Residual power line winding device for screw rod sliding block type stator assembly production

A technology of stator assembly and screw slider, which is applied in the directions of transportation and packaging, delivery of filamentous materials, thin material processing, etc., can solve the problems of low efficiency of manual winding recovery, affecting the speed of production change, etc., and achieves It is convenient to switch, increase the speed of production change, and speed up the production cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

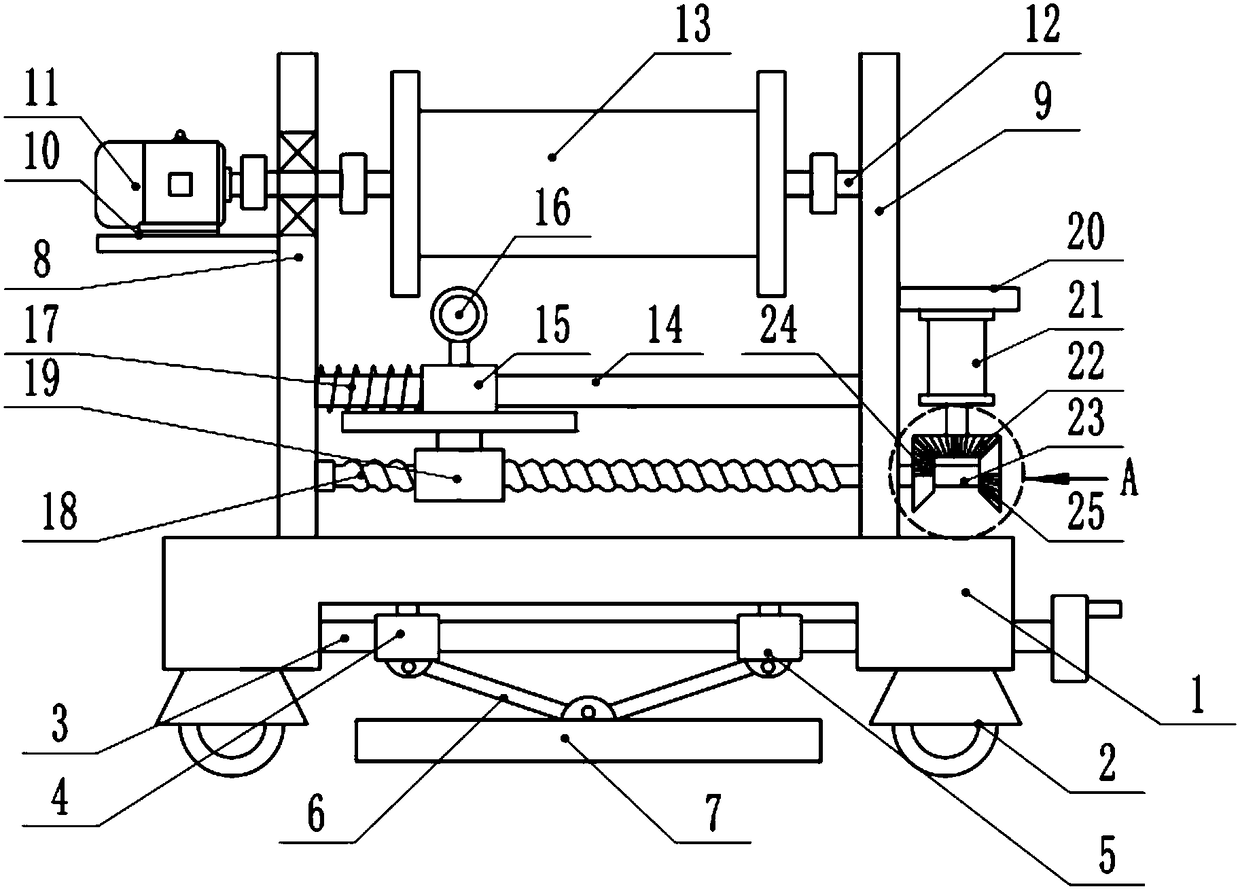

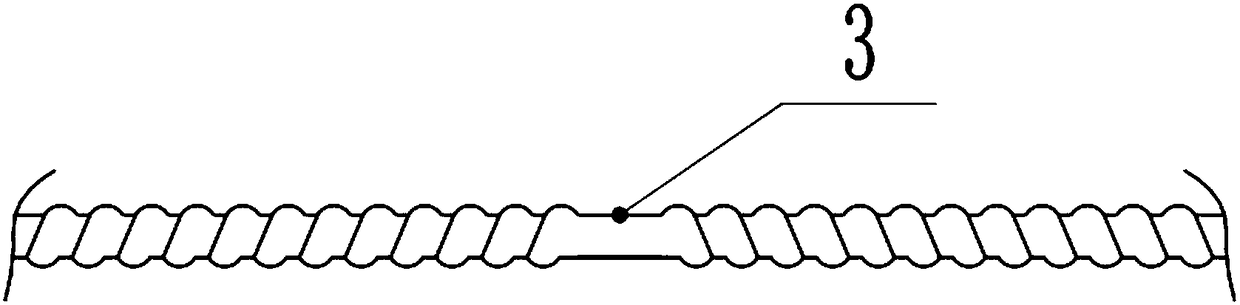

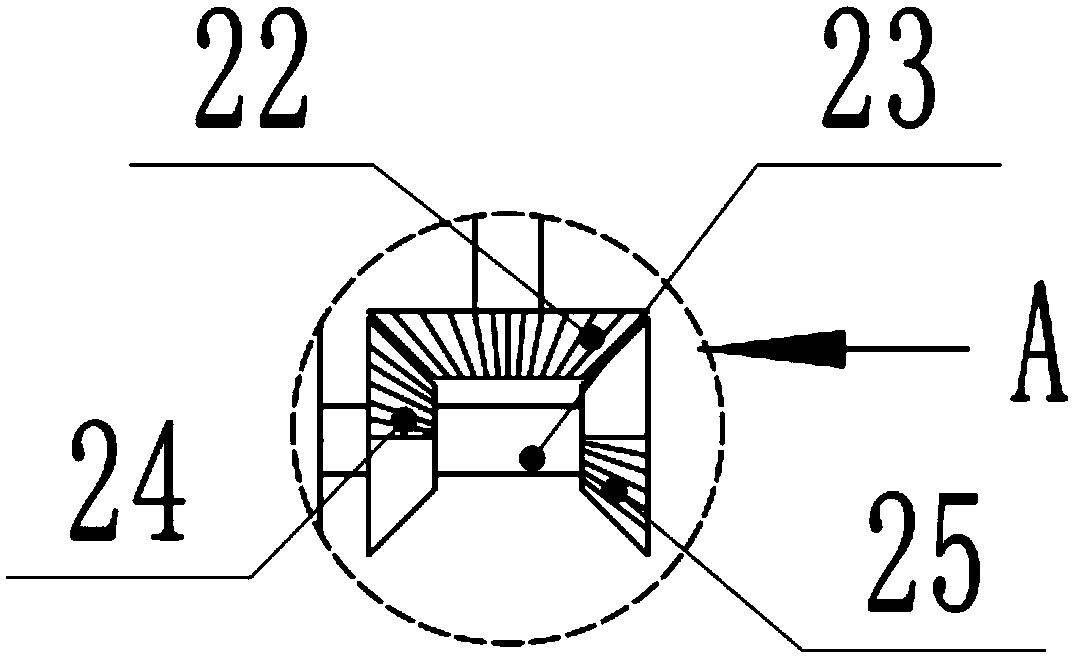

[0021] see Figure 1-3 , a screw slider type stator assembly production surplus power cord winding device, including a base 1, a stable base 7, a first drive motor 11, a bobbin 13, a lead coil 16 and a second drive motor 21, the The four corners of the lower side of the base 1 are provided with universal wheels 2, the bottom of the base 1 is a groove, and a ball screw 3 is installed through the bearing rotation, and the right end of the ball screw 3 passes through the base 1 and is fixedly connected with a rocking wheel (Fig. not marked in ), the left and right parts of the ball screw 3 are tapped with threads and the thread directions of the left and right parts of the ball screw 3 are opposite, and the left and right sliders are threaded on the left and right parts of the ball screw 3 respectively. 4 and the right slider 5, the upper sides of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com