Multi-continuum robot modular unit, continuum robot and application

A continuum, robot technology, applied in manipulators, claw arms, manufacturing tools, etc., can solve problems such as low bending and torsional stiffness, difficulty in improving the load capacity of continuum, and large maintenance tasks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

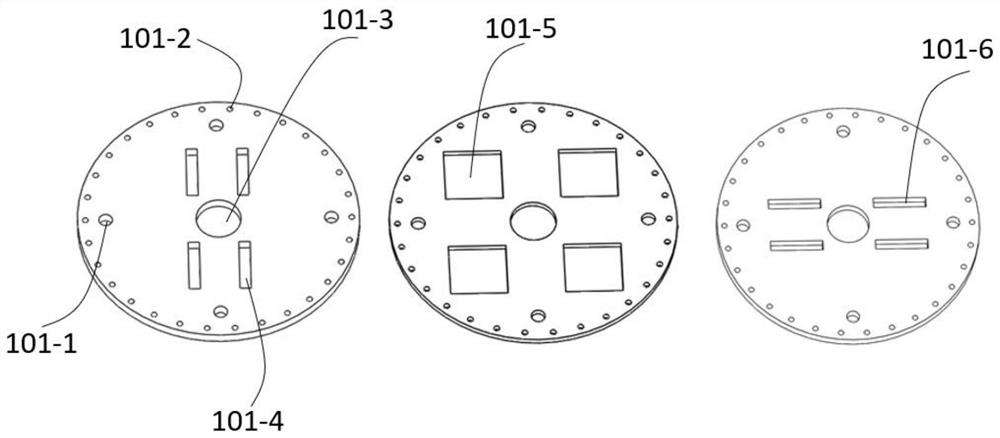

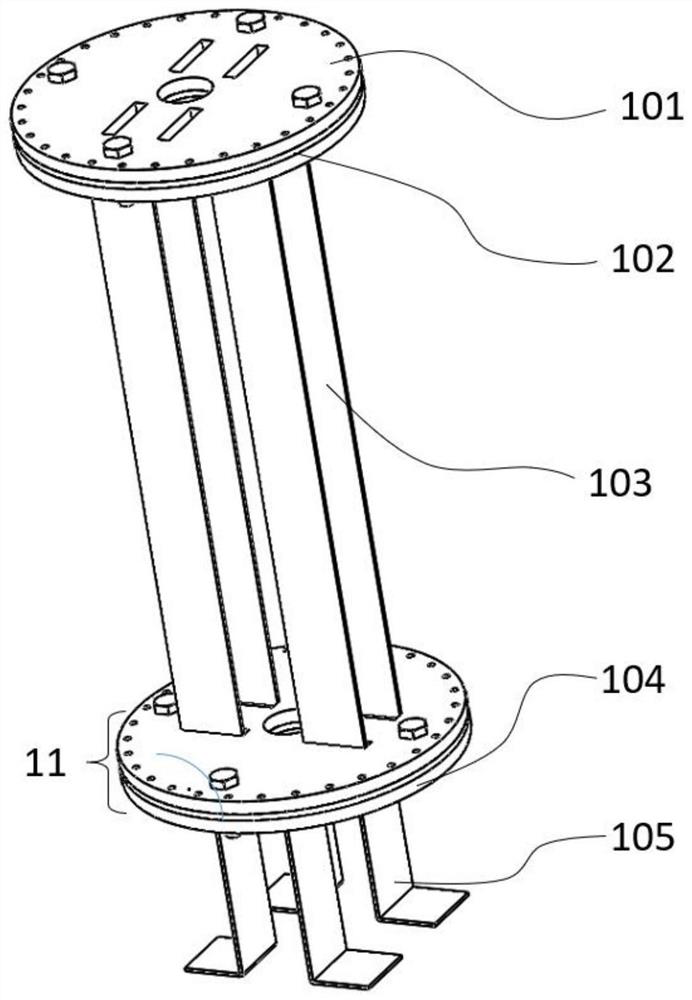

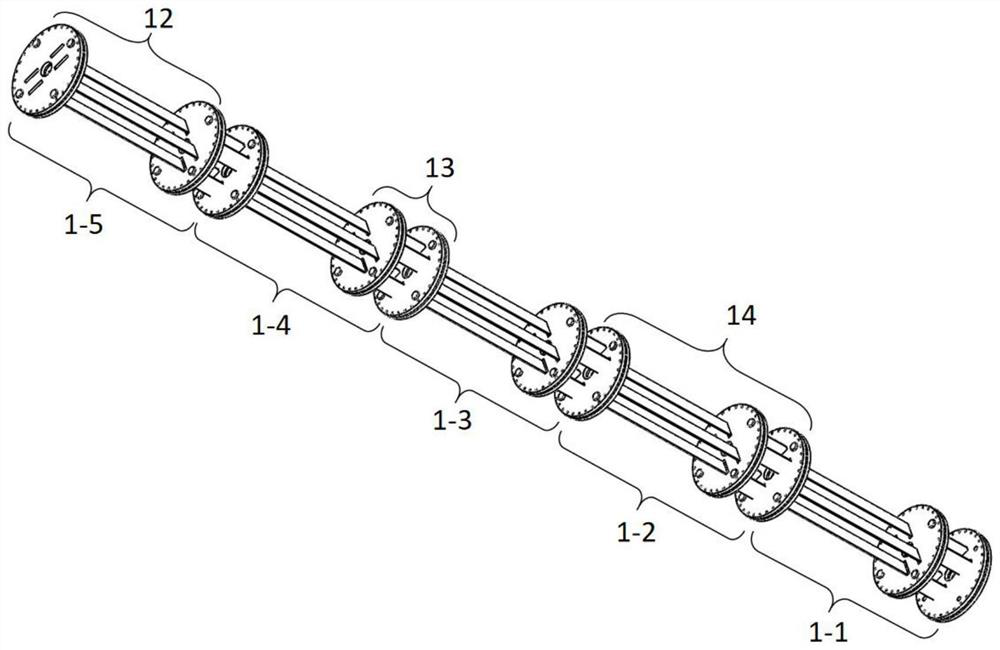

[0062] The first modular unit configuration of the continuum robot in the present invention includes: a fixed plate or spacer plate 11 , a long flexible piece 103 , and a short flexible piece 105 .

[0063] Furthermore, the fixed disk is composed of three structural disks: the upper fixed disk 101, the middle fixed disk 102 and the lower fixed disk 104. The three disks have order requirements, and the correct assembly of the three disks can achieve effective positioning with the flexible sheet.

[0064] Further, the flexible sheet includes a long flexible sheet 103 and a short flexible sheet 105, and changing the thickness, width, and spacing between two flexible sheets can change the stiffness of the execution arm of the continuum robot in the current segment; the continuum robot module Each small section of the unit is separated by a long flexible piece 103 and a short flexible piece 105 by a fixed plate 11. Wherein, a circle of lead holes 101-2 is arranged around the fixed ...

Embodiment 2

[0071] The modular unit 2 - 1 of the second type of continuum robot, etc., features a fixed plate, a flexible sheet 205 and a middle rod 204 . The fixed plate is used to fix and limit the layout of the flexible sheet. The flexible sheet is a highly elastic material. The middle rod 204 is a material with a higher modulus of elasticity than the flexible sheet 205, and the distance between the middle rods 204 can be adjusted according to different rigidities required.

[0072] Further continuum robot modular units are symmetrically arranged up and down.

[0073] The further upper and lower discs consist of three different discs respectively.

[0074] Further, a circle of lead holes is arranged on the inner side of the edge of the disc, and a lead hole with a slightly larger diameter is arranged in the middle of the disc.

[0075] Compared with the prior art, the second invention has the following technical effects: each small section of the present invention is composed of fou...

Embodiment 3

[0077] The modular unit of the third type of continuum robot is characterized by a flexible sheet 305, a flexible rod 304 and a fixed plate. The flexible sheet 305 includes at least one long or a short flexible sheet 305; the flexible rod 304 includes at least one long or a short flexible rod 305; a section of the fixed disk includes at least three discs .

[0078] The modular unit 3-1 etc. of the further continuum robot is composed of two interlaced discs.

[0079] The further two staggered disc parts are connected in two configurations.

[0080] The further shorter part is connected by flexible sheet 305 , and the longer part is connected by elastic rod 304 .

[0081] Further, the segments connected by the elastic rods 304 and the segments connected by the flexible sheet 305 are interleavedly connected to form a modular unit of the continuum robot.

[0082] Compared with the prior art, the third invention has the following technical effects: the present invention is compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com