Versatile and modular workpiece holding device

A technology for holding devices and workpieces, which is applied in the direction of grinding workpiece supports, maintenance and safety accessories, manufacturing tools, etc. It can solve problems such as difficult universal workpiece holding devices, and achieve the effects of optimizing acceleration, convenient operation, and avoiding play and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

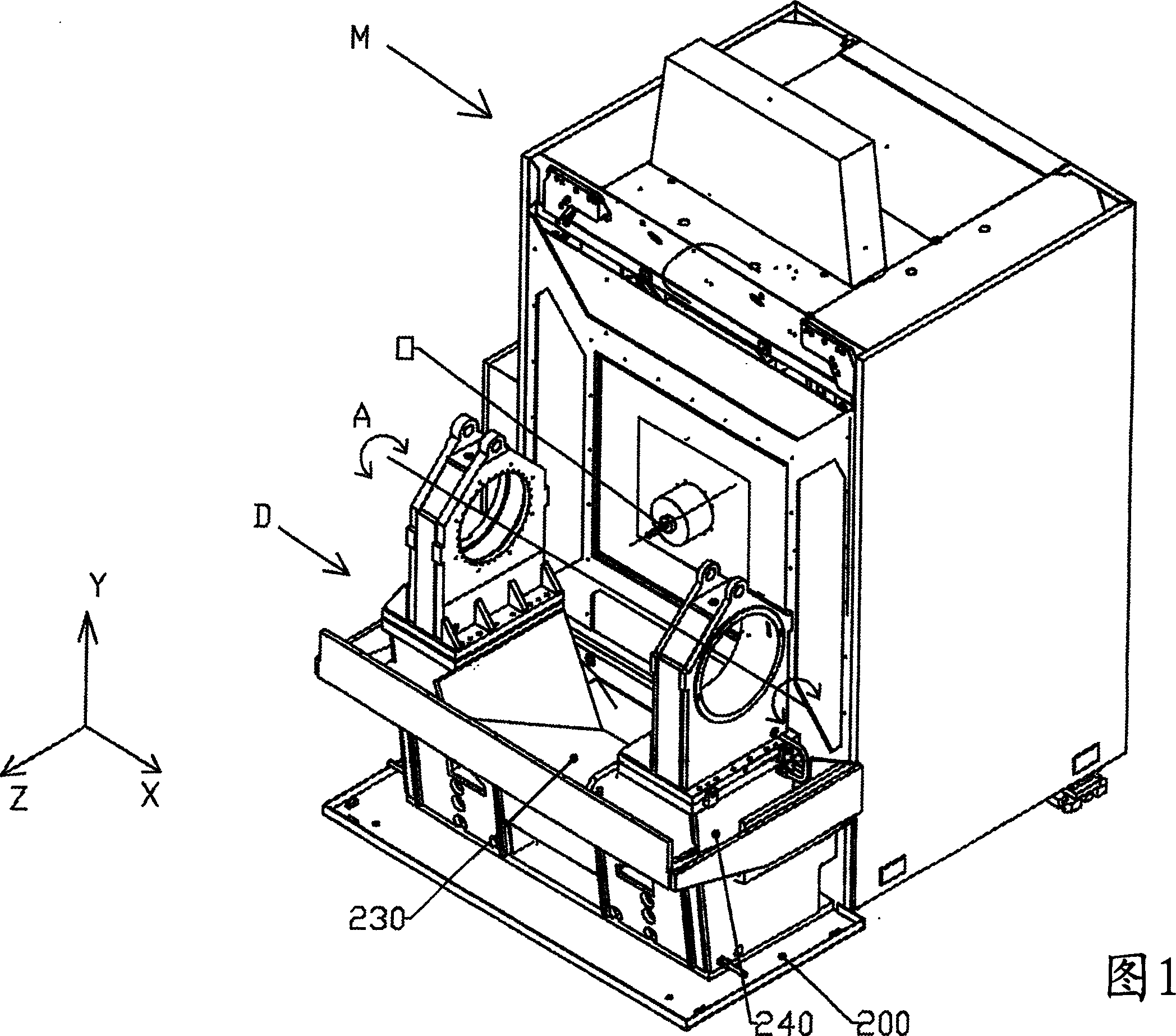

[0037] As shown in FIG. 1, the workpiece holding device generally designated D has a reference axis of rotation A which intersects the longitudinal axis Z of a tool O of a processing machine M associated with the device D . According to the illustrated but non-limiting embodiment, the machining machine M is a high-speed machining tool that provides actuation in three axes X, Y, Z along a sliding tool holder O. According to the non-limiting embodiment shown, said device D thus provides for the rotation of the workpiece (not shown) to be machined along a horizontal axis of rotation A intersecting the longitudinal axis of rotation Z of said tool O. Therefore, axis A is parallel to axis X.

[0038]In order to better show the position of the device D relative to the processing tool, the rotatable table of the device has been removed, so that only the frame supporting the two bearings appears.

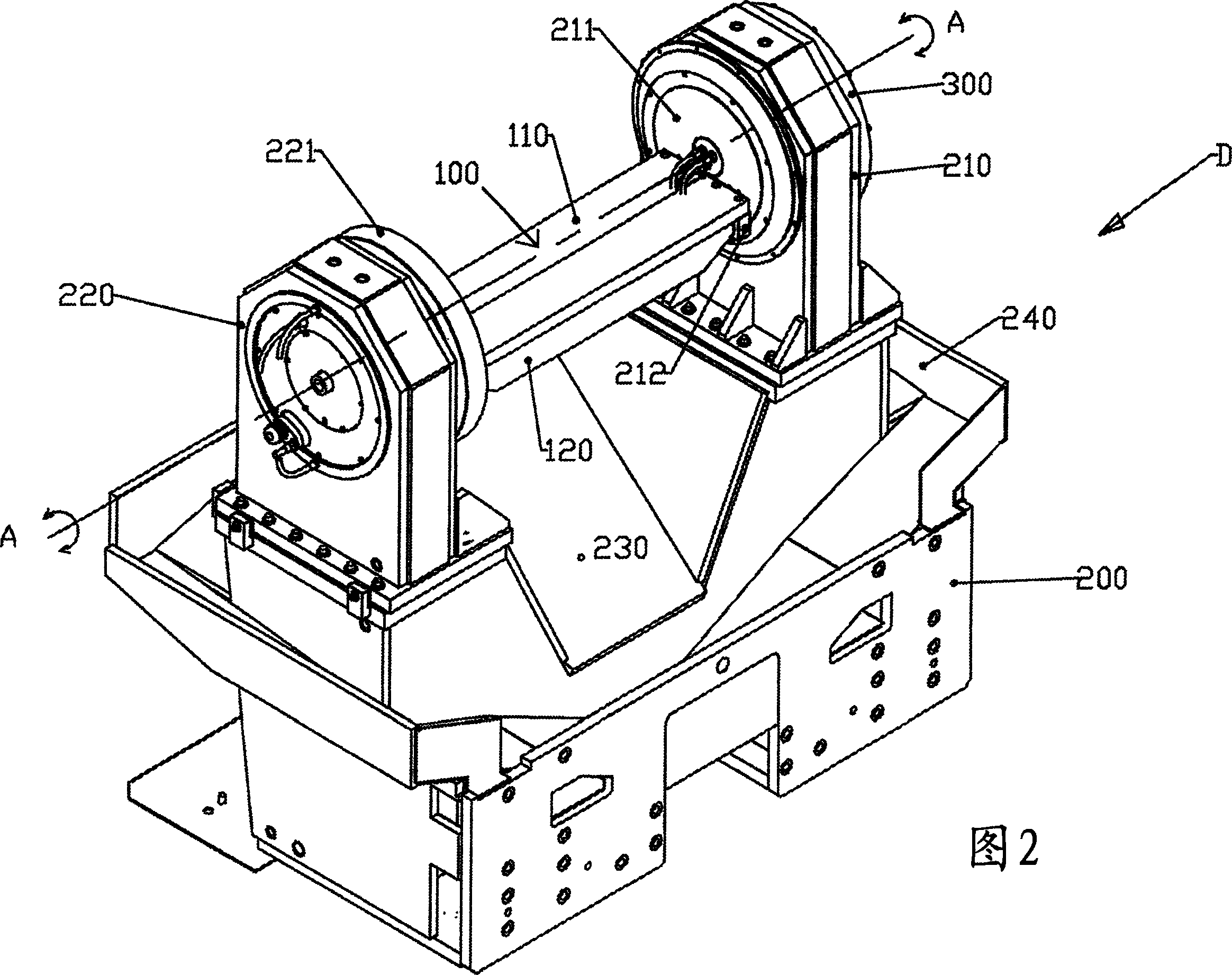

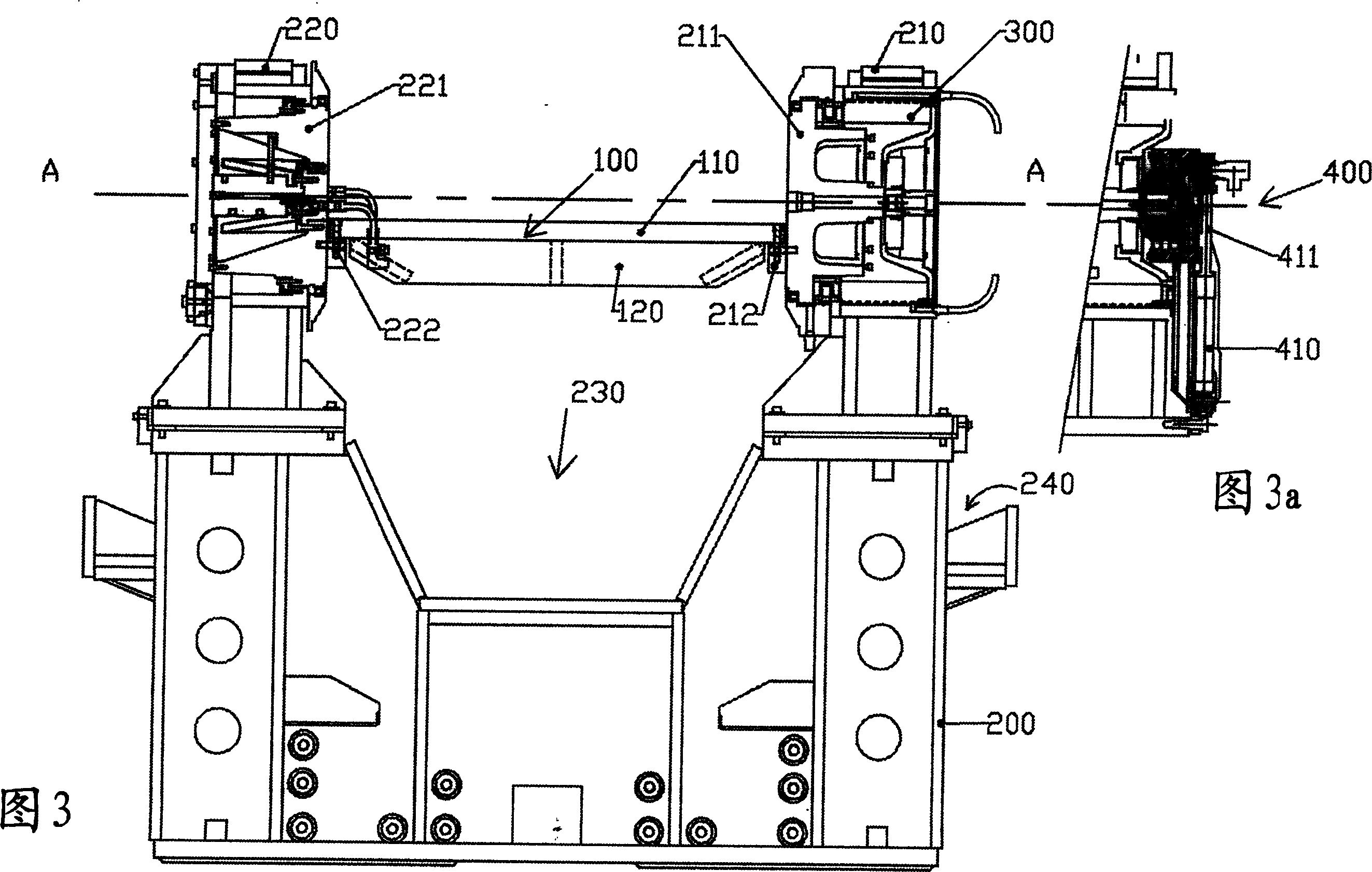

[0039] According to the invention, and as shown in Figures 2 and 3, the device D compr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com