Apparatus for rotating aligning a substrate

A technology for aligning devices and substrates, which is applied in the manufacture of electrical components, electrical solid devices, semiconductor/solid devices, etc., can solve the problems of lower precision and lower deposition quality, and achieve the effect of preventing reversal phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Hereinafter, a substrate rotational alignment device according to an embodiment of the present invention will be described in detail with reference to the accompanying drawings.

[0031] A substrate rotation alignment device according to an embodiment of the present invention relates to a phenomenon in which a rotation axis is prevented from being twisted by a pressing force when a mounting part on which a substrate is mounted is rotated to align a substrate on a mask, thereby Rotary alignment device for substrates capable of precise alignment.

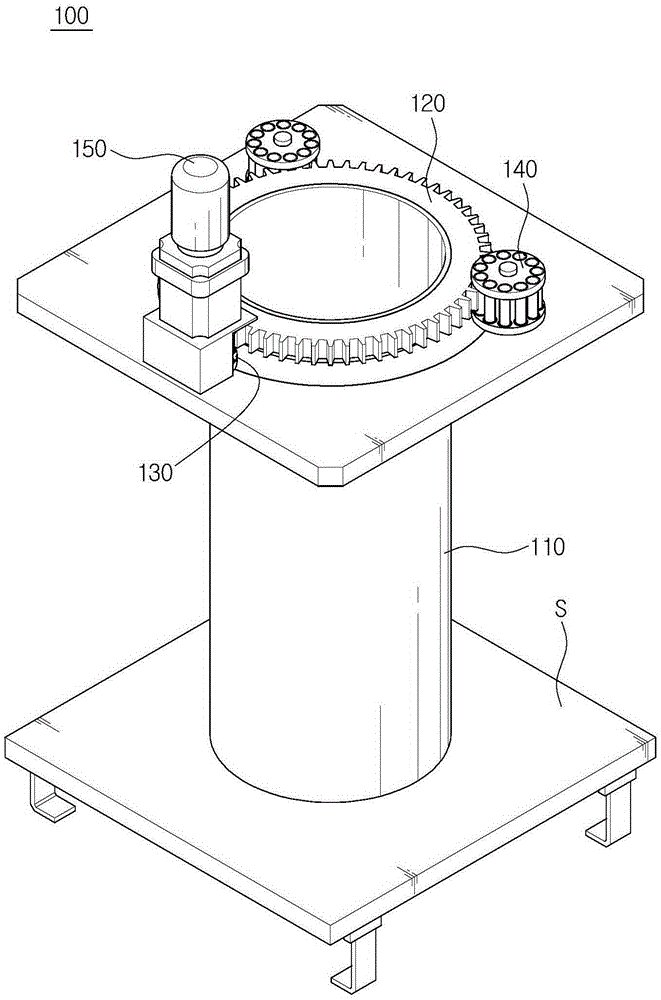

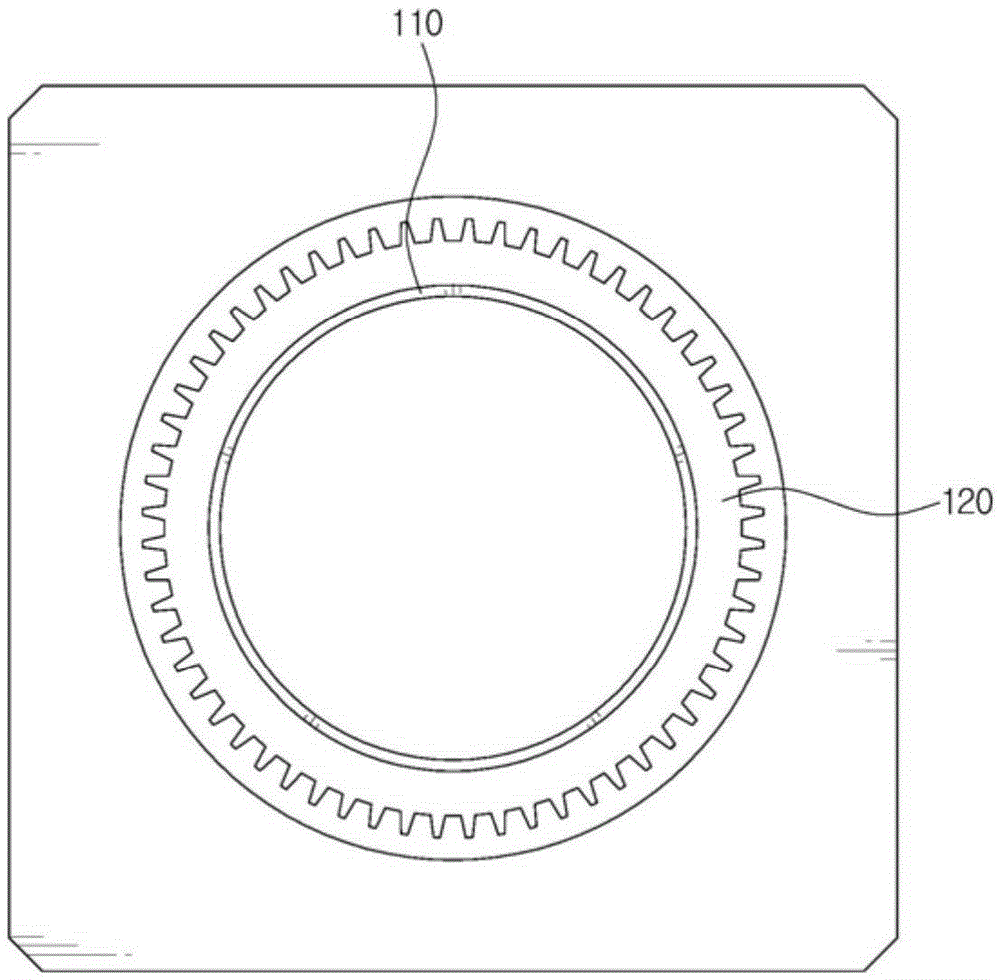

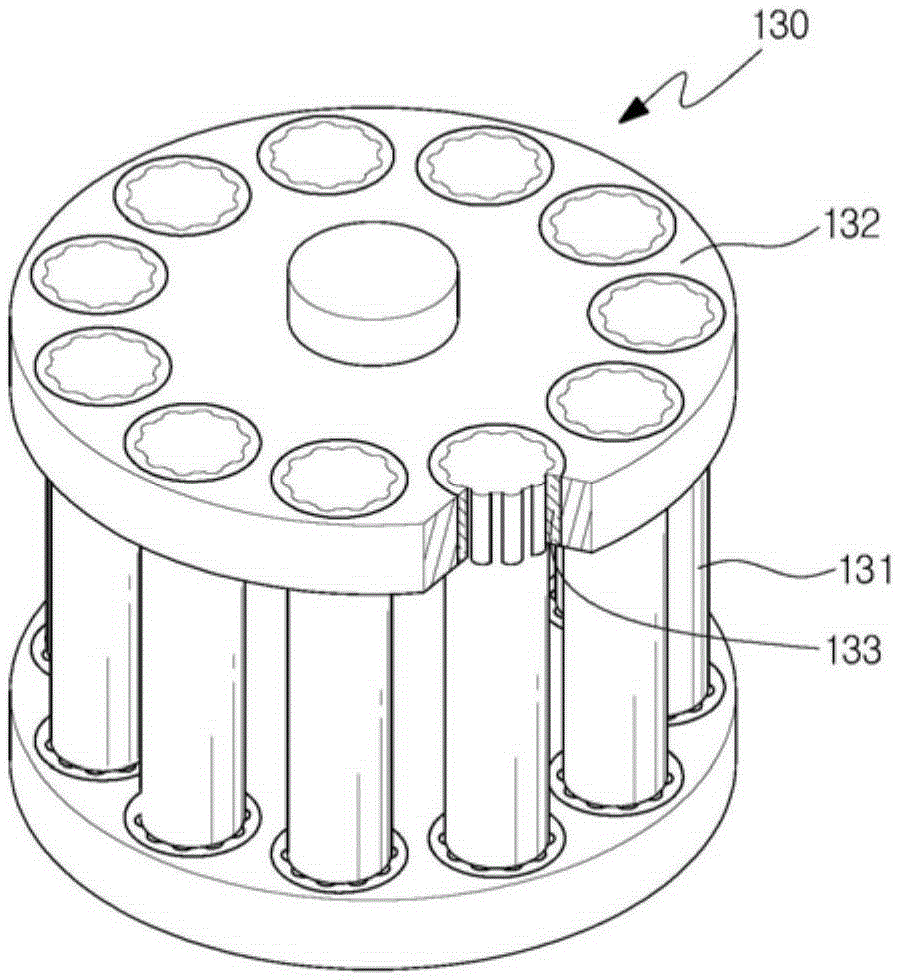

[0032] figure 1 It is a schematic perspective view of a substrate rotational alignment device according to an embodiment of the present invention. refer to figure 1 , the substrate rotation alignment device according to one embodiment of the present invention includes a connecting column 110, a rotary stage 120 for fixing the connecting column 110, and a power transmission part 130 that engages with the area of the rotary s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com