Combined frame front overhang structure

A combined and combined bracket technology, which is applied in the substructure, vehicle components, transportation and packaging, etc., can solve the problems of insufficient strength and torsional rigidity at the front end of the frame, insufficient space for parts layout, and excessive torsion of the vehicle, etc., to achieve Meet the strength requirements, save layout space, and reduce the effect of types

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The features and principles of the present invention will be described in detail below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, not to limit the protection scope of the present invention.

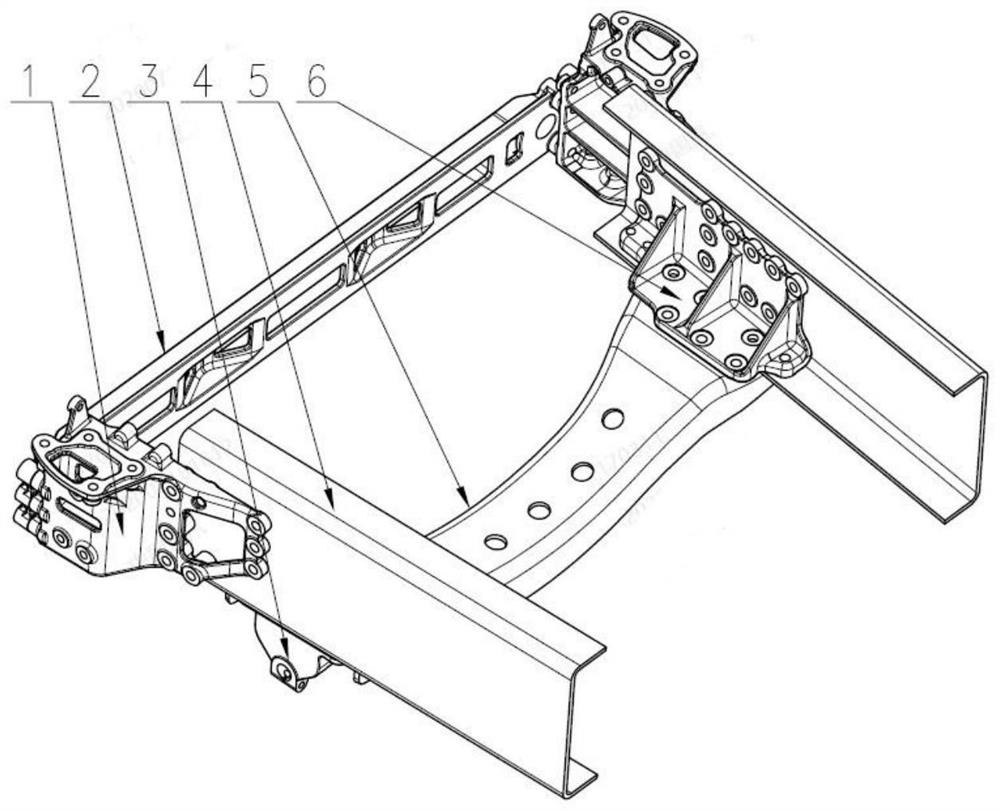

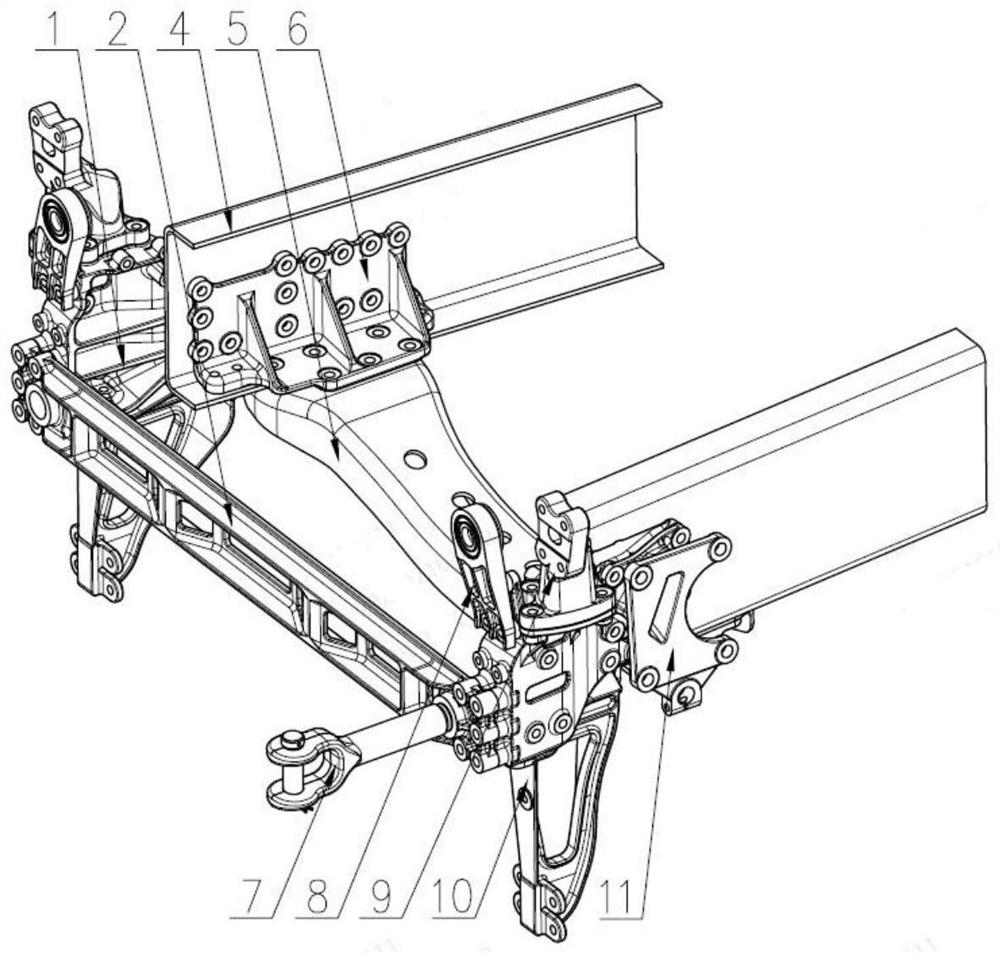

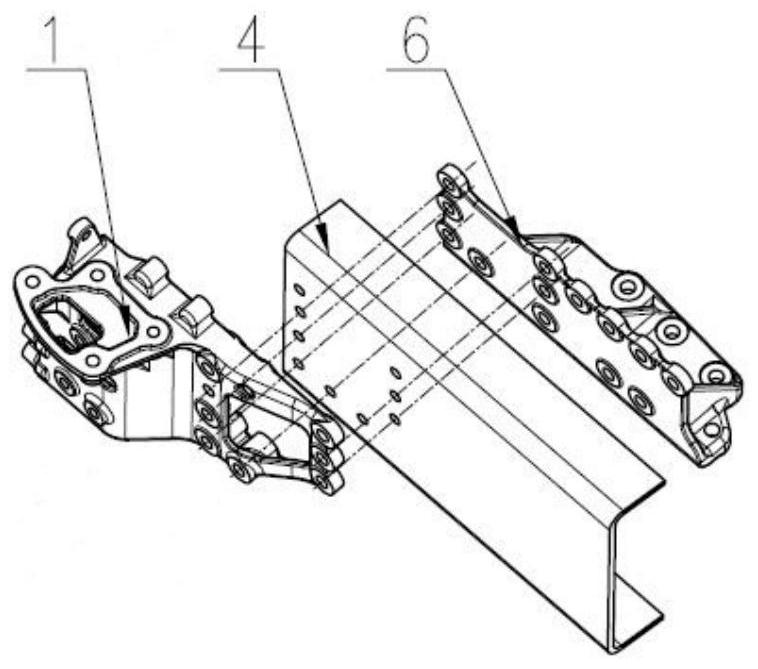

[0023] Such as figure 1 As shown, a combined frame front suspension structure involved in this technical solution includes a front beam 2, a front suspension composite bracket 1, an inner reinforcement bracket 6, a rear curved beam 5, a leaf spring bracket 3 and a vehicle frame 4. The front beam, the front suspension combination bracket, the inner reinforcement bracket, the rear curved beam, the leaf spring bracket and the vehicle frame body are installed and fixed to form a quadrilateral frame structure.

[0024] The rear end of the front suspension combined bracket 1 is fixedly connected with the belly surface of the vehicle frame 4 by bolts, and the front suspension combined bracket 1 is symmetrically dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com