Stator core, motor and motor making production method

A stator core and stator technology, which is applied in the manufacture of motor generators, electrical components, electromechanical devices, etc., can solve the problems of small effective contact area, low production efficiency, and complicated process, so as to simplify the production process and improve the production efficiency. , The effect of high winding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

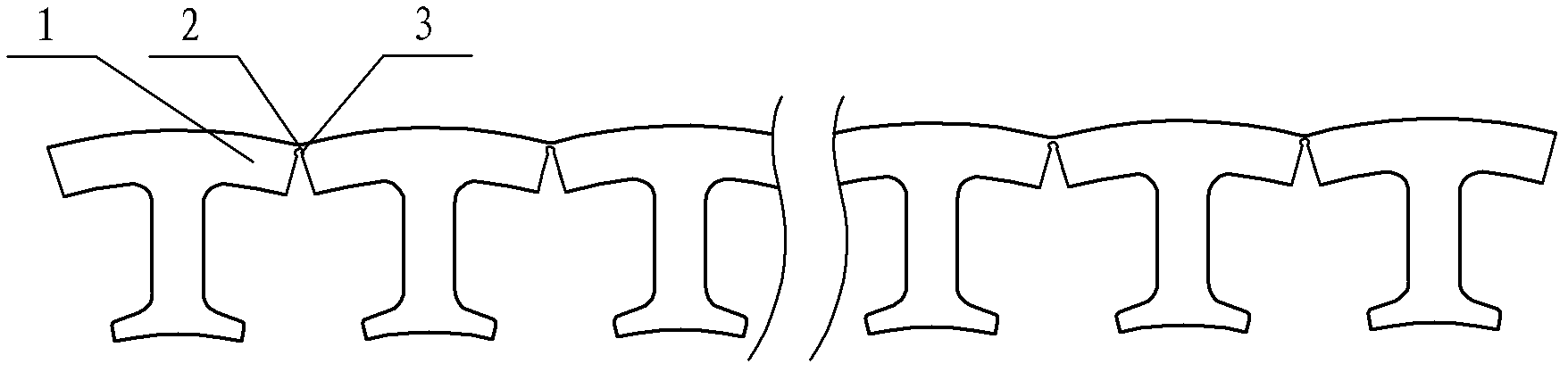

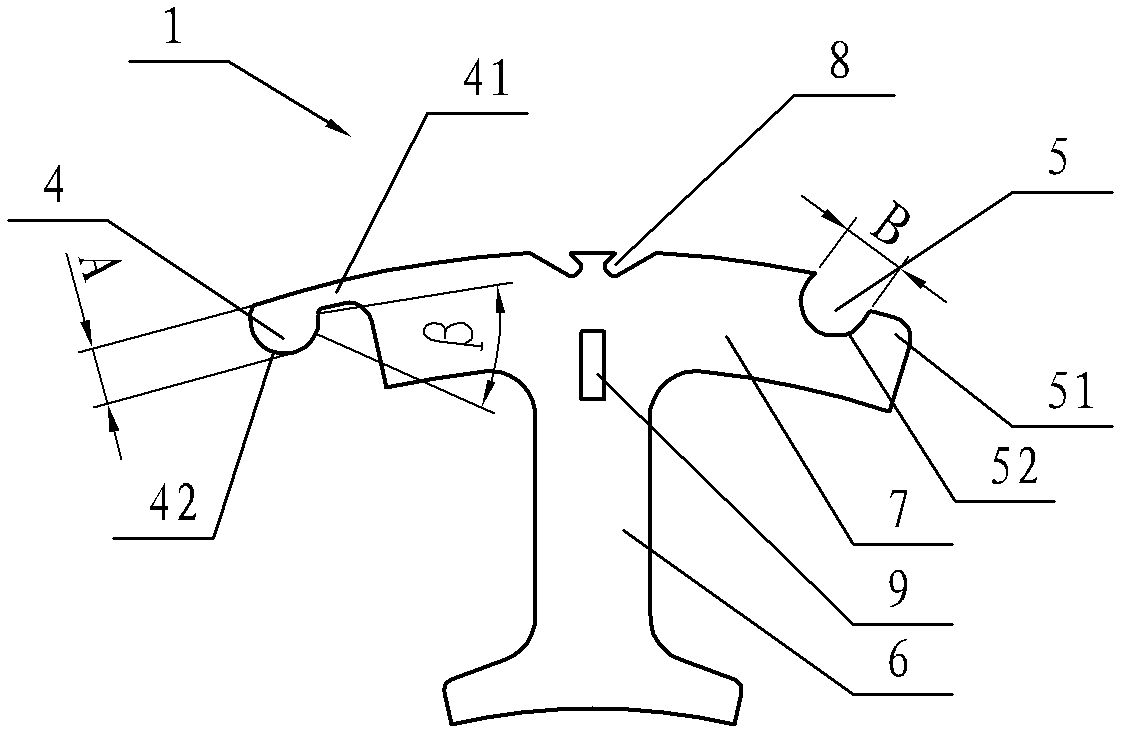

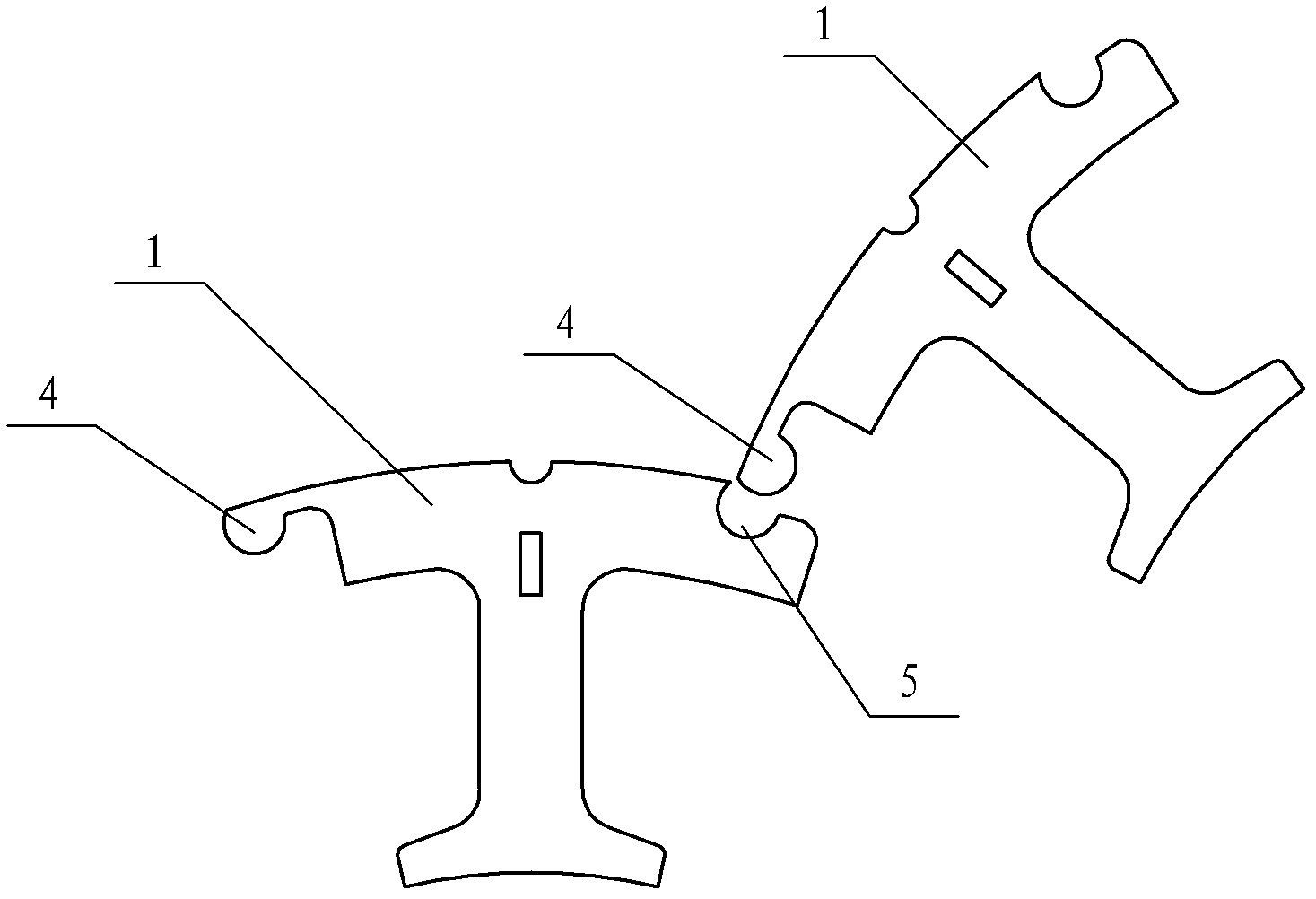

[0028] The stator core is formed by assembling a plurality of tooth-shaped units 1 in the circumferential direction. Each tooth-shaped unit 1 is formed by stacking a certain number of tooth-shaped unit sheets, which has a certain thickness. figure 2 is the plane view of toothed unit 1, and each piece of toothed unit has figure 2 the shape shown. Such as figure 2 As shown, the tooth-shaped unit 1 includes a tooth part 6 for winding, one end of which is provided with a stopper for preventing the coil from slipping, and the other end is a yoke part 7 forming the outer circumference of the stator core, and the winding slots are separated from the teeth. The left and right sides of part 2. The side of the yoke 7 of the tooth-shaped unit 1 away from the tooth is provided with a positioning groove 8 as a positioning part. The shape of the positioning groove 8 can be freely set according to needs, such as dovetail, trapezoid, triangle, arc, etc., as long as it can realize The po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com