Numerical control precision micro-fine super-long deep hole drilling machine

A kind of deep hole drilling machine, micro technology, applied in the direction of boring/drilling, drilling/drilling equipment, parts of boring machine/drilling machine, etc., to avoid the moment of inertia, high control accuracy and low friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

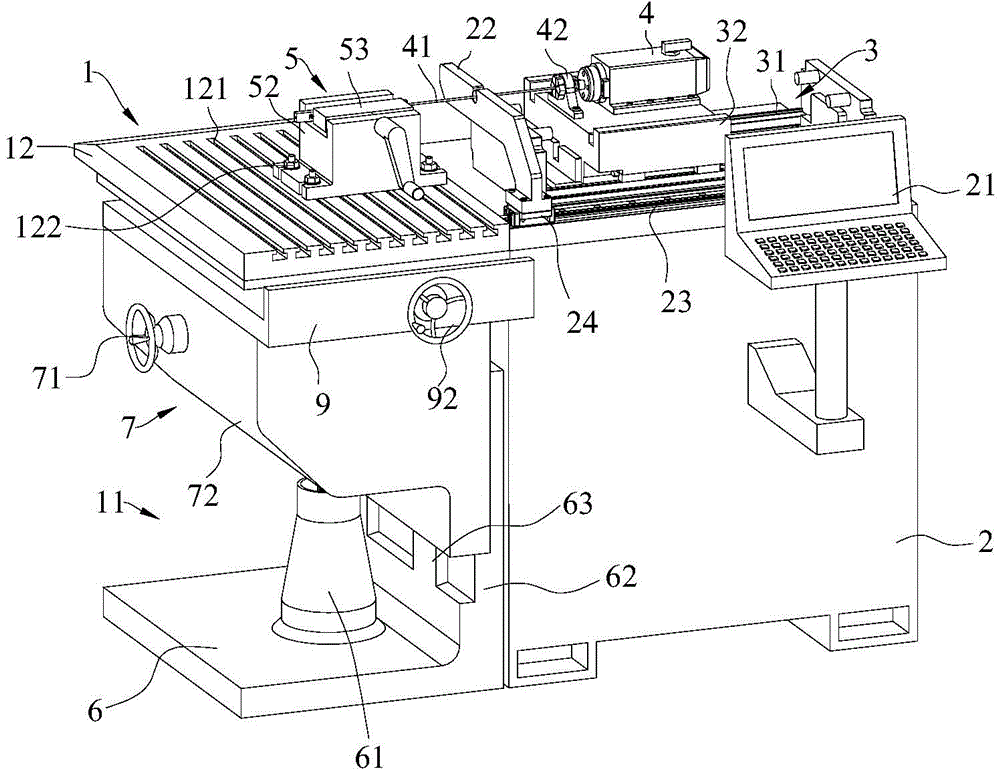

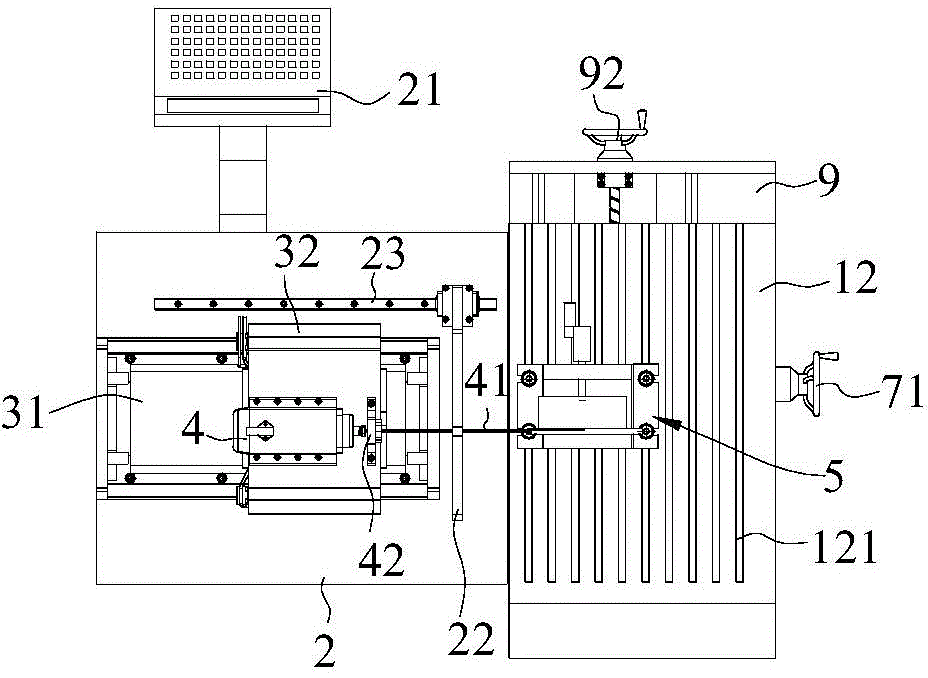

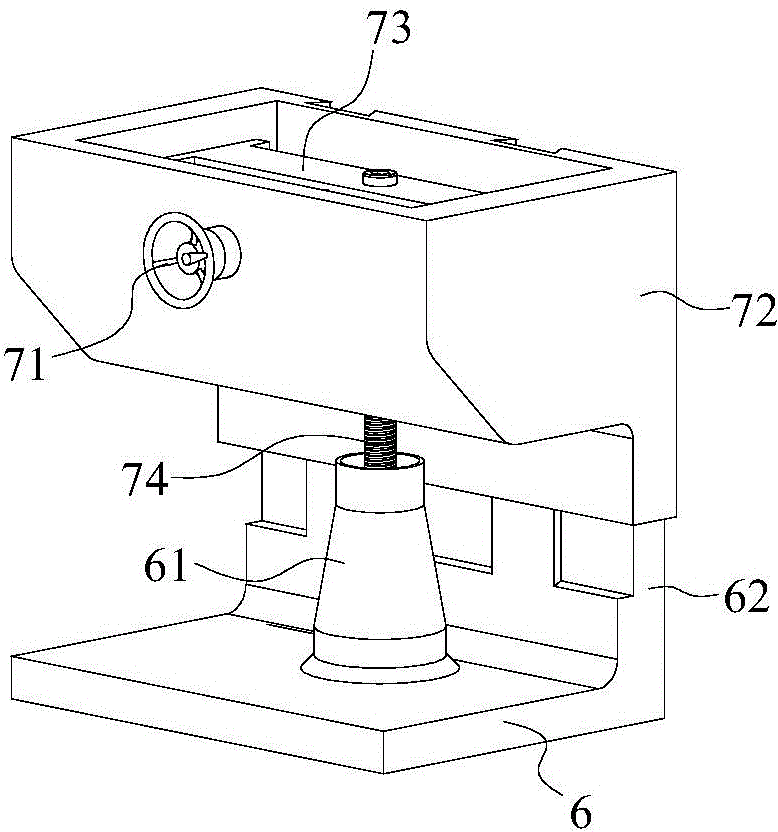

[0023] refer to Figure 1 to Figure 7 , the present invention provides a kind of numerical control precision micro-fine ultra-long deep hole drilling machine, comprises workbench 1, the main control box 2 of peripheral control panel 21, linear motor 3 and the servomotor 4 that drill bit 41 is housed on the output shaft, described linear The motor 3 includes a primary 31 mounted on the main control box 2 and a secondary 32 of the servo motor 4, the secondary 32 is provided with a torque detector 42 on the front side of the servo motor 4, and the drill bit 41 passes through the torque detector 42, and is connected and locked with the rotating shaft of the servo motor 4 through the collet. The secondary 32 drives the servo motor 4 to move so that the drill bit 41 extends or retracts above the workbench 1. The workbench 1 includes a lifting base 11 and a working table 12 arranged on the lifting base 11. A fixture 5 for fixing the workpiece 10 is mounted on the worktable 12 . The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com