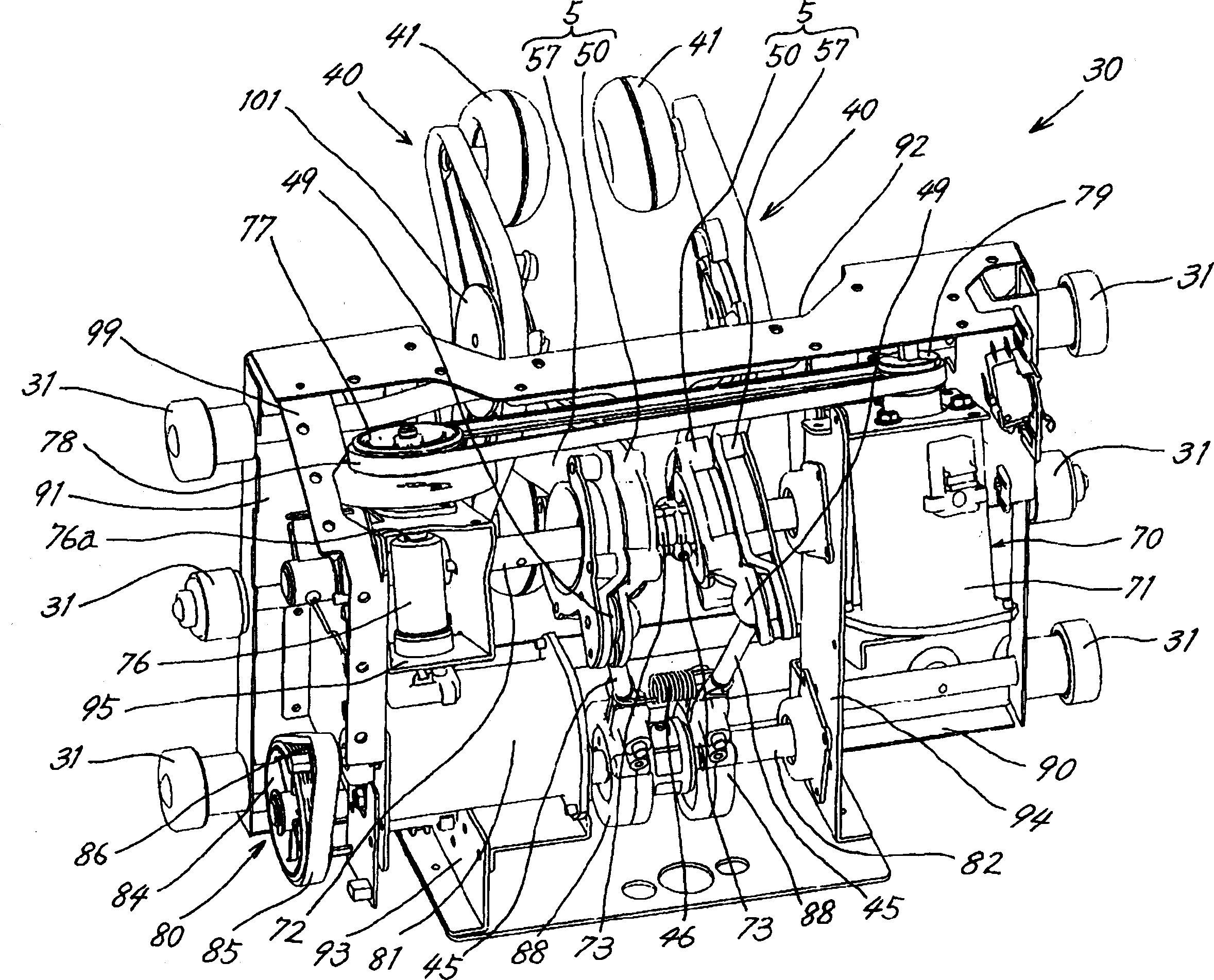

Versatile and modular workpiece holding device

InactiveCN1871101AEasy to implementEasy to handlePrecision positioning equipmentLarge fixed membersEngineeringAxial force

Owner:COMAU SYST FRANCE

Efficient charging pile for new energy vehicle

InactiveCN112659939AAvoid enteringImprove sealingCharging stationsElectric vehicle charging technologyNew energyStructural engineering

The invention discloses an efficient charging pile for a new energy vehicle, and relates to the technical field of automobile charging piles. In order to improve the safety during charging, The charging pile specifically comprises two main bodies symmetrically installed on a base, operation screens are arranged on the outer walls of one sides of the two main bodies correspondingly, second supports are fixed to the outer walls of the adjacent sides of the two main bodies through screws, handles are clamped to the second supports correspondingly, the handles are connected into internal circuits of the main bodies through roll type charging wires, and charging heads are arranged at one ends of the handles; and the circumferential outer wall, close to the charging head, of the handle is in threaded connection with a protective cover. By arranging the protective cover, the annular air cushion and other structures, the protective cover can be rotated to the handle through threads according to needs, then the charging head and a charging port of an automobile are protected, the automobile charging device is particularly suitable for external rainy and snowy weather, water can be effectively prevented from entering, and the size of the annular air cushion can be adjusted through the air bag according to actual conditions; therefore, the sealing performance is improved.

Owner:陈秋霖

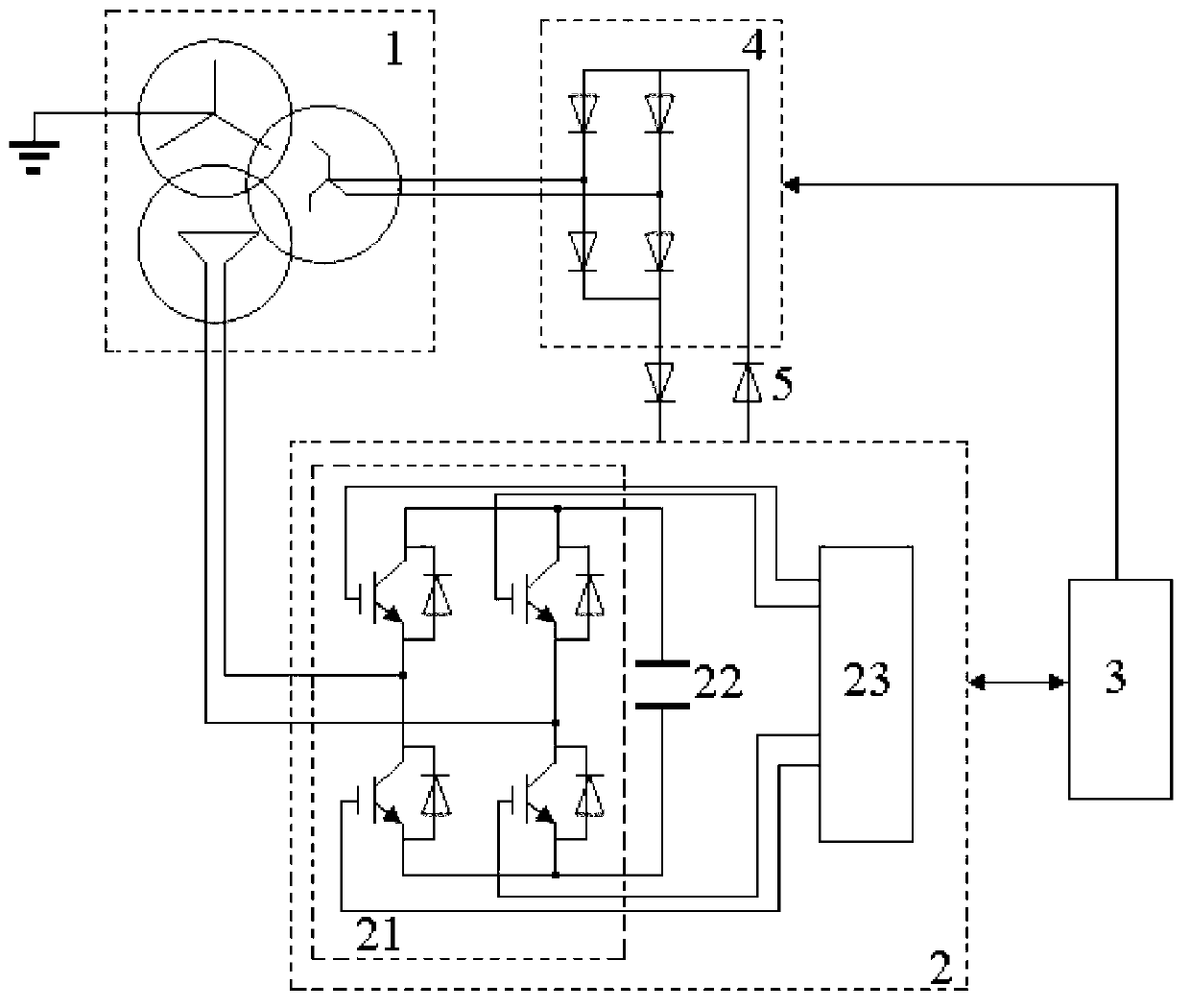

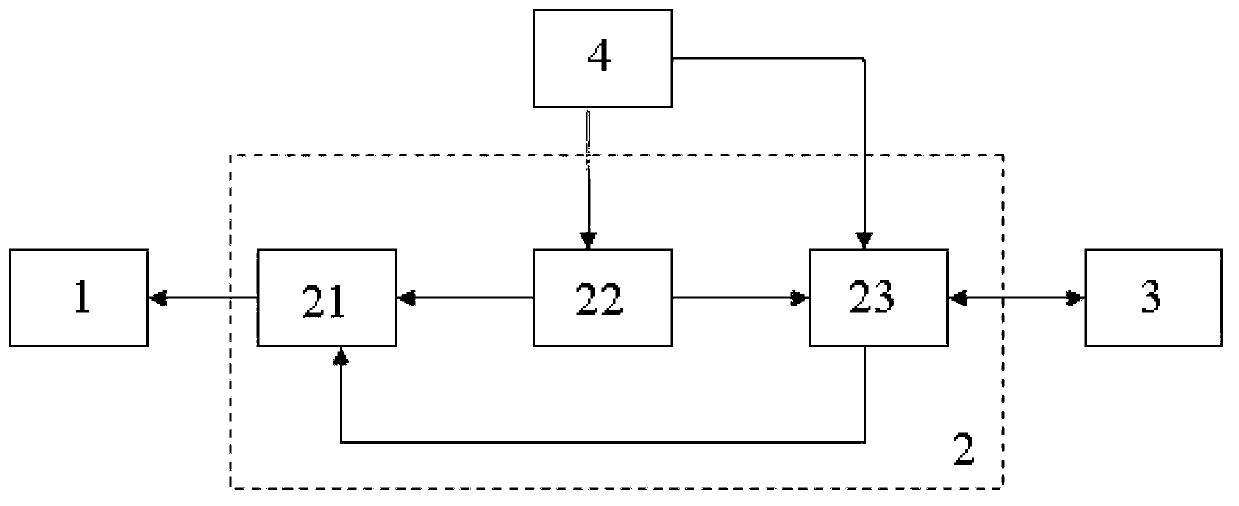

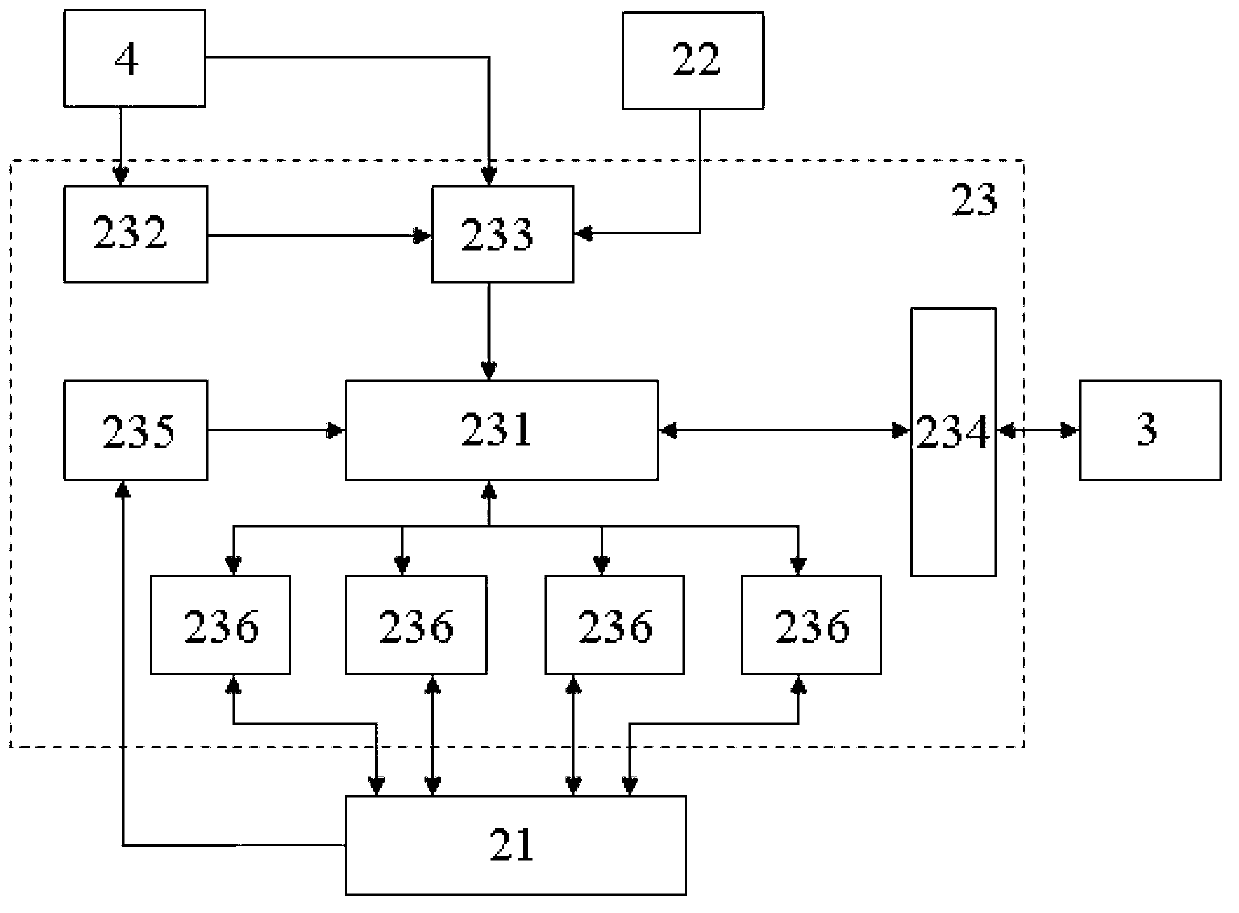

Electric network grounding compensation device based on arc suppression transformer

ActiveCN103280793AQuick compensationReduce in quantityEmergency protective arrangements for limiting excess voltage/currentCapacitanceConnection type

The invention relates to an electric network grounding compensation device based on an arc suppression transformer. The electric network grounding compensation device comprises the arc suppression transformer connected with an electric network bus, wherein the arc suppression transformer is a three-phase five-pole type arc suppression transformer of which the primary side winding is in star-shaped connection with a neutral point directly grounded, and the secondary side winding is of an opening delta connection type, a secondary side opening end of the three-phase five-pole type arc suppression transformer is connected with an active inverter regulating device used for outputting compensating voltage to the arc suppression transformer, and the controlled end of the active inverter regulating device is connected with a controller used for controlling the active inverter regulating device to output compensating voltage. According to the electric network grounding compensation device, the number of equipment mounted in a primary system is smaller; and when the system generates a grounding failure, the compensating state of the arc suppression transformer can be directly regulated through the active inverter regulating device, so the fast compensation of great-capacitance current when the system generates the grounding failure is realized, and the electric network grounding compensation device has the advantages of high compensating speed, low cost, small occupied area and the like.

Owner:HEBEI XUHUI ELECTRIC

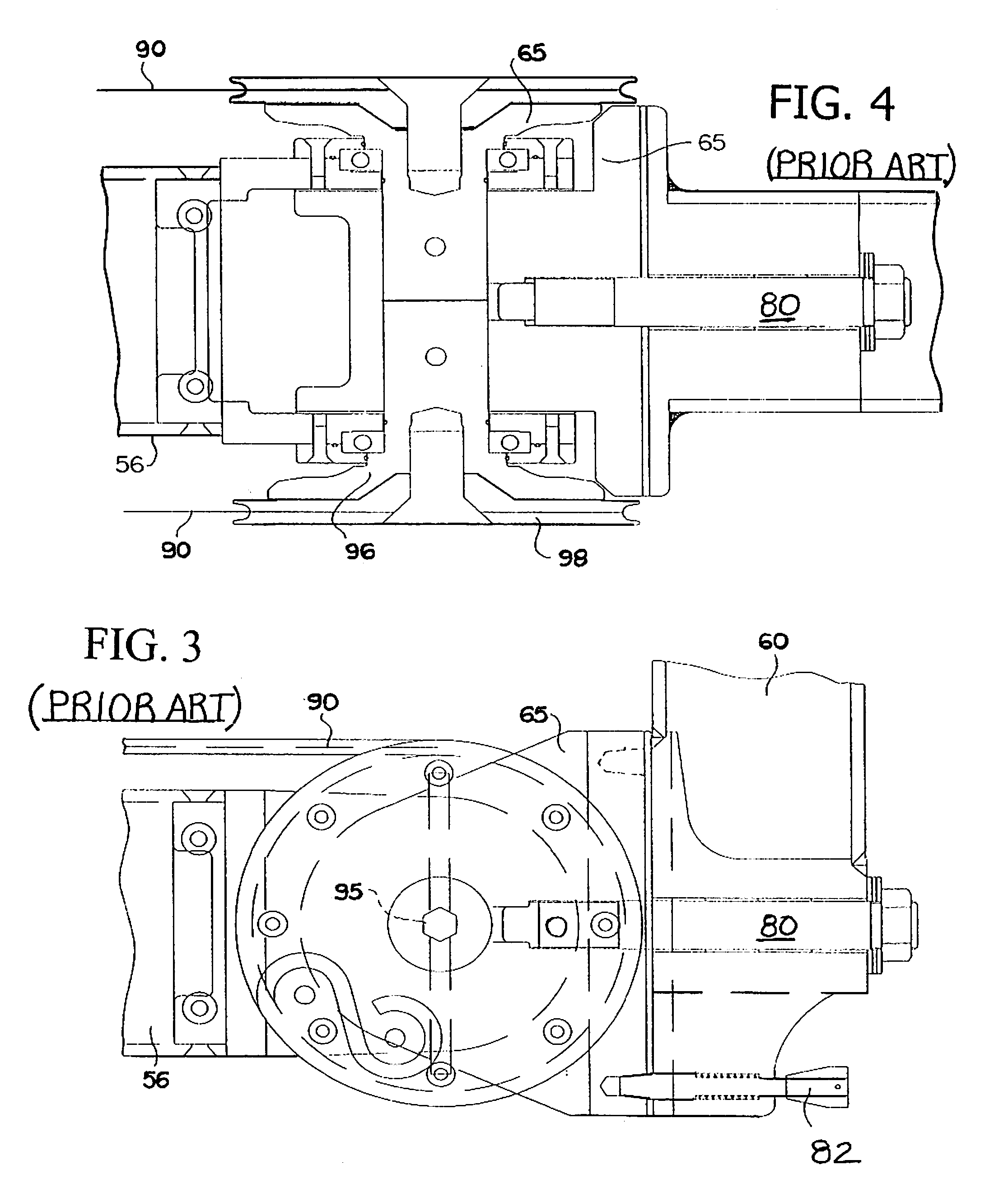

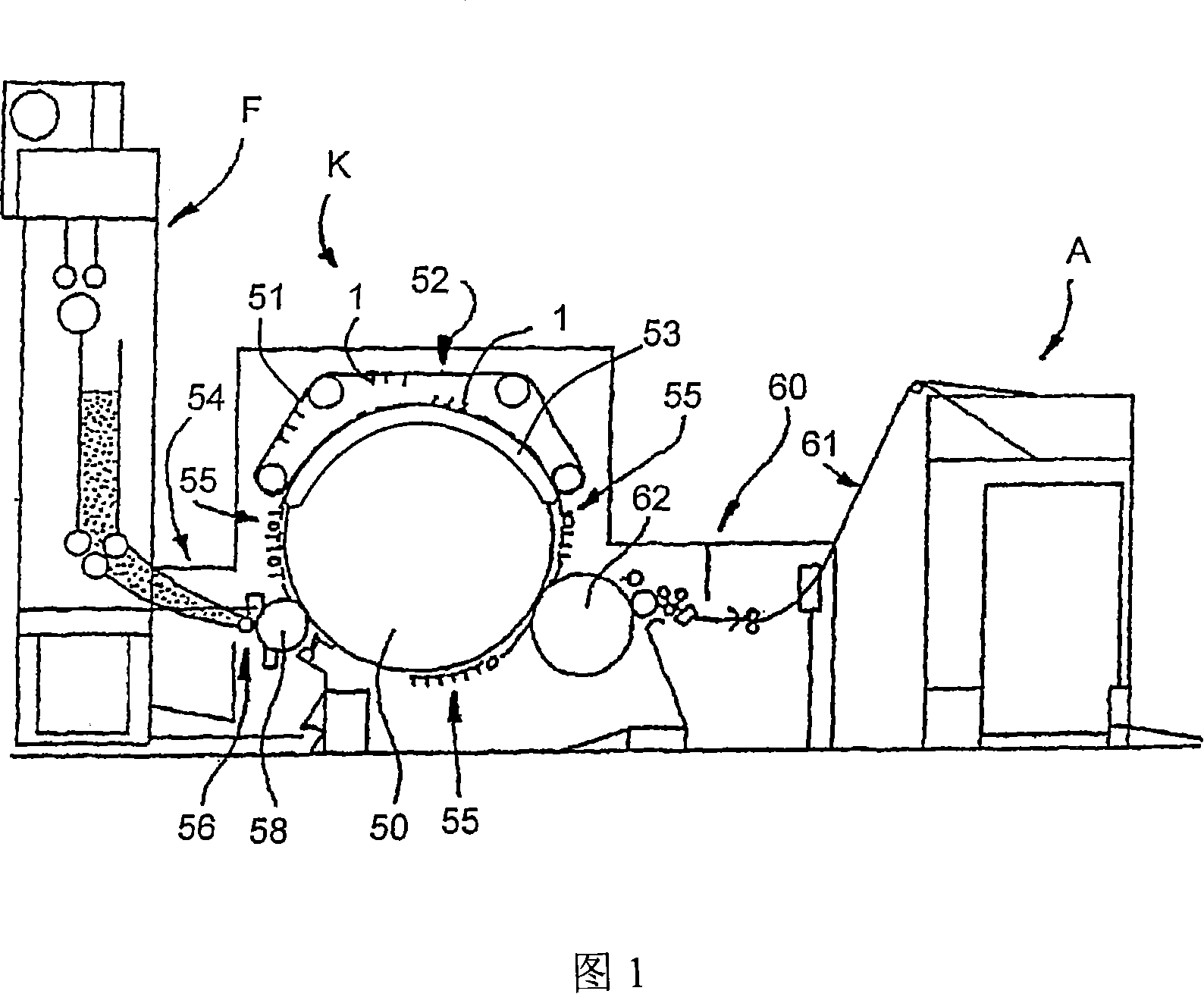

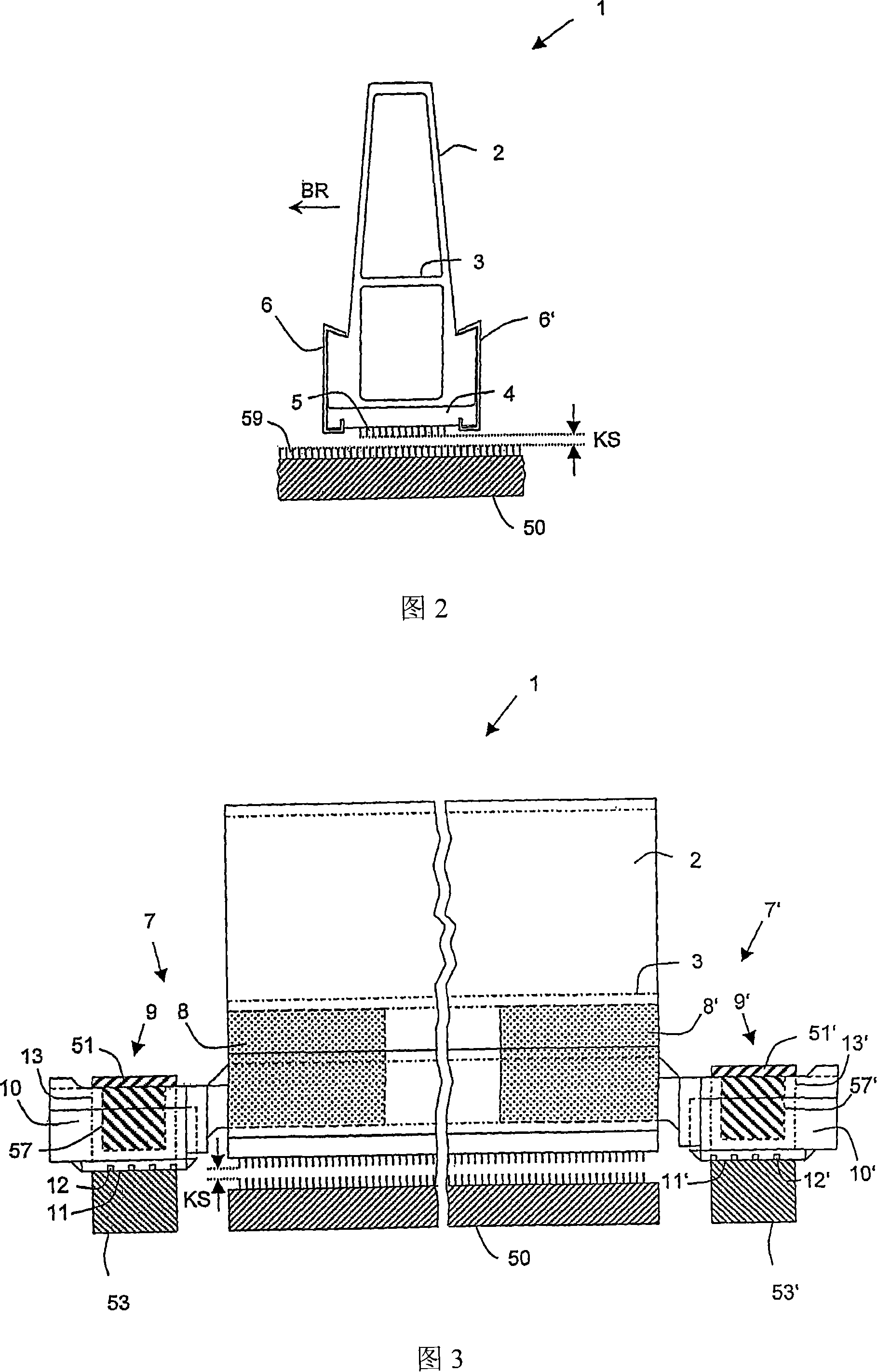

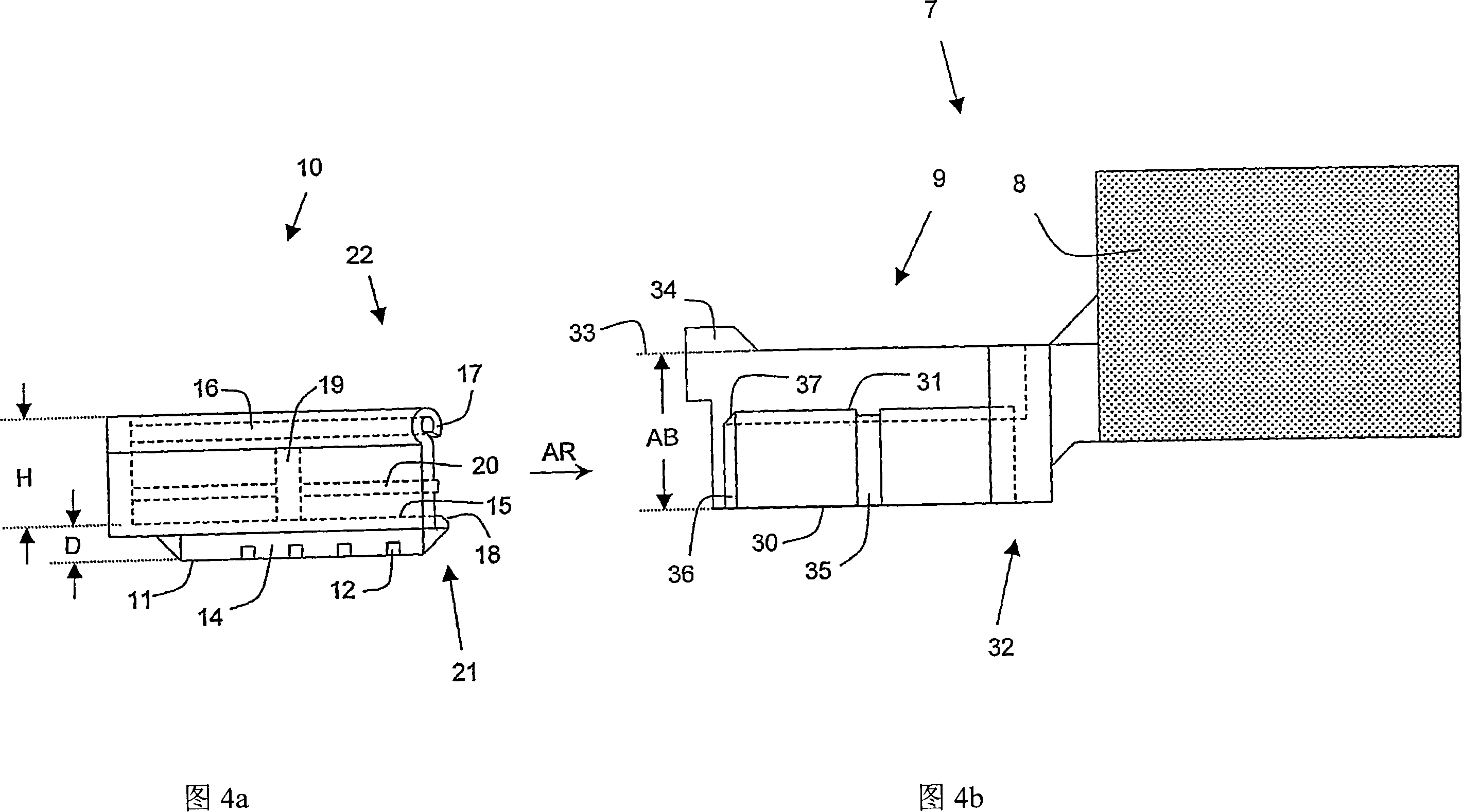

Guide shoe and carding head for the carding bar of a card

The invention relates to a guide shoe (10) for a carding head (7) of a carding bar (1) of a card (K). Said shoe can be pushed onto the carding head (7) in an axial direction (AR). The shoe comprises at least one sliding section (14), which can be positioned between the carding head (7) and a flexible arc (53) and which comprises a sliding surface (11) that co-operates with the flexible arc (53) and is situated on the side facing the latter (53). The sliding section (14) comprises a contact surface (15) on the side facing the carding head (7), said surface being applied, without leaving a gap, to a corresponding supporting surface (30) of the carding head (7). The invention also relates to a corresponding carding head and carding bar.

Owner:MASCHINENFABRIK RIETER AG

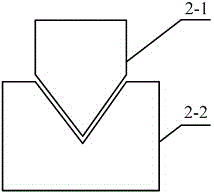

Slotting type metal plate bending device

InactiveCN112548580AGuaranteed normal bendingAvoid backlashOther manufacturing equipments/toolsGrinding machinesThin metalAcute angle

The invention relates to the field of metal plates, in particular to a slotting type metal plate bending device. According to the technical scheme, the slotting type metal plate bending device comprises a working machine bottom plate, a slotting system, a pressurizing bending system and a bending seam welding system; and the slotting system, the pressurizing bending system and the bending seam welding system are sequentially connected to the upper portion of the working machine bottom plate. The center of a plate is slotted before bending, normal bending of materials is guaranteed, the phenomenon that the left side and the right side of a fold line in a central fold line area extrude each other and then protrude reversely is avoided, a thin metal plate is bent in positioned and protected modes through slotting, obtuse-angle and acute-angle bending with the accurate angle is achieved, and a crack on the outer side of the bent part in the bending process of the acute-angle metal plate isrepaired in positioned and welded modes.

Owner:田振宇

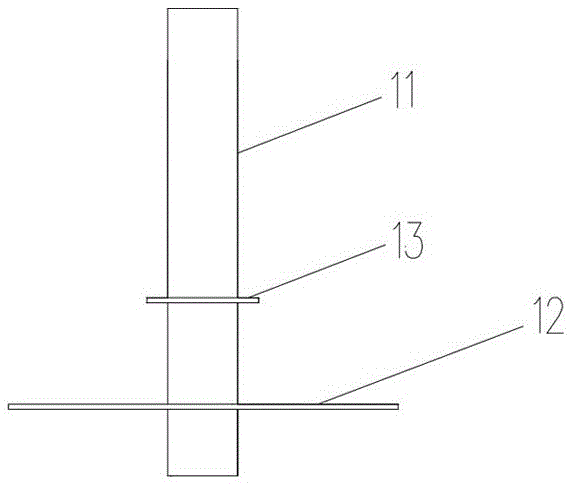

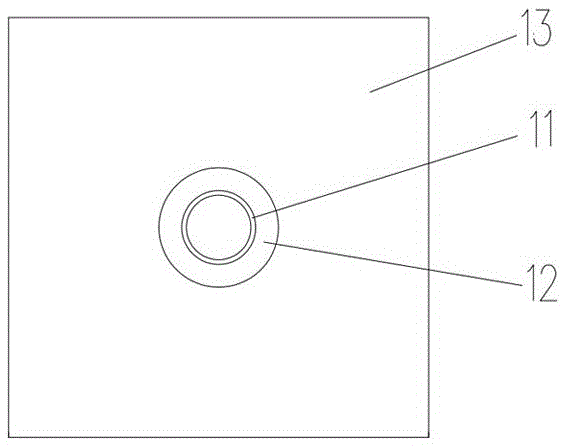

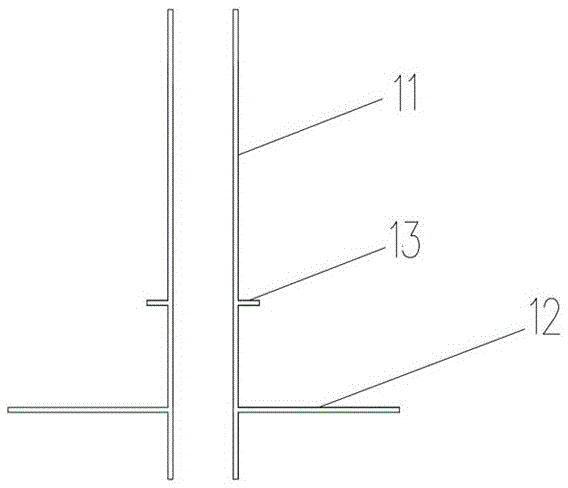

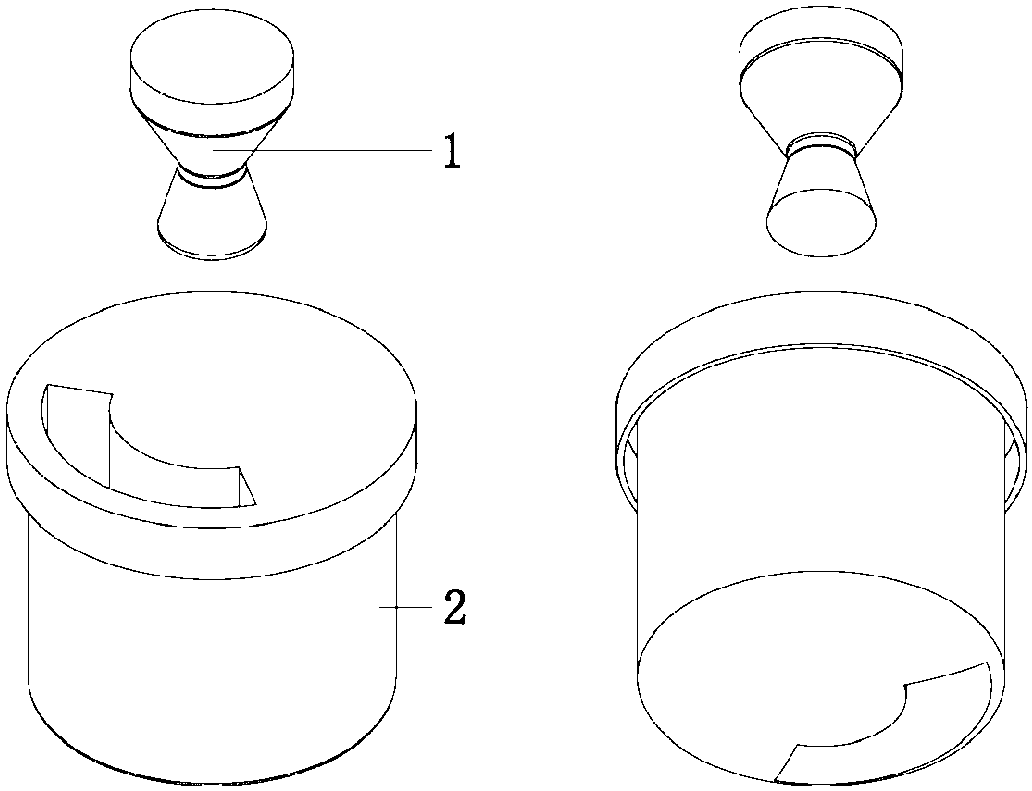

Component for tubular well precipitation construction in elevator foundation pit or sump and construction method

InactiveCN105484277AEasy constructionGuarantee the waterproof quality of constructionFoundation engineeringBasementEaves

The invention relates to the technical field of basement building construction, in particular to the technical field of high-water-level elevator foundation pit or sump construction, and particularly discloses a component for tubular well precipitation construction in an elevator foundation pit or sump. The component comprises a hollow sleeve, wherein a horizontal support plate, perpendicular to the sleeve, is arranged at the lower part of the sleeve, the sleeve is provided with an eave board above the support plate, the sleeve penetrates through the eave board and the support plate, and the eave board and the support plate are fixed with and in seamless connection with the sleeve; and the part, below the support plate, of the lower part of the sleeve is inserted into a tubular well, and the support plate is horizontally erected outside the opening of the tubular well and used for supporting the sleeve. The invention further discloses a construction method. The construction method comprises the following steps of tubular well precipitation, earth excavation, component mounting, cushion layer construction, water-proof layer construction, foundation raft concrete pouring, earth backfilling, tubular well blocking and the like. By applying the component and the construction method, the construction of the cushion layer, the water-proof layer and the foundation raft of the elevator foundation pit or sump can be conveniently carried out, the construction water-proof quality can be ensured, the construction efficiency can be improved, and the construction cycle can be shortened.

Owner:CHINA CONSTR SEVENTH ENG DIVISION CORP LTD

Drawing folding device for petroleum pipeline design

The invention discloses a drawing folding device for petroleum pipeline design. The device structurally comprises a bottom plate, a fixing rod, a torsion spring, a pressing strip and a folding device.The fixing rod is welded to the middle of the bottom plate, the fixing rod is sleeved with the torsion spring, one end of the torsion spring is embedded to the bottom plate, the other end of the torsion spring is embedded into the top face of the pressing strip, the pressing strip is in fit with the bottom plate, and the folding device is connected to the side face of the bottom plate. The drawing folding device has the beneficial effects that the paper page turning action of the human body can be simulated through a paper pick-up mechanism, the excessive paper page turning phenomenon can beavoided, the skidding phenomenon is avoided since timely power is provided by an electromagnetic device for a push device, drawing can be pushed rightwards when the drawing is unfolded, page turning is assisted, the back falling phenomenon is prevented, the drawing flying phenomenon can be avoided through the pressing block, automatic page turning is achieved through the folding device, the excessive page turning phenomenon is avoided, and the error rate is reduced.

Owner:连三琼

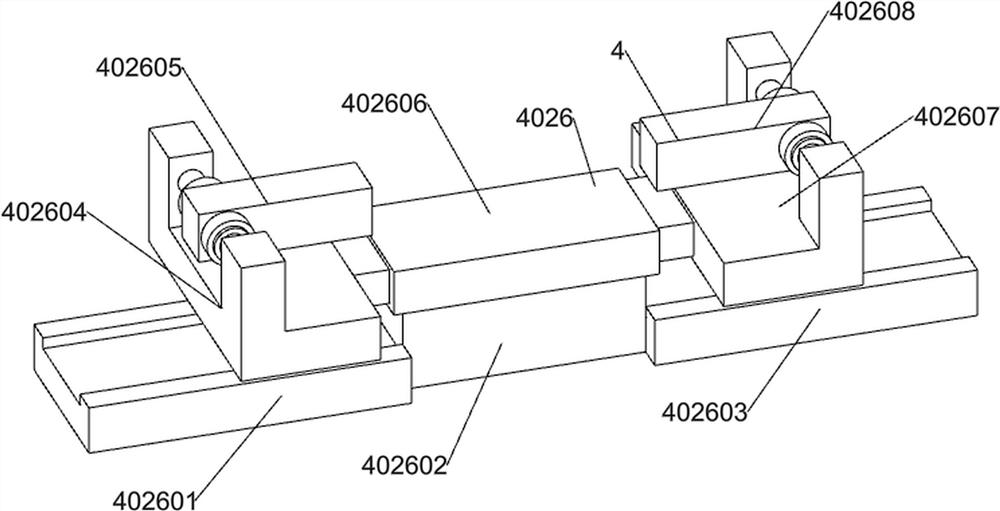

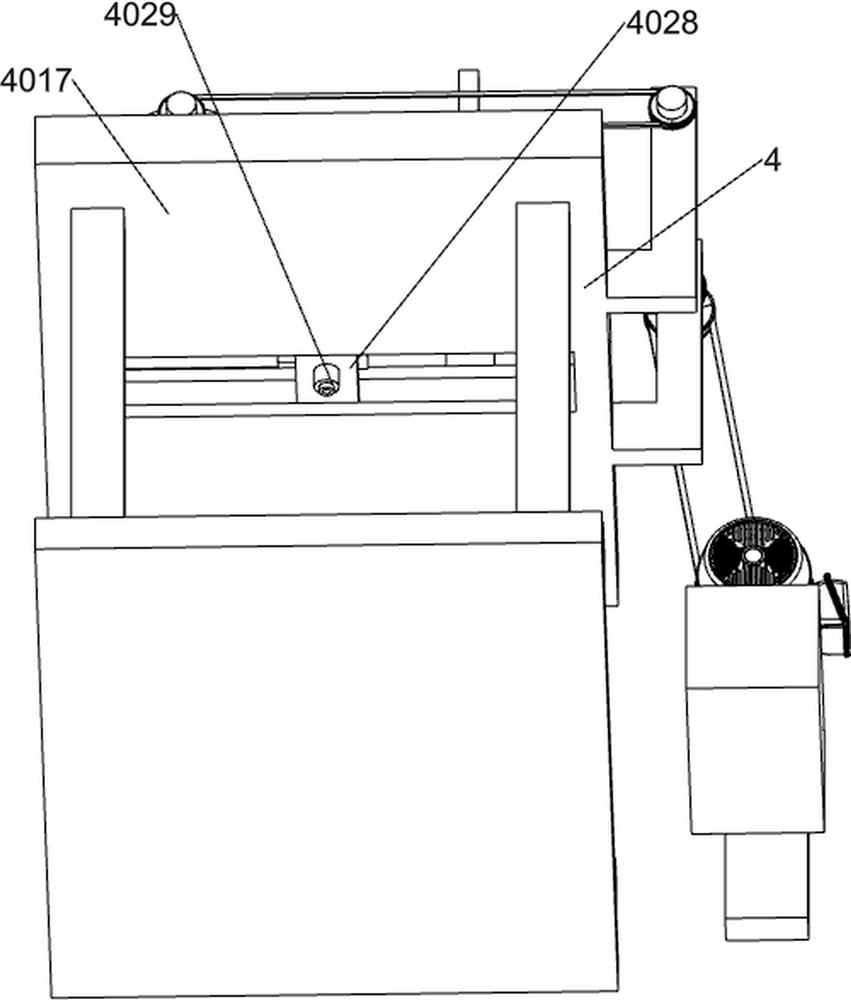

Seven-axis machine tool

PendingCN111360552ANovel structureLow costLarge fixed membersDriving apparatusEngineeringMachine tool

The invention discloses a seven-axis machine tool. The seven-axis machine tool comprises a machine tool body and a workbench installed on the machine tool body, the workbench can move in the directionof the machine tool body, the two sides of the machine tool body are each provided with a stand column, a cross beam is installed on the two stand columns, a ram is movably installed on the surface of the cross beam through a sliding rail, a one-axis connecting piece is installed on the ram through a power speed reduction component, a two-axis connecting piece is installed on the surface of the tail end of the one-axis connecting piece through the power speed reduction component, a three-axis connecting piece is installed on the surface of the tail end of the two-axis connecting piece throughthe power speed reduction component, a four-axis connecting piece is installed on the surface of the tail end of the three-axis connecting piece through the power speed reduction component, and a machining main shaft is installed on the surface of the tail end of the four-axis connecting piece through the power speed reduction component. According to the seven-axis machine tool, a series of structures are arranged, so that the seven-axis machine tool has the seven-axis five-linkage function, a Z-axis component of a traditional machine tool is omitted, the structure is simplified, and machining multiple faces of a large workpiece can be carried out.

Owner:天津三合智能装备制造有限公司

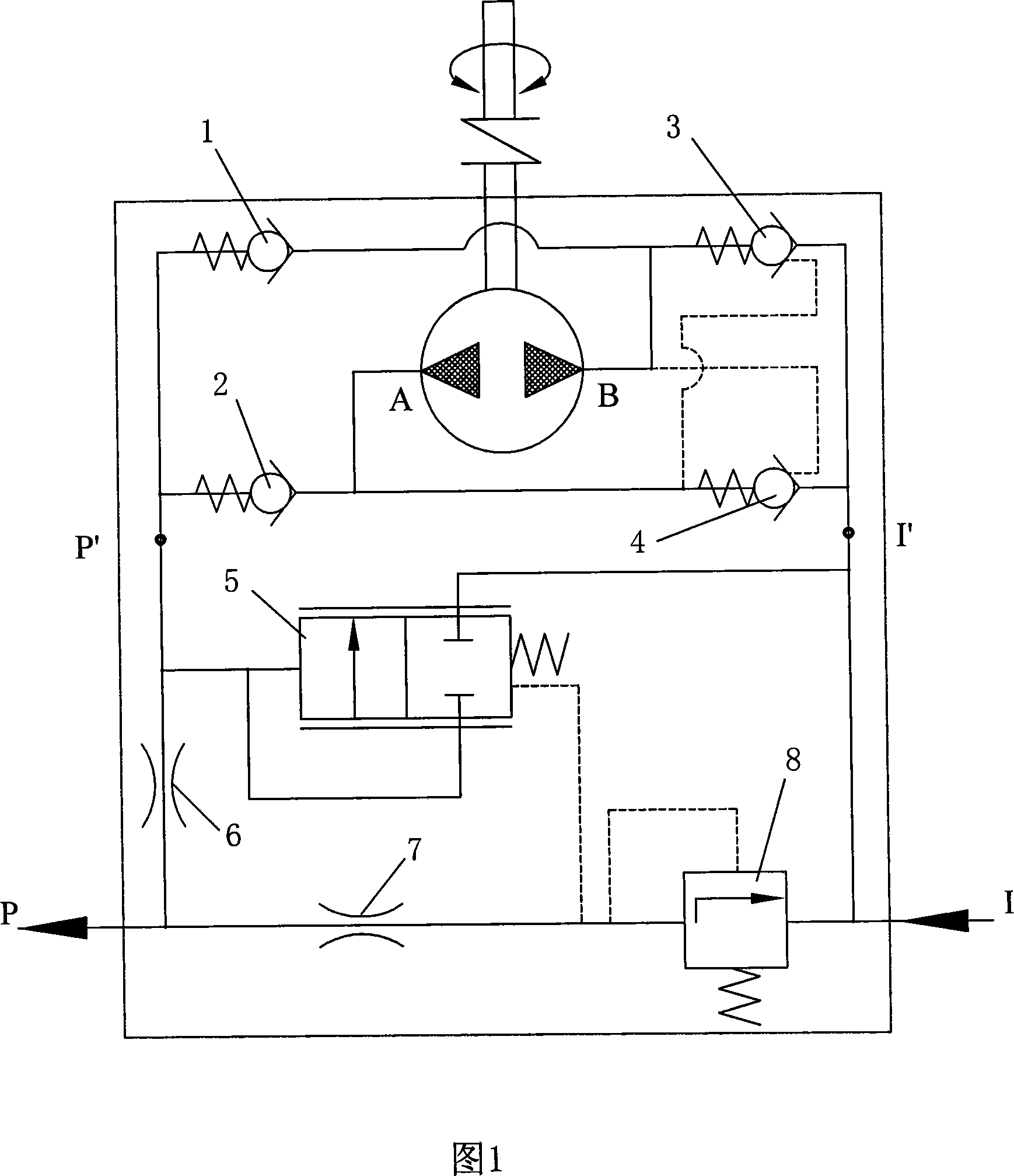

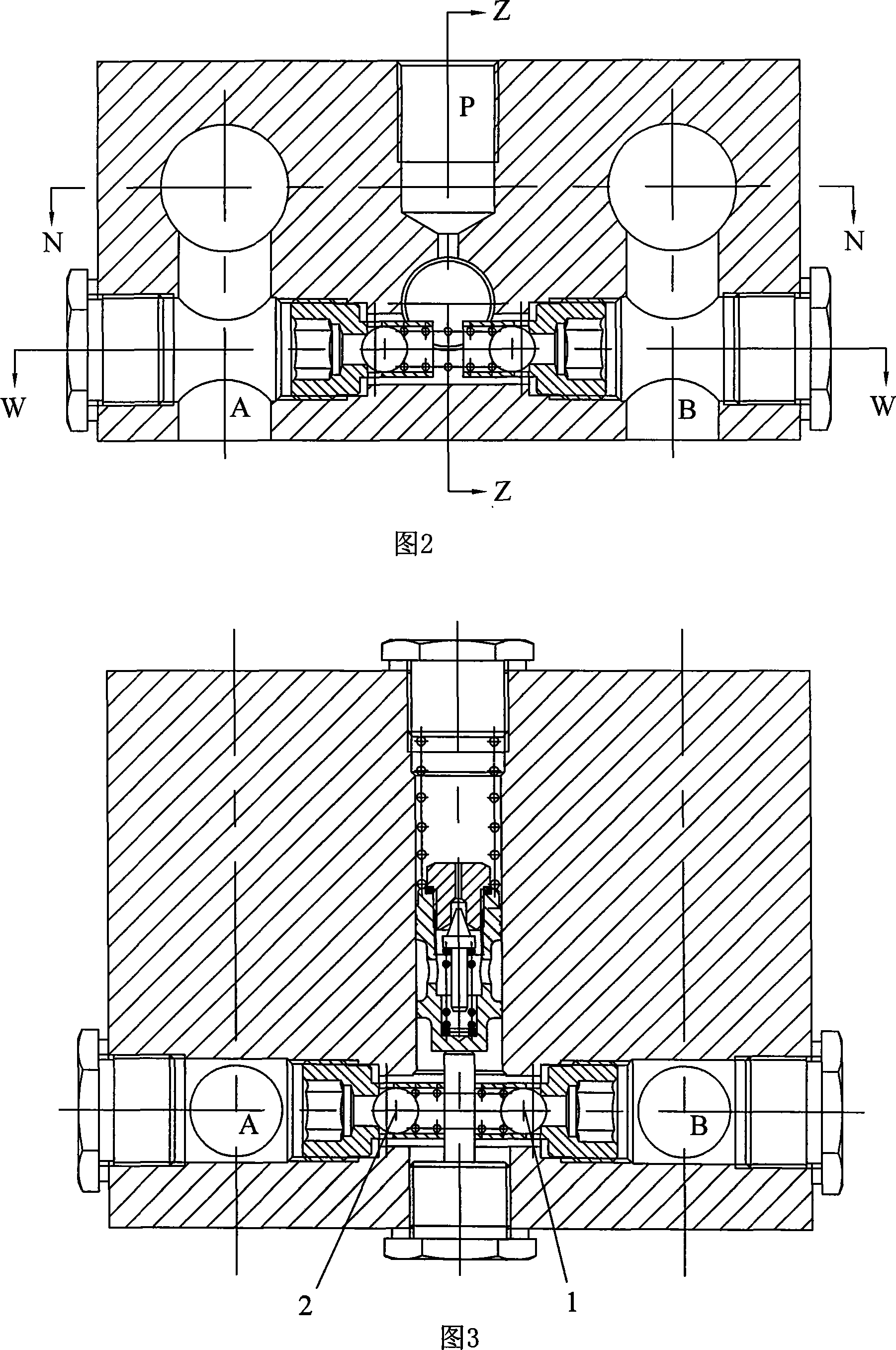

Bidirectional constant flux gear pump

InactiveCN101196189ARealize two-way rotationSmooth oil absorptionRotary piston pumpsRotary piston liquid enginesGear pumpHydraulic pump

The invention provides a double direction constant flow gear pump, which relates to the technical field of double direction rotation of hydraulic pump. The gear pump mainly comprises a double direction constant flow control device, a general oil pump inlet (I), a general oil pump outlet (P), an oil pump inlet (I'), an oil pump outlet (P'), a normative hydraulic pump oil port (A) and a normative hydraulic pump oil port (B). The double direction constant flow control device comprises a one-way valve (1), a one-way valve (2), a hydraulic control one-way valve (3), a hydraulic control one-way valve (4), a slide valve (5), a flow control orifice (6), a pressure control orifice (7), a cone valve (8), a hydraulic control piston (9) and a hydraulic control piston (10). The invention has the advantages that: when the gear pump rotates in two direction, the constant flow gear pump can keep the position of the oil inlet and oil outlet unchanged, at the same time, maintain constant output flow and realize safe restriction for the output pressure.

Owner:孙玉清 +1

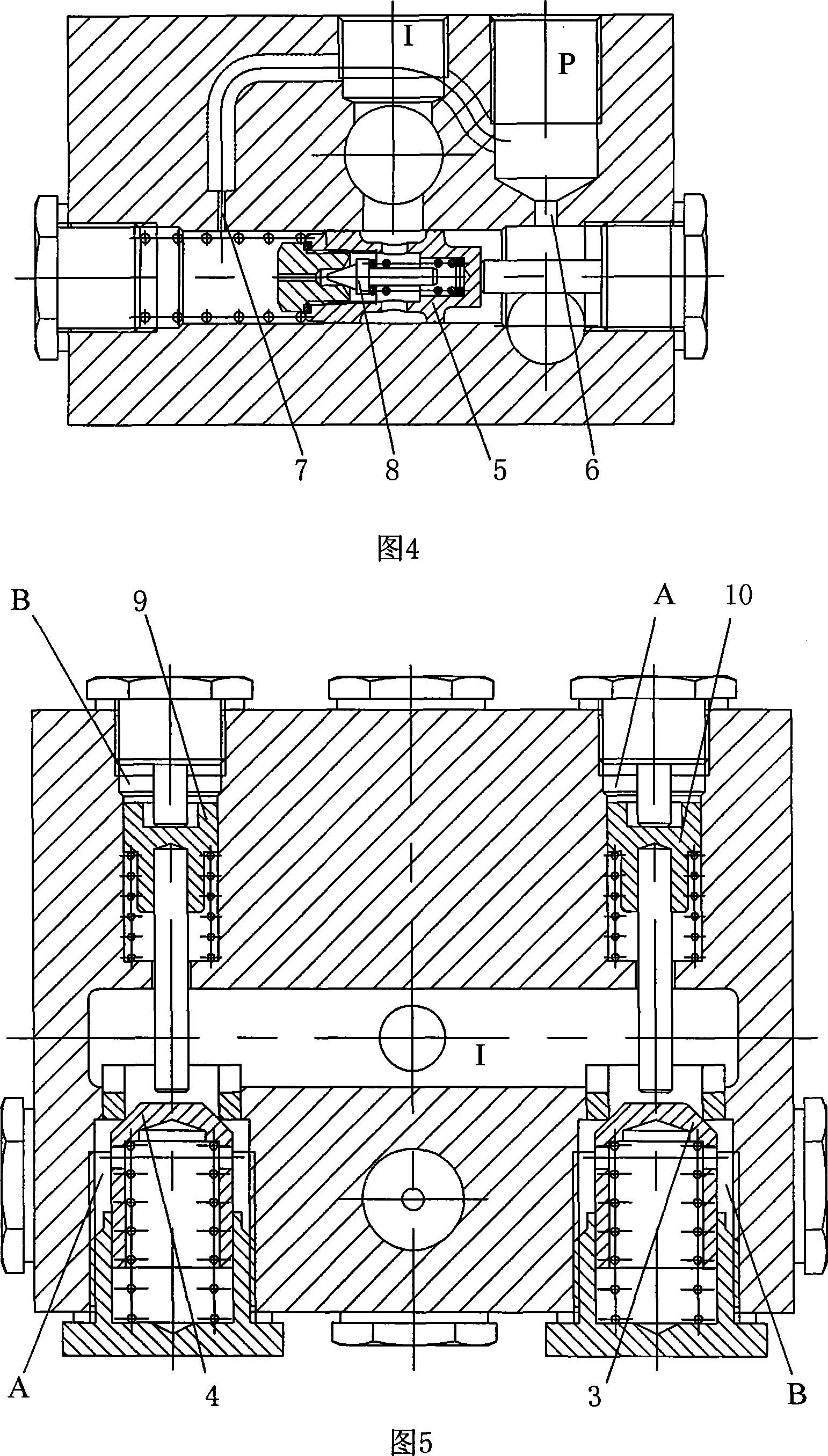

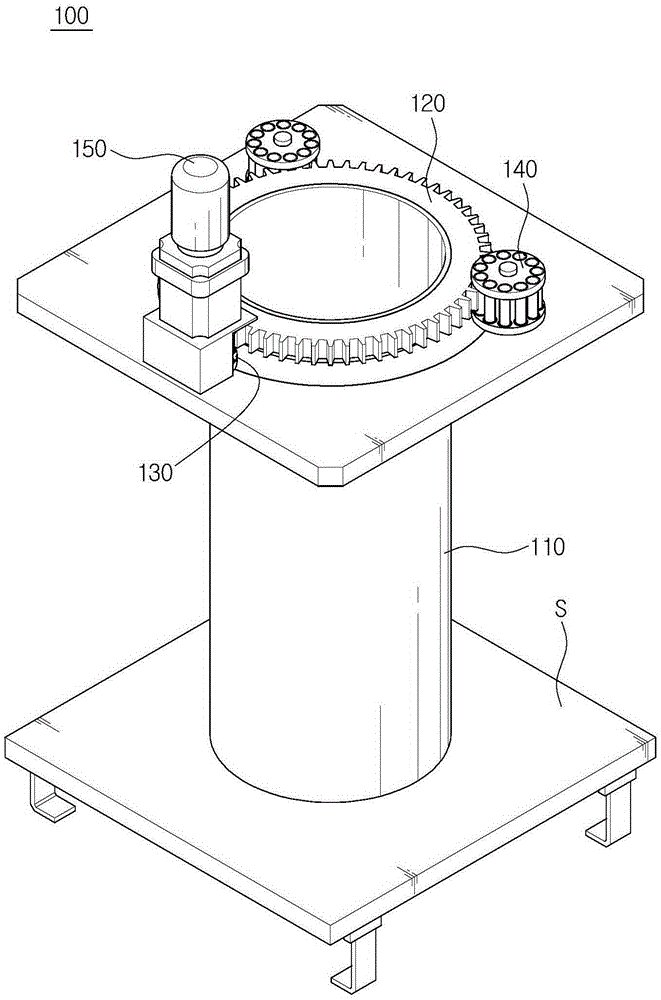

Apparatus for rotating aligning a substrate

InactiveCN105552013AAvoid distortionPrecise alignmentSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringDeposition process

The present invention relates to an apparatus for rotating and aligning a substrate, and more specifically to an apparatus for rotating and aligning a substrate which aligns a substrate on a mask in a deposition process. The present invention may include: a connection pillar connected to a settling part on which the substrate is settled; a rotating stage which is circular-shaped, fixed with the connection pillar, and a protruding part and a concave part are alternately formed; a power delivering unit which has multiple roller pins arranged separately from one another at fixed intervals, and delivers the power to the rotating stage by rotating in the state that at least one roller pin is pressured and adhered to the concave part at a region of the rotating stage; and a fixing unit which adheres at least one fixing pin to the concave part at another region in the rotating stage in order to have the opposite force of vector to the force applied to the rotating stage of the power delivering unit.

Owner:SNU PRECISION CO LTD

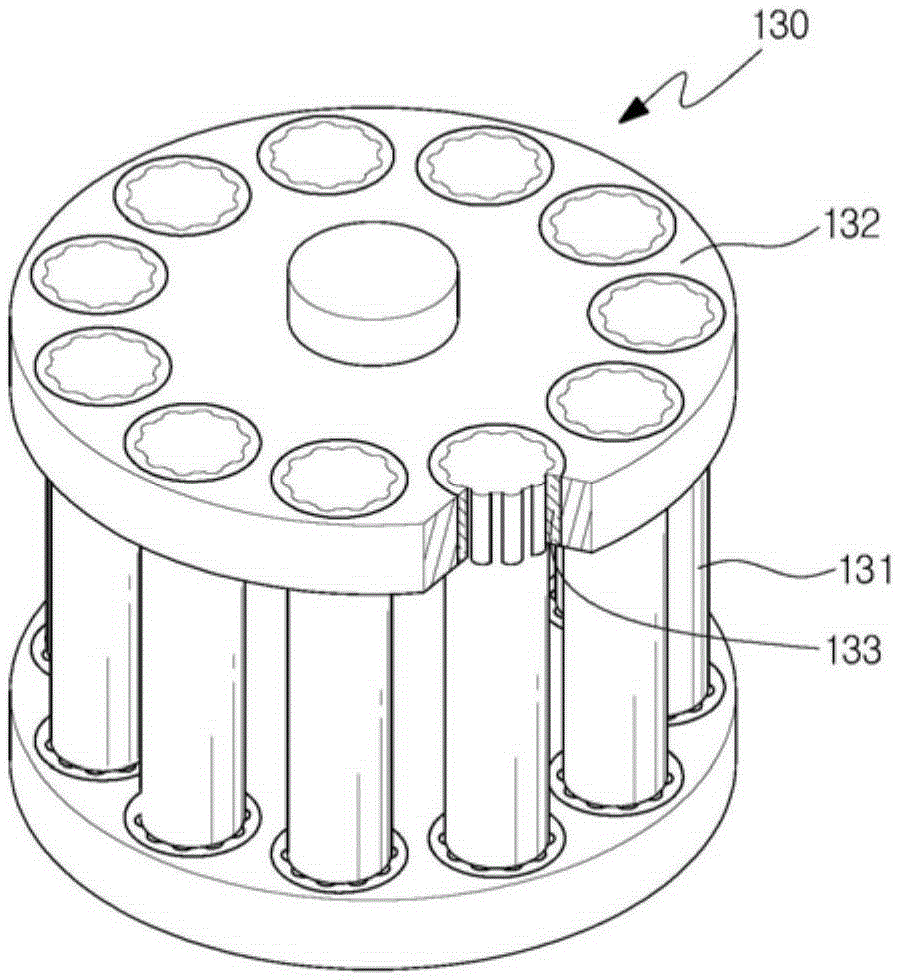

Robot end executor

PendingCN107336220AHigh precisionAvoid backlashProgramme-controlled manipulatorLinear motionMotor drive

The invention provides a robot end executor. The robot end executor comprises a spindle module, a feeding module and a connecting assembly; the spindle module comprises a spindle and a spindle shell wrapping the periphery of the spindle, the feeding module comprises a screw, a feeding motor driving the screw to rotate and a sliding block fixed to the screw, a machine shell is arranged on the outer side of the screw, the connecting assembly comprises a mounting part fixed to the spindle shell, and the mounting part is fixedly connected with the sliding block. According to the robot end executor, rotation motion of the feeding motor is converted into the linear motion of the spindle through the screw, the influence caused by the reverse gap in a robot transmission chain can be avoided, and the machining precision is improved.

Owner:YUANMENG PRECISION TECH SHENZHEN INST

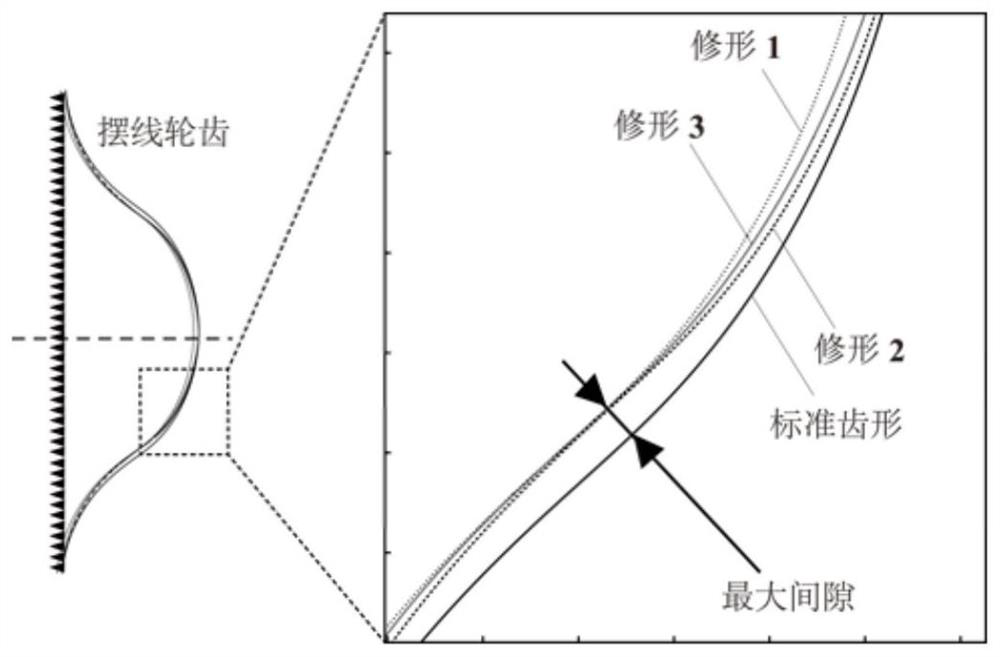

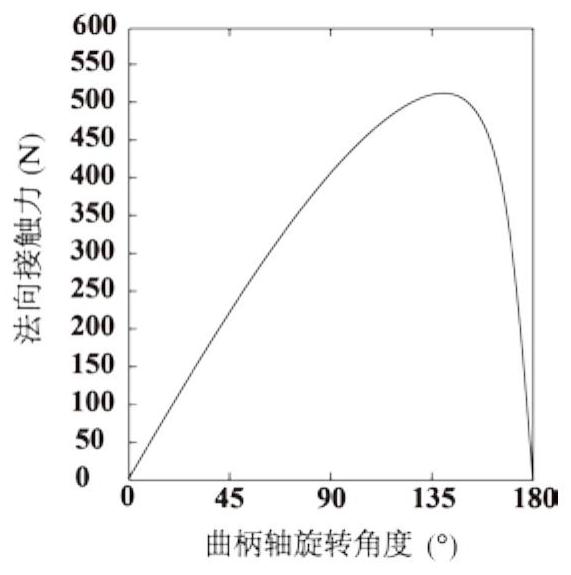

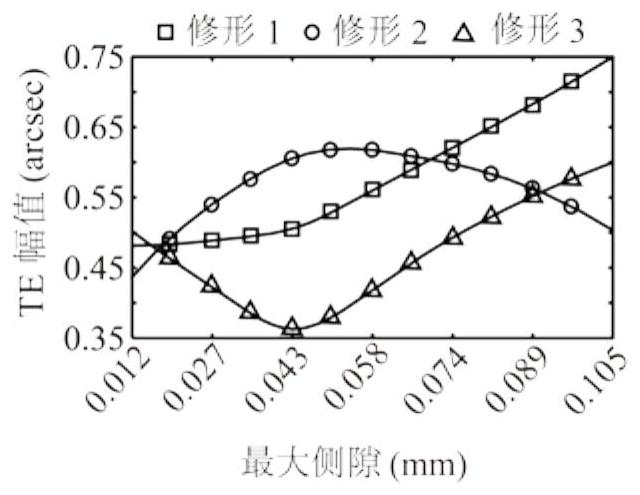

Cycloid tooth profile matching modification method of precision speed reducer for robot

PendingCN112035968AMitigation of impairmentAvoid backlashGeometric CADSpecial data processing applicationsPhysicsTransmission performance

The invention relates to the technical field of cycloid tooth profile design and mechanical transmission of speed reducers, in particular to a cycloid tooth profile matching modification method of a precision speed reducer for a robot, which has the advantages of adapting to the requirement of the robot on the transmission performance of the precision speed reducer under a large-load working condition, and meeting the mutual matching of a cycloid modification tooth profile and meshing contact force; the cycloid tooth profile modification gap is uniform, and the transmission error mean value caused by tooth profile modification is reduced; the normal force at the meshing point of the meshing tooth surface is reduced, and the speed reducer obtains better transmission performance; the methodcomprises the following steps: S1, calculating according to a classical cycloid tooth profile contact force formula to obtain a normal contact force curve; s2, taking the normal contact force curve asa modification parameter to calculate the modification amount of the tooth profile of the cycloid gear in the rectangular coordinate system; s3, on the basis, removing the modification amount coordinate values from the theoretical cycloid tooth profile to obtain a modified cycloid tooth profile; and S4, further calculating the normal backlash generated after cycloid gear tooth profile modification through the modification amount coordinates.

Owner:YANCHENG INST OF TECH

Gravity opening-closing-type deodorization floor drain

The invention discloses a gravity opening-closing-type deodorization floor drain, and belongs to the technical field of indoor sanitary pipeline devices. The gravity opening-closing-type deodorizationfloor drain includes a gravity opening-closing-type valve element, a copper or stainless steel valve and a valve pipeline design mode. According to the device, gravity generated by the valve elementitself is utilized, so that an upper annular conical surface of the valve element is in contact with a valve annular valve base, upper and lower cavities of the floor drain are sealed, and odor of a drainage pipeline is prevented from returning to a room or the ground; moreover, insects and mice are prevented, water-free isolation is achieved, and the floor drain can be kept in the sealed state all the time; when there is water flow, the water flow enters a water storage container at the bottom of the valve through a valve channel, and the valve element generates buoyancy and the floor drain is opened after water is stored in the water storage container at the bottom of the valve; when the drainage pipeline has reverse surge, the floor drain is automatically closed to prevent the reverse surge. By means of the floor drain, the floor drain is continuously kept closed when there is no water, gas in the drainage pipeline is effectively prevented from overflow, the indoor air quality is improved, and the purpose of deodorization of indoor sanitary pipelines is achieved.

Owner:王敏

Massaging device

InactiveCN1827075APrevent Backlash or NoiseReduce clearanceVibration massageSuction-kneading massagePhysical therapyMassage

The invention provides a gear box forming a retarding mechanism by chassis, and a massage appliance with a certain axial distance between worm gear and worm. The massage appliance comprises: massage unit (30), which is formed by embarking the massage axis (72) equipped with treating finger (40), massage generator (71) driving said massage axis and reducing mechanism connected by way of transmitting force between massage axis and massage generator on metal chassis (90). The massage appliance is characterized in that the gear box (95) on reducing mechanism is formed by bending the metal board (93) on chassis.

Owner:SANYO ELECTRIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com