Patents

Literature

35results about How to "Guaranteed torsional rigidity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

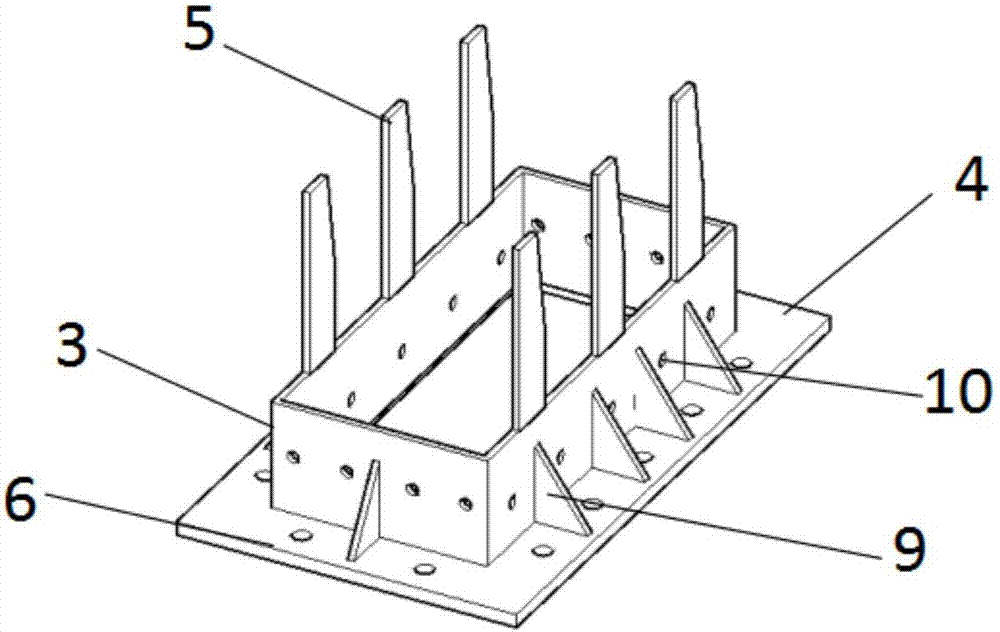

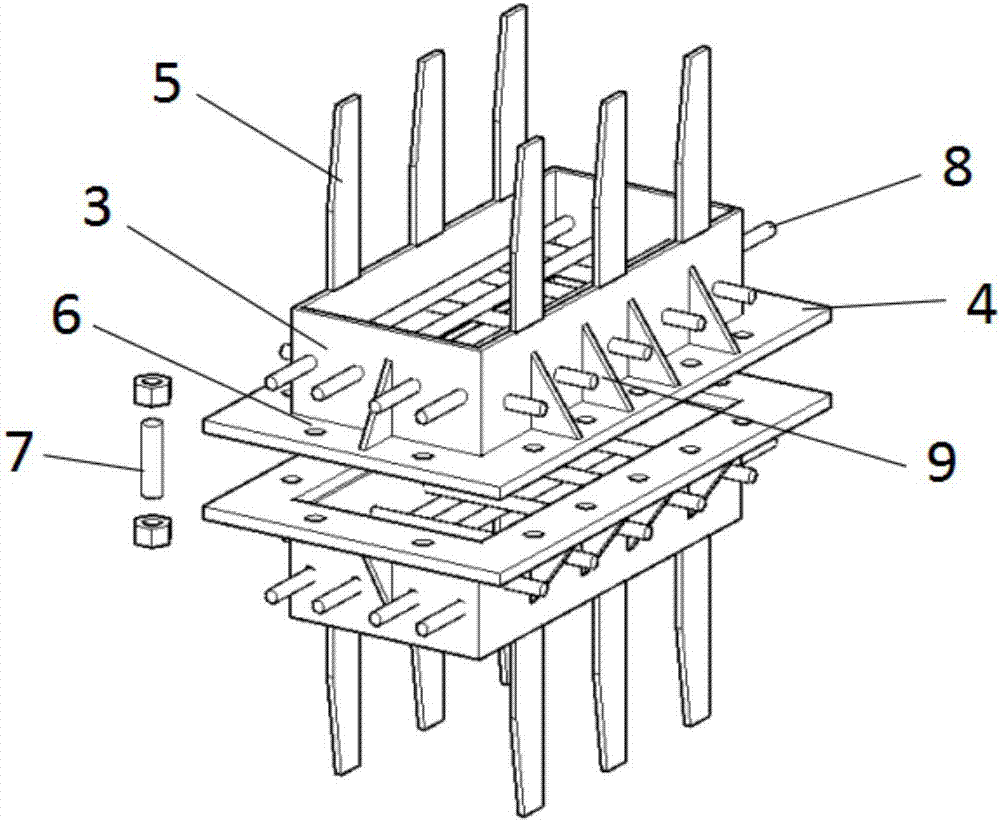

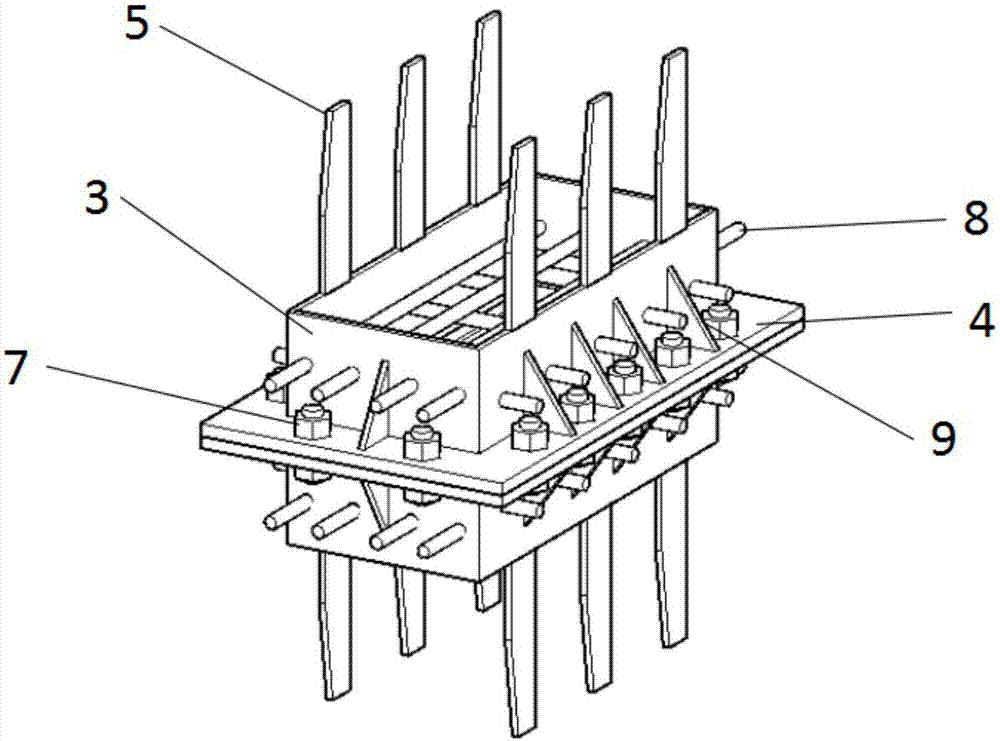

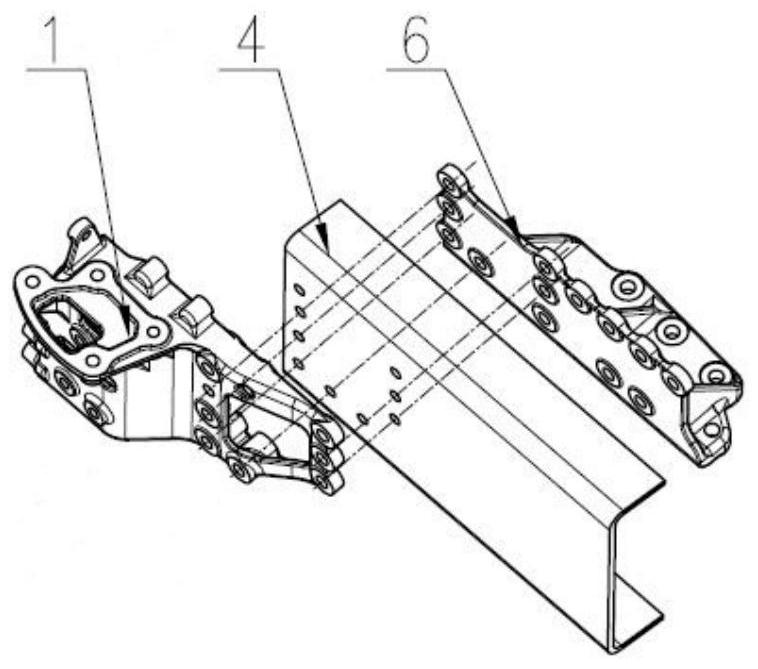

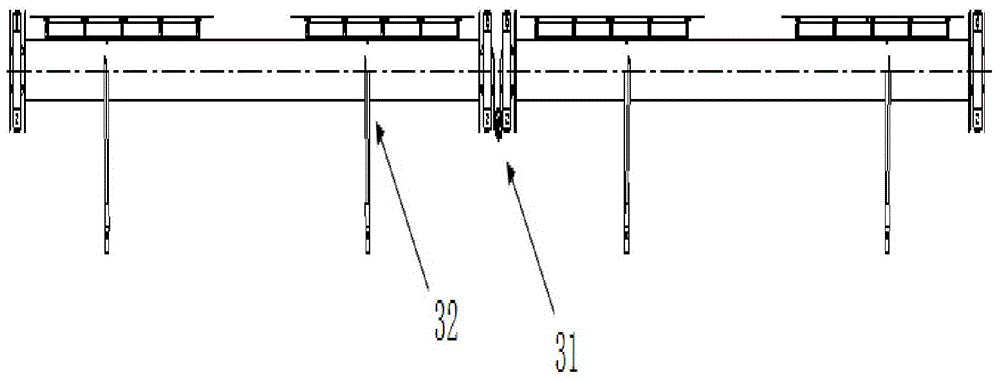

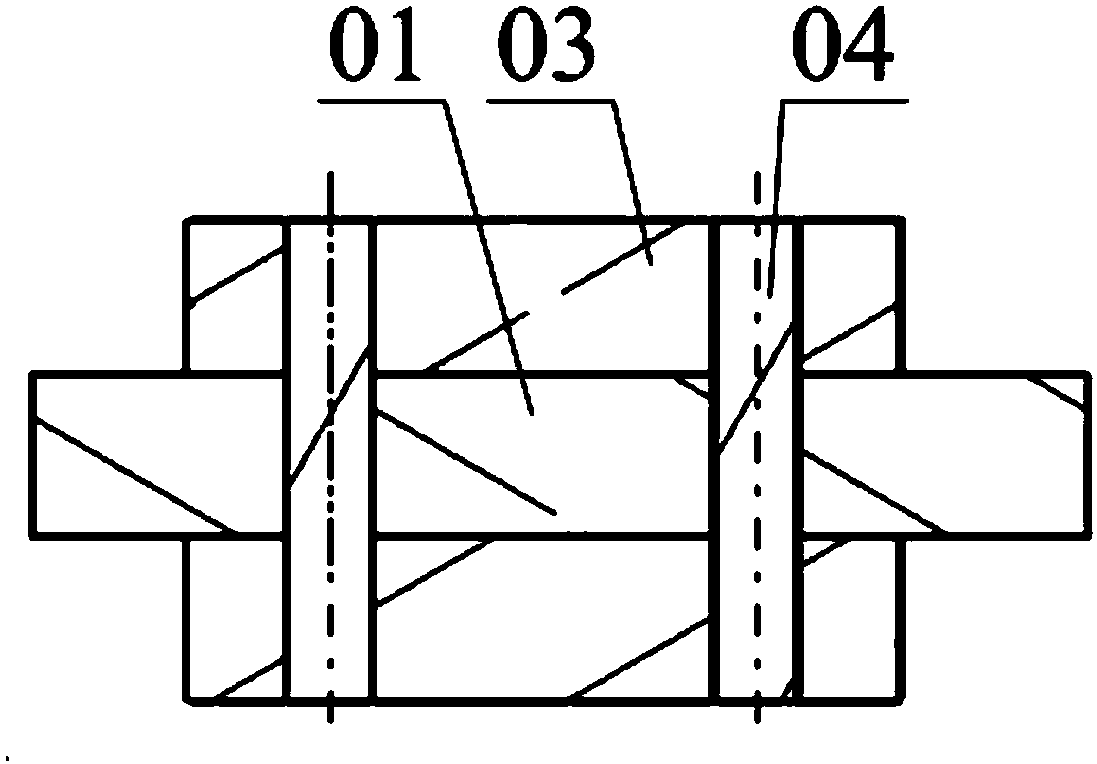

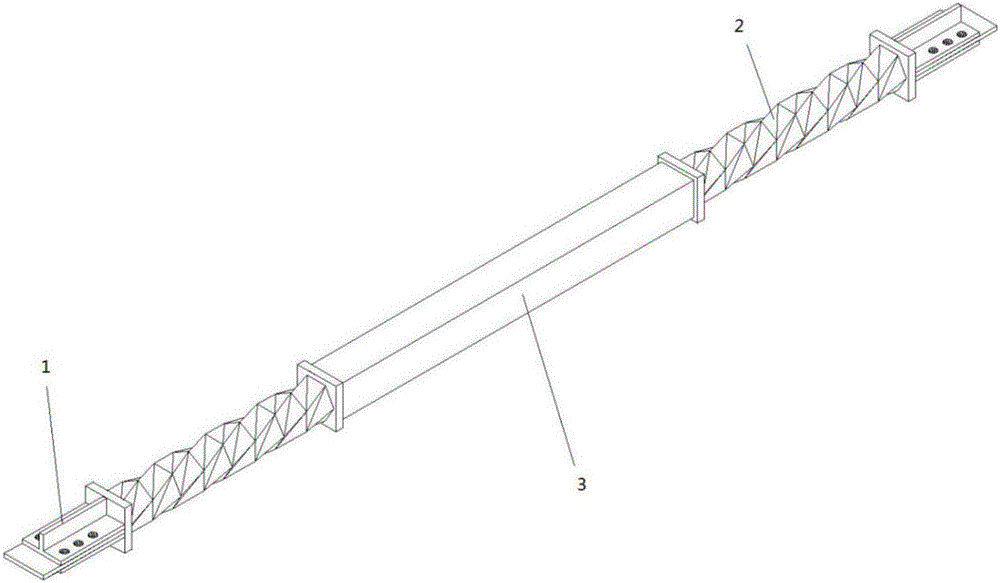

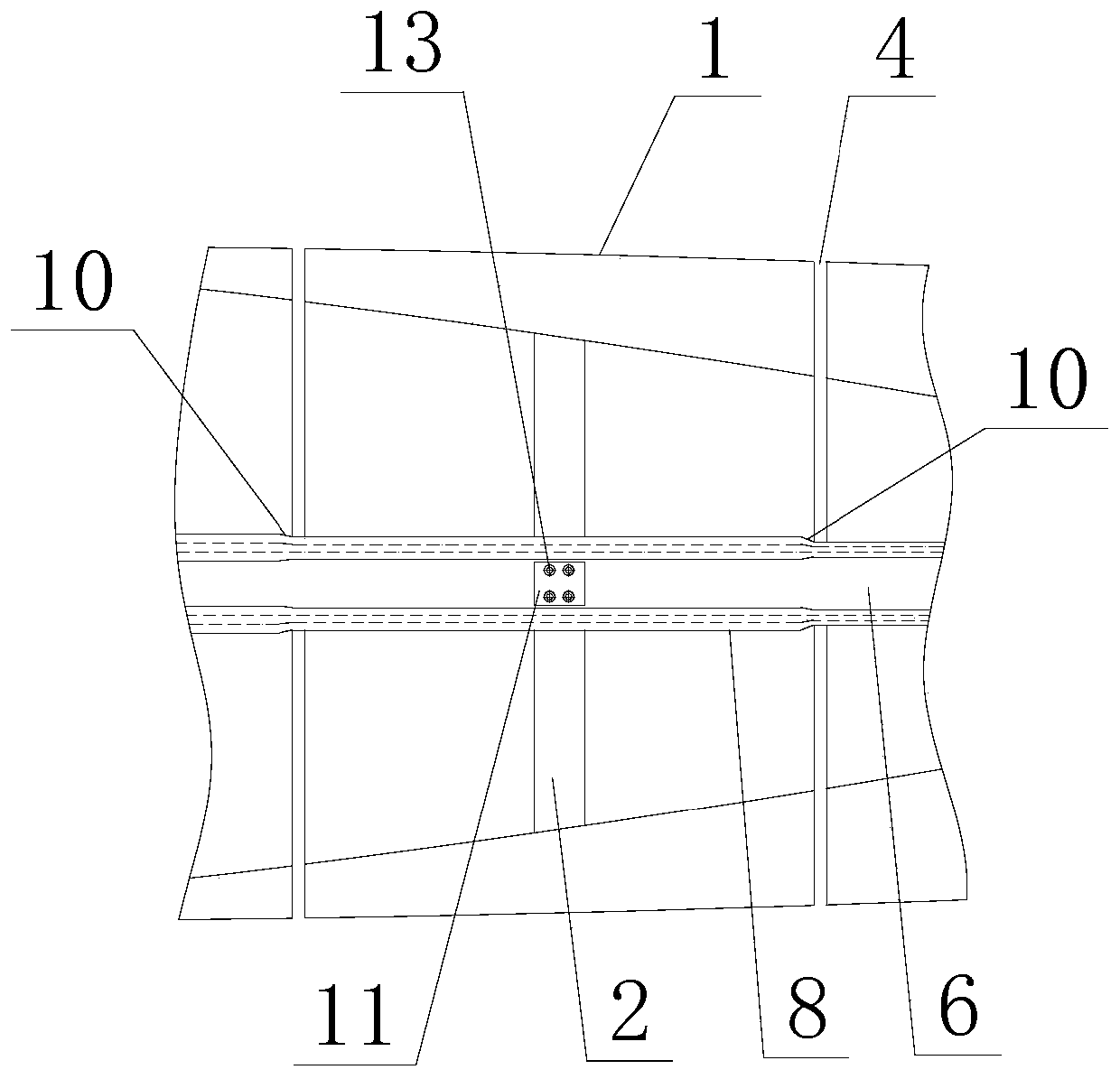

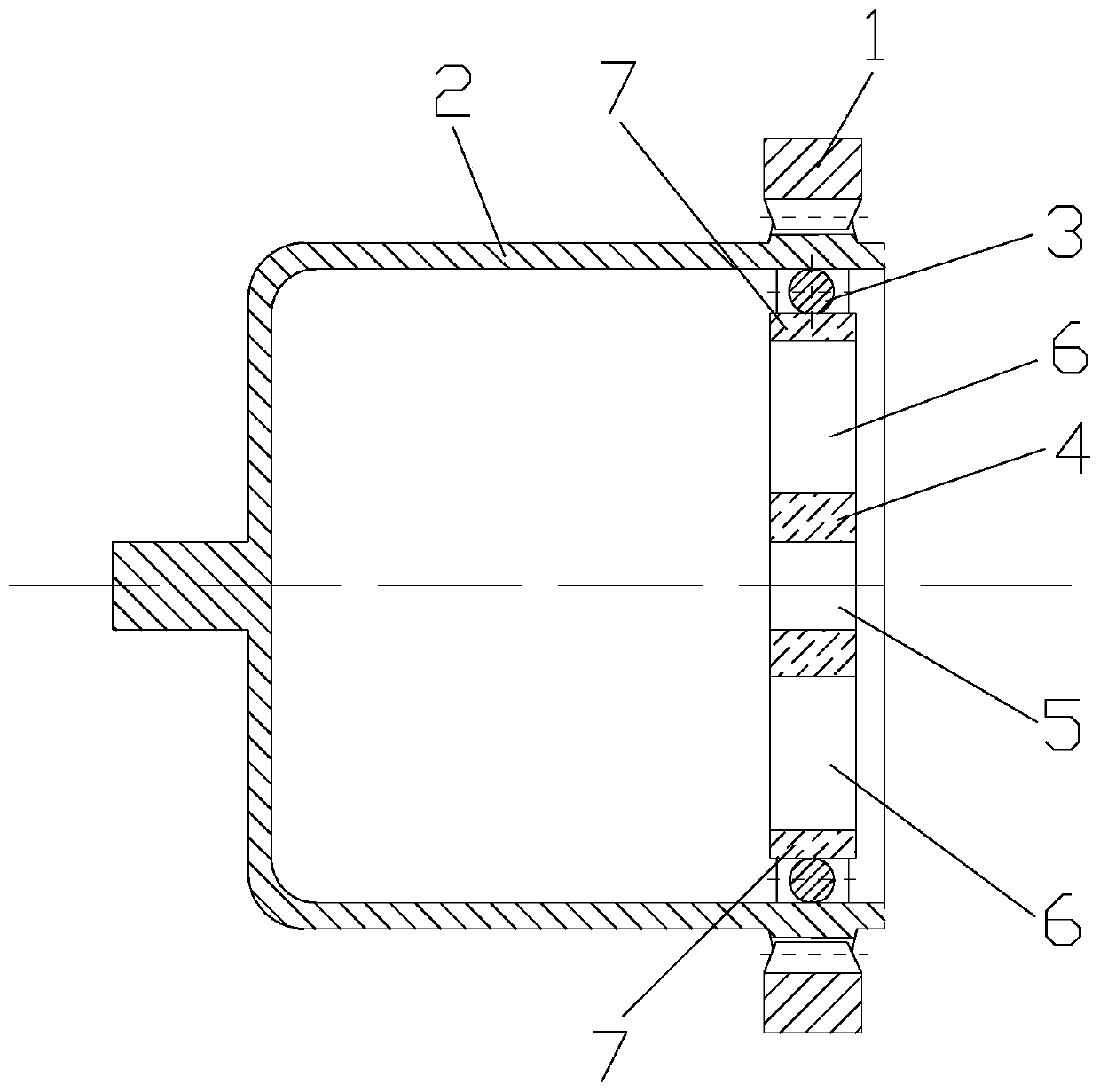

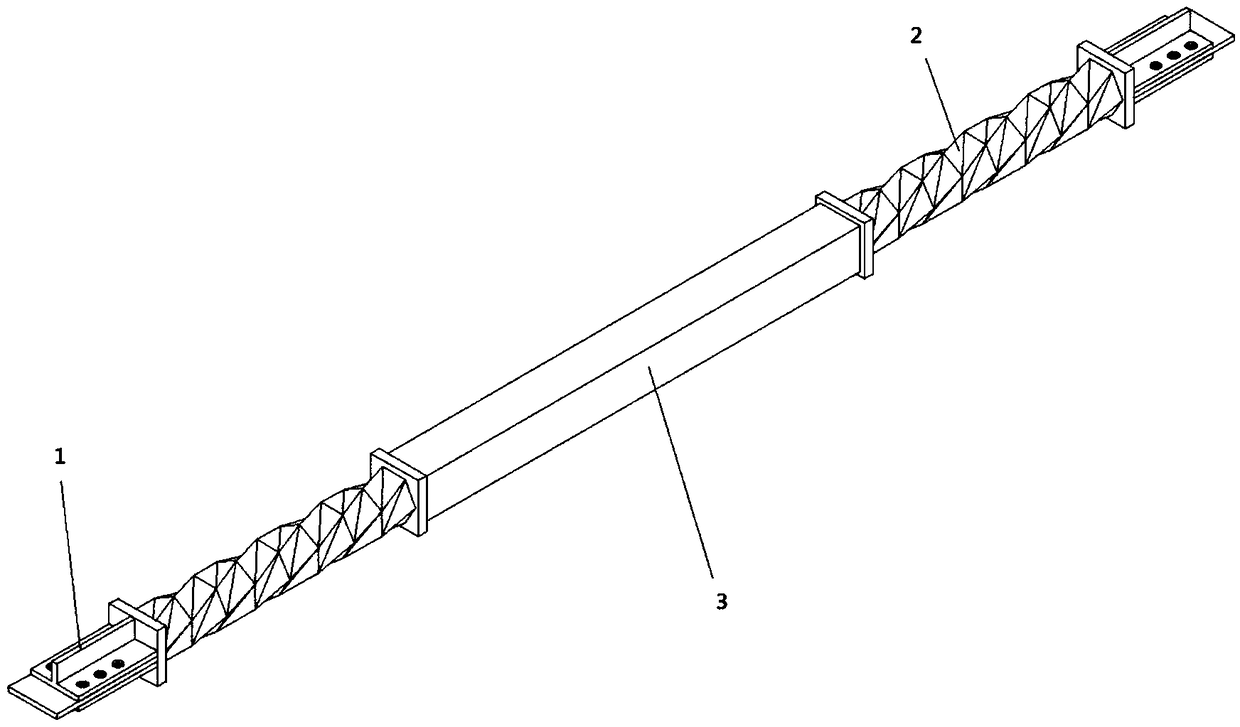

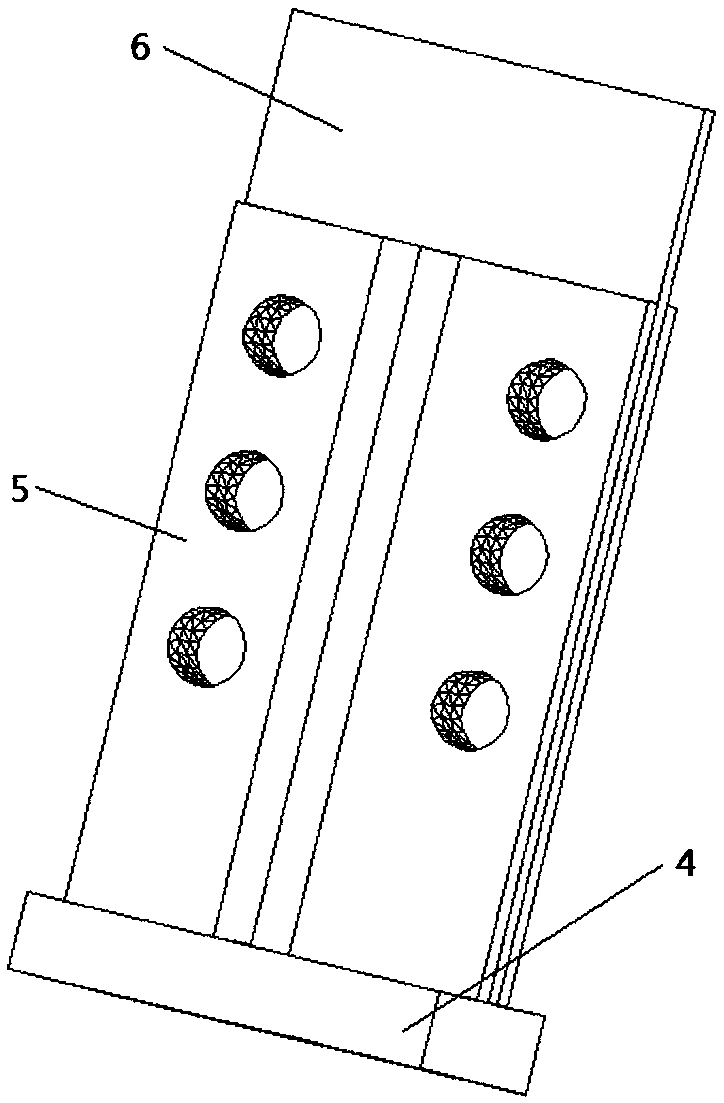

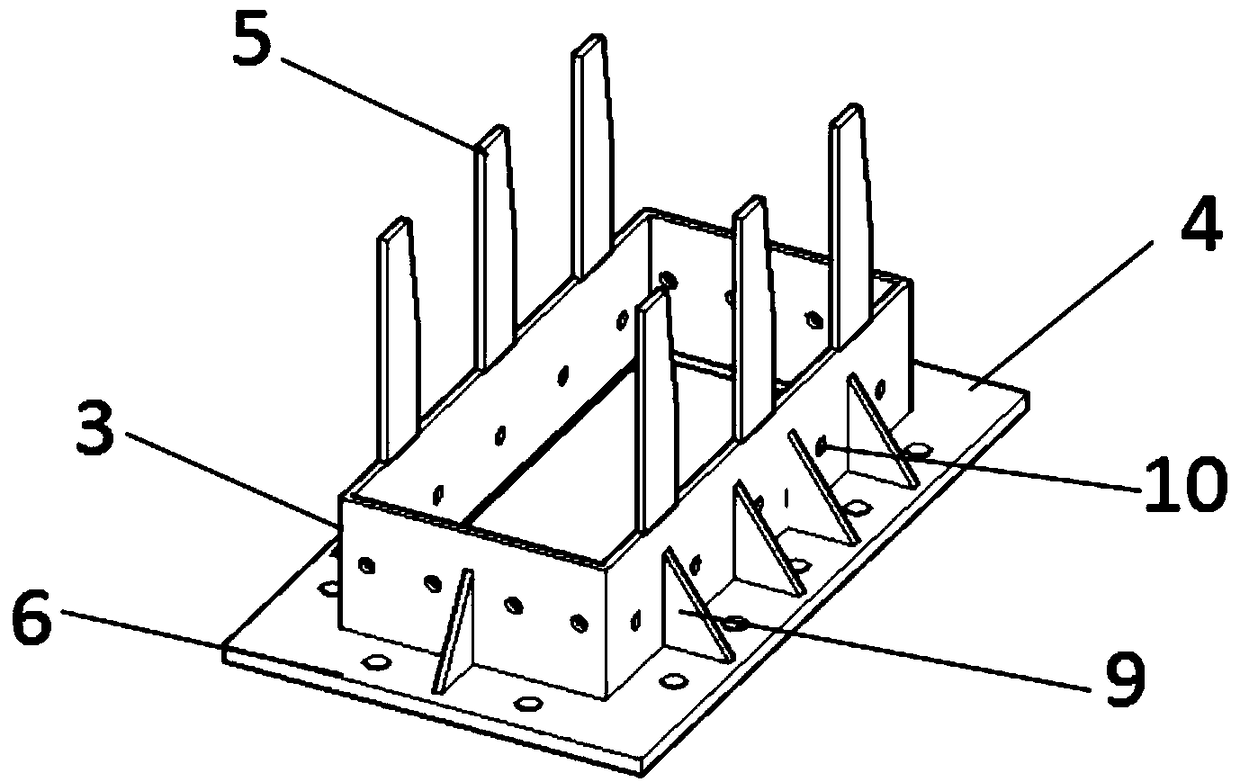

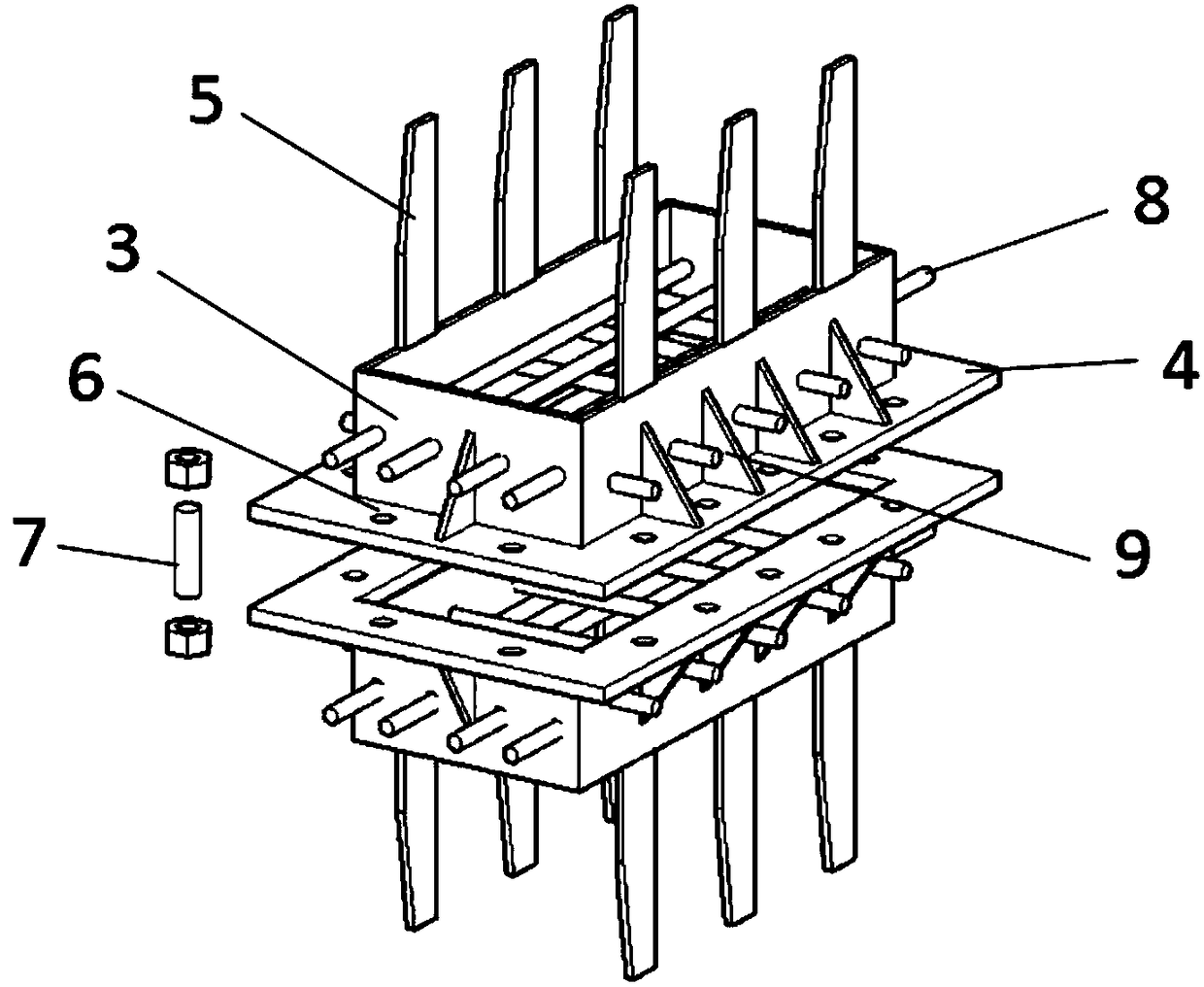

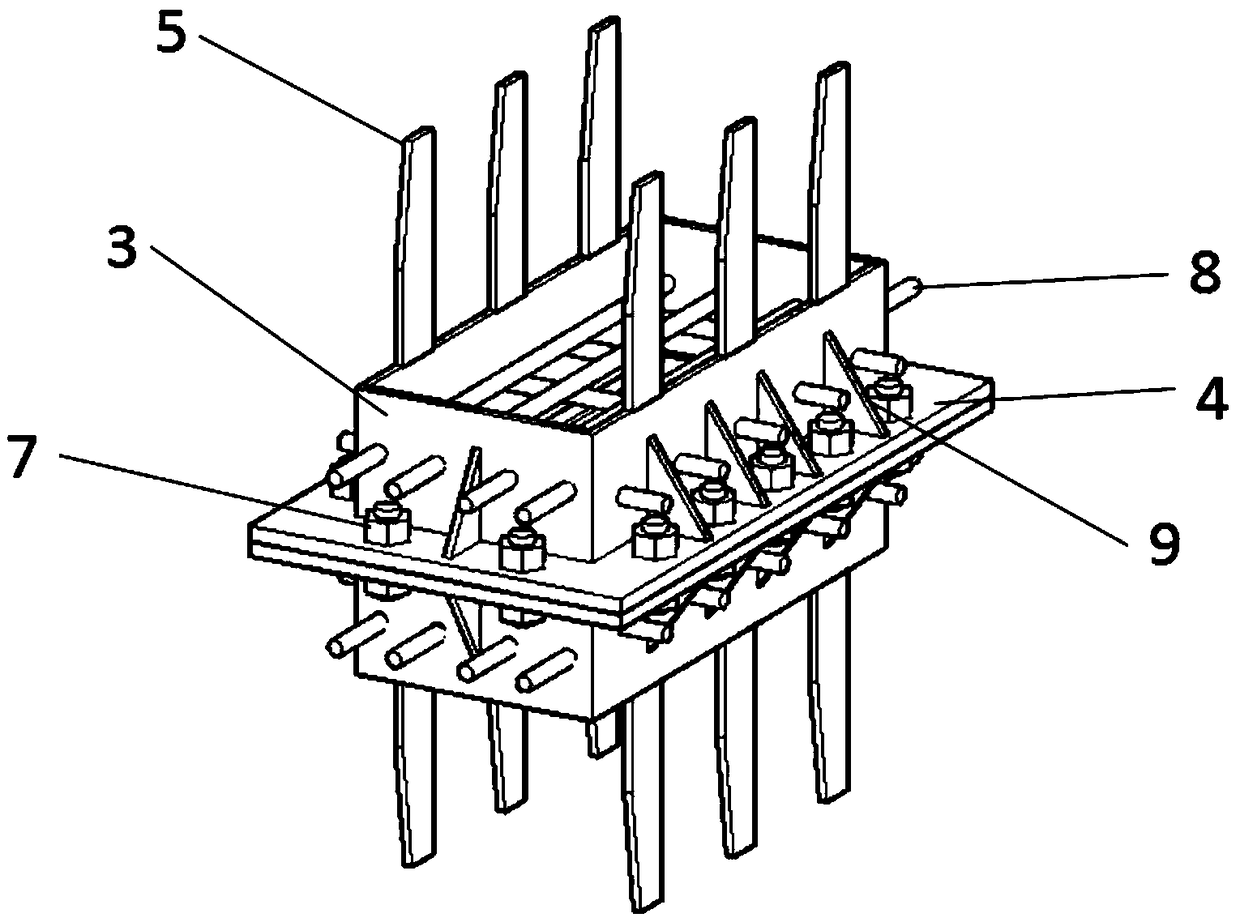

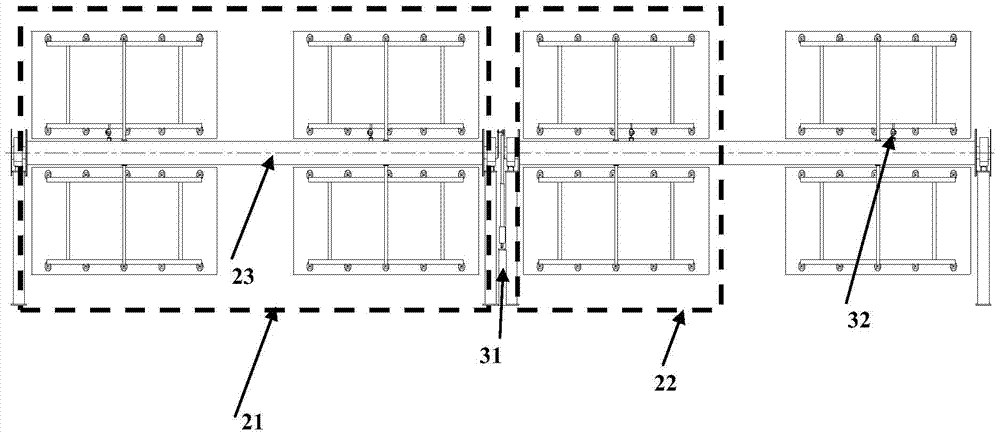

Positioning device for achieving embedded-sectional steel flat-joint bolt connection of concrete sectional prefabricated arch ribs and construction method of positioning device

ActiveCN107022947AIncrease stiffnessAvoid confictBridge structural detailsBridge erection/assemblyRear quarterFlat joint

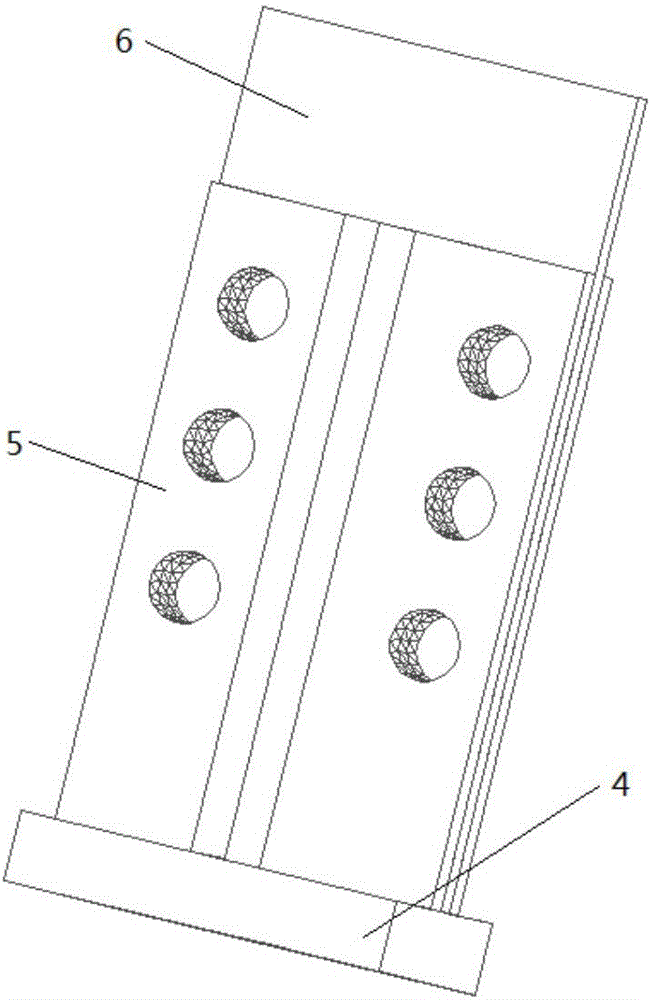

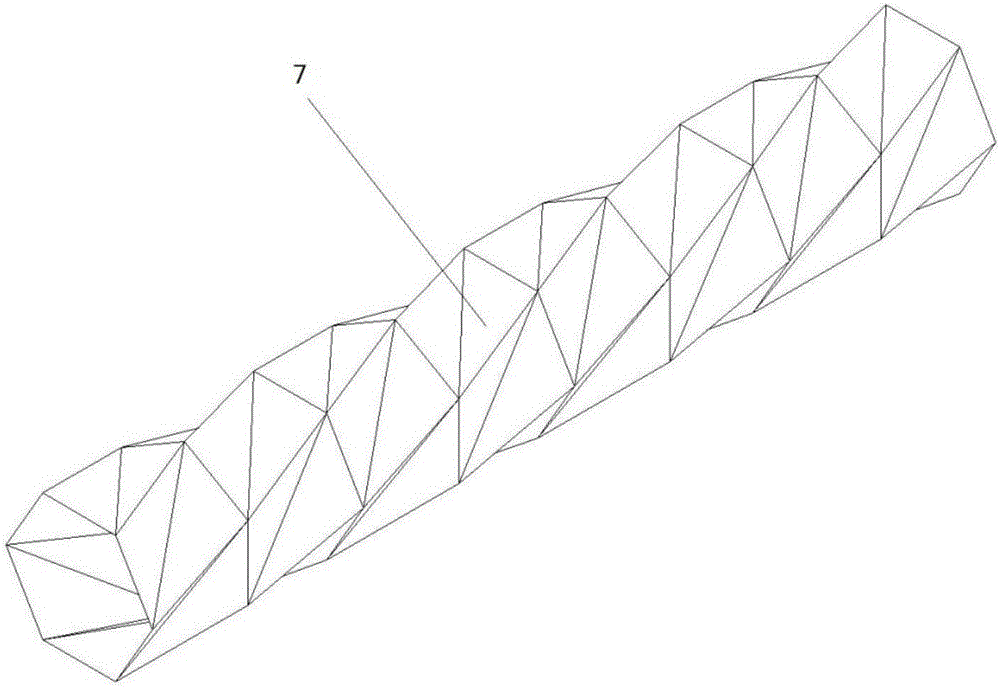

The invention discloses a positioning device for achieving embedded-sectional steel flat-joint bolt connection of concrete sectional prefabricated arch ribs and a construction method of the positioning device. The positioning device is arranged at a junction of the concrete sectional prefabricated arch ribs, and comprises a pair of rectangular flanges adopting the same structure, wherein the two rectangular flanges are arranged at the centers of the prefabricated arch ribs respectively; each rectangular flange comprises a flange panel and a flange side plate; bolt connection holes are formed in the flange panels; the flange panels of the two rectangular flanges are fixedly connected through bolts; one end of each flange side plate is connected with the corresponding flange panel; spikes connected with concrete on the prefabricated arch ribs in an embedded manner are arranged at the other ends of the flange side plates. The positioning device is used for rapid positioning and connection of the sectional prefabricated arch ribs, shortens the construction period, improves the adjusting speed and the adjusting accuracy of arch axes of the sectional prefabricated arch ribs, reduces additional unfavorable eccentricity at a joint of the arch ribs, and improves the force performance of a wet joint of the arch ribs.

Owner:中交投资南京有限公司

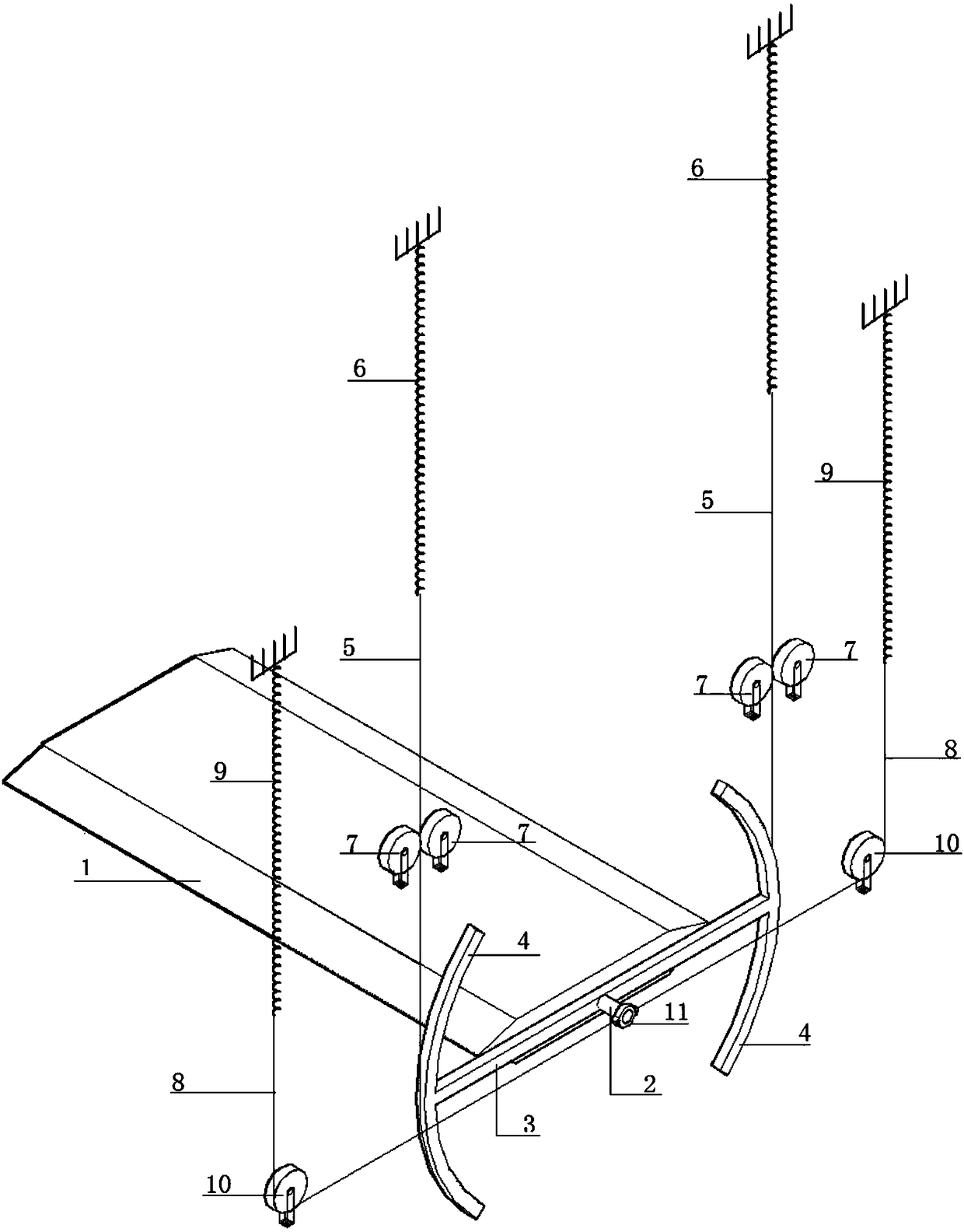

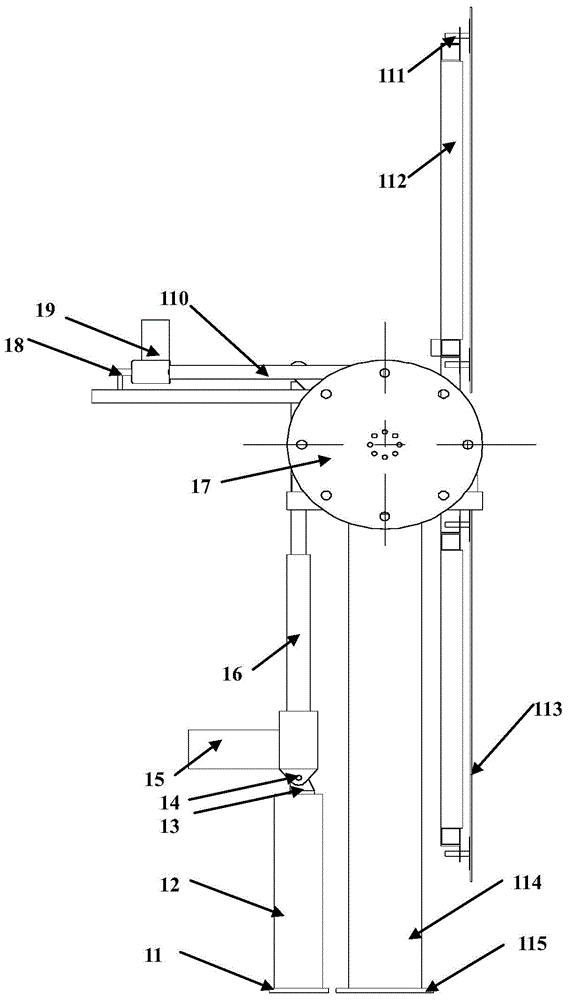

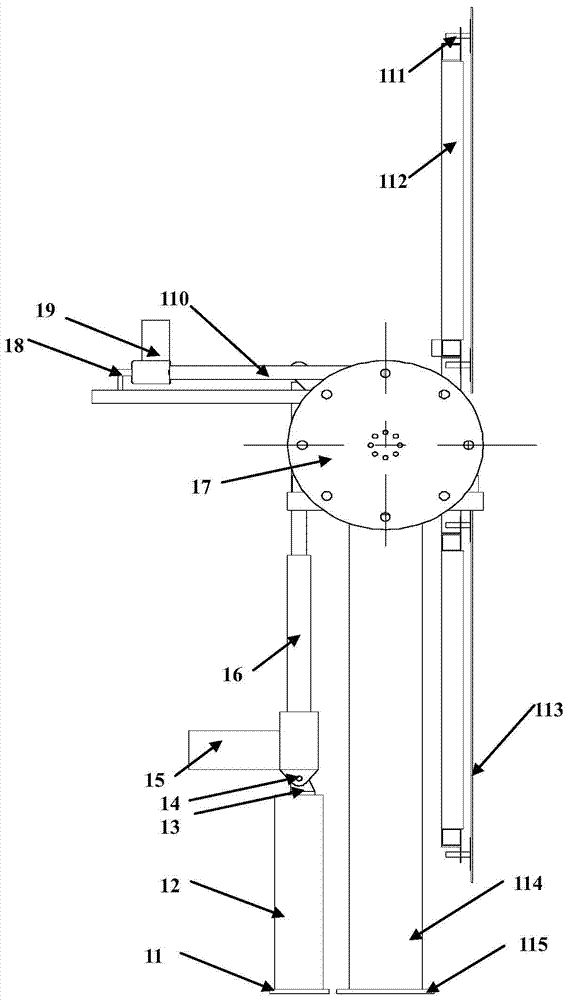

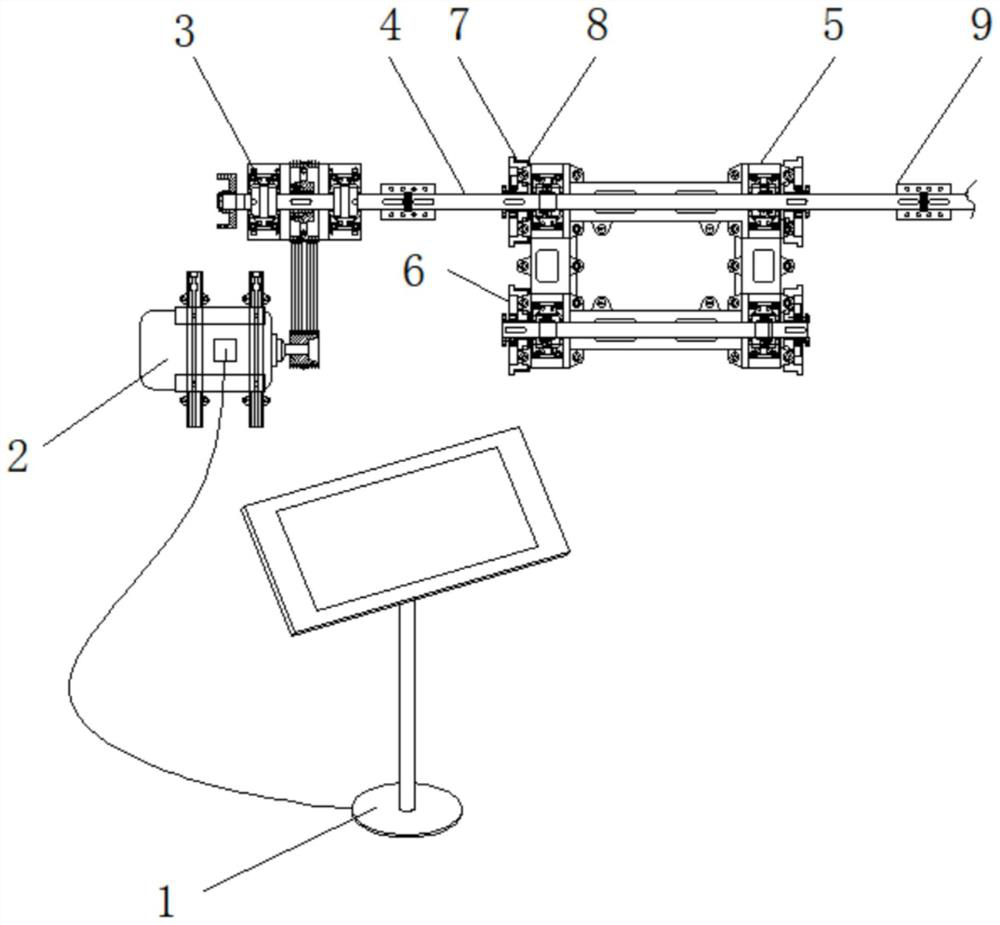

Large-amplitude free vibration wind tunnel test device with three degrees of freedom

ActiveCN108225715ANo lateral tiltAvoid geometric nonlinearityAerodynamic testingVibration testingThree degrees of freedomEngineering

The invention provides a large-amplitude free vibration wind tunnel test device with three degrees of freedom, and belongs to the technical field of wind tunnel test devices for bridges. The large-amplitude free vibration wind tunnel test device which is a large-amplitude free vibration wind tunnel test device with three degrees of freedom coupling for bridges comprises a rigid test model, a rigidround bar, a rigid suspension arm, arc blocks with grooves, light high-strength strings, linear extension springs, fixed pulleys and a bearing. The large-amplitude free vibration wind tunnel test device has the advantages that the problem of incapability of guaranteeing the linear vertical rigidity, the linear torsional rigidity and the linear lateral rigidity due to down warping of lateral springs horizontally arranged in the traditional vibration test device with three degrees of freedom and lateral tilting of vertical springs under large-amplitude conditions can be effectively solved by the aid of the large-amplitude free vibration wind tunnel test device; the large-amplitude free vibration wind tunnel test device is simple and is convenient to mount, initial attack angles are easy toadjust, down warping and tilting of the springs are prevented in vibration procedures, accordingly, the linear rigidity and stable vibration frequencies of systems still can be guaranteed even in large-amplitude vibration procedures, and research on the three-dimensional nonlinear pneumatic characteristics of the bridges becomes possible under large-amplitude conditions.

Owner:DALIAN UNIV OF TECH

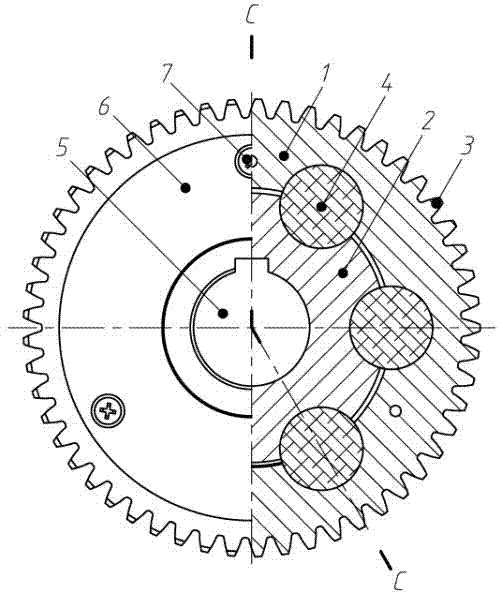

Rigid-flexible composite filtering gear

InactiveCN104500693AGuaranteed transmission accuracyGuaranteed torsional rigidityPortable liftingToothed gearingsElastomerGear wheel

Owner:CHONGQING UNIV

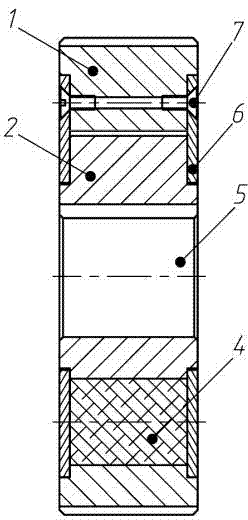

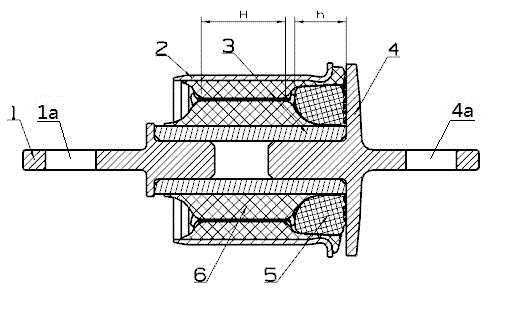

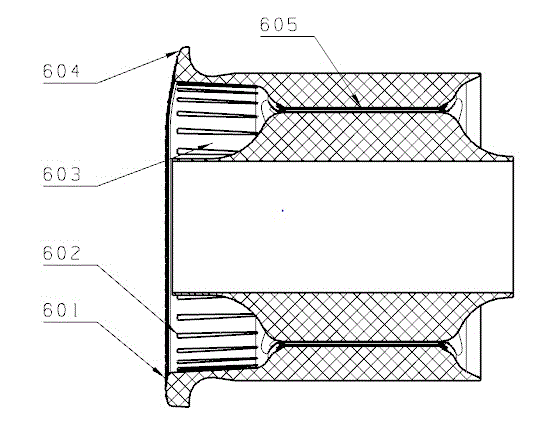

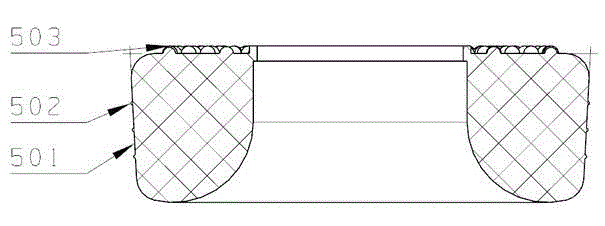

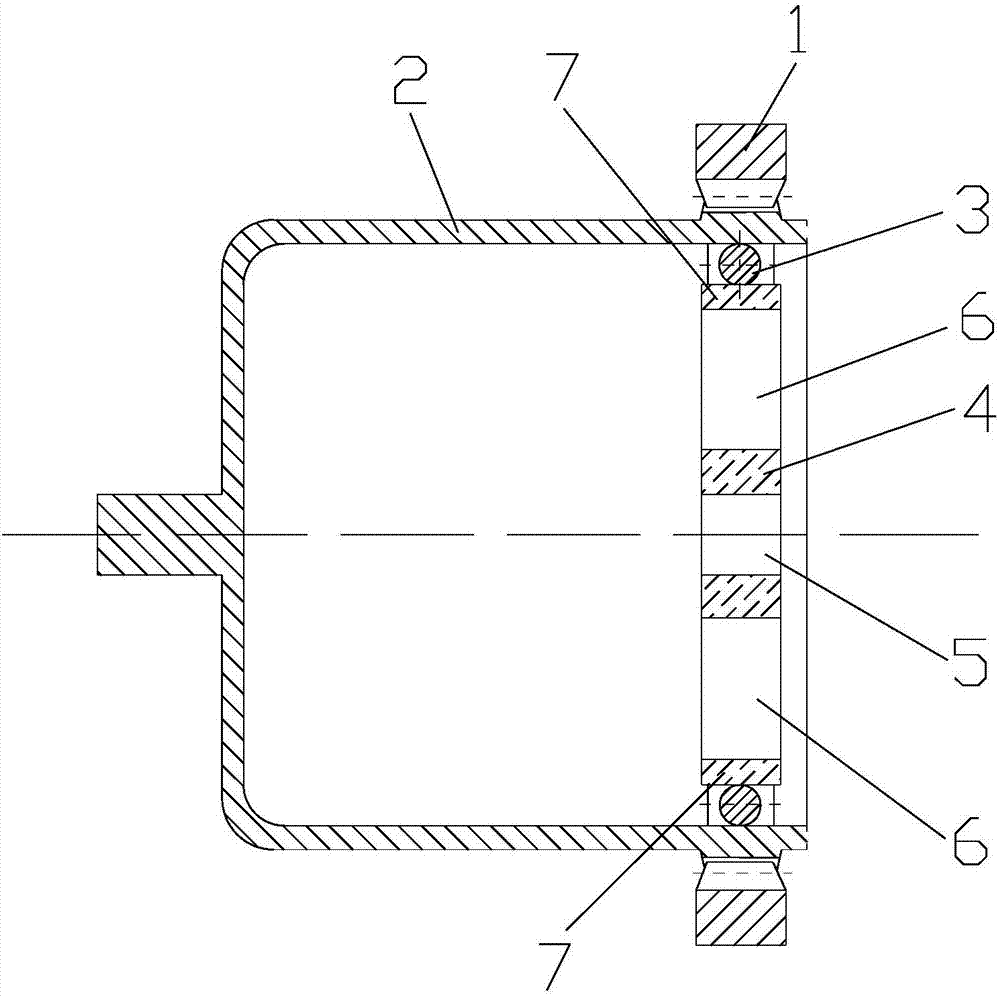

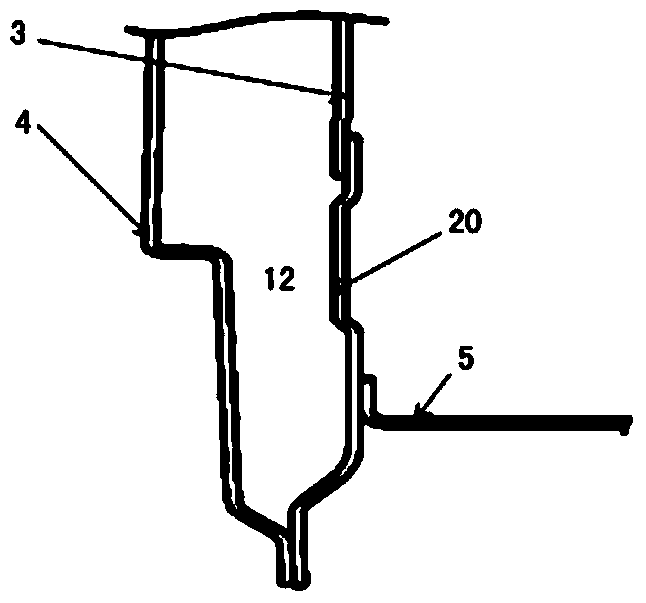

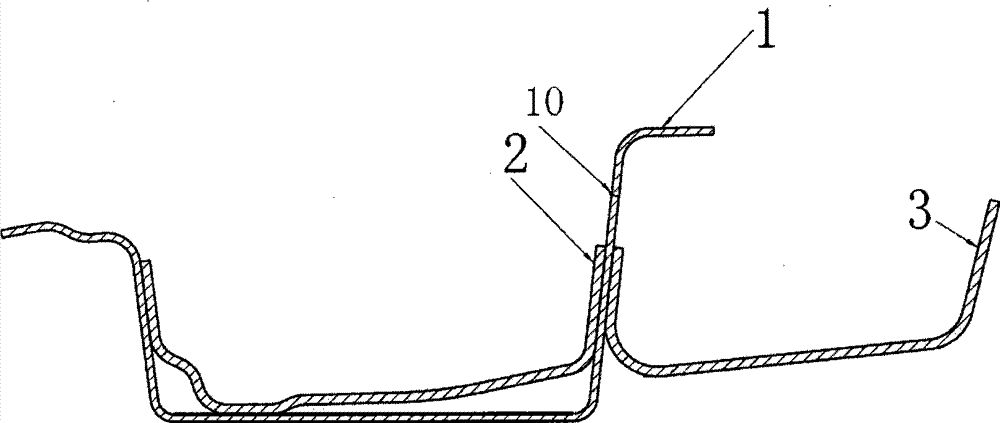

Torsion beam rear suspension frame lining assembly

InactiveCN104309440AGuaranteed torsional rigidityIncrease yaw stiffnessInterconnection systemsRubber-like material springsReinforced rubberEngineering

The invention discloses a torsion beam rear suspension frame lining assembly. The torsion beam rear suspension frame lining assembly comprises an inner sleeve, an outer sleeve, a rubber lining, a lining bracket I, a lining bracket II and inner reinforcing rubber, wherein the inner sleeve and the outer sleeve are arranged between the lining bracket I and the lining bracket II; the rubber lining is vulcanized between the inner sleeve and the outer sleeve; the inner reinforcing rubber is arranged between the lining bracket II and the rubber lining. The inner reinforcing rubber is additionally arranged on a rubber lining assembly of a vehicle torsion beam rear suspension frame, the defect of low deflection stiffness of an ordinary lining under the condition that the torsion stiffness is met can be solved; the best torsion stiffness and the deflection stiffness can be obtained by adjusting the height h of the inner reinforcing rubber and the working height H of the rubber lining.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

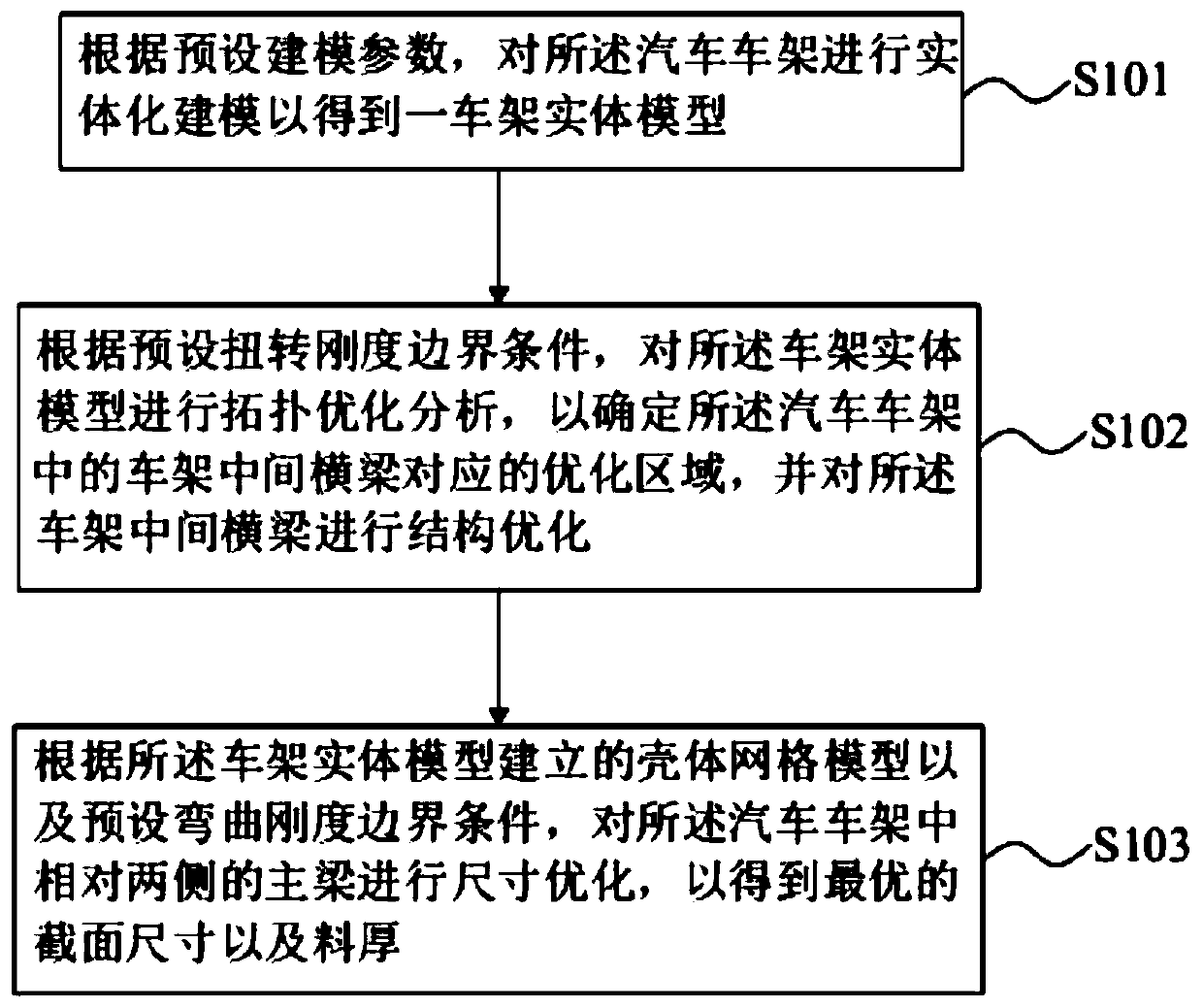

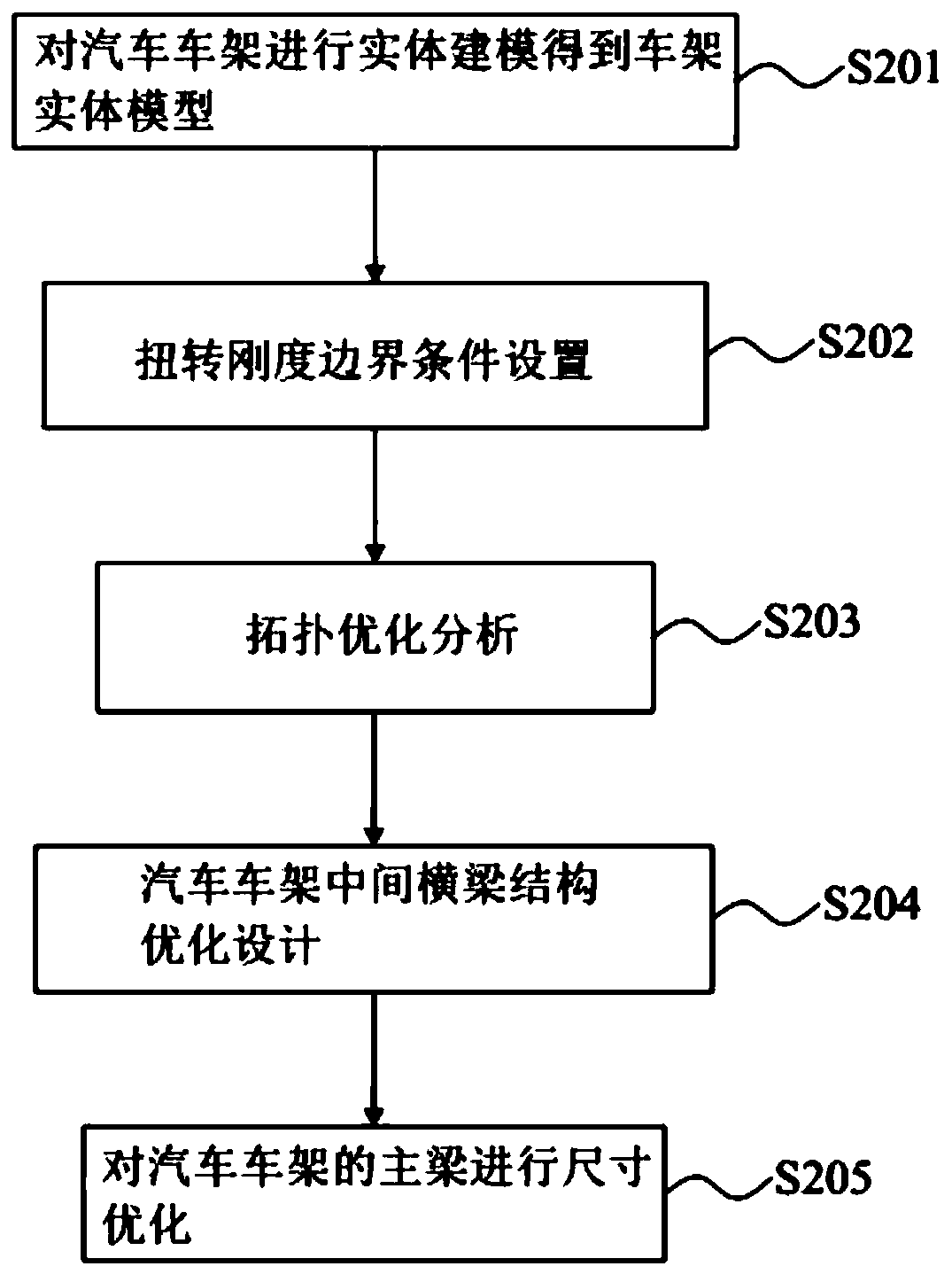

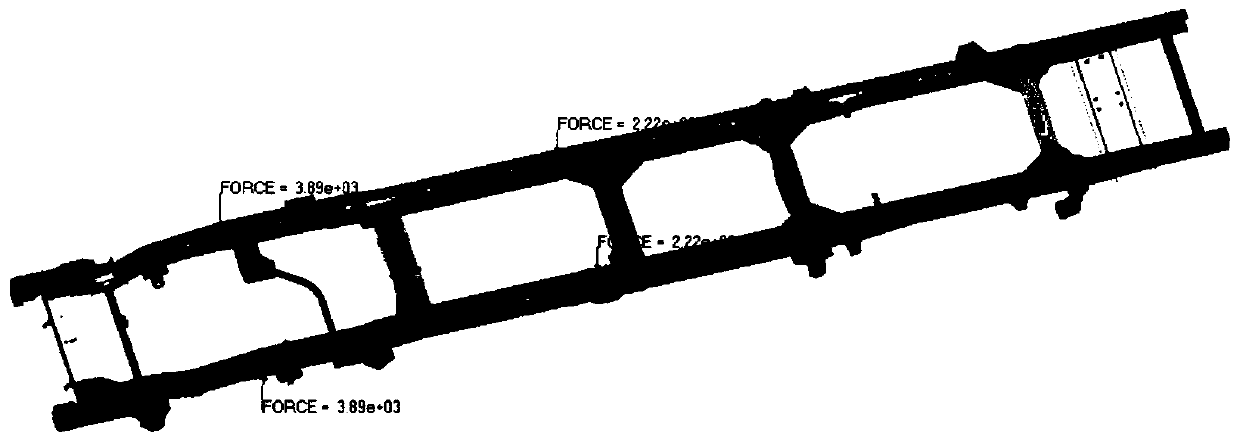

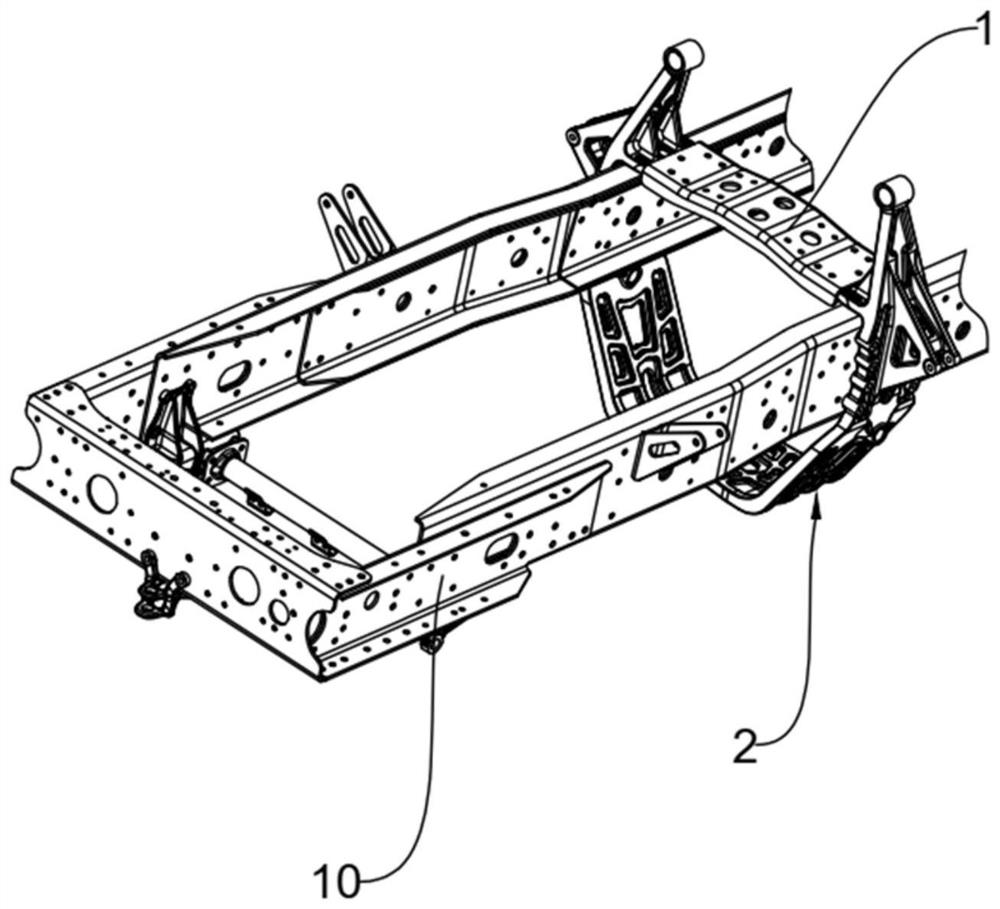

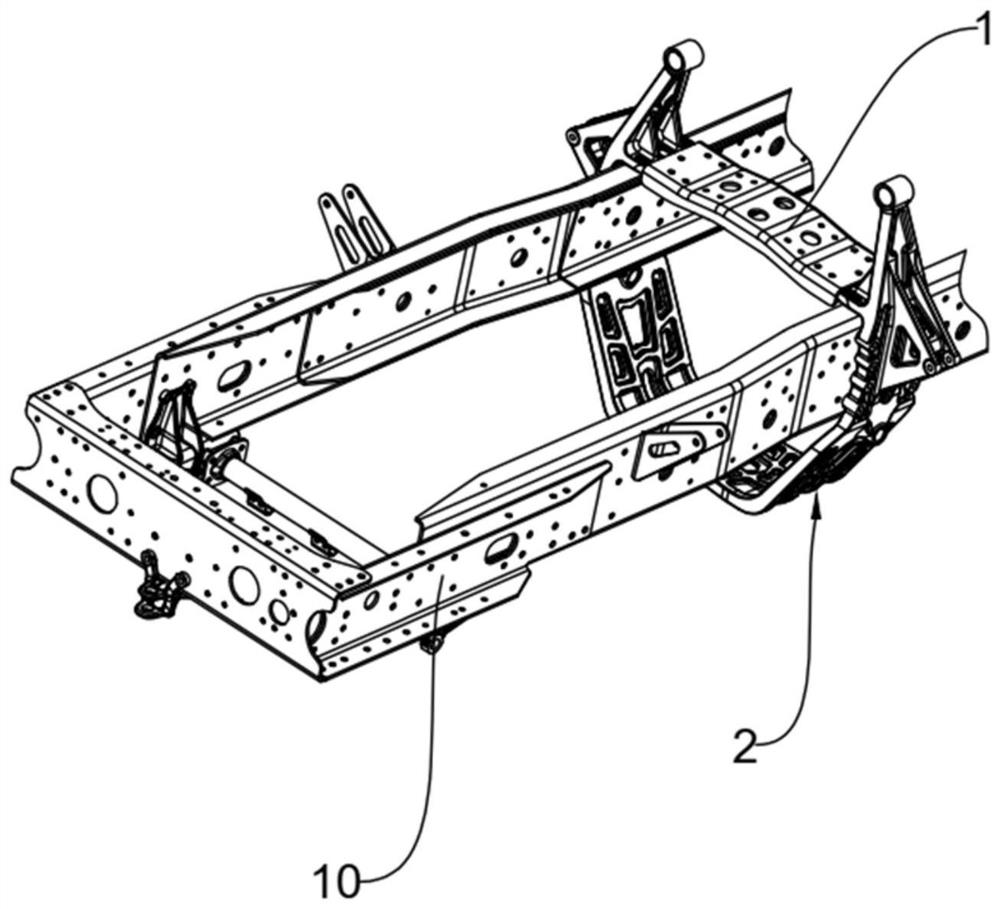

Lightweight optimization method for automobile frame

ActiveCN109829257AGuaranteed torsional rigidityReduce weightSpecial data processing applicationsVehicle frameTopology optimization

The invention relates to an automobile frame lightweight optimization method which comprises the following steps: according to preset modeling parameters, carrying out entity modeling on an automobileframe to obtain a frame entity model; Carrying out topological optimization analysis on the frame solid model according to a preset torsional rigidity boundary condition so as to determine an optimization area corresponding to a frame middle cross beam in the automobile frame, and carrying out structure optimization on the frame middle cross beam; And according to a shell grid model established by the frame entity model and a preset bending boundary condition, carrying out size optimization on girders on two opposite sides in the automobile frame to obtain an optimal section size and an optimal material thickness. According to the automobile frame lightweight optimization method provided by the invention, the overall torsional rigidity and bending rigidity of the automobile frame can be ensured, and the product quality is further improved.

Owner:JIANGLING MOTORS

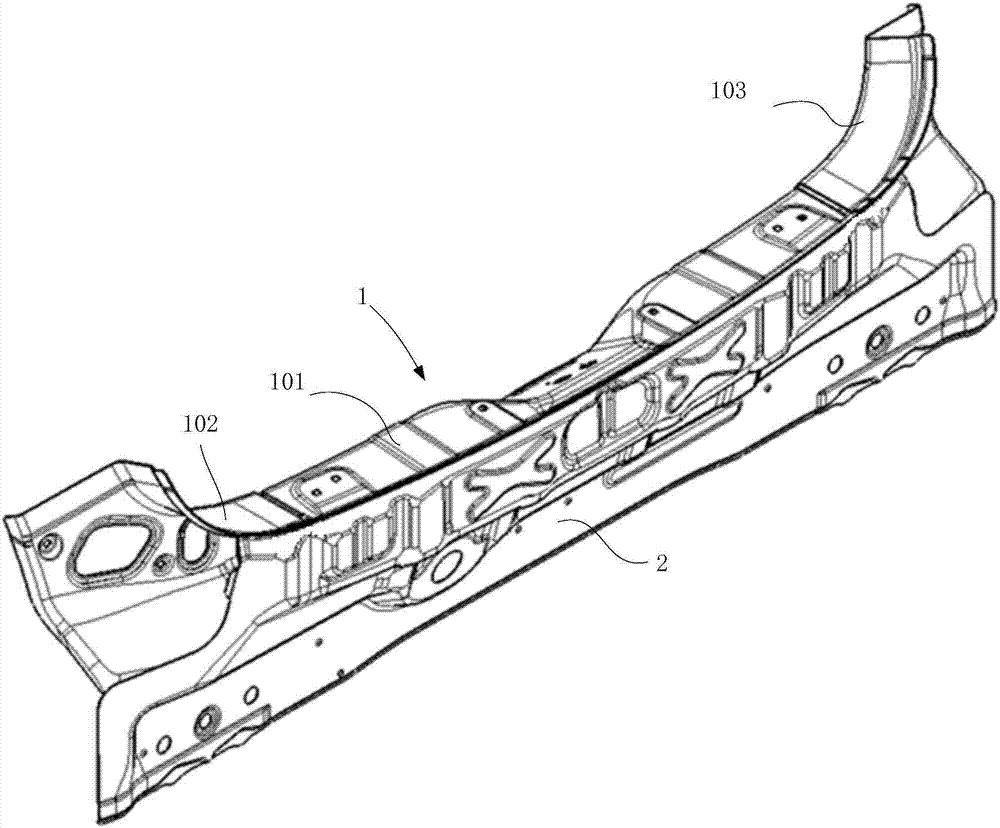

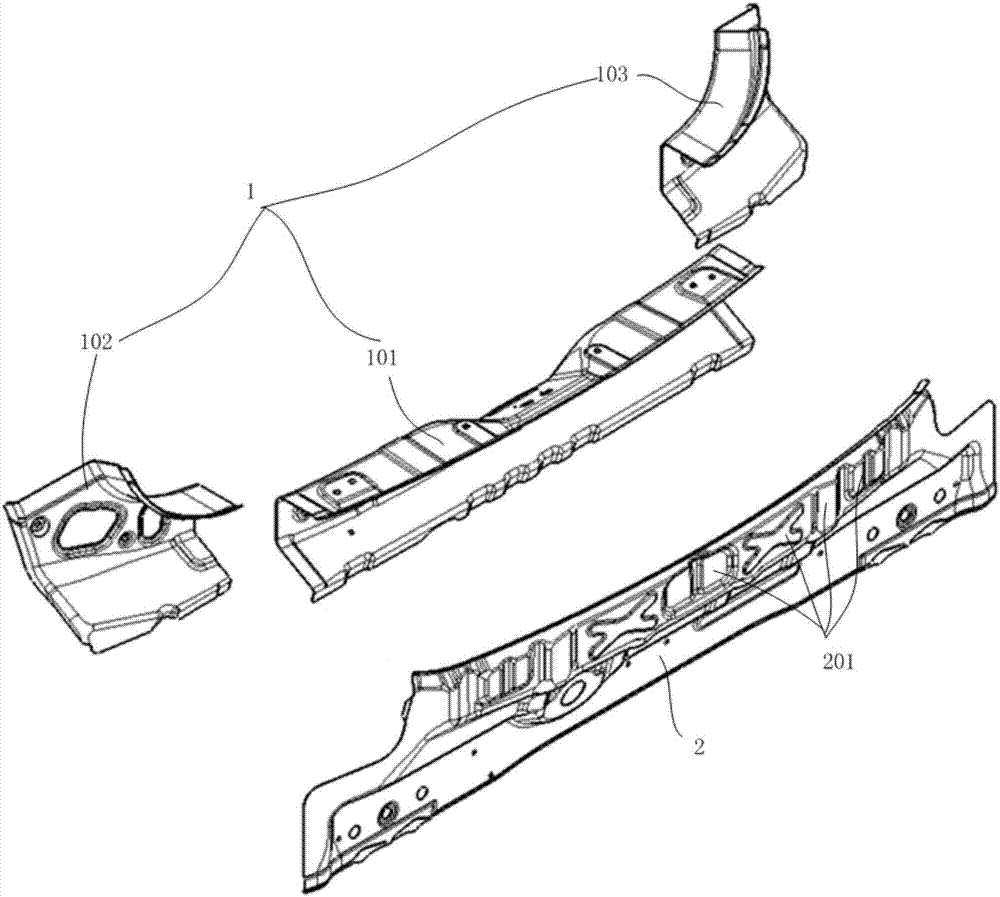

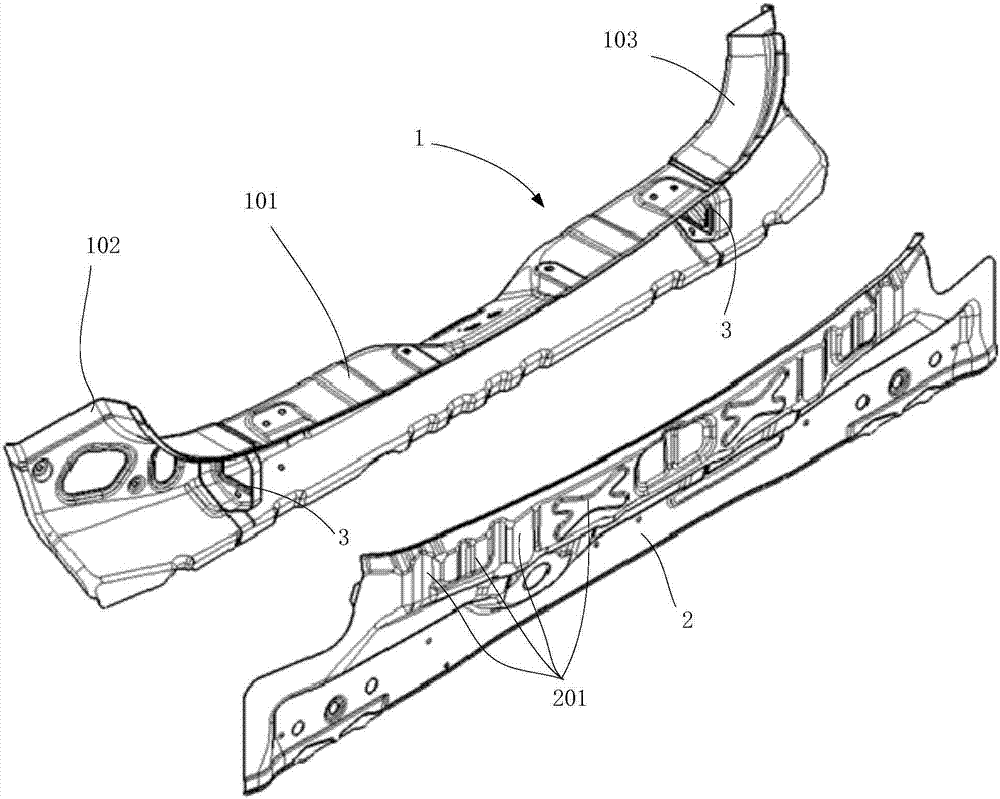

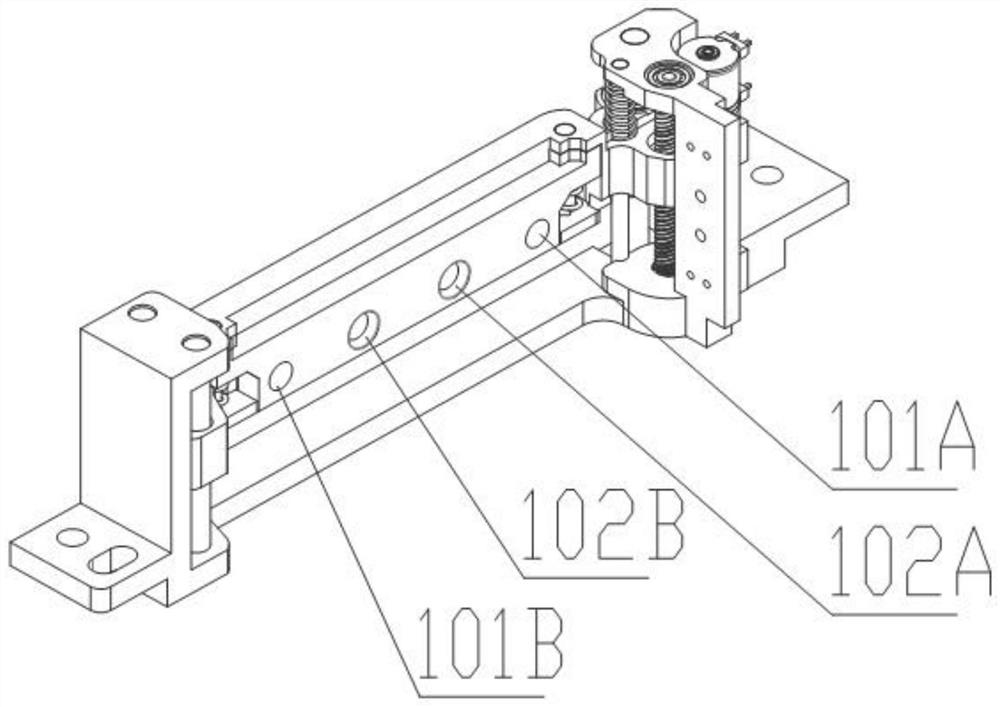

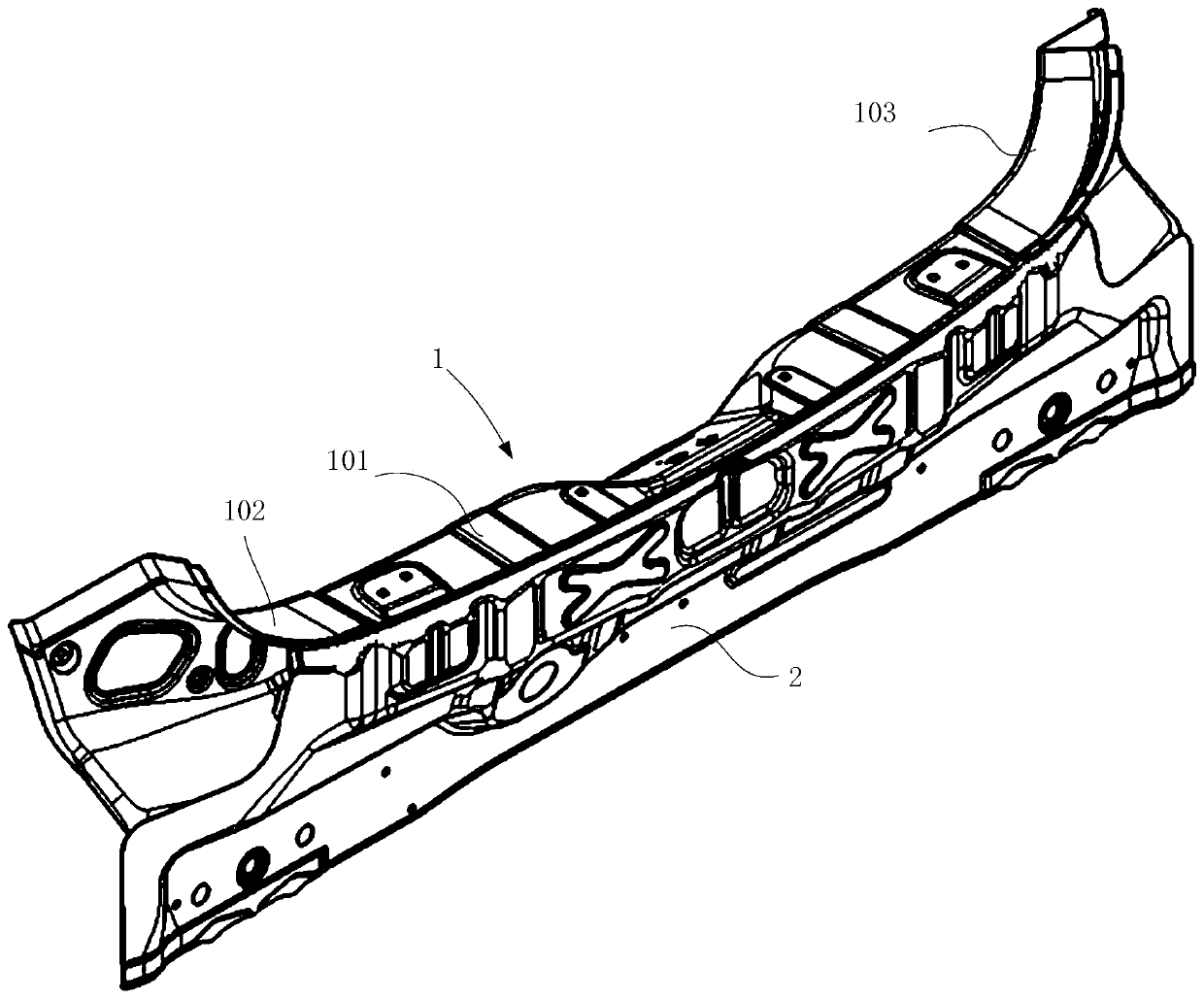

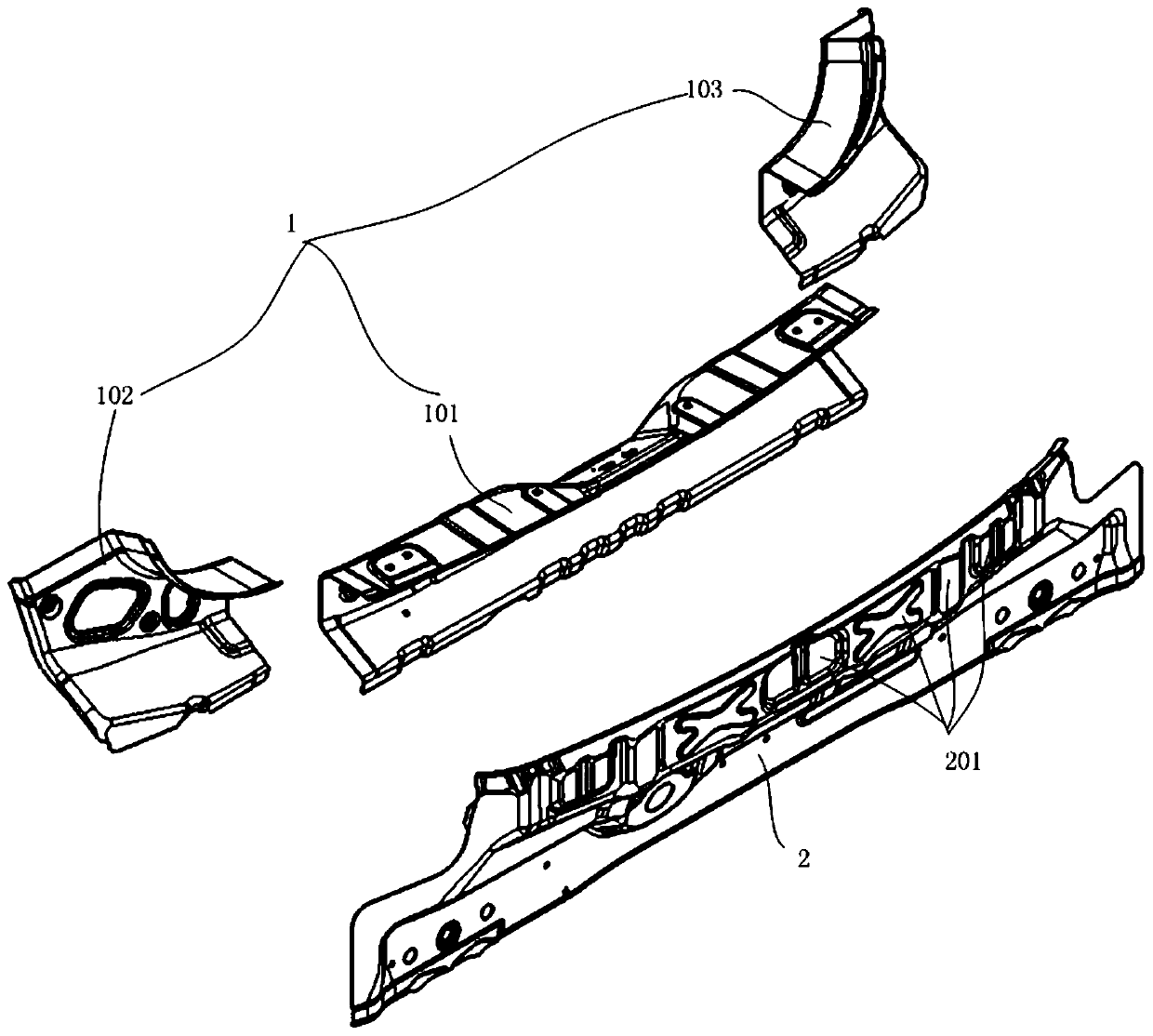

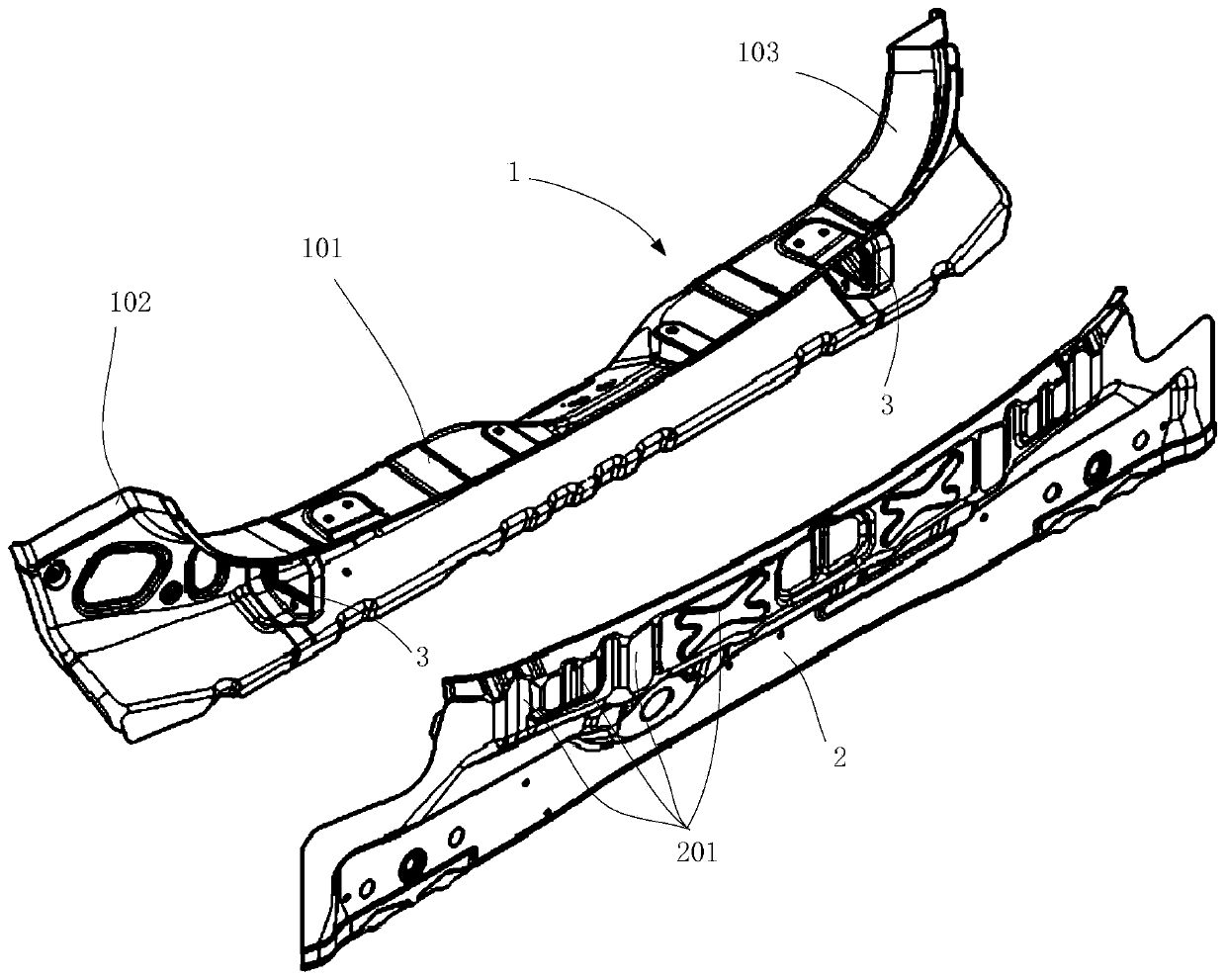

Automobile rear wall assembly

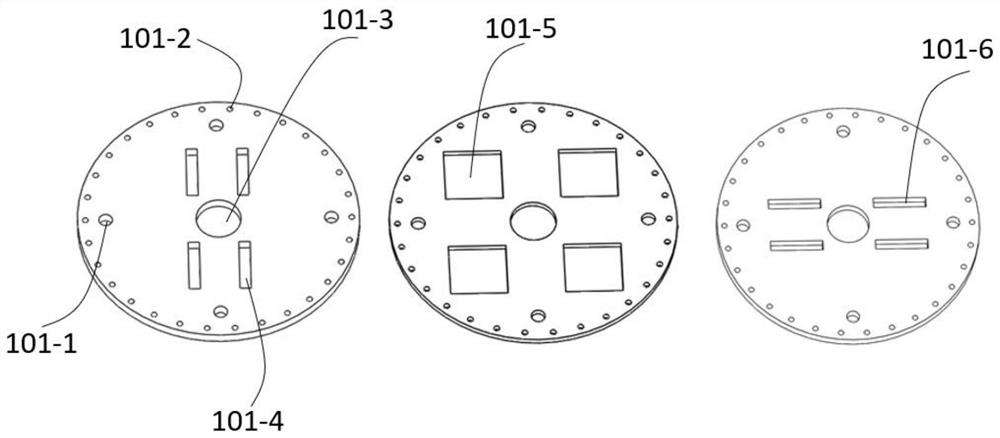

ActiveCN107187504AExtended service lifeReduce weightSuperstructure subunitsTorsional rigidityAutomotive engineering

The invention discloses an automobile rear wall assembly. The automobile rear wall assembly comprises a rear wall inner panel assembly (1); the rear wall inner panel assembly (1) comprises a rear wall inner panel (101), a first rear wall connecting plate (102), a second rear wall connecting plate (103) and a rear wall outer panel (2), wherein the first rear wall connecting plate (102) is connected with a first end of the rear wall inner panel (101), and the second rear wall connecting plate (103) is connected with a second end of the rear wall inner panel (101); and the rear wall inner panel (101), the first rear wall connecting plate (102), the second rear wall connecting plate (103) and the rear wall outer panel (2) enclose a three-dimensional cavity structure. Compared with the existing automobile rear wall with a plate-shaped structure, the automobile rear wall assembly has the advantages that the automobile rear wall assembly is the three-dimensional cavity structure enclosed by the rear wall inner panel assembly and the rear wall outer panel; the torsional rigidity of the automobile rear wall assembly is greatly improved so that the torsional rigidity of an automobile framework is improved, the automobile performance is improved and the service life of the automobile is prolonged. The rear wall inner panel assembly adopts a separated design so that the rear wall inner panel assembly is convenient to manufacture.

Owner:CHERY AUTOMOBILE CO LTD

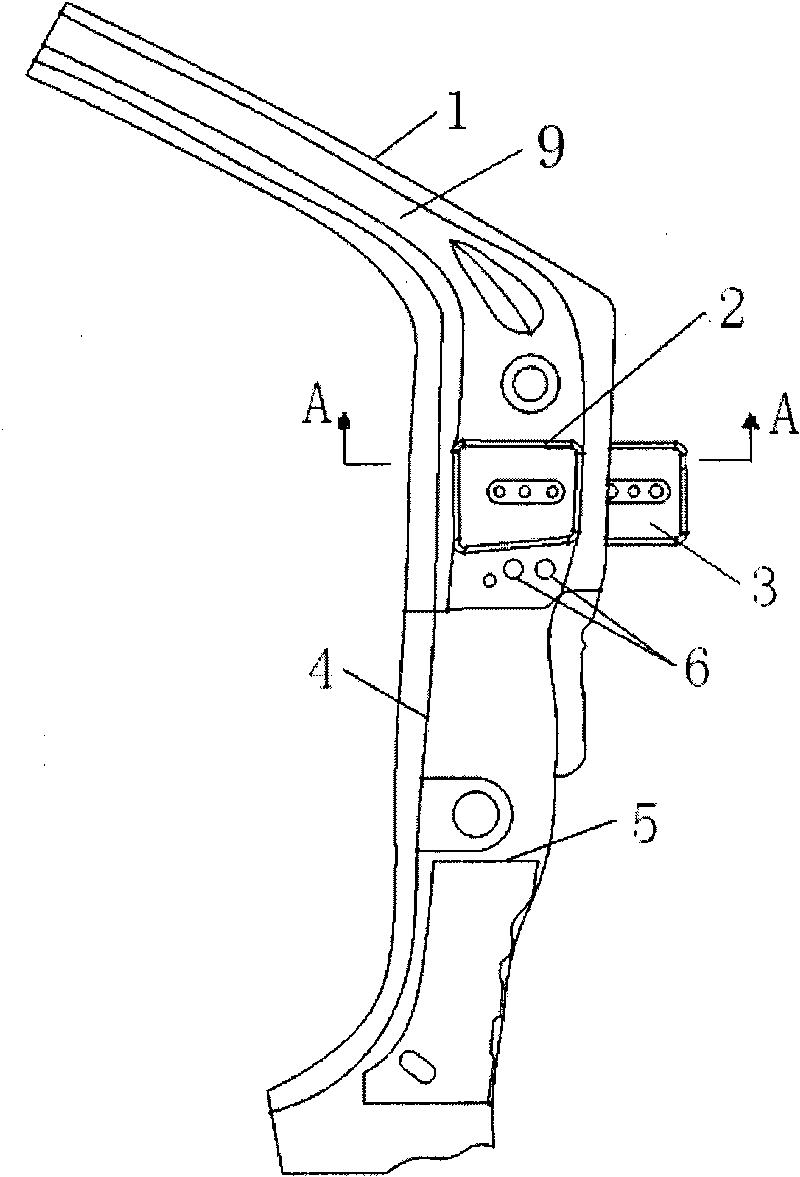

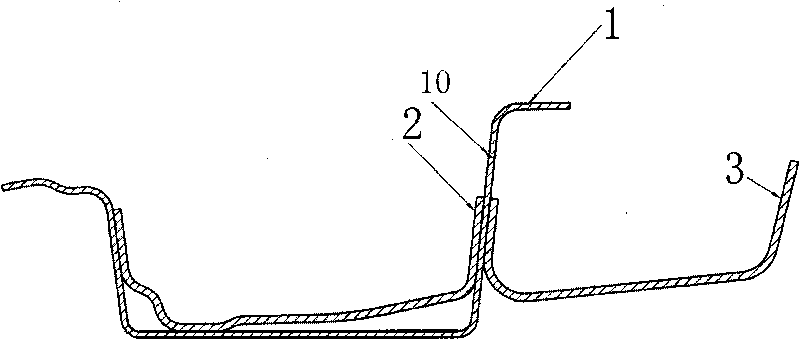

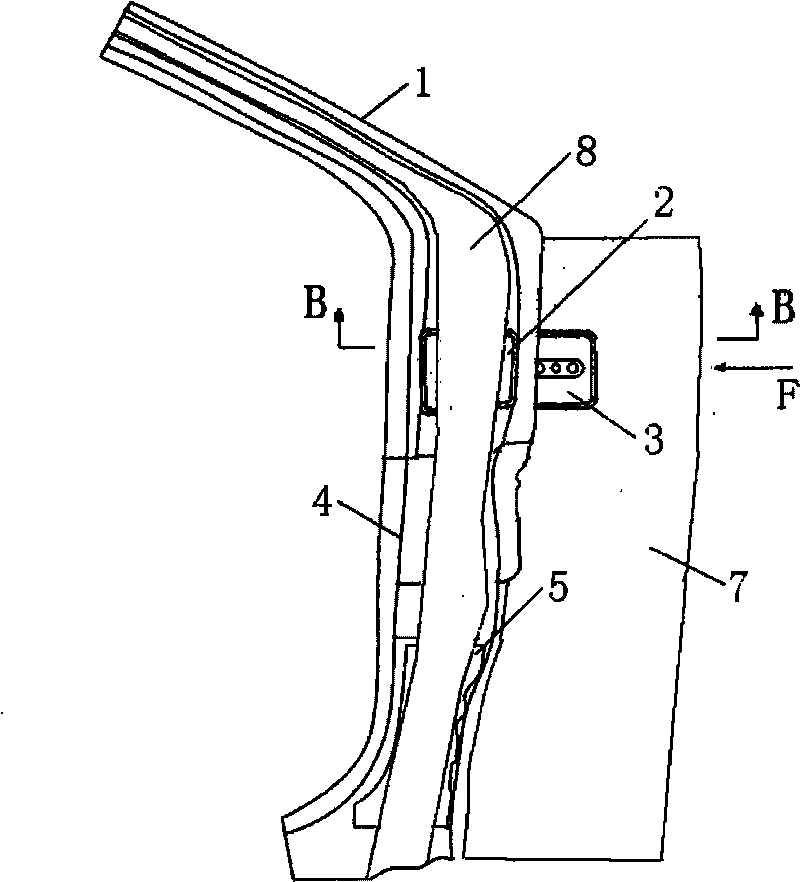

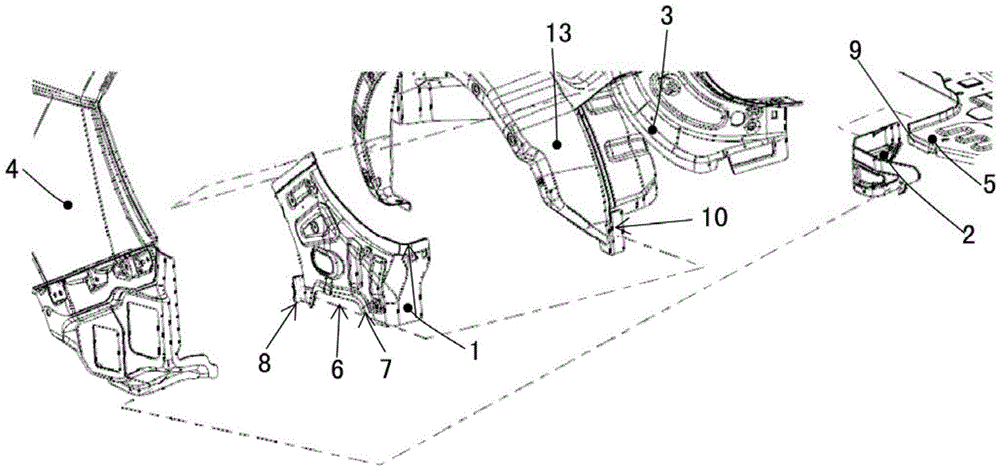

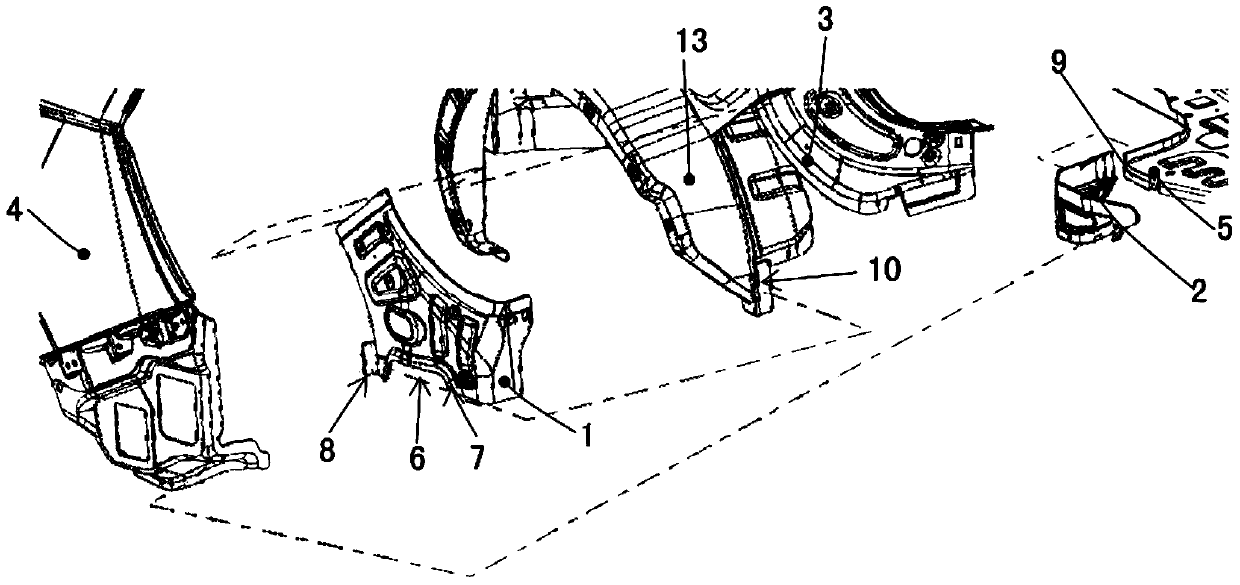

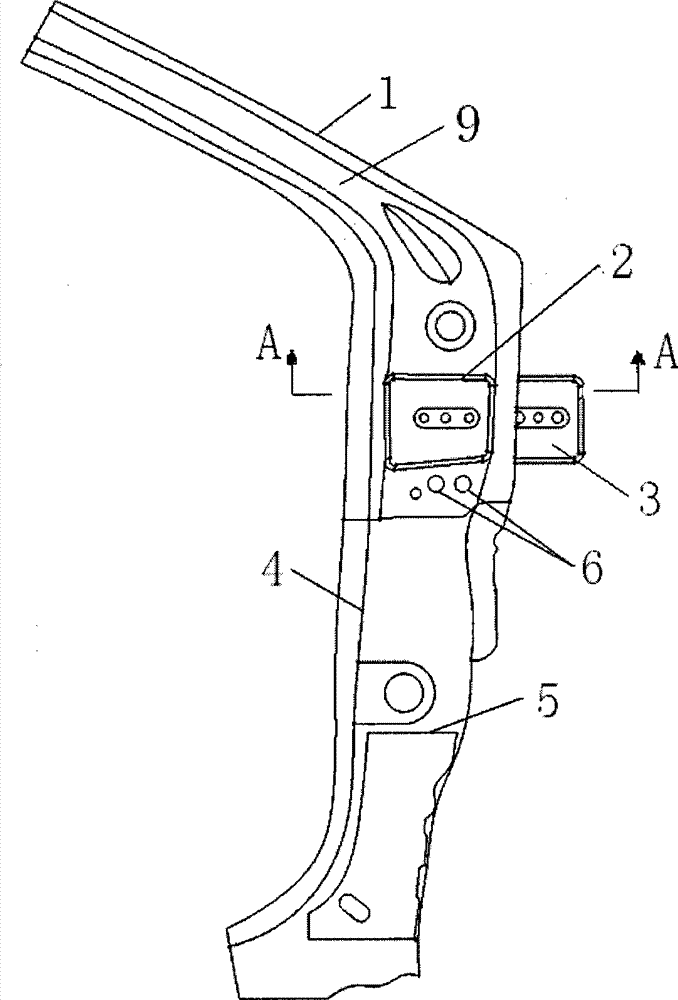

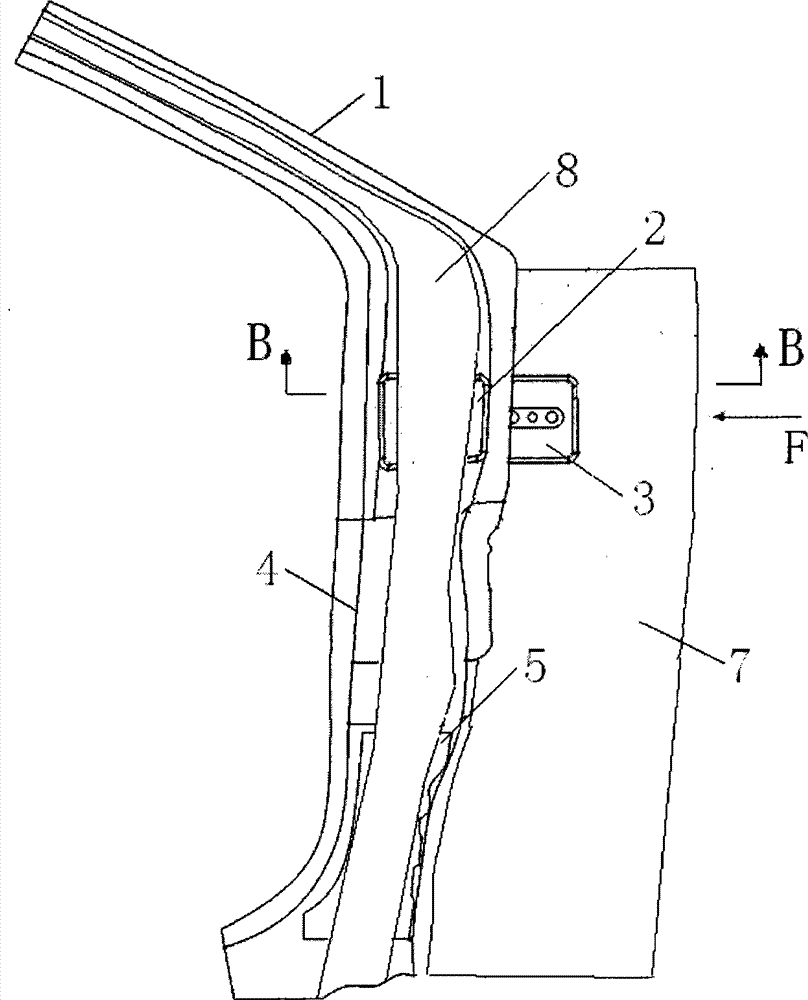

A-column reinforced assembly of car body and A-column reinforced structure of car body using same

ActiveCN101734286AEasy to fabricate and weldLow costSuperstructure subunitsAutomotive engineeringBack support

The invention provides an A-column reinforced assembly of a car body. The A-column reinforced assembly of the car body comprises an A-column reinforced plate; a groove (9) for covering the A-column of the car body is formed on the A-column reinforced plate; the A-column reinforced assembly further comprises an upper part front support plate (3) and a lower part back support plate (2) which are fixed at the two corresponding sides of the front side wall (10) of the groove (9). Furthermore, the invention also provides an A-column reinforced structure of the car body by using the A-column reinforced assembly. The A-column reinforced structure of the car body can remarkably increase the strength of the A-column of the car body without influencing the visual field of a driver.

Owner:BYD CO LTD

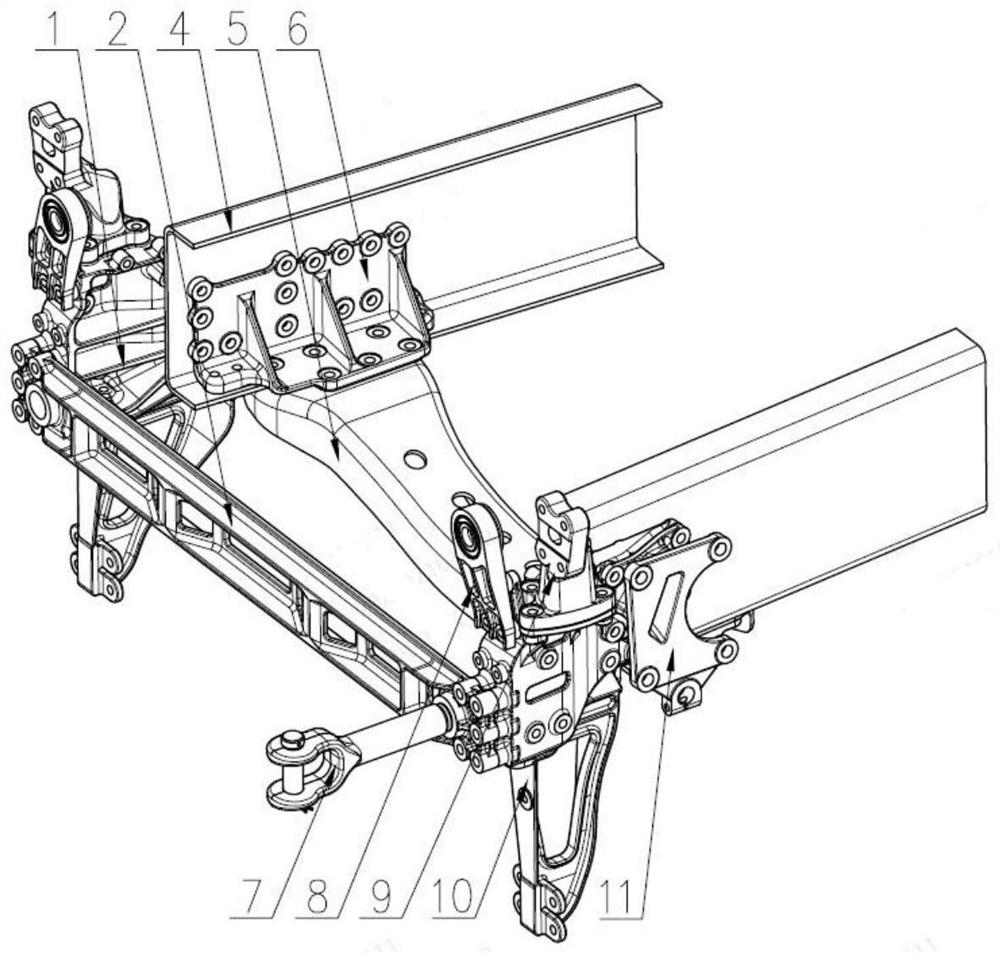

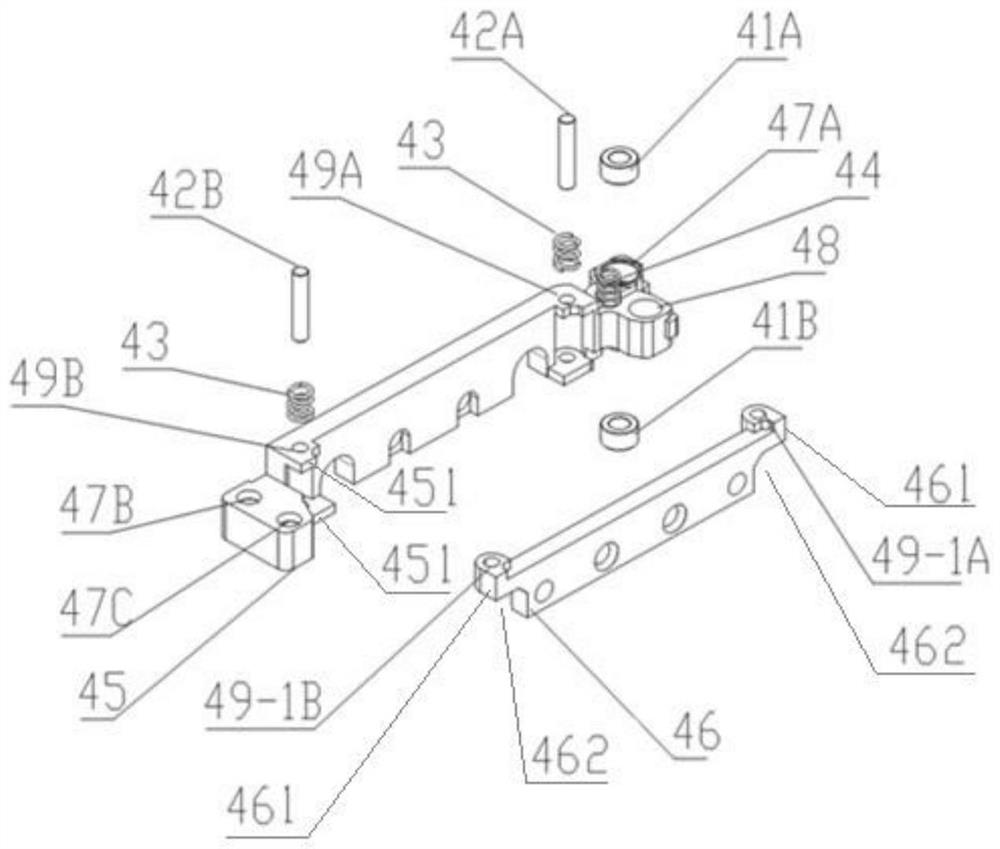

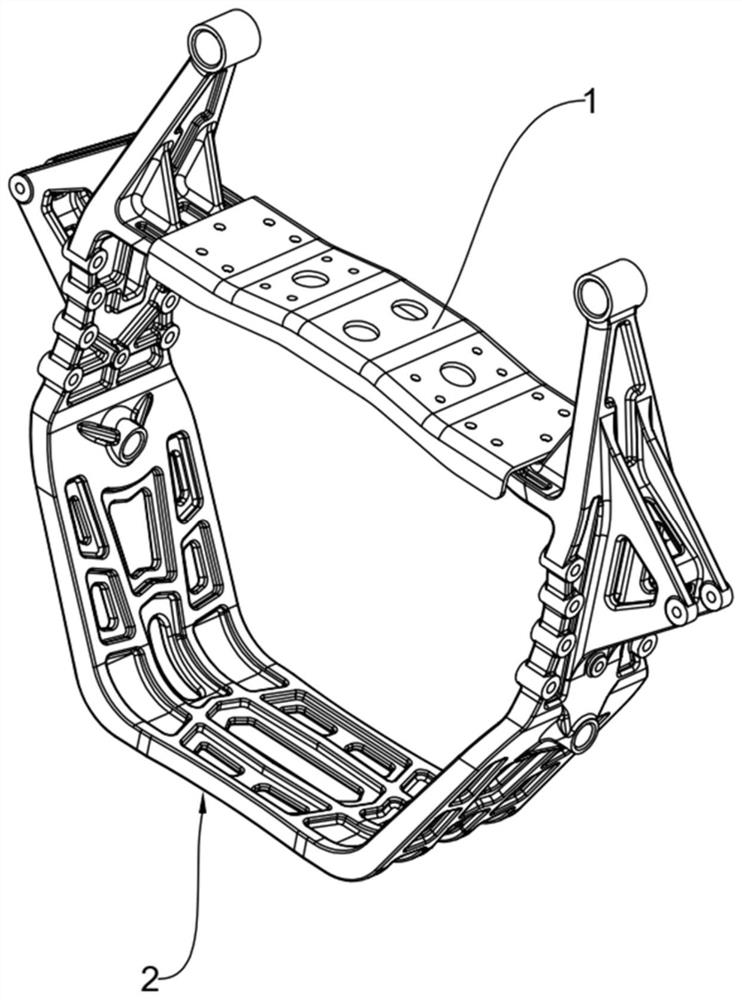

Combined frame front overhang structure

InactiveCN112722079AGuaranteed StrengthGuaranteed torsional rigidityUnderstructuresVehicle frameClassical mechanics

The invention provides a combined frame front overhang structure. The combined frame front overhang structure comprises a front cross beam, a front overhang combined support, an inner reinforcing support, a rear camber beam, a plate spring support and other parts. The technical scheme has the advantages that the front cross beam, the front overhang combined support, the inner reinforcing support, the rear camber beam, the plate spring support and the frame body are fixedly installed, so that the front end of the frame is of a quadrilateral frame structure, the strength and torsional rigidity of the front end of the frame can be effectively guaranteed, and the problems that the frame cracks and parts are damaged due to excessive torsion of the whole vehicle are solved; according to the front overhang structure scheme, overall modular design is achieved, the multiple module installation structures are integrated to be used for fixedly installing other components, the types of parts can be effectively reduced, the arrangement space of the whole vehicle is saved, and the front overhang structure of the whole vehicle is reasonable and compact; all parts of the combined frame front overhang structure are designed in a light weight mode, the strength requirement is met, and meanwhile the weight of the whole vehicle is reduced.

Owner:SINO TRUK JINAN POWER

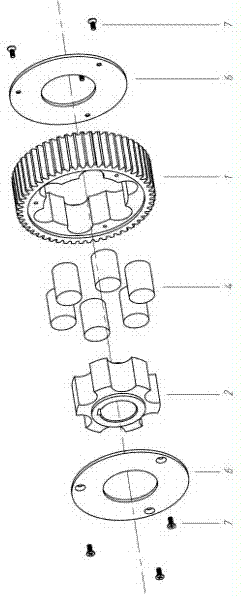

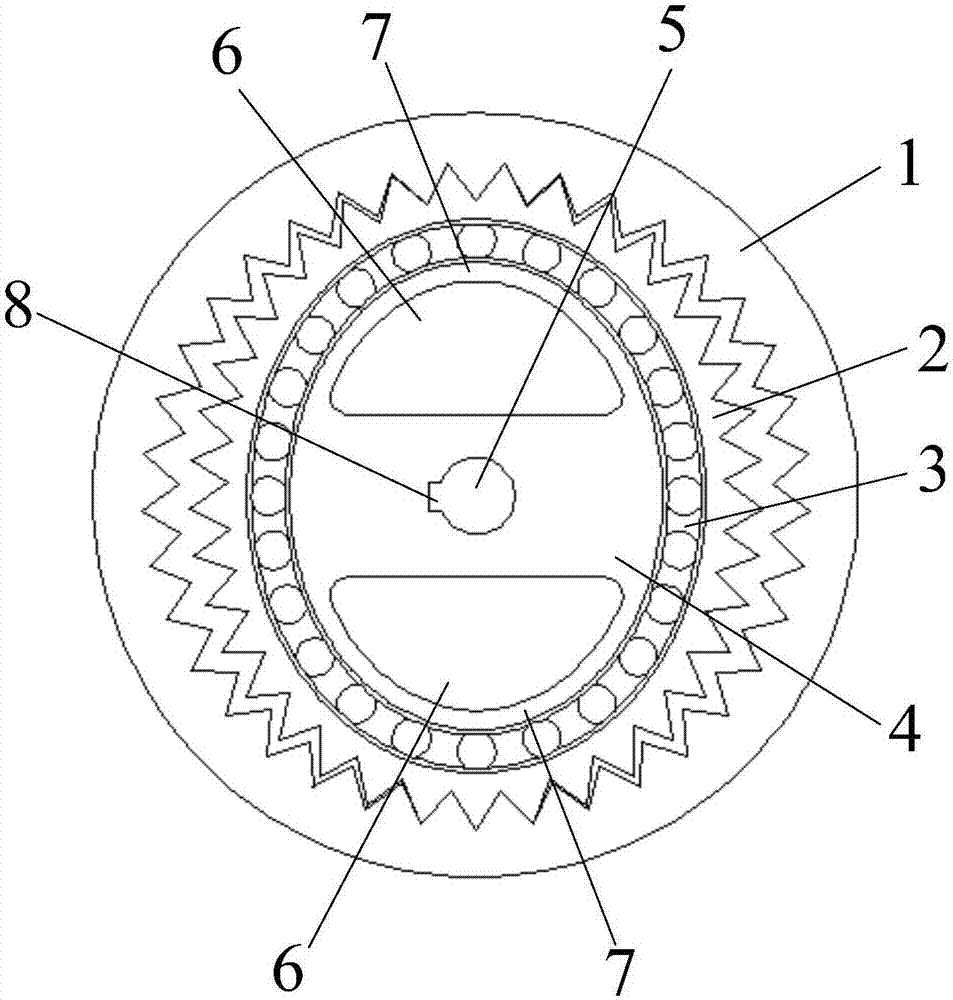

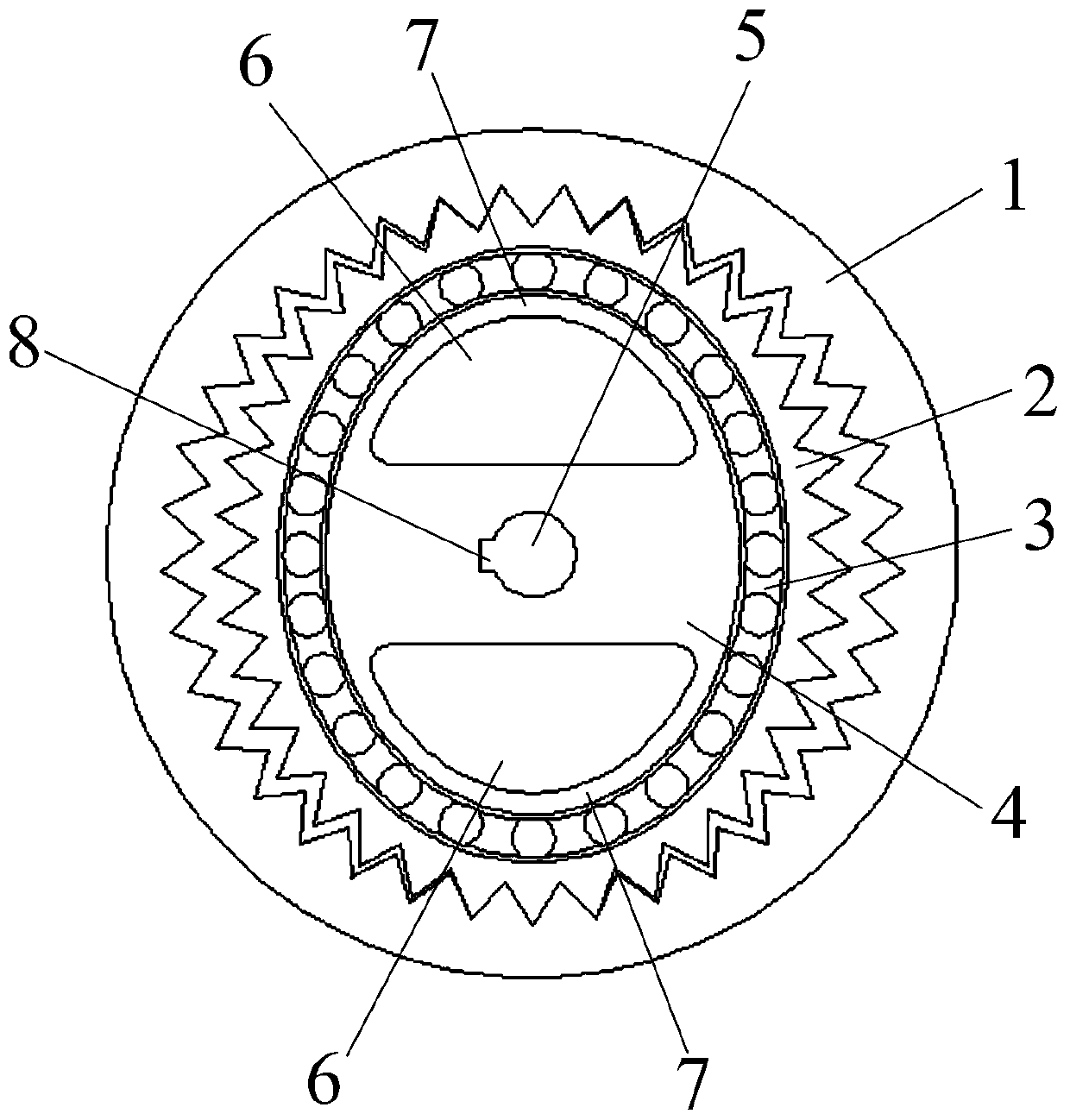

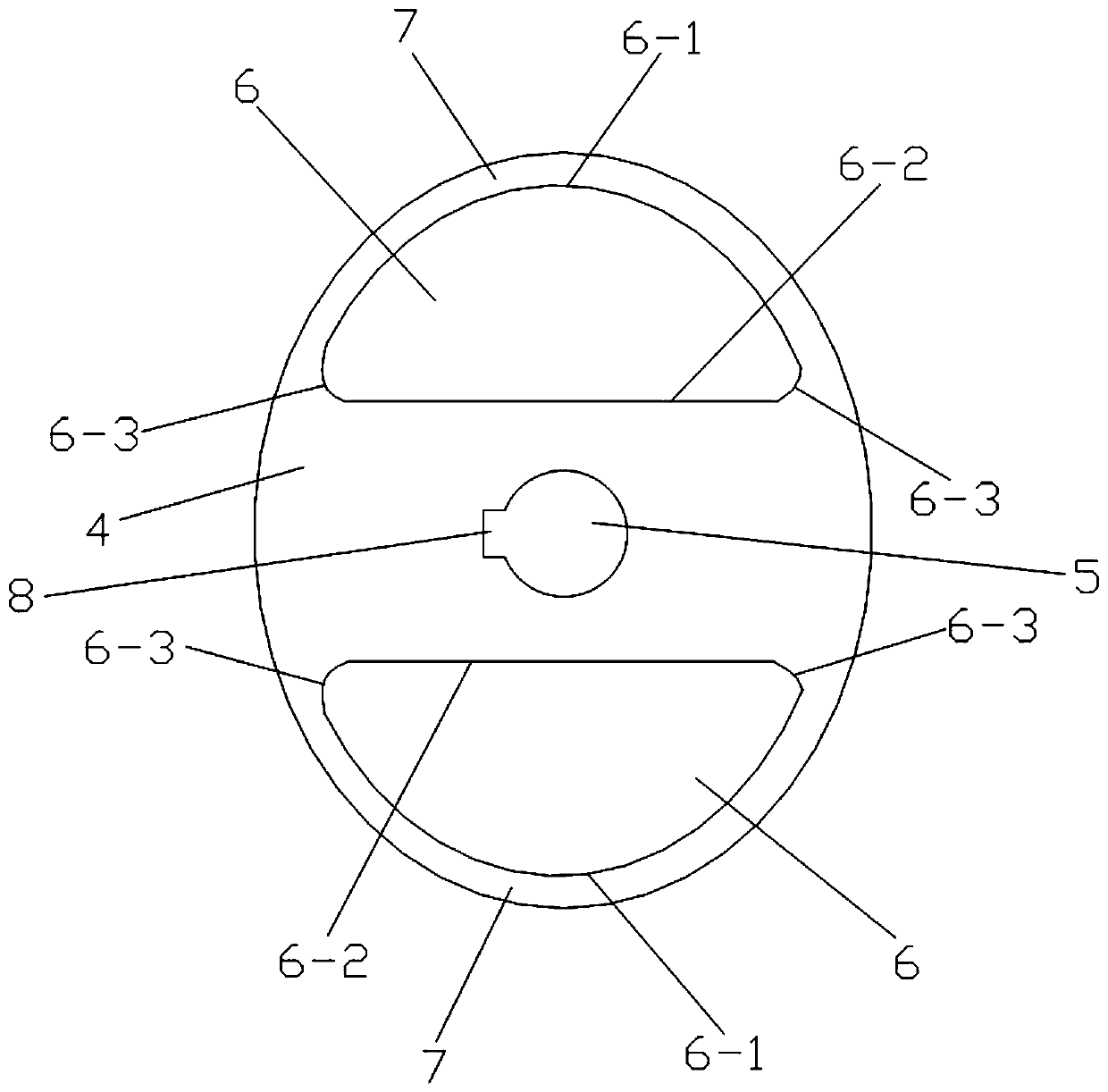

Zero-return-difference harmonic gear transmission device

ActiveCN107100982AContinuous adjustmentMeet the requirements of zero backlash transmissionToothed gearingsHarmonicLong axis

The invention discloses a zero-return-difference harmonic gear transmission device. The zero-return-difference harmonic gear transmission device comprises a rigid gear, a flexible gear and a wave generator; the wave generator is composed of a flexible bearing and an elastic cam; the flexible gear is located in the rigid gear; the upper end and the lower end of the flexible gear mesh with the upper end and the lower end of the rigid gear; the flexible bearing is located between the elastic cam and the flexible gear; the shape of the elastic cam is oval; a shaft hole is formed in the center of the elastic cam; and two structural holes used for forming thin walls of the cam at the two ends in the long axis direction of the elastic cam are formed in the positions, located on the two sides of the shaft hole, in the long axis direction of the elastic cam respectively. The zero-return-difference harmonic gear transmission device is simple in structure, reasonable in design and convenient to implement, backlash in circular teeth can be effectively eliminated, the transmission return difference can be effectively eliminated, in addition, the torsional rigidity can be guaranteed, the service life can be long, the application range can be wide, the practicability can be high, and the popularization and application values can be high.

Owner:王家梁

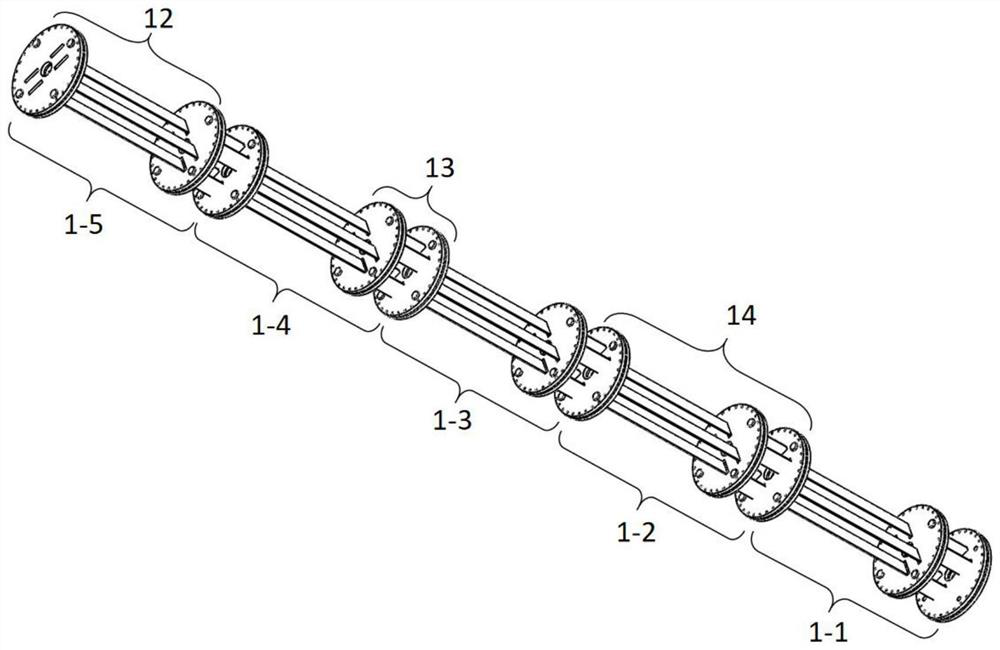

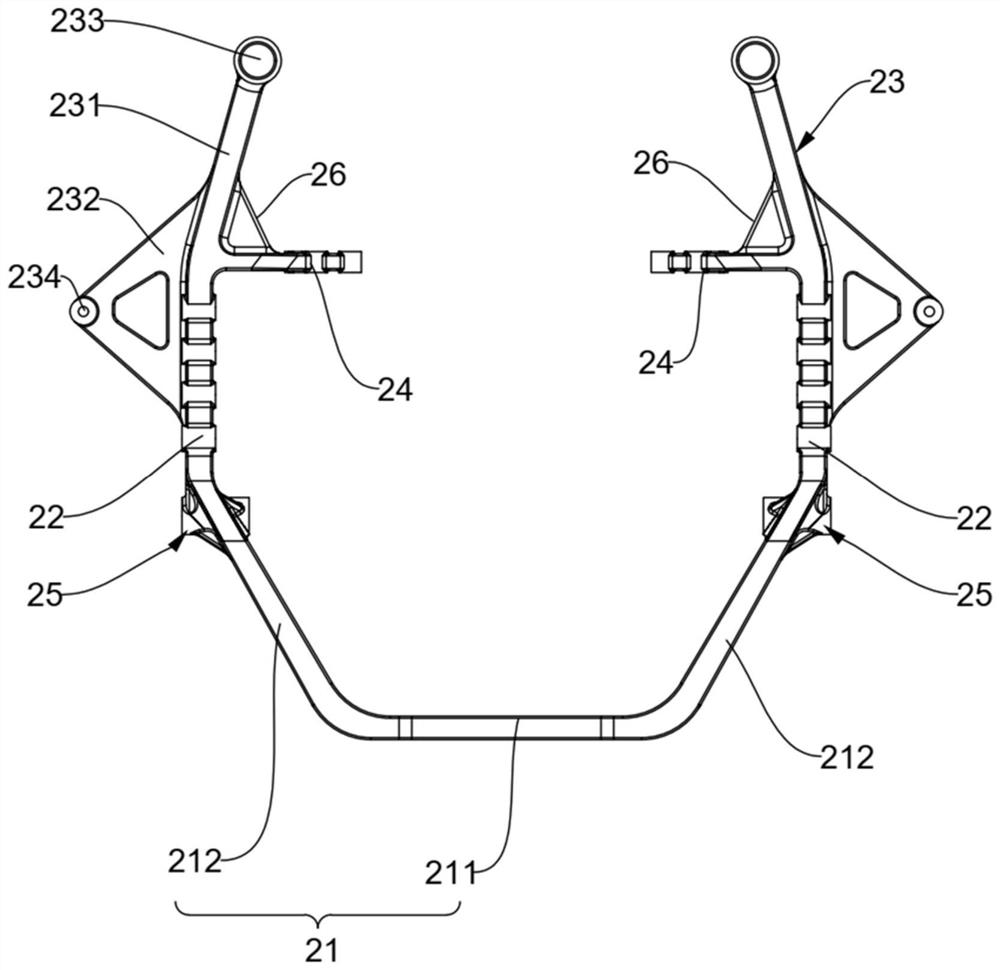

Novel linkage heliostat

ActiveCN104483979ALower the altitudeReduce weightControl using feedbackEngineeringMechanical engineering

The invention discloses a novel linkage heliostat. The novel linkage heliostat is characterized by comprising an elevation angle driving mechanism, wherein the elevation angle driving mechanism drives at least two reflector modules to commonly do elevation angle rotation movement. The novel linkage heliostat employs combined motion setting of the multiple reflector modules, unit reflectors are connected in series through a torque axis to form a reflector module, the multiple reflector modules are connected through flange discs, the multiple reflector modules are driven to simultaneously move by employing the elevation angle driving mechanism, through reducing height of the reflector modules and the reflection area of the reflector modules to reduce wind load, weight of the reflector modules per a reflection area unit is reduced, mounting and debugging difficulty is reduced, relevant cost is reduced, moreover, the novel linkage heliostat can guarantee tracking precision of multiple unit reflectors in the elevation angle direction, so cost of the elevation angle driving mechanism is further reduced.

Owner:STATE GRID CORP OF CHINA +3

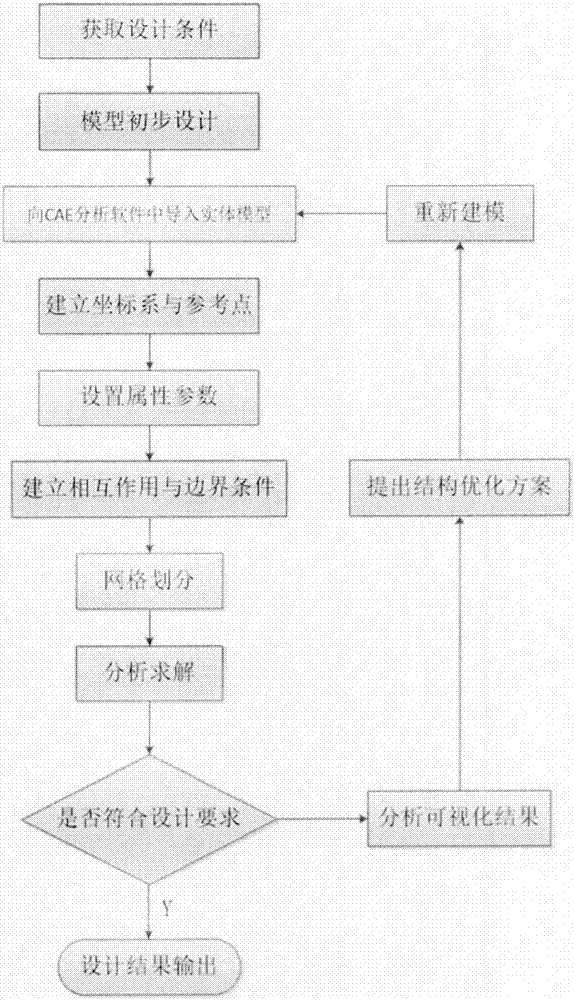

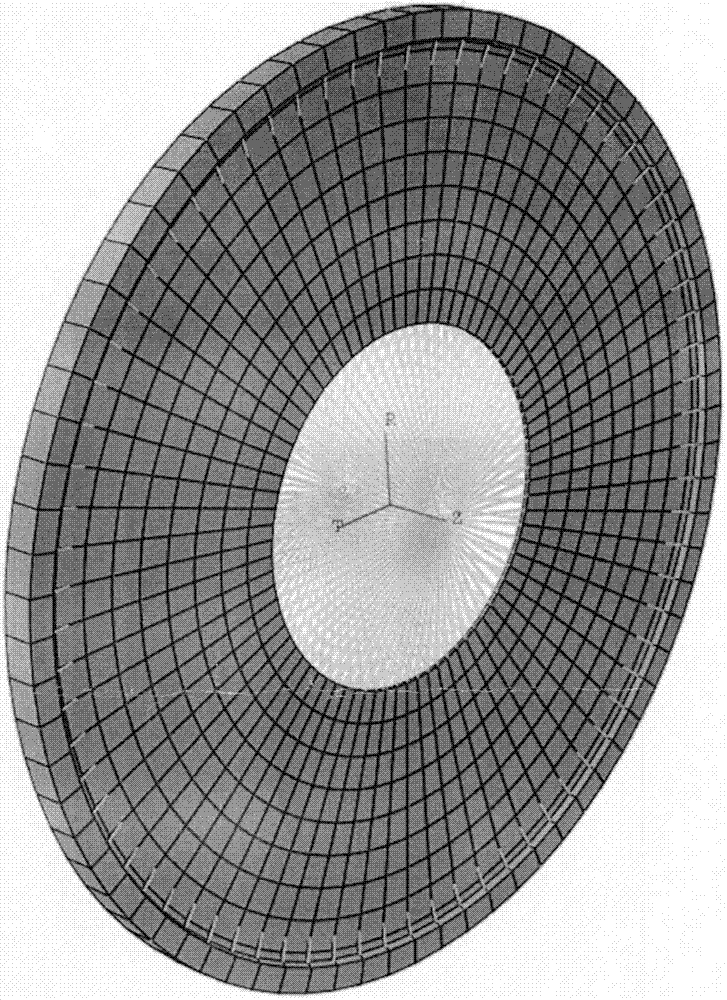

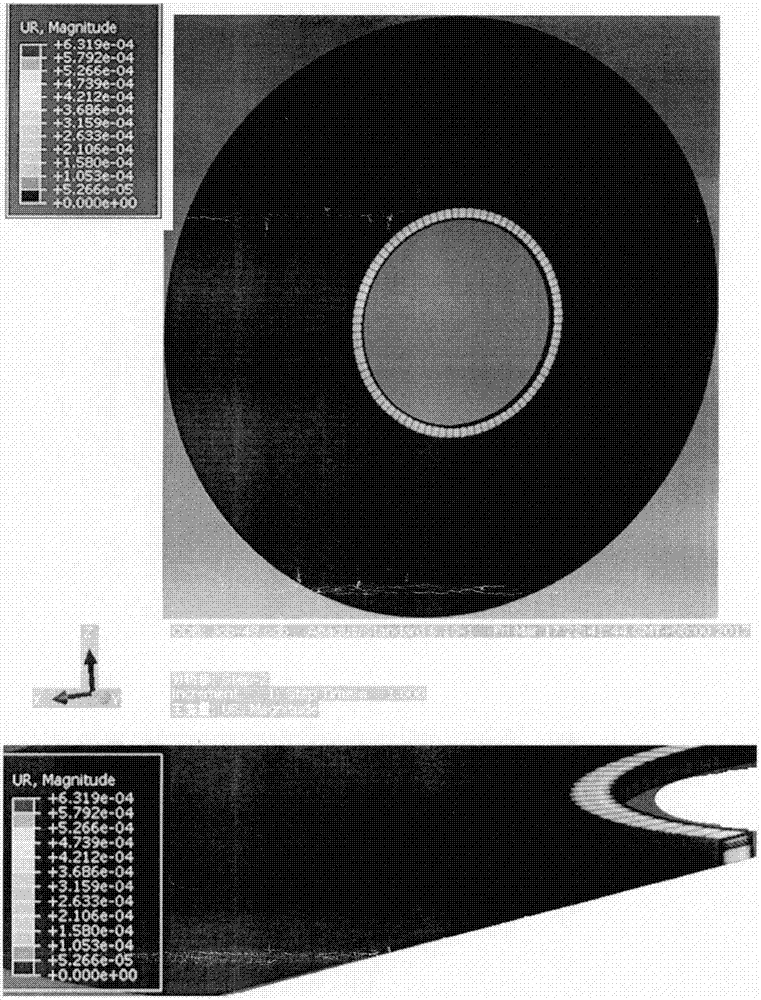

Composite flexible element design method

ActiveCN107977538AGuaranteed StrengthGuaranteed torsional rigidityDesign optimisation/simulationSpecial data processing applicationsOptimal designModeling software

The invention discloses a composite flexible element design method which includes the steps: building a model and storing the model in a general format according to preliminary dimension and lay-up design in modeling software according to technical parameter requirements of a flexible element; leading a solid model into CAE (computer aided engineering) analysis software, building a cylindrical-coordinate system in a model attribute and building a reference point on a rotating axis according to the design content of the preliminary model; setting the attribute, the area and direction parametersof composite layer materials; building coupling constraint and clustering constraint in interaction attributes, and associating the constraint with the built reference point; building condition parameters of applied force and setting boundary conditions; building a hexahedral mesh, inputting living example distribution values and then creating a job file for solution; comparing solved visual results with preliminary design expected results. Design cost can be reduced, design and analysis cycle period is shortened, and an optimal design approach is provided.

Owner:刘长喜

Multi-continuum robot modular unit, continuum robot and application

PendingCN112936336AImprove flexibilityImprove adaptabilityArmsTotal factory controlCompliant mechanismCircular disc

The invention belongs to the technical field of continuum robots, particularly relates to a multi-continuum robot modular unit, a continuum robot and an application, and relates to ten continuum robot modular unit configurations which can be applied to operation tasks such as minimally invasive medical treatment and deep cavity maintenance according to the characteristics of the continuum robot modular units. A spring, a compliant mechanism, a spacing disc, a flexible rod, a flexible sheet, a fastening and locking ring and the like form seven unit configurations, so that the modularized variable stiffness characteristic of the continuum robot can be realized. According to the other three types, in the first type, motors are arranged in the modular units, so that the decoupling problem in the aspect of configuration is achieved. The second type is a modular unit formed by staggering the flexible sheets and the flexible rods, so that the continuum robot has certain torsional rigidity, and the flexible characteristic of continuous bending of the continuous arm can be realized. The third robot is a discrete continuum robot, the torsional rigidity of the structure is guaranteed through a Hooke hinge, and the compliance adaptability of a flexible arm is improved through the flexible sheets.

Owner:XIDIAN UNIV

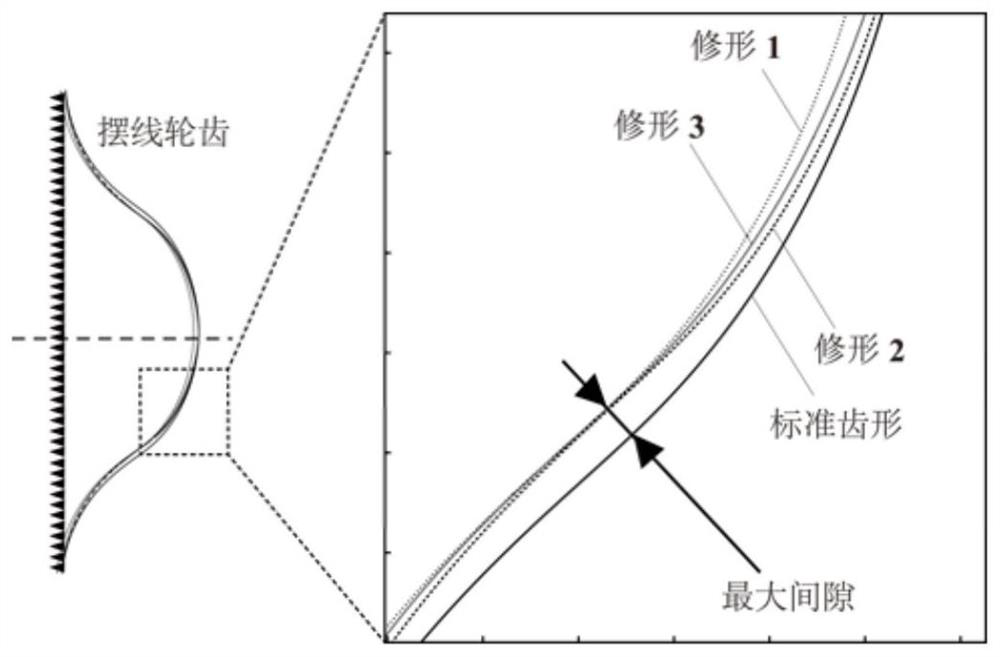

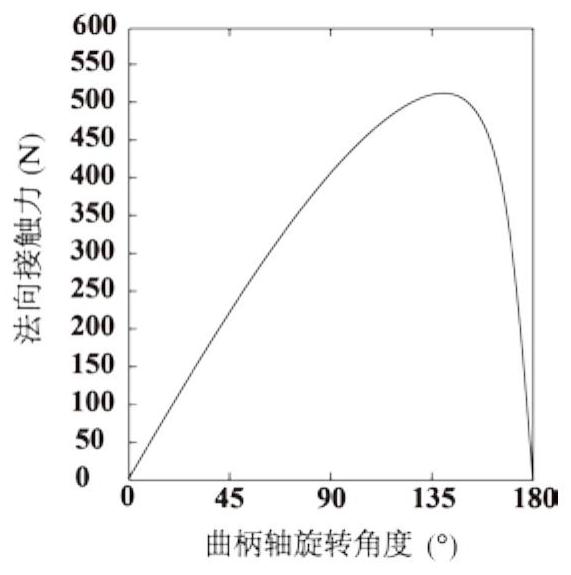

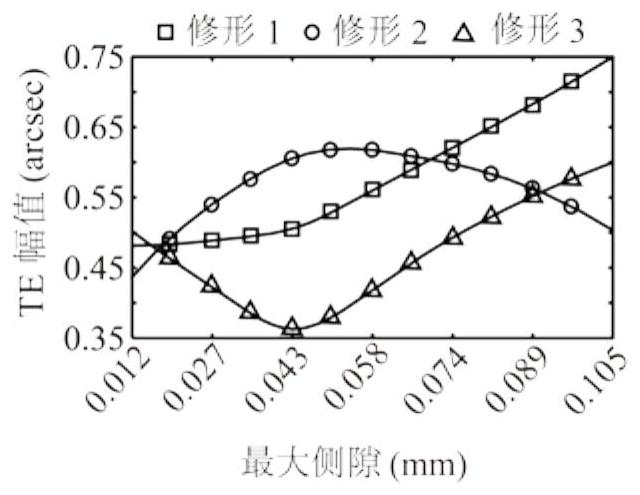

Cycloid tooth profile matching modification method of precision speed reducer for robot

PendingCN112035968AMitigation of impairmentAvoid backlashGeometric CADSpecial data processing applicationsPhysicsTransmission performance

The invention relates to the technical field of cycloid tooth profile design and mechanical transmission of speed reducers, in particular to a cycloid tooth profile matching modification method of a precision speed reducer for a robot, which has the advantages of adapting to the requirement of the robot on the transmission performance of the precision speed reducer under a large-load working condition, and meeting the mutual matching of a cycloid modification tooth profile and meshing contact force; the cycloid tooth profile modification gap is uniform, and the transmission error mean value caused by tooth profile modification is reduced; the normal force at the meshing point of the meshing tooth surface is reduced, and the speed reducer obtains better transmission performance; the methodcomprises the following steps: S1, calculating according to a classical cycloid tooth profile contact force formula to obtain a normal contact force curve; s2, taking the normal contact force curve asa modification parameter to calculate the modification amount of the tooth profile of the cycloid gear in the rectangular coordinate system; s3, on the basis, removing the modification amount coordinate values from the theoretical cycloid tooth profile to obtain a modified cycloid tooth profile; and S4, further calculating the normal backlash generated after cycloid gear tooth profile modification through the modification amount coordinates.

Owner:YANCHENG INST OF TECH

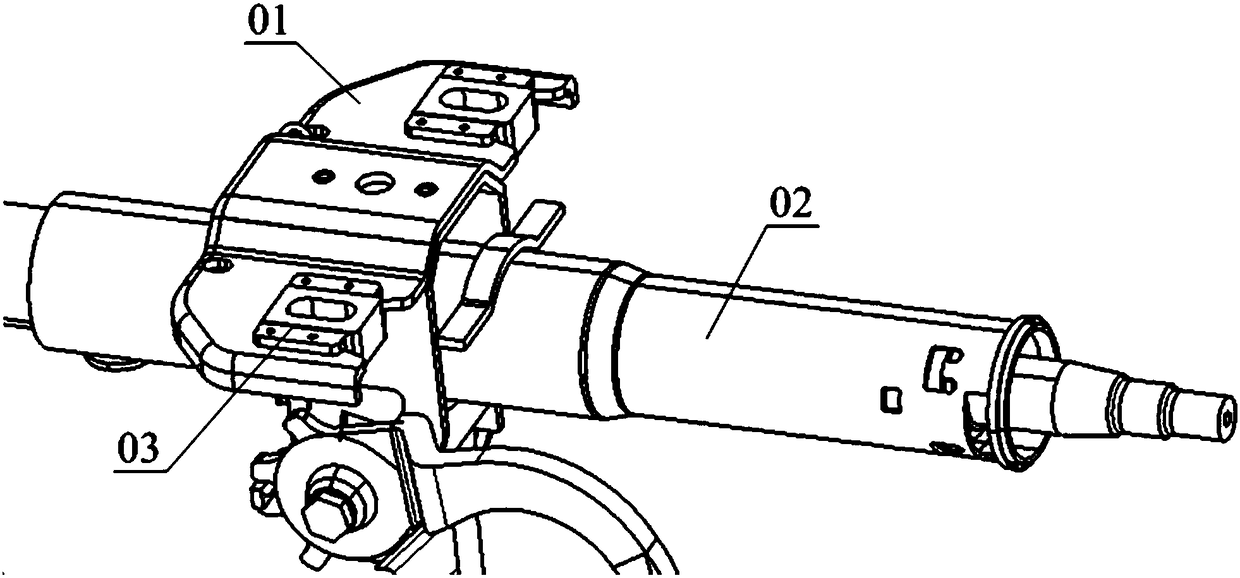

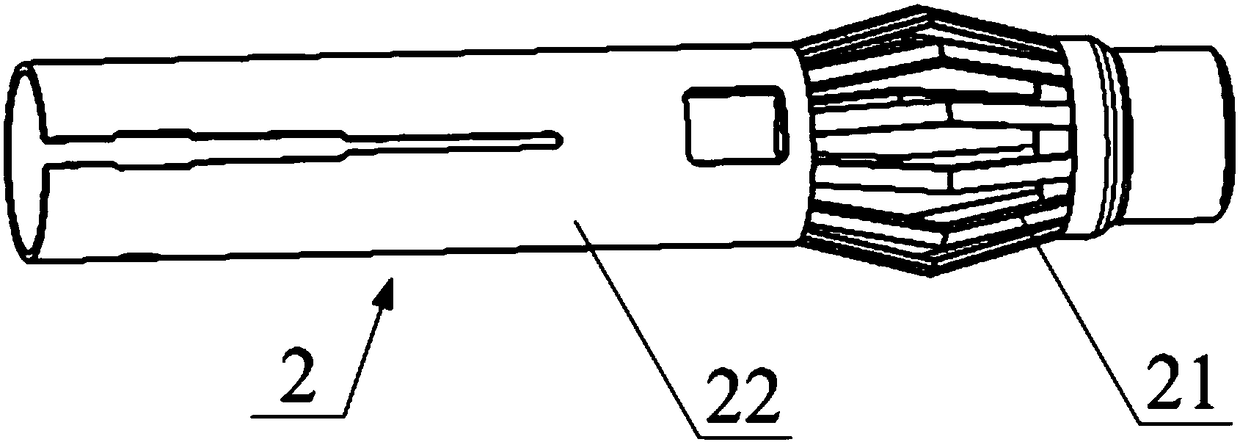

Crumple type steering column and automobile

InactiveCN108407882AGuaranteed torsional rigidityReduced axial strengthSteering columnsSteering columnEnergy absorption

The invention discloses a crumple type steering column. The crumple type steering column comprises a column external sleeve; the wall of the column external sleeve comprises a straight sleeve part anda cage part; and the cage part is a hollowed-out structure which is distributed in the circumferential direction of the column external sleeve. The hollowed-out cage part can guarantee the torsionalrigidity of the column external sleeve and can appropriately reduce the axial strength of the column external sleeve; and moreover, the collision energy can be further absorbed to realize a purpose ofsecondary crumpling energy absorption of the column. When an automobile comes into a collision, the energy absorption in the first stage can be realized by using the existing injection-molded shearing block structure; when the column external sleeve moves down to an extreme position, the cage part can be further crumpled in the axial direction and absorb energy under an effect of collision forceso that two-stage energy absorption is realized; and therefore, the acting time of the collision force on a human body is prolonged and the safety of a driver is guaranteed. The invention further discloses an automobile including the crumple type steering column

Owner:BEIJING CHANGAN AUTOMOBILE ENG TECH RES

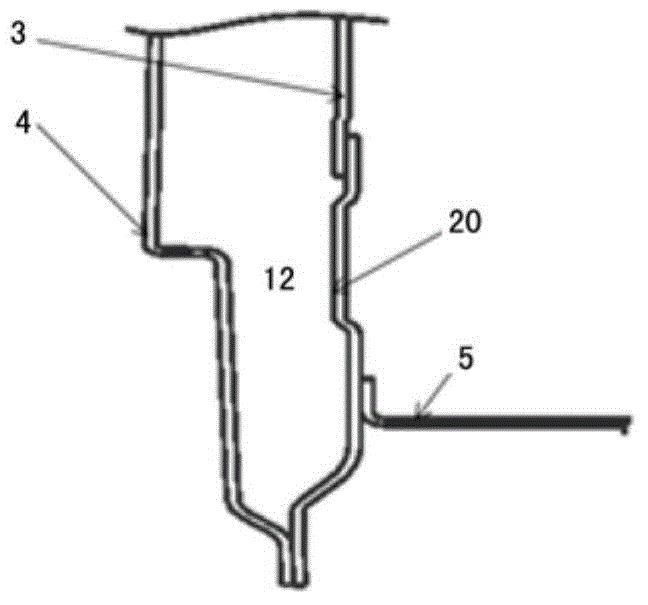

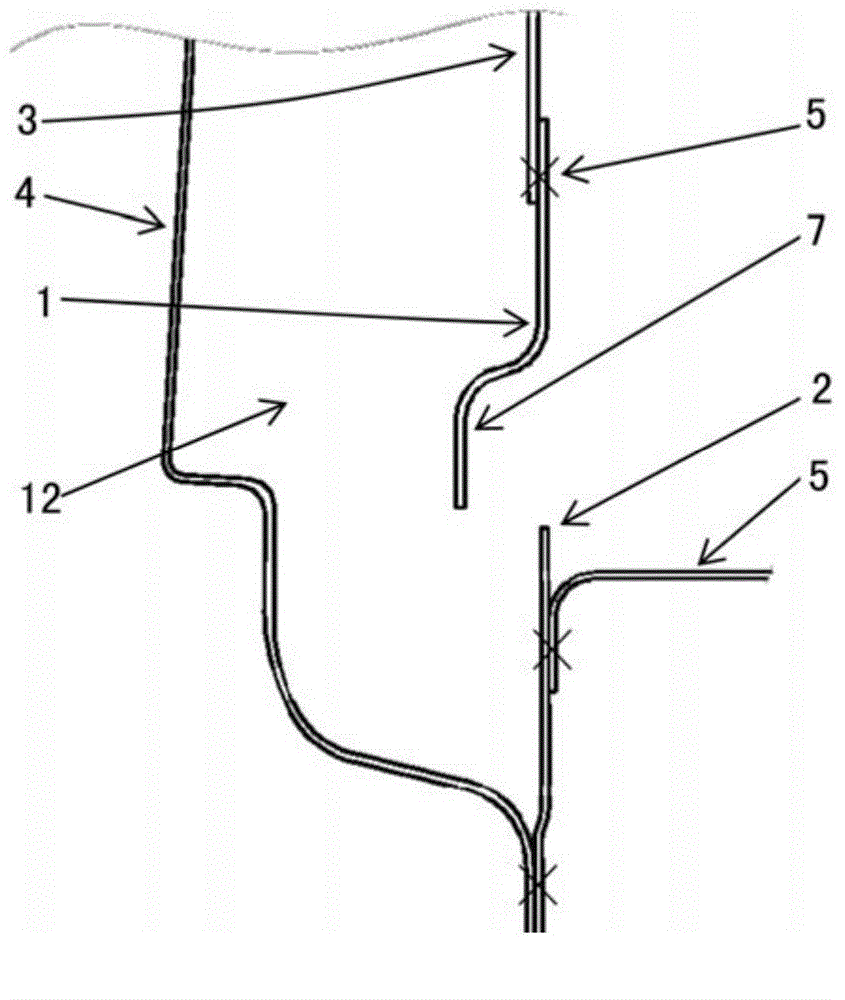

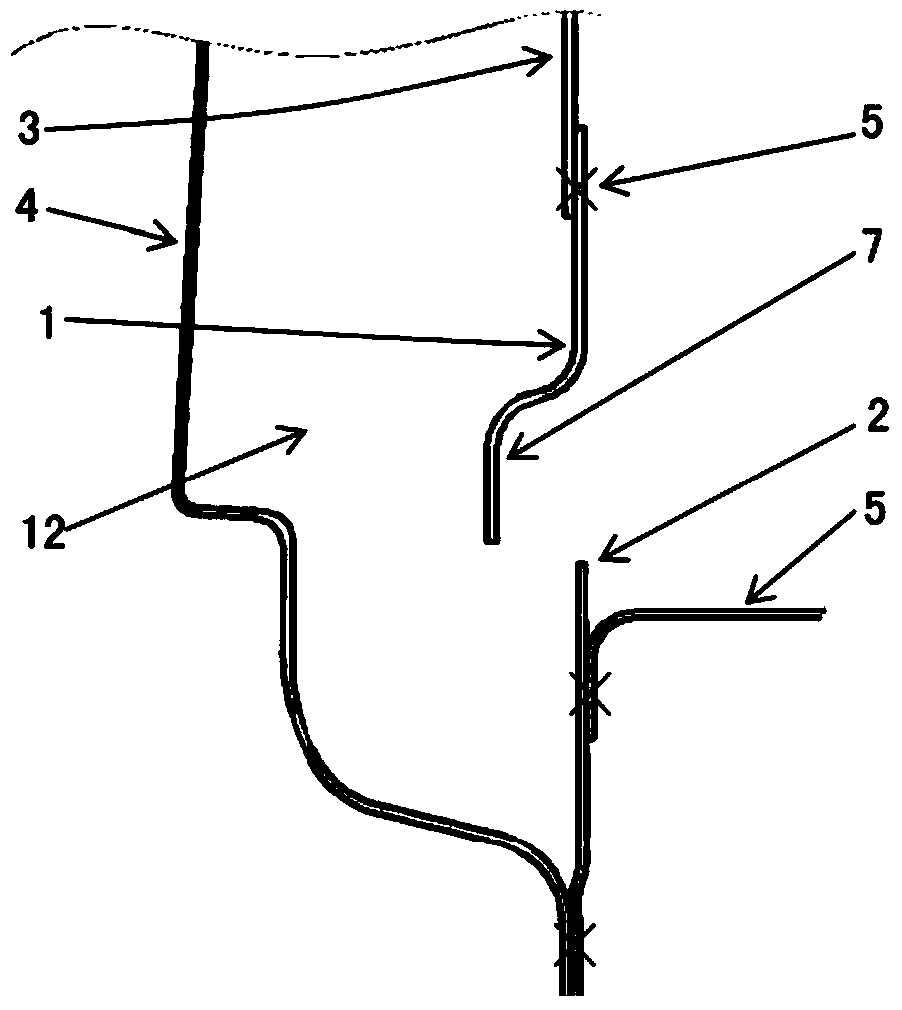

Rear connecting assembly of rear wheel cover

ActiveCN106275095AAvoid pollutionGuaranteed torsional rigiditySuperstructure subunitsEngineeringMechanical engineering

The invention discloses a rear connecting assembly of a rear wheel cover. The rear connecting assembly comprises an upper connecting plate fixed to a side body inner plate, and a lower connecting plate fixed to a rear floor and a side body outer plate. A gap is reserved between the lower end of the upper connecting plate and the lower connecting plate, the upper portion of the upper connecting plate is fixed to the lower portion of the side body inner plate, the inner side of the upper portion of the lower connecting plate is fixed to the outer side of the end of the rear floor, the outer side of the lower portion of the lower connecting plate is fixed to the inner side of the lower portion of the side body outer plate, a side body cavity is formed among the side body inner plate, the upper connecting plate, the lower connecting plate and the side body outer plate, and the upper connecting plate and an outer plate of the rear wheel cover are in lap joint. The rear connecting assembly of the rear wheel cover is simple in structure and ensures that the torsional rigidity of the tail of a vehicle body is achieved; meanwhile, in the rear area of the rear wheel cover, the electric-arc welding technology does not need to be adopted for a side body sub-assembly and the rear floor, the production efficiency is effectively improved, the potential safety hazard of workers is eliminated, and pollution is avoided.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

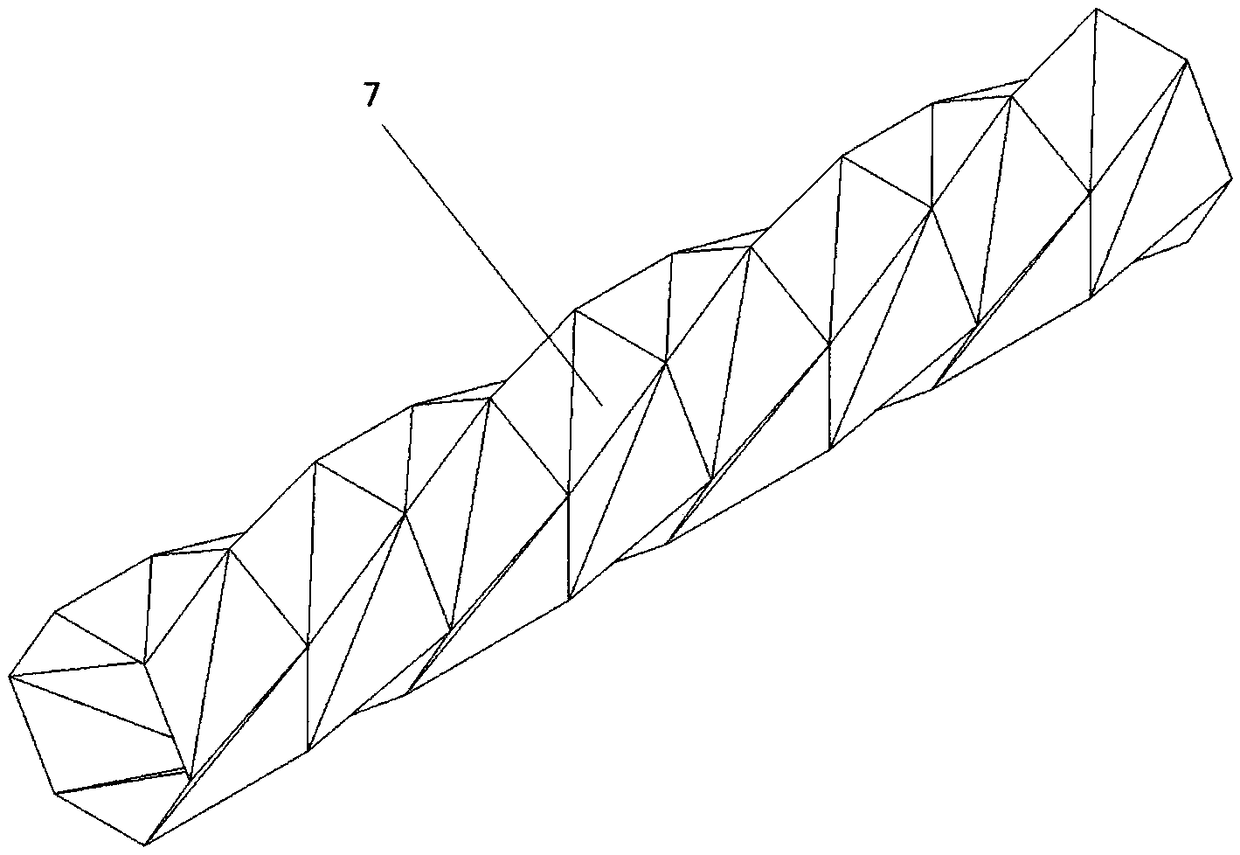

Buckling inducing brace with ends provided with annular screw-type induction units

ActiveCN106567594AReduced torsional stiffnessGuaranteed torsional rigidityProtective buildings/sheltersShock proofingBuckling-restrained braceEngineering

The invention discloses a buckling inducing brace with the ends provided with annular screw-type induction units. The buckling inducing brace with the ends provided with the annular screw-type induction units comprises retraining sections and energy dissipation sections and further comprises a brace straight section. The energy dissipation sections are arranged at the two ends of the brace straight section. Each energy dissipation section is composed of at least one annular screw-type induction unit in the axial direction of the brace. Each annular screw-type induction unit is a space body with a regular polygon section, wherein the space body is formed in the manner that m annular screw-type induction subunits are annularly and sequentially arranged. Each annular screw-type induction subunit is a space body which is formed by two collinear triangular plates through folding. The buckling inducing brace with the ends provided with the annular screw-type induction units keeps elasticity under the action of a small earthquake; and under the action of an intermediate earthquake or a large earthquake, the buckling inducing brace enters a yielding stage, and the buckling inducing brace can achieve the effect of a damper through the good hysteretic energy dissipation capacity. Compared with a traditional buckling restraining brace, the buckling inducing brace with the ends provided with the annular screw-type induction units lightens the on-site construction workload, saves energy and is environmentally friendly.

Owner:SOUTHEAST UNIV

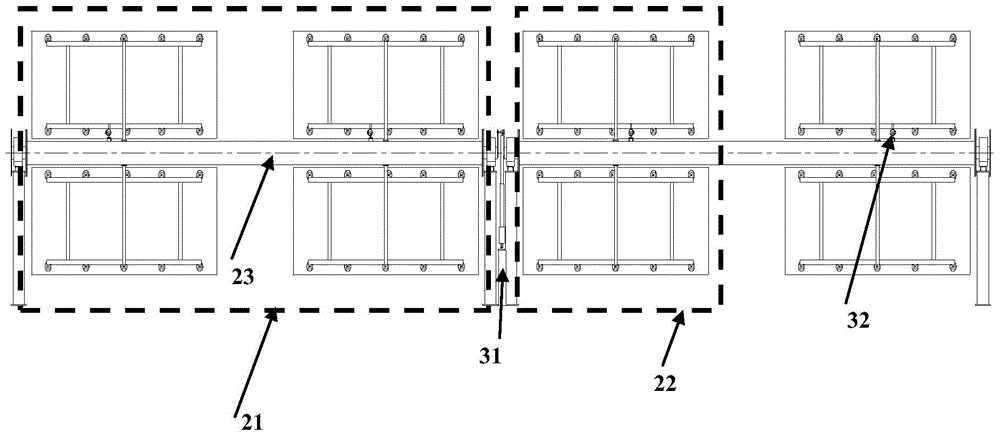

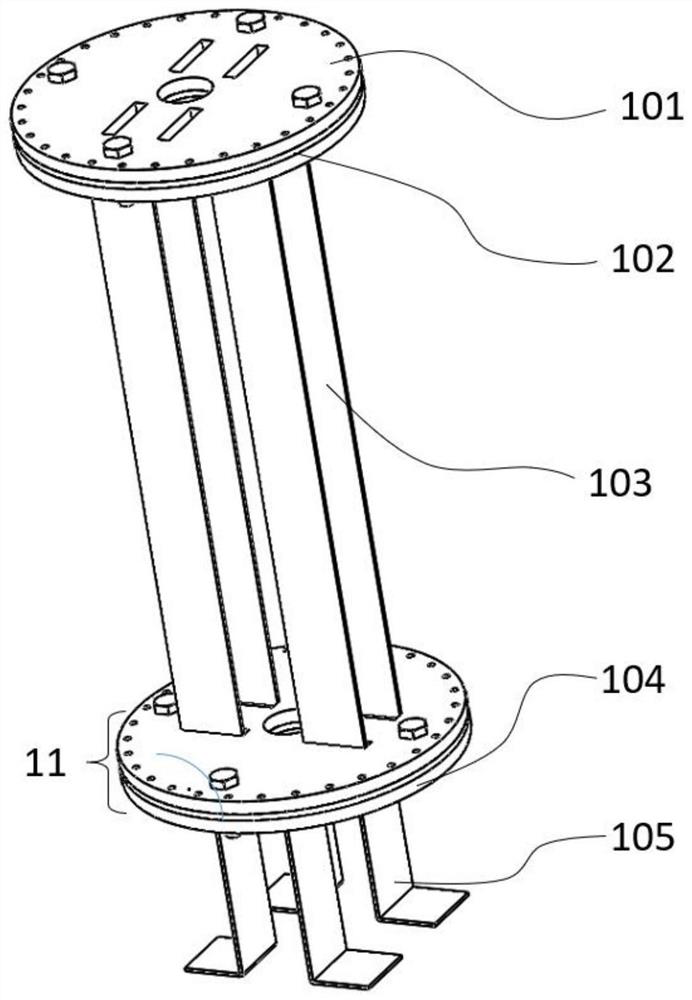

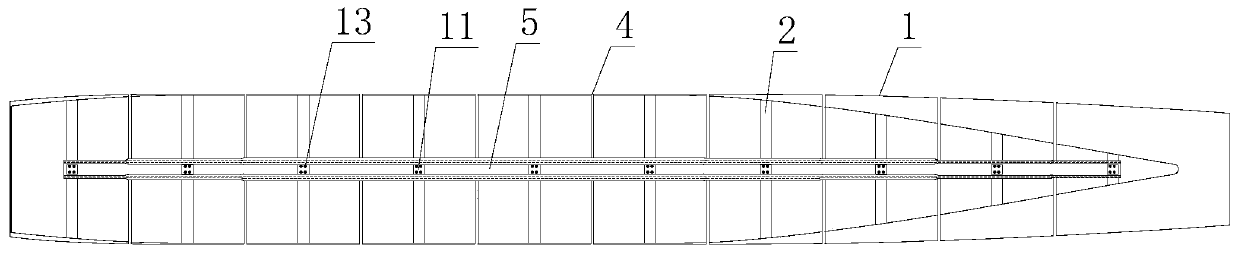

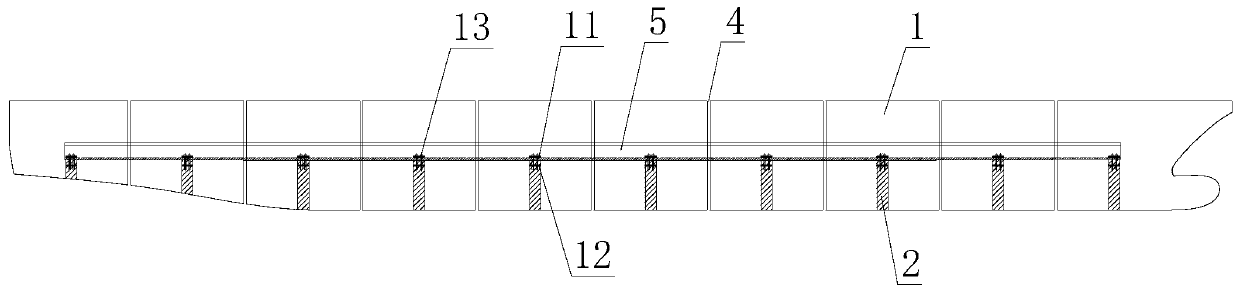

Hydroelasticity test ship model adopting U-shaped keel beam and design method thereof

The invention discloses a hydroelasticity test ship model adopting a U-shaped keel beam and a design method thereof. The hydroelasticity test ship model comprises a ship hull system and a U-shaped keel beam, wherein the ship hull system comprises segmented ship hulls, a base and ballast blocks; the outer contours of the segmented ship hulls are obtained by scaling a real ship profile; the ship hull is broken at a load measurement section to form a plurality of segmented ship hulls; and gaps between the adjacent segmented ship hulls are connected in a sealed mode through silica gel strips; thebase is installed in the middle of the interior of each segmented ship hull; the ballast block is placed in the ship hull; the U-shaped keel beam is longitudinally and continuously arranged from the bow to the stern and is rigidly and fixedly connected with the base on the segmented ship shells; the U-shaped keel beam comprises a horizontal bottom plate, a vertical web plate and a horizontal wingplate; the width of the inner wall of the horizontal bottom plate, the height of the vertical web plate and the thickness of the horizontal wing plate are kept unchanged in the length direction of theship, and the vertical bending rigidity, the horizontal bending rigidity and the torsional rigidity of the U-shaped keel beam in the segmented ship shells are similar to those of a real ship. The invention relates to the technical field of ship tests.

Owner:SOUTH CHINA UNIV OF TECH

A zero-backlash harmonic gear drive

ActiveCN107100982BContinuous regulationMeet the requirements of zero backlash transmissionToothed gearingsGear wheelCam

The invention discloses a zero-return-difference harmonic gear transmission device. The zero-return-difference harmonic gear transmission device comprises a rigid gear, a flexible gear and a wave generator; the wave generator is composed of a flexible bearing and an elastic cam; the flexible gear is located in the rigid gear; the upper end and the lower end of the flexible gear mesh with the upper end and the lower end of the rigid gear; the flexible bearing is located between the elastic cam and the flexible gear; the shape of the elastic cam is oval; a shaft hole is formed in the center of the elastic cam; and two structural holes used for forming thin walls of the cam at the two ends in the long axis direction of the elastic cam are formed in the positions, located on the two sides of the shaft hole, in the long axis direction of the elastic cam respectively. The zero-return-difference harmonic gear transmission device is simple in structure, reasonable in design and convenient to implement, backlash in circular teeth can be effectively eliminated, the transmission return difference can be effectively eliminated, in addition, the torsional rigidity can be guaranteed, the service life can be long, the application range can be wide, the practicability can be high, and the popularization and application values can be high.

Owner:王家梁

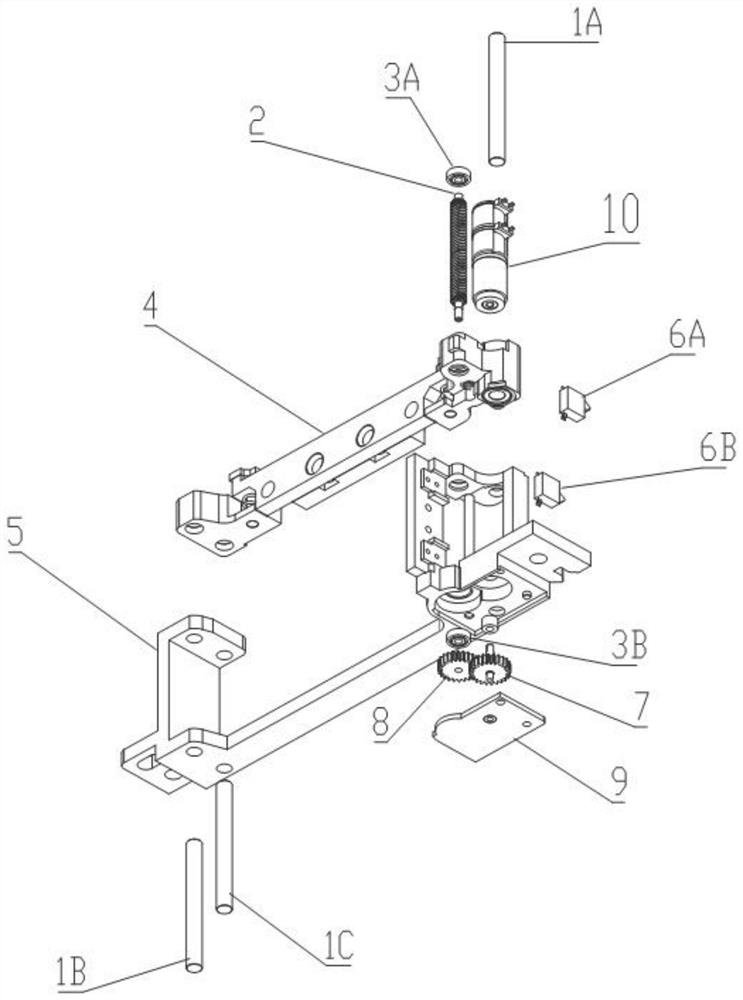

Anti-seismic and anti-impact camera lifting module and camera mechanism comprising same

PendingCN114719147AImprove impact resistanceEliminate the effects ofTelevision system detailsNon-rotating vibration suppressionClassical mechanicsElectric machinery

The camera lifting module comprises a support, a gear motor, a guide column, a lead screw mechanism and a sliding assembly, and an output shaft of the gear motor is connected with a lead screw; the sliding assembly comprises a movable frame, a guide shaft, a camera mounting frame and a first elastic element, the movable frame movably penetrates through the guide column, the transmission nut is fixedly arranged on the movable frame, the movable frame is provided with a limiting pair, the limiting pair comprises two limiting parts, the first elastic element penetrates through the guide shaft, and the camera mounting frame is provided with a penetrating part; and one end of the first elastic element is pressed on one limiting part of the movable frame, and the other end of the first elastic element is pressed on the penetrating part of the camera mounting frame, so that shock absorption can be carried out when a camera mounted on the camera mounting frame encounters an obstacle. The elastic element is installed in the sliding assembly, the influence caused by impact can be eliminated to the maximum extent, and the impact resistance of the camera lifting module is improved.

Owner:ONCE TOP MOTOR MFG

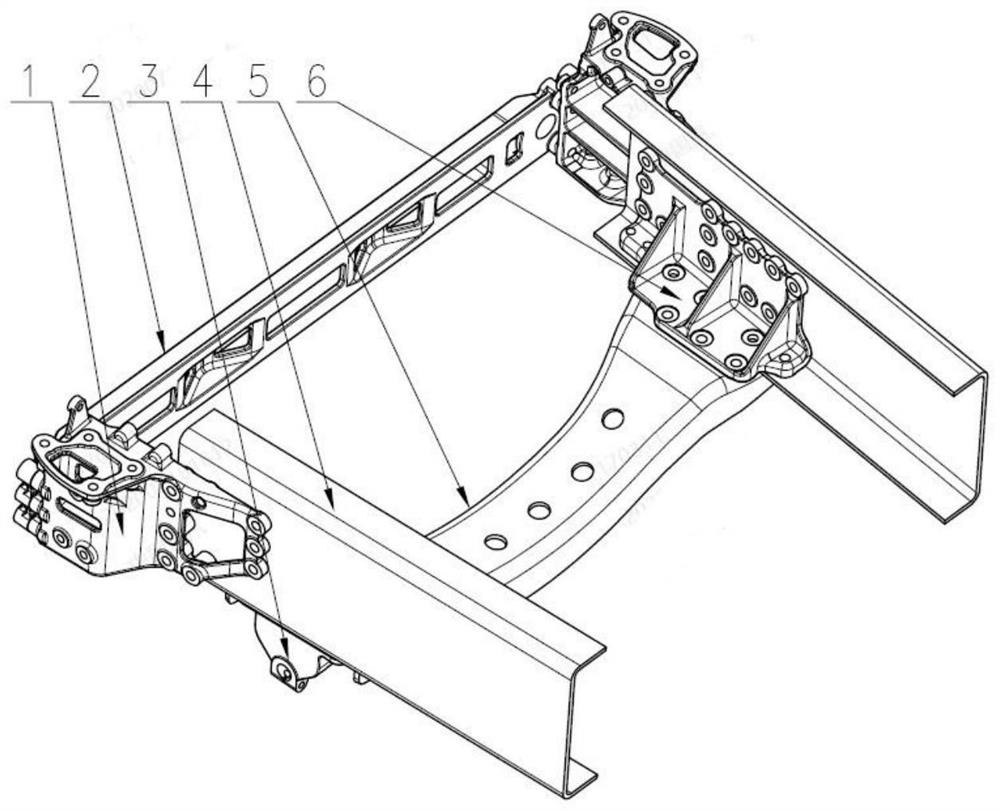

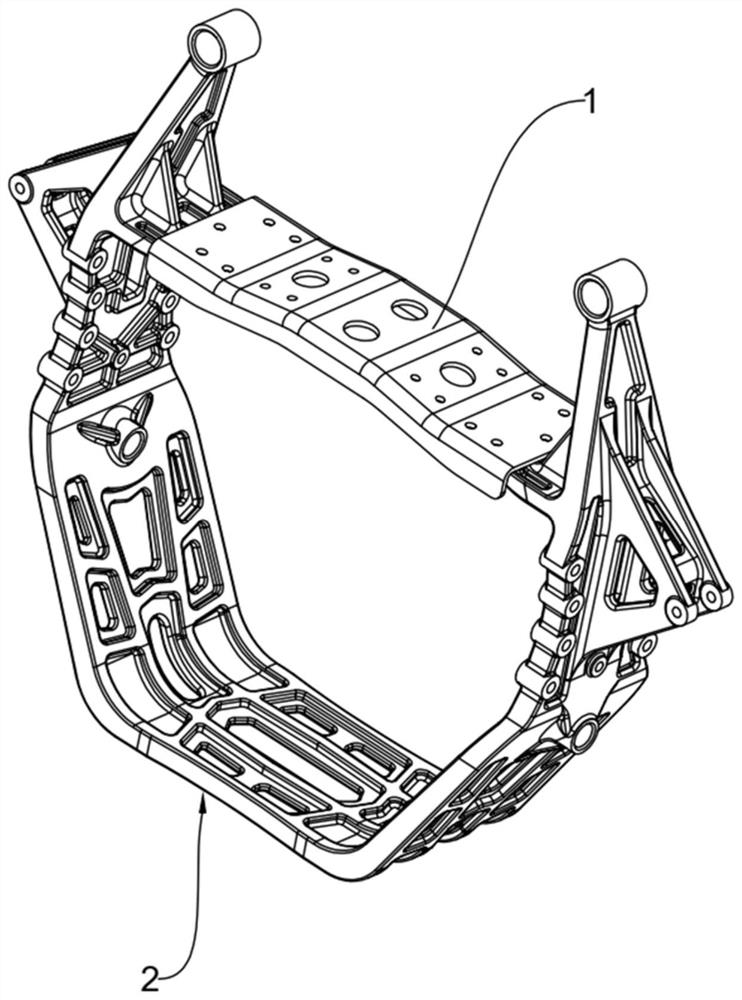

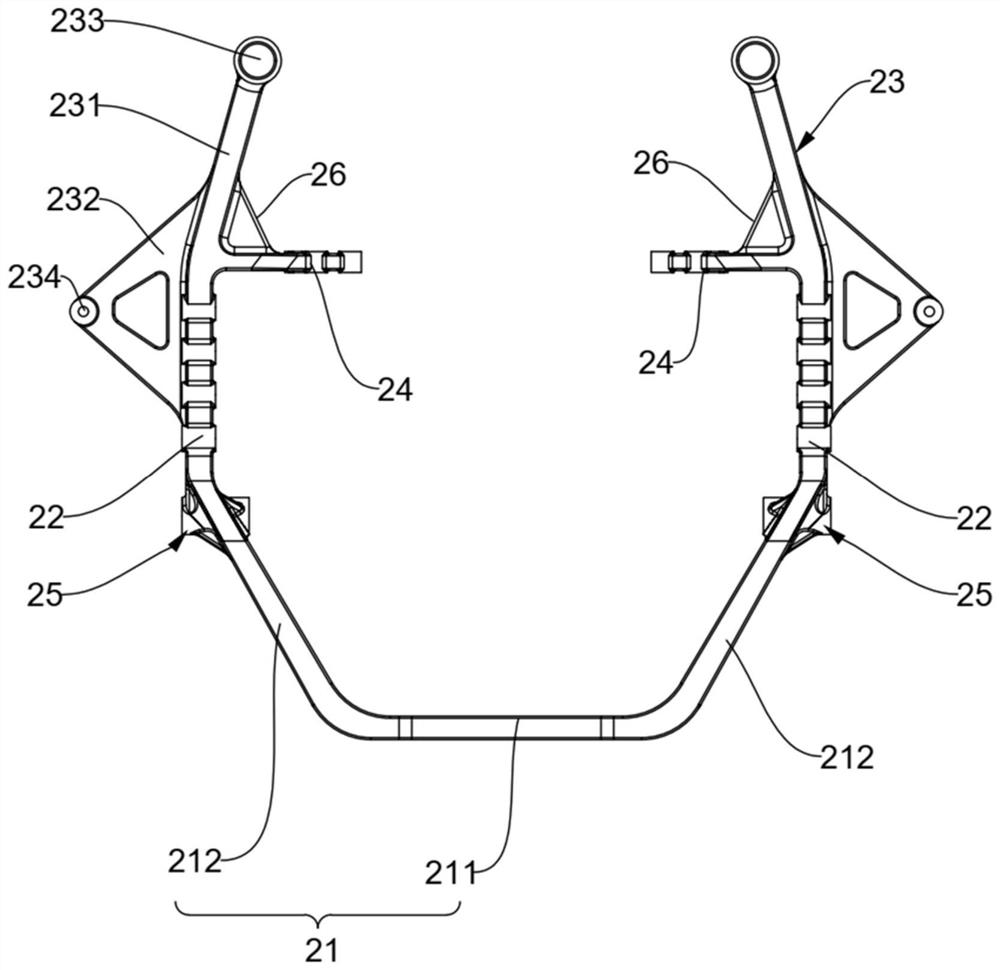

A beam assembly

The invention relates to the technical field of automobile parts, and specifically discloses a beam assembly. The beam assembly includes: a suspension beam; a front spring and a rear support beam assembly are integrally formed by casting. The front spring and rear support beam assembly includes: a front spring The rear support beam, the front spring and the rear support beam include a bottom plate and a side plate, and the opposite ends of the bottom plate are connected with side plates; the frame fixing part is used for connecting with the frame, and the two side plates are connected with the frame fixing part ;The rear suspension bracket of the cab is used to connect the rear suspension of the cab, and the two frame fixing parts are connected with the rear suspension bracket of the cab; the suspension beam bracket is used to connect the suspension beam, the rear of the two cabs The suspension brackets are all connected with suspension beam brackets, the suspension beam, the frame fixing part and the front spring rear bracket beam form a ring structure; the leaf spring lifting ring bracket is used to connect the leaf spring lifting ring, and both side plates are provided with plates Spring Ring Bracket. The torsional rigidity of the beam assembly is high, the outer width is high precision, the production cost is low, and the layout of the chassis is optimized.

Owner:FAW JIEFANG AUTOMOTIVE CO

A Buckling Induced Brace with Circular Helical Induced Units at the End

ActiveCN106567594BReduced torsional stiffnessGuaranteed torsional rigidityProtective buildings/sheltersShock proofingBuckling-restrained braceEngineering

The invention discloses a buckling inducing brace with the ends provided with annular screw-type induction units. The buckling inducing brace with the ends provided with the annular screw-type induction units comprises retraining sections and energy dissipation sections and further comprises a brace straight section. The energy dissipation sections are arranged at the two ends of the brace straight section. Each energy dissipation section is composed of at least one annular screw-type induction unit in the axial direction of the brace. Each annular screw-type induction unit is a space body with a regular polygon section, wherein the space body is formed in the manner that m annular screw-type induction subunits are annularly and sequentially arranged. Each annular screw-type induction subunit is a space body which is formed by two collinear triangular plates through folding. The buckling inducing brace with the ends provided with the annular screw-type induction units keeps elasticity under the action of a small earthquake; and under the action of an intermediate earthquake or a large earthquake, the buckling inducing brace enters a yielding stage, and the buckling inducing brace can achieve the effect of a damper through the good hysteretic energy dissipation capacity. Compared with a traditional buckling restraining brace, the buckling inducing brace with the ends provided with the annular screw-type induction units lightens the on-site construction workload, saves energy and is environmentally friendly.

Owner:SOUTHEAST UNIV

A concrete segment prefabricated arch rib pre-embedded section steel flat seam bolt type connection positioning device and its construction method

ActiveCN107022947BIncrease stiffnessAvoid confictBridge structural detailsBridge erection/assemblyFlat jointBolt connection

The invention discloses a positioning device for achieving embedded-sectional steel flat-joint bolt connection of concrete sectional prefabricated arch ribs and a construction method of the positioning device. The positioning device is arranged at a junction of the concrete sectional prefabricated arch ribs, and comprises a pair of rectangular flanges adopting the same structure, wherein the two rectangular flanges are arranged at the centers of the prefabricated arch ribs respectively; each rectangular flange comprises a flange panel and a flange side plate; bolt connection holes are formed in the flange panels; the flange panels of the two rectangular flanges are fixedly connected through bolts; one end of each flange side plate is connected with the corresponding flange panel; spikes connected with concrete on the prefabricated arch ribs in an embedded manner are arranged at the other ends of the flange side plates. The positioning device is used for rapid positioning and connection of the sectional prefabricated arch ribs, shortens the construction period, improves the adjusting speed and the adjusting accuracy of arch axes of the sectional prefabricated arch ribs, reduces additional unfavorable eccentricity at a joint of the arch ribs, and improves the force performance of a wet joint of the arch ribs.

Owner:中交投资南京有限公司

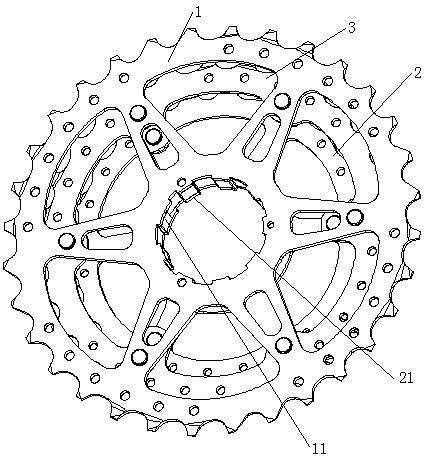

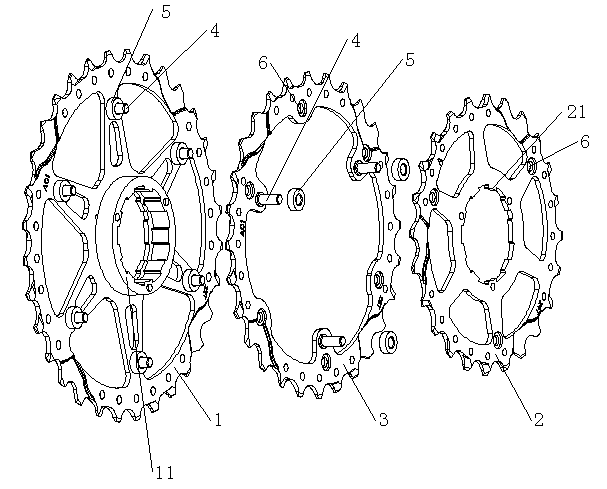

Bicycle rear chain wheel assembly

The invention discloses a bicycle rear chain wheel assembly. The bicycle rear chain wheel assembly comprises at least three chain wheels which are arranged from large to small in parallel, wherein the largest and smallest chain wheels are radial wheels; the centers of the largest and smallest chain wheels are provided with splines which can be sleeved out of a rear hub of a bicycle; the intermediate chain wheel is a hollow ring-type chain wheel, namely the center of the intermediate chain wheel does not contact the rear hub of the bicycle directly; adjacent chain wheels are connected with each other through a plurality of fastening pieces distributed circumferentially; and separation tables for separating the adjacent chain wheels in parallel are arranged on the fastening pieces. The bicycle rear chain wheel assembly is reasonable in structure, low in production cost, light in weight, high in torsional rigidity, and easy to produce and assemble.

Owner:ZHONGSHAN XINBAO PRECISION SCI & TECH

A linked heliostat

ActiveCN104483979BReduce reflective areaGuaranteed torsional rigidityControl using feedbackElevation angleHeliostat

The invention discloses a novel linkage heliostat. The novel linkage heliostat is characterized by comprising an elevation angle driving mechanism, wherein the elevation angle driving mechanism drives at least two reflector modules to commonly do elevation angle rotation movement. The novel linkage heliostat employs combined motion setting of the multiple reflector modules, unit reflectors are connected in series through a torque axis to form a reflector module, the multiple reflector modules are connected through flange discs, the multiple reflector modules are driven to simultaneously move by employing the elevation angle driving mechanism, through reducing height of the reflector modules and the reflection area of the reflector modules to reduce wind load, weight of the reflector modules per a reflection area unit is reduced, mounting and debugging difficulty is reduced, relevant cost is reduced, moreover, the novel linkage heliostat can guarantee tracking precision of multiple unit reflectors in the elevation angle direction, so cost of the elevation angle driving mechanism is further reduced.

Owner:STATE GRID CORP OF CHINA +3

Rear connection assembly of a rear wheel housing

ActiveCN106275095BAvoid pollutionGuaranteed torsional rigiditySuperstructure subunitsLap jointEngineering

The invention discloses a rear connection assembly of a rear wheel house, which comprises an upper connection plate fixed to the side wall inner panel and a lower connection plate fixed to the rear floor and the side wall outer panel, the lower end of the upper connection plate is connected to the There is a gap between the lower connecting plates, the upper part of the upper connecting plate is fixed to the lower part of the side wall inner panel, the inner side of the upper part of the lower connecting plate is fixed to the outer side of the end of the rear floor, and the lower connecting plate The outer side of the lower part of the connecting plate is fixed to the inner side of the lower part of the side wall outer panel, and a side wall cavity is formed between the side wall inner panel, upper connecting plate, lower connecting plate and the side wall outer panel, and the upper connecting panel The plate overlaps with the rear wheelhouse outer panel. The rear wheel house rear connection assembly of the present invention has a simple structure. While ensuring the torsional rigidity of the rear part of the vehicle body, the arc welding process is avoided in the rear area of the rear wheel house, the side wall subassembly and the rear floor, and the production efficiency is effectively improved. Eliminate potential safety hazards for personnel and avoid pollution.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

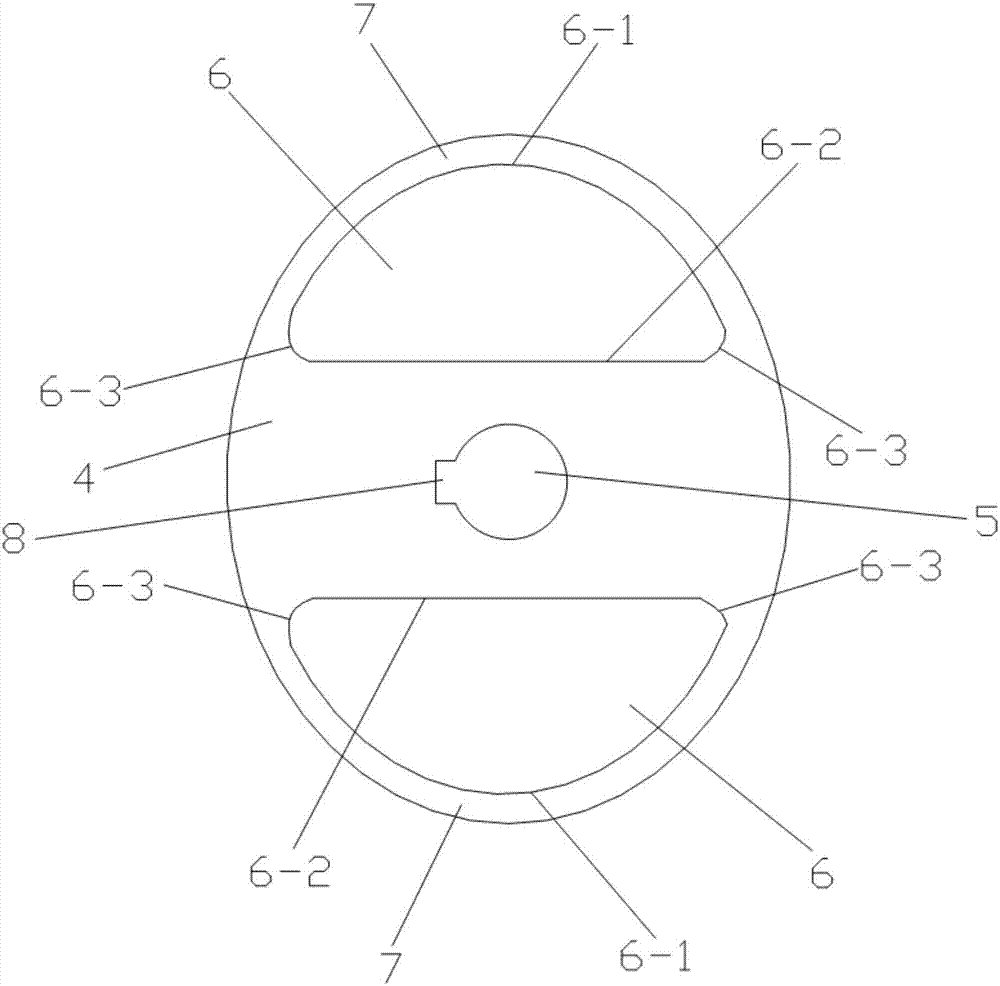

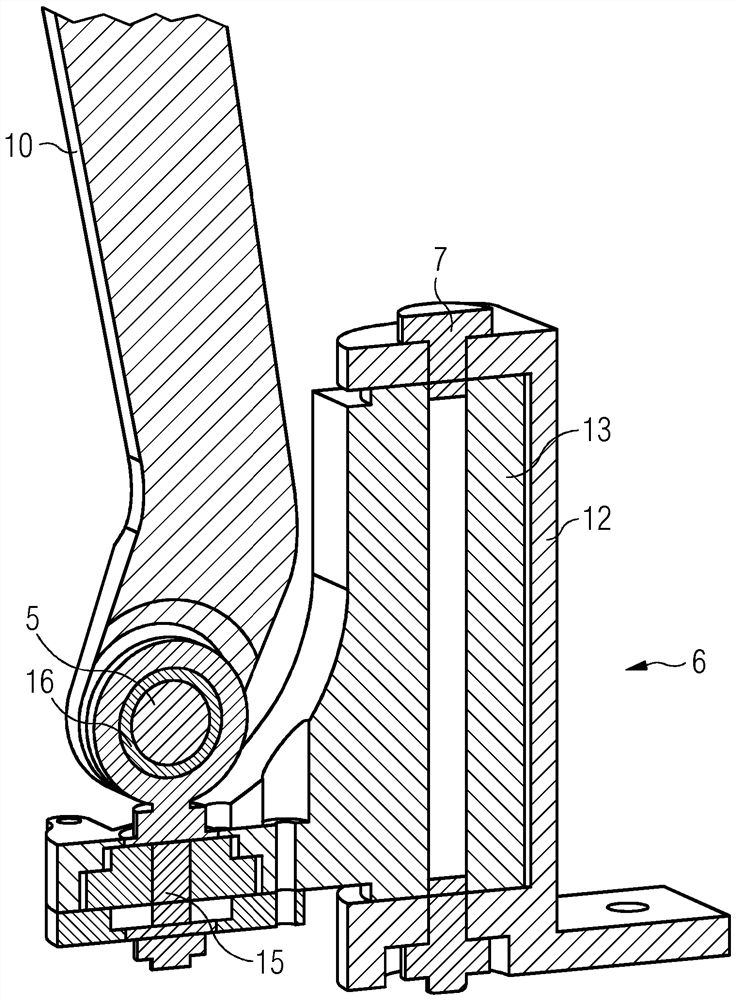

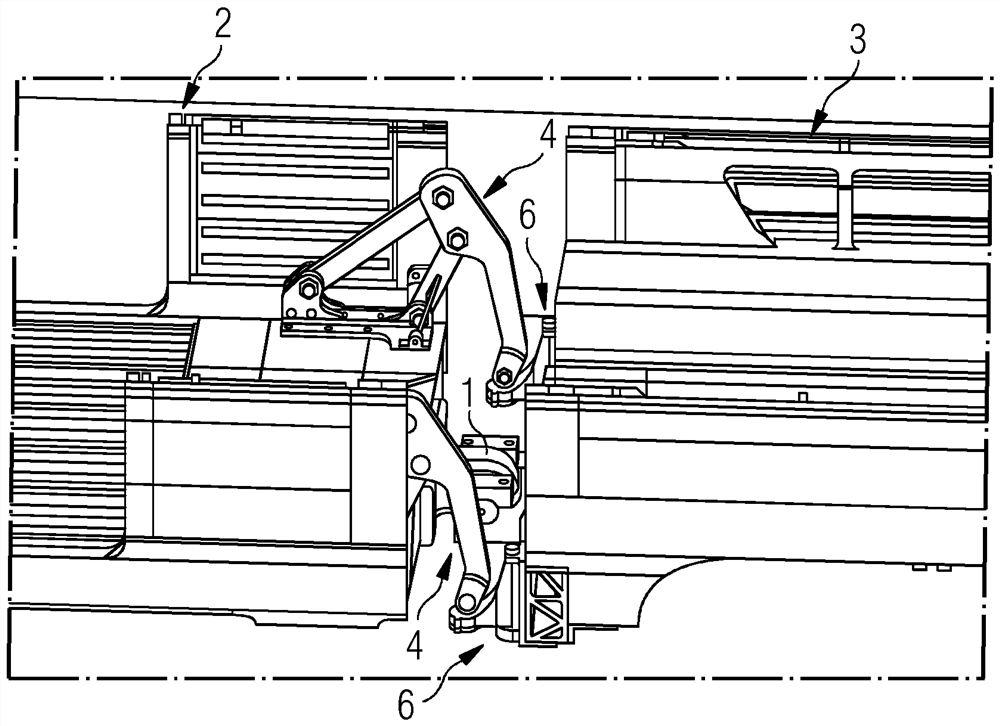

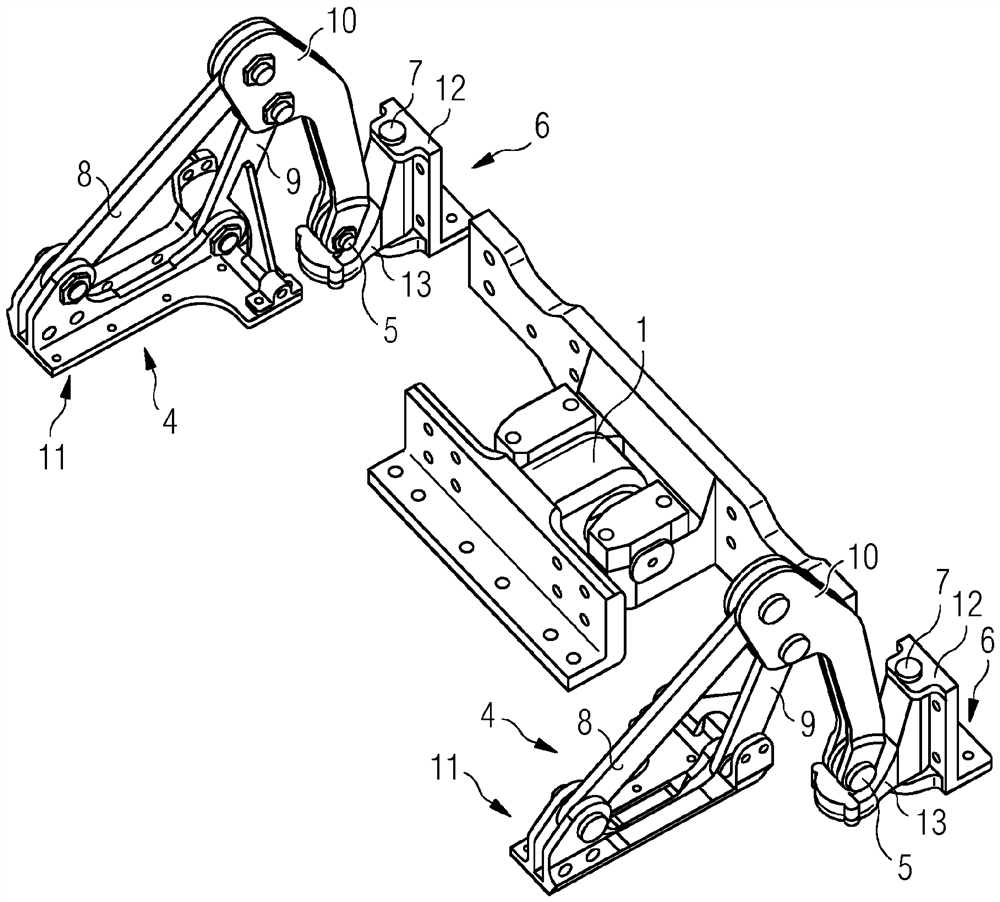

device for preventing torsional motion between two coupled rail vehicles

ActiveCN109311486BHave degrees of freedomPrevent twistingAxle-box lubricationRailway couplingsTransverse axisClassical mechanics

The invention relates to a device for blocking a torsional movement between two coupled rail vehicles (2, 3). In a first vehicle, at least one flat guide mechanism (4) is arranged in an outer wall-side end region, said guide mechanism guiding a point (5) of an element of the guide mechanism (4) in a substantially horizontal manner in a specific section of the guide path of the guide mechanism, and the point (5) is connected to a paired pivoting device (6) which is arranged on the second vehicle in a pivotal manner about a vertical axis (7). The connection of the point (5) to the paired pivoting device (6) has degrees of freedom about the transverse axis and the perpendicular axis relative to the coupled rail vehicles (2, 3).

Owner:SIEMENS MOBILITY AUSTRIA GMBH

A-column reinforced assembly of car body and A-column reinforced structure of car body using same

ActiveCN101734286BHigh strengthEasy to stamp and formSuperstructure subunitsBack supportAutomotive engineering

The invention provides an A-column reinforced assembly of a car body. The A-column reinforced assembly of the car body comprises an A-column reinforced plate; a groove (9) for covering the A-column of the car body is formed on the A-column reinforced plate; the A-column reinforced assembly further comprises an upper part front support plate (3) and a lower part back support plate (2) which are fixed at the two corresponding sides of the front side wall (10) of the groove (9). Furthermore, the invention also provides an A-column reinforced structure of the car body by using the A-column reinforced assembly. The A-column reinforced structure of the car body can remarkably increase the strength of the A-column of the car body without influencing the visual field of a driver.

Owner:BYD CO LTD

Silencing energy-saving centrifugal machine for pipe pile

PendingCN112109197ASmooth turn rate curveGood transmission synchronizationAuxillary shaping apparatusDrive wheelDrive shaft

The invention discloses a silencing energy-saving centrifugal machine for a pipe pile, and belongs to the technical field of centrifugal machines. The centrifugal machine comprises a control center, aservo motor, a speed reducer, a transmission shaft, a driving wheel, a driven wheel, a silencing ring, a silencing ring locking device and couplers. The servo motor, the couplers and the control center are electrically connected. The control center is connected with a wiring port of the servo motor through a data line. According to the centrifugal machine, by installing the couplers, the couplerscan meet production requirements of different pipe pile lengths through the operation characteristics of connection and excision. When the pipe pile is too long, the couplers ensure torsional rigidity through the good connection ability, thus a centrifugal technology has good transmission synchronicity in high-speed rotating, noise is reduced, and energy is saved. When acceleration is needed at the initial section of the centrifugal technology and deceleration is needed at the tail end, by means of the excision ability of all the couplers, curves of rotating rates of acceleration and deceleration pipe pile molds can be more smooth, transmission stability is improved, and the purposes of reducing the noise and saving energy are achieved.

Owner:浙江龙鼎混凝土建材股份有限公司 +1

Auto rear wall assembly

ActiveCN107187504BExtended service lifeReduce weightSuperstructure subunitsControl theoryMechanical engineering

The invention discloses an automobile rear wall assembly. The rear wall assembly of the automobile comprises: a rear wall inner panel assembly (1); the rear wall inner panel assembly (1) includes a rear wall inner panel (101); and the second rear wall inner panel (101) a first rear wall connection plate (102) connected at one end; and a second rear wall connection plate (103) connected to the second end of the rear wall inner panel (101); and a rear wall outer panel (2); The rear wall inner panel (101), the first rear wall connecting plate (102) and the second rear wall connecting plate (103) form a three-dimensional cavity structure with the rear wall outer panel (2). Compared with the existing plate-shaped automobile rear wall, the automobile rear wall assembly provided by the present invention is a three-dimensional cavity structure synthesized by the rear wall inner panel assembly and the rear wall outer panel, which greatly improves the automobile rear wall assembly. The torsional rigidity of the car is improved, thereby improving the torsional rigidity of the car frame, improving the performance of the vehicle and prolonging the service life of the car. The rear wall inner panel assembly adopts a split design to facilitate manufacture.

Owner:CHERY AUTOMOBILE CO LTD

Cross beam assembly

The invention relates to the technical field of automobile parts, and particularly discloses a cross beam assembly which comprises: a suspended cross beam; a front spring rear support cross beam assembly which is formed through integral casting, wherein the front spring rear support cross beam assembly comprises a front spring rear support cross beam, the front spring rear support cross beam comprises a bottom plate and side plates, and the two opposite ends of the bottom plate are connected with the side plates. frame fixing parts, wherein the frame fixing parts are used for being connected with a frame, and the two side plates are connected with the frame fixing parts; a cab rear suspension support, wherein the cab rear suspension support is used for being connected with a cab rear suspension, and the two frame fixing parts are both connected with the cab rear suspension support; suspension cross beam supports which are used for being connected with a suspension cross beam, wherein the two cab rear suspension supports are both connected with the suspension cross beam supports, and the suspension cross beam, the frame fixing parts and the front spring rear support cross beam forman annular structure; plate spring hanging ring supports which are used for being connected with a plate spring hanging ring, wherein the two side plates are provided with the plate spring hanging ring supports. The cross beam assembly is large in torsional rigidity, high in outer width precision and low in production cost, and the layout of the chassis is optimized.

Owner:FAW JIEFANG AUTOMOTIVE CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com