Cycloid tooth profile matching modification method of precision speed reducer for robot

A technology of precision reducer and cycloidal teeth, which is applied in the field of cycloid tooth profile matching and modification of precision reducer for robots, which can solve the problems of increasing the meshing clearance, reducing the torsional stiffness and transmission accuracy of the reducer, and avoiding backlash, Uniform and reasonable modification of the tooth profile to ensure torsional rigidity and transmission accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

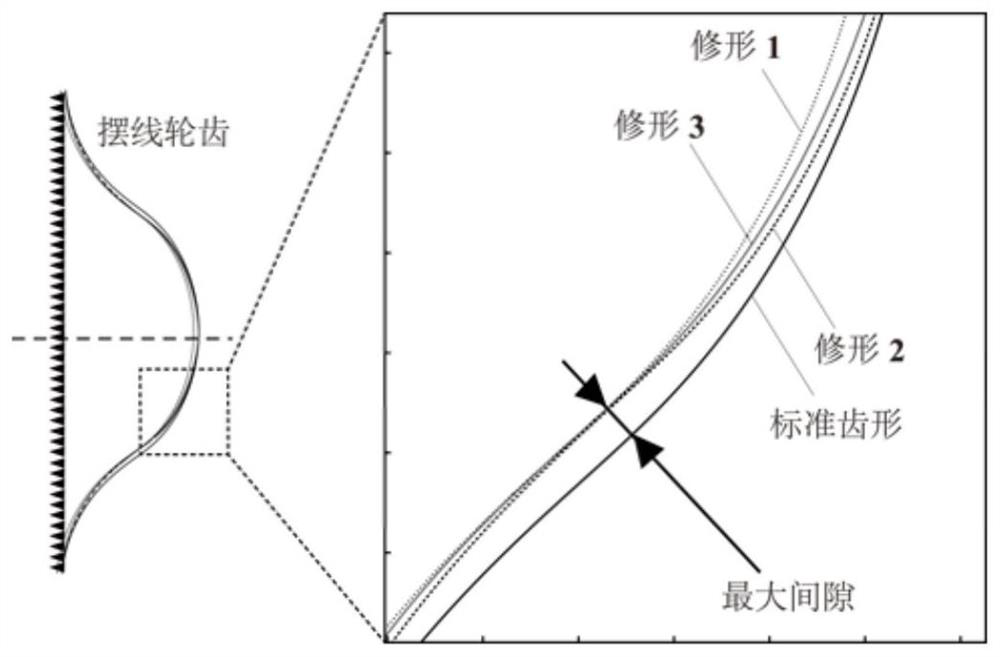

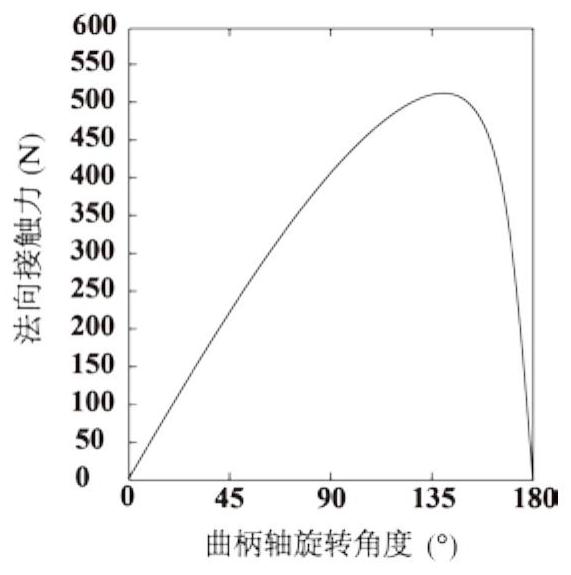

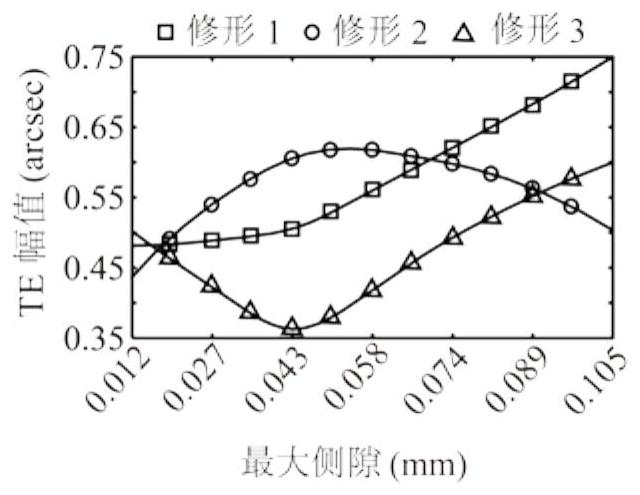

[0039] like Figure 1 to Figure 9 As shown, this method takes a certain type of precision reducer of an industrial robot as an example to illustrate the specific processing process. The number of teeth of the cycloid wheel Z p 40, the number of pin wheel teeth Z c is 39; R p is the radius of the pin tooth distribution circle, the value is 114.5mm; r rp is the radius of the pin tooth, with a value of 5mm; a is the eccentricity of the crankshaft, with a value of 2.2mm; in order to compare with the traditional modification method, two combined modification methods were used to obtain the same maximum modification backlash. The first combination modification method is to f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com