High repetition frequency narrow pulse laser emission circuit

A technology of laser emission and narrow pulse, which is applied in the field of laser measurement, can solve the problems of peak power drop and narrowing, and achieve the effects of simple circuit, prevention of reverse overexcitation, and constant working temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] It is easy to understand that, according to the technical solution of the present invention, those skilled in the art can imagine various implementations of the high repetition rate narrow pulse laser emitting circuit of the present invention without changing the essence of the present invention. Therefore, the following specific embodiments and drawings are only exemplary descriptions of the technical solution of the present invention, and should not be regarded as the entirety of the present invention or as a limitation or limitation on the technical solution of the present invention.

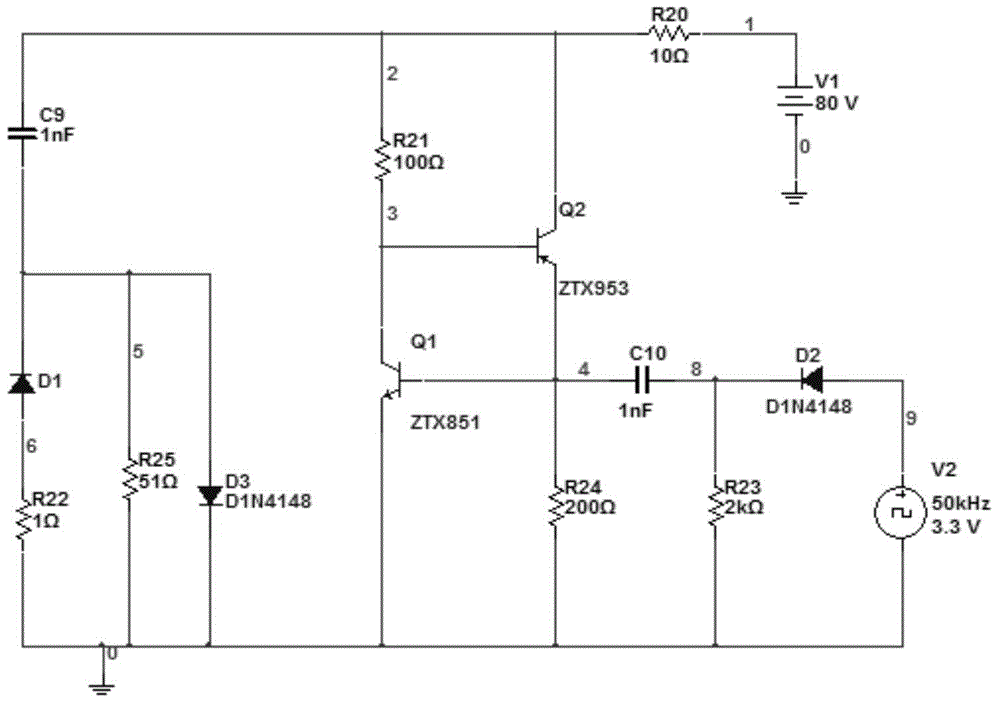

[0017] Drive circuit

[0018] In this example, if figure 1 As shown, the driving circuit of the laser diode SPLLL90_3 includes a charging voltage source V1, a trigger signal source V2, a twentieth resistor R20, a twenty-first resistor R21, a twenty-second resistor R22, a twenty-third resistor R23, a twentieth resistor Four resistors R24, twenty-fifth resistor R25, ninth capacitor C9, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com