Method for performing single repiecing operation on yarn at work station position of free-end spinning machine

A technology of spinning machine and free end, which is applied in the field of separate spinning operation of yarn at the station of free end spinning machine, which can solve the problems of longer total time and relatively long occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

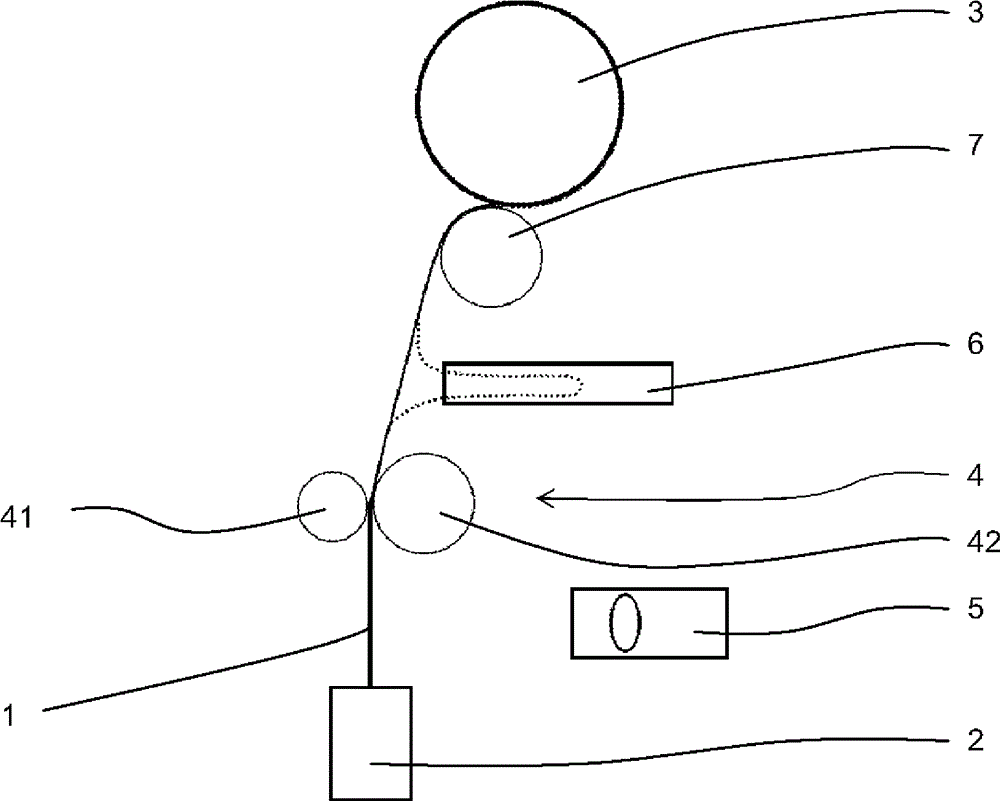

[0008] The method of spinning-in yarn at the station of the open-end spinning machine according to the present invention is intended for a separately-driven open-end spinning machine with a winding drum and a take-out mechanism, The station is equipped with a yarn length undervoltage compensator in the space between the winding drum and the lead-out mechanism-see figure 1 .

[0009] During the spinning-up of the yarn 1, for example after it is broken, the machine operator first cleans the spinning rotor of the spinning unit 2 not shown if necessary, and may also clean other parts of the station, where the yarn has stopped. If necessary, the technical device or the operator of the station lifts it to find the end of the yarn 1, or extracts it from the unshown device for finding the end of the yarn 1, and measures The length of the yarn 1 necessary for inserting the end of the yarn 1 into the extraction tube (not shown) outside the gathering groove of the spinning rotor of the spi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com