A zero-backlash harmonic gear drive

A technology of harmonic gears and transmissions, which is applied in the direction of gear transmissions, transmissions, belts/chains/gears, etc., can solve the problems of large transmission hysteresis, achieve the elimination of transmission hysteresis, strong bearing capacity, and stable transmission Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

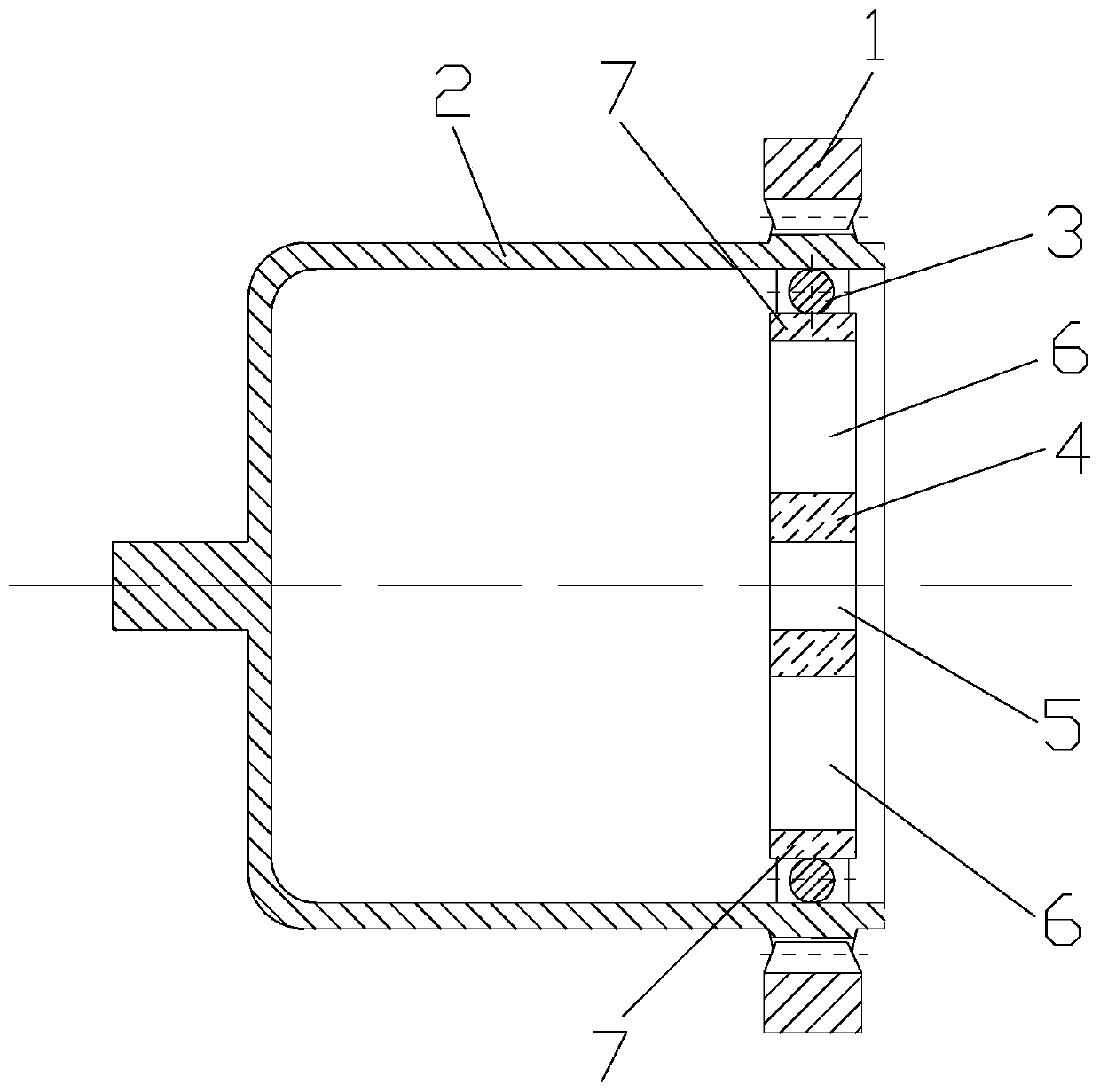

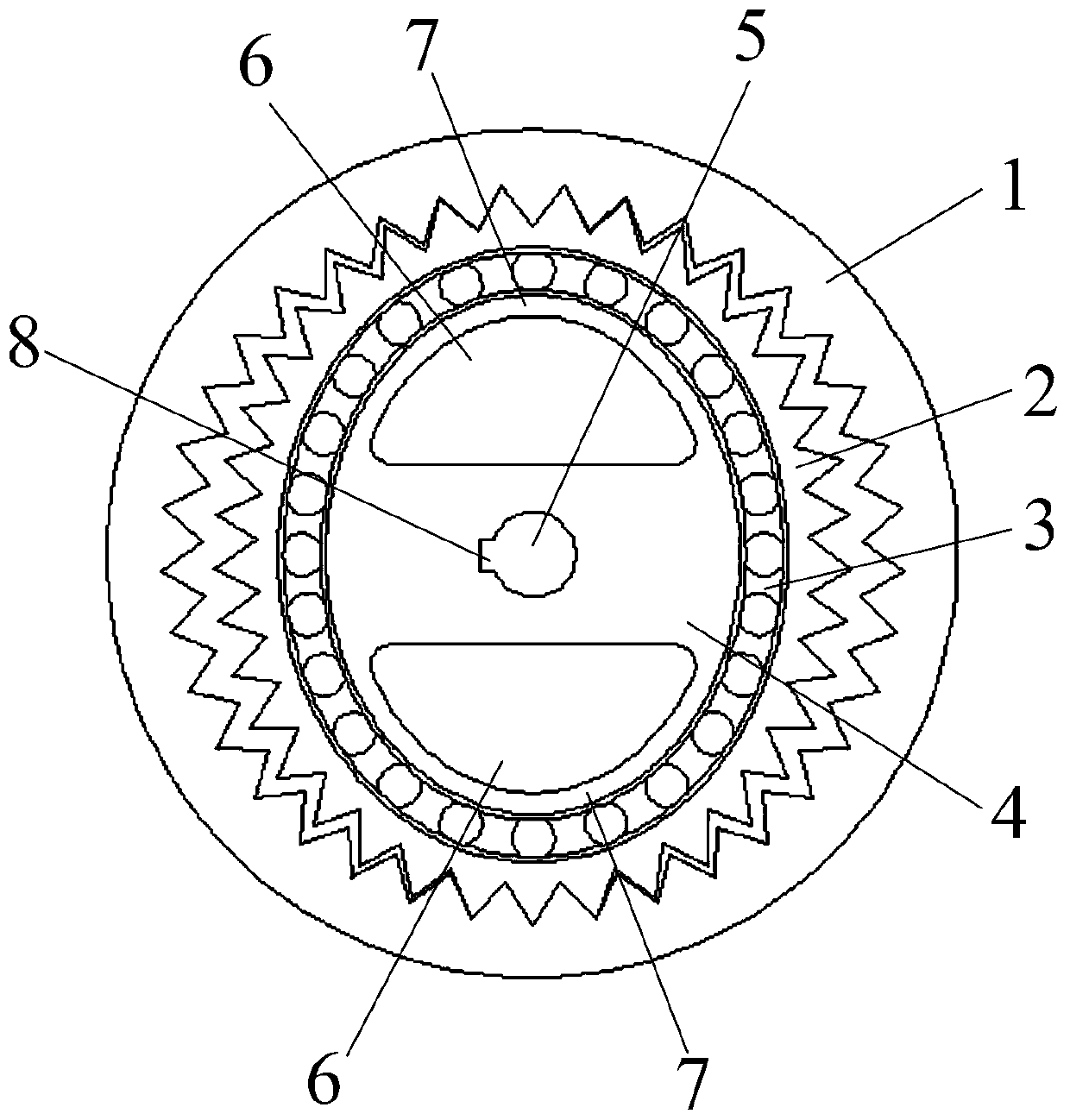

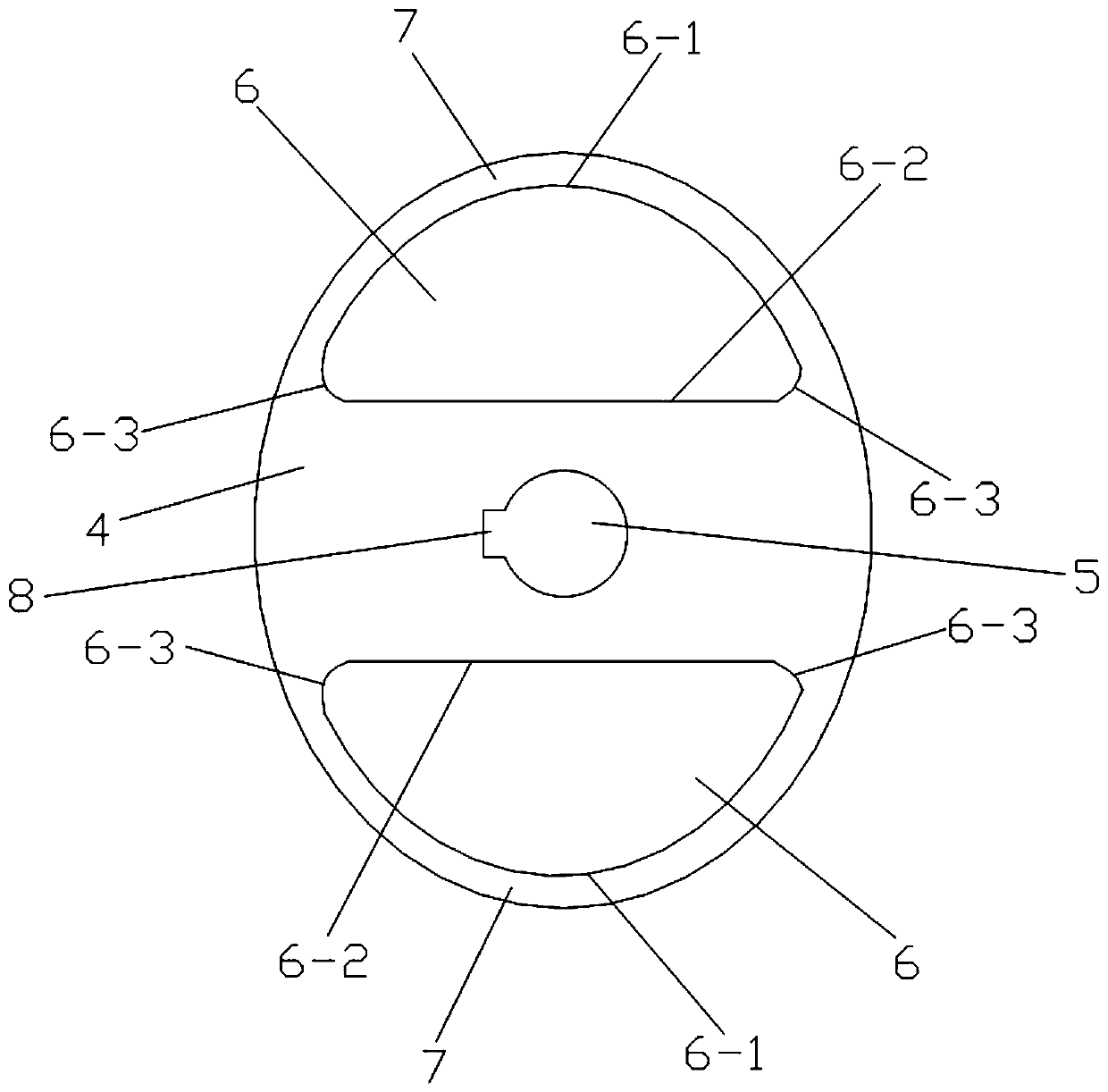

[0035] like figure 1 and figure 2 As shown, the zero-backlash harmonic gear transmission of the present invention includes a rigid gear 1, a flexible gear 2 and a wave generator, the wave generator is composed of a flexible bearing 3 and an elastic cam 4, and the flexible gear 2 is located on a rigid In the gear 1, the upper and lower ends of the flexible gear 2 mesh with the upper and lower ends of the rigid gear 1, the flexible bearing 3 is located between the elastic cam 4 and the flexible gear 2, and the elastic cam 4 is oval in shape , the central portion of the elastic cam 4 is provided with a shaft hole 5, and the two sides of the shaft hole 5 in the direction of the long axis of the elastic cam 4 are respectively provided with one for forming at both ends in the direction of the long axis of the elastic cam 4 Structural hole 6 of cam thin wall 7 . The use of the elliptical elastic cam 4 can maximize the number of meshing teeth between the flexible gear 2 and the rig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com