Thermal shrinkage film automatic winding mechanism

A heat-shrinkable film and roll material technology, which is applied in the direction of winding strips, thin material processing, transportation and packaging, etc., can solve the problems of uneven winding of shrink film, inconvenient transportation and use, and insufficient shrinkage tension, etc., to achieve production High efficiency, reasonable structure and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

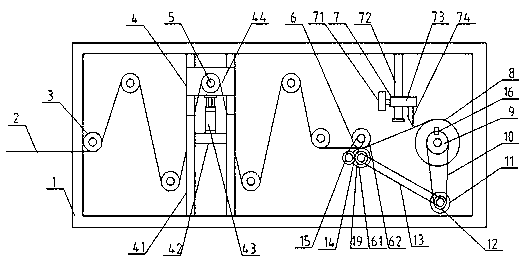

[0030] see Figure 1-4 , the present embodiment provides a heat-shrinkable film automatic rolling mechanism, including a fixed frame 1, a heat-shrinkable film 2, a fixed guide roller 3, and a coil 8; A tension adjustment mechanism 4 is set between the guide rollers 3, and the movable guide roller 5 is installed on the tension adjustment mechanism 4. The heat shrinkable film 2 bypasses the fixed guide roller 3 and the movable guide roller 5, and then passes through the flattening mechanism 6 and is wound on the coil drum 8 Above, the motor 11 drives the reel drum 8 to rotate through the chain drive to roll the material. The film cutting mechanism 7 is arranged at the front of the reel drum 8. When the heat shrinkable film 2 is wound to the set thickness on the reel drum 8, the heat shrinkable film 2 Contact with the film cutting mechanism 7 to automatically cut off the heat shrinkable film 2;

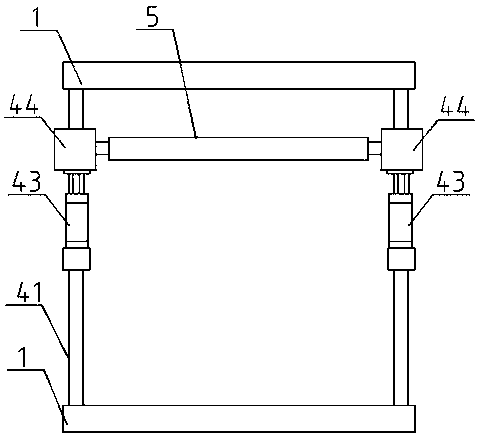

[0031] Described tension adjustment mechanism 4 comprises connecting column 41, cyl...

Embodiment 2

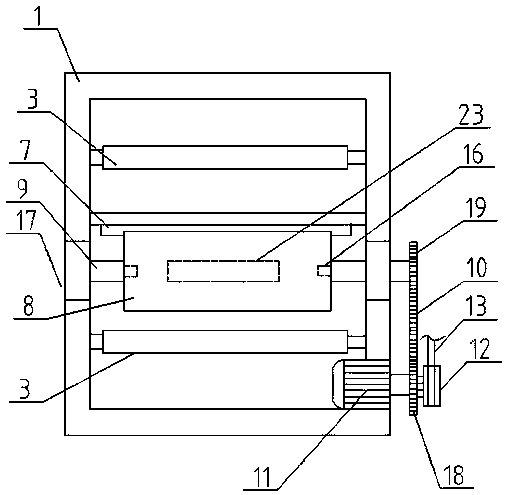

[0038] see figure 2 , the structure of this embodiment is the same as that of Embodiment 1. An electric heater 23 is arranged on the coil material roller 9, and the electric heater 23 is located in the coil material drum 8. When being wound on the reel 8, the electric heater 23 heats it, making it more tightly wound on the reel 8.

[0039] Working principle of the present invention:

[0040]The present invention provides an automatic winding mechanism for heat-shrinkable film. The heat-shrinkable film 2 bypasses the fixed guide roller 3 and the movable guide roller 5, and then winds on the winding drum 8 through the flattening mechanism 6, and the motor 11 drives the winding drum 8. Rotate to roll the material; the flattening mechanism 6 rolls and cooperates with the lower flattening roller 61 and the upper flattening roller 62 to flatten the heat shrinkable film 2 and transport it to the coiling drum 8; the connection between the coiling drum 8 and the coiling roll 9 Set t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com