Hydroelasticity test ship model adopting U-shaped keel beam and design method thereof

A design method and hydro-elastic technology, applied in ship design, ship components, ship construction, etc., can solve the problem of not being able to guarantee the natural frequency of the ship model at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

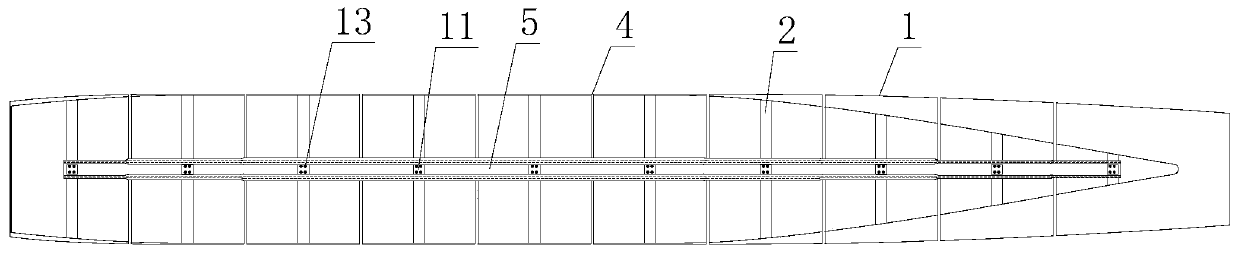

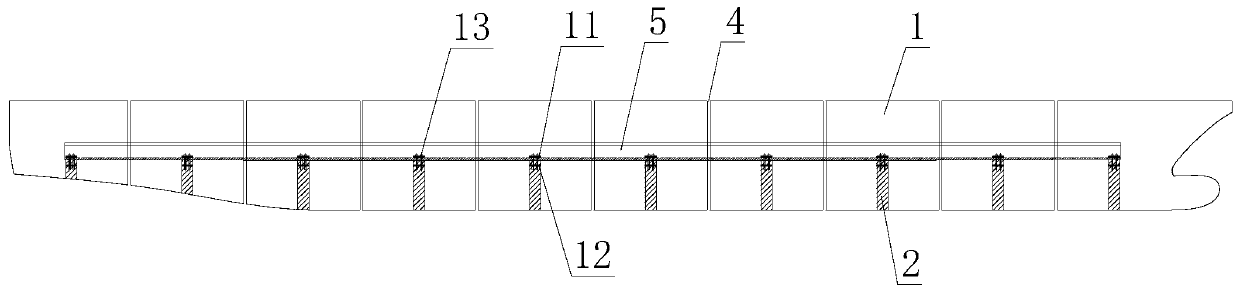

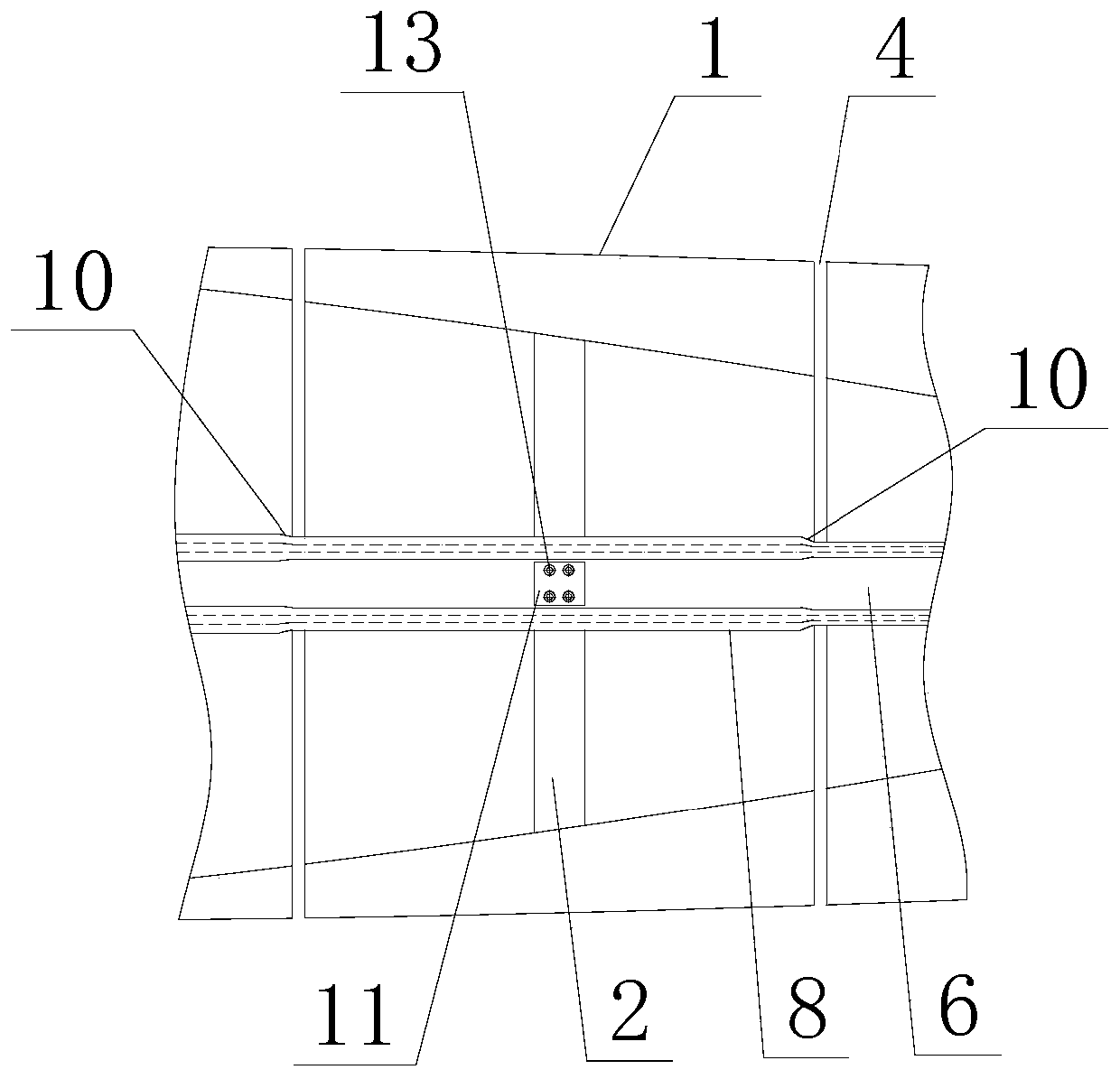

[0028] like figure 1 , 2As shown, a hydroelastic test ship model using U-shaped keel beams, including the hull system and U-shaped keel beams. The hull system consists of segmented hulls, foundations and ballast blocks. The outer contour of the segmented hull is scaled according to the real ship shape line to ensure that the flow field distribution around the ship model is similar to the actual situation. Disconnect the hull at the load measurement section and cut off the corresponding hull width to form a certain gap, the purpose is to prevent the collision and influence of each section of the hull when it is deformed by motion. Silicone strips are used to seal the gaps between adjacent segmented hulls, which can prevent water from entering the interior of the hull f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com