A-column reinforced assembly of car body and A-column reinforced structure of car body using same

A technology for strengthening components and strengthening structures, which is applied to vehicle components, superstructures, and superstructure sub-assemblies, etc., can solve problems such as threatening the safety of drivers and passengers, reducing the driver's escape probability, and inability to open the front door, so as to improve the overall performance. Safety, area reduction, effect of attenuating loads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

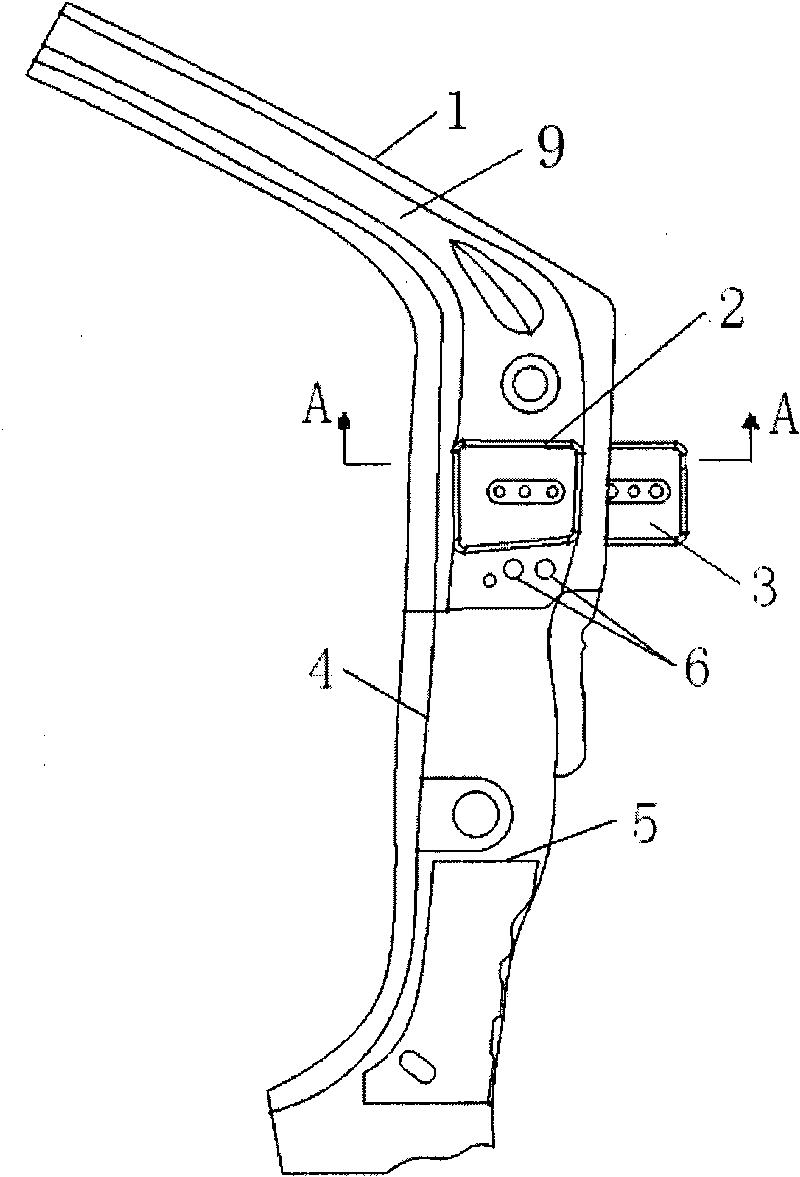

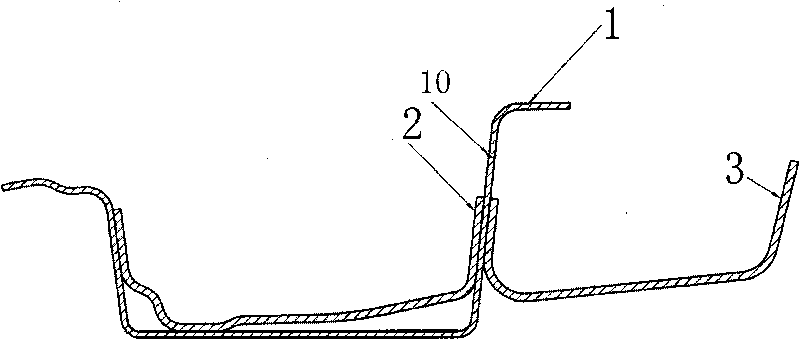

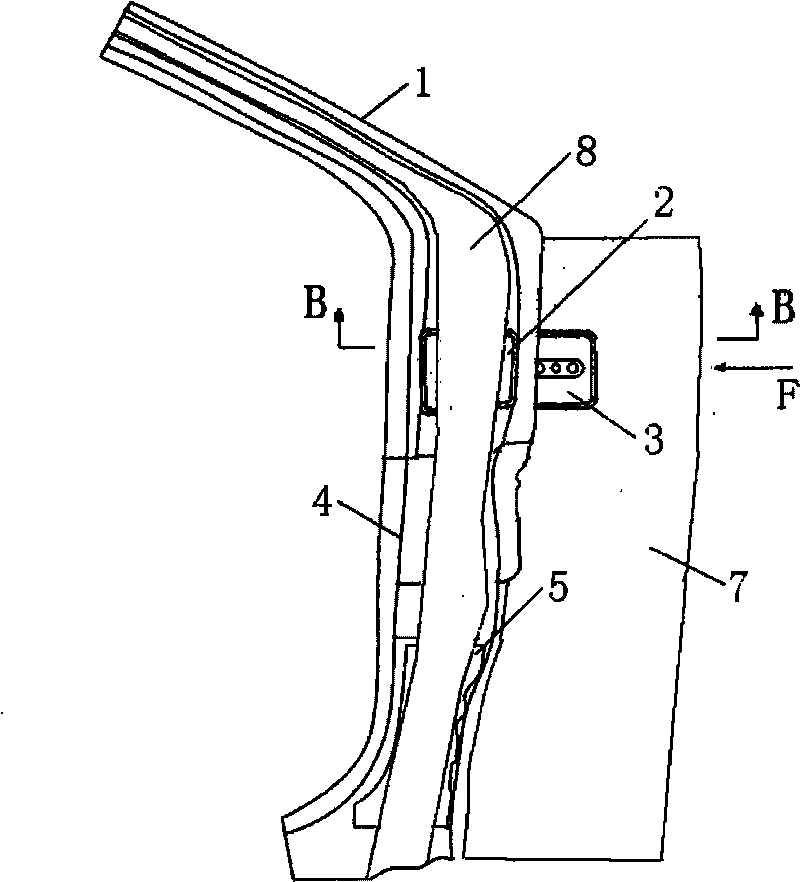

[0017] figure 1 Shown is a schematic diagram of the body A-pillar reinforcement assembly, figure 2 for along figure 1 A cross-sectional view of the body A-pillar reinforcement assembly cut along line A-A in the center.

[0018] Such as figure 1 , figure 2 As shown, the vehicle body A-pillar reinforcement assembly includes an A-pillar reinforcement plate. The A-pillar reinforcement plate is a stamped plate with flanging formed on both sides and bent to form a groove 9 for covering the A-pillar 8 of the vehicle body. . In order to ensure the smooth progress of the stamping process, the A-pillar reinforcement plate is divided into upper and lower sections, that is, the upper section 1 of the A-pillar reinforcement panel and the lower section 4 of the A-pillar reinforcement panel. The upper section 1 of the A-pillar reinforcement panel and the lower section 4 of the A-pillar reinforcement panel are welded firmly connected together. In the groove 9 of the upper part 1 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com