Patents

Literature

125 results about "Rotational alignment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

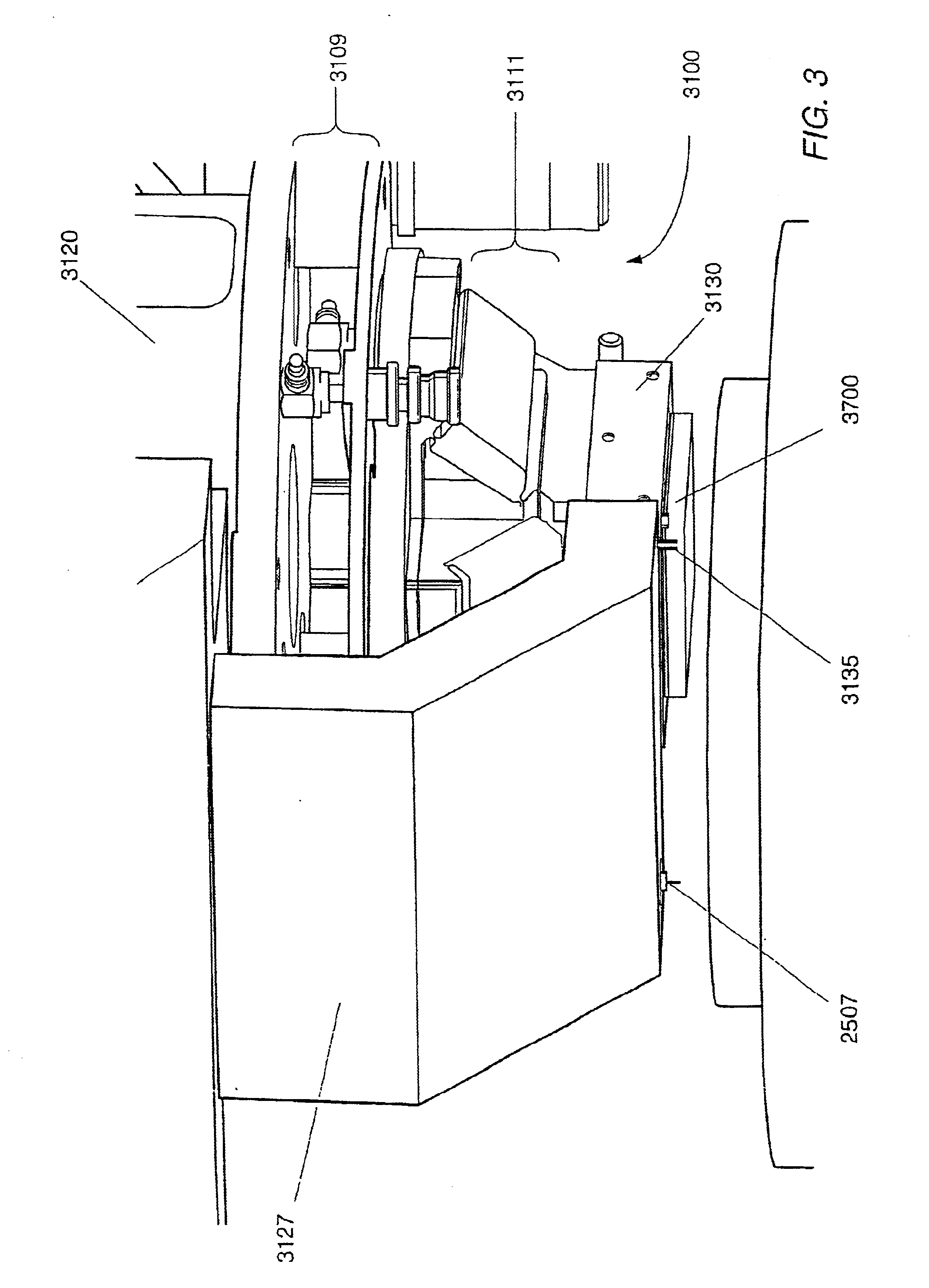

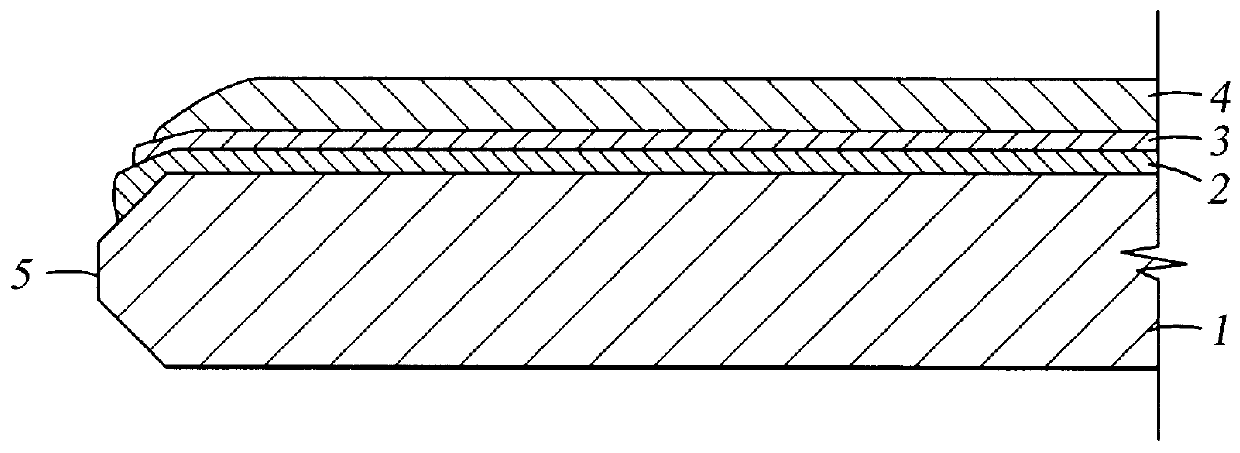

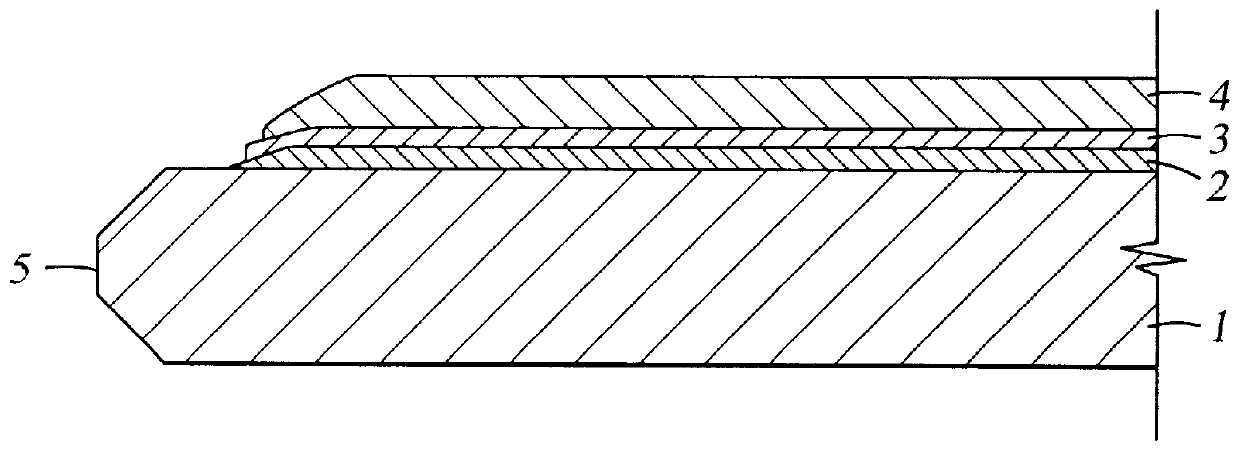

Alignment methods for imprint lithography

InactiveUS6916584B2Enhance lithography processLow viscosity liquidNanoinformaticsSemiconductor/solid-state device manufacturingEngineeringRotational alignment

Described are methods for patterning a substrate by imprint lithography. Imprint lithography is a process in which a liquid is dispensed onto a substrate. A template is brought into contact with the liquid and the liquid is cured. The cured liquid includes an imprint of any patterns formed in the template. Alignment of the template with the substrate is performed prior to curing the liquid. Alignment of the template with the substrate includes rotational alignment of the template with respect to the substrate.

Owner:CANON KK

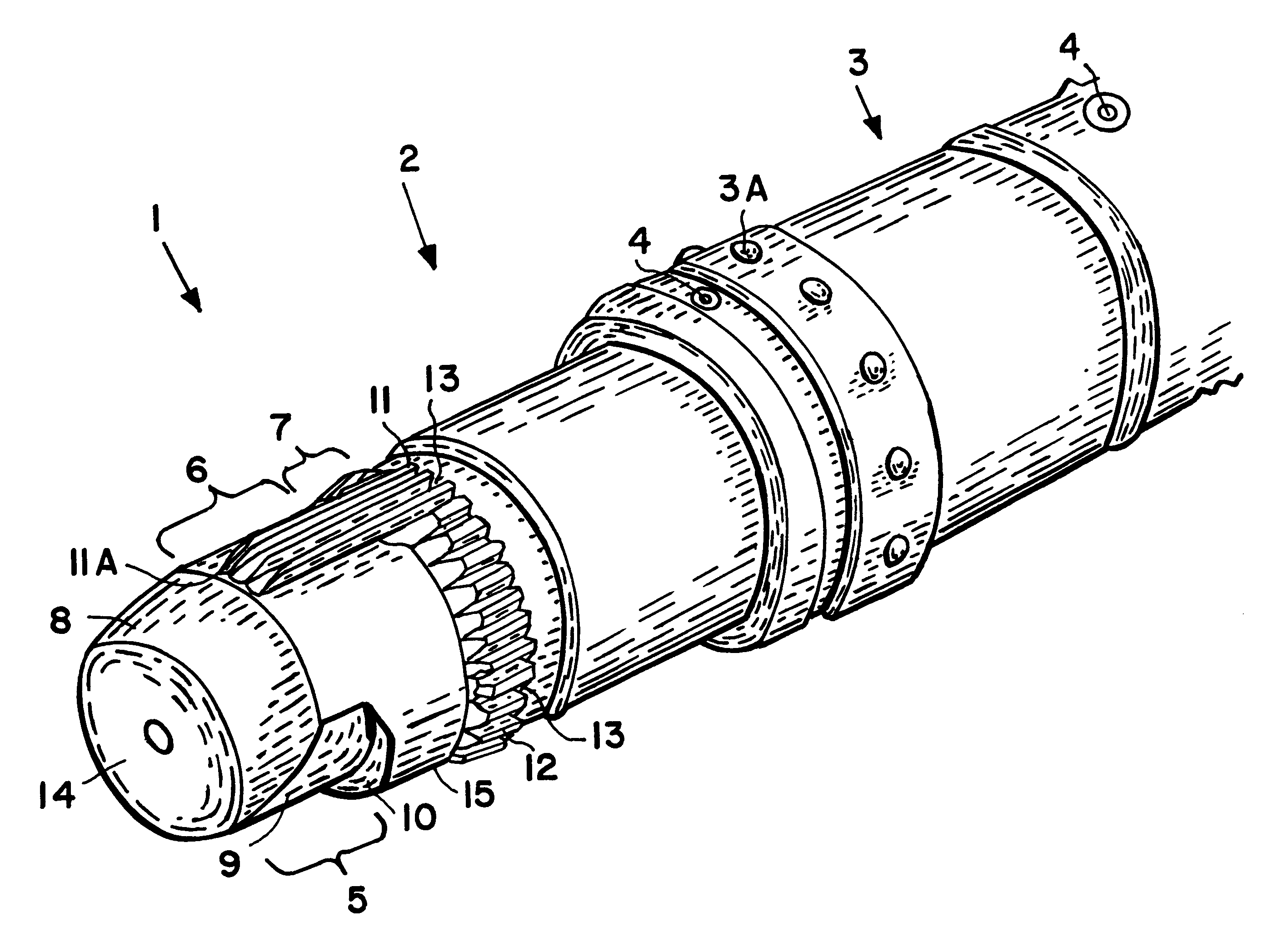

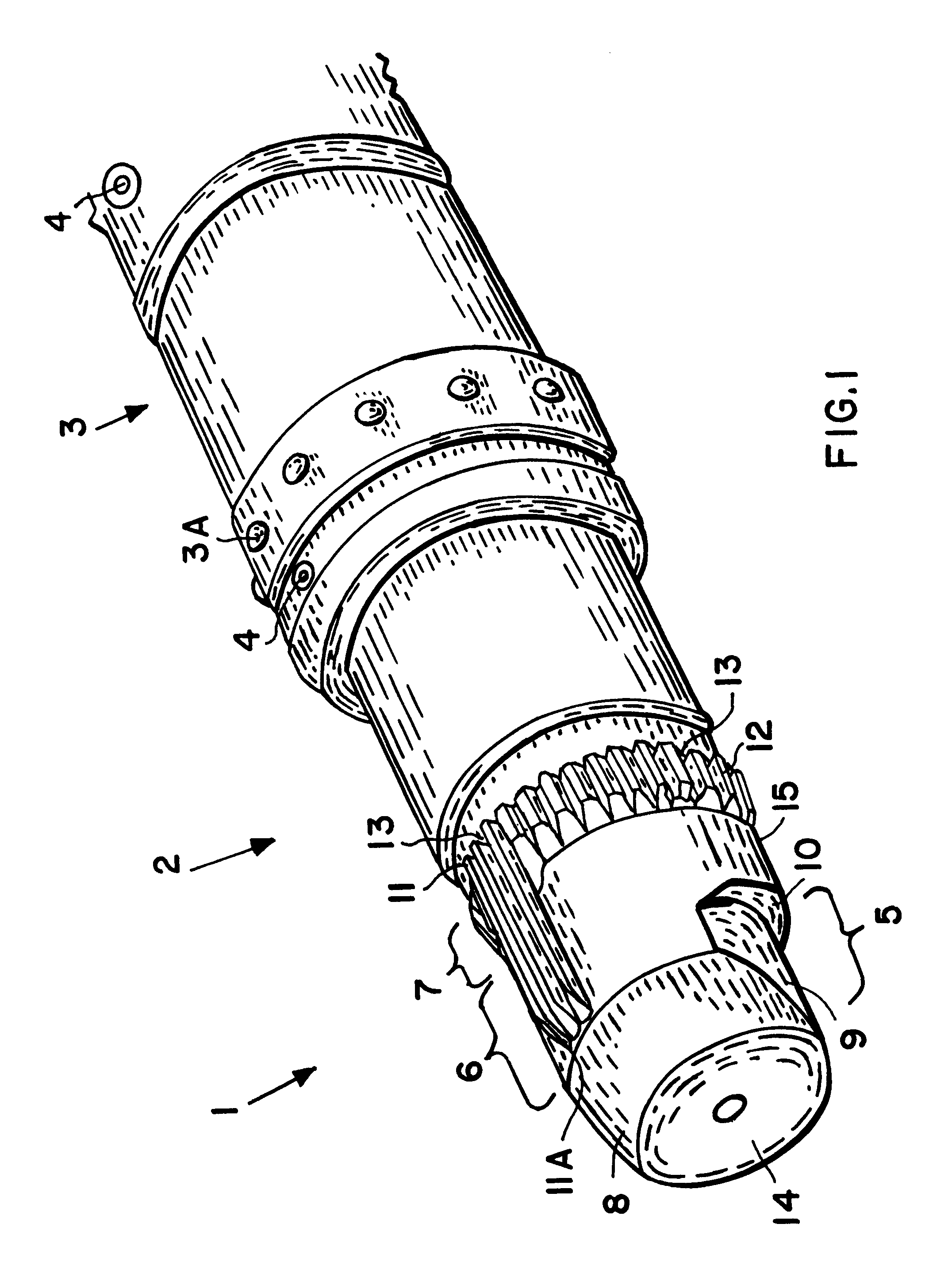

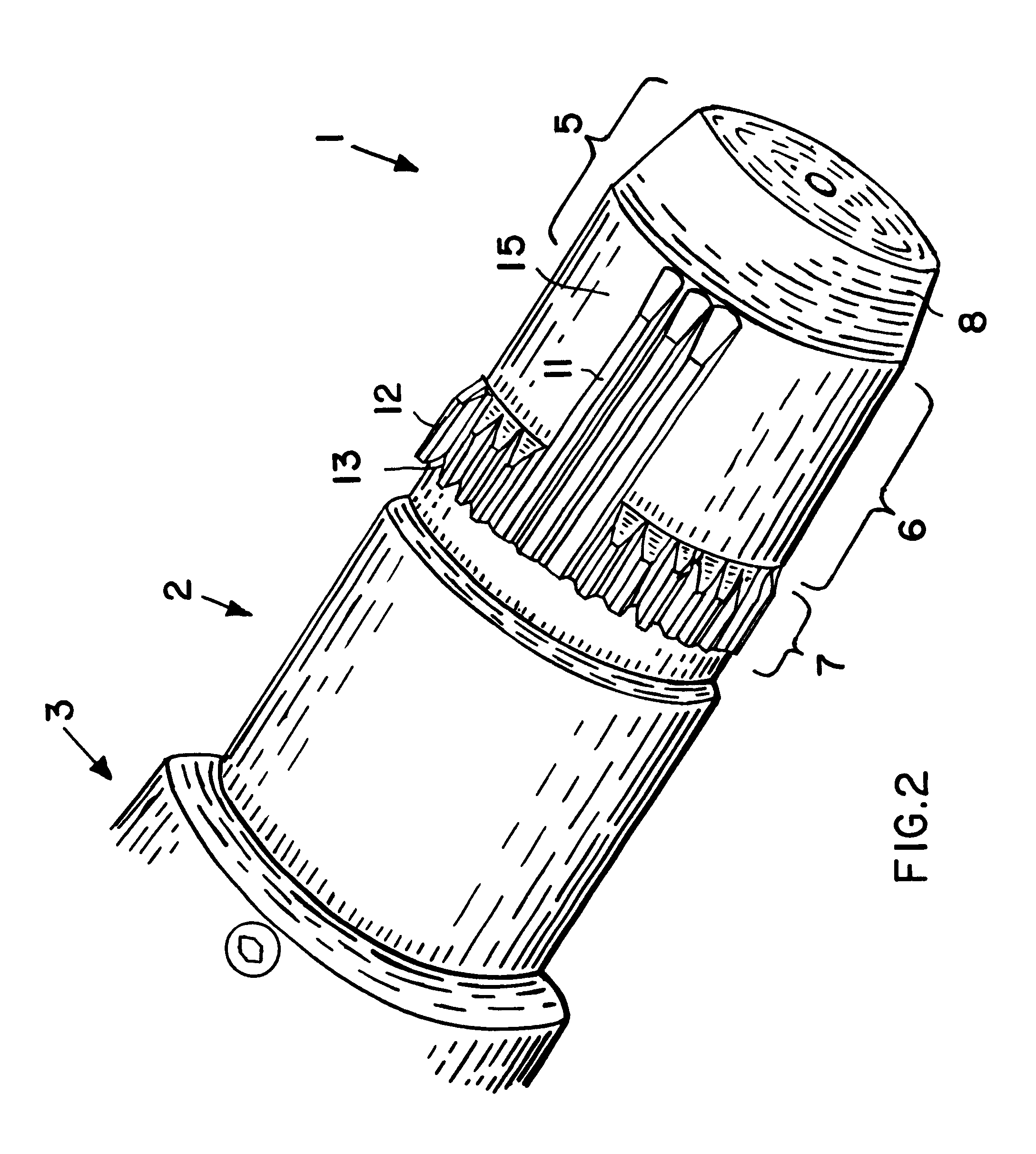

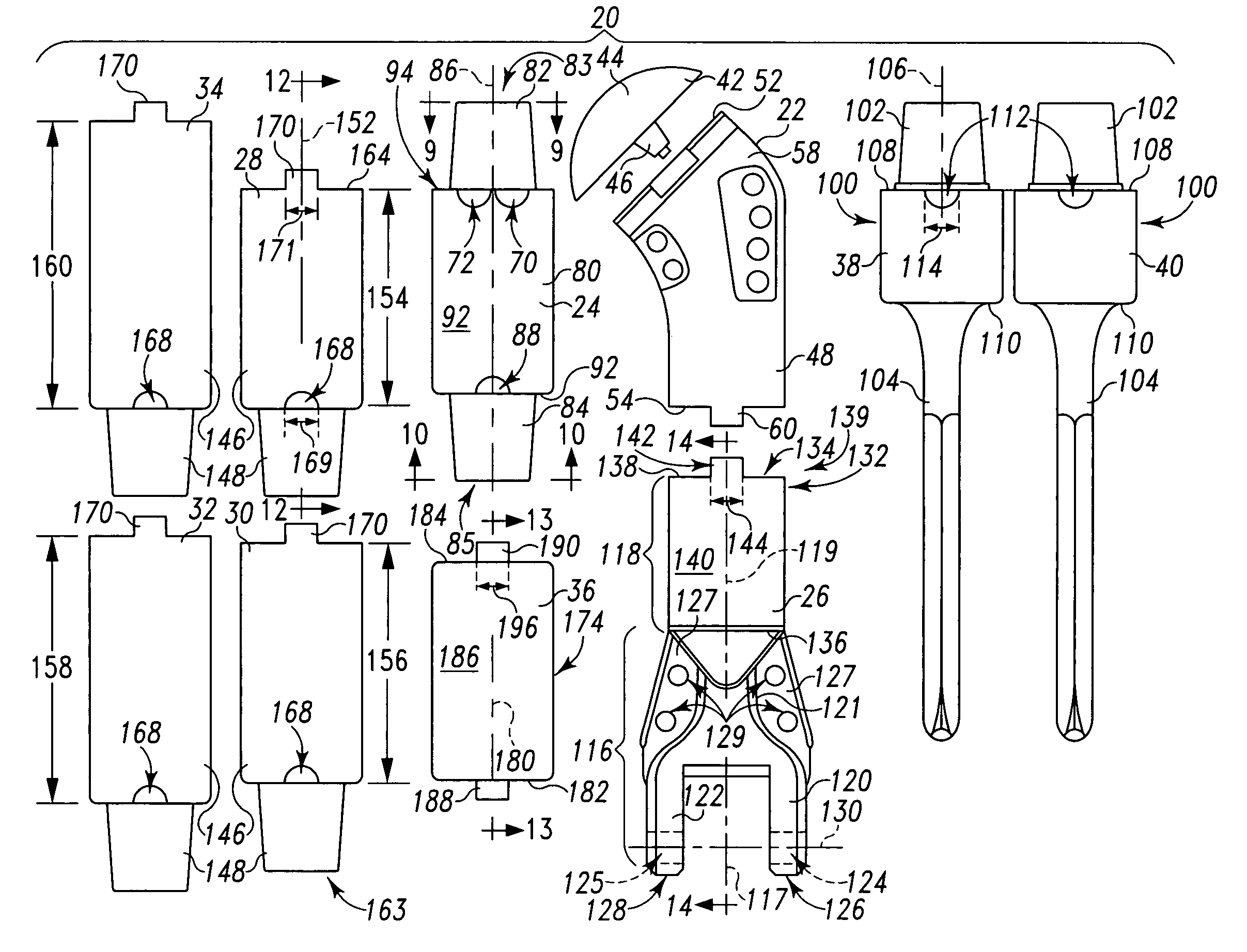

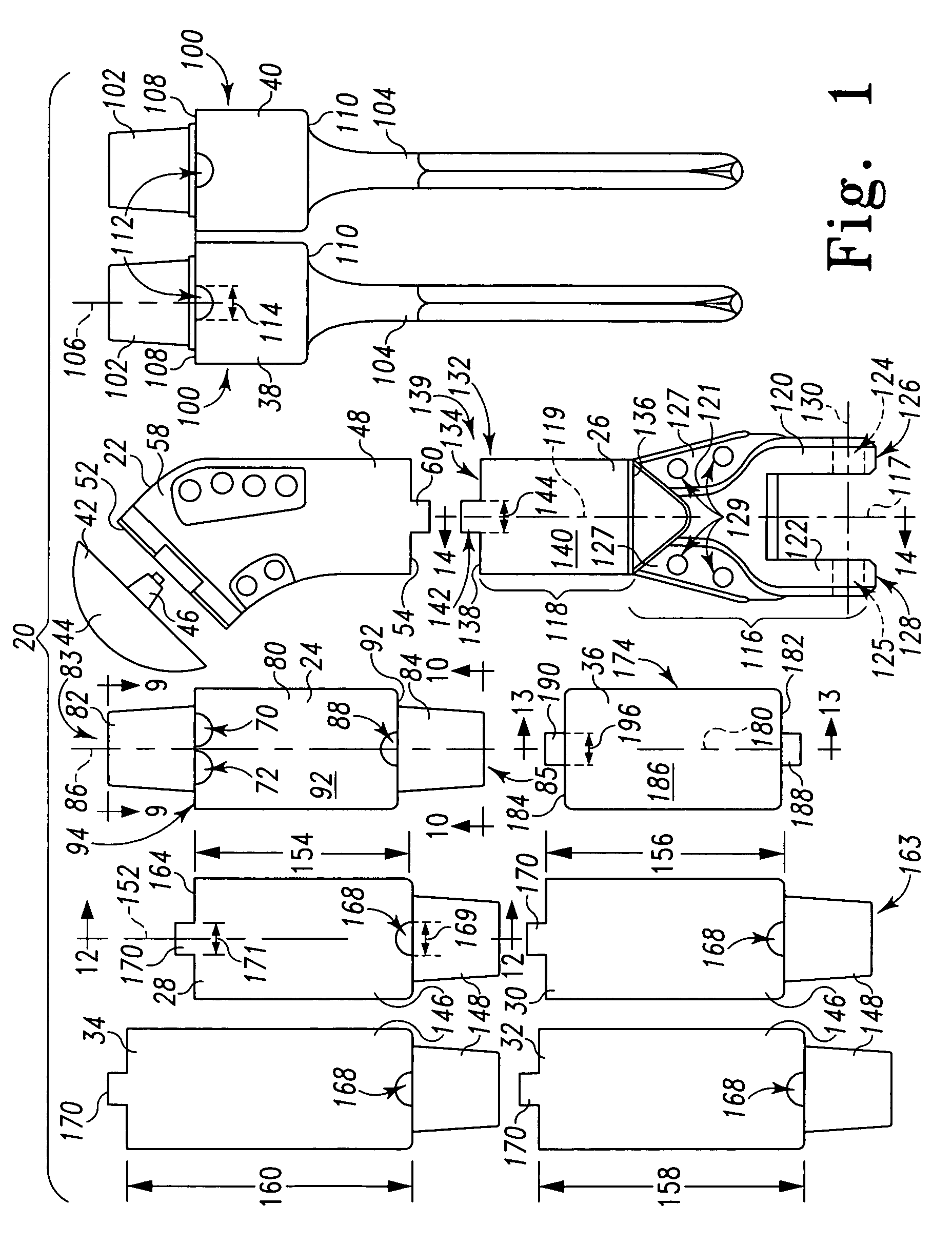

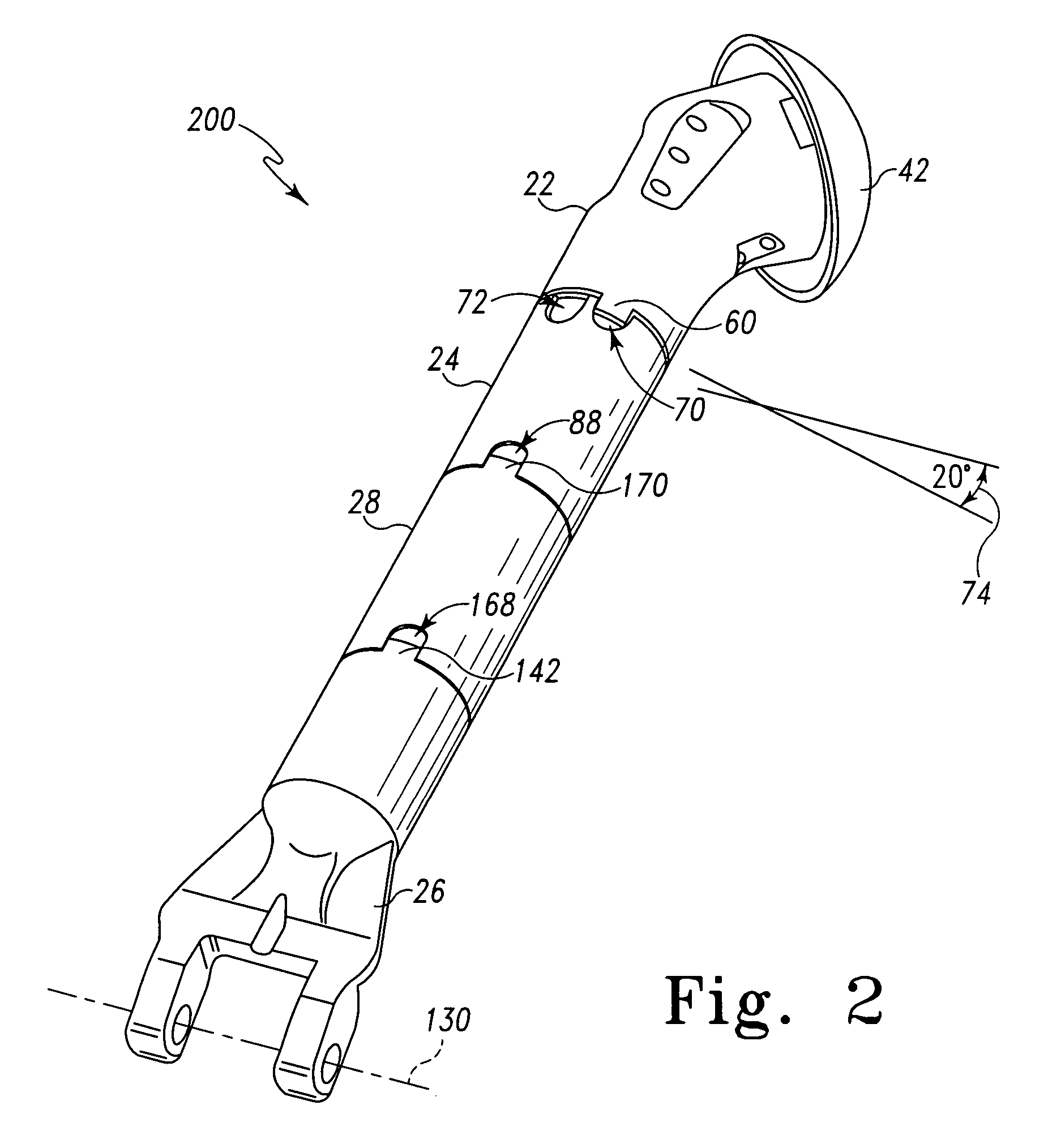

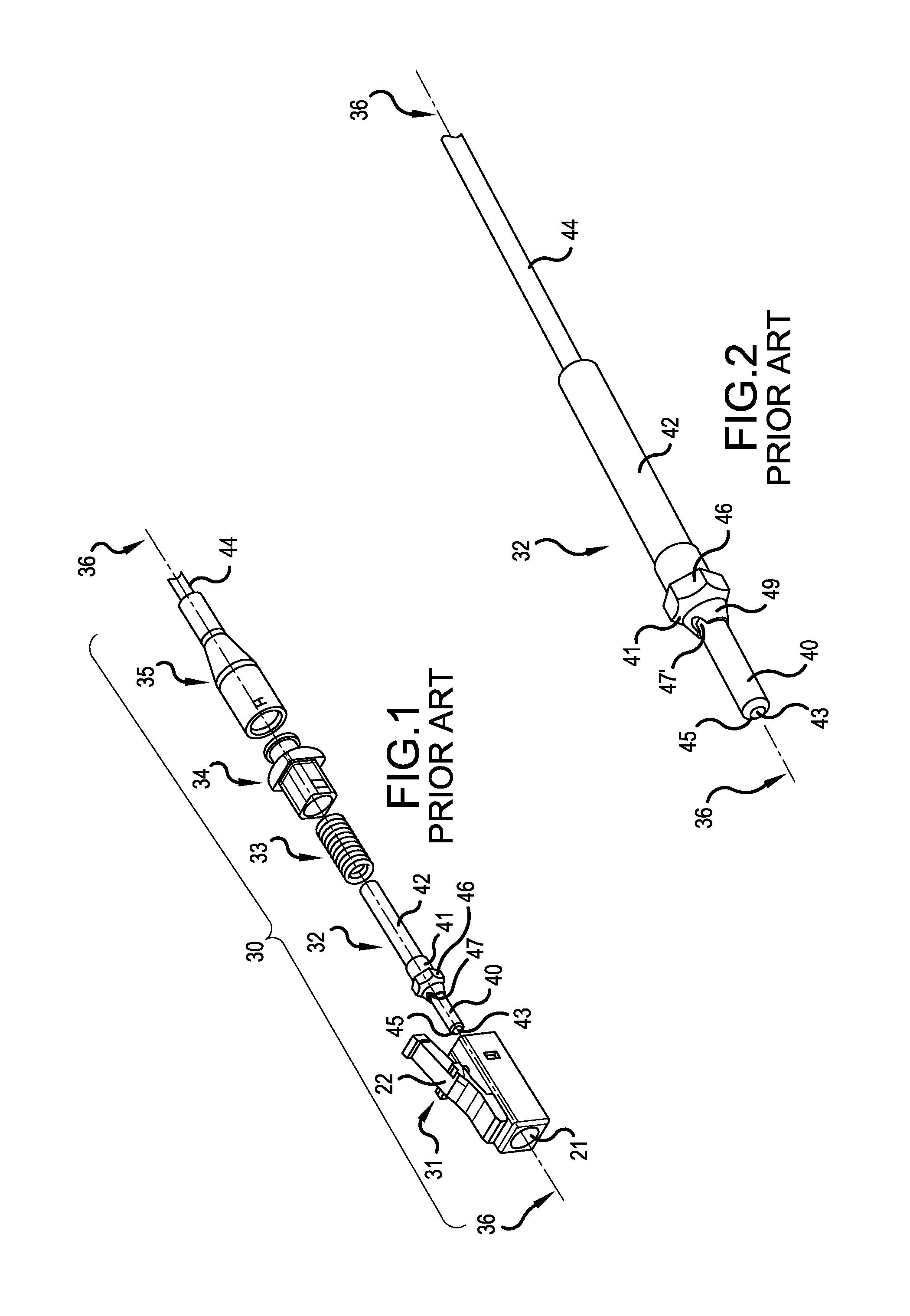

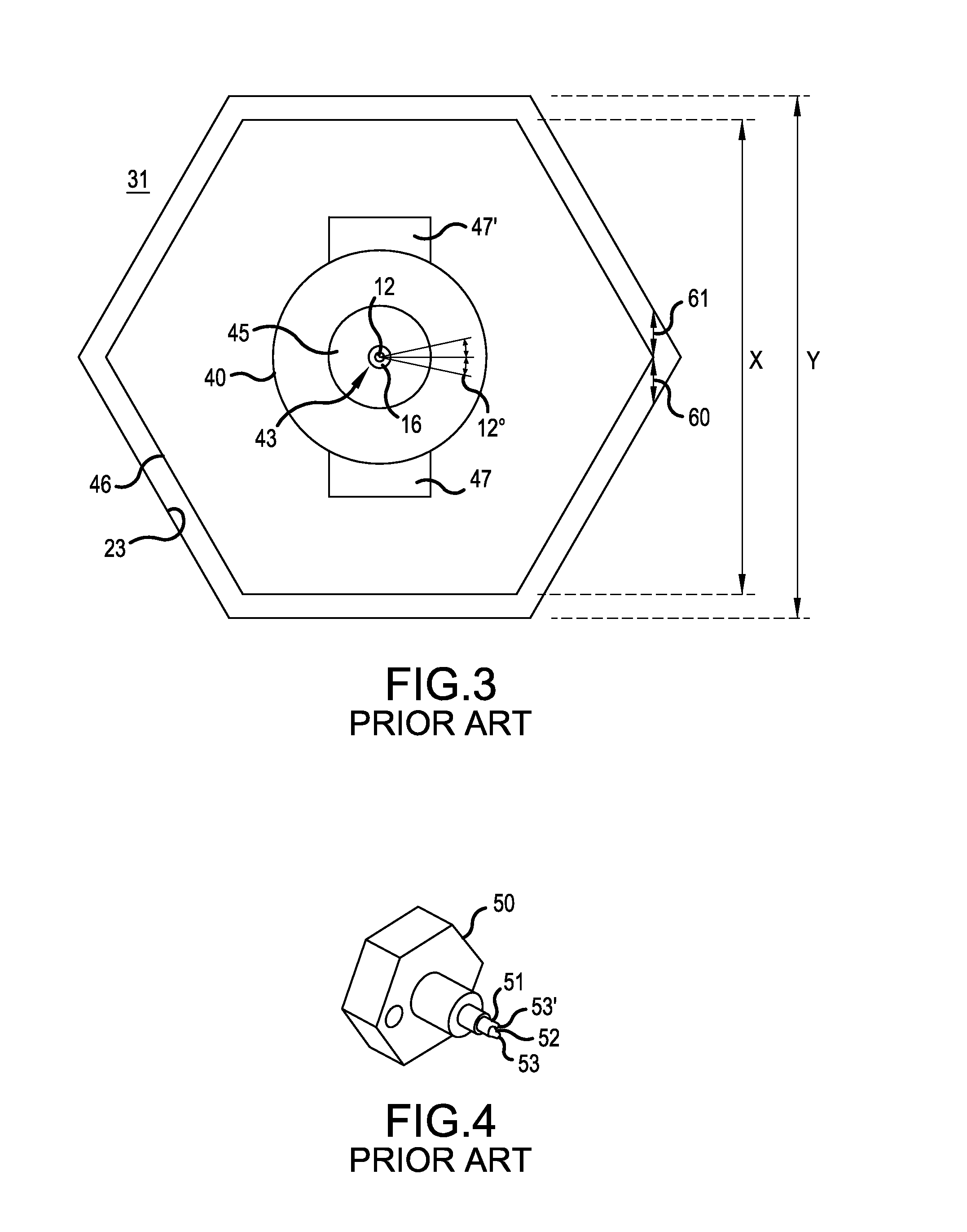

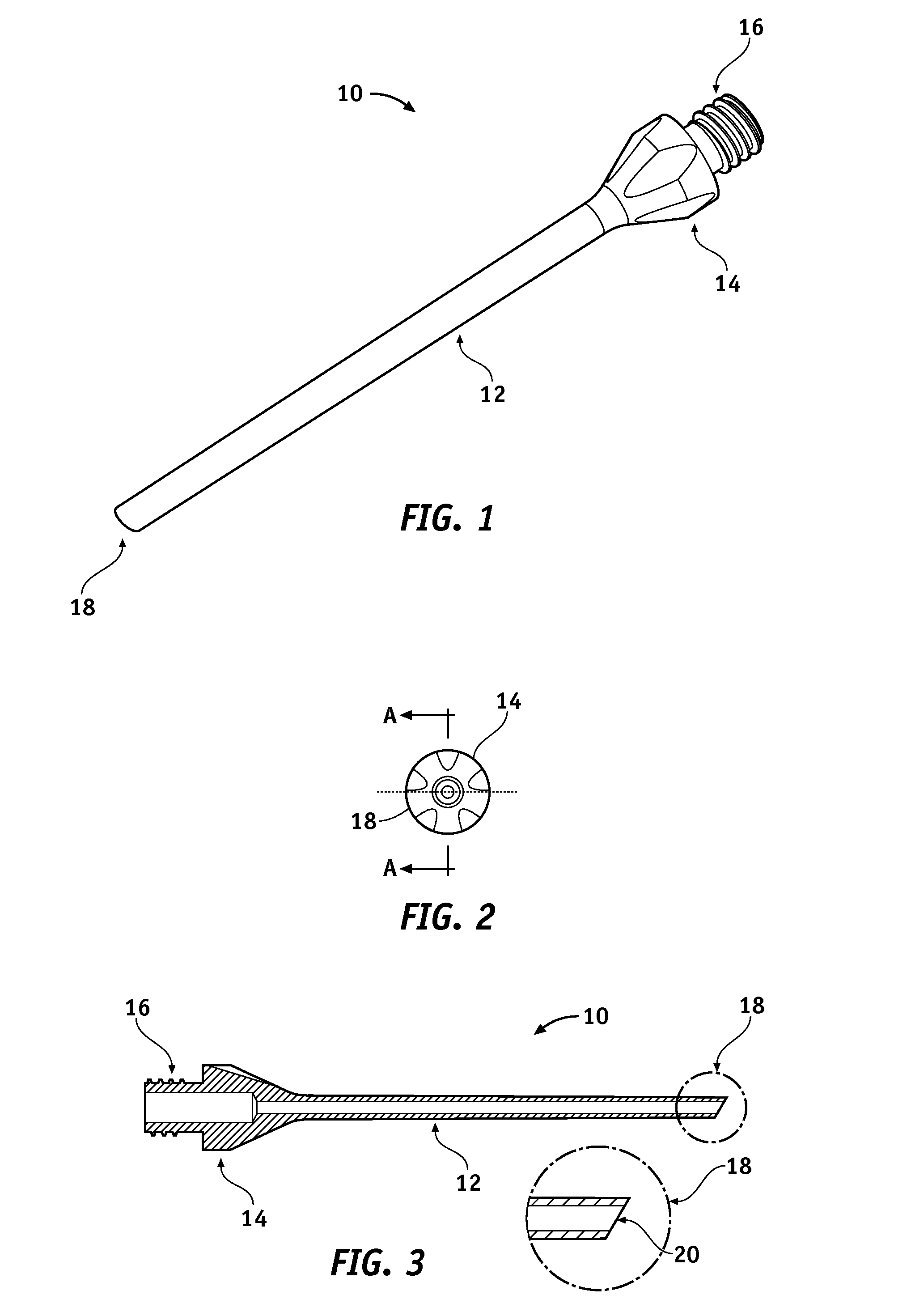

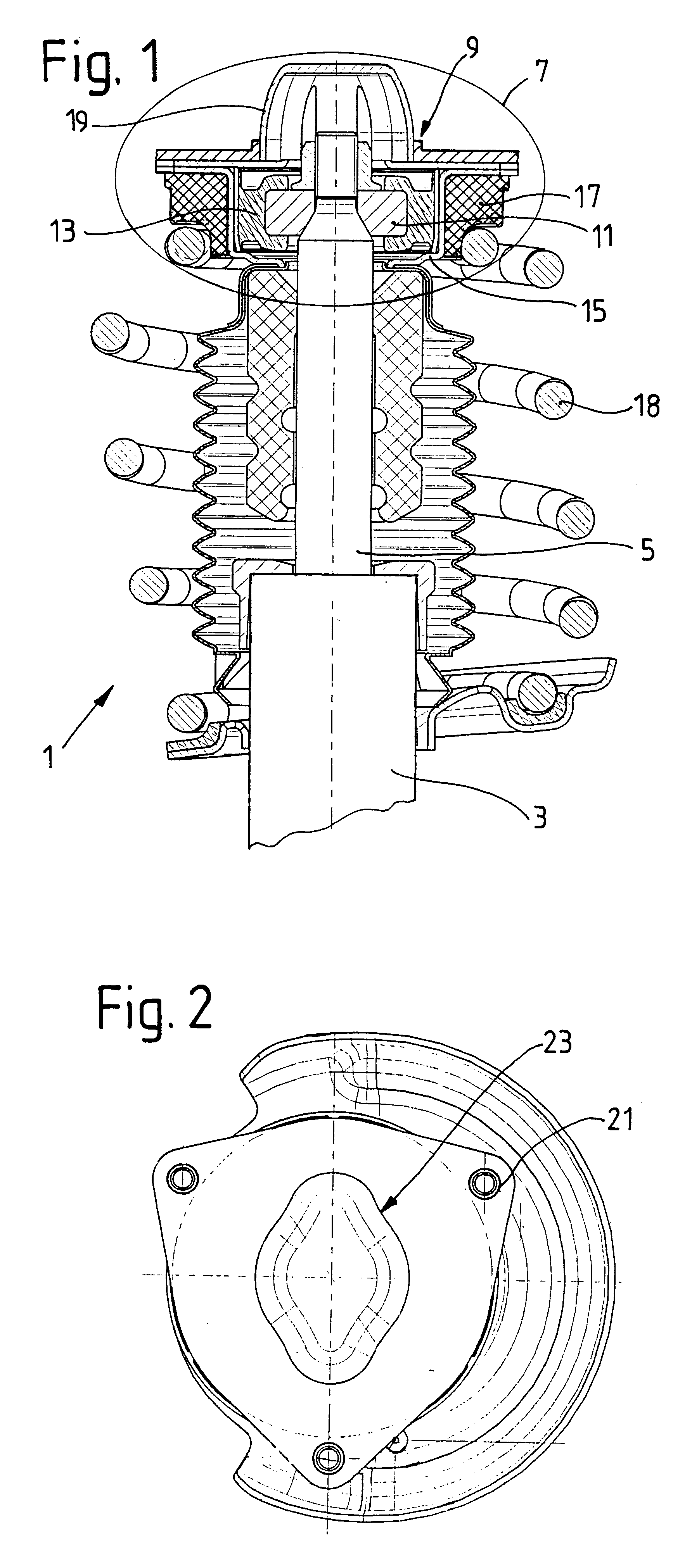

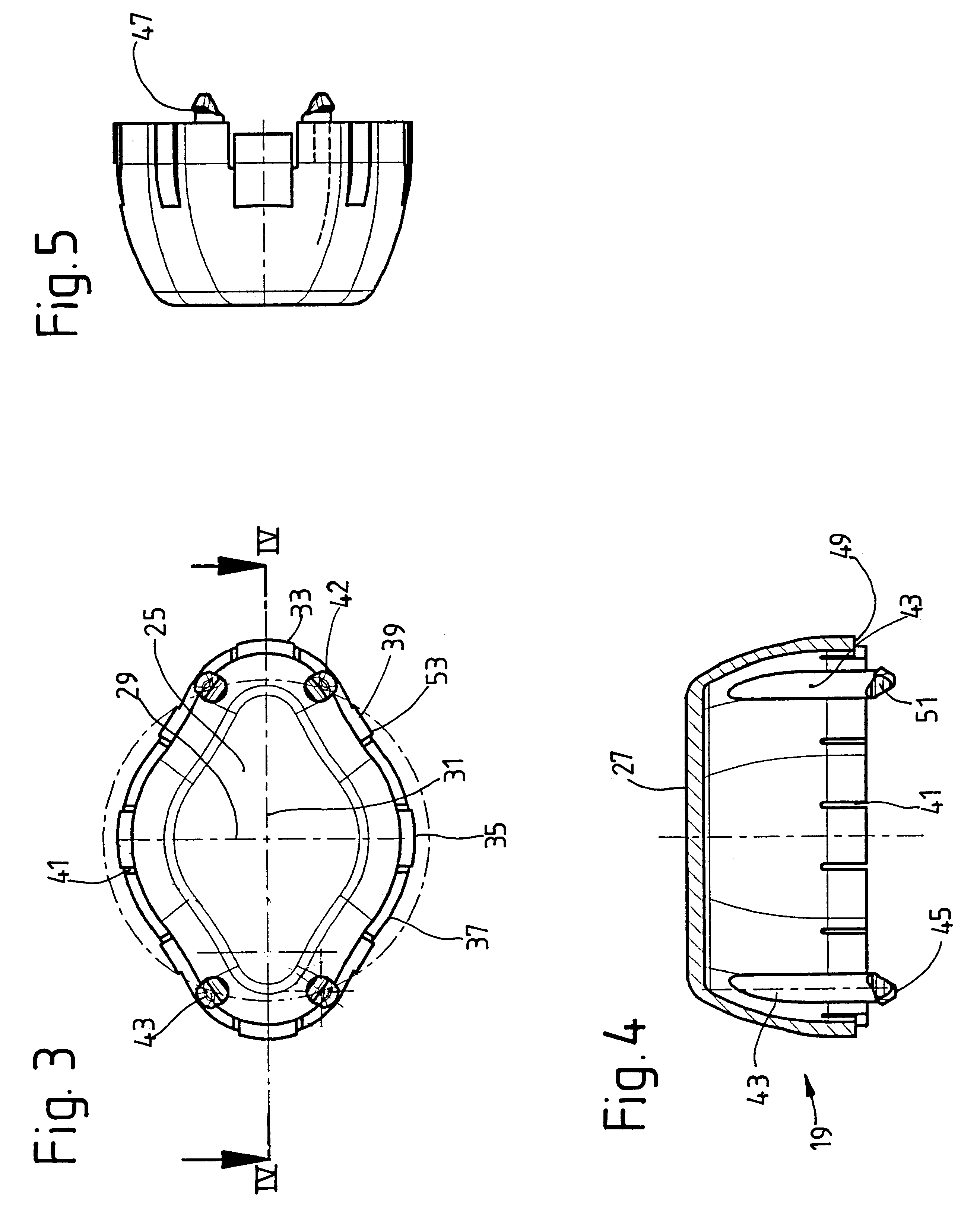

Self-aligning splined male shaft head and engagement method

InactiveUS6482094B2Simple processReduce wearShaftsInterengaging clutchesMechanical engineeringRotational alignment

A splined shaft head for engaging a splined hub includes first, second and third stages. The first stage has a conical taper on one side, and a cylindrical setback on the other side, which transitions through a tapered shoulder to the cylindrical body of the shaft head. The second stage includes lead spline teeth extending along the cylindrical body to the conical taper. The third stage includes torque-transmitting main spline teeth regularly arranged around the circumference. The shaft head is rotated while being inserted axially into the hub. The first stage allows radial free play and de-centering of the hub so the lead spline teeth find a proper rotational alignment with spline grooves of the hub. Then, the tapered shoulder at the end of the first stage positively centers the hub on the shaft axis, and finally the main spline teeth of the third stage provide full form-locking engagement.

Owner:SCHENCK ROTEC GMBH

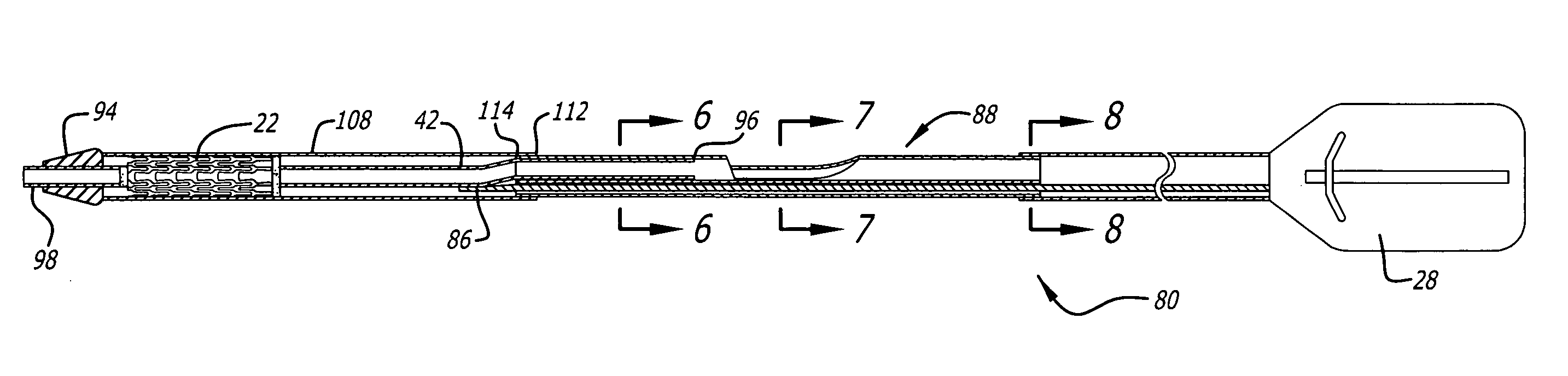

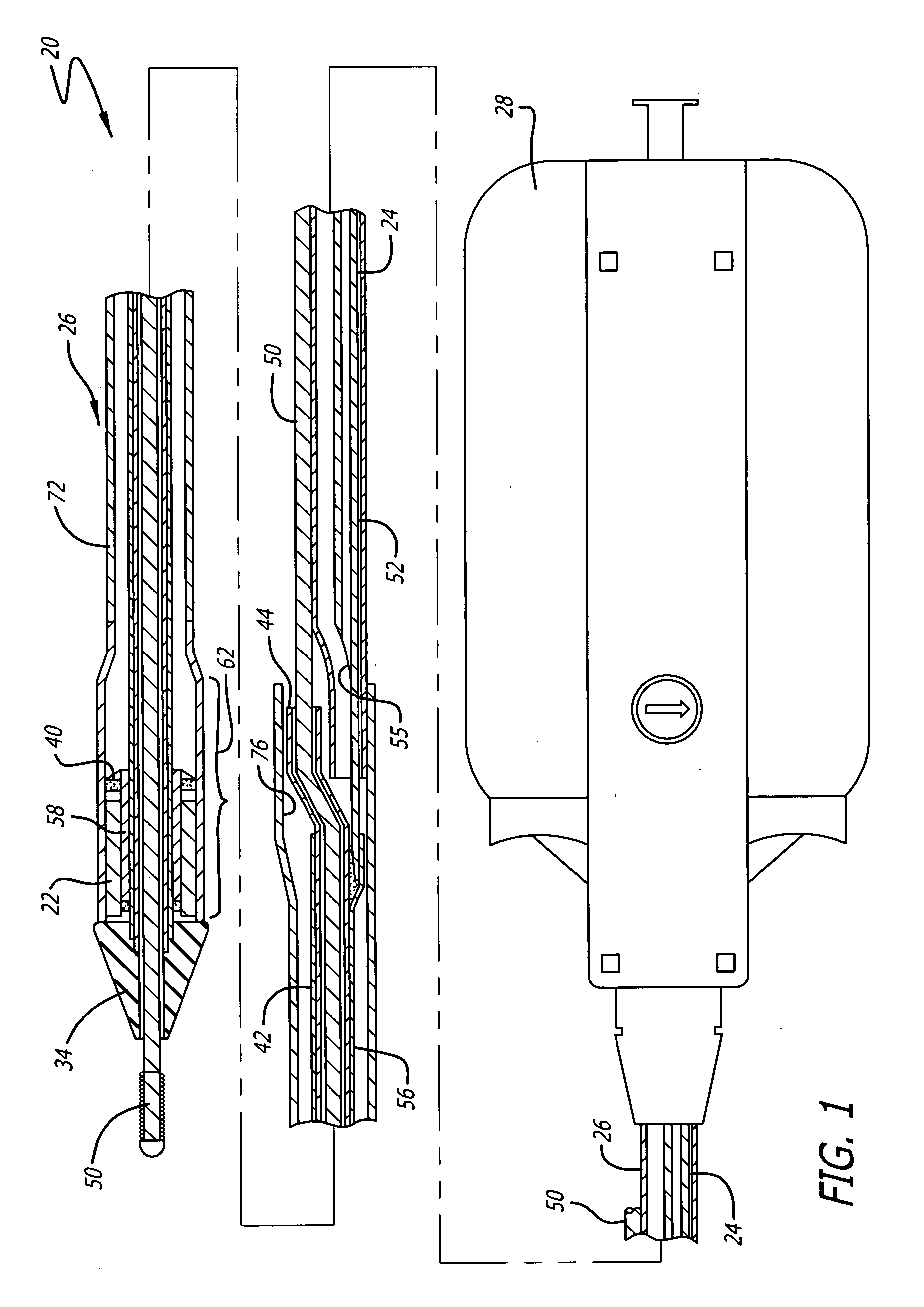

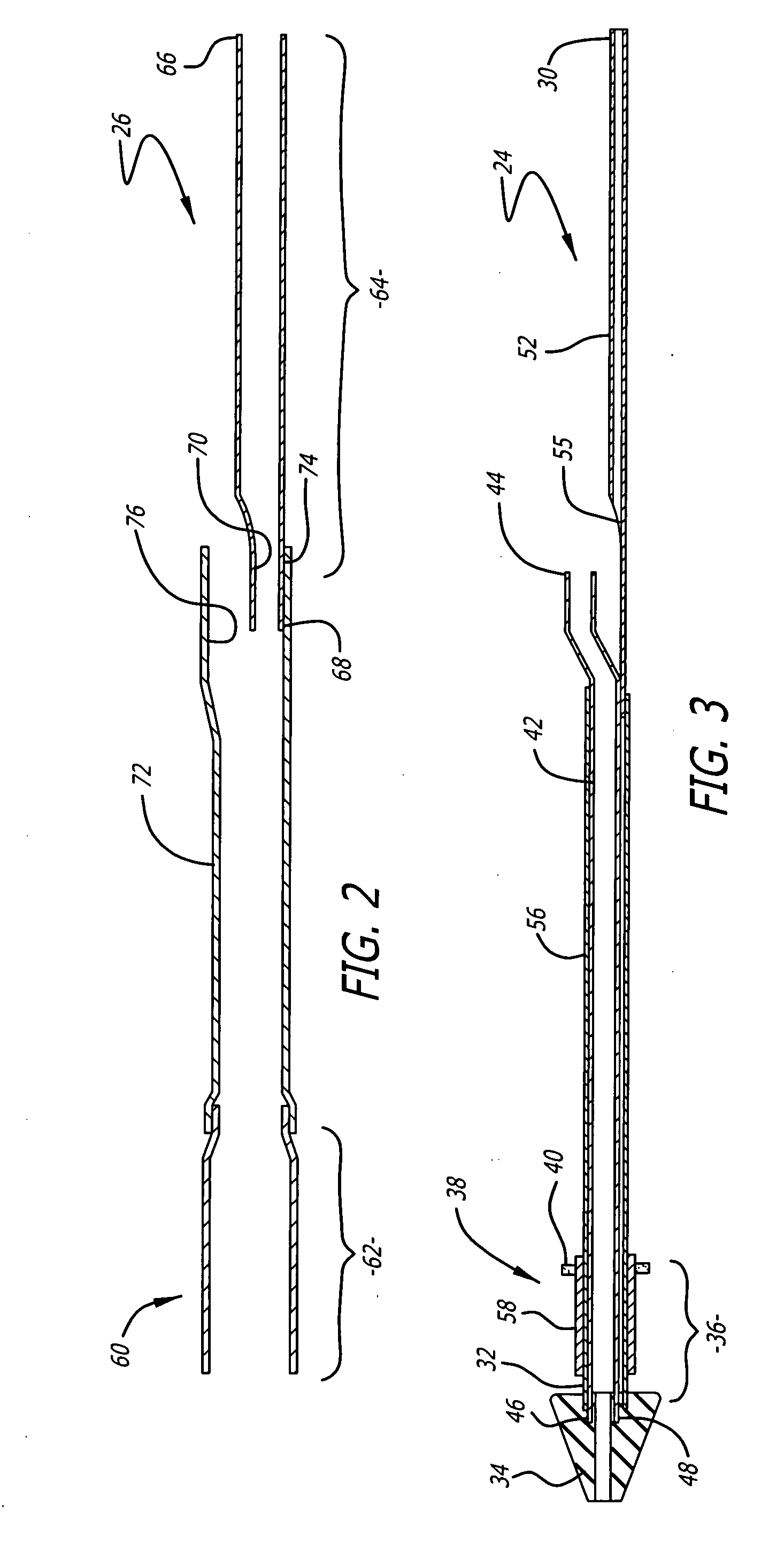

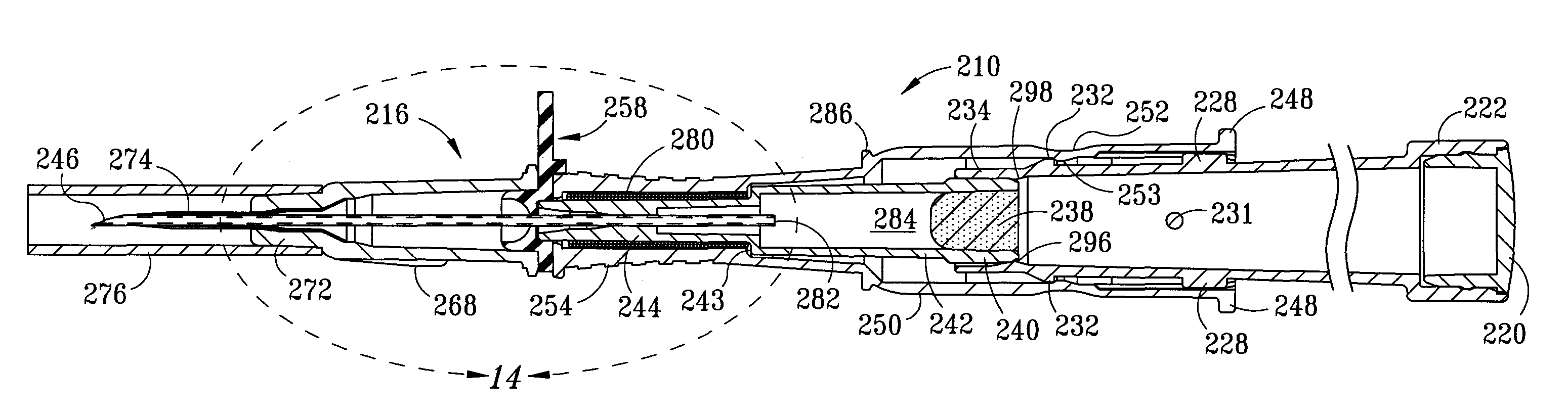

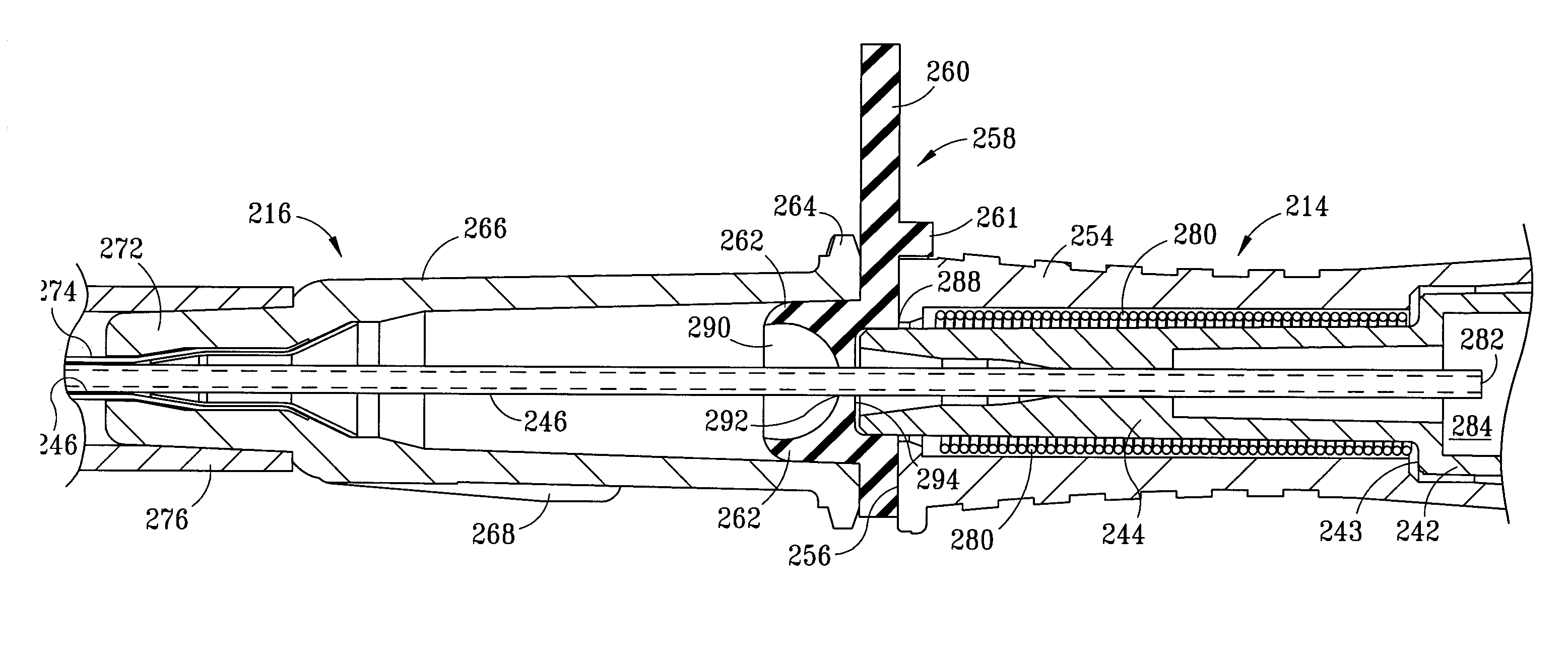

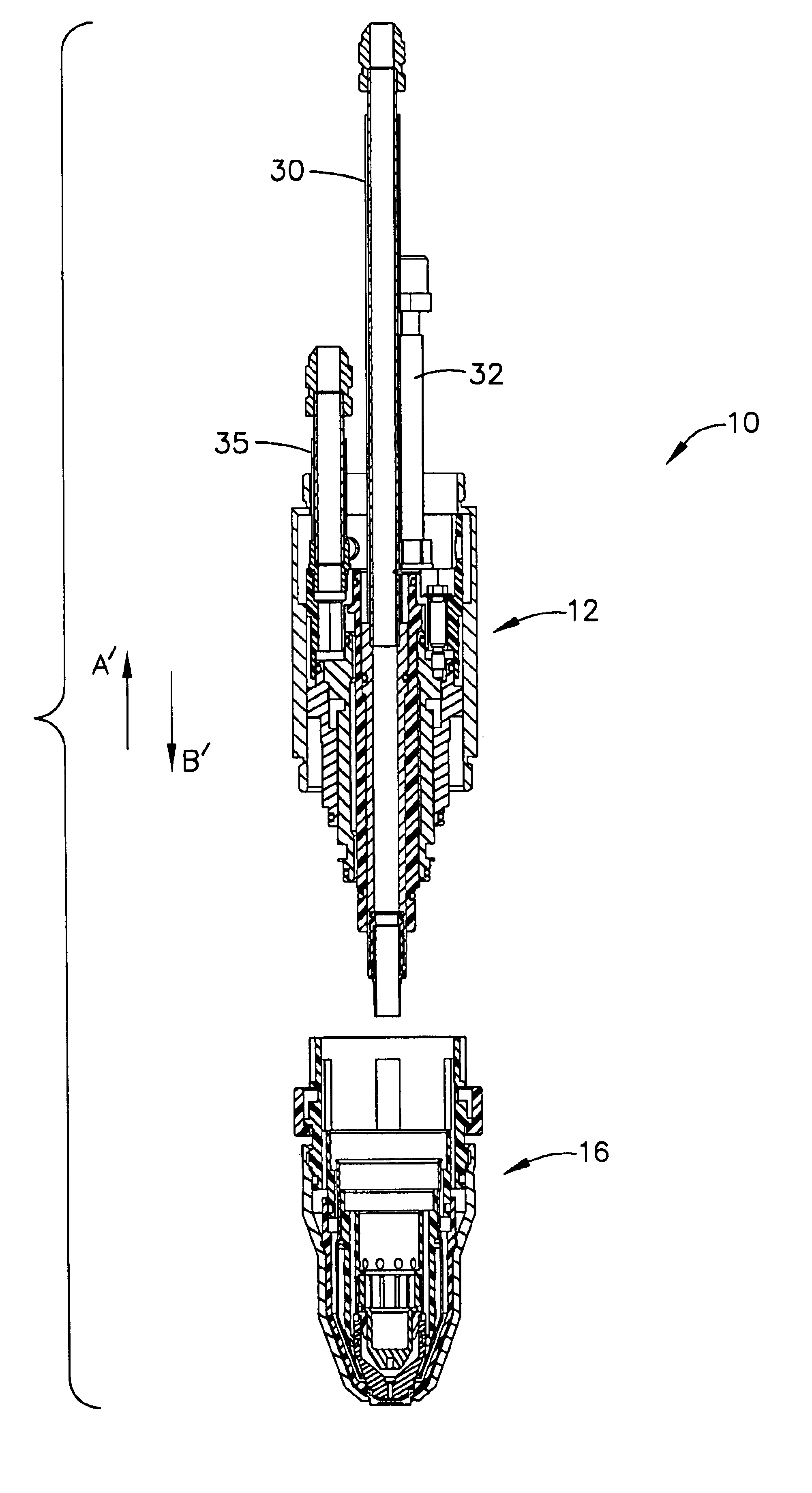

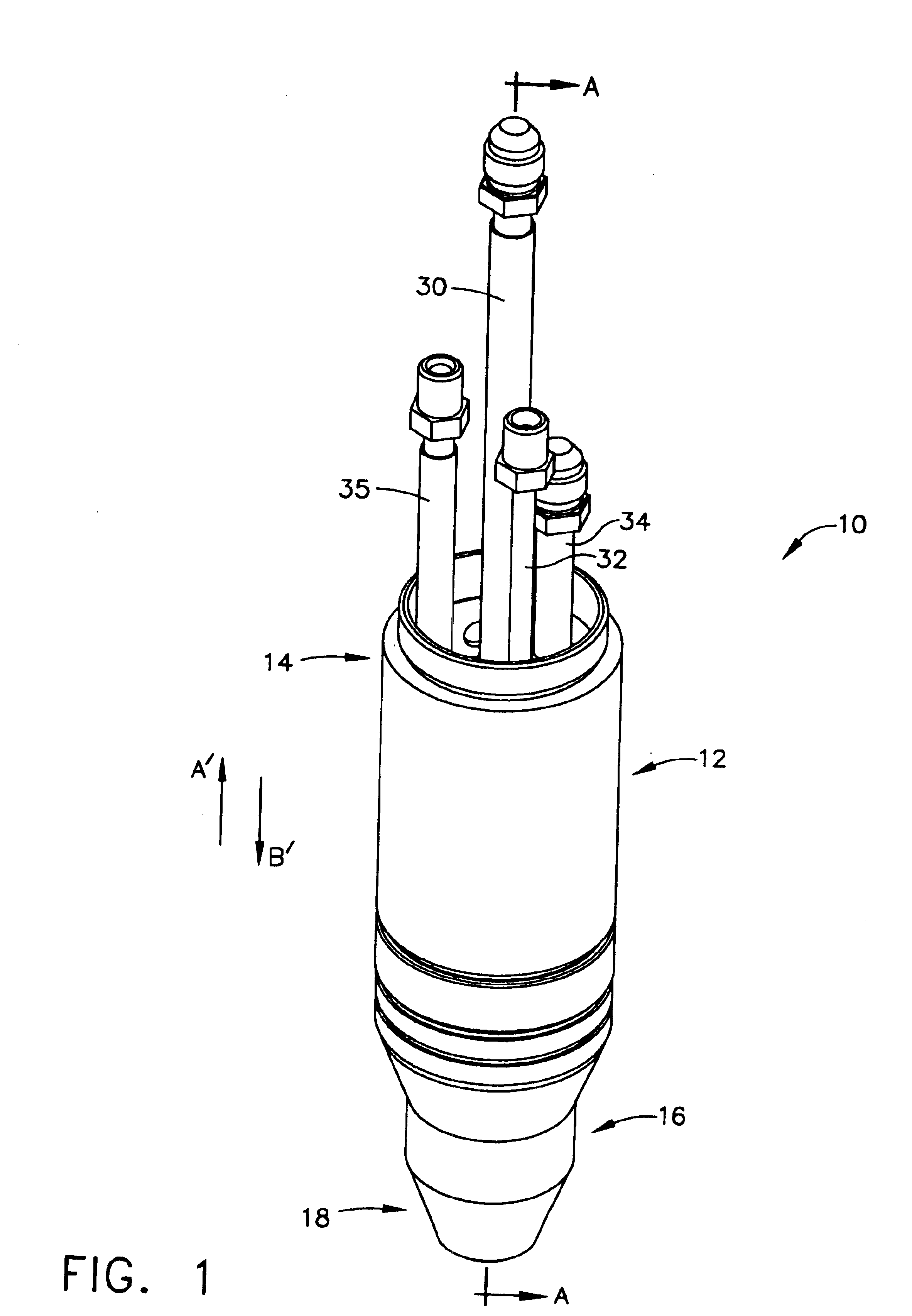

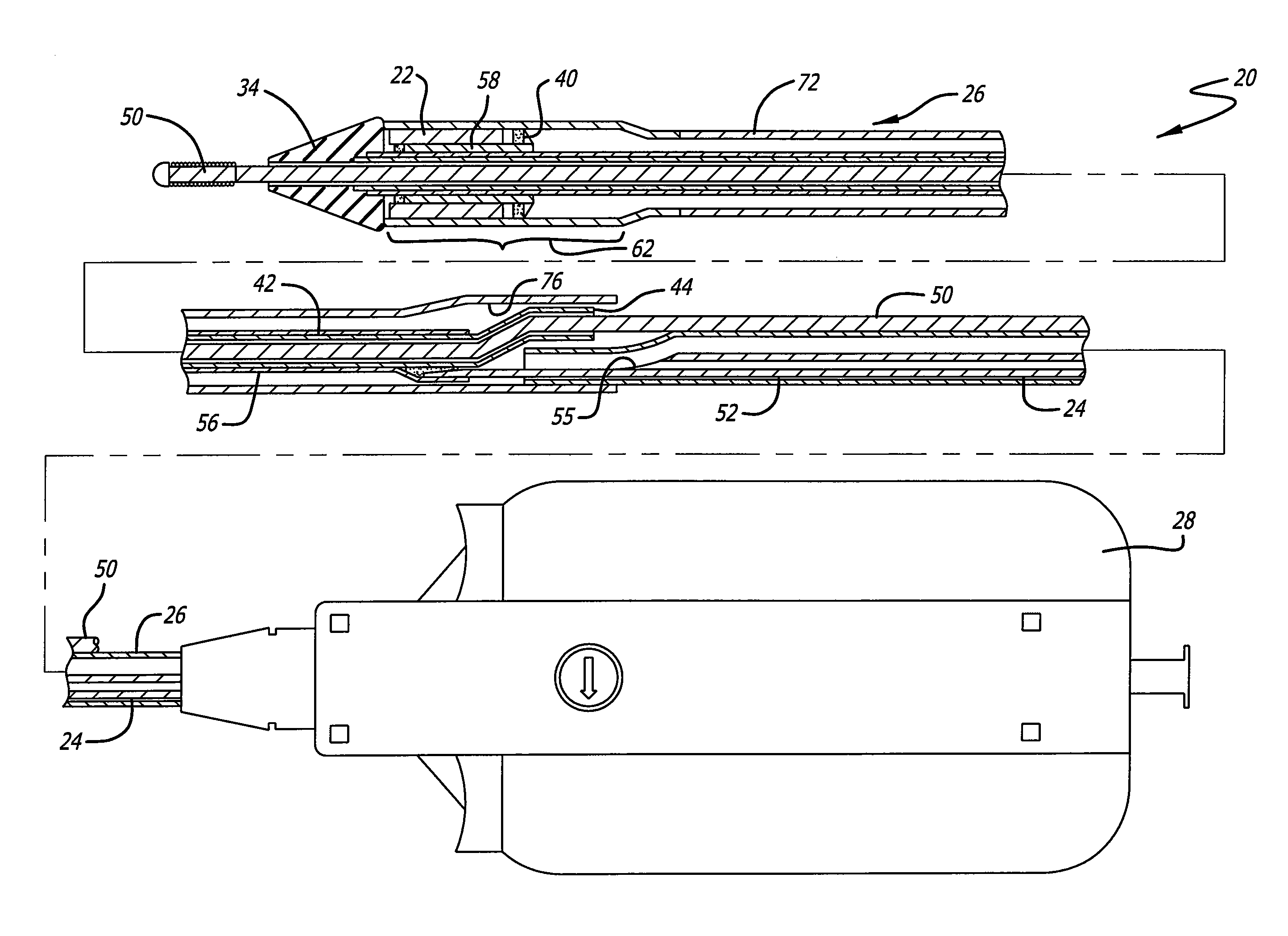

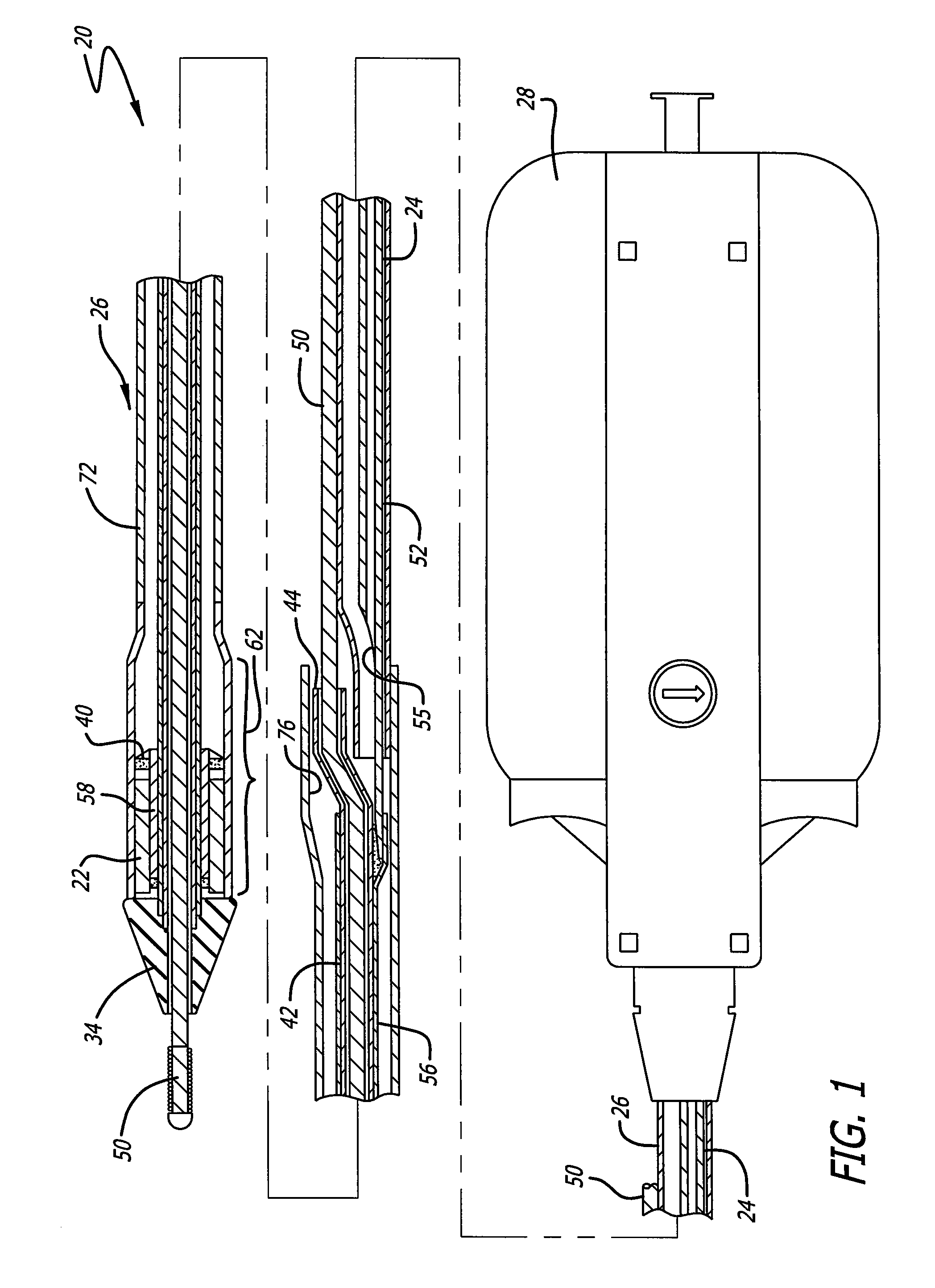

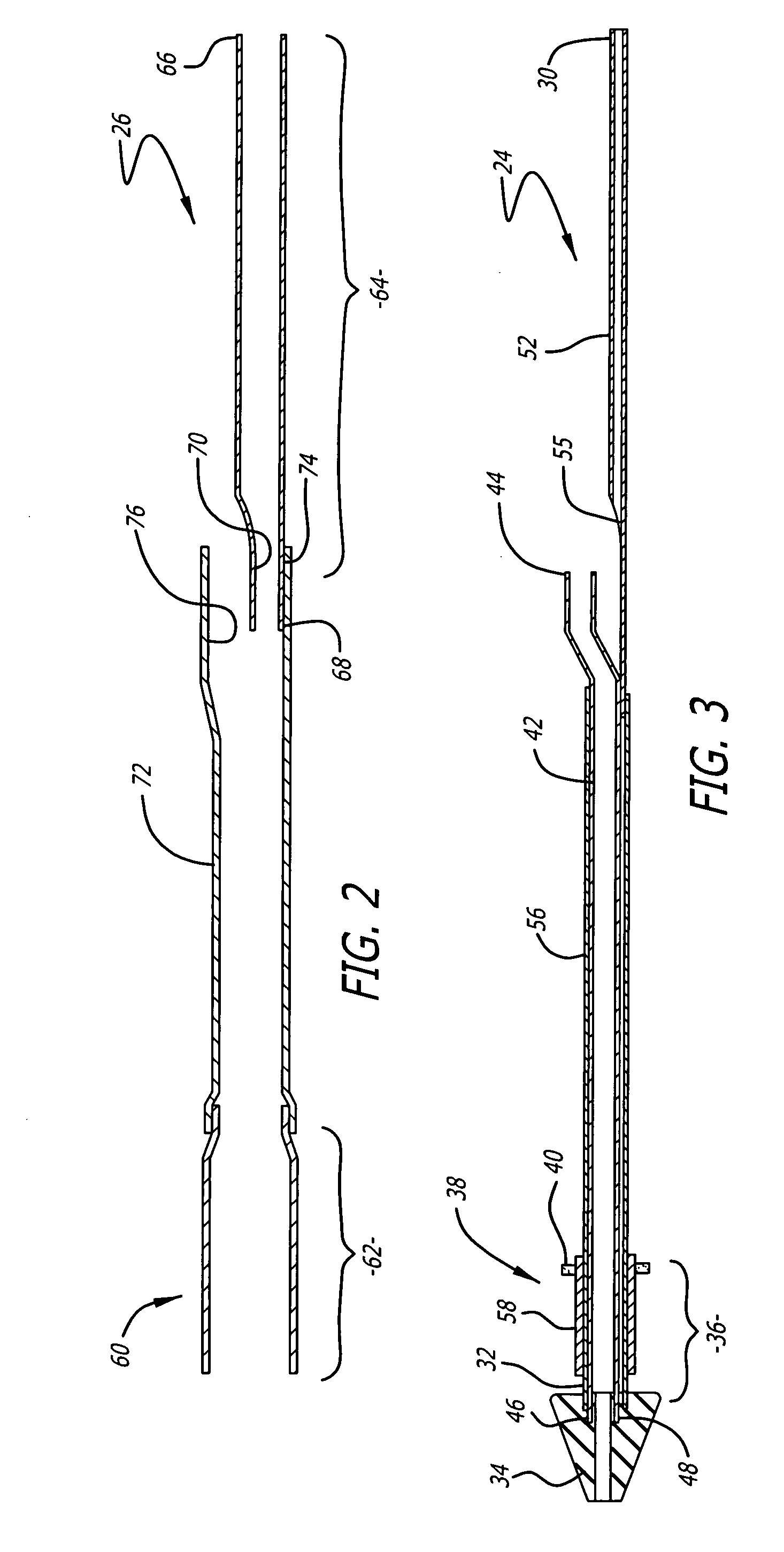

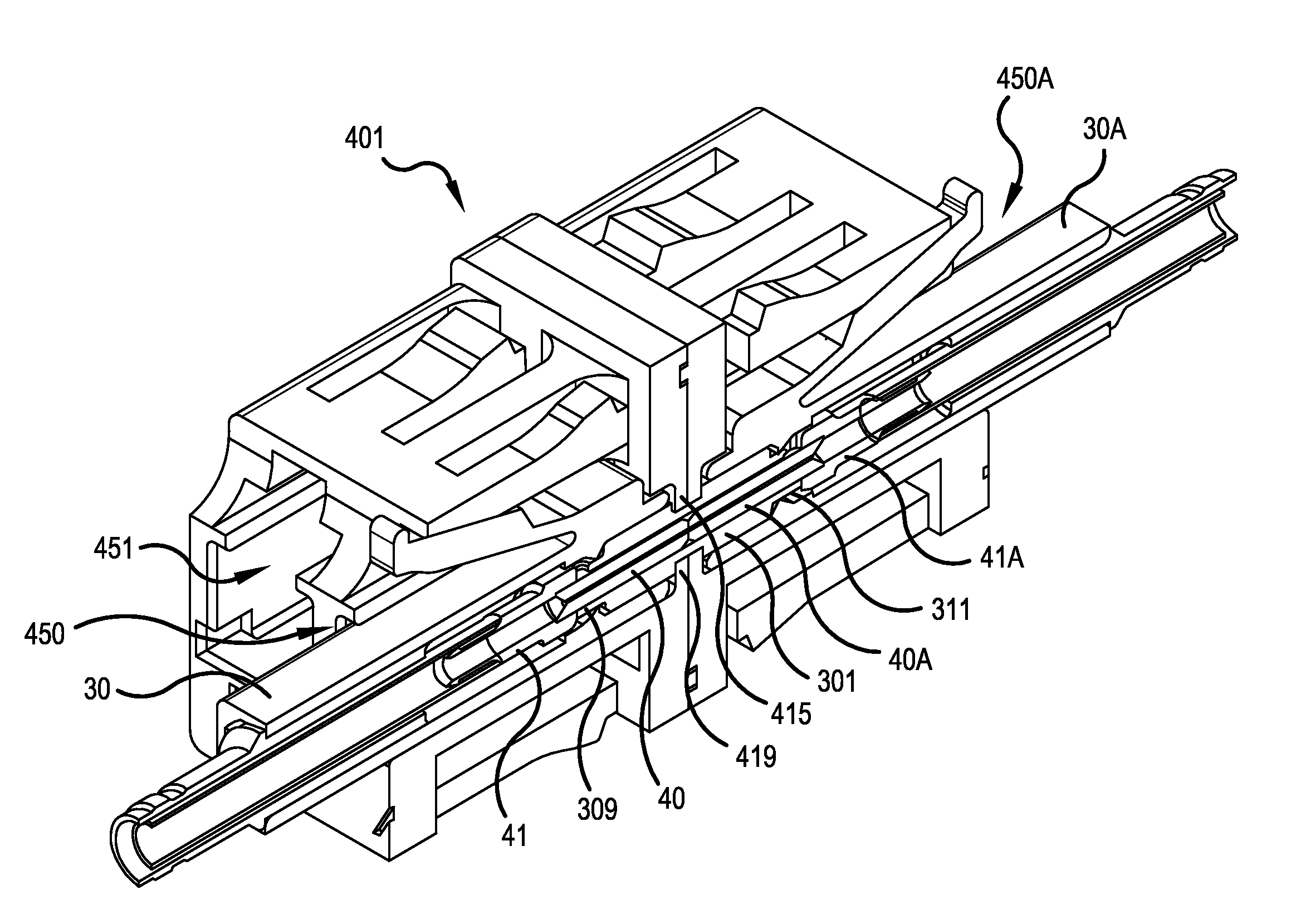

Rapid-exchange delivery systems for self-expanding stents

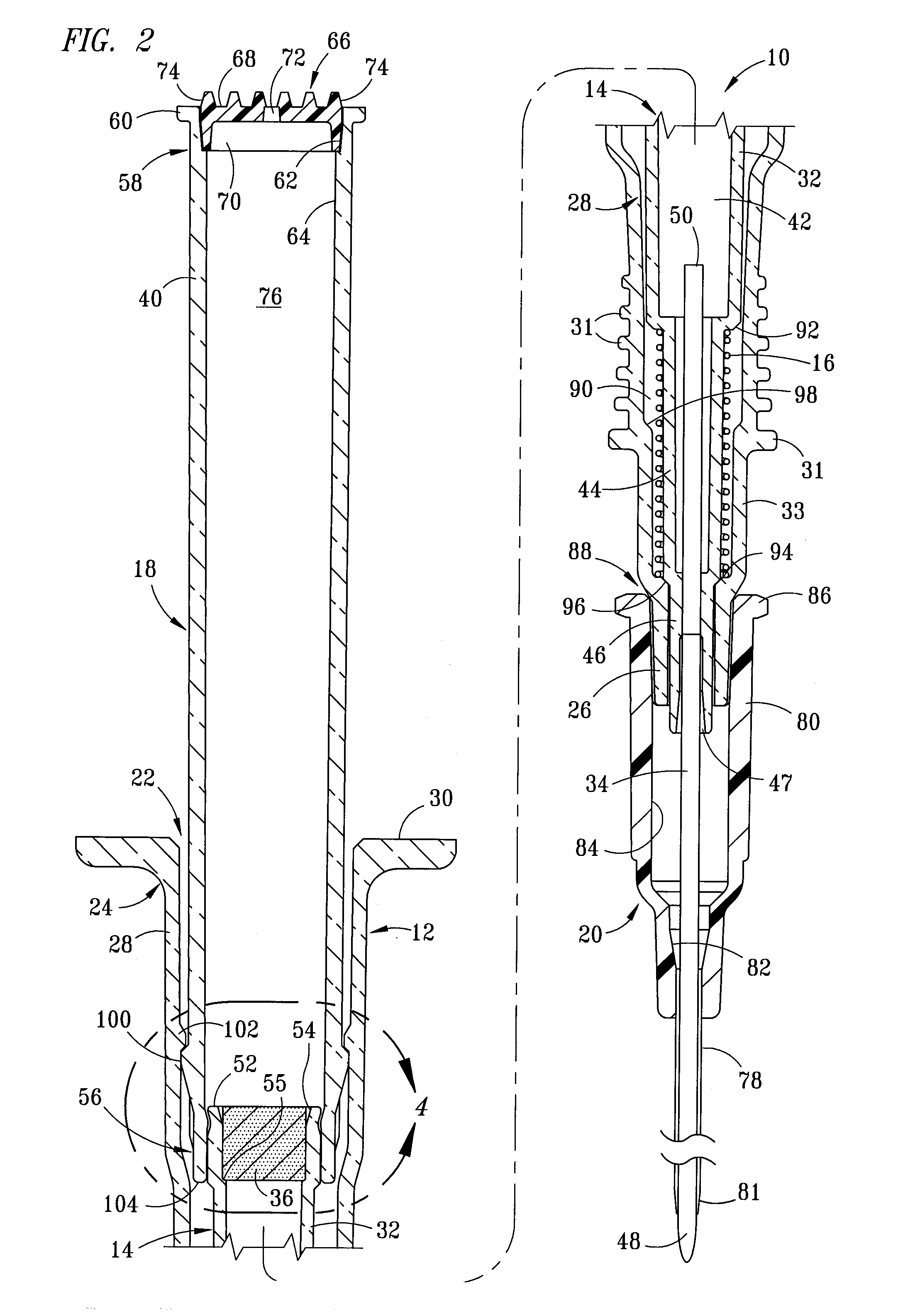

A catheter assembly is provided having an inner member and an outer member extending along a longitudinal axis, the inner member and the outer member having a coaxial configuration and dimensioned for relative axial movement. The outer member may include an anti rotation member adapted to engage with a longitudinal slot formed on the inner member so as to maintain rotational alignment between inner member and outer member. The inner member can be made with a proximal portion made from a tubing such as hypotubing or a coil tubing. The inner member also may be made with a proximal portion made with a support mandrel. A coil tubing can be utilized to form the guide wire receiving member which is attached to the inner member.

Owner:ABBOTT CARDIOVASCULAR

Modular long bone prosthesis for partial or total bone replacement

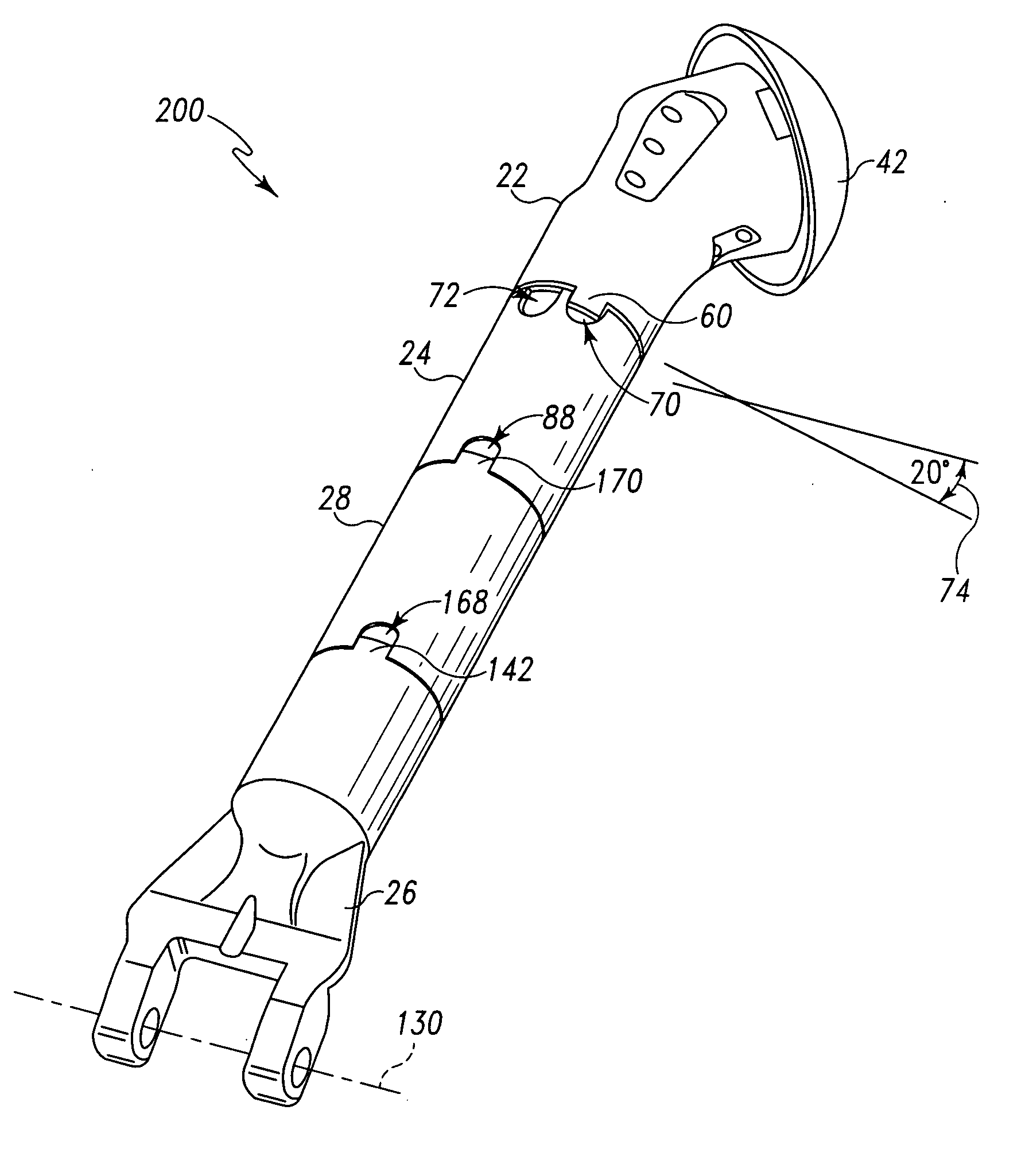

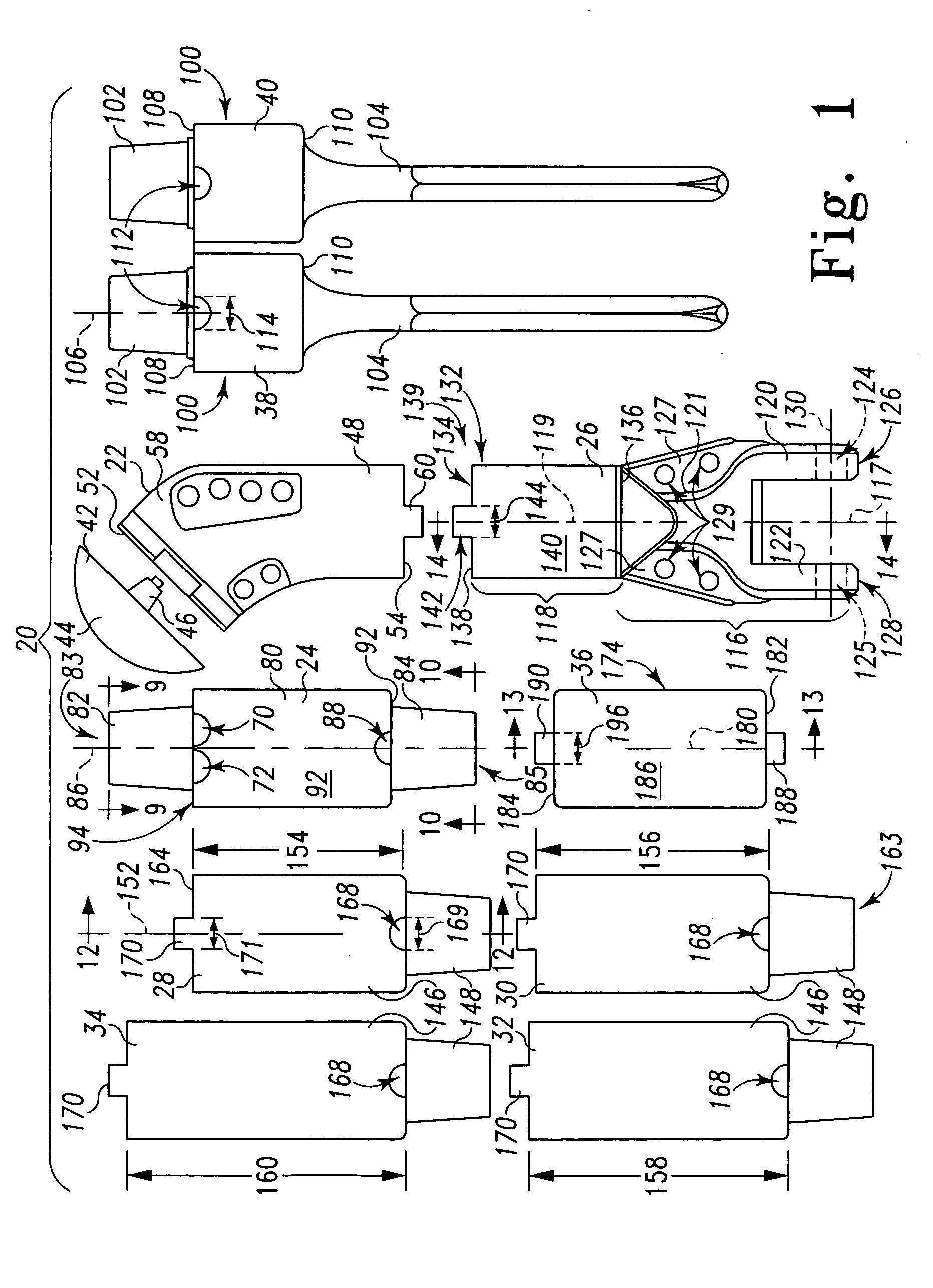

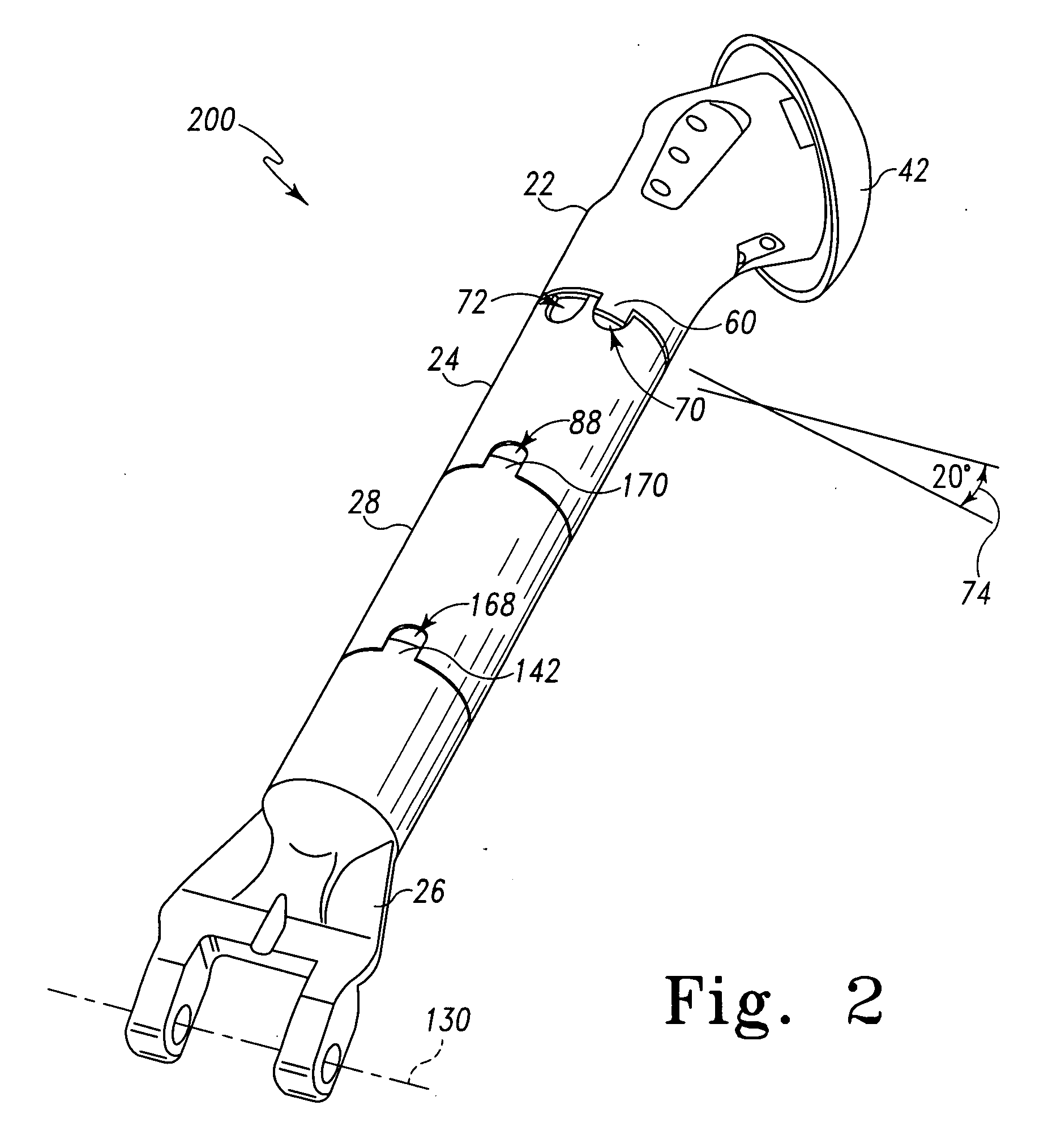

ActiveUS20050071014A1Facilitate rotational alignmentEasy alignmentBone implantJoint implantsProsthesisBone replacement

A modular long bone prosthesis is provided having a proximal component and a retroversion component. The proximal component is configured at a proximal end to receive a head forming a portion of a joint and is formed at a distal end to mate with additional prosthesis components. The proximal component is formed to simulate an angle inherent in the proximal end of the bone to be replaced and includes an indicator adjacent the distal end to facilitate rotational alignment of the proximal component and additional prosthesis components. The retroversion component includes a proximal end configured to mate with the distal end of the proximal component. The proximal end includes alignment indicia for positioning relative to the indicator on the proximal component. When the indicator is in a first position relative to the alignment indicia the proximal component and the retroversion component establish a first alignment orientation forming an angle simulating the angle inherent in the proximal end of the right long bone of the long bone to be replaced. When the indicator is in a second position relative to the alignment indicia the proximal component and the retroversion component establish a second alignment orientation forming an angle simulating the angle inherent in the proximal end of the left long bone of the long bone to be replaced.

Owner:DEPUY PROD INC

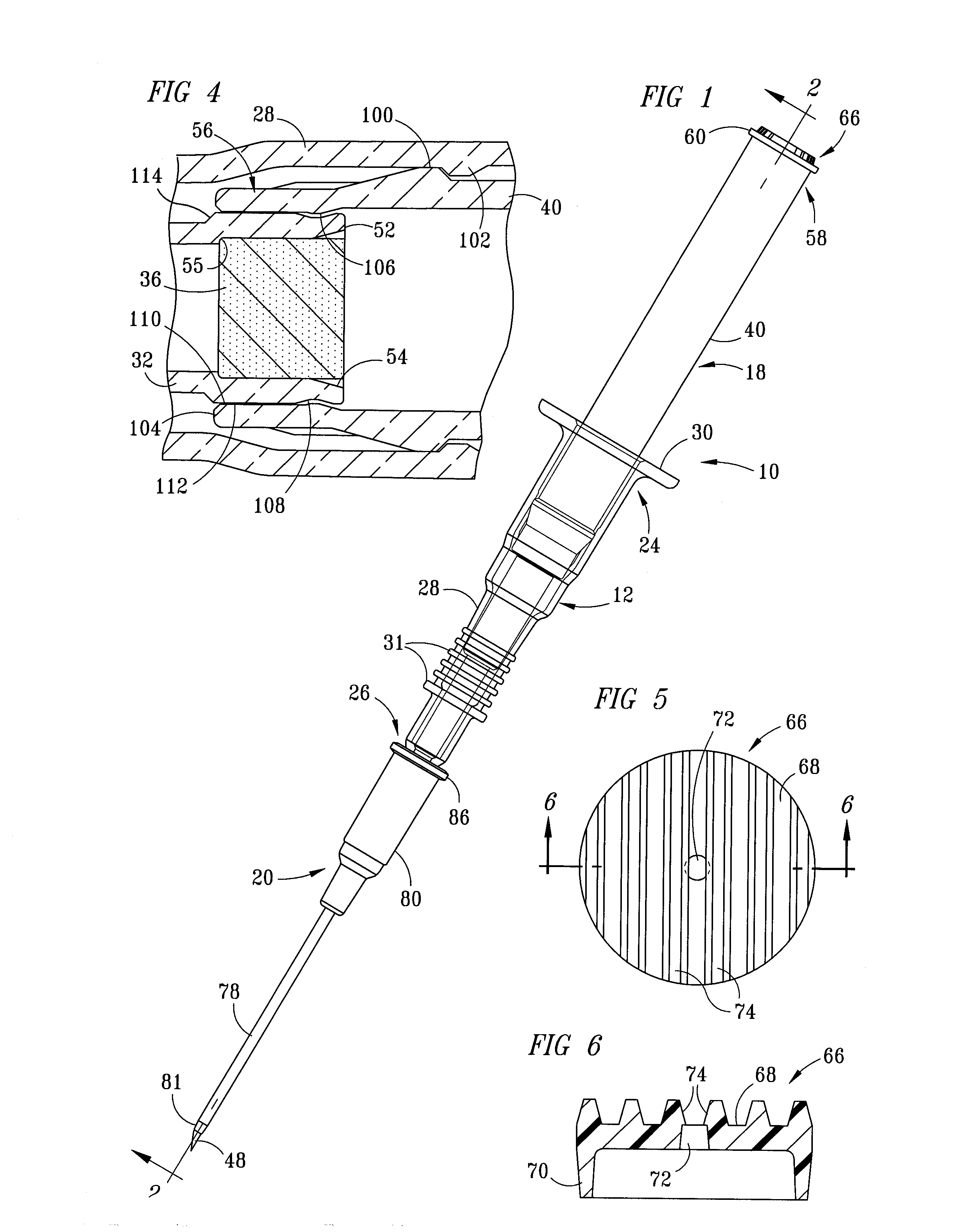

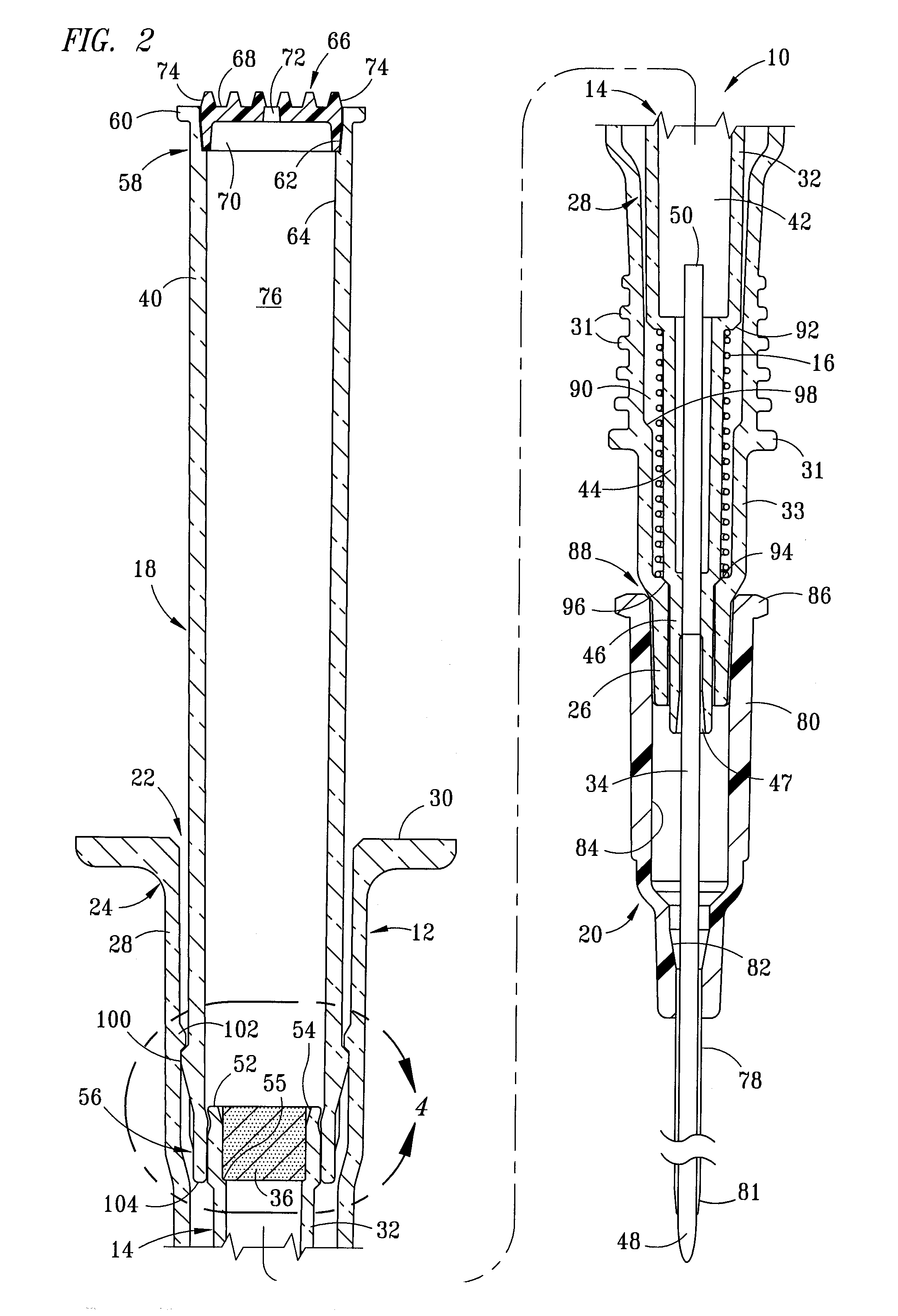

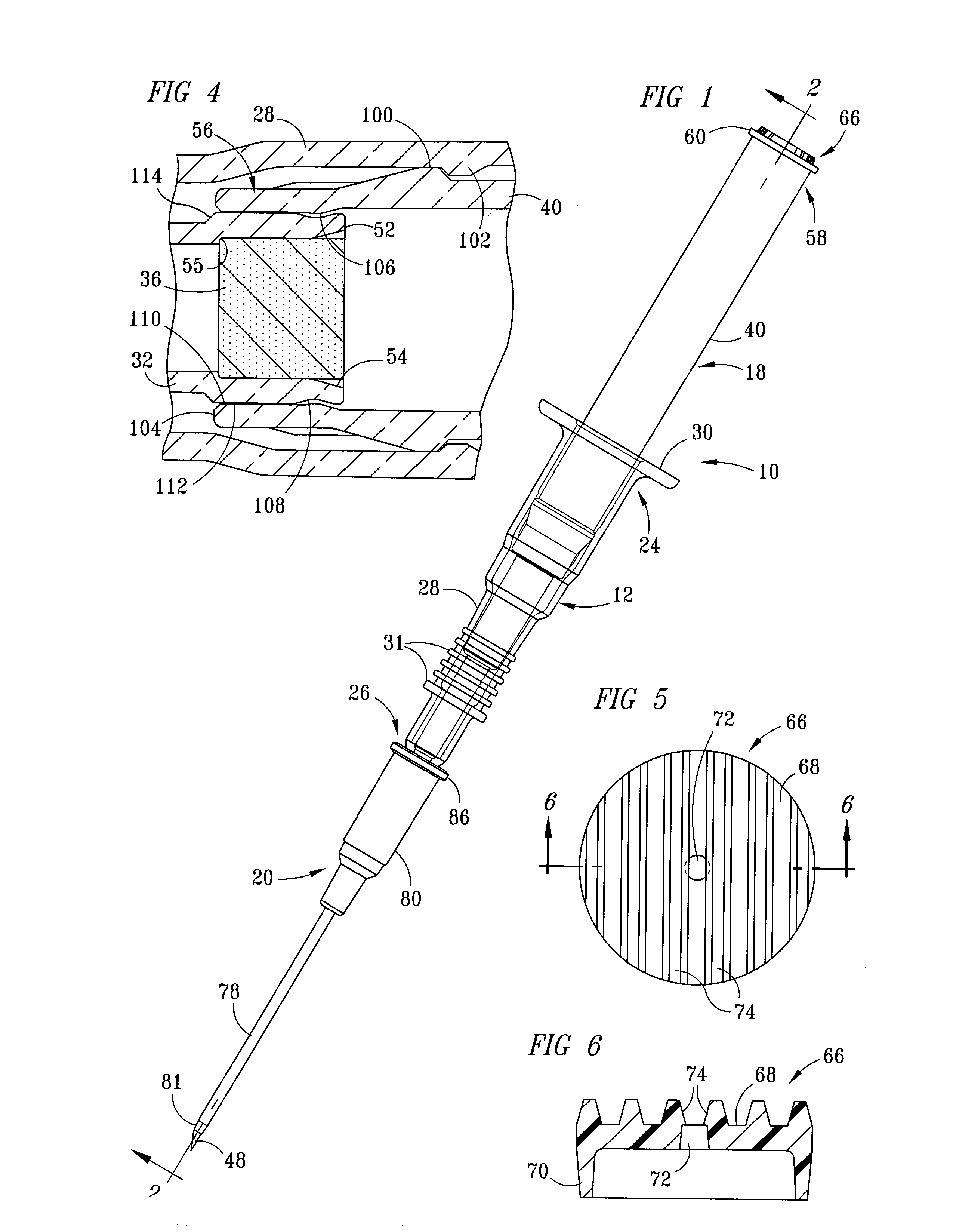

IV catheter introducer

ActiveUS8048031B2Reduce the possibilityDampens retraction forceInfusion syringesInfusion devicesCatheter hubCatheter introducer

An IV catheter introducer having an elastomeric grommet disposed between the housing and the IV catheter assembly that helps avoid unintentional separation of IV catheter assembly from the housing during shipping and handling prior to use, that acts as a needle guide, that helps align the housing and IV catheter assembly coaxially, that indicates that top side of the catheter introducer, that provides proper rotational alignment between the grommet and housing, that wipes blood off the needle during withdrawal of the needle from the catheter assembly and grommet, that impedes blood flow out of the catheter hub after needle withdrawal, and that assists the user in separating the housing from the IV catheter assembly following insertion of the catheter and withdrawal of the needle.

Owner:RETRACTABLE TECH INC

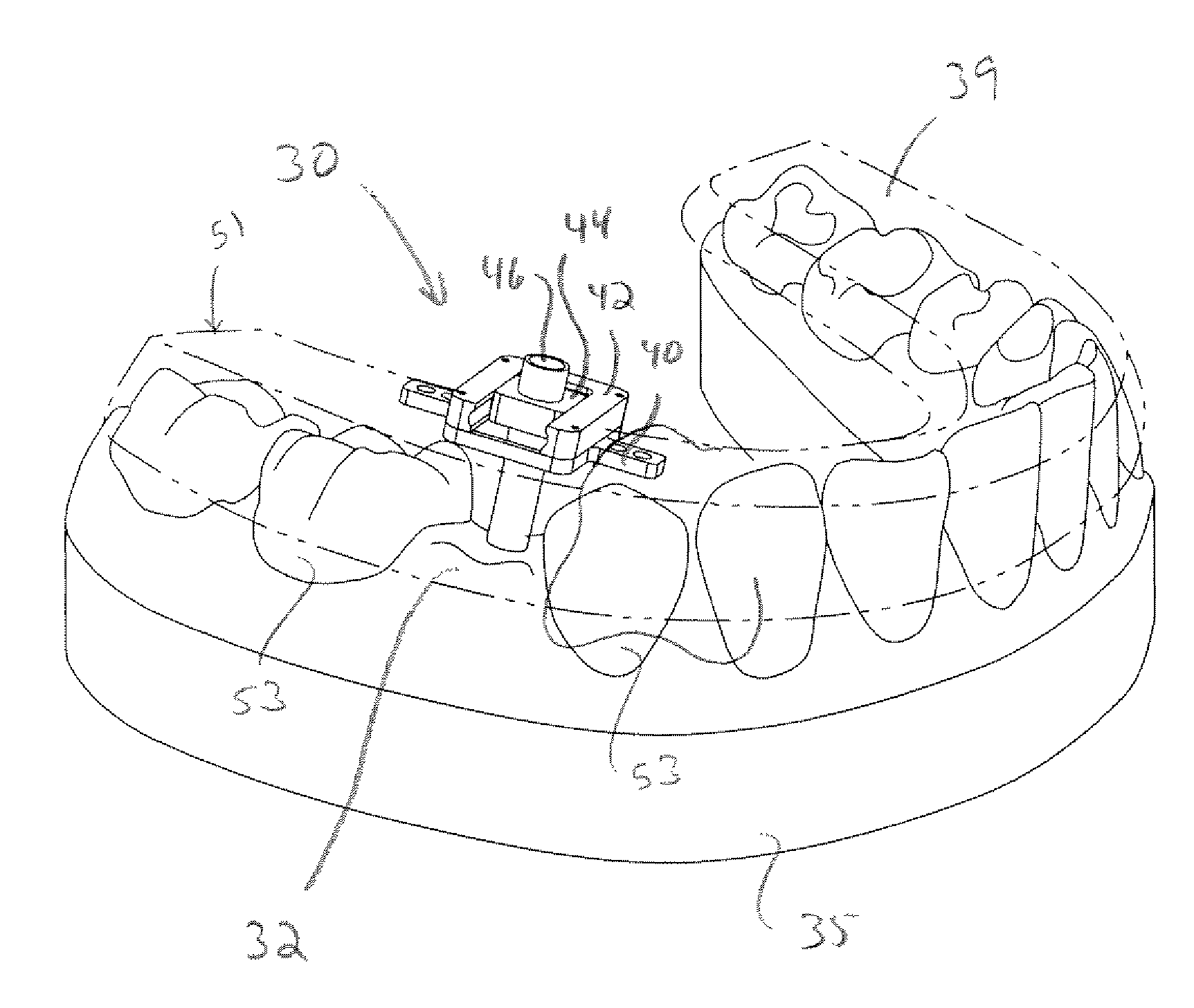

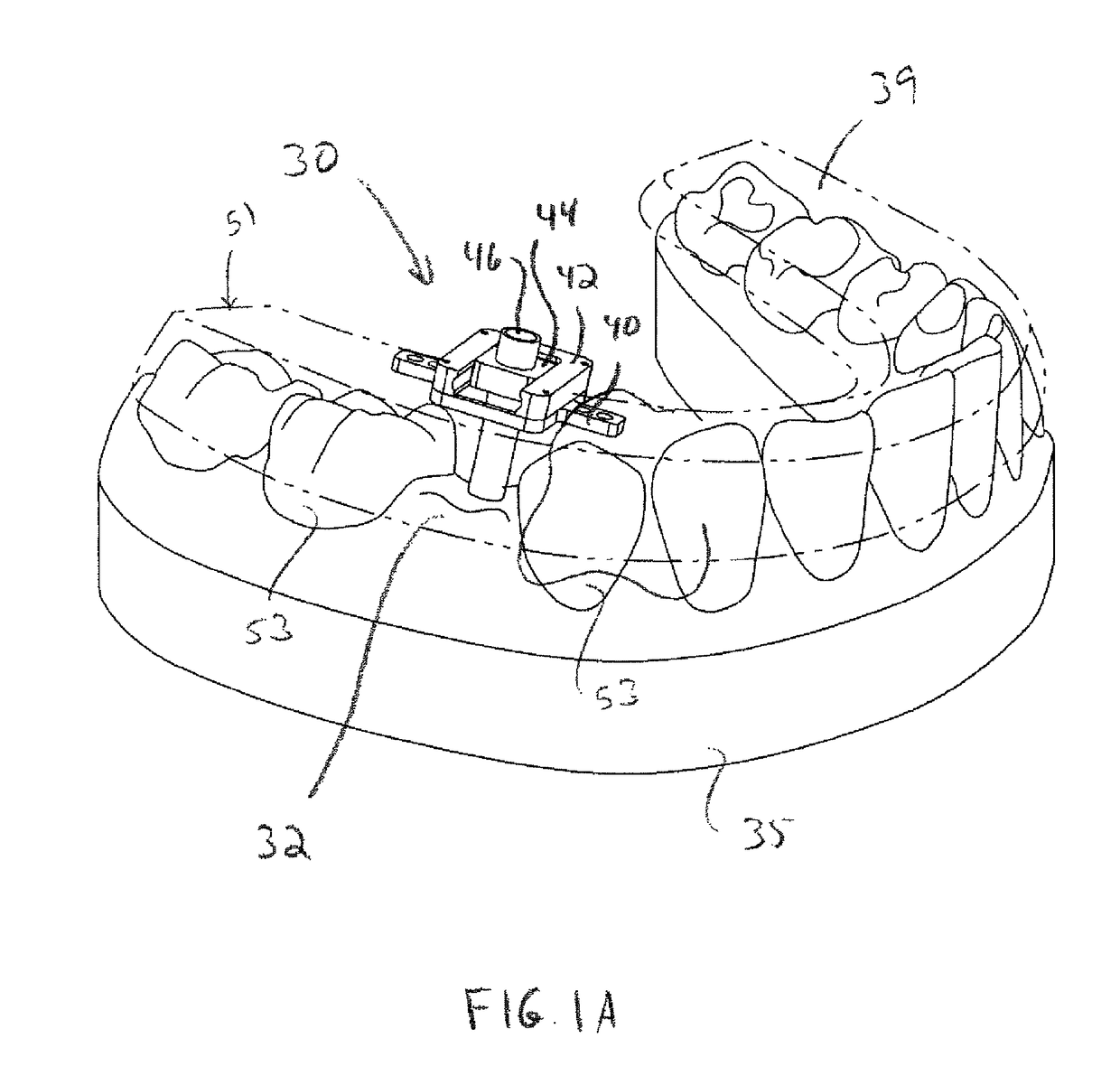

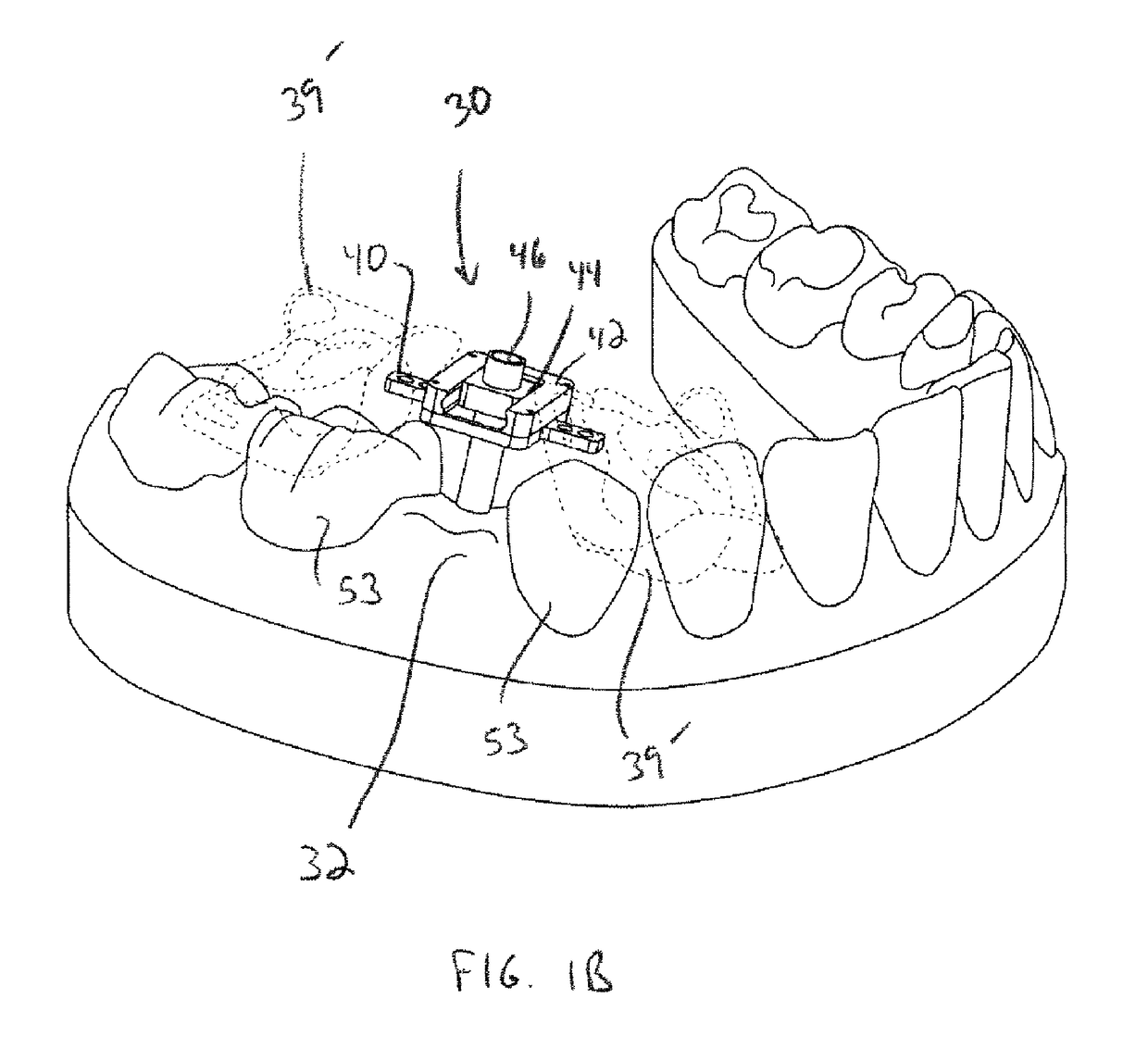

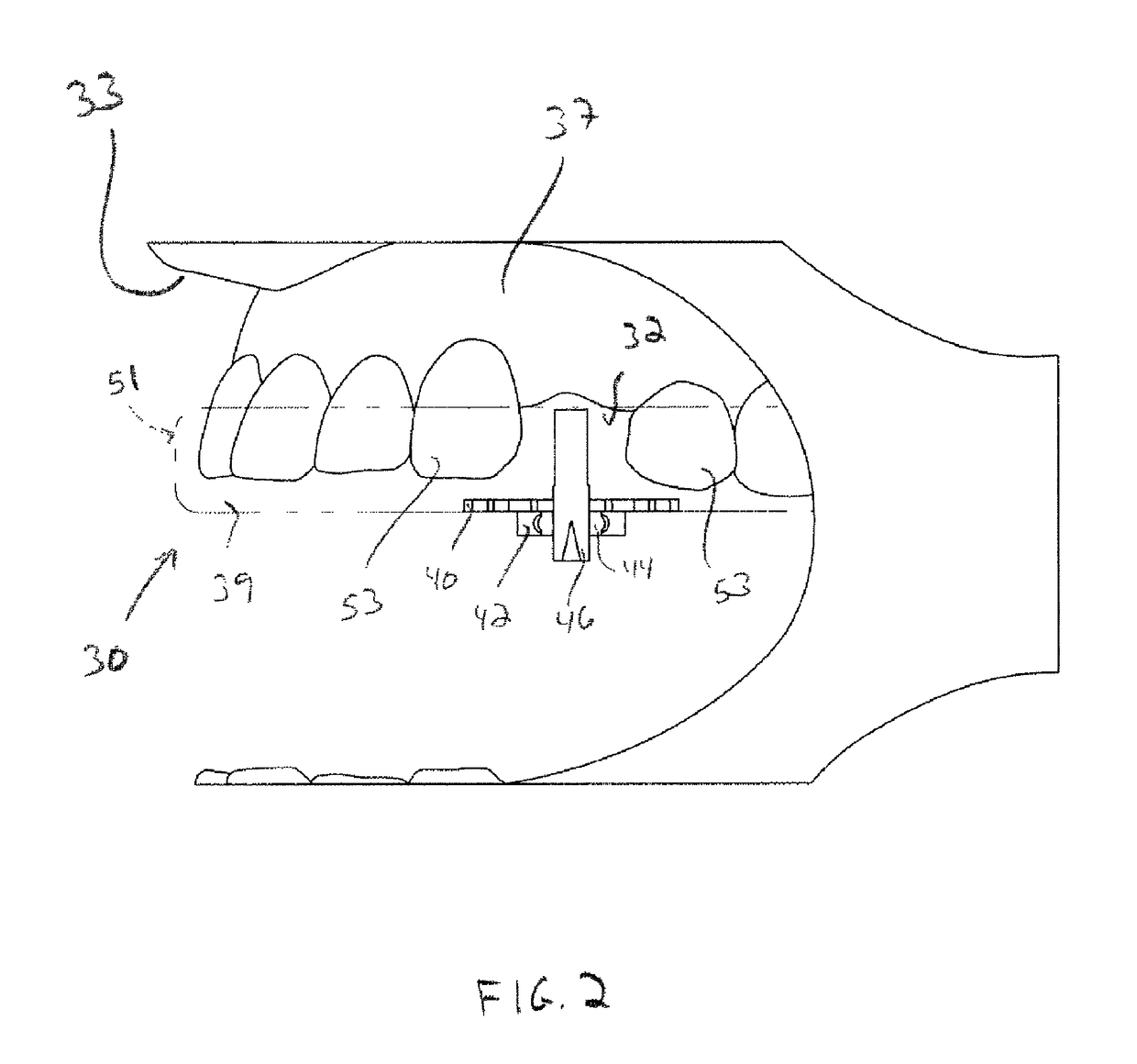

Surgical guide for dental implant and methods therefor

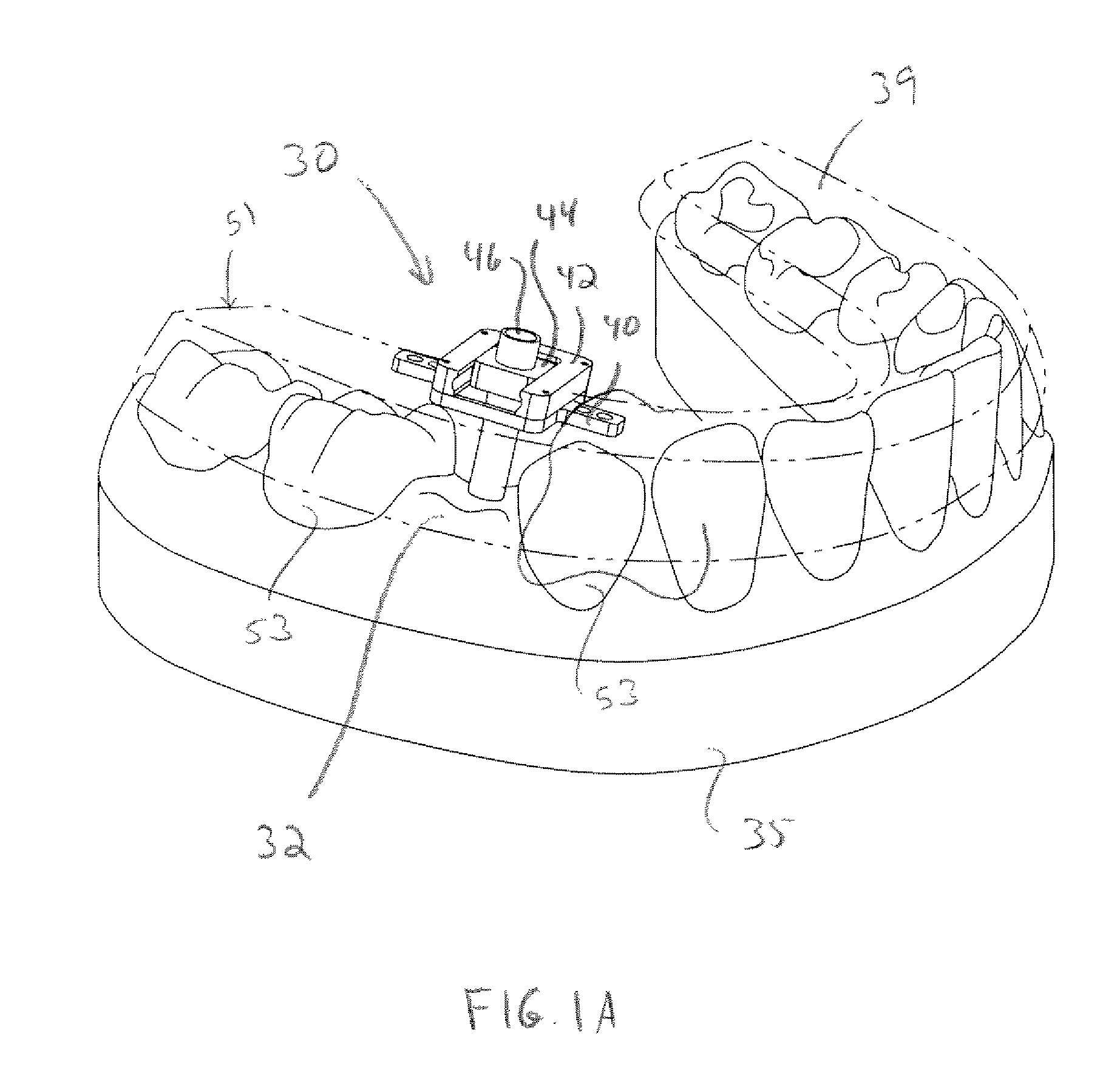

A surgical guide assembly is provided for positioning a drill bit during a dental implant procedure. The guide assembly includes a mounting member configured to mount to one or more teeth adjacent to an edentulous area, a base connected to the mounting member and dimensioned to extend over the edentulous area, a translation member adjustable with respect to the base, and a rotation member adjustable with respect to the translation member. The rotation member includes an aperture configured to receive a radiographic marker or a drill. The translation and rotation members may be configured to adjust one of the mesio-distal (MD) rotational alignment and the buccal-lingual (BL) rotational alignment of the radiographic marker inserted in the aperture while holding the other of the MD and BL rotational alignment mechanically fixed. Also, the translation and rotation members may be configured to adjust the other of the MD and BL translational alignment of the radiographic marker while holding said one of the MD and BL translational alignment mechanically fixed. A method of using the dental implant positioning assembly is also disclosed.

Owner:STUMPEL LAMBERT J

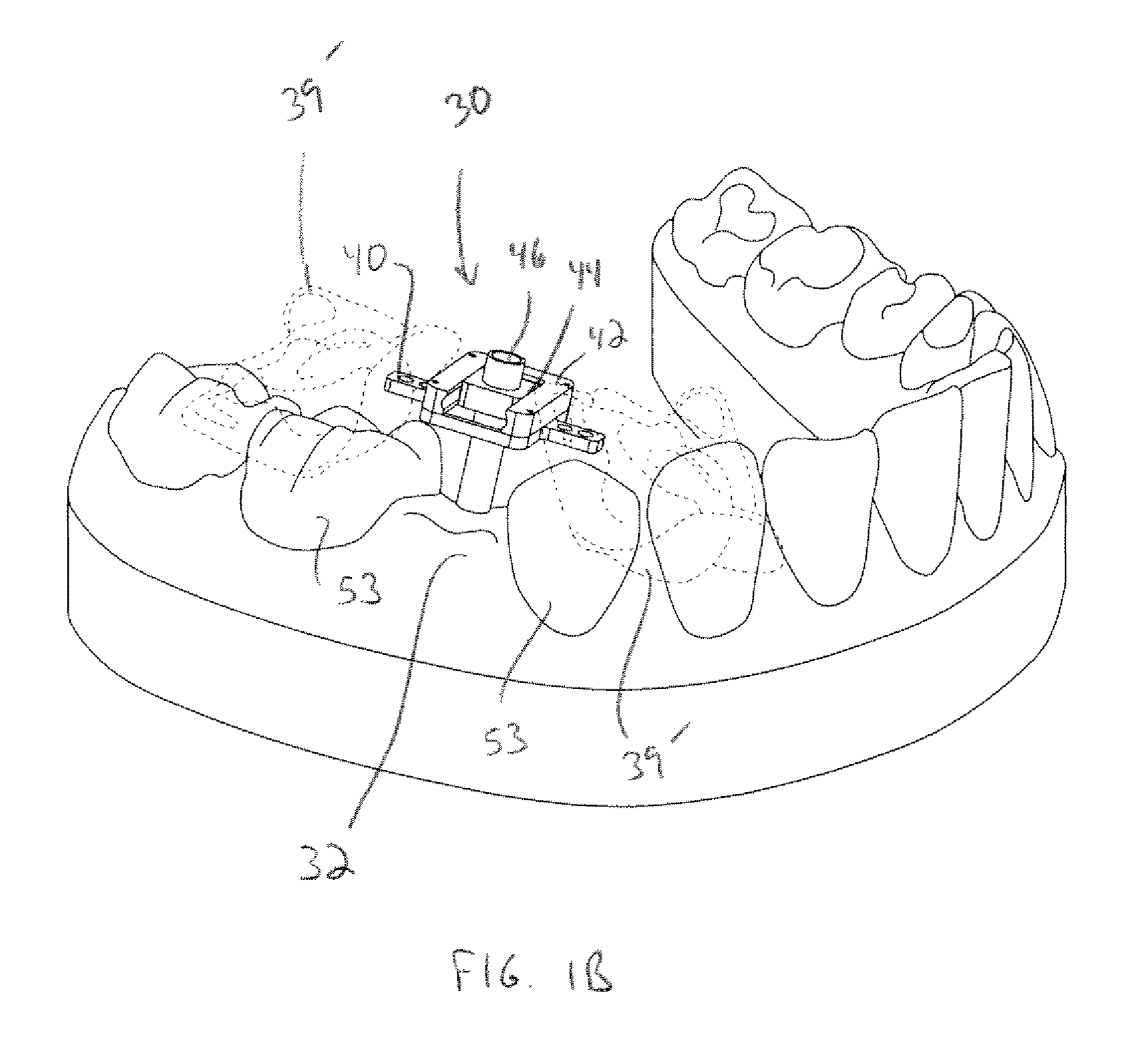

Method for improved rotational alignment in joint arthroplasty

InactiveUS20080249394A1Improve accuracySurgical navigation systemsDiagnostic recording/measuringTibiaJoint arthroplasty

A method for improved rotational alignment of the bones in joint surgery is described. The method involves the tracking of the relative motion of a third bone in with respect to the movement of the first and second bone. In one aspect of the invention, the motion of the patella is used to derive the axis of rotation of the femoral and tibial components in total knee arthroplasty, either alone or in combination with other techniques.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

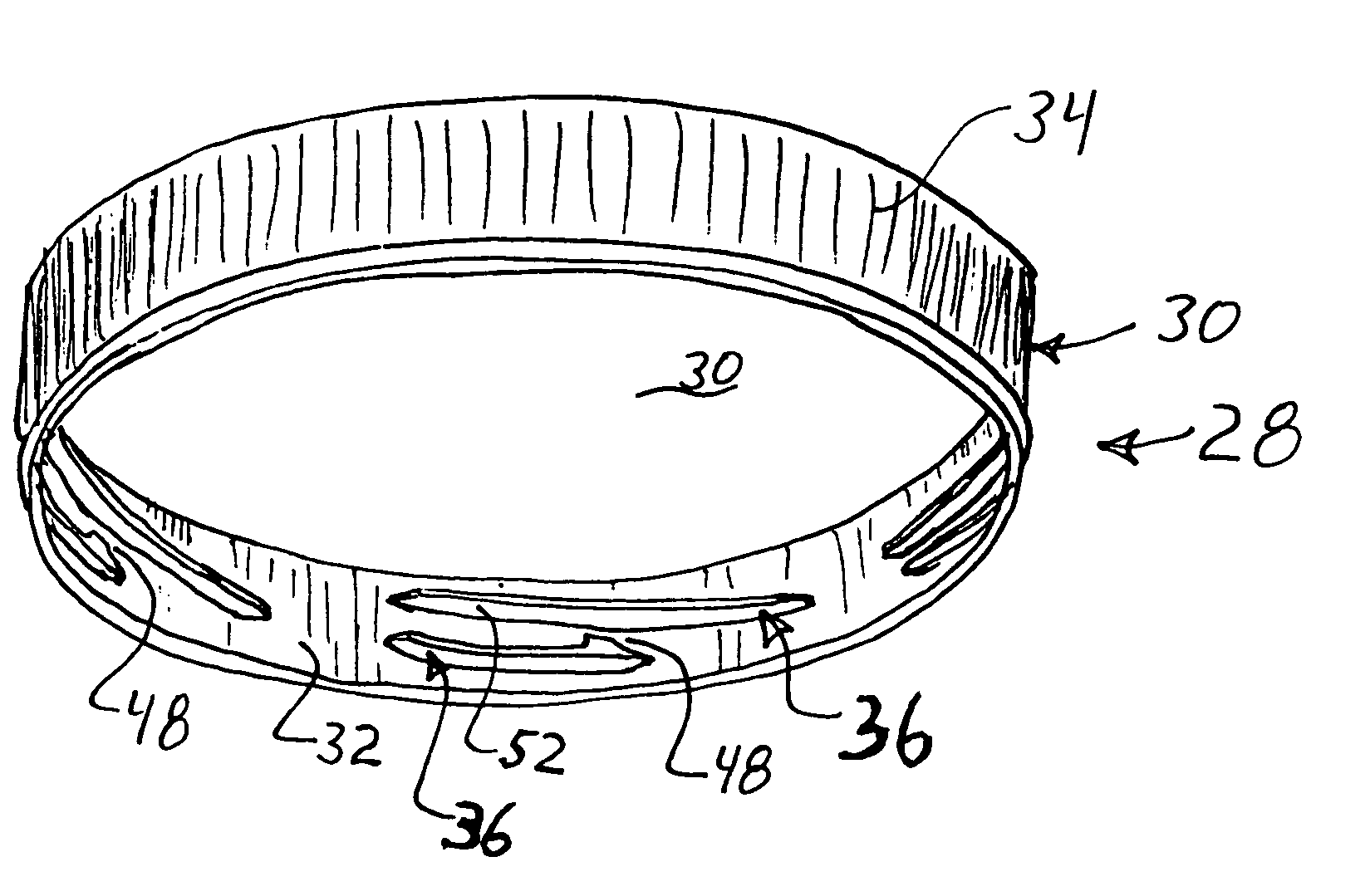

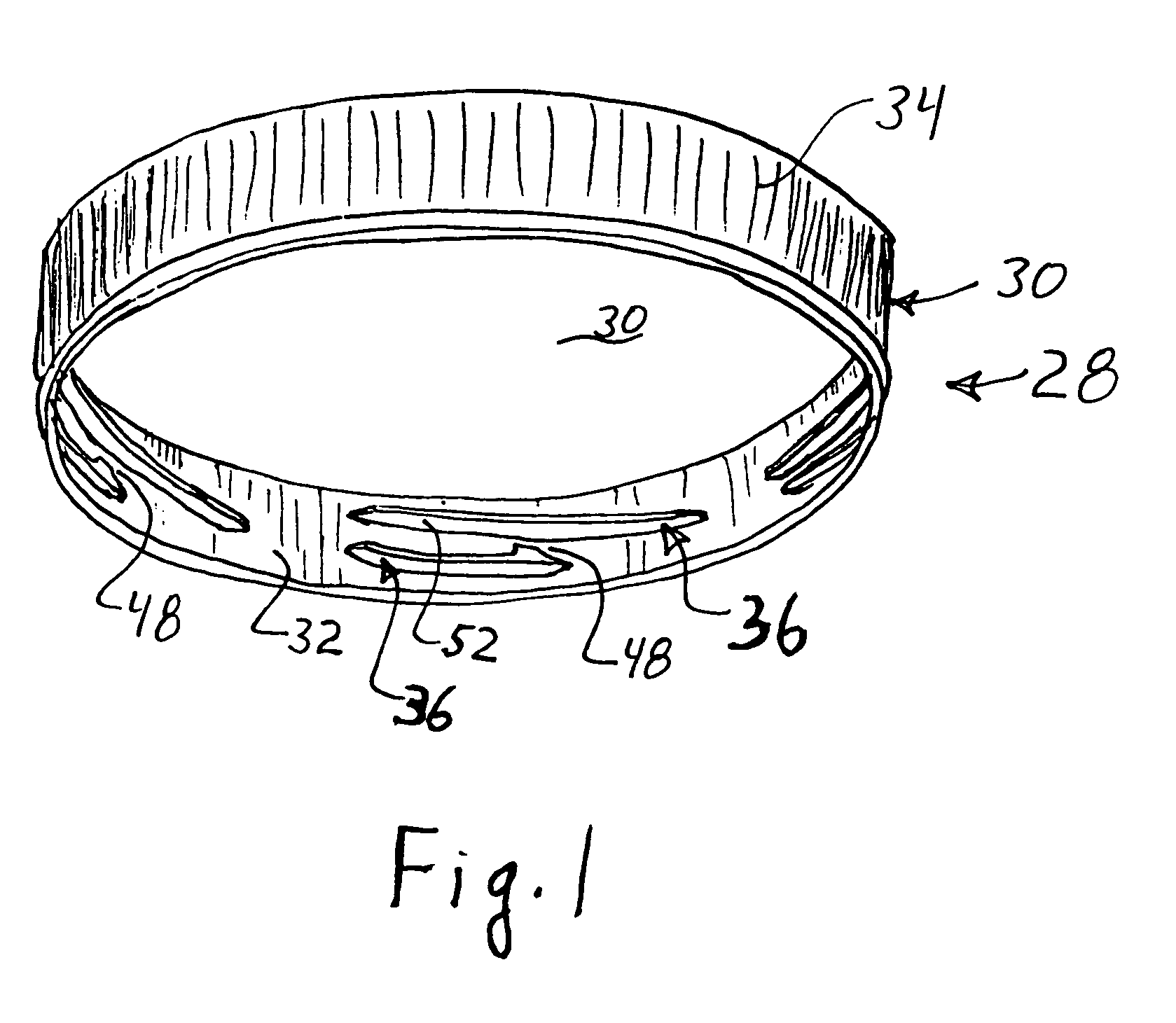

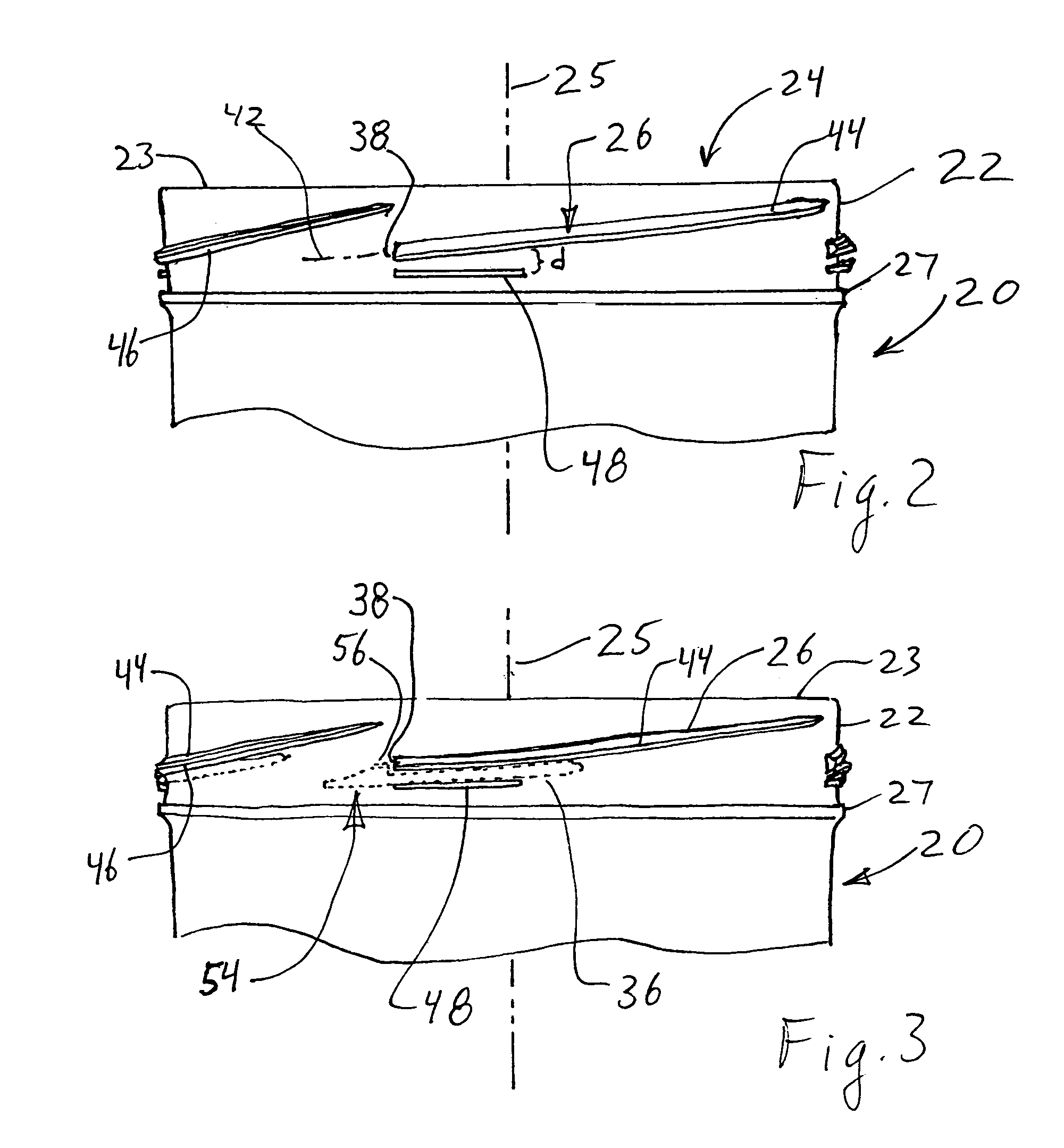

Child resistant container and cap

A locking cap and container is provided for a container having an opening surrounded by a neck with container threads thereon that are sized and located to threadingly engage cap threads formed on a skirt of the cap. A shaped distal end is formed on a distal end of the container threads and a barb is formed on the distal end of the cap threads. A resilient locking tab extends from the container, and is located below the shaped distal end and spaced apart from the shaped distal end a distance sufficient to allow passage of the barb beyond the shaped distal end but sufficiently close to resiliently urge the barb into overlapping rotational alignment with the shaped end. The shaped end is configured to lockingly engage the barb when the tab holds them in alignment. Pushing down on the cap pushes the thread against the locking tab and allows disengagement of the barb from the shaped distal end and movement of the barb past the shaped distal end to unlock the cap.

Owner:REXAM PRESCRIPTION PROD INC

Modular long bone prosthesis for partial or total bone replacement

A modular long bone prosthesis is provided having a proximal component and a retroversion component. The proximal component is configured at a proximal end to receive a head forming a portion of a joint and is formed at a distal end to mate with additional prosthesis components. The proximal component is formed to simulate an angle inherent in the proximal end of the bone to be replaced and includes an indicator adjacent the distal end to facilitate rotational alignment of the proximal component and additional prosthesis components. The retroversion component includes a proximal end configured to mate with the distal end of the proximal component. The proximal end includes alignment indicia for positioning relative to the indicator on the proximal component. When the indicator is in a first position relative to the alignment indicia the proximal component and the retroversion component establish a first alignment orientation forming an angle simulating the angle inherent in the proximal end of the right long bone of the long bone to be replaced. When the indicator is in a second position relative to the alignment indicia the proximal component and the retroversion component establish a second alignment orientation forming an angle simulating the angle inherent in the proximal end of the left long bone of the long bone to be replaced.

Owner:DEPUY PROD INC

Surgical guide for dental implant and methods therefor

A surgical guide assembly is provided for positioning a drill bit during a dental implant procedure. The guide assembly includes a mounting member configured to mount to one or more teeth adjacent to an edentulous area, a base connected to the mounting member and dimensioned to extend over the edentulous area, a translation member adjustable with respect to the base, and a rotation member adjustable with respect to the translation member. The rotation member includes an aperture configured to receive a radiographic marker or a drill. The translation and rotation members may be configured to adjust one of the mesio-distal (MD) rotational alignment and the buccal-lingual (BL) rotational alignment of the radiographic marker inserted in the aperture while holding the other of the MD and BL rotational alignment mechanically fixed. Also, the translation and rotation members may be configured to adjust the other of the MD and BL translational alignment of the radiographic marker while holding said one of the MD and BL translational alignment mechanically fixed. A method of using the dental implant positioning assembly is also disclosed.

Owner:STUMPEL LAMBERT J

IV Catheter Introducer

ActiveUS20100168674A1Reduce the possibilityEasy to useInfusion syringesInfusion devicesCatheter hubCatheter introducer

An IV catheter introducer having an elastomeric grommet disposed between the housing and the IV catheter assembly that helps avoid unintentional separation of IV catheter assembly from the housing during shipping and handling prior to use, that acts as a needle guide, that helps align the housing and IV catheter assembly coaxially, that indicates that top side of the catheter introducer, that provides proper rotational alignment between the grommet and housing, that wipes blood off the needle during withdrawal of the needle from the catheter assembly and grommet, that impedes blood flow out of the catheter hub after needle withdrawal, and that assists the user in separating the housing from the IV catheter assembly following insertion of the catheter and withdrawal of the needle.

Owner:RETRACTABLE TECH INC

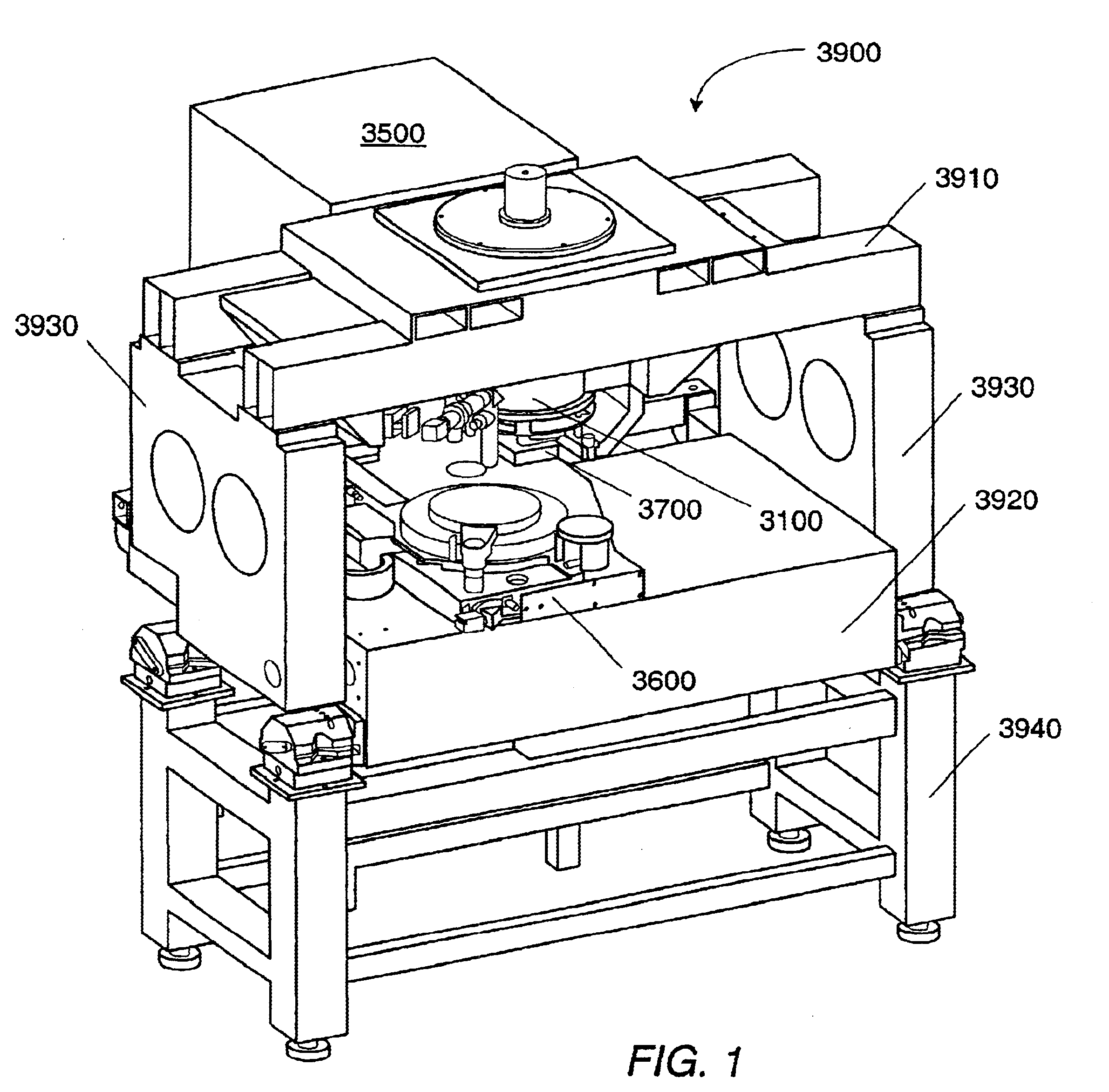

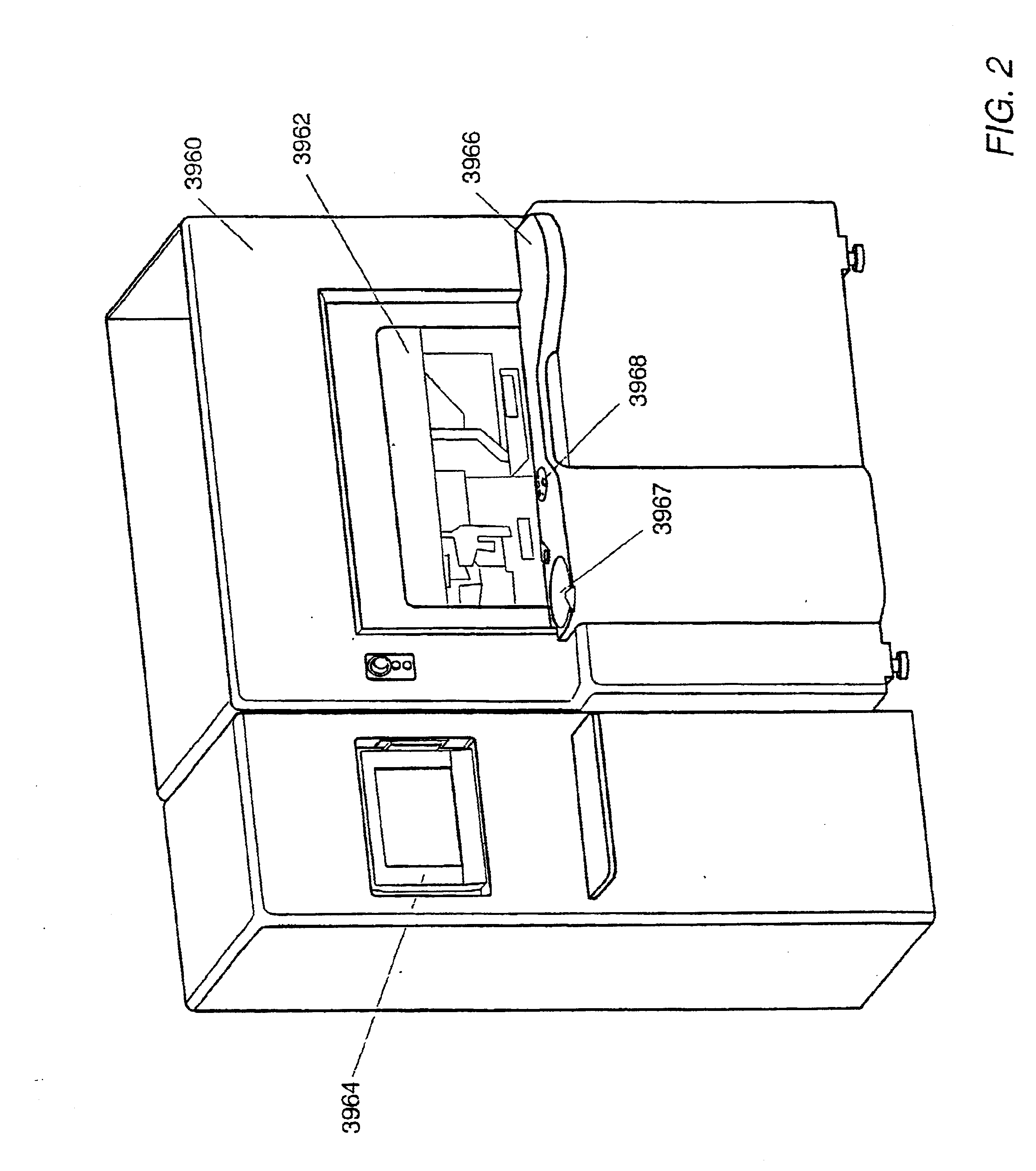

Wafer edge deposition elimination

InactiveUS6231674B1Avoid depositionReduce frictionCellsLiquid surface applicatorsThermal expansionRotational alignment

Owner:APPLIED MATERIALS INC

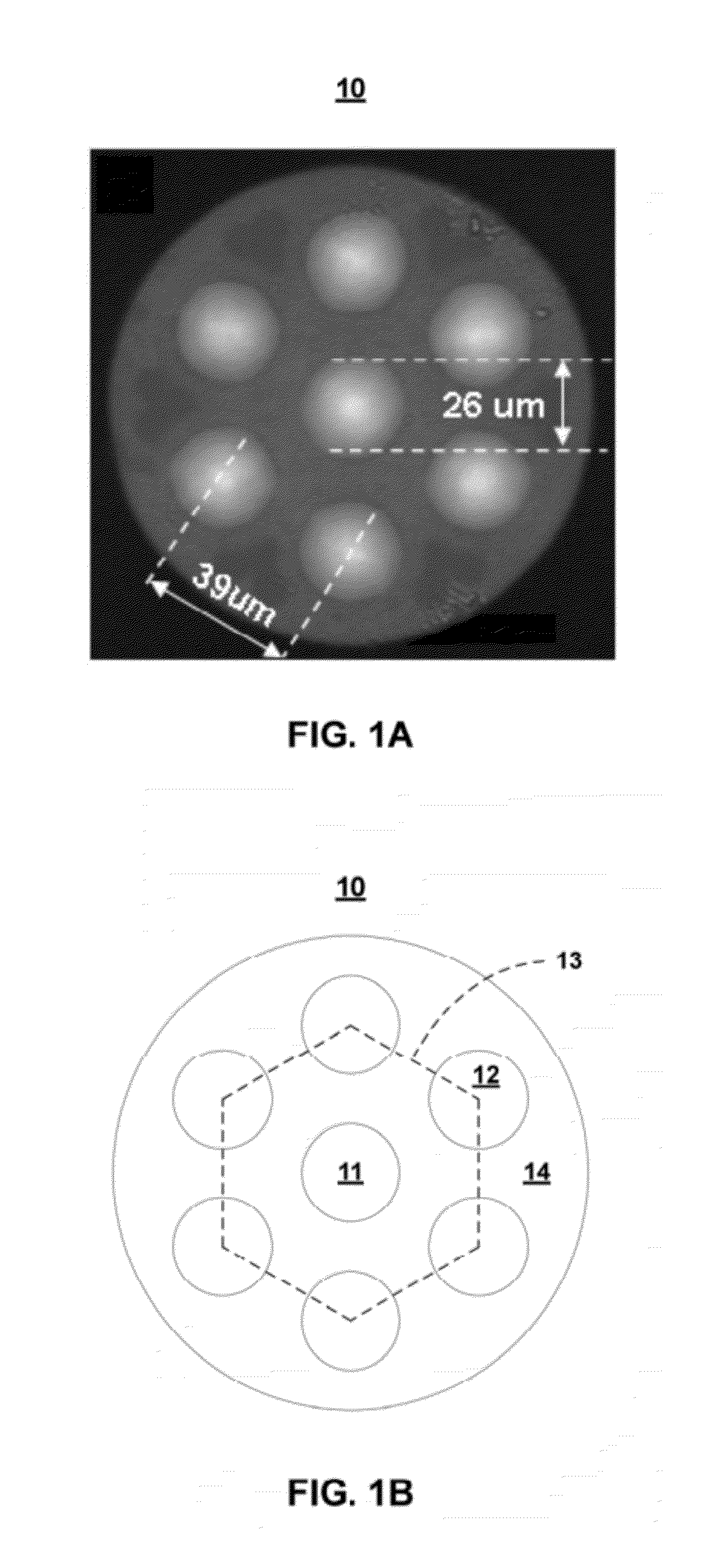

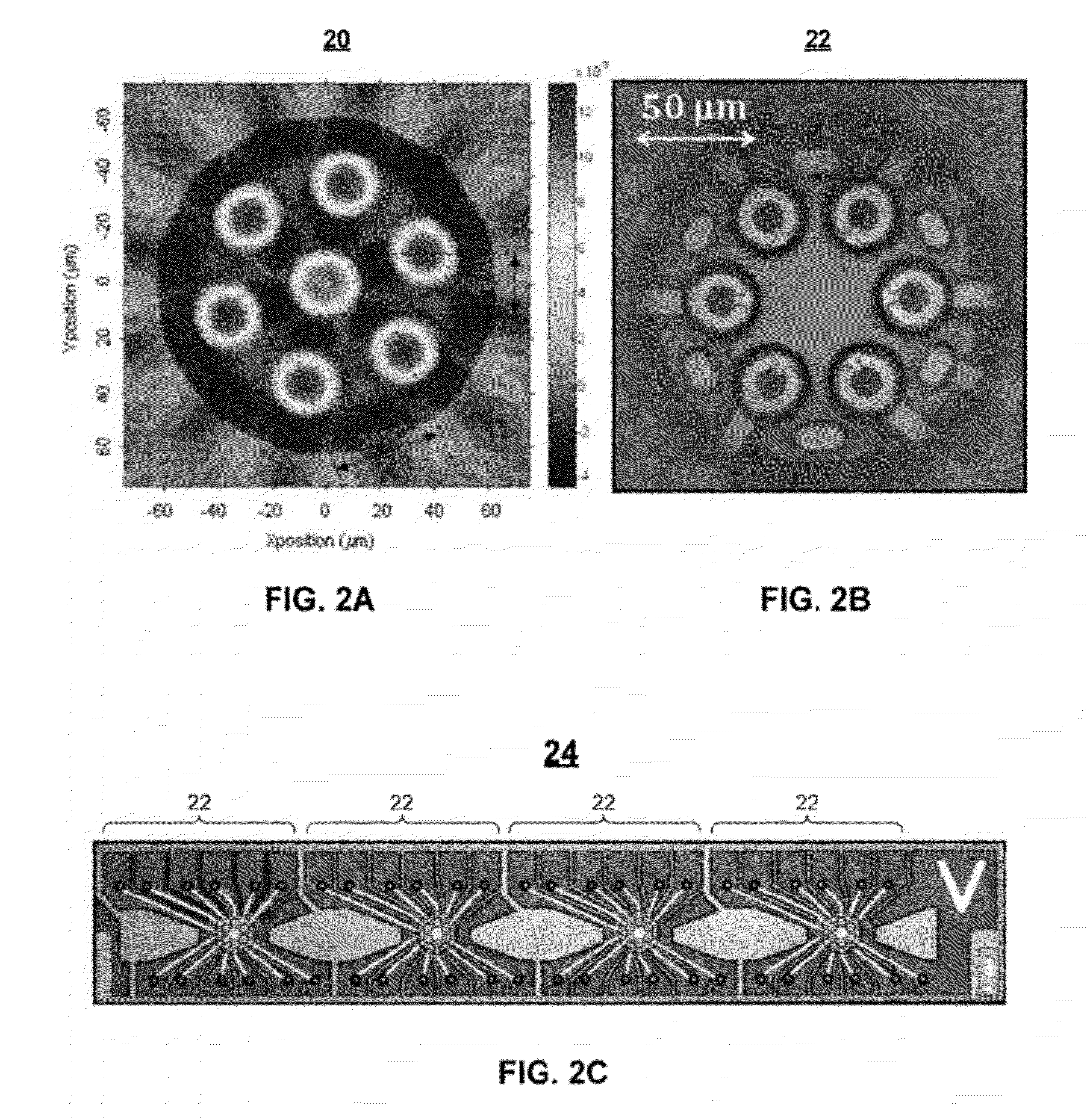

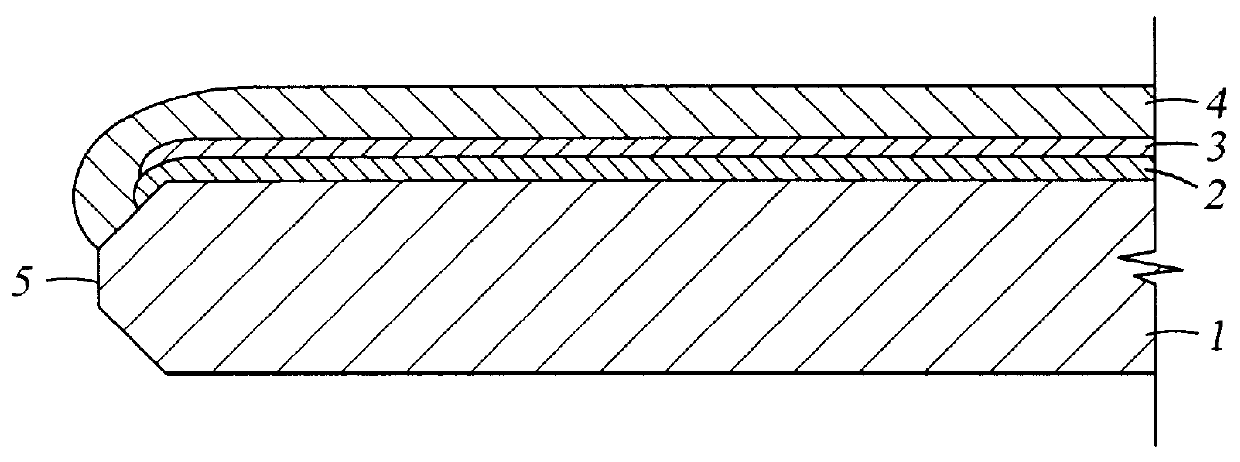

Connectors for use with polarization-maintaining and multicore optical fiber cables

ActiveUS20120219255A1Optical fibre with polarisationMeasurement/indication equipmentsFiberEngineering

An optical fiber ferrule has a plurality of guide holes therein for guiding a respective plurality of flat-sided fibers at an end of a multifiber optical fiber cable. The fibers' flat sides identify a particular rotational orientation of the fiber. Rotational alignment is achieved by urging the fibers' flat sides against a corresponding reference surface within the ferrule or within an alignment fixture. Also described is a fiber array block having a plurality of V-shaped grooves extending across an outer surface and terminating at an endface. The V-shaped grooves are shaped to guide a respective plurality of flat-sided fibers. A lid is installable across the plurality of V-shaped grooves, over fibers that have been loaded therein.

Owner:OFS FITEL LLC

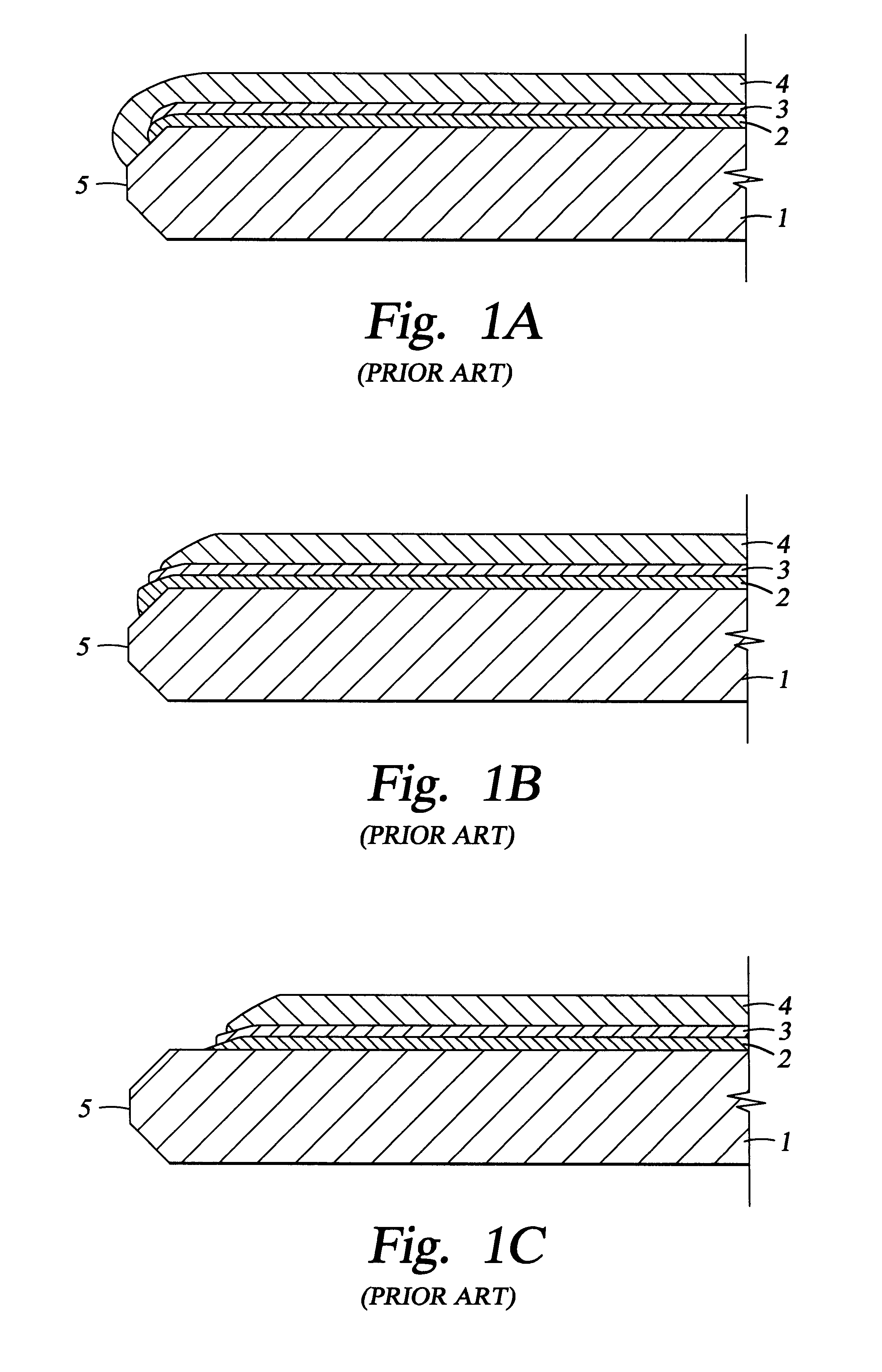

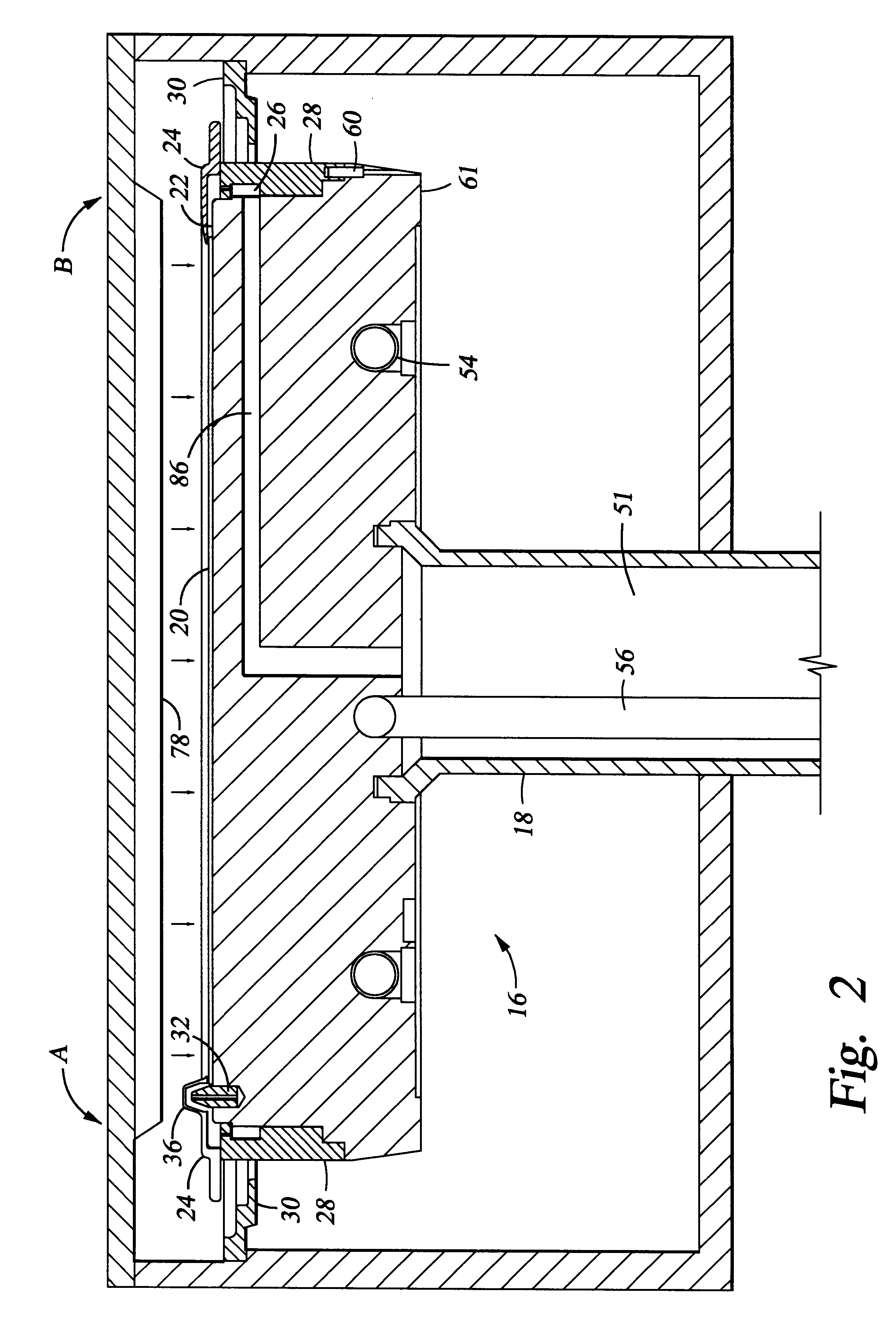

Wafer edge deposition elimination

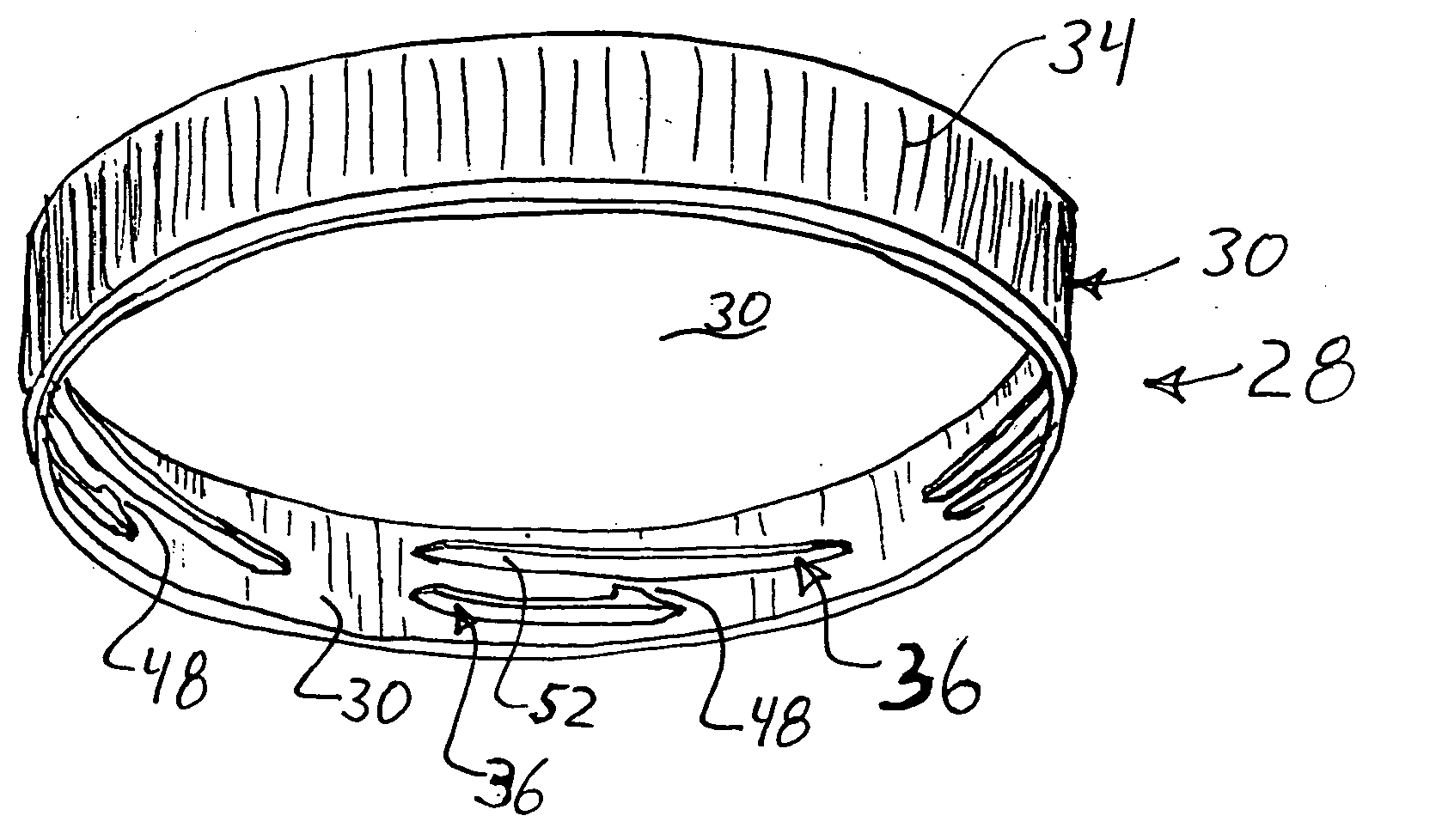

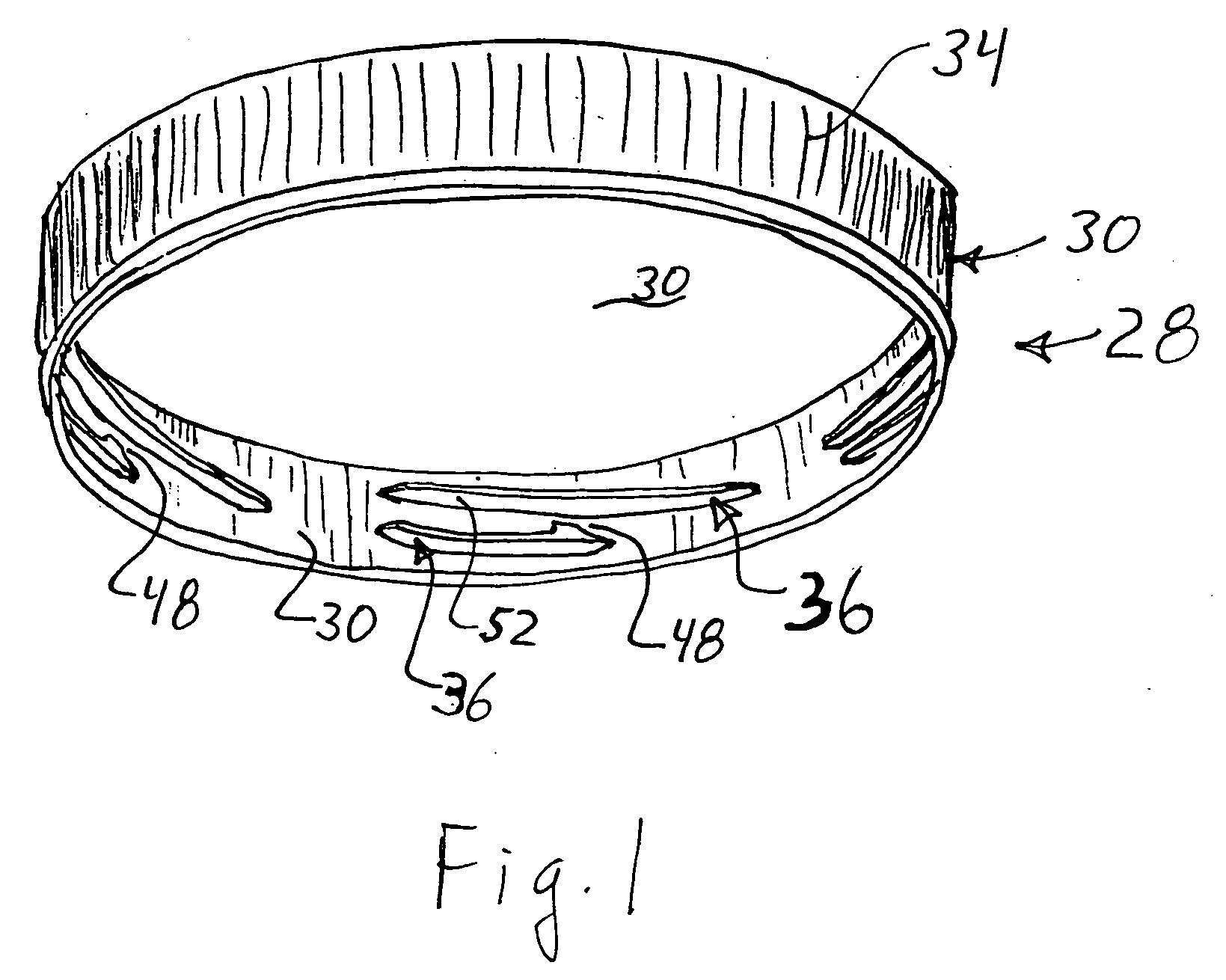

InactiveUS6033480AAvoid depositionReduce frictionChemical vapor deposition coatingAdhesivesThermal expansionRotational alignment

This invention provides a method and apparatus for substantially eliminating deposition on the edge of a wafer supported on a pedestal in a processing chamber. Process gas flow onto the wafer surface is inhibited from reaching the wafer edge and backside, by means of a shadow ring placed over the wafer without touching it. Deposition on the edge and backside of the wafer are therefore substantially eliminated. The shadow ring defines a cavity which circumscribes the wafer edge, into which purge gas is flowed. This purge gas flows out from the cavity through the gap between the shadow ring and the upper surface of the wafer. Alignment pins are placed on the wafer supporting surface of the pedestal. These pins have sloping surfaces and are arranged to guide the wafer to a centered position on the pedestal when the wafer is placed on the pedestal. These pins also serve to align the shadow ring to the pedestal and thence to the wafer. The shadow ring has a plurality of keyed formations which mate to the pins, and as the shadow ring and pedestal are brought together, the pins serve to align the shadow ring. This precise rotational alignment and centering of the shadow ring results in substantial elimination of edge deposition. The keyed formations have elliptical cross-sections to provide for radial movement of the pins with respect to the keyed formations due to thermal expansion.

Owner:APPLIED MATERIALS INC

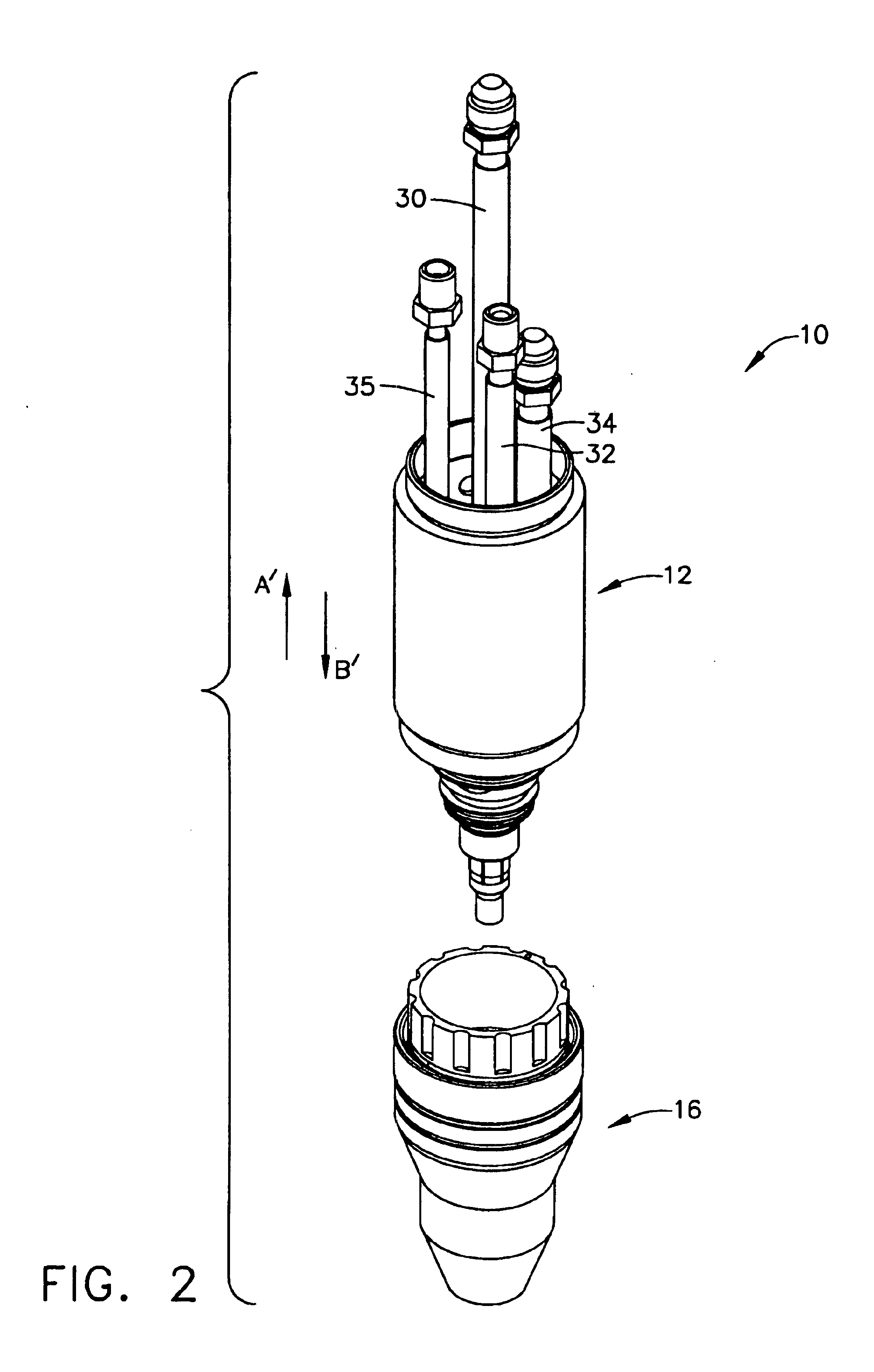

Plasma arc torch head connections

InactiveUS6919526B2Precision coolingHigh trafficSupport devices with shieldingPlasma welding apparatusElectrical connectionTorch

A plasma arc torch is provided that comprises torch head connections that are made between consumable components and a torch head independent of rotational alignment of the consumable components. Accordingly, connections for the flow of a cooling fluid, plasma gas, and / or a secondary gas are made independent of rotational alignment. Additionally, electrical connections are also provided that are independent of rotational alignment of the various plasma arc torch components.

Owner:THERMAL DYNAMICS

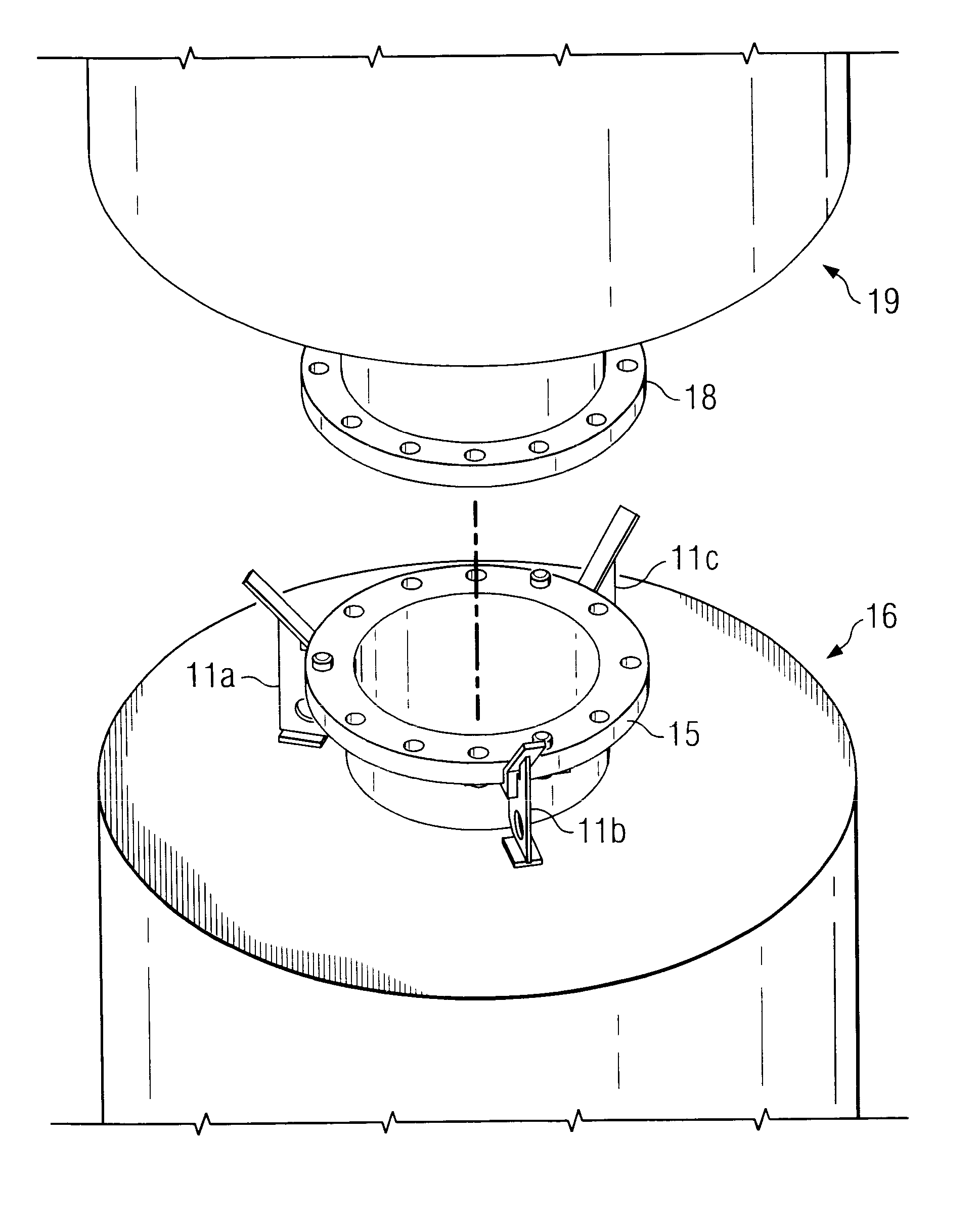

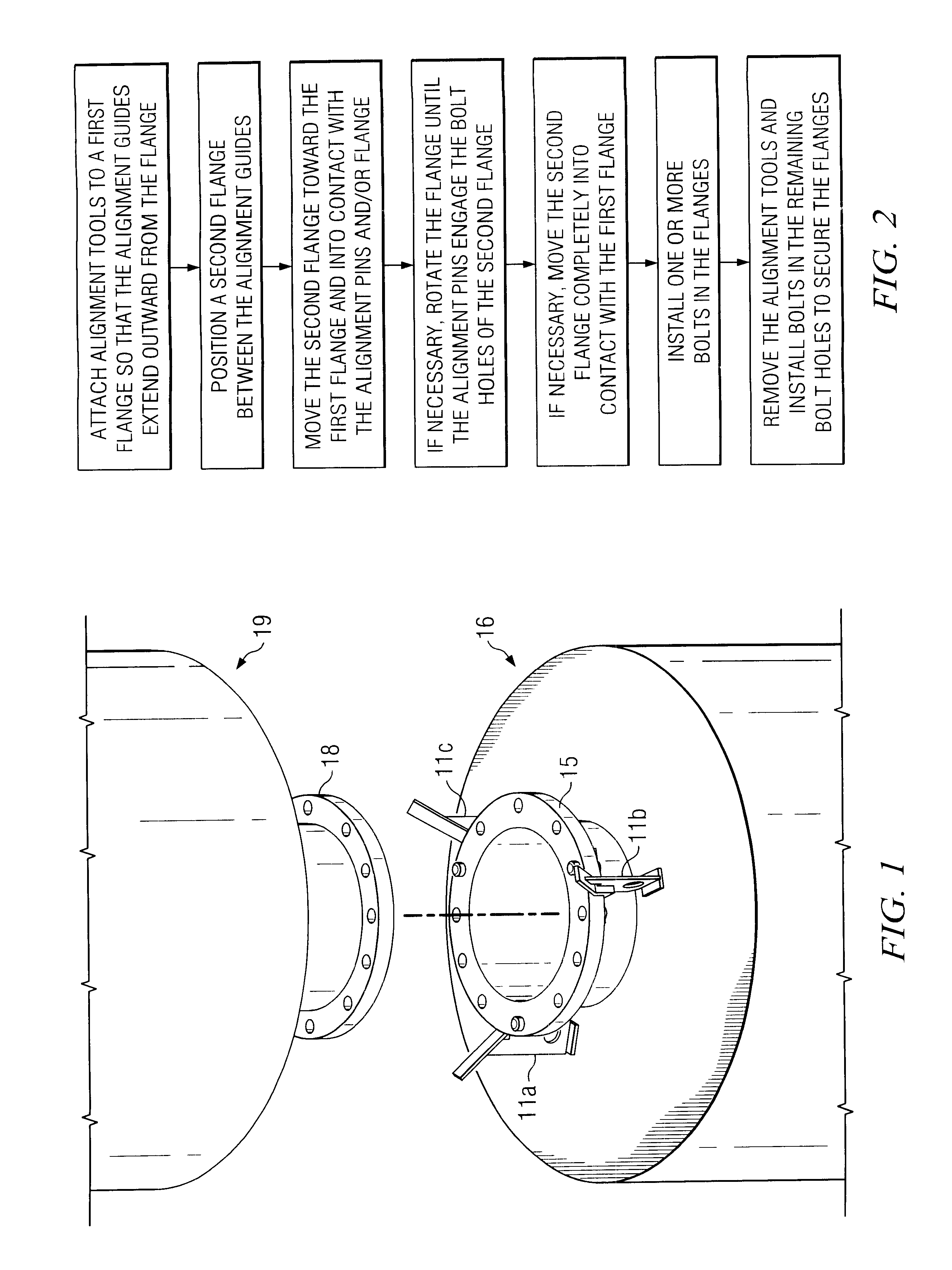

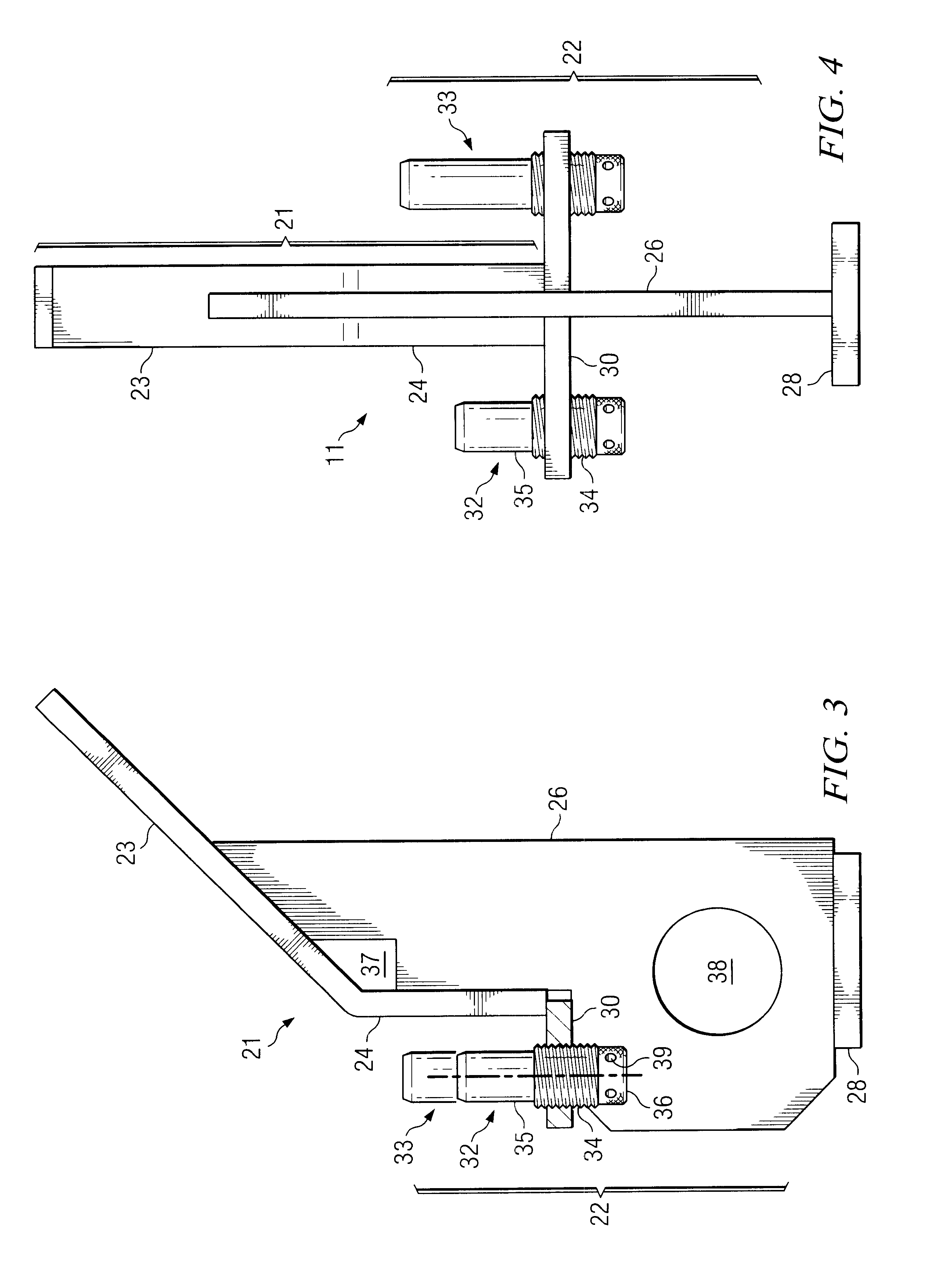

Alignment tool for pipe couplings

An alignment tool configured to be coupled to a first flange, the alignment tool having an alignment guide extending outward from the periphery of the first flange at an angle of between 0 and 90 degrees from the axis of the first flange. A plurality of such alignment guides are coupled to the first flange so that a second flange which is positioned off-axis from the first flange, but between the alignment guides of the alignment tools will be constrained to move toward an on-axis position as the second flange approaches the first flange. In one embodiment, one or more of the alignment tools includes at least one alignment pin which extends through a bolt hole of the first flange and beyond the face of the flange so that the alignment pin can engage one of the bolt holes of the second flange and thereby maintain rotational alignment of the flanges. In one embodiment, the alignment pin comprises a spring-loaded, telescoping pin which, when the flanges are not rotationally aligned, is compressed and does not extend beyond the face of the first flange, and when the flanges are rotationally aligned, extends beyond the face of the first flange to engage a bolt hole of the second flange.

Owner:TAPER LOK

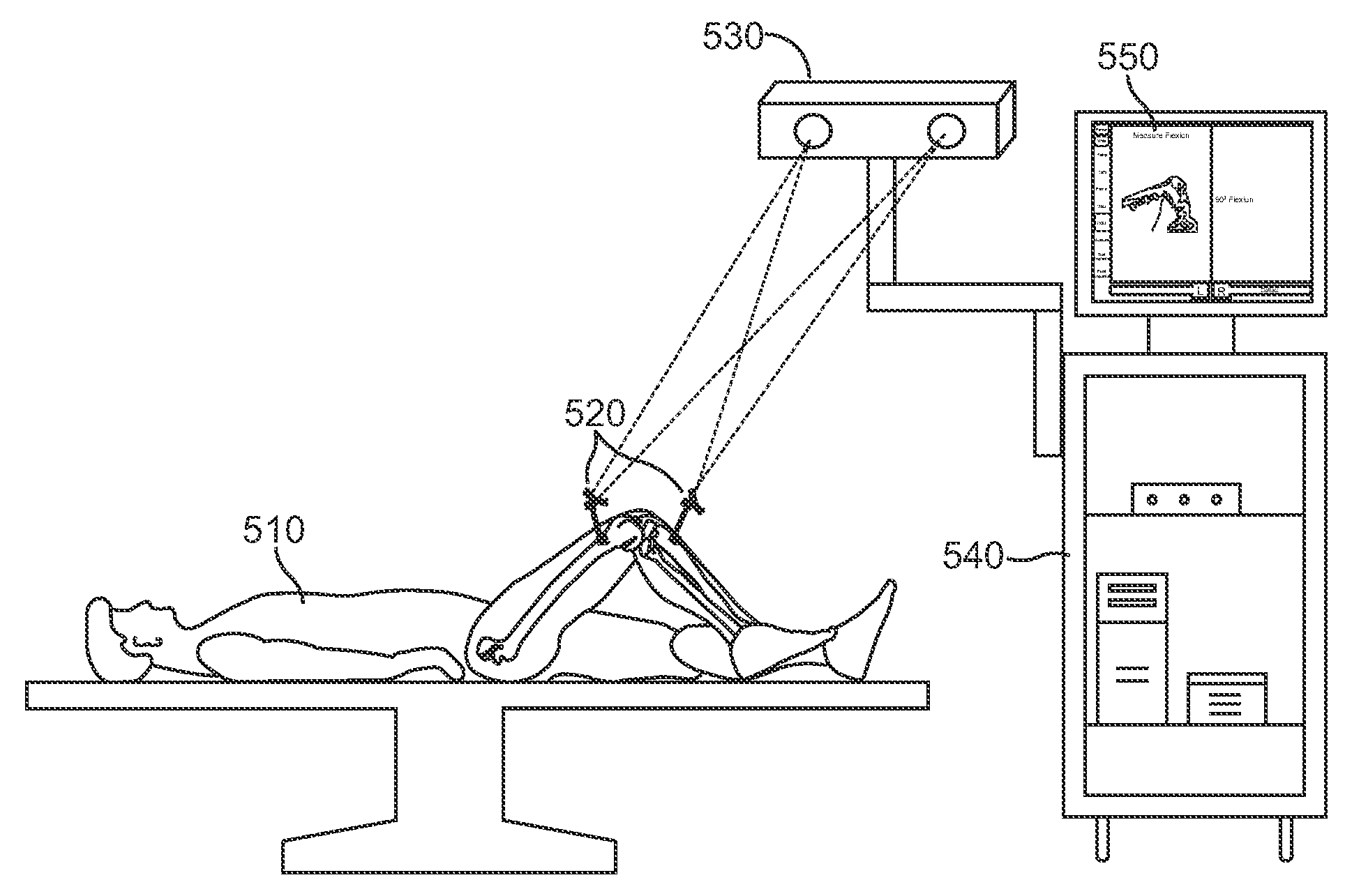

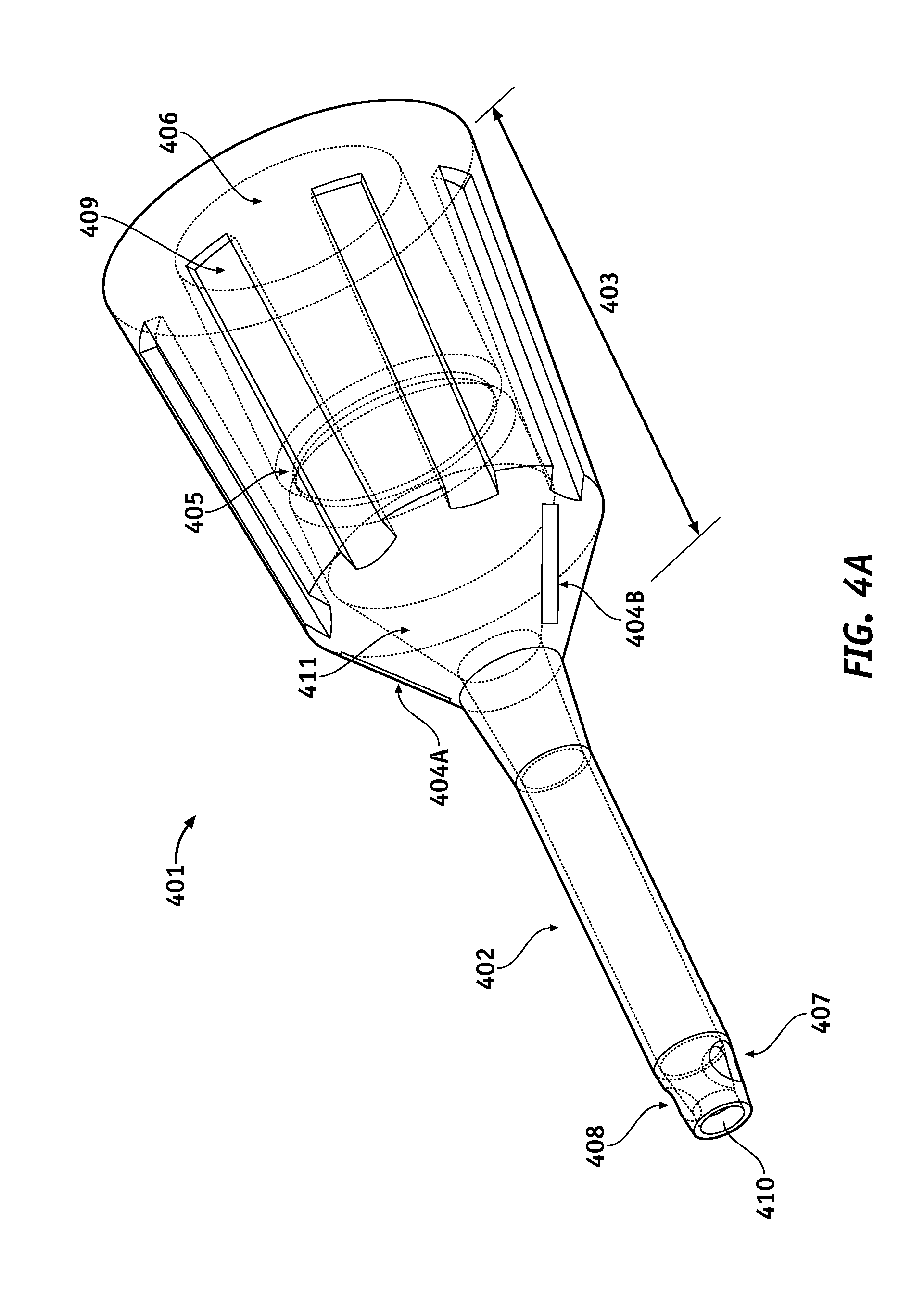

Rotational alignment femoral sizing guide

Embodiments of the present invention allow unlimited rotational alignment between two boundaries for alignment with anatomic landmarks while still referencing both posterior condyles for A / P sizing of the distal femur. In particular embodiments, the system provides at least one movable paddle that provides a reference point from the condyles so that the measuring assembly can be aligned to be parallel with the epicondylar axis. Once the measuring assembly is properly angled, the A / P length of the bone can then be measured from a proper reference point.

Owner:SMITH & NEPHEW INC

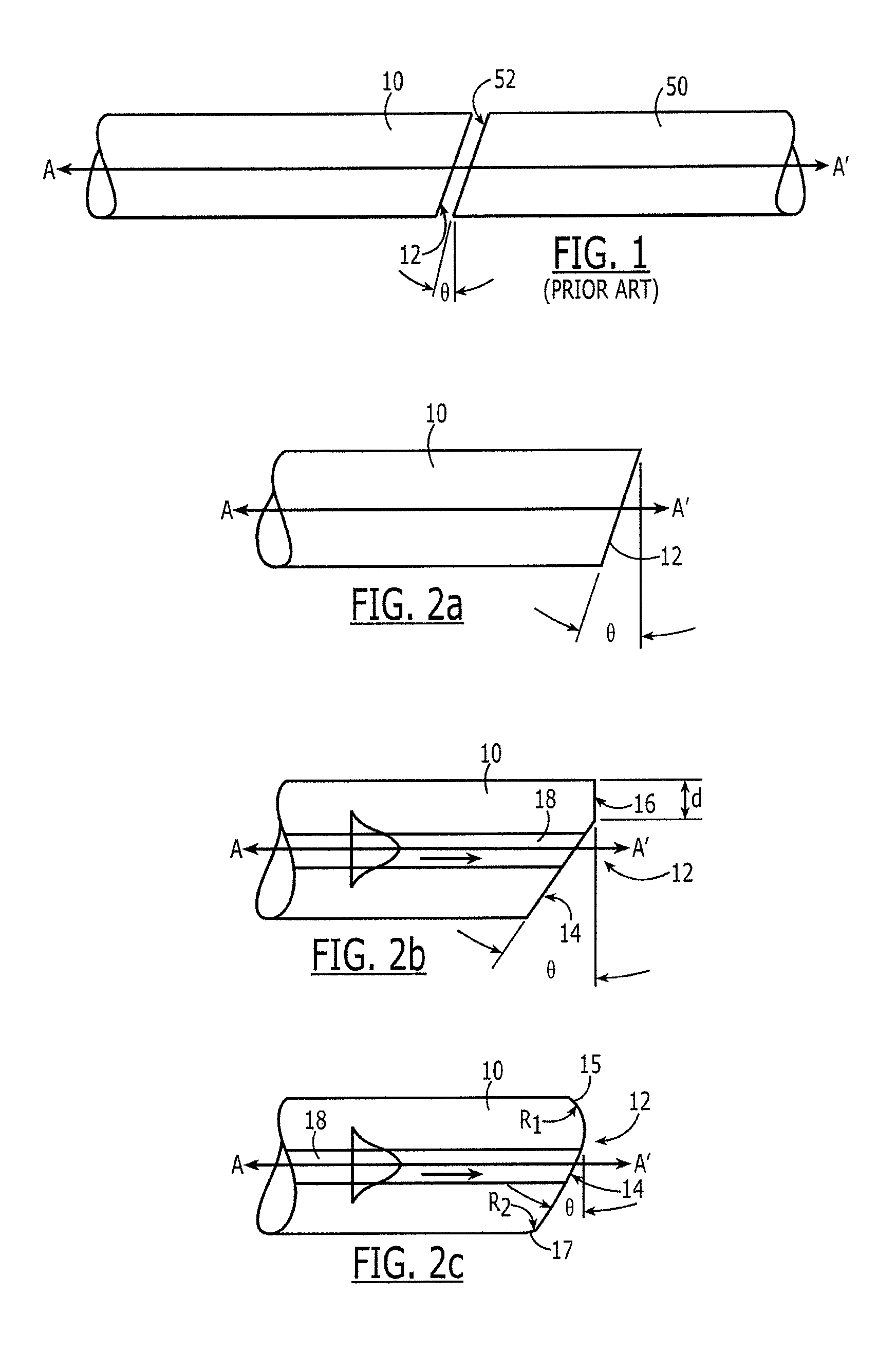

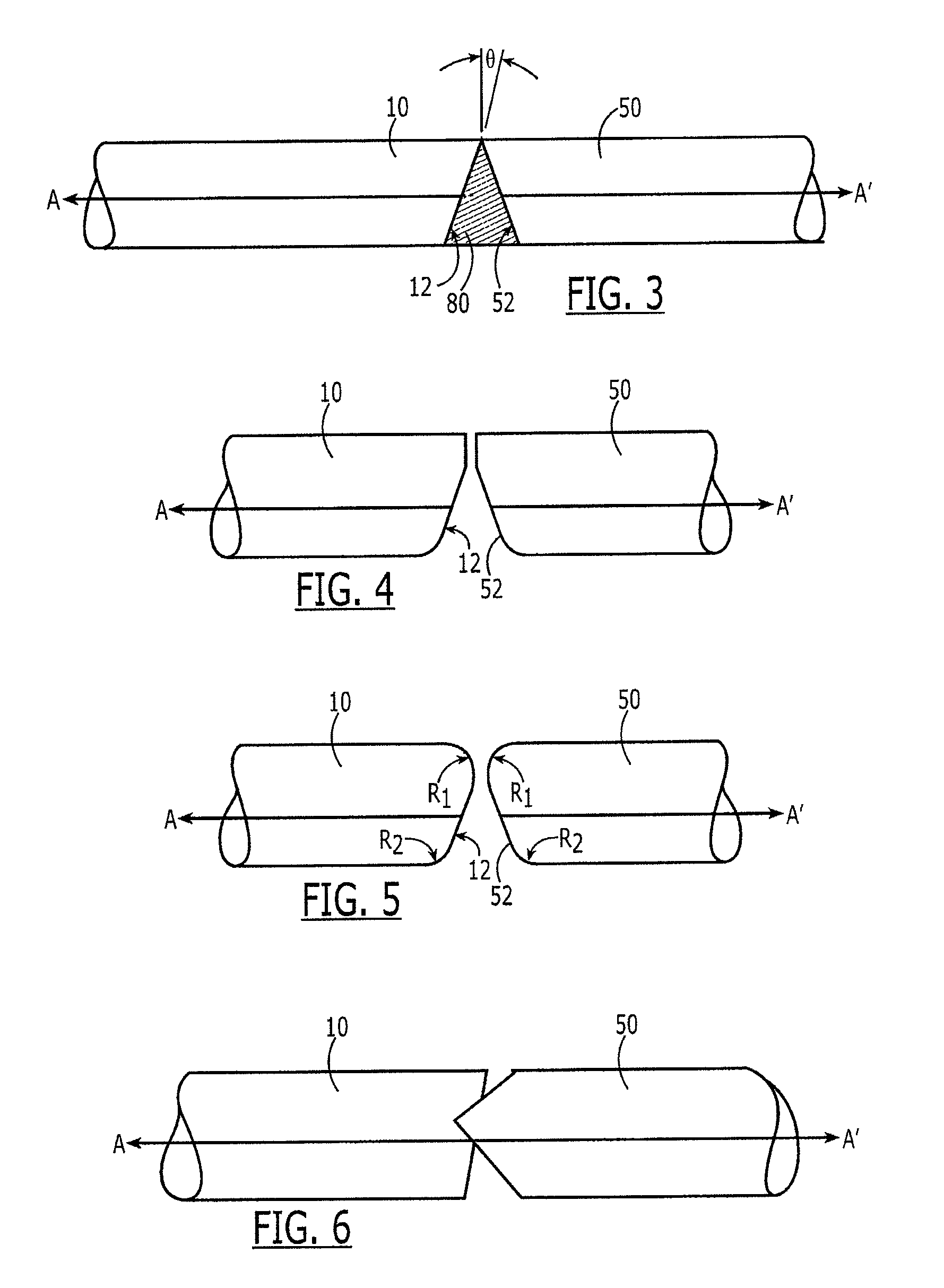

Mating of optical fibers having angled end faces

ActiveUS8104974B1Satisfactory optical connectionEliminate needOptical articlesCoupling light guidesFiberEngineering

A method for mating optical fibers, a fiber optic connector, and a fiber optic subassembly are provided in which mating fibers have angled end faces joined by index matching fluid, but in which the angled end faces of the fibers are positioned relative to one another in rotationally misaligned relationship. Applicants discovered unexpectedly that optical fibers can be spliced, to provide satisfactory optical connections, without the need for matched cleaves, and without the need for precise rotational alignment of the cleaves, provided that angled end faces are provided on both the launch and receive fibers and that index matching gel is provided between the angled end faces. Thus, the fibers are mated in positions other than in the precise rotationally aligned position previously believed essential to adequate optical performance. Angled end faces may be positioned less than 165 degrees out of phase.

Owner:COMMSCOPE TECH LLC

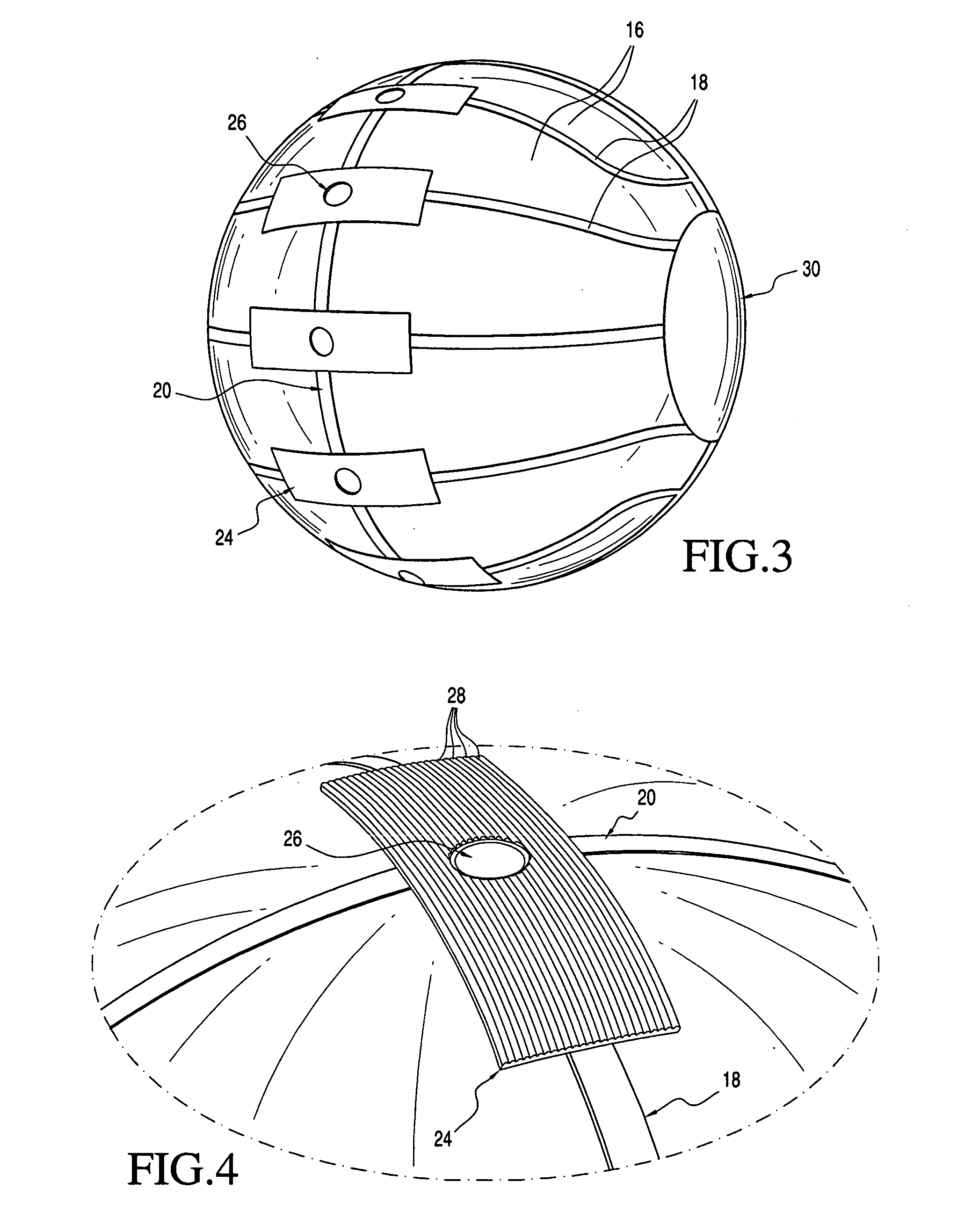

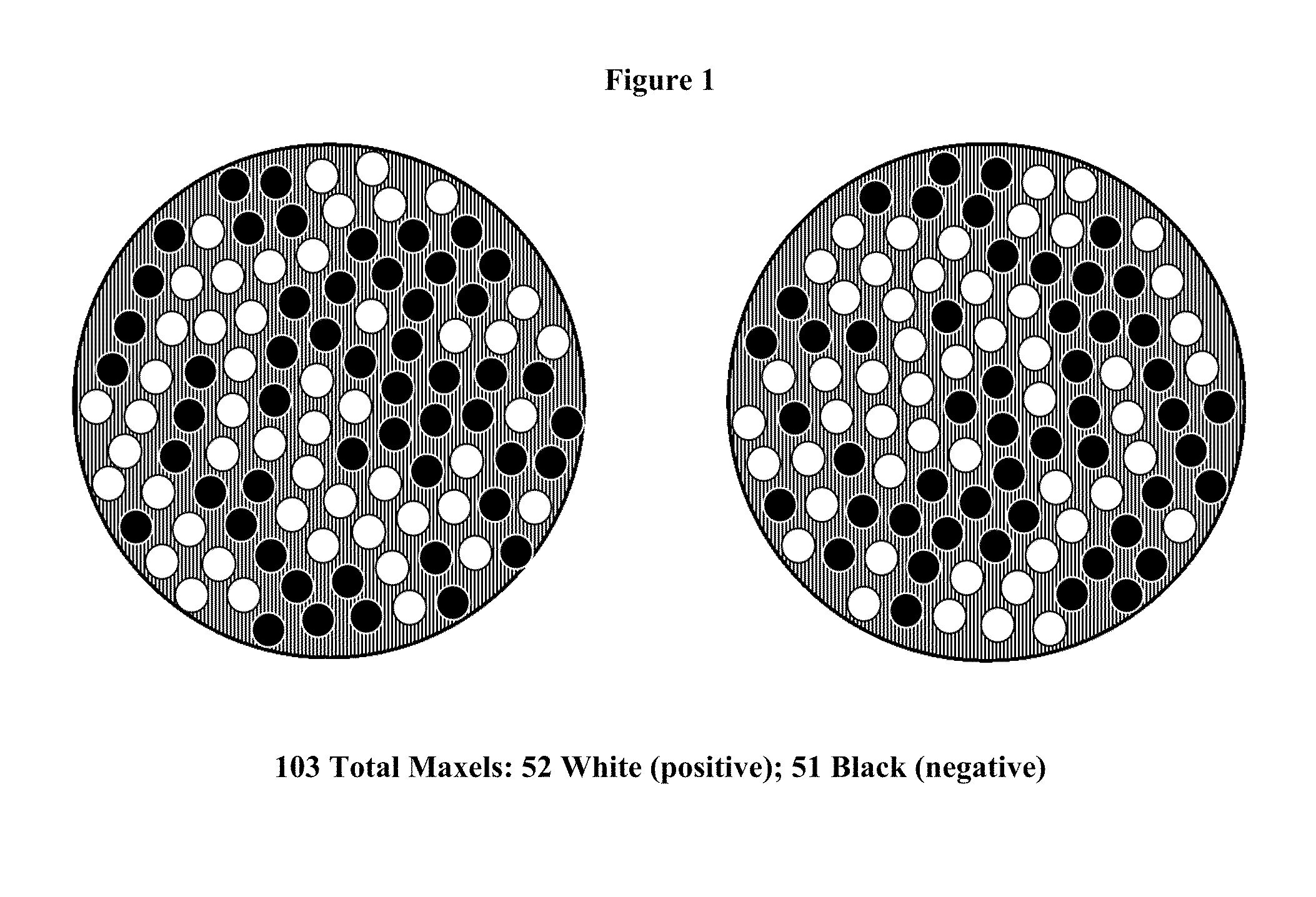

Training basketball

InactiveUS7037224B1Easy to distinguishPrecise positioningHollow inflatable ballsHollow non-inflatable ballsTouch PerceptionEngineering

A training game ball is described having cues for visually indicating the rotational alignment of the ball when it is thrown. If the ball is improperly thrown so that the axis of rotation does not stay perpendicular to the direction of flight, then the rotational alignment cue line will appear to wobble as the ball travels. The ball also has a rotational speed cue formed from a plurality of spaced panels arranged parallel with the alignment cue. If the ball is thrown with a high rotational speed, the panels will appear to the player as a solid line. Still further, the ball also includes hand alignment cues for assisting a player in properly positioning his or her hands for throwing the ball. The hand alignment cues include finger positioning pads, which are positioned sufficiently close together about the circumference of the ball to allow even a small youth's hand to easily reach a finger positioning pad from any position of the ball. The hand alignment cues may also include a stabilizing hand positioning mark located over one or both opposite poles of the ball. Each of the cues may have a different appearance, so that they may be visually distinguished. The hand alignment cues may also have a different surface to provide a tactile indication of their location to a player.

Owner:NIKE INC

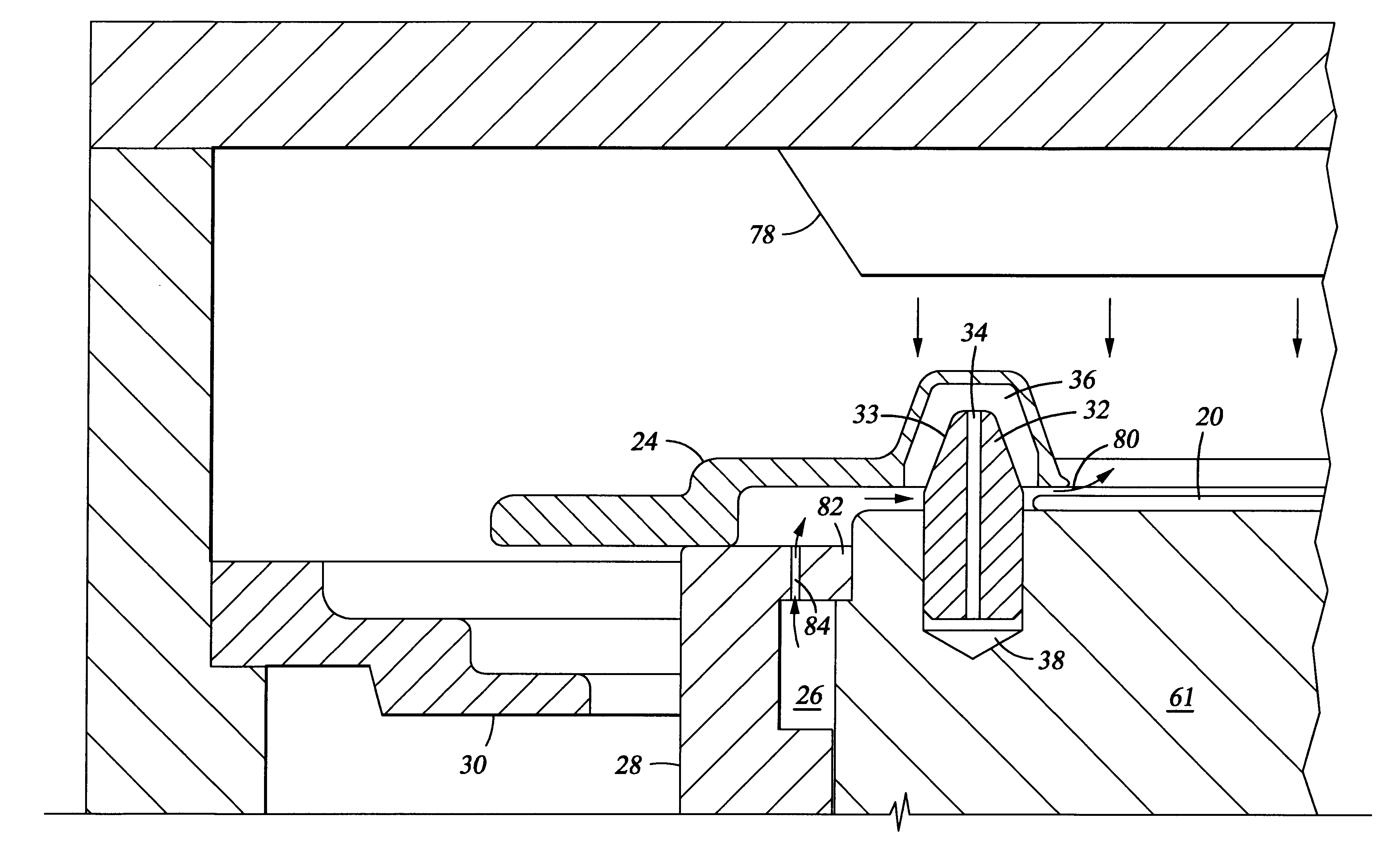

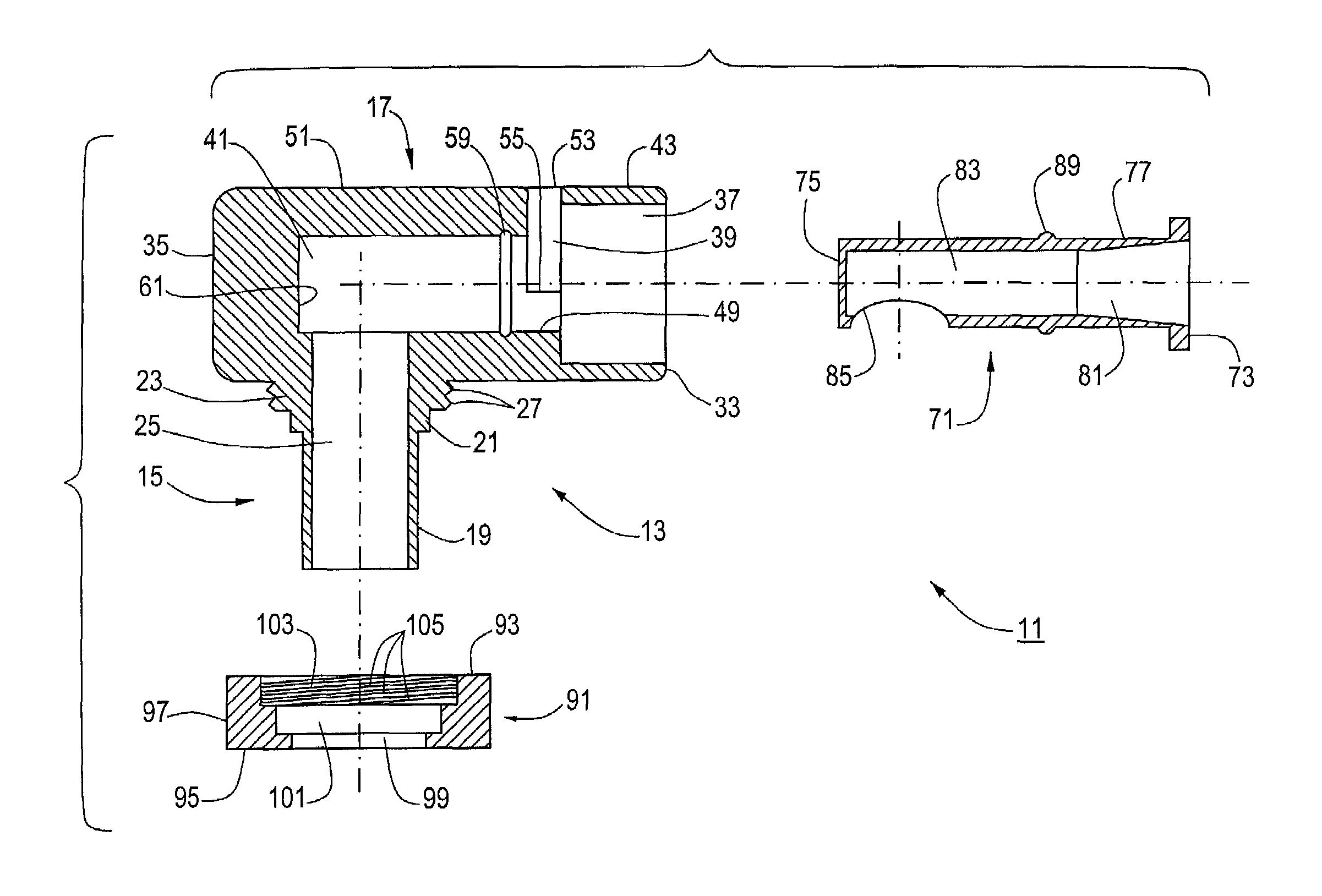

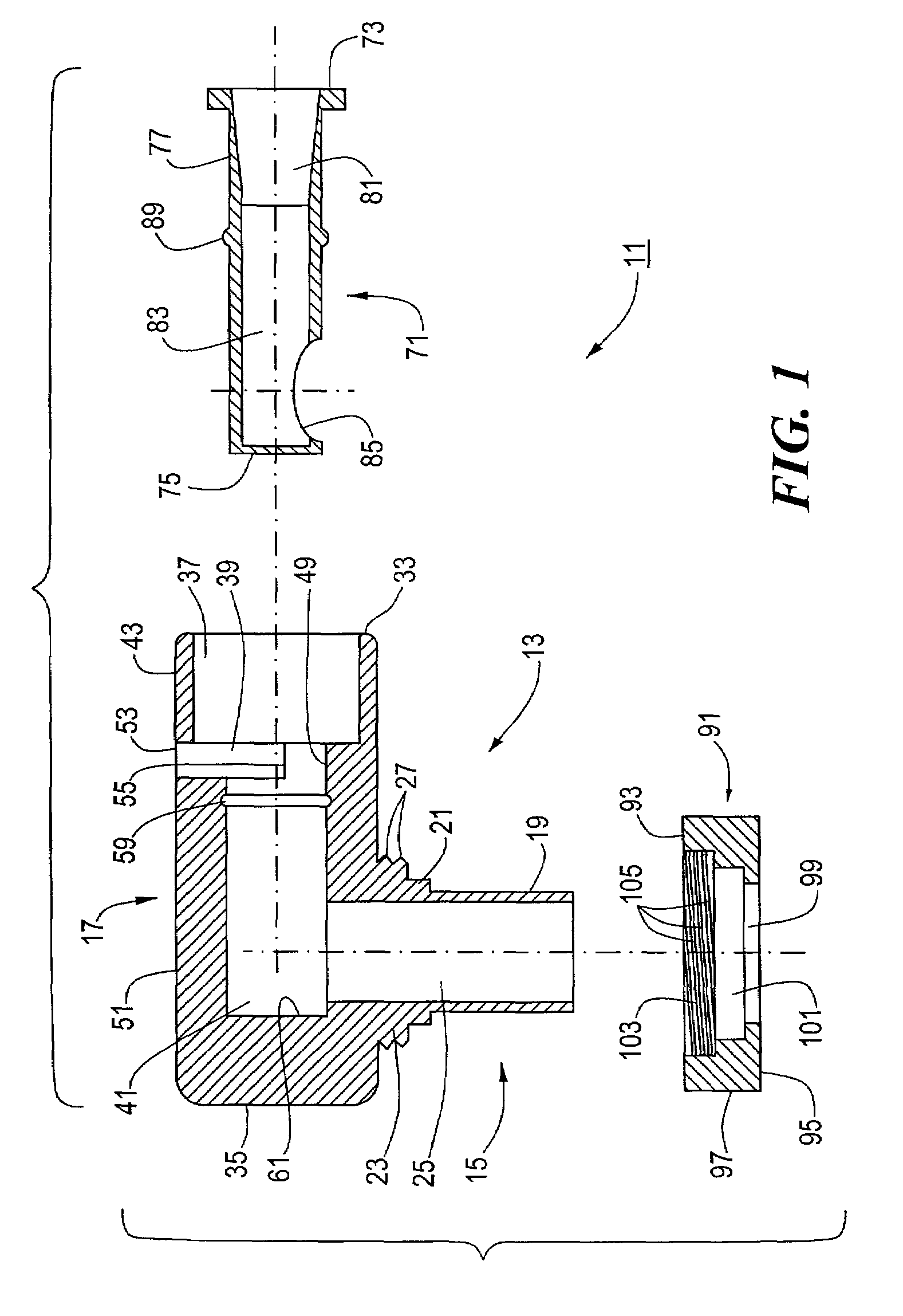

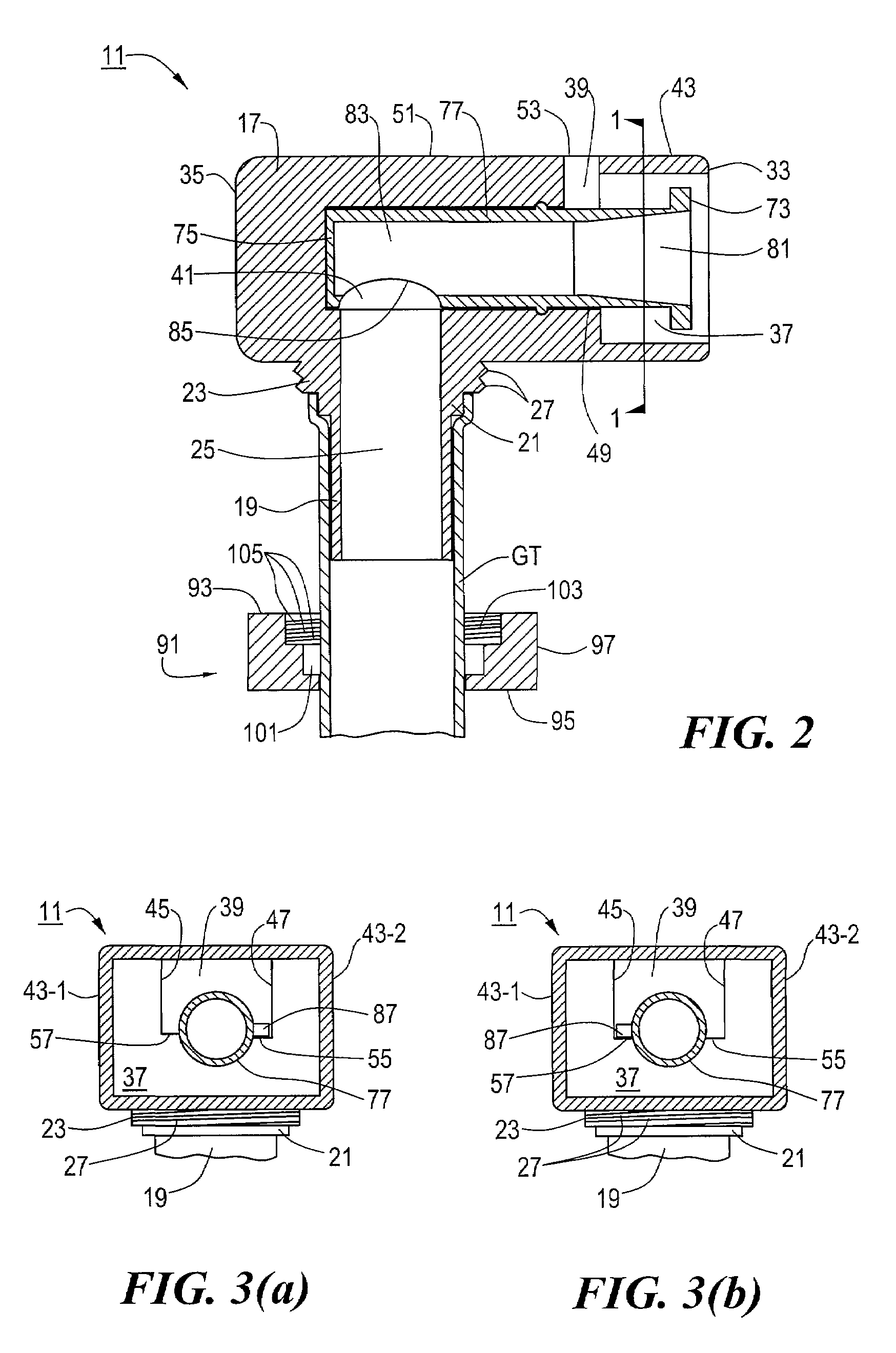

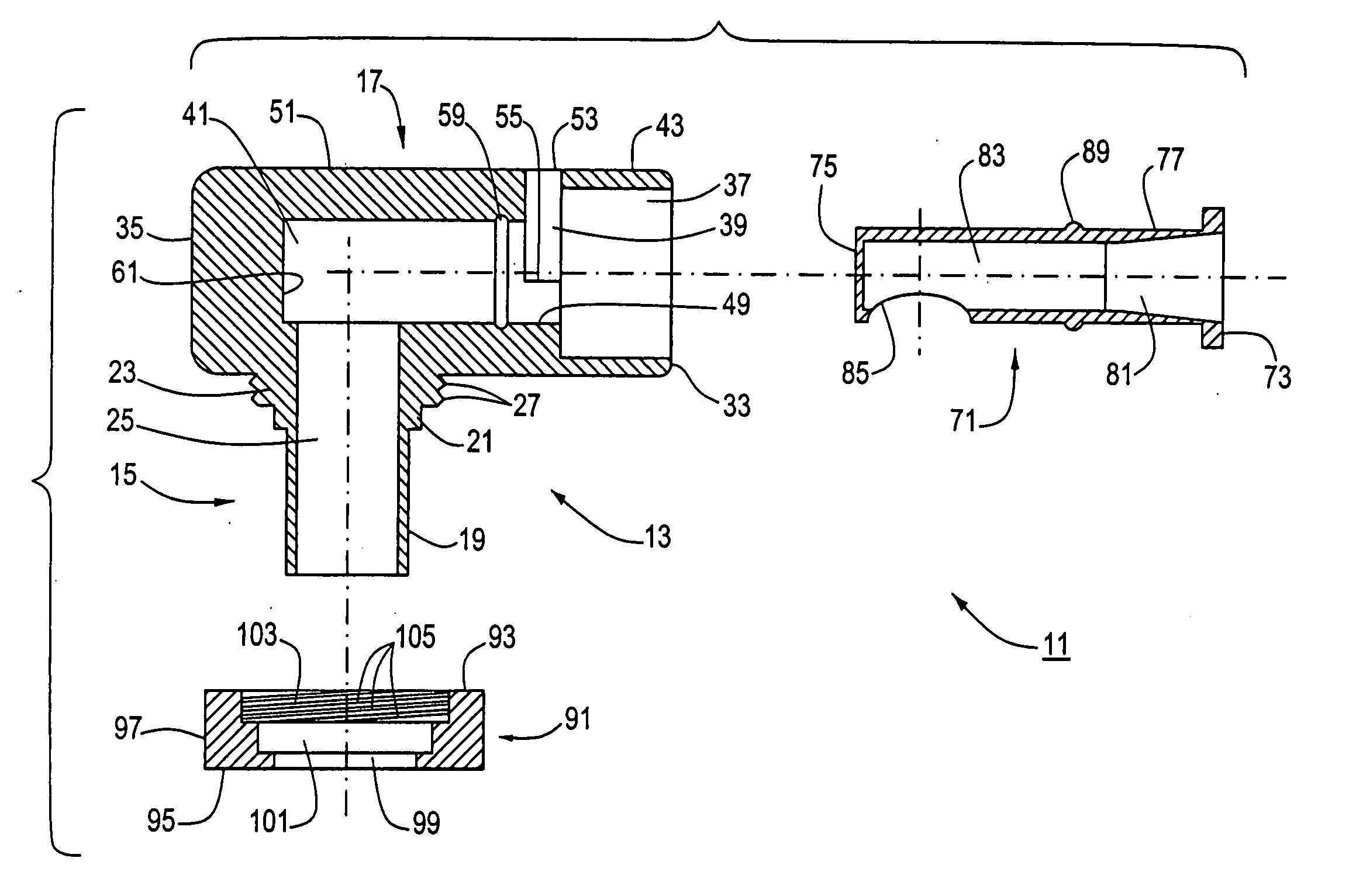

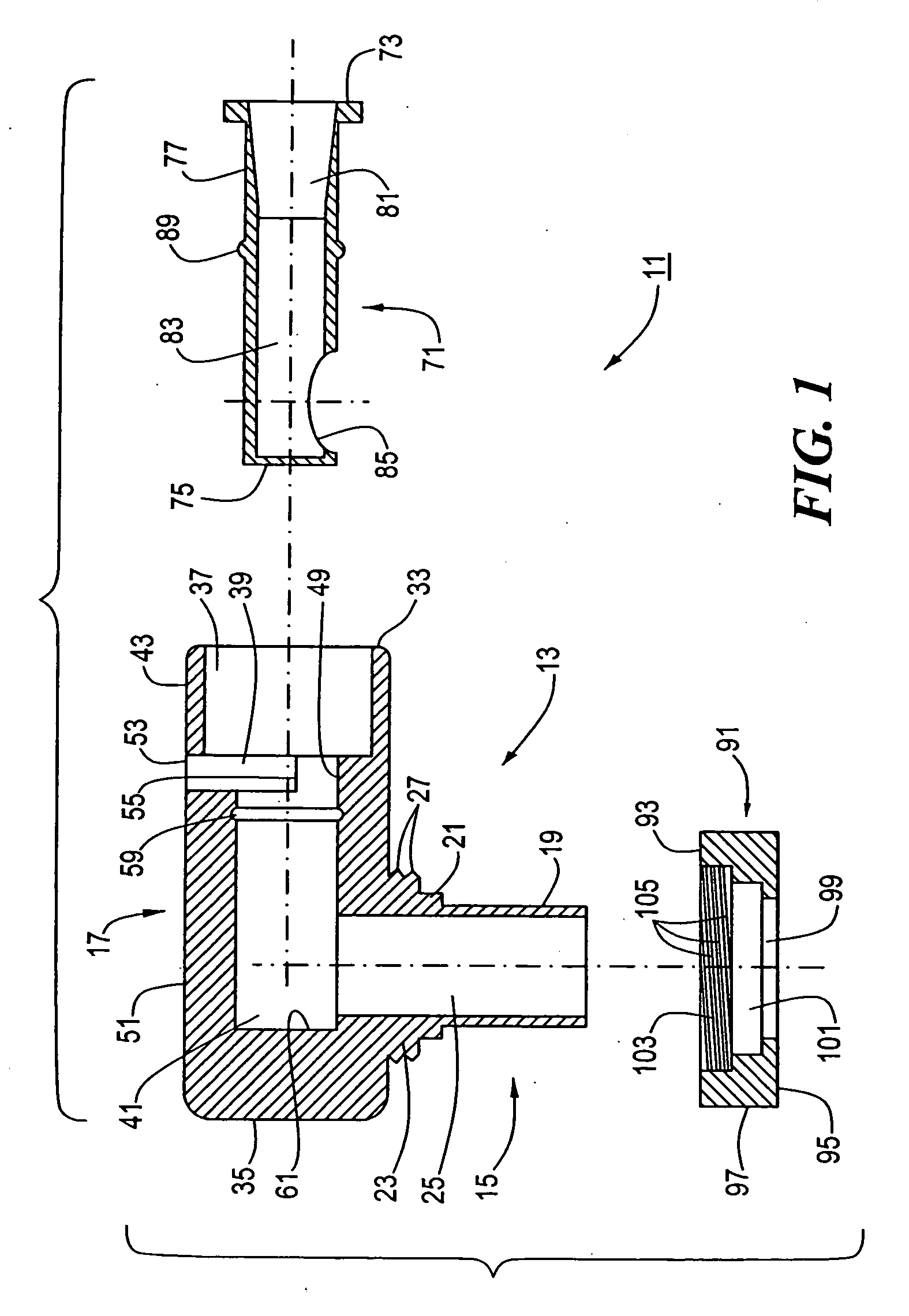

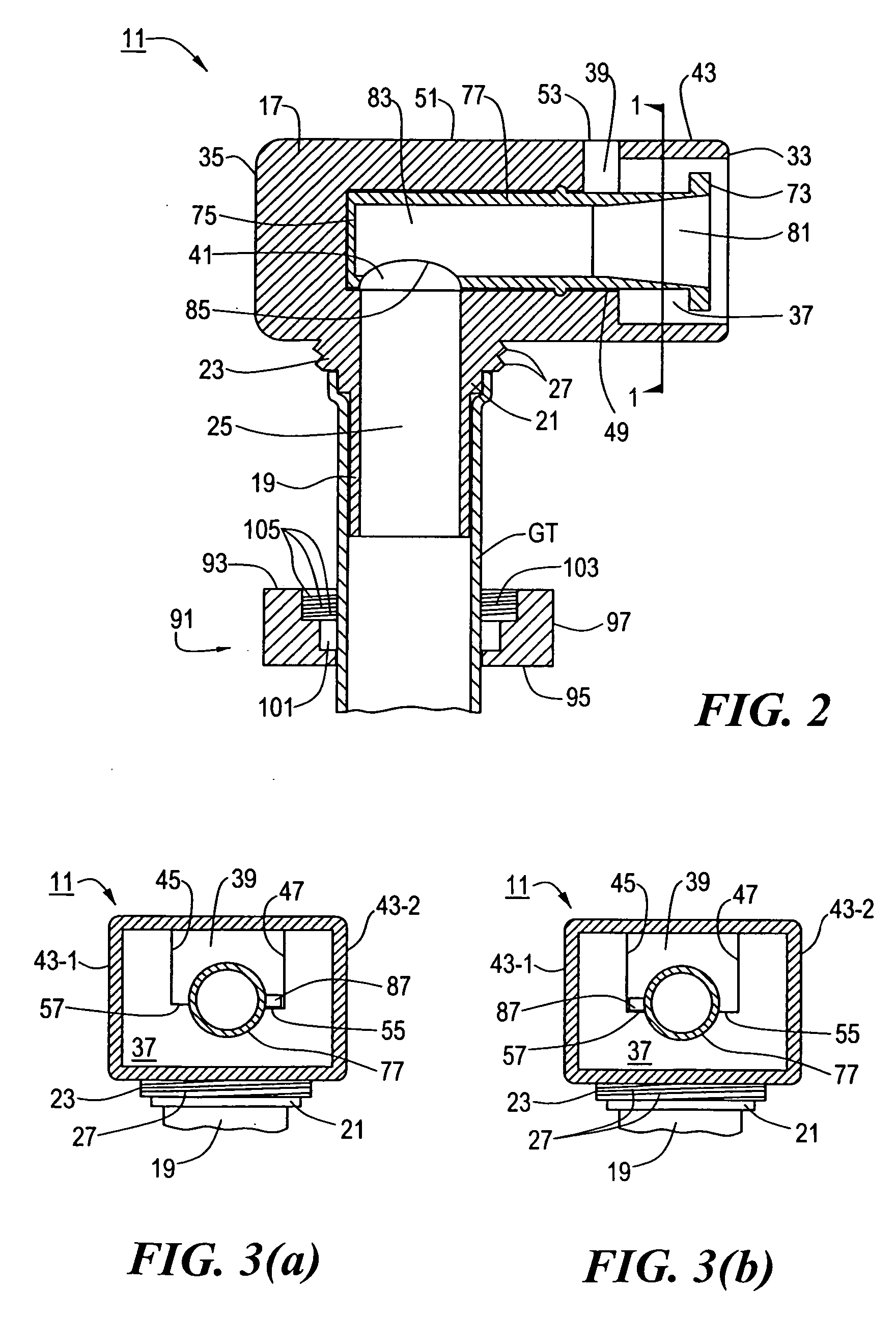

Low profile adaptor for use with a medical catheter

InactiveUS6979322B2Facilitate rotational alignmentPrevent unnecessary rotationSurgeryCatheterGastrostomy feedingEngineering

Low profile adaptor for use with a medical catheter, such as a gastrostomy feeding tube. In a preferred embodiment, the adaptor comprises a body having a lower portion and an upper portion. A first channel is provided in the lower portion, and a second channel is provided in the upper portion, the first and second channels being perpendicular to and in fluid communication with one another. A generally cylindrical stem is coaxially positioned within the second channel, the stem being rotatably mounted about its longitudinal axis. The stem is hollow and has an open front end, a closed rear end and a hole in its side wall, the hole being rotatably alignable with the first channel. To facilitate rotational alignment of the hole with the first channel, a stop is formed on the exterior of the stem, the stop being engageable with a surface positioned within the second channel. The front end of the stem is recessed relative to the front end of the second channel to prevent unwanted rotation of the stem. Rotation of the stem from a closed position to an open position is achieved by screwing a syringe onto the front end of the stem. The proximal end of the gastrostomy feeding tube is inserted over the lower portion of the body and is secured thereto with a nut.

Owner:BOSTON SCI SCIMED INC

Child resistant container and cap

InactiveUS7331479B2Little strengthEasy to manufactureCapsClosure capsScrew threadBiomedical engineering

A locking cap and container is provided for a container having an opening surrounded by a neck with container threads thereon that are sized and located to threadingly engage cap threads formed on a skirt of the cap. A shaped distal end is formed on a distal end of the container threads and a barb is formed on the distal end of the cap threads. A resilient locking tab extends from the container, and is located below the shaped distal end and spaced apart from the shaped distal end a distance sufficient to allow passage of the barb beyond the shaped distal end but sufficiently close to resiliently urge the barb into overlapping rotational alignment with the shaped end. The shaped end is configured to lockingly engage the barb when the tab holds them in alignment. Pushing down on the cap pushes the thread against the locking tab and allows disengagement of the barb from the shaped distal end and movement of the barb past the shaped distal end to unlock the cap.

Owner:REXAM PRESCRIPTION PROD INC

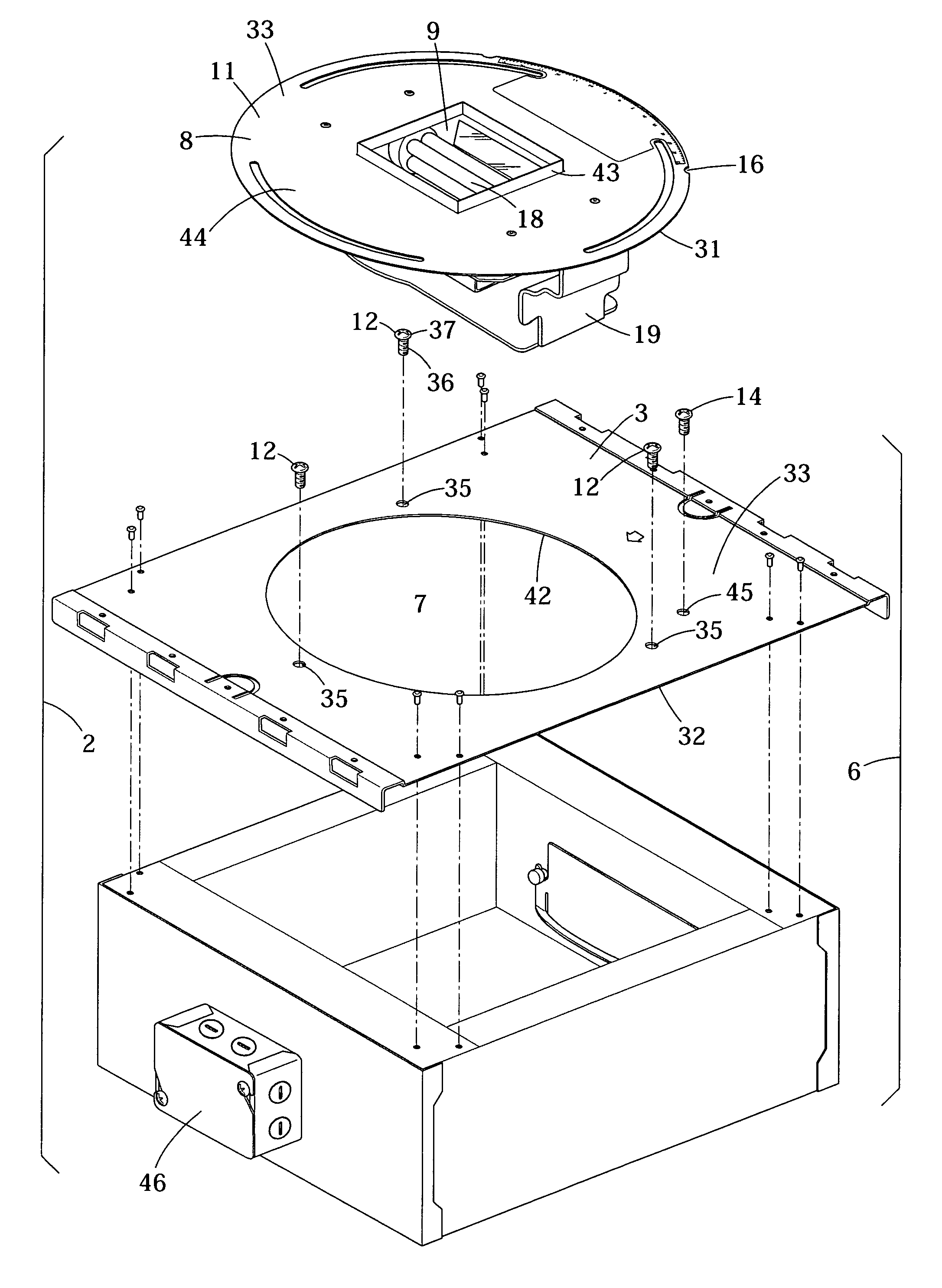

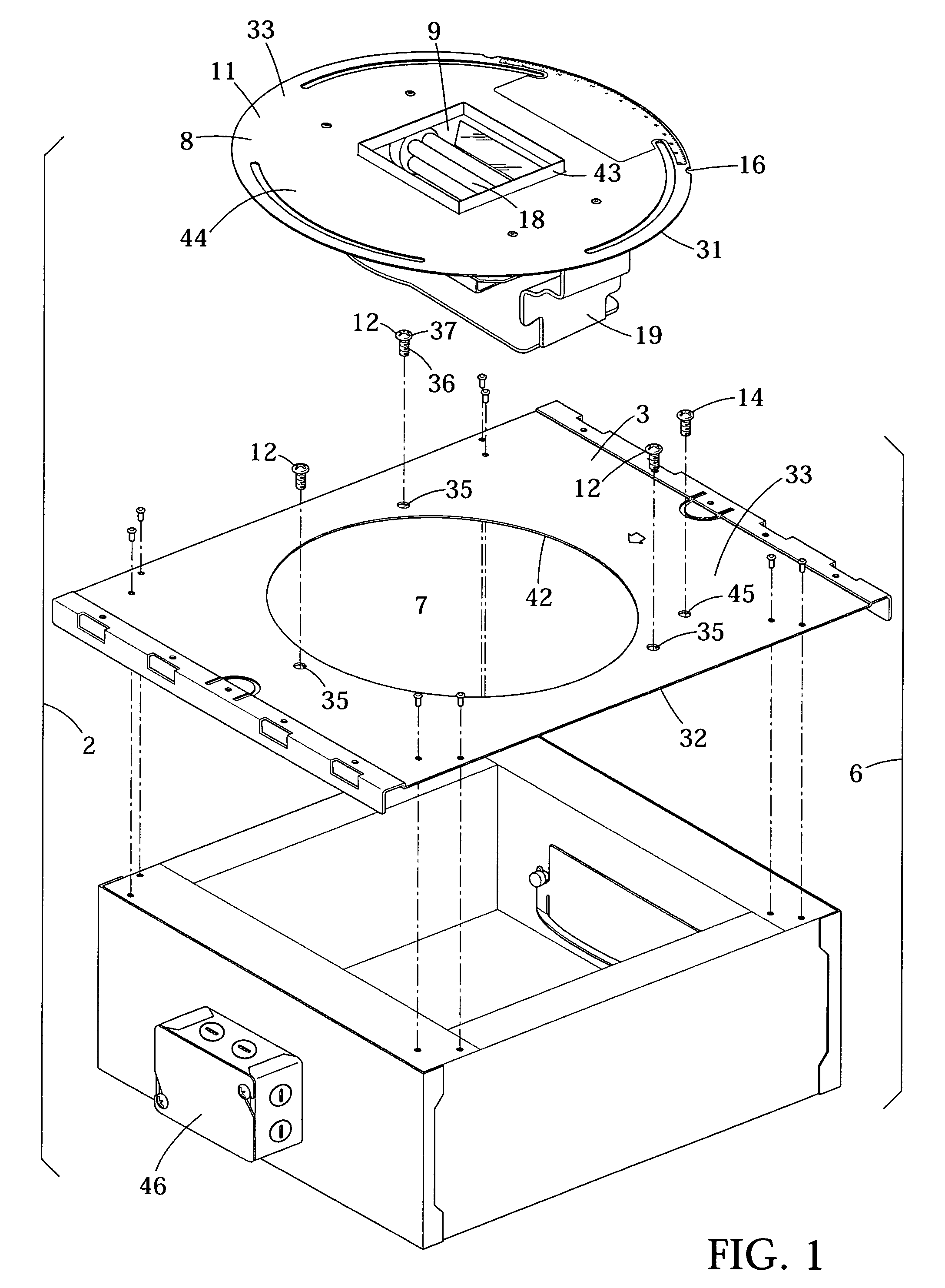

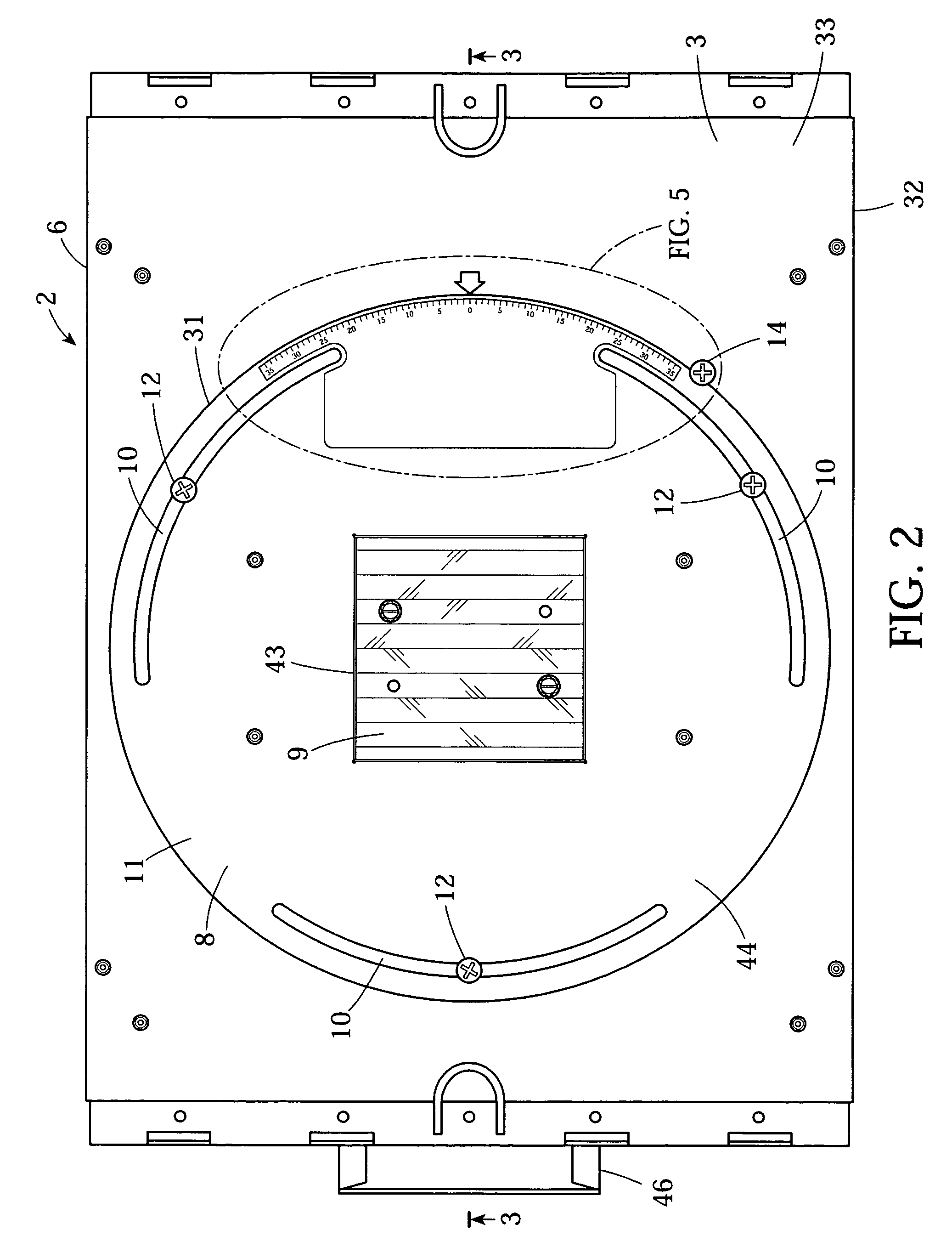

Recessed light housing with a rotatable aperture

A recessed light assembly having an illumination element and having an enclosure attachable to a support structure of a dwelling has a rotating aperture plate rotatably mounted to a wall of the enclosure. The rotating aperture plate has an illumination aperture disposed over an opening in the wall of the enclosure and the recessed light assembly has adjustable fasteners, accessible from an exterior of the recessed light assembly, which adjustable fasteners selectively permit and prevent rotation of the rotating aperture plate relative to the enclosure allowing a user to adjust the rotational alignment of the illumination aperture relative to the enclosure of an installed light assembly without disengaging an attached assembly from the support structure. The illumination element may be fixed relative to the rotating aperture plate or may be fixed relative to the enclosure. The rotating aperture plate and the enclosure may have rotational alignment reference marks and a rotational alignment indicator which serve to indicate a present rotational alignment of the aperture plate relative to the enclosure.

Owner:USAI LLC

Rapid-exchange delivery systems for self-expanding stents

A catheter assembly is provided having an inner member and an outer member extending along a longitudinal axis, the inner member and the outer member having a coaxial configuration and dimensioned for relative axial movement. The outer member may include an anti rotation member adapted to engage with a longitudinal slot formed on the inner member so as to maintain rotational alignment between inner member and outer member. The inner member can be made with a proximal portion made from a tubing such as hypotubing or a coil tubing. The inner member also may be made with a proximal portion made with a support mandrel. A coil tubing can be utilized to form the guide wire receiving member which is attached to the inner member.

Owner:ABBOTT CARDIOVASCULAR

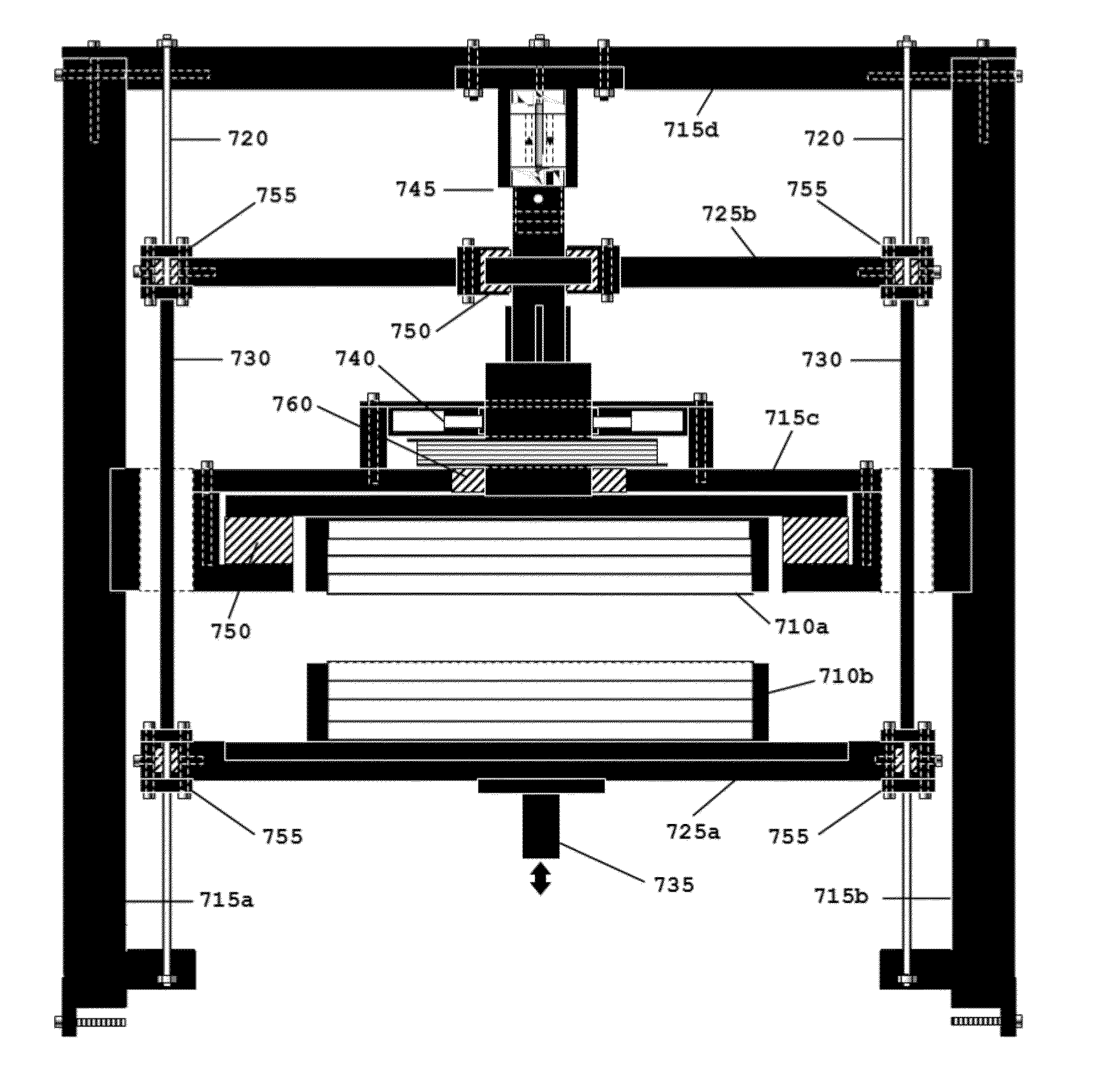

Periodic correlated magnetic actuator systems and methods of use thereof

InactiveUS20120007704A1Minimizes distance requiredMinimizes required timePermanent magnetsMagnetic materialsLinear motionCoupling

The present invention comprises correlated magnet actuators, devices incorporating said actuators, and methods of use thereof. The actuators utilize magnetic drives comprising a pair of complimentary correlated permanent magnet pairs, arranged in a separable and opposing fashion. The attractive or repulsive force of each correlated magnet pair drops significantly after only a few degrees of rotation off of a prime attractive or repulsive rotational alignment, allowing the magnets to be binarily manipulated between a correlated and decorrelated alignment. The linear motion resulting from the periodic coupling and decoupling of the magnetic pair can be translated to supporting conveyance structures to produce rotary (torque) output work. This output work can be harnessed to drive secondary utilization components such as a generator or a pump, or other devices dependent on rotary work output for their operation.

Owner:NANO CARBON FOOTPRINT

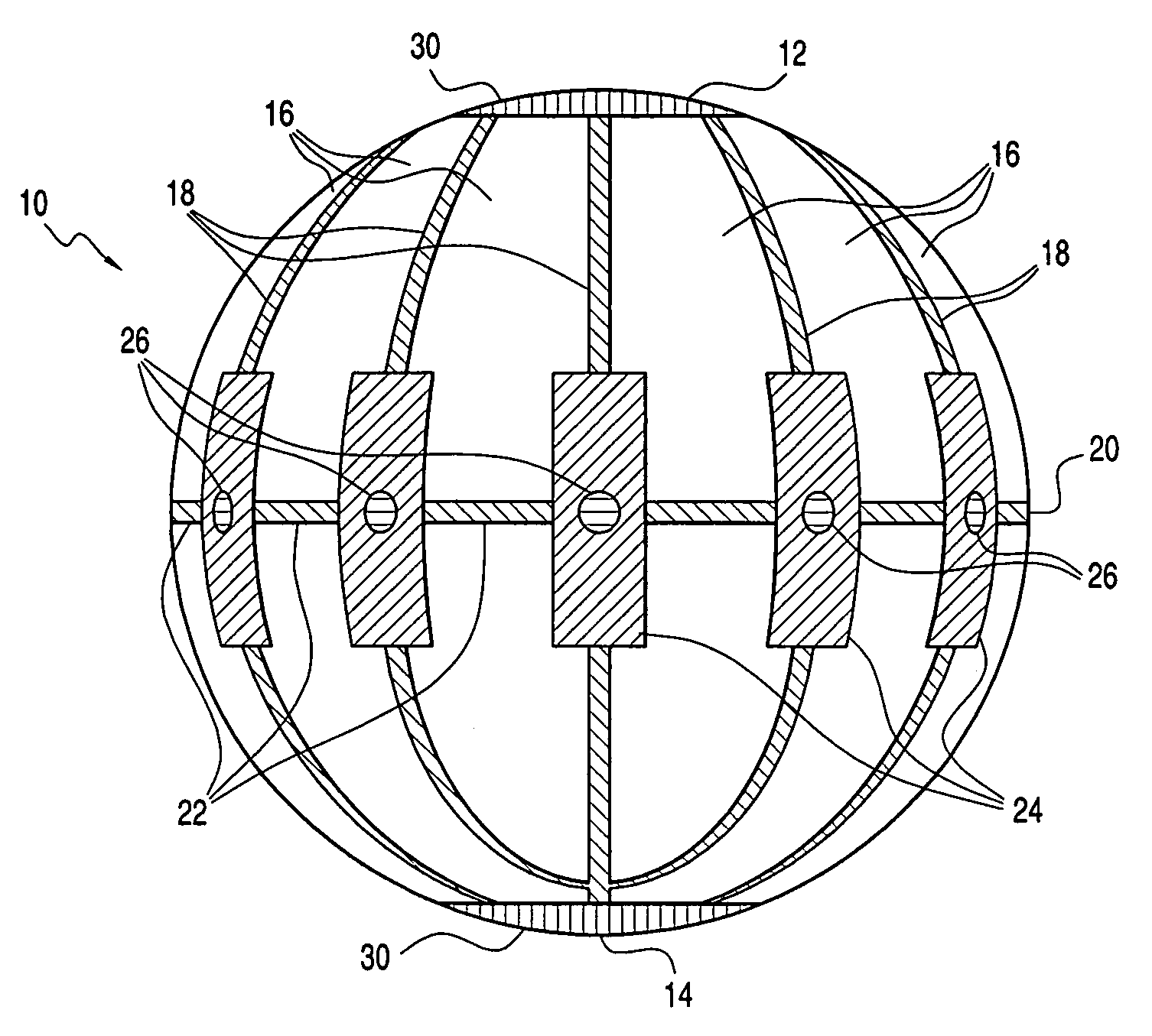

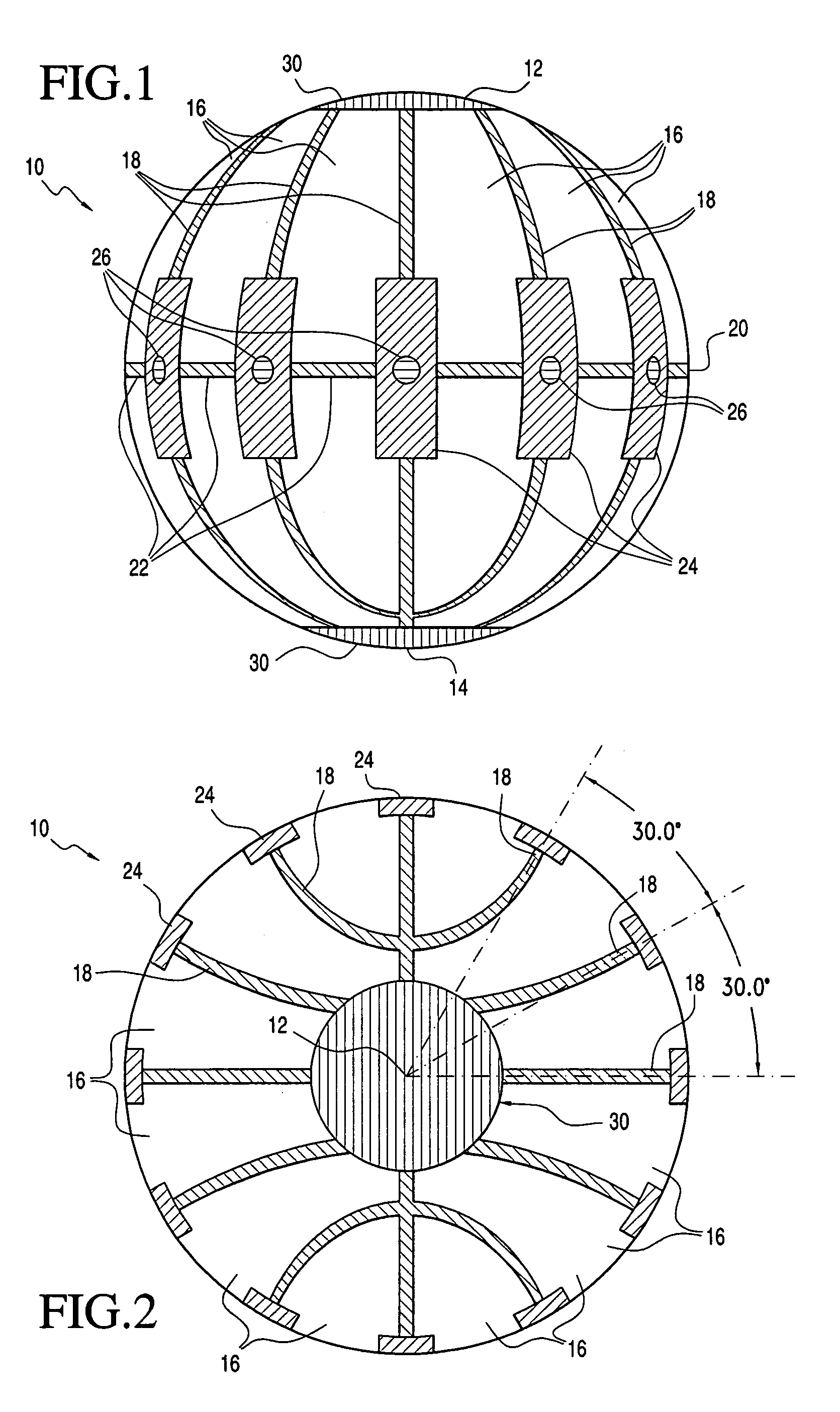

Cylindrical Optical Ferrule Alignment Apparatus

An alignment sleeve for an optical fiber adapter includes features to bring precision alignment between optical fiber cores. The sleeve includes a tubular inner area to accept first and second ferrule ends of first and second connectors. First and second tabs project from first and second ends of the sleeve. The first and second tabs slide into holes in the ferrule holders or barrels of the first and second connectors, so as to provide rotational alignment of the first and second ferrules, which may be presenting multi-core optical fibers. A mid-portion of the sleeve may include geometrical features to enable a snap fit of the sleeve into a housing of the adapter. More than one tab may be employed at the ends of the sleeve, and the tabs may have defined spacing and / or dimensions to enable security keying, only permitting coupling between connectors possessing matching holes in the ferrule barrels.

Owner:COMMSCOPE INC

Low profile adaptor for use with a medical catheter

Low profile adaptor for use with a medical catheter, such as a gastrostomy feeding tube. In a preferred embodiment, the adaptor comprises a body having a lower portion and an upper portion. A first channel is provided in the lower portion, and a second channel is provided in the upper portion, the first and second channels being perpendicular to and in fluid communication with one another. A generally cylindrical stem is coaxially positioned within the second channel, the stem being rotatably mounted about its longitudinal axis. The stem is hollow and has an open front end, a closed rear end and a hole in its side wall, the hole being rotatably alignable with the first channel. To facilitate rotational alignment of the hole with the first channel, a stop is formed on the exterior of the stem, the stop being engageable with a surface positioned within the second channel. The front end of the stem is recessed relative to the front end of the second channel to prevent unwanted rotation of the stem. Rotation of the stem from a closed position to an open position is achieved by screwing a syringe onto the front end of the stem. The proximal end of the gastrostomy feeding tube is inserted over the lower portion of the body and is secured thereto with a nut.

Owner:BOSTON SCI SCIMED INC

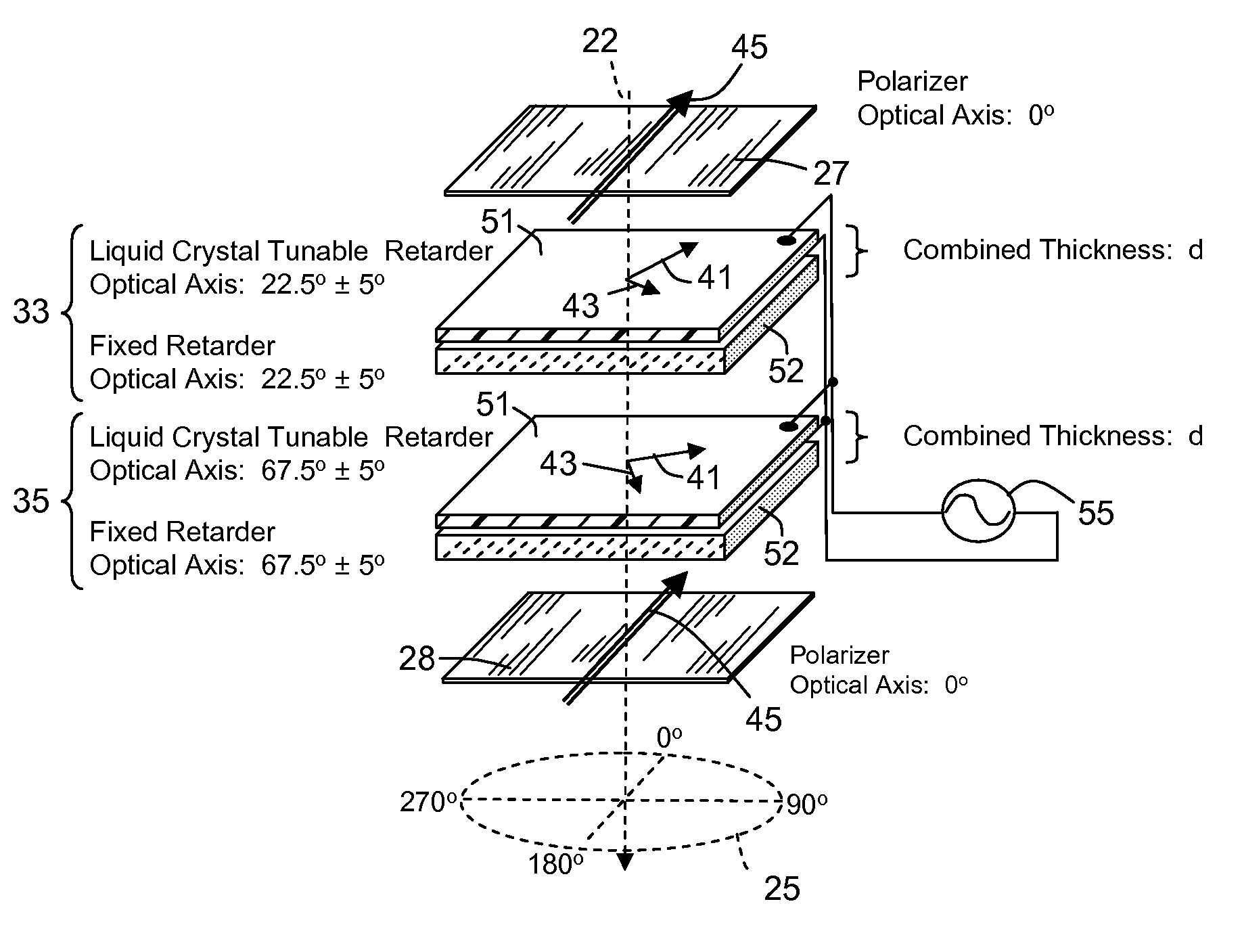

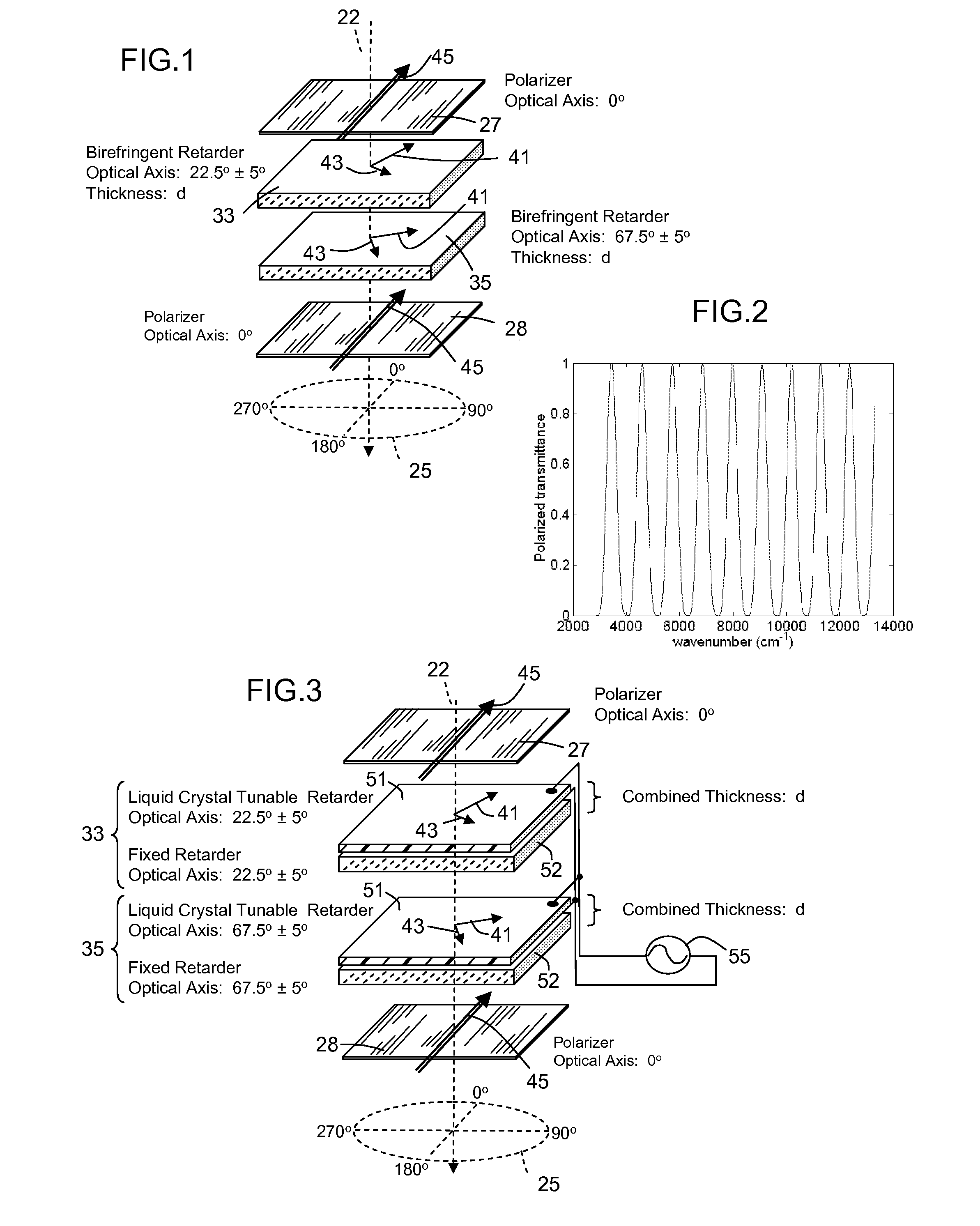

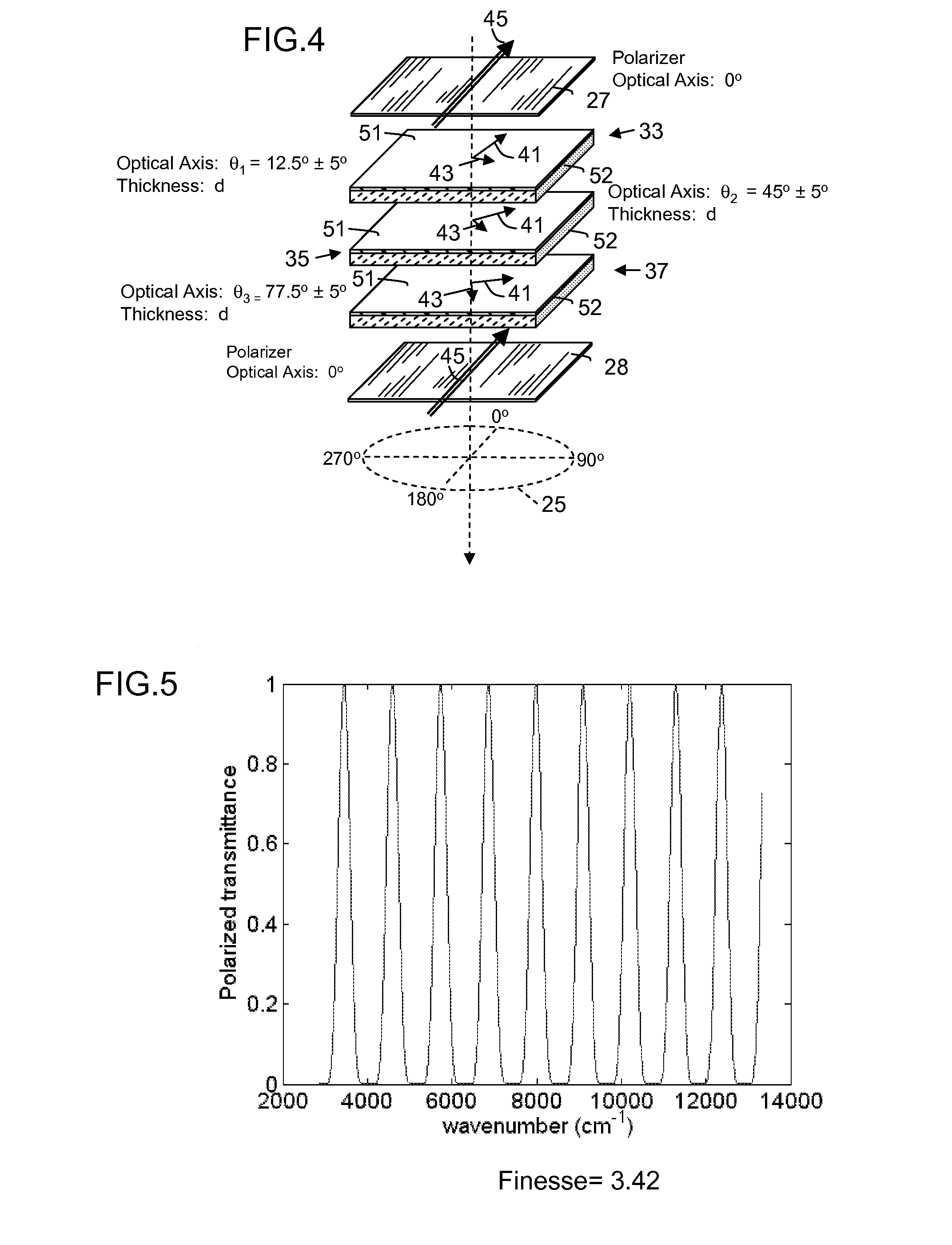

Wavelength discrimination filter for infrared wavelengths

An optical comb filter has polarizers placed before and after two or more birefringent elements, each having a fixed retarder and an aligned tunable liquid crystal. The birefringent elements are equal in birefringence and thickness and are tuned in unison. Wavelength-dependent polarization state changes are contributed by retardation in unequal proportions on the fast and slow axes of the successive birefringent elements. The filter is tolerant of rotational alignment errors. A two element filter uses angles of 22.5 and 67.5°; a three element version has 12.5, 45 and 77.5°; and a four element filter has 7.5, 29.5, 60.5 and 82.5°; all these angles being ±5°.

Owner:CHEMIMAGE TECH

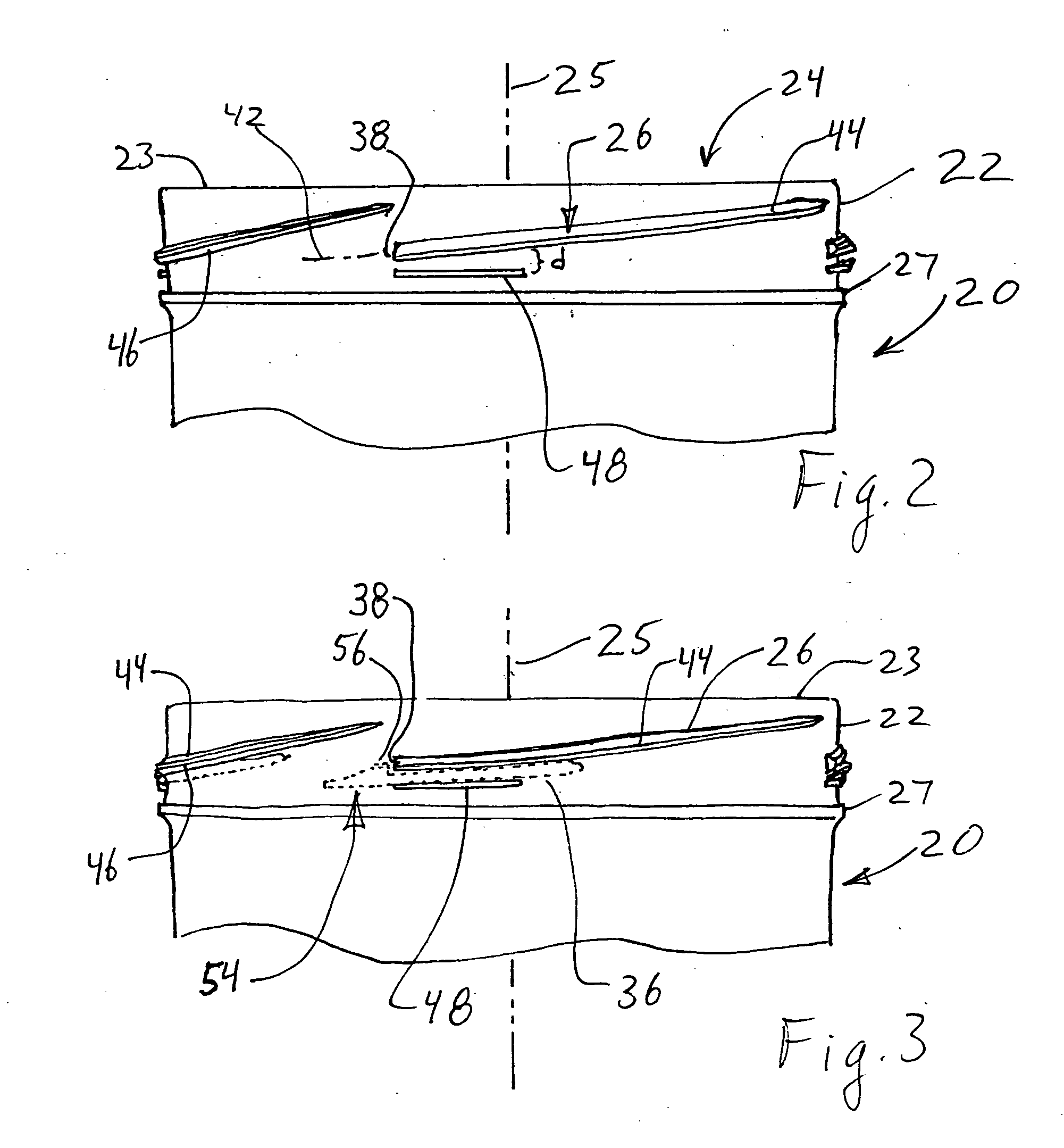

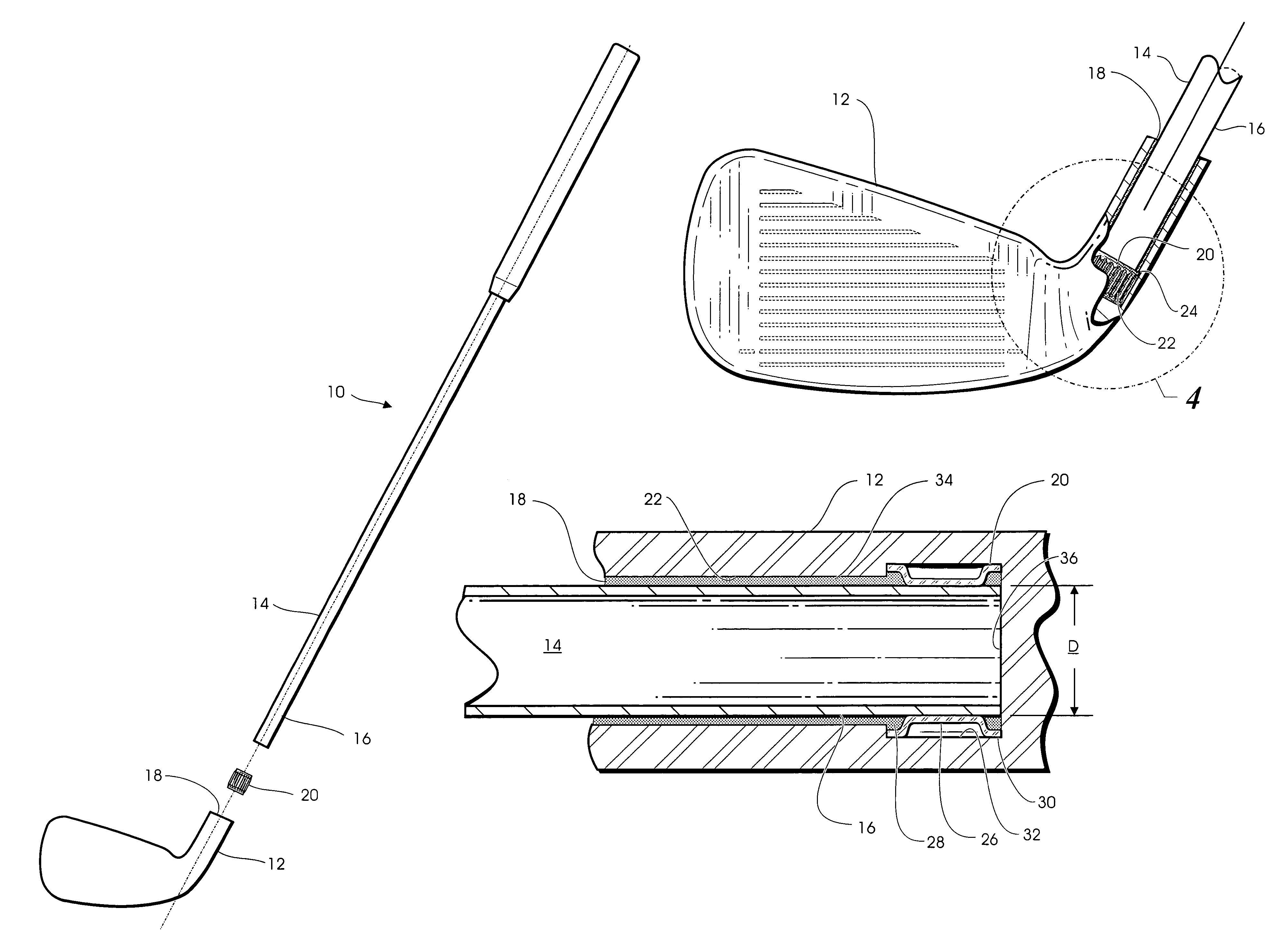

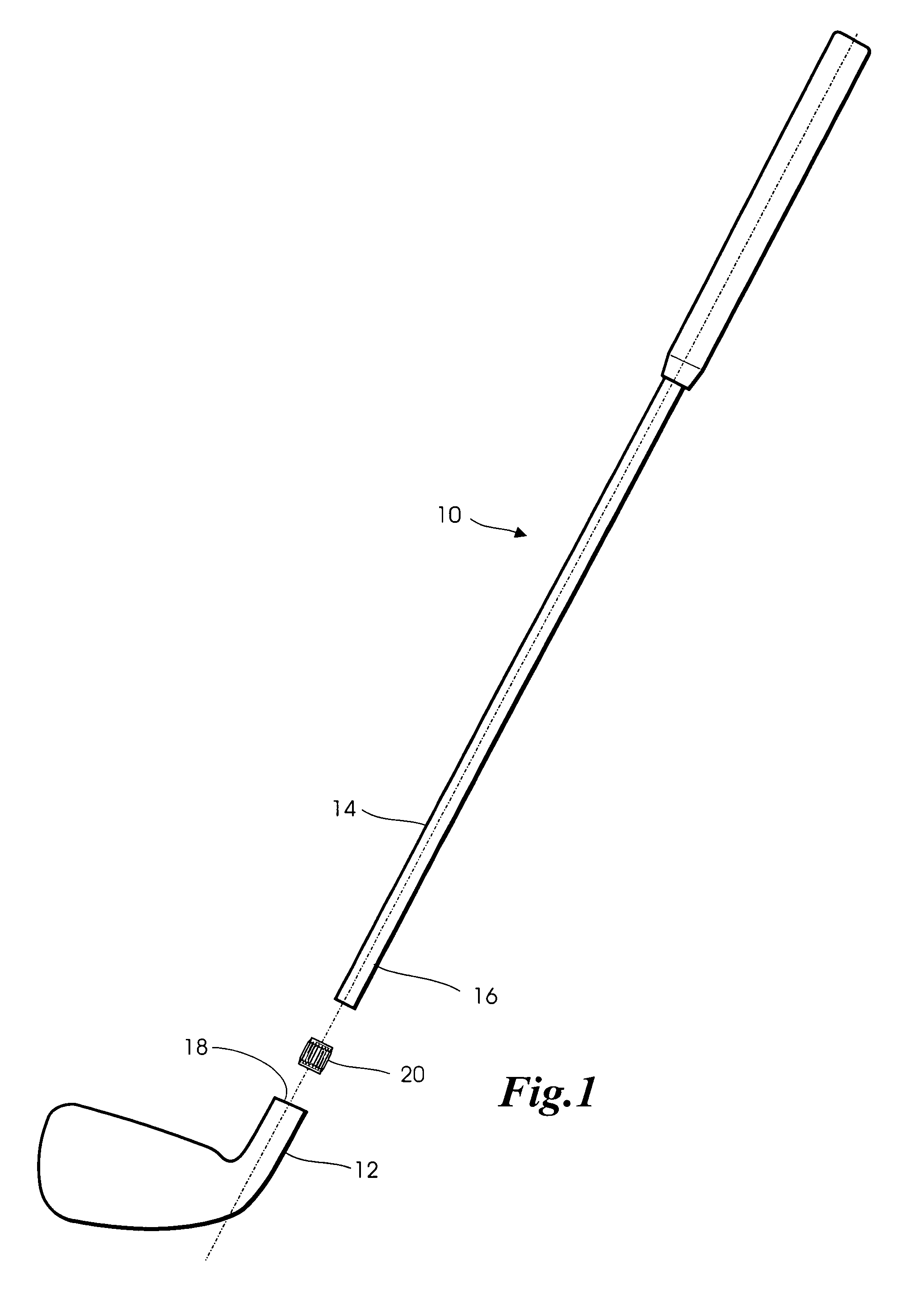

Golf club and method of manufacturing

A golf club is manufactured according to a method in which a radially compliant crush sleeve is interposed between the shaft tip and hosel of the club head. The crush sleeve is fabricated from a strip of metal formed into a substantially cylindrical metallic band with a plurality of radially-extending dimples or corrugations that grip the shaft. The crush sleeve is retained either in an undercut region in the hosel bore, on a mandrel extending from the hosel, or on a pilot shaft at the tip of the golf club shaft. After the interface between the shaft and hosel is coated with an adhesive, the shaft is assembled to the hosel with the crush sleeve squeezed in between. The crush sleeve secures the shaft to the club head with sufficient rigidity to allow the adhesive to set while maintaining the appropriate axial and rotational alignment.

Owner:KARSTEN MFG CORP

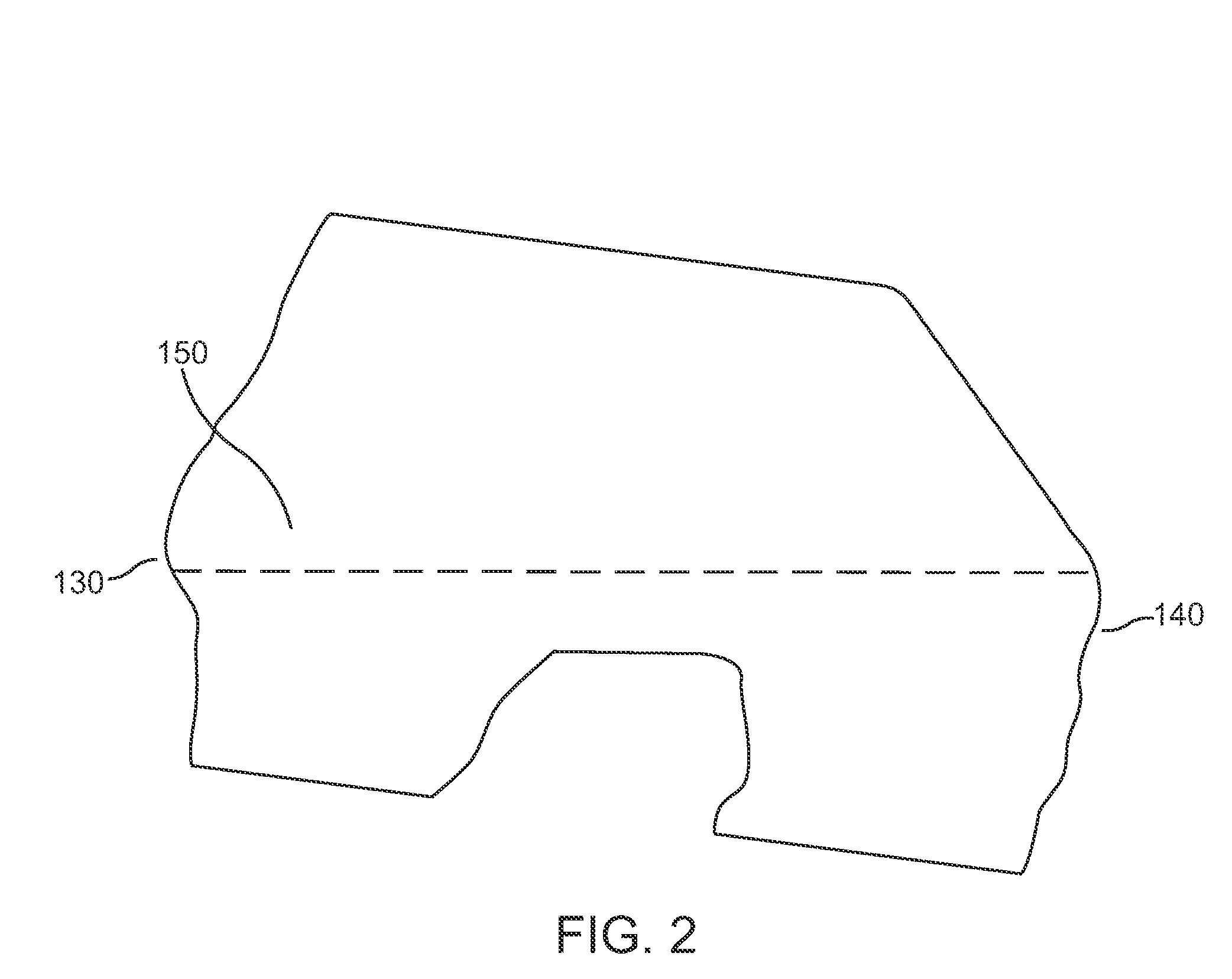

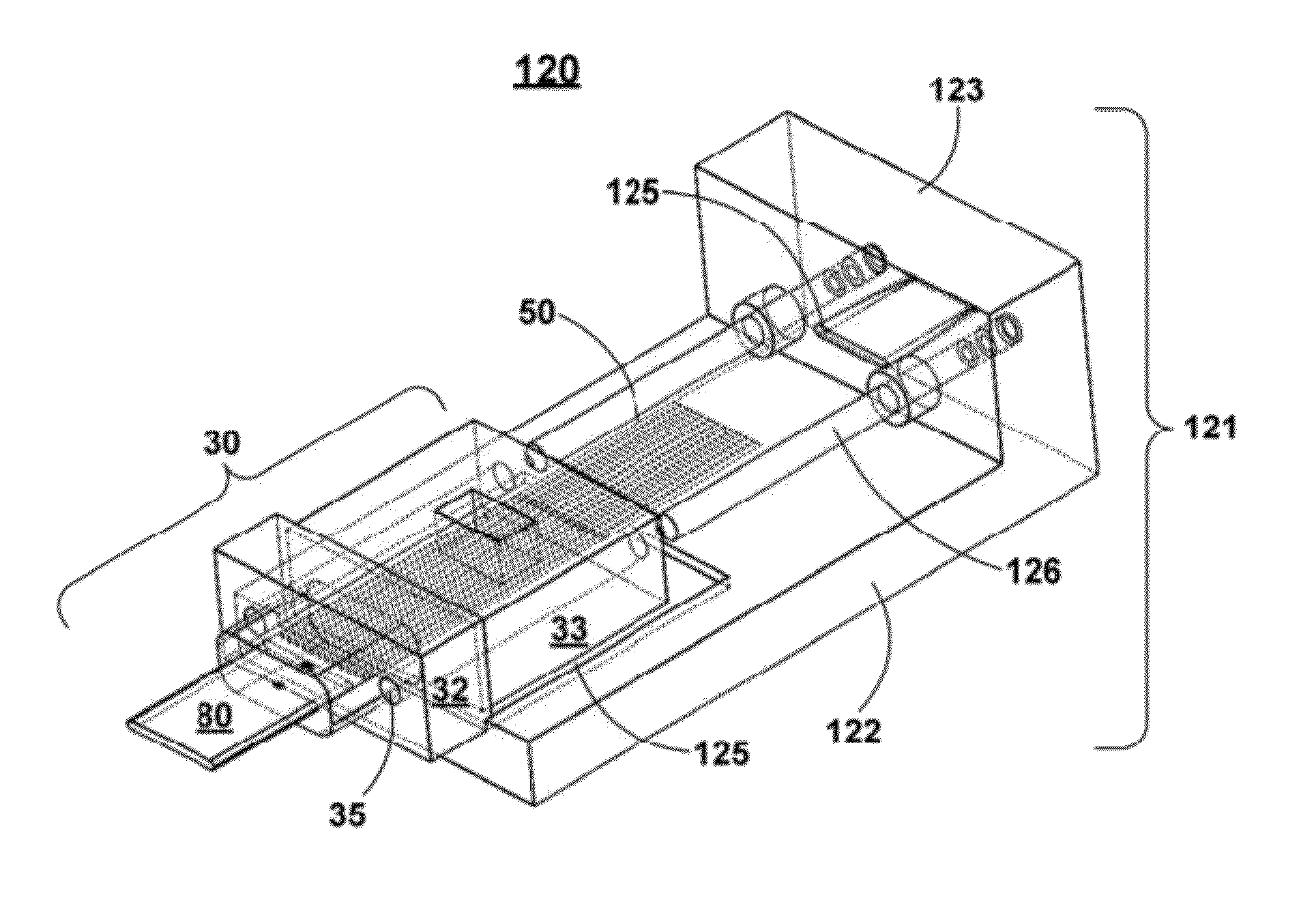

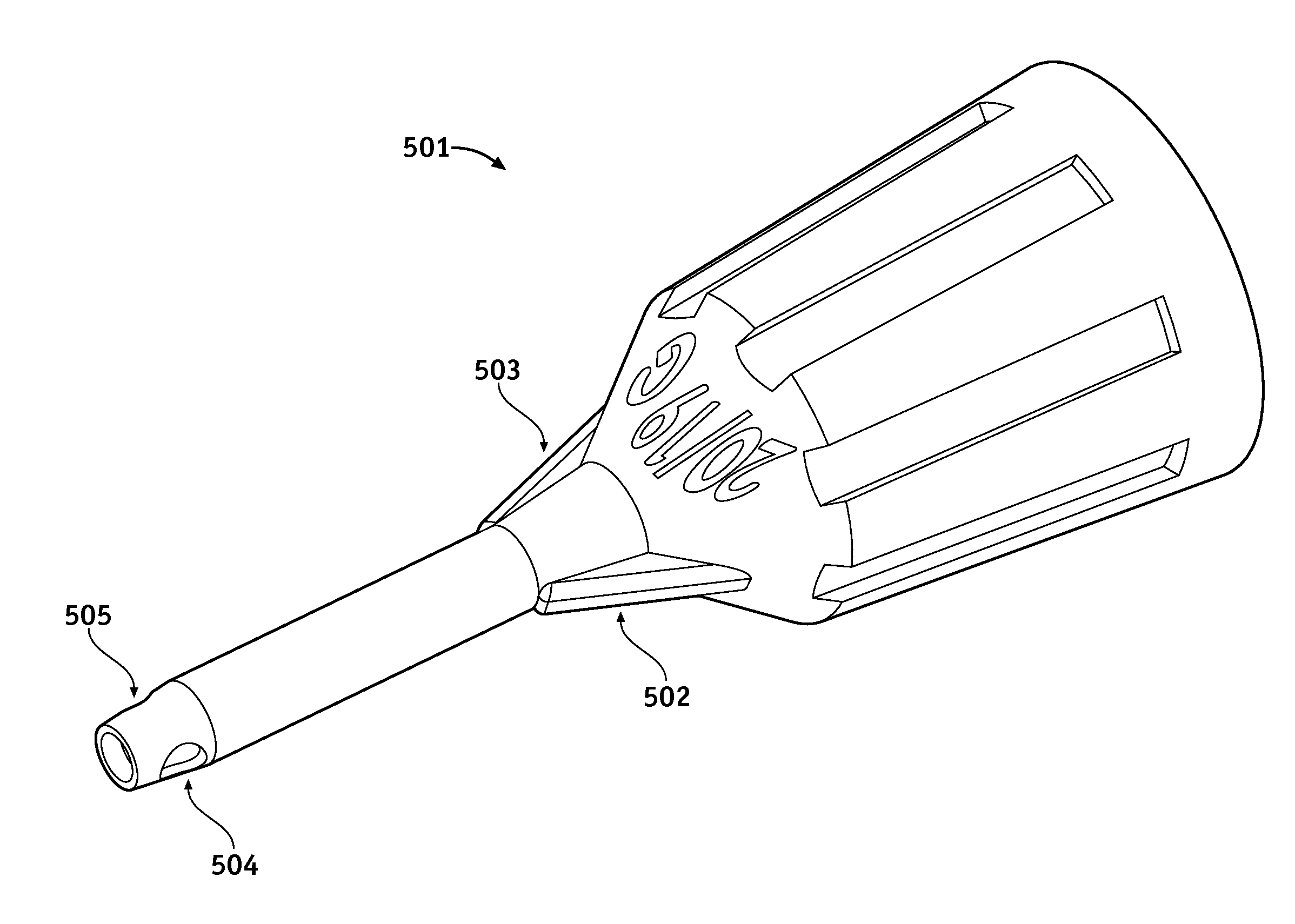

Rotational alignment of fluid delivery device

A device configured for use in an ocular surgical procedure is provided. The device, such as a sleeve or a needle, includes a proximal portion, a distal portion including at least one fluid opening formed at a predetermined orientation, and at least one visual marking provided at the proximal portion at a predetermined marking orientation relative to said predetermined orientation. The visual marking or markings provide a visual indication of orientation of the fluid opening when the device is employed in the ocular surgical procedure.

Owner:JOHNSON & JOHNSON SURGICAL VISION INC

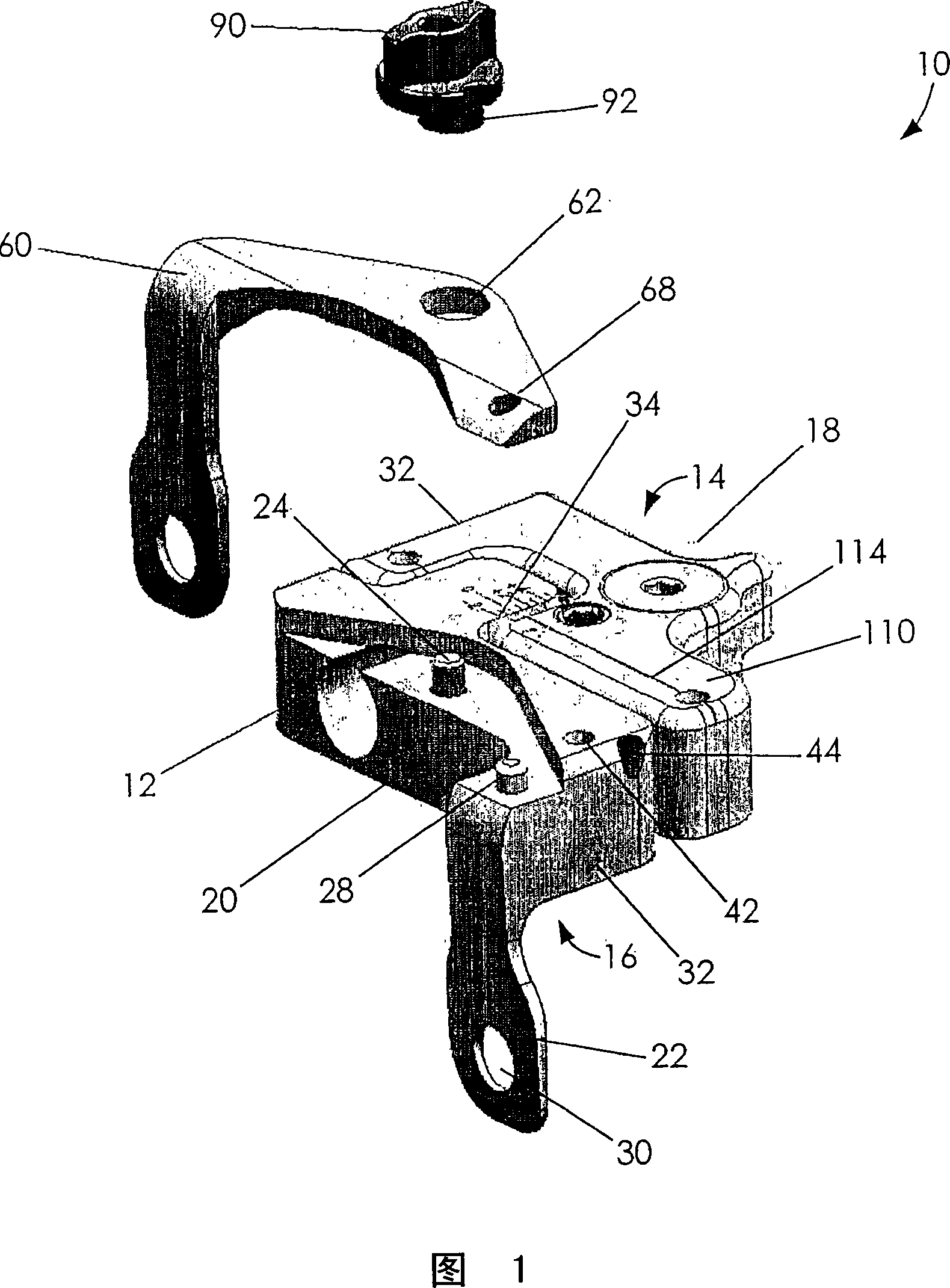

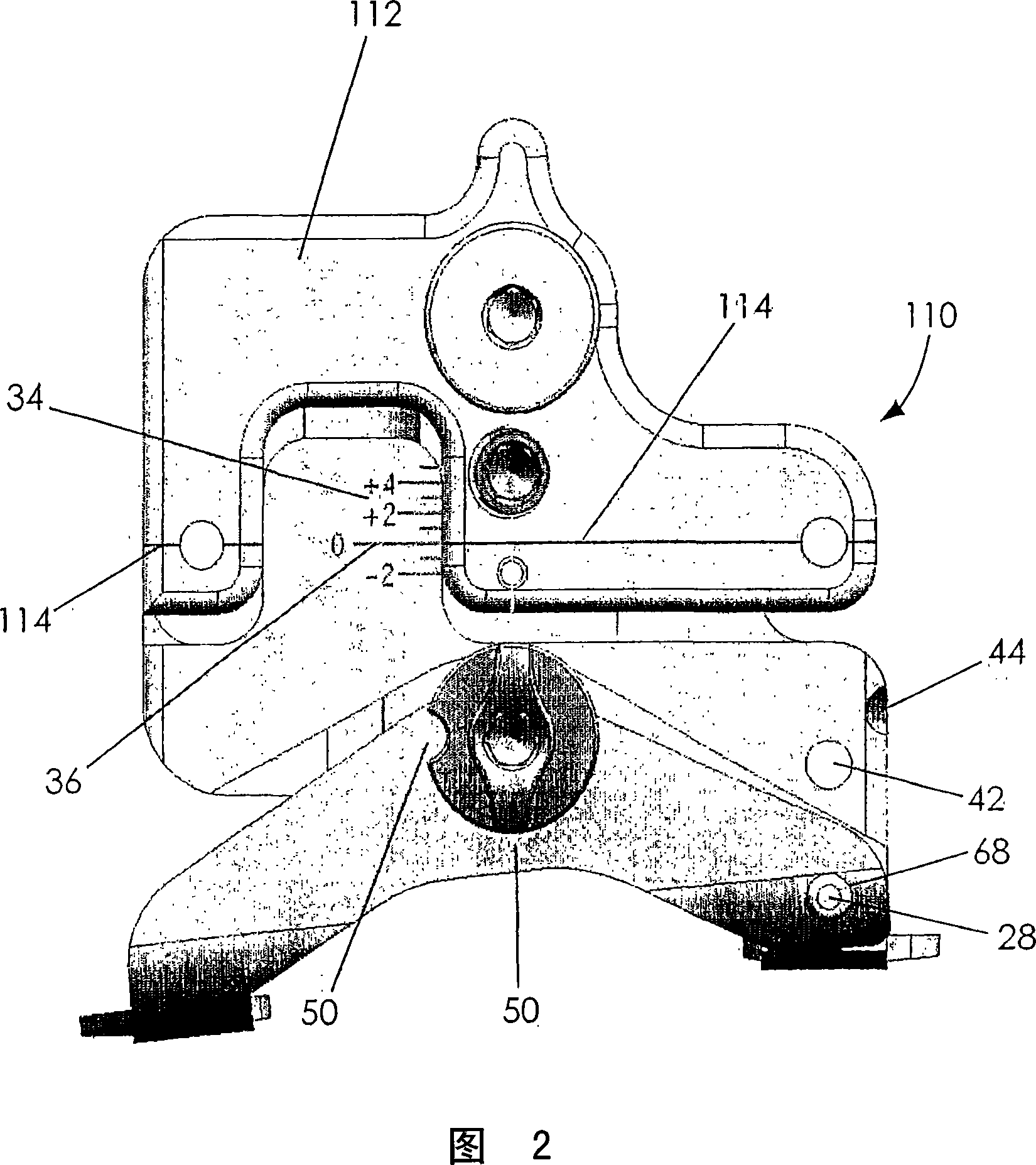

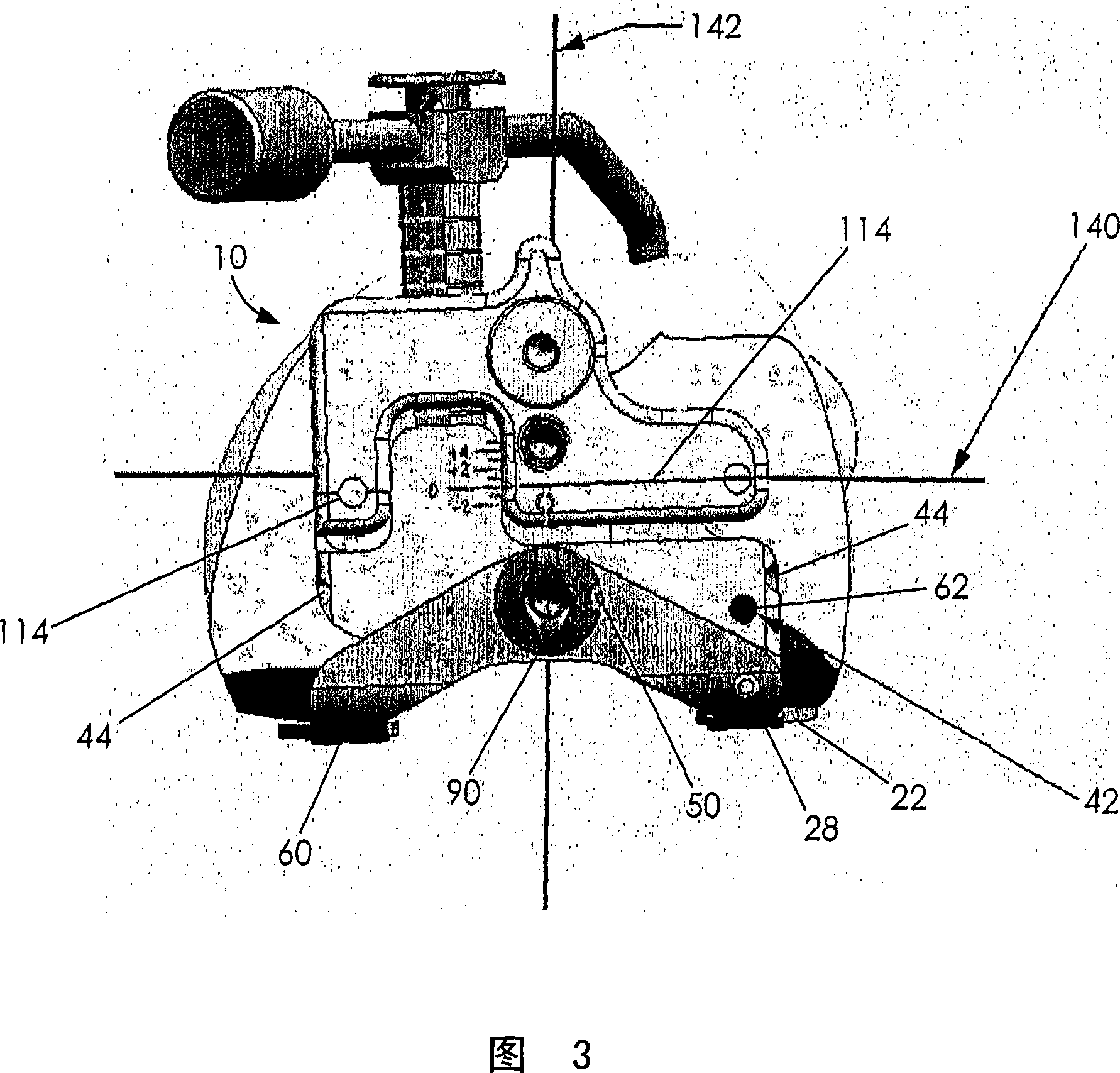

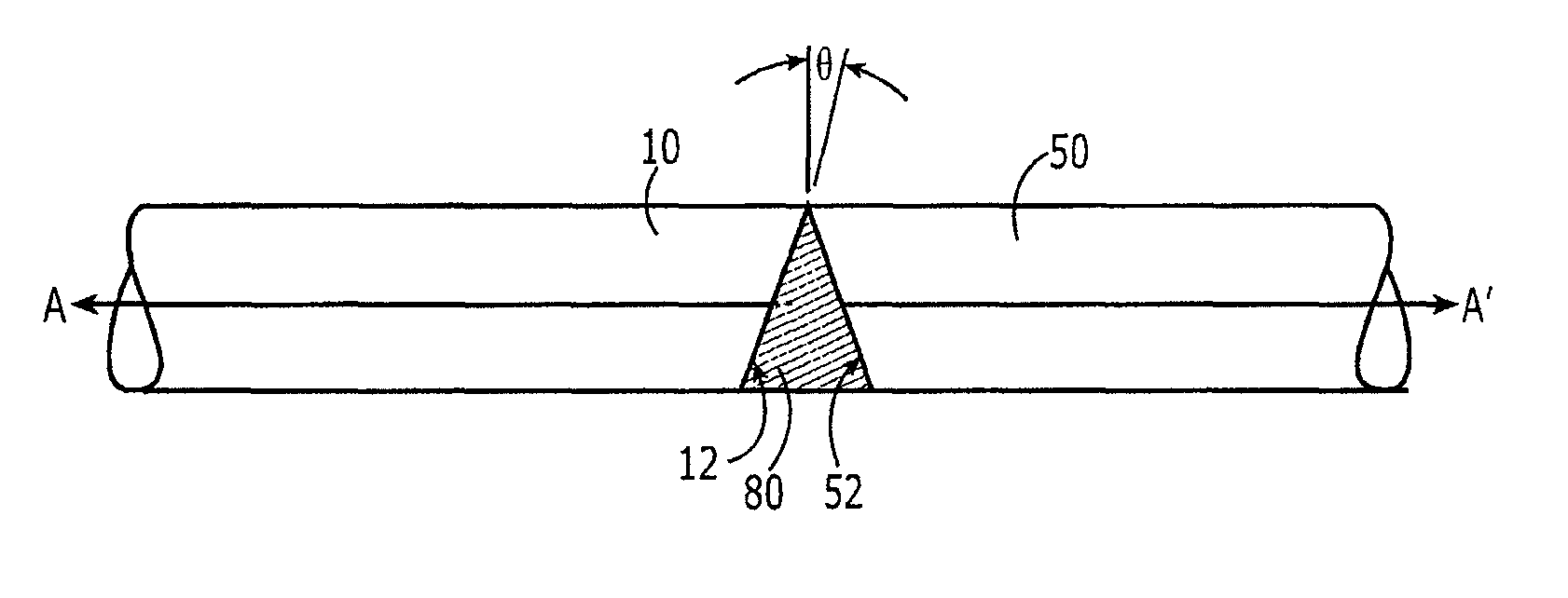

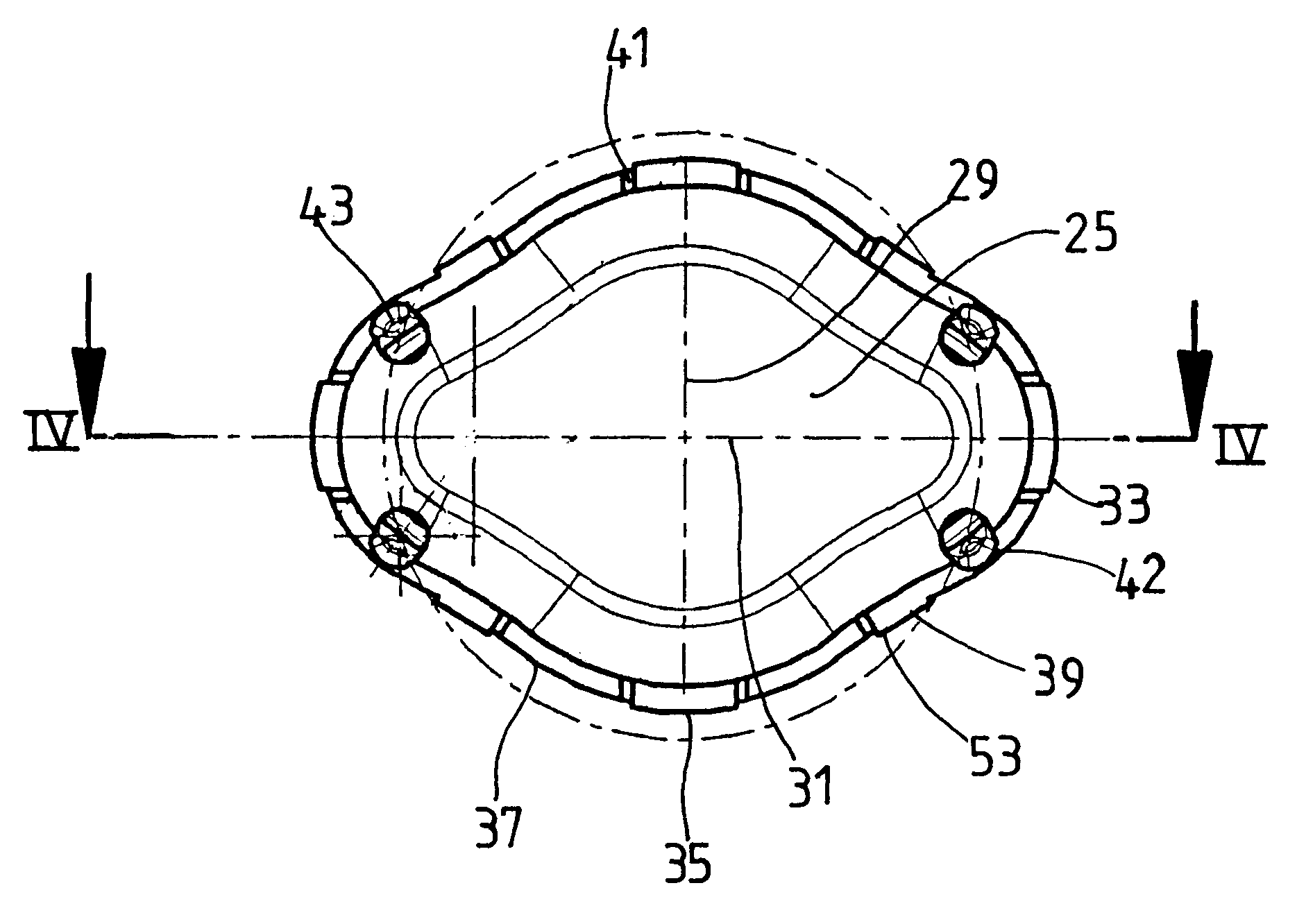

Mount for a shock absorber

InactiveUS6572089B2High positioning accuracyIncrease torqueSpringsResilient suspensionsEngineeringShock absorber

Mount for a shock absorber includes a cap in working torque-transmitting connection with the entire mount. The twisting surface, which is in working connection with an opposing surface on the vehicle at least during the installation of the shock absorber in a mounting hole in the vehicle. The twisting surface and the opposing surface ensure the rotational alignment of the connecting means on the mount side with the connecting means on the vehicle side.

Owner:ZF FRIEDRICHSHAFEN AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com