Bicycle rear chain wheel assembly

A bicycle and rear sprocket technology, which is applied to vehicle components, vehicle gearboxes, chain/belt transmissions, etc., can solve the problems of high cost of sprocket components, increased number of parts and assembly time, and high processing requirements, so as to save materials , weight reduction and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

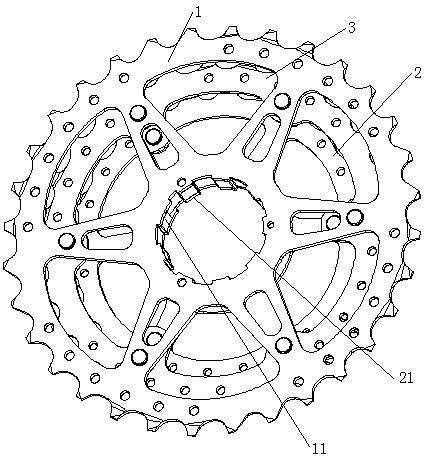

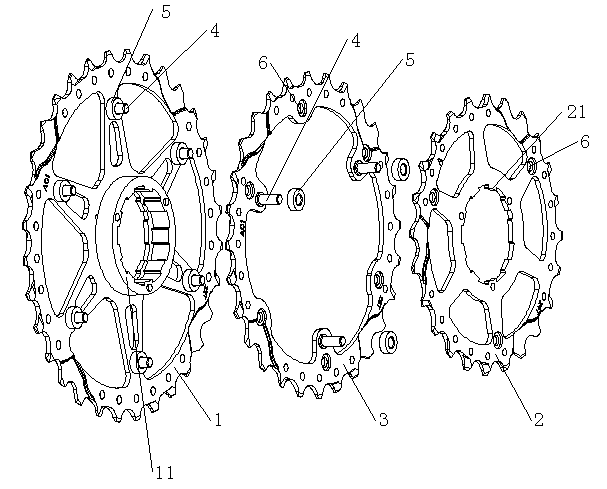

[0013] The present invention is a kind of rear sprocket assembly of bicycle, as figure 1 , 2 As shown, it includes at least three sprockets arranged in parallel from large to small, wherein the largest and small sprockets 1, 2 are spoke type sprockets, and the centers of the largest and small sprockets 1, 2 are equipped with The splines I1 and 21 are socketed outside the rear hub of the bicycle; and the intermediate sprocket 3 is a hollow ring sprocket, that is, the center of the intermediate sprocket 3 does not directly contact the rear hub of the bicycle; between adjacent sprockets The fasteners 4 are connected by several fasteners 4 distributed at intervals in the circumference. The fasteners 4 are provided with a separation table 5 that separates adjacent sprockets in parallel. Because the present invention is sleeved on the rear hub of the bicycle by splines II, 21 of the largest and small sprockets 1, 2, and the intermediate sprocket 3 is not socketed with the rear hub ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com