Guide shoe and carding head for the carding bar of a card

The technology of a flat head and a carding machine is applied in the field of guiding shoes of the carding head, which can solve the problems of obtaining and the like, and achieve the effect of avoiding elastic deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

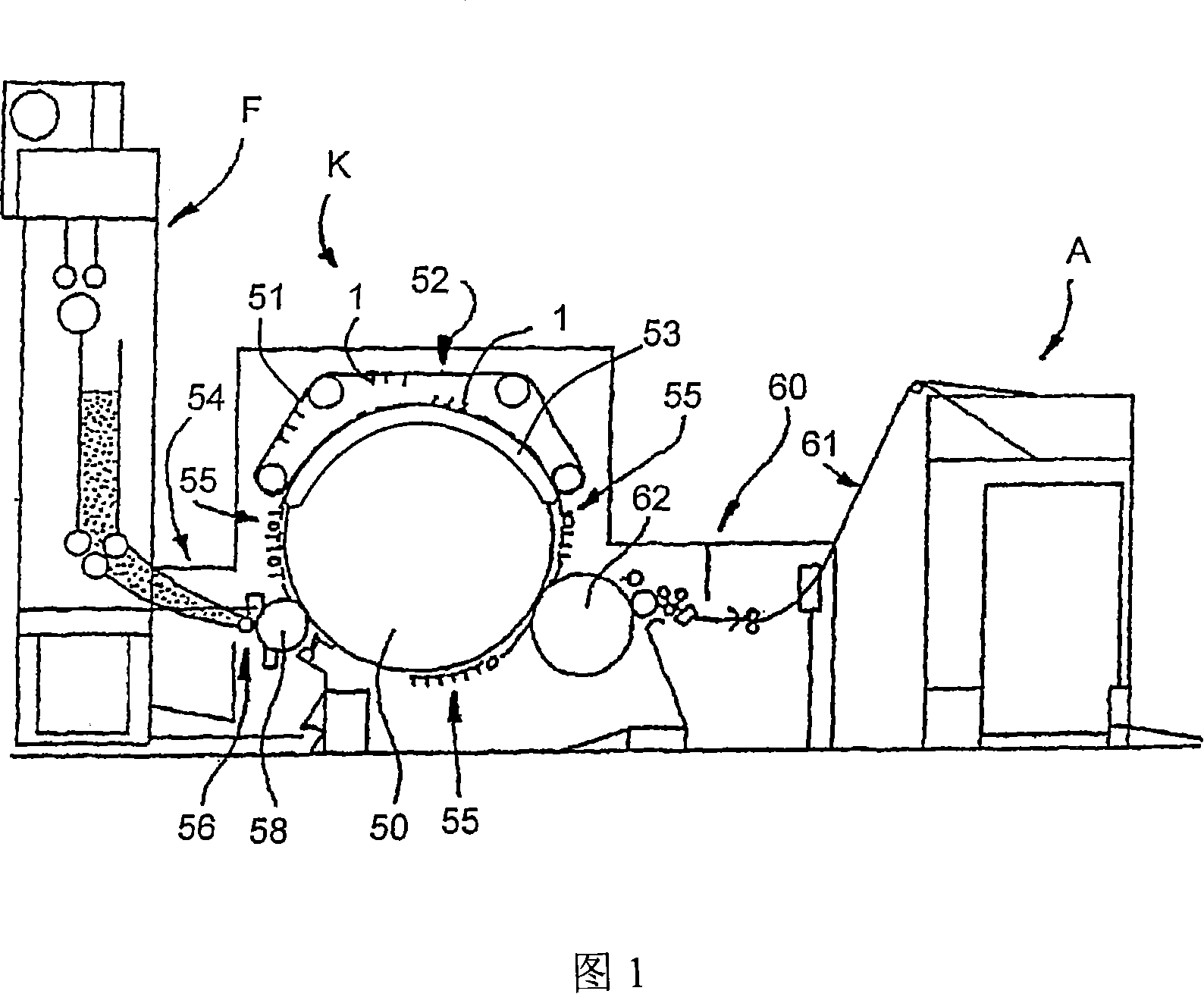

[0052] FIG. 1 shows a known card K in which the fiber tow from a feed box F is fed to a feed roller 56 followed by a licker-in 58 . The card K comprises a cylinder 50 (so-called main cylinder or drum) rotatably mounted in a frame. The cylinder 50 cooperates in a known manner with a rotary flat unit 52, a fiber feed system 54, comprising in particular a feed roller 56 and a licker-in roller 58, and a fiber removal system 60, the fiber discharge system 60 In particular, so-called doffing cylinder 62 is included. The fixed carding elements 55 can be attached to the pre-carding zone, the post-carding zone and the carding zone of the carding machine K. The fiber discharge system 60 delivers the sliver 61 to the sliver storage system A shown in the figure.

[0053] A plurality of card flats 1 are arranged on said rotating flat arrangement 52 , of which only the individual card flats 1 are shown schematically in FIG. 1 . The carding flats 1 are transported near their respective fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com