Patents

Literature

142results about How to "Neatly rolled" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

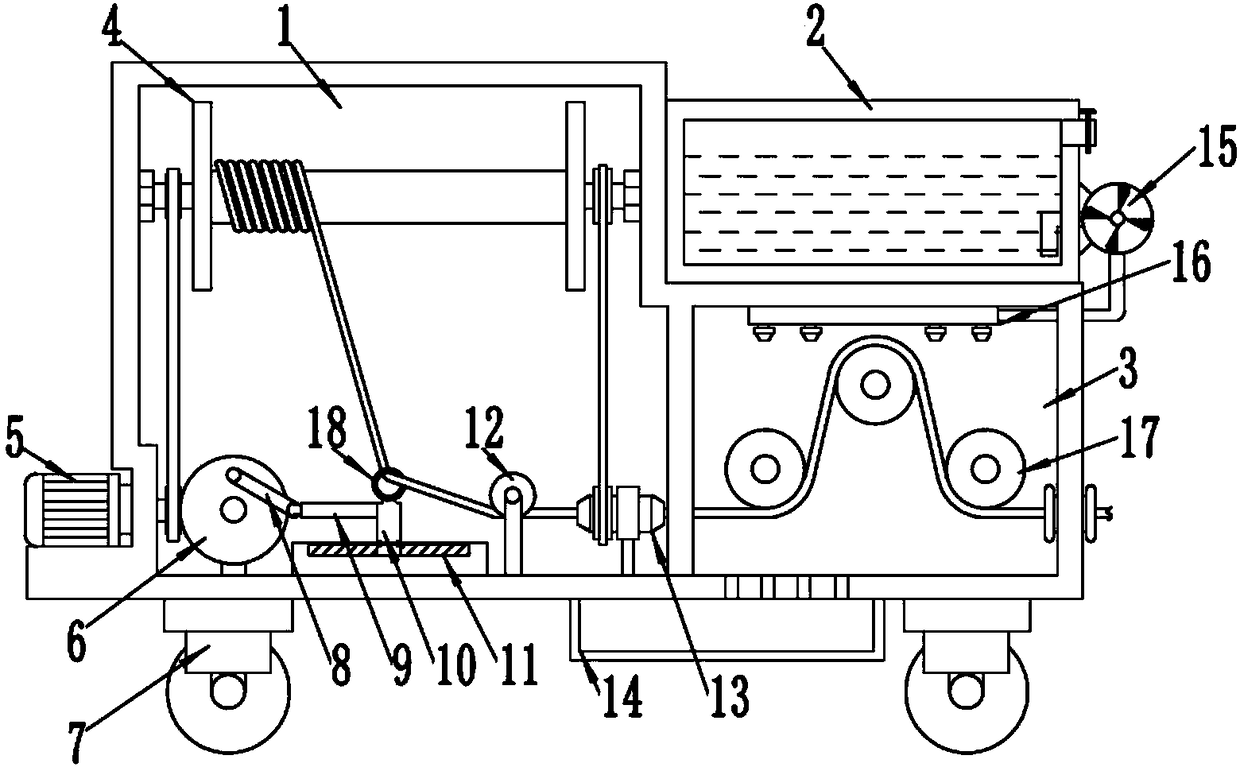

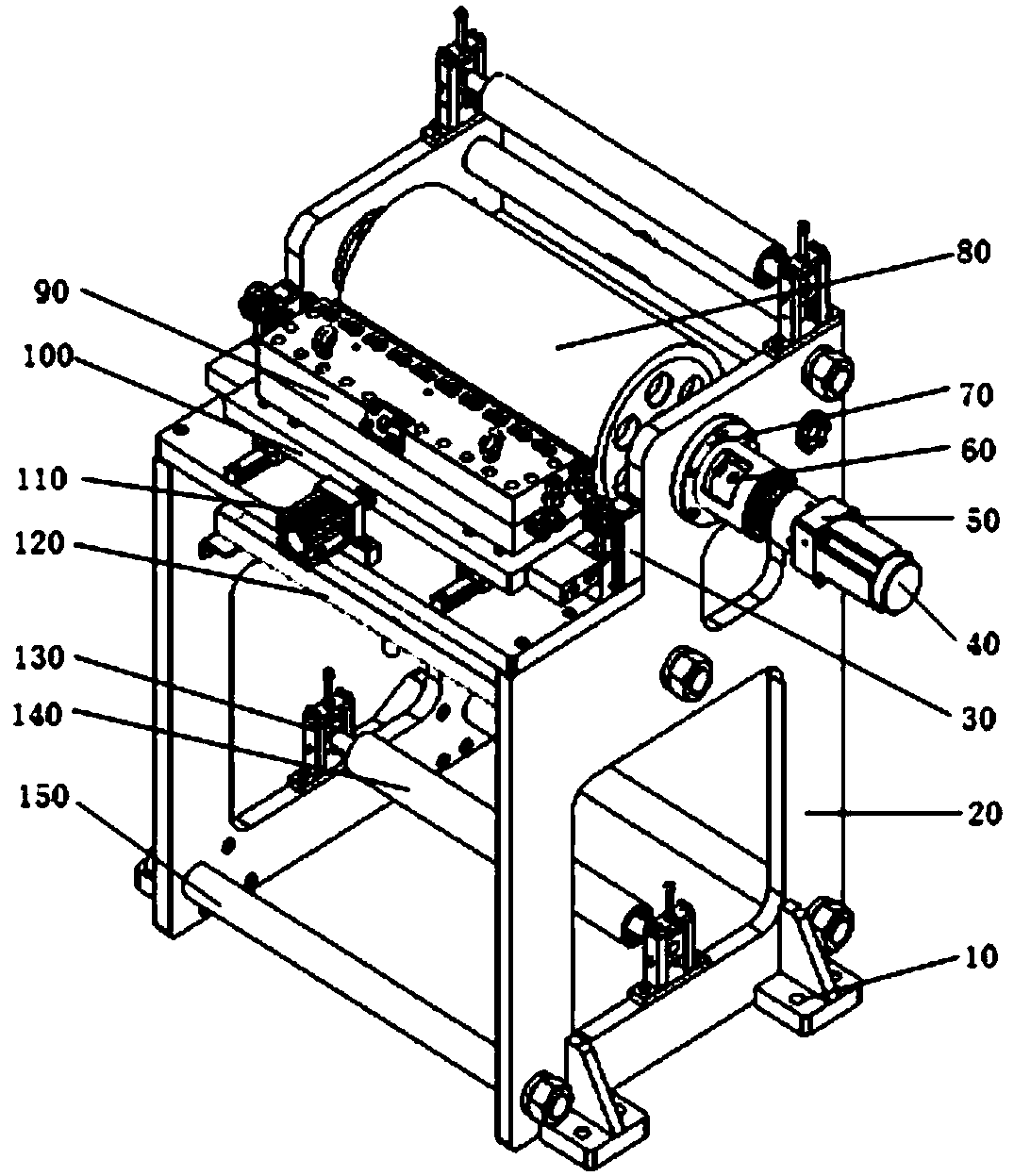

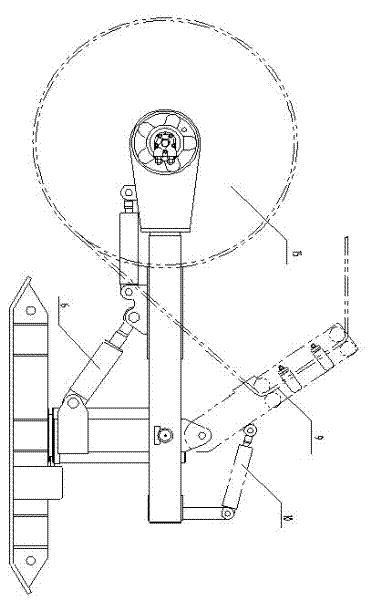

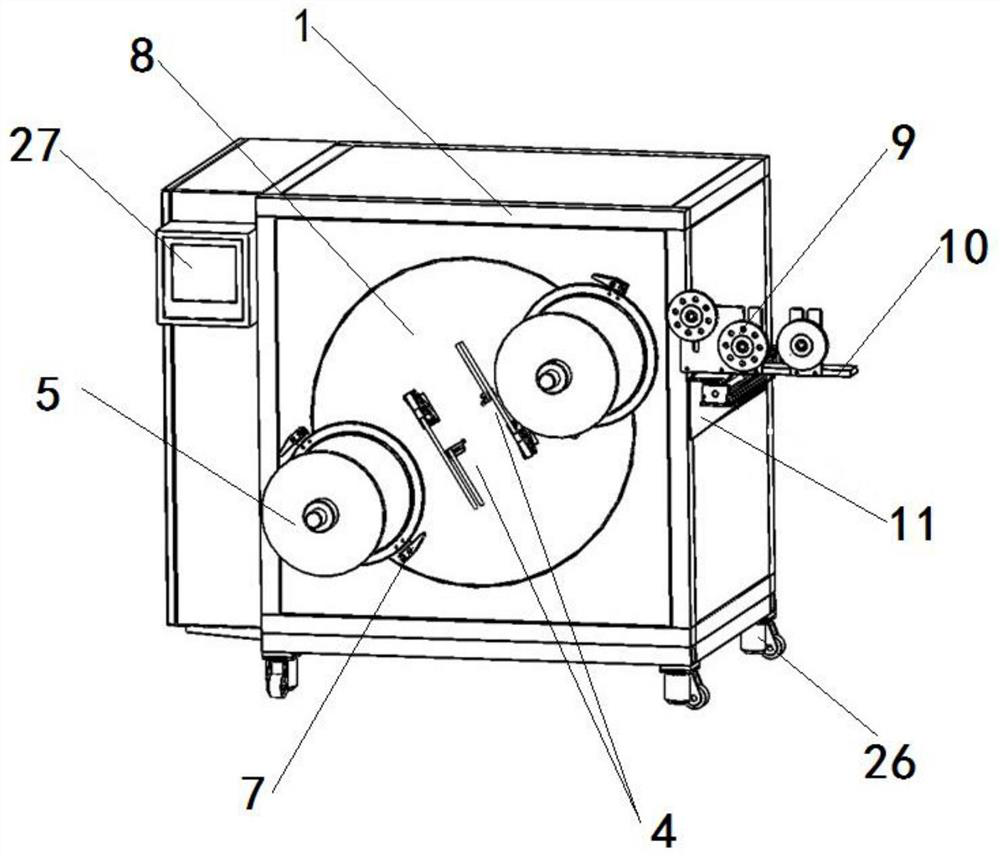

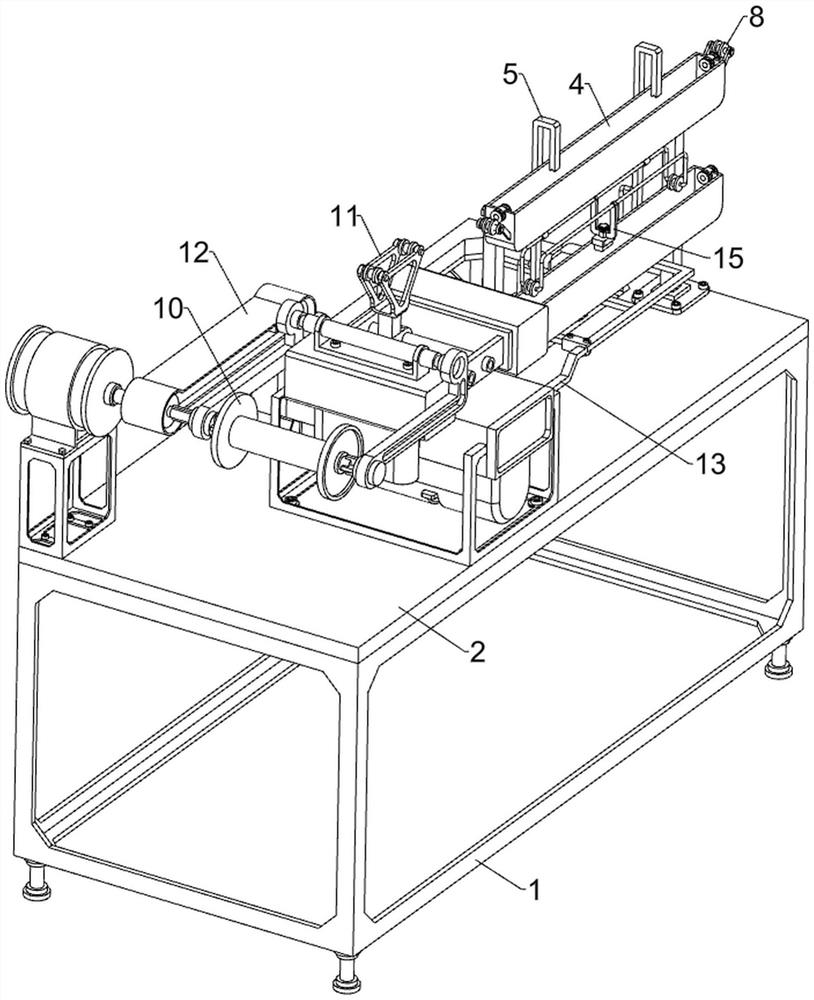

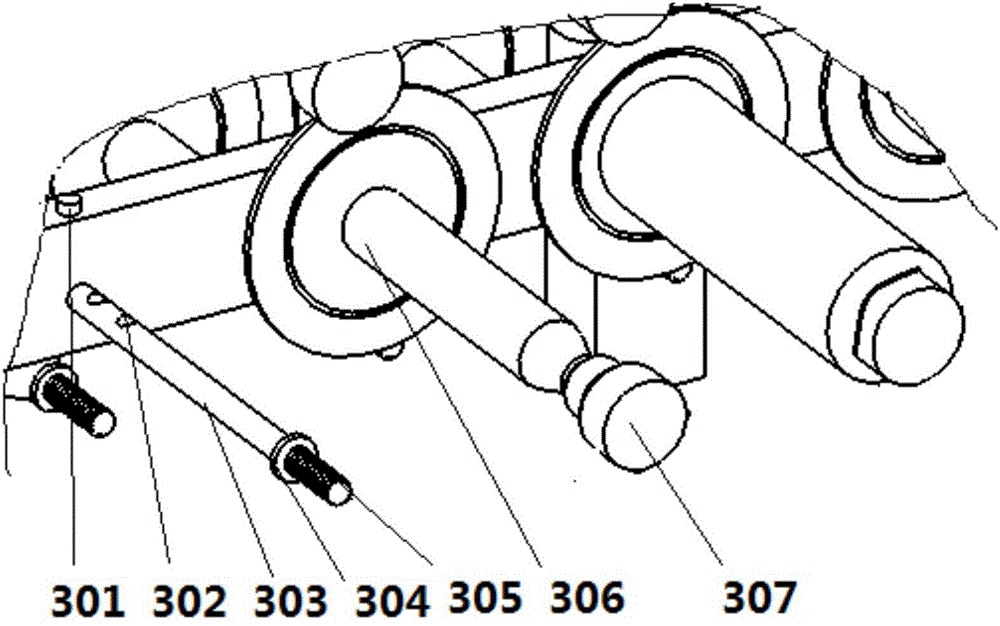

Splitting winding machine for base paper

ActiveCN101301969ACut evenlyOffset is automatically eliminatedMetal working apparatusArticle deliveryWinding machineEngineering

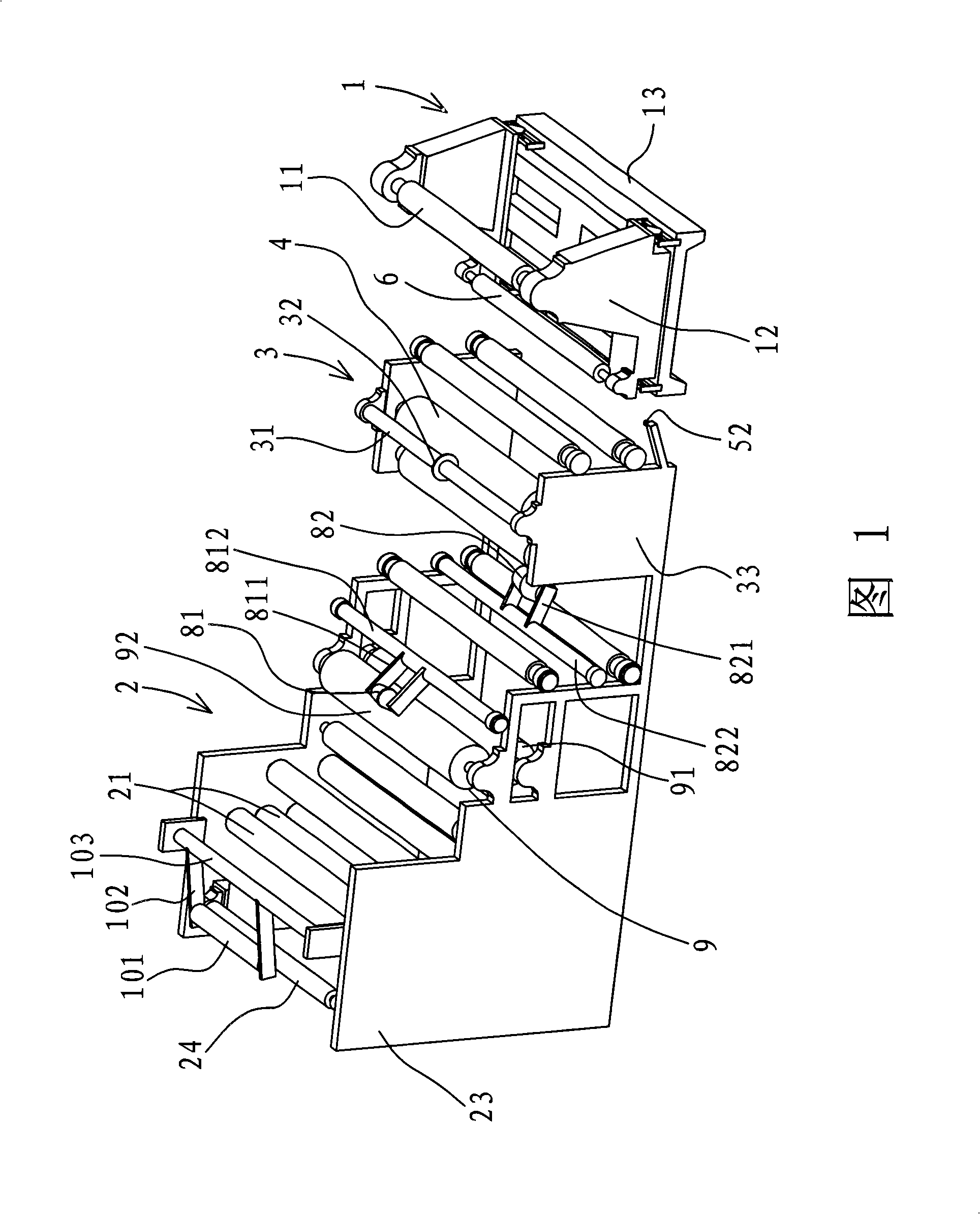

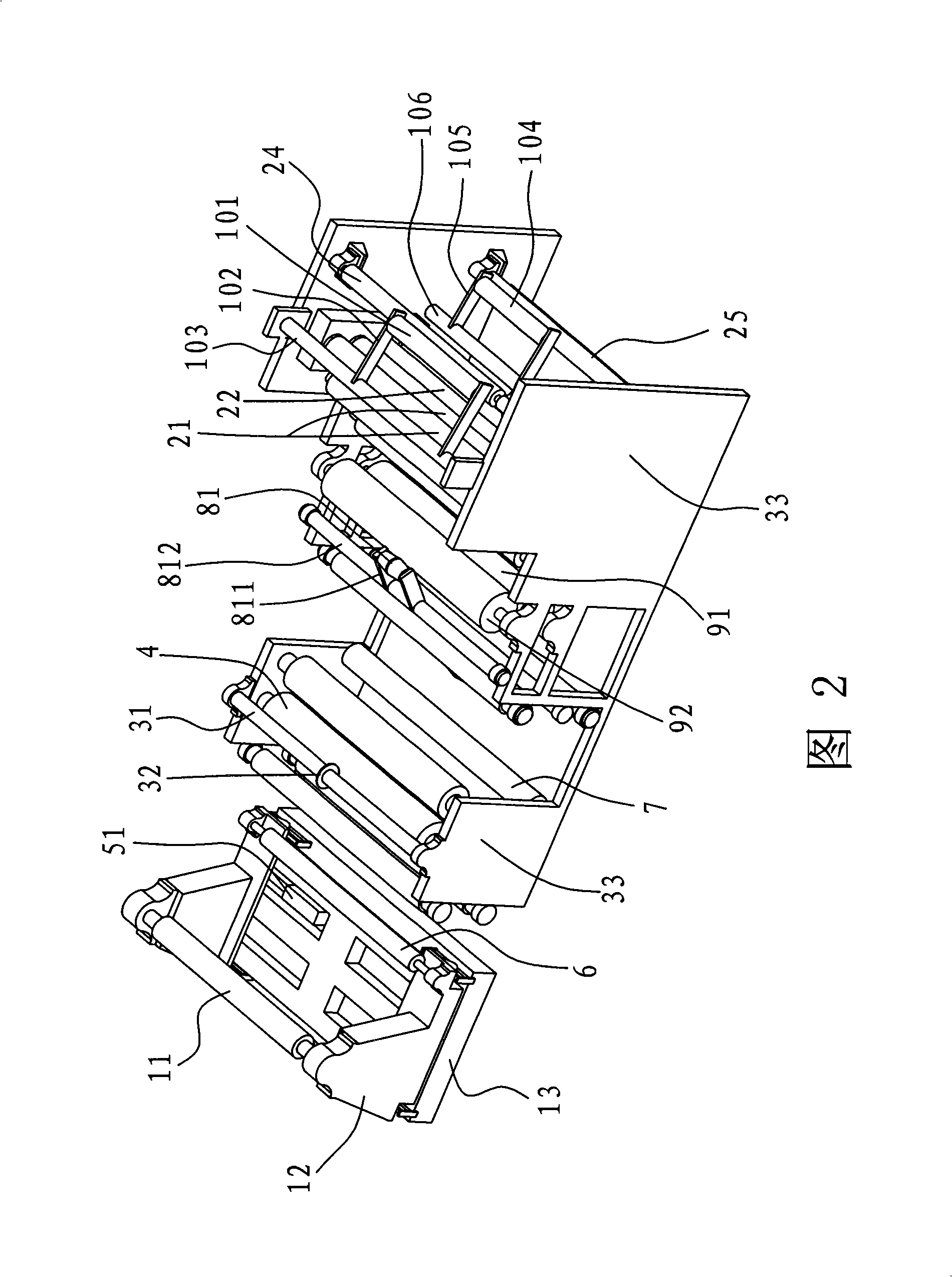

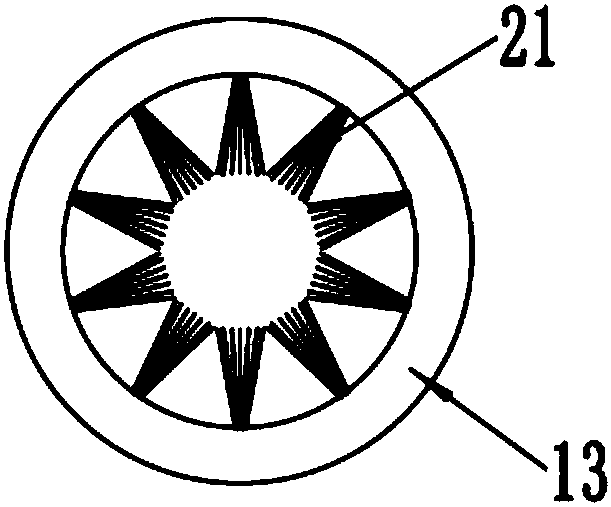

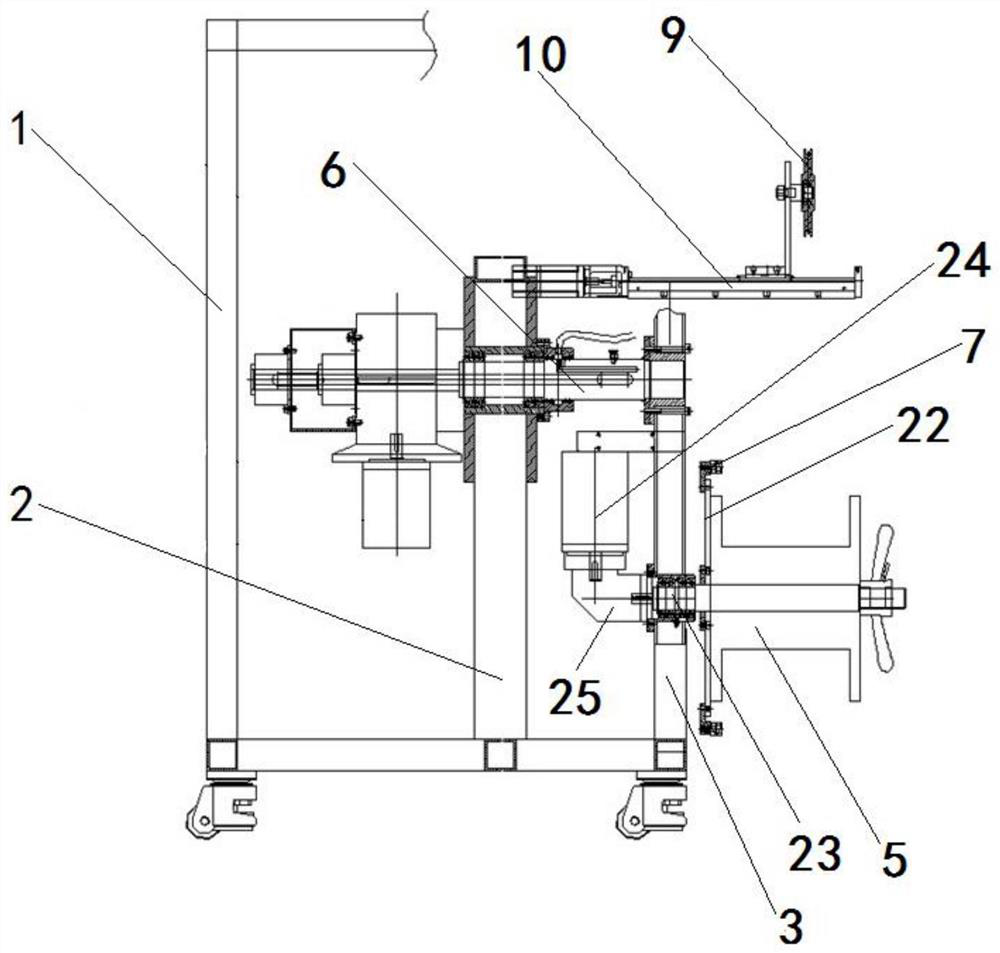

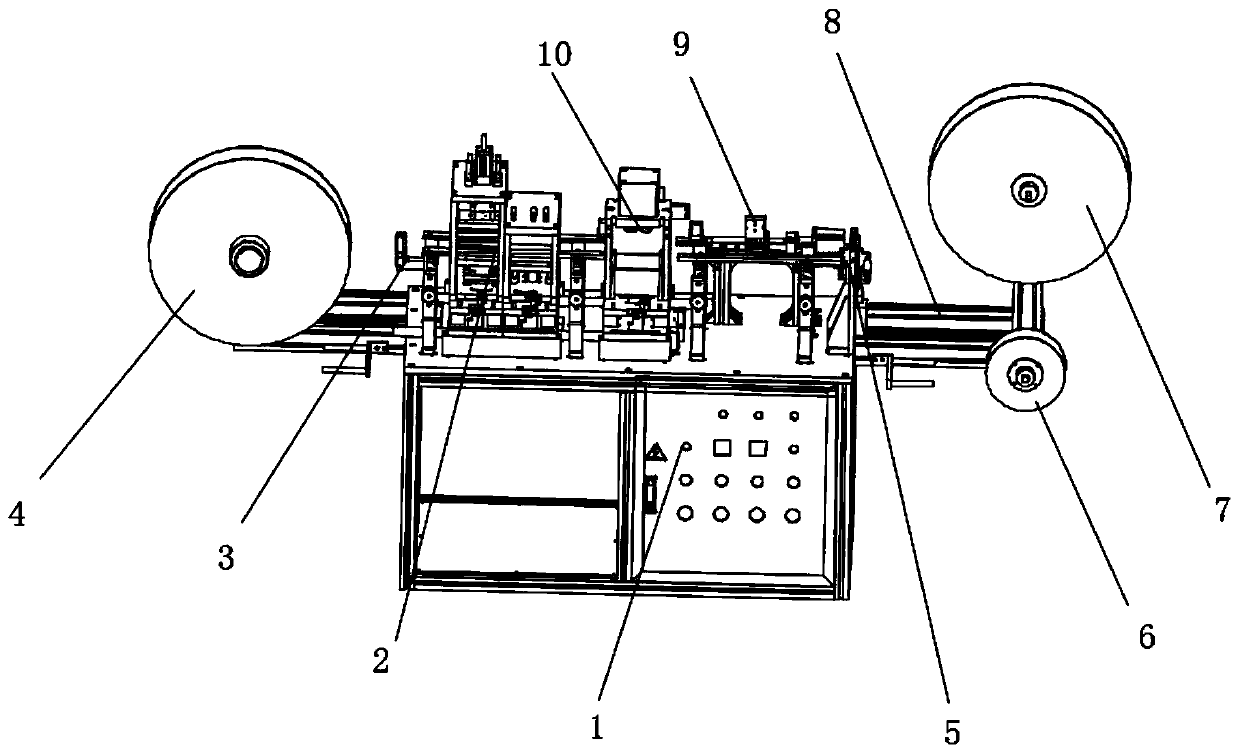

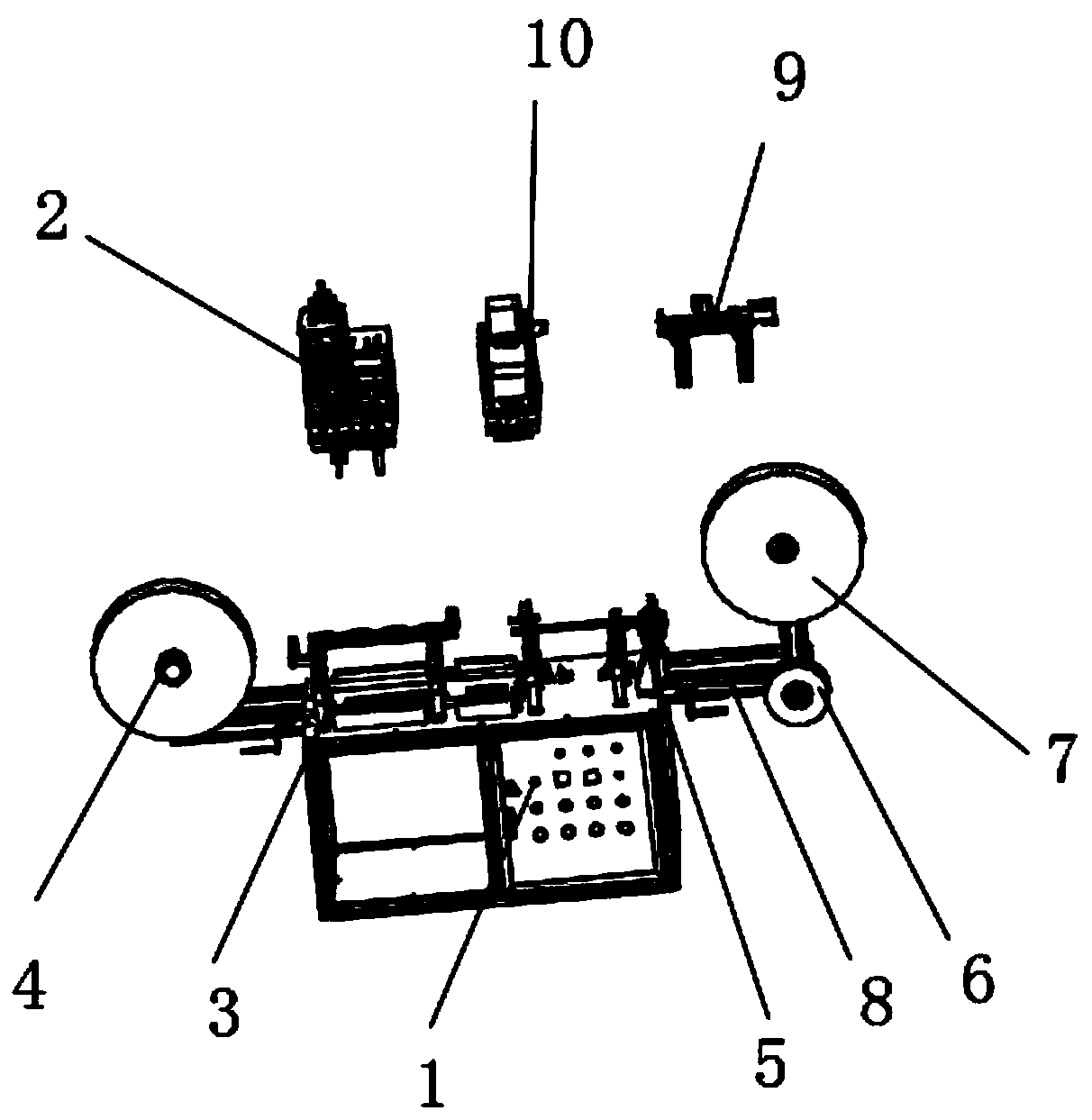

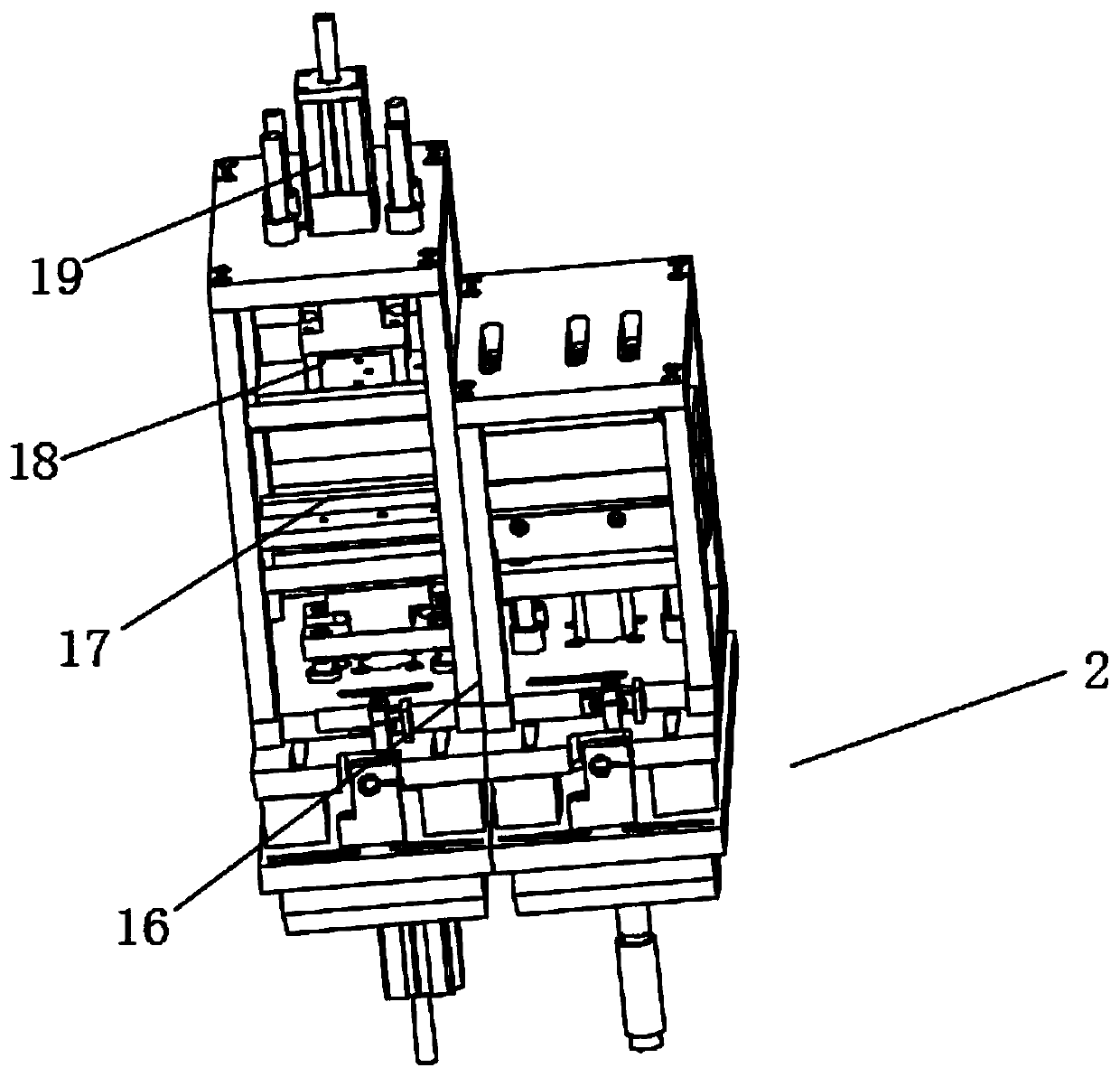

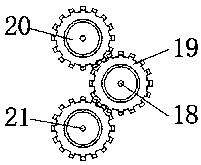

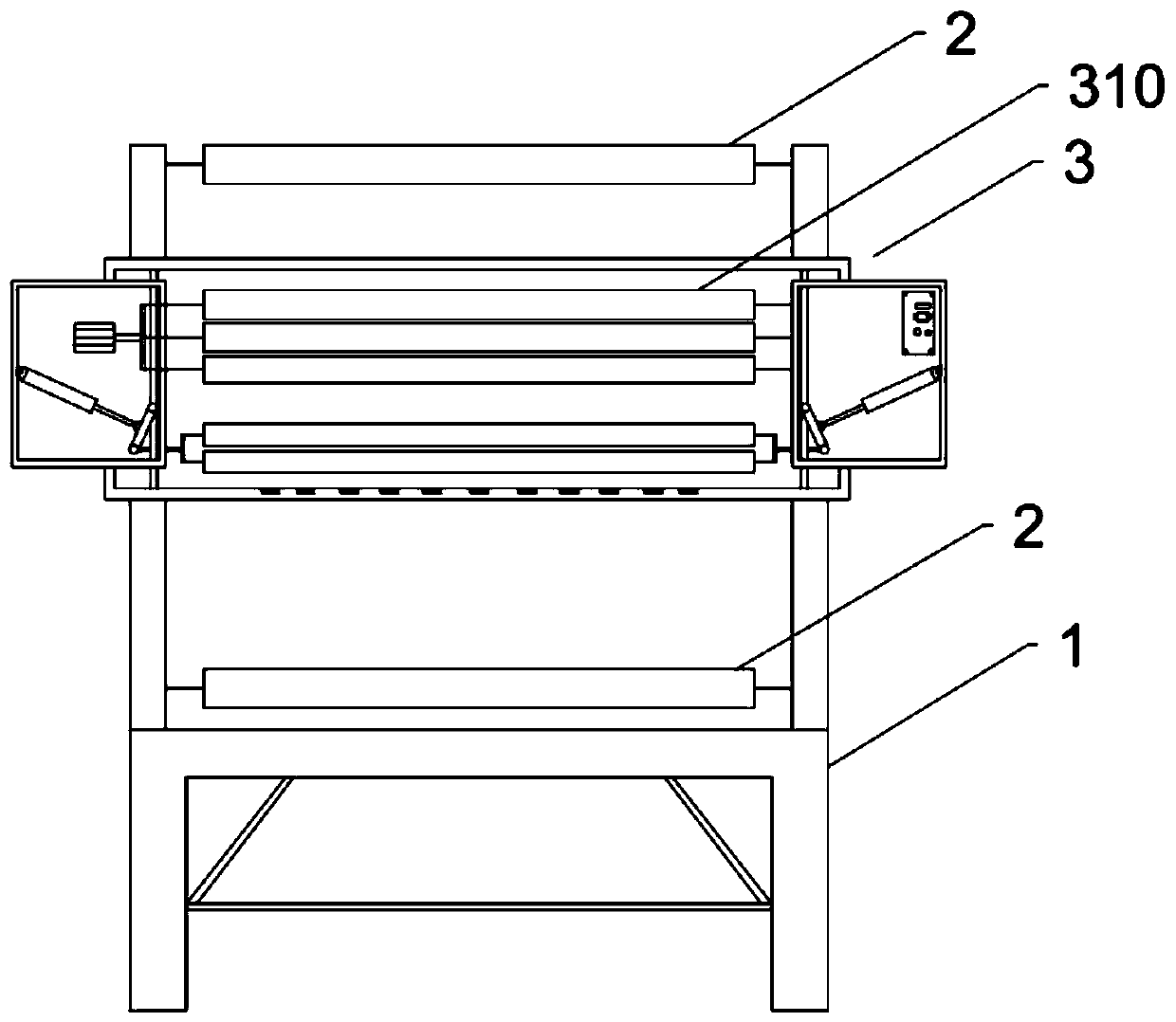

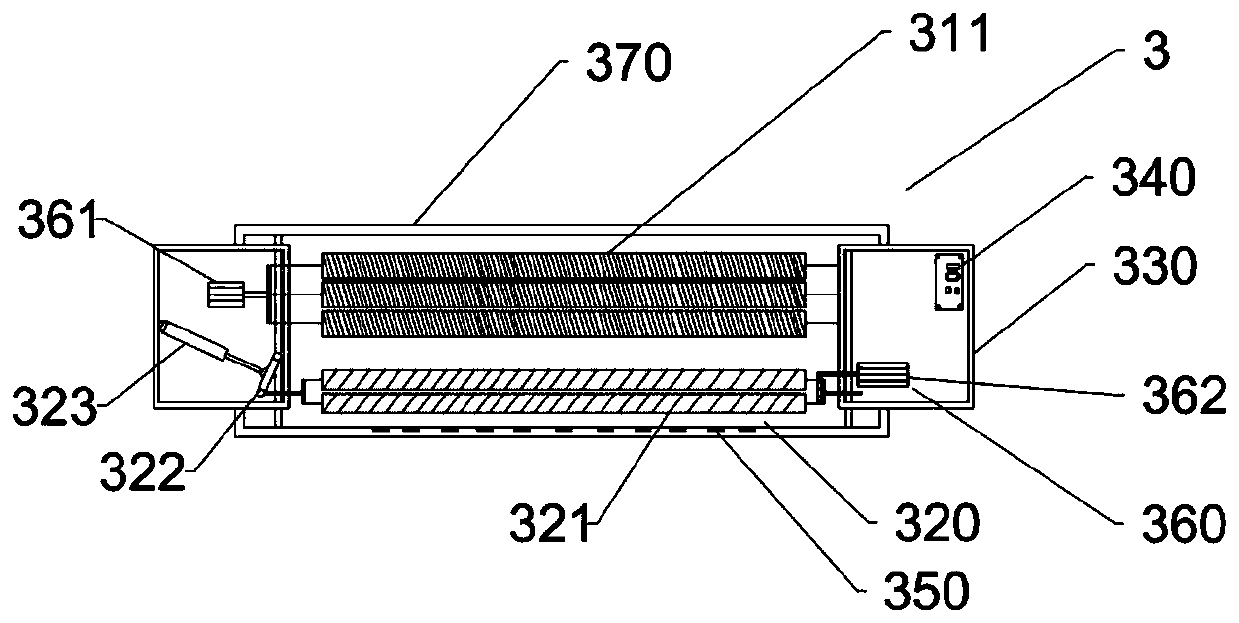

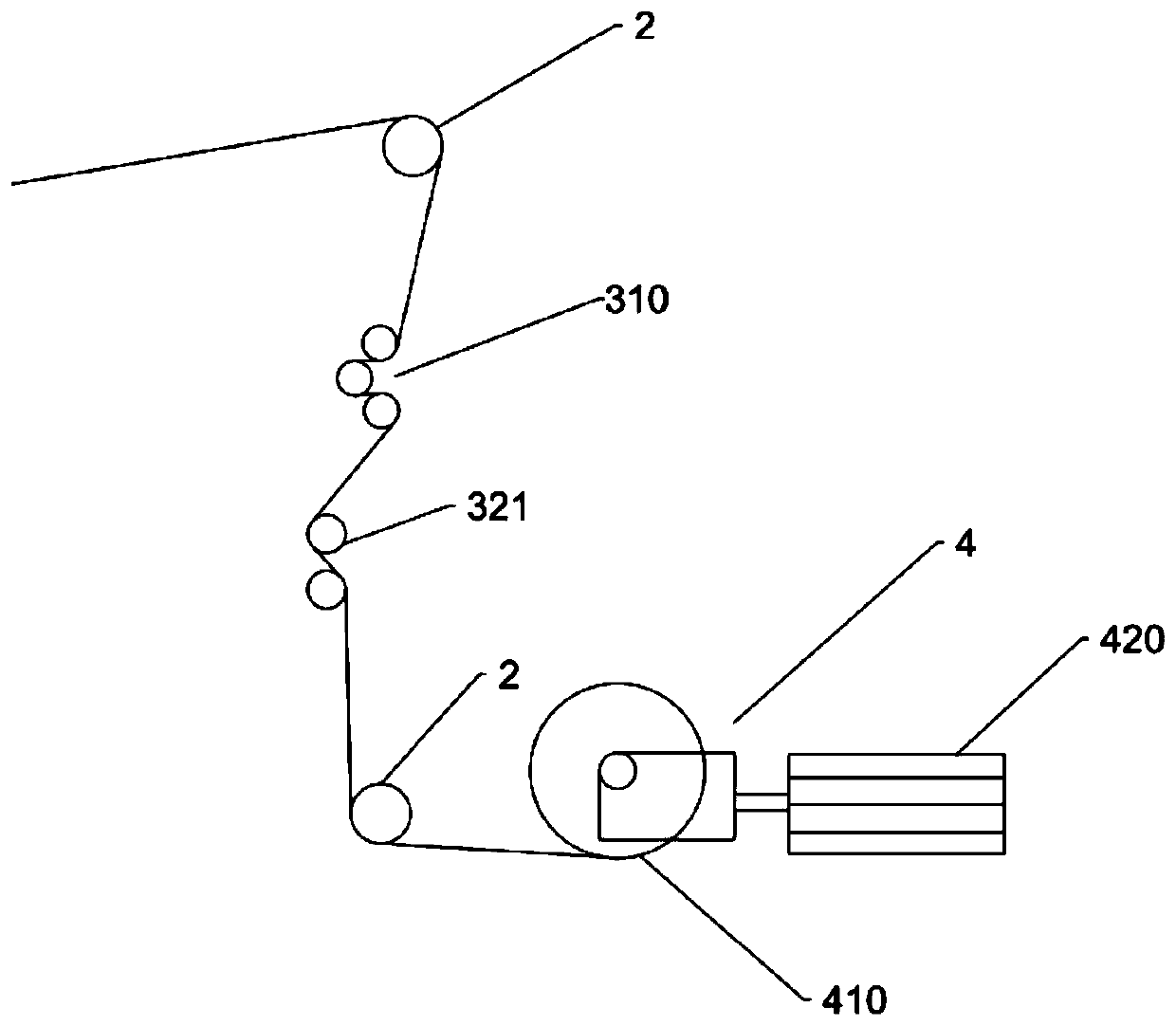

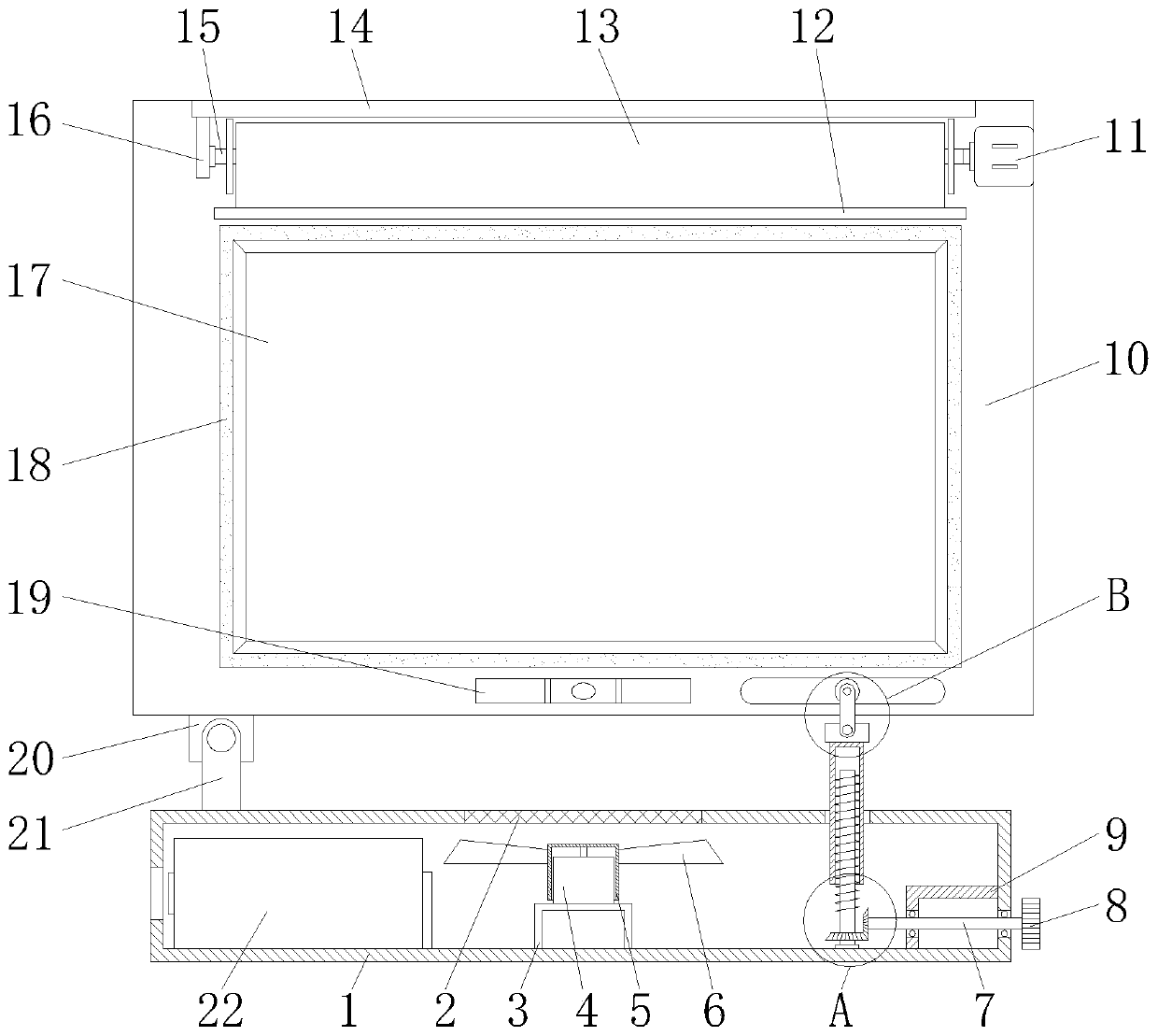

The invention relates to the decorative winding device technical field, in particular to a base paper cutting winding machine which comprises an unwinding device and a winding device. A cutting mechanism comprising a cutting roller and a cutting knife is arranged between the unwinding device and the winding device, the two ends of the cutting roller are movably arranged on a cutting bracket, and the cutting knife is coaxially arranged on the cutting roller. A driving roller is arranged right under the cutting roller, the two ends of the driving roller are movably arranged on the cutting bracket, and the cutting roller is respectively connected with the two ends of the driving roller by driving pairs. Two groups of guiding roller sets are arranged on the winding device, and the guiding roller sets are arranged on a winding frame. A first winding roller and a second winding roller are respectively arranged on the upper part and the lower part of the winding frame, and the first and the second winding rollers are respectively connected with a first driving mechanism and a second driving mechanism. By utilizing the cutting winding machine, cutting and winding works can be completed by one time, furthermore, the cutting is equal and the winding is neat, thus conserving manpower and cost.

Owner:东莞市华富立装饰建材有限公司

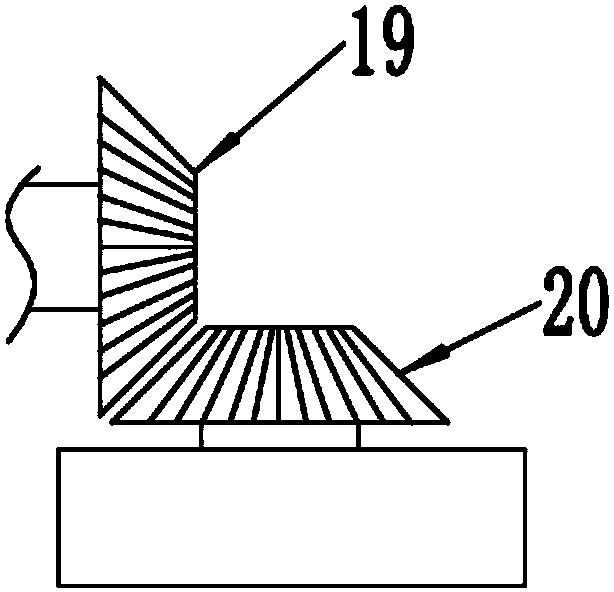

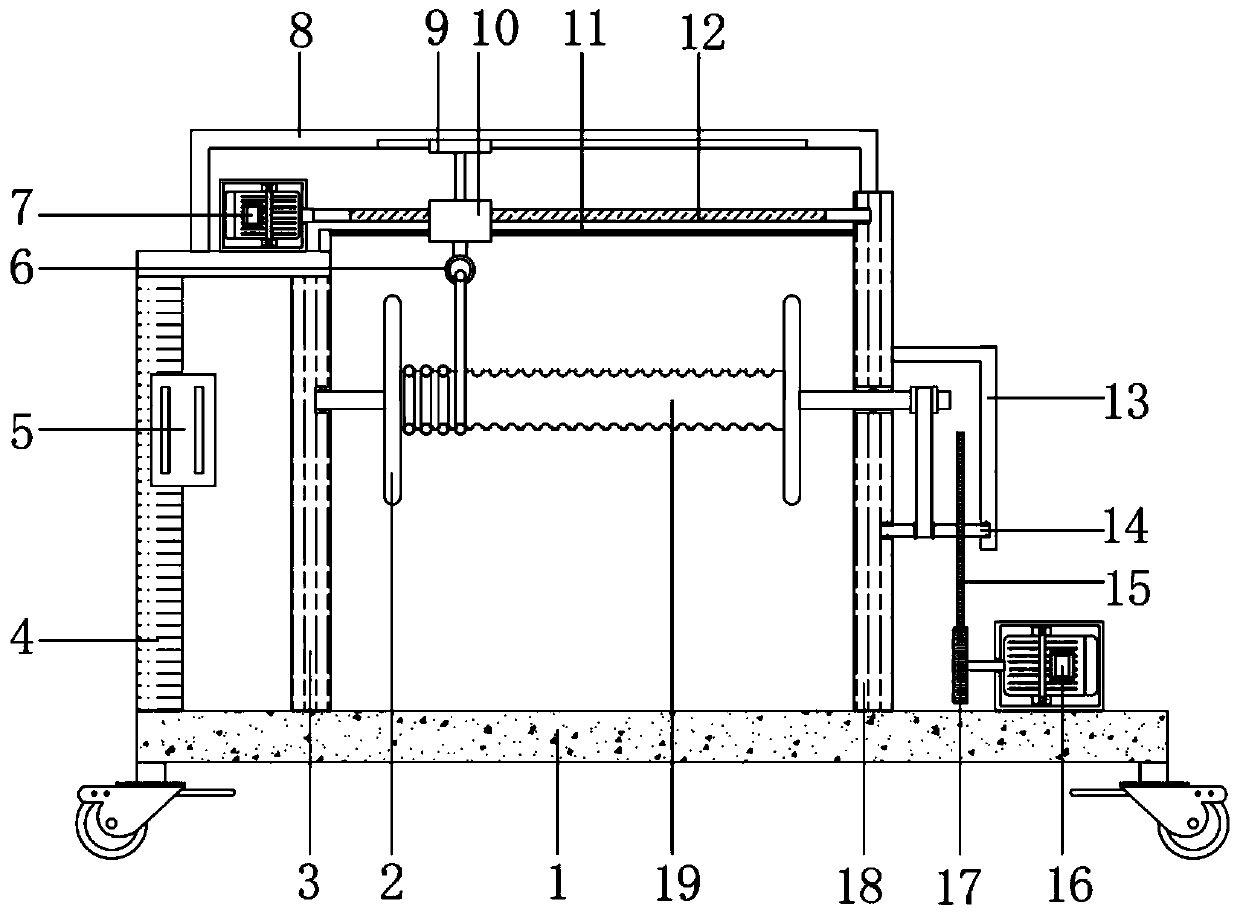

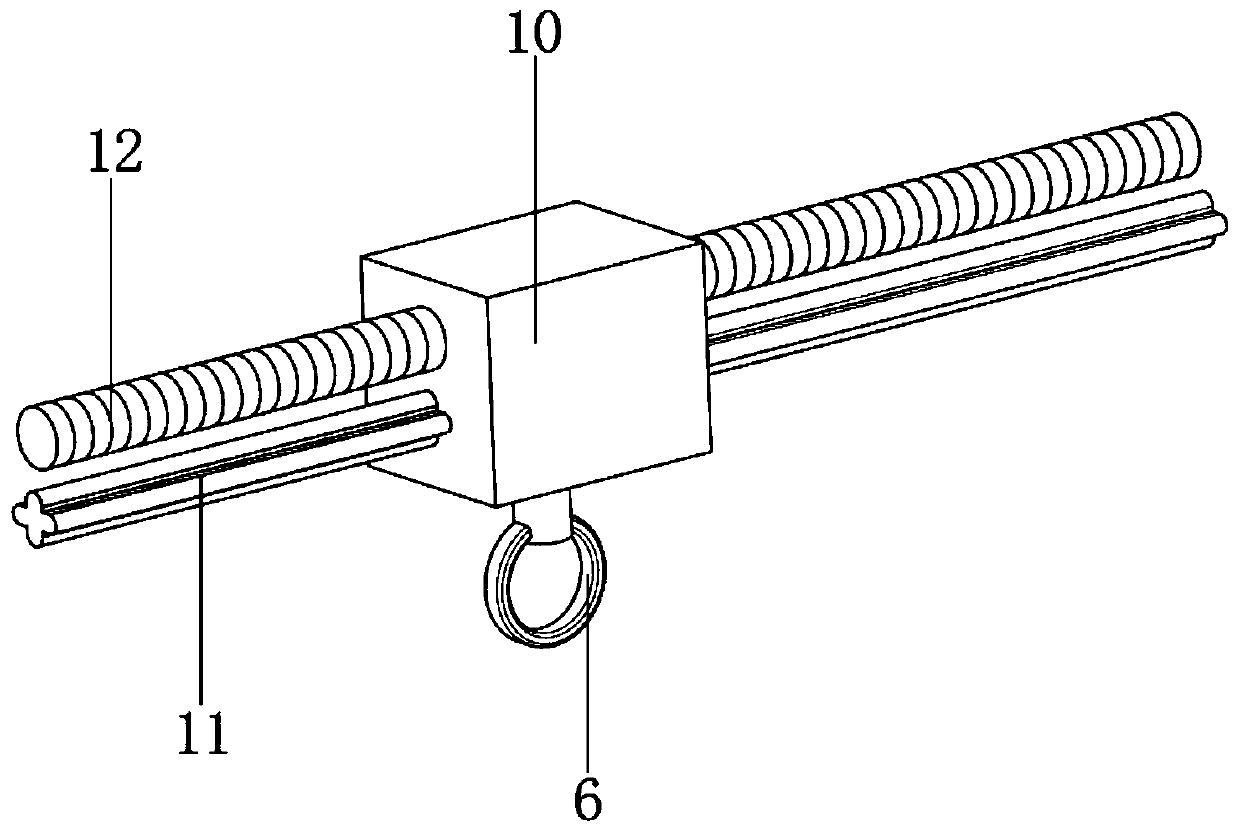

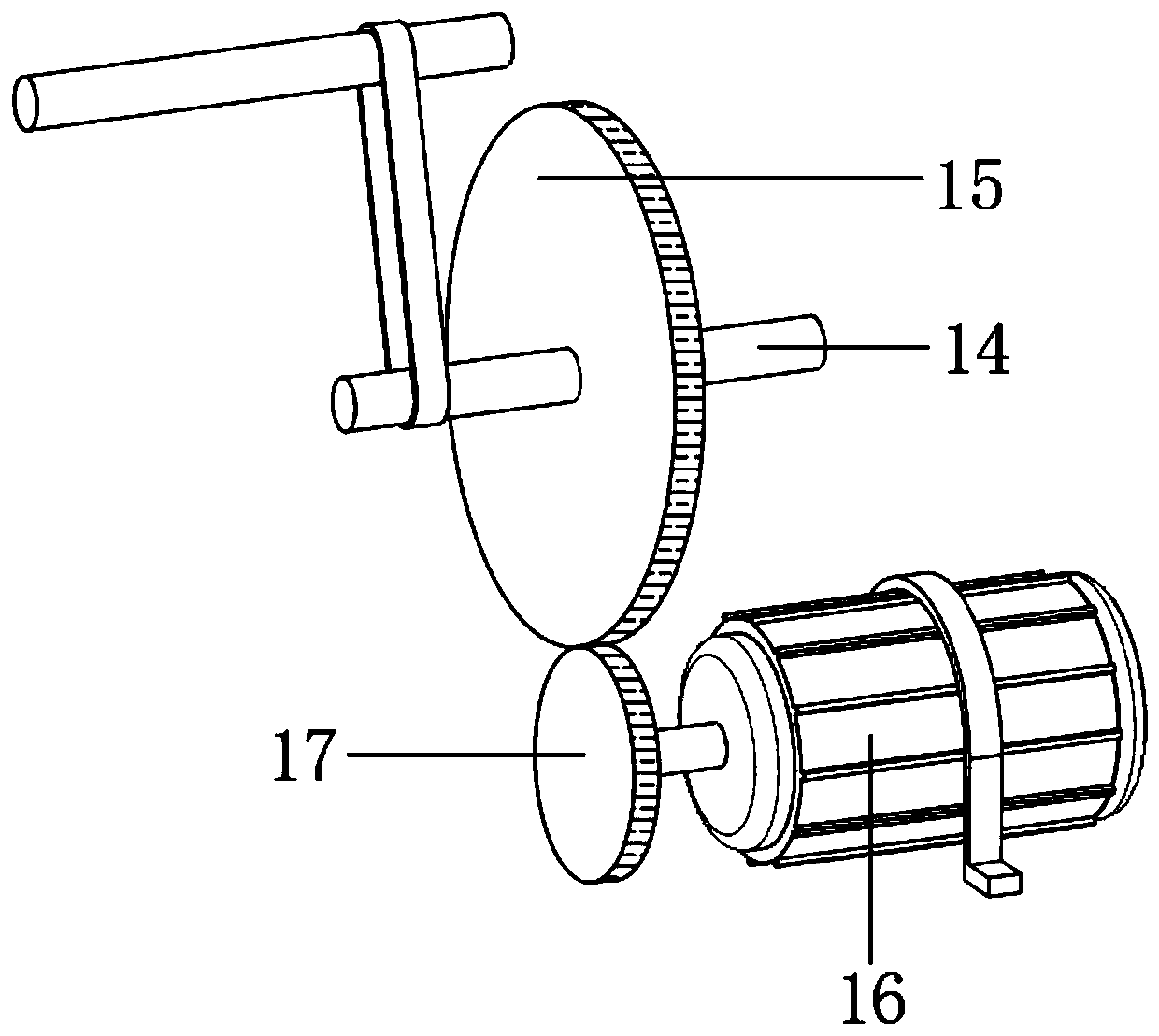

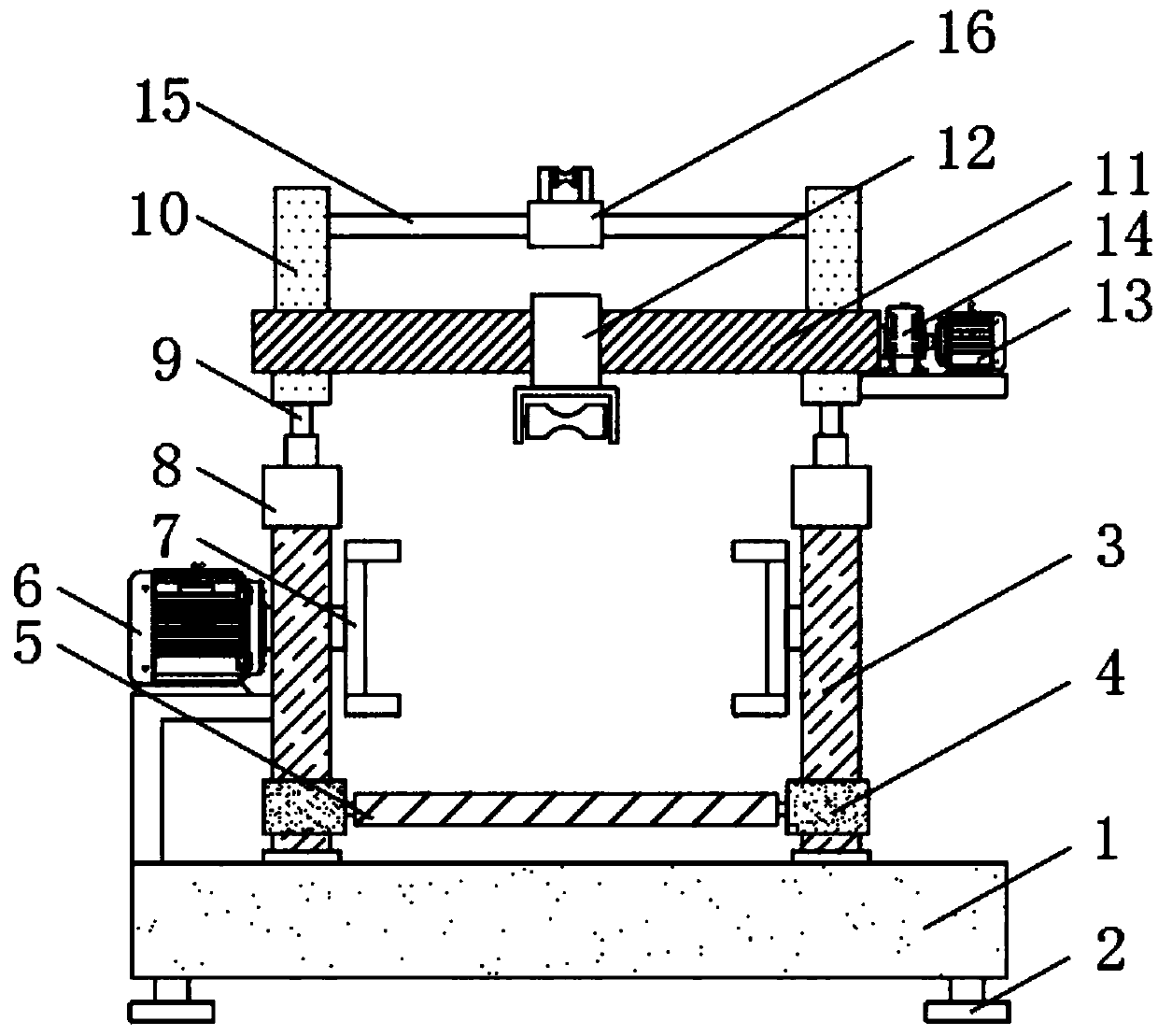

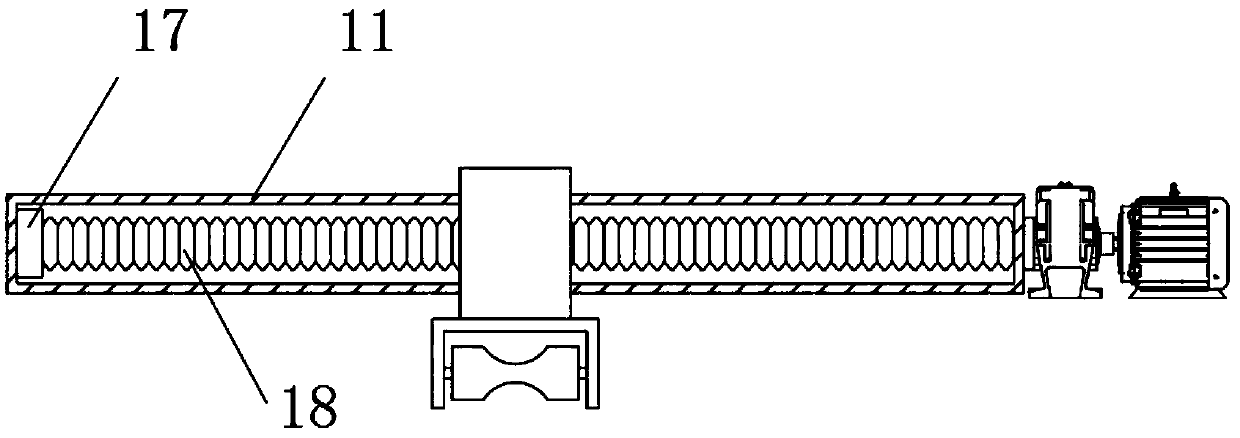

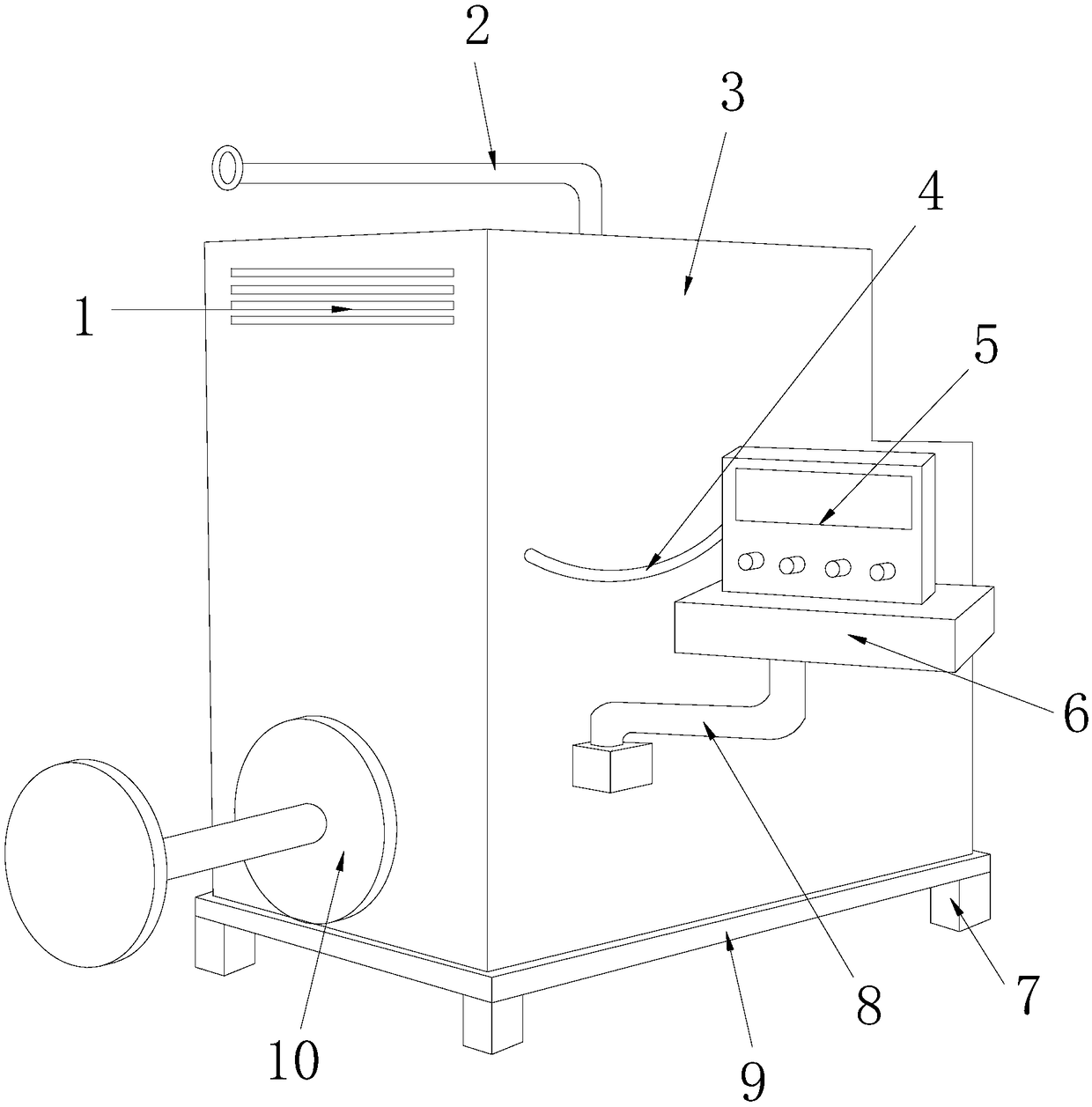

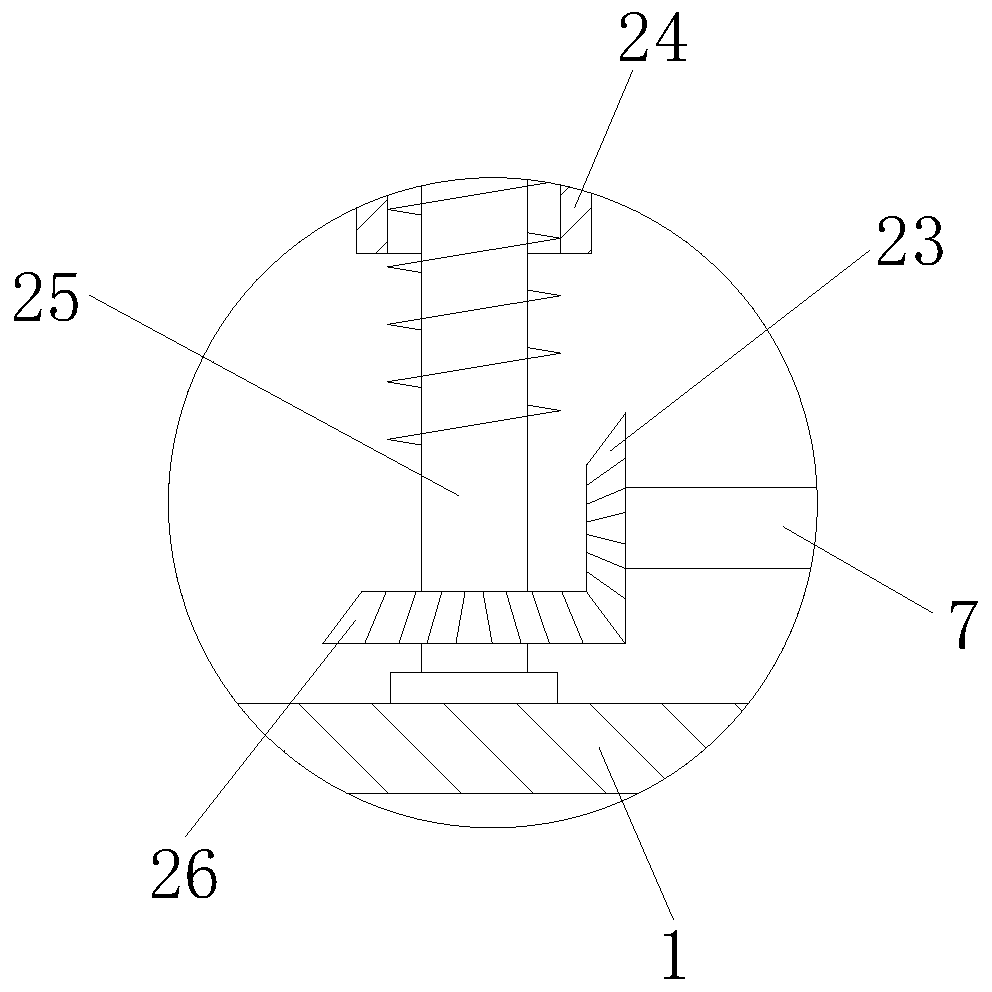

Convenient-to-adjust cable winding device for municipal engineering

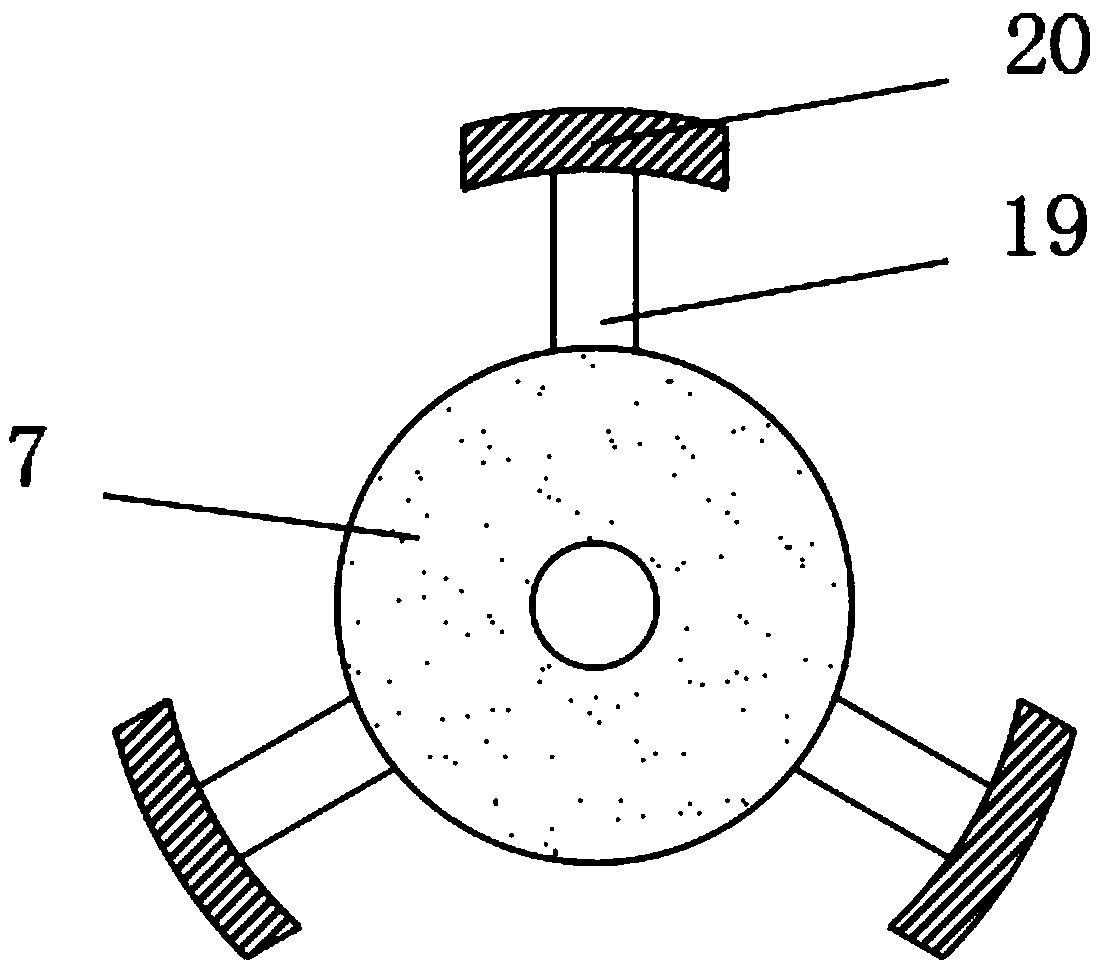

InactiveCN108861818AEasy to install and disassembleNeatly rolledFilament handlingEngineeringBevel gear

The invention discloses a convenient-to-adjust cable winding device for municipal engineering. The device comprises a bottom substrate, and a vertical supporting rod frame is arranged on the upper endsurface of the bottom substrate, a supporting rotating cross tube is rotationally installed at the top end of the supporting rod frame, and the top ends of the connecting rods are hinged to the lowerside ends of the arc top plates which are close to each other, an output shaft of an adjusting motor is provided with a driving gear, a rotating gear is arranged at the left end shaft section of an adjusting screw rod shaft, the rotating gear is meshed with the driving gear, a sliding transverse screw rod is arranged on the fixing base, the lower end of a sliding spiral sleeve is connected with the upper end face of a bottom base plate through a limiting mechanism, a transmission vertical shaft is further arranged on one side of the supporting rod frame, and a transmission bevel gear is arranged on the top end of the transmission vertical shaft and the output shaft of a winding motor. The winding device is simple in structure, the cables are orderly wound, winding is avoided, disassemblyand installation of the winding drum body are facilitated, and winding device is suitable for cylinder bodies with different diameters, is convenient to operate and is worthy of popularization.

Owner:ZIBO TRICKS EDUCATION TECH CO LTD

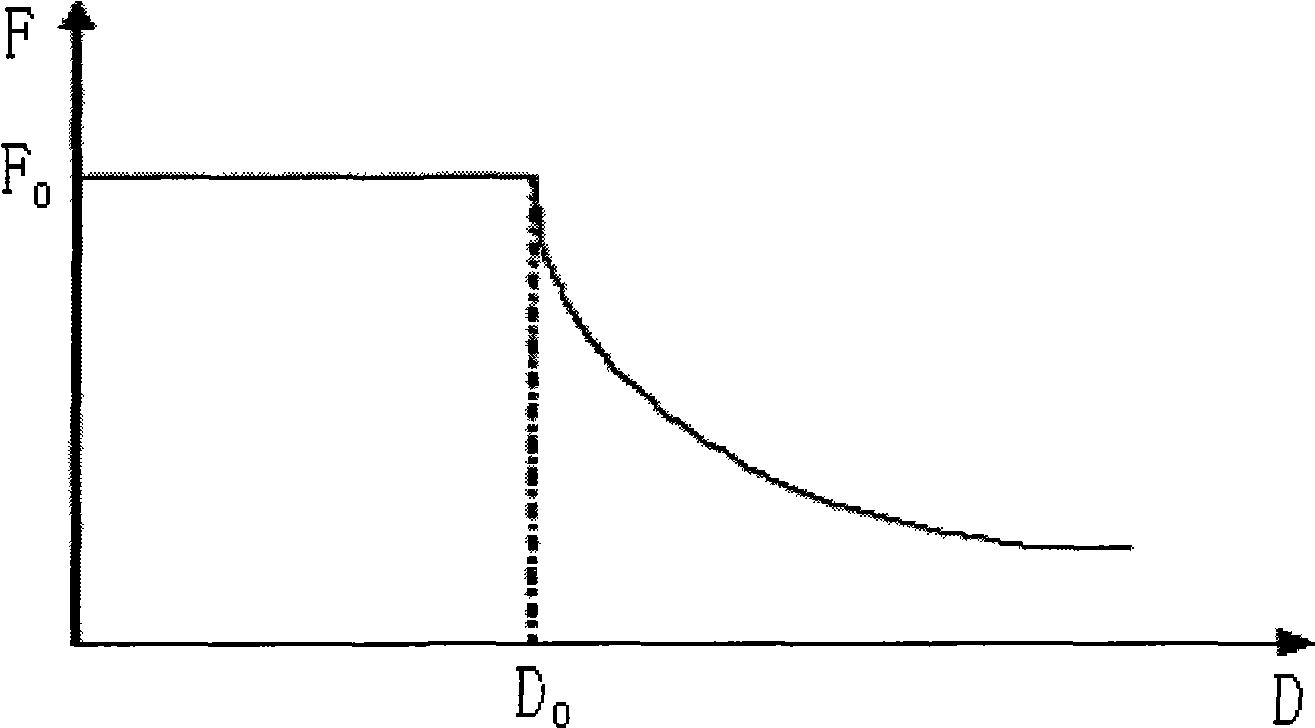

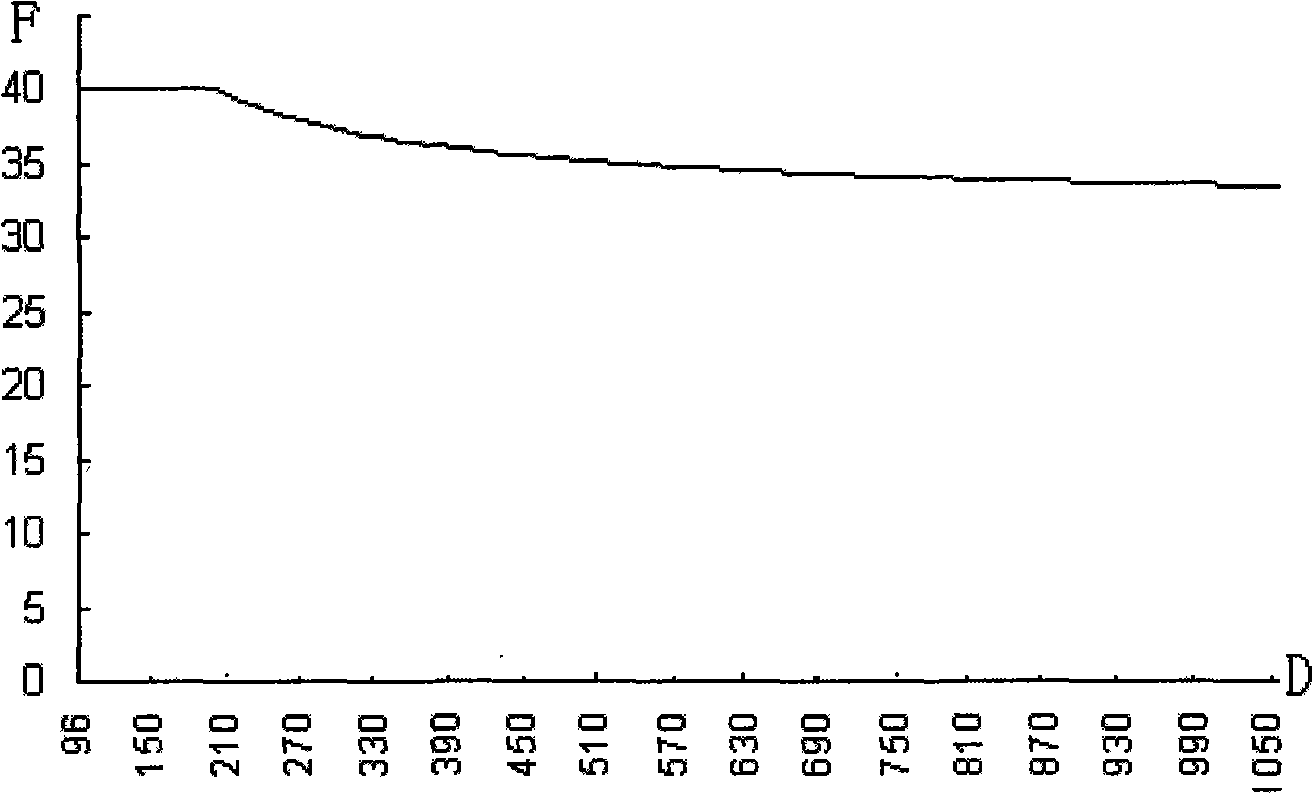

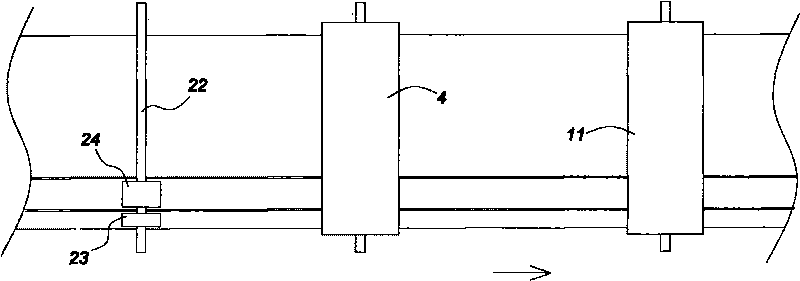

Nonlinear rolling tension control process

ActiveCN101306773AImprove the winding effectImprove pass rateWebs handlingComputer scienceTension control

The invention discloses a non-linear rolling-up tension control method, which comprises the following steps: in the printing and rolling-up process, selecting the value of a tension taper coefficient K in a range of 0 to 1 based on different requirements of POP, OPP, PE and other composite materials, setting an initial tension F0 and an initial rolling-up diameter D0, calculating the value of real-time outputted tension F based on the real-time variation of the rolling-up diameter D in accordance with the function formula F=F0(1-K(1-D0 / D)), and controlling a rolling-up device to adjust the rolling-up tension in time. The inventive rolling-up tension control method is suitable for PE, OPP, POP and other composite materials; and has the advantages of good rolling-up quality, tidy rolling-up, remarkably improved qualification rate of printed finished product, and improved production efficiency.

Owner:SHAANXI BEIREN PRINTING MACHINERY

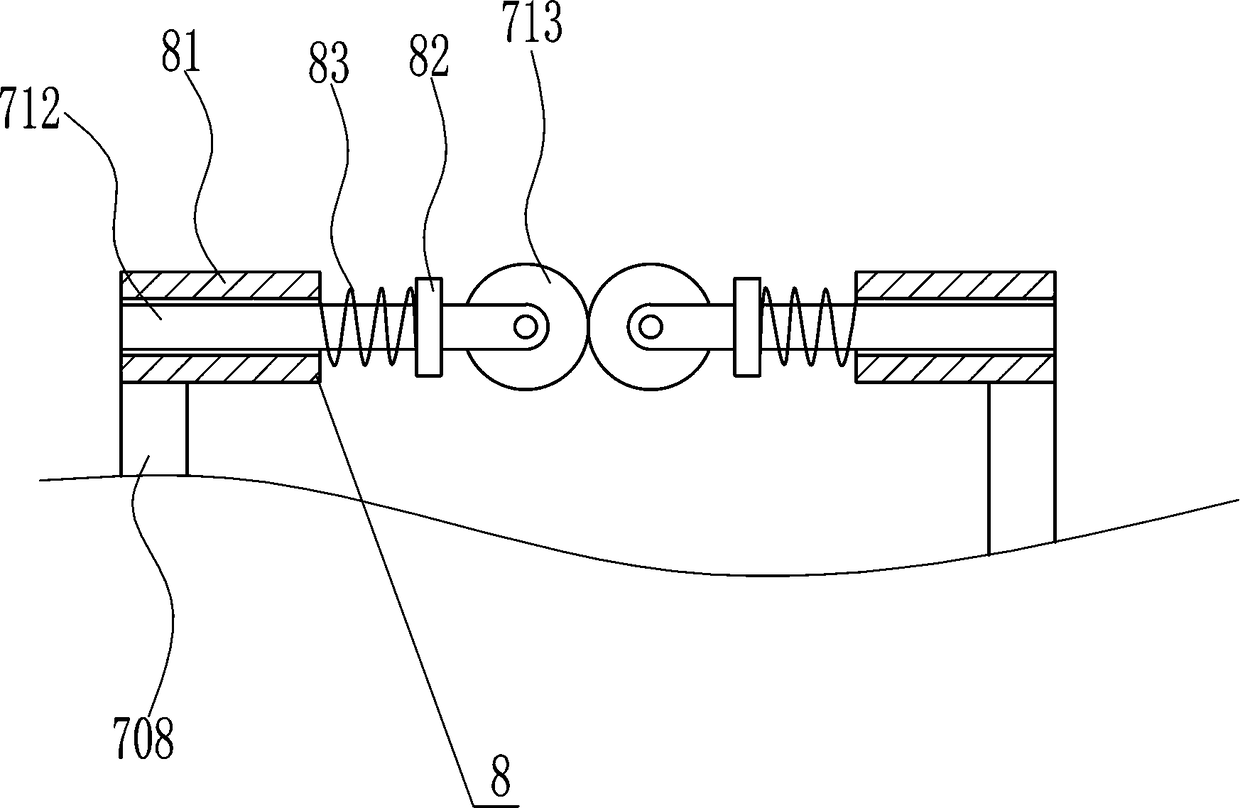

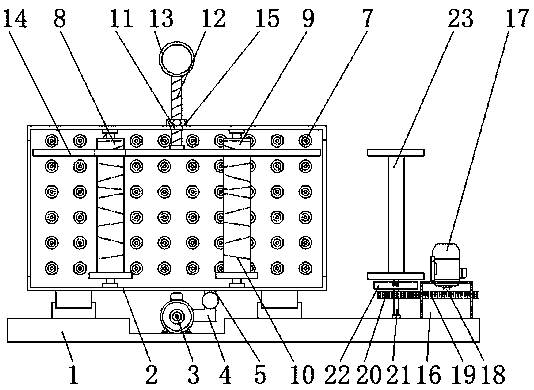

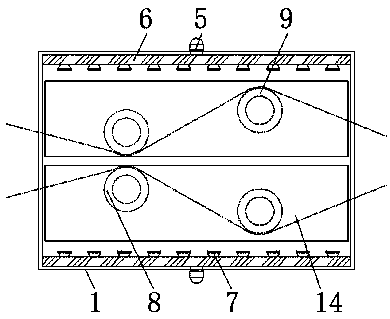

Roller tensioning communication cable winding equipment

InactiveCN108423486ANeatly rolledHas a cleaning effectFilament handlingCleaning using liquidsEngineeringConductor Coil

The invention discloses roller tensioning communication cable winding equipment comprising a winding cavity, a water tank, a cleaning cavity, a guide mechanism and a cleaning sleeve; the winding cavity and the cleaning cavity are separated through a baffle, and the water tank is arranged at the upper end of the cleaning cavity; the inside upper end of the winding cavity is rotatably connected to awinding roller, and a rotating shaft at the upper end of the winding cavity is rotatably connected to an output shaft of a motor; the guide mechanism is arranged below the winding roller; and the cleaning cavity is internally provided with a tensioning wheel group, and the inside upper end of the cleaning cavity is provided with a water spraying pipe. The winding equipment is novel in design, andcables can be tidily wound on the winding roller through the arranged guide mechanism in a reciprocating manner; water in the water tank is pumped out and conveyed into the water spraying pipe duringoperation of a suction pump, and sprayed toward the cables through nozzles arranged at the lower end of the water spraying pipe so that the water plays a role in washing, and the appearances of the cables are cleaned, thereby facilitating the use of next time; and the practicability is high, and the winding equipment is worth popularizing.

Owner:宗立武

Jet-dyeing device with good cloth spraying uniformity and application method thereof

ActiveCN110424112AEasy to rewindNeatly rolledMechanical cleaningTextile storage in wounded formEngineeringMechanical engineering

The invention discloses a jet-dyeing device with good cloth spraying uniformity and an application method thereof. The jet-dyeing device comprises a base, a rack, a box body, a heating box and an unwinding roller. The unwinding roller is in drive connection with one end of the top of the base; the box body is fixedly mounted at the top center of the base; the inside of the box body is divided intoa drying chamber and a spraying chamber through a partition arranged; a second adjustment is fixedly mounted at the side, close to the unwinding roller, of the interior of the spraying chamber; a mounting plate is fixedly mounted at one side of the second adjustment. Processing and guiding can be performed on cloth different in thickness by adjusting a distance between an adjusting roller and a driving roller through the two adjustments; clamp rings are driven to move back and forth on the unwinding roller by enabling an electric telescopic bar to operate, a distance between the two clamp rings can be adjusted, and therefore, cloth different in width can be wound conveniently; winding evenness is better, operating is simple, and using is facilitated.

Owner:安徽宜民服饰股份有限公司

Decorative cloth cleaning and winding device

PendingCN108411518AImprove finished product qualityGuarantee the quality of windingLiquid/gas/vapor removal by vibrationTextile treatment by spraying/projectingMechanical engineeringTextile

Owner:浙江开盛新材料有限公司

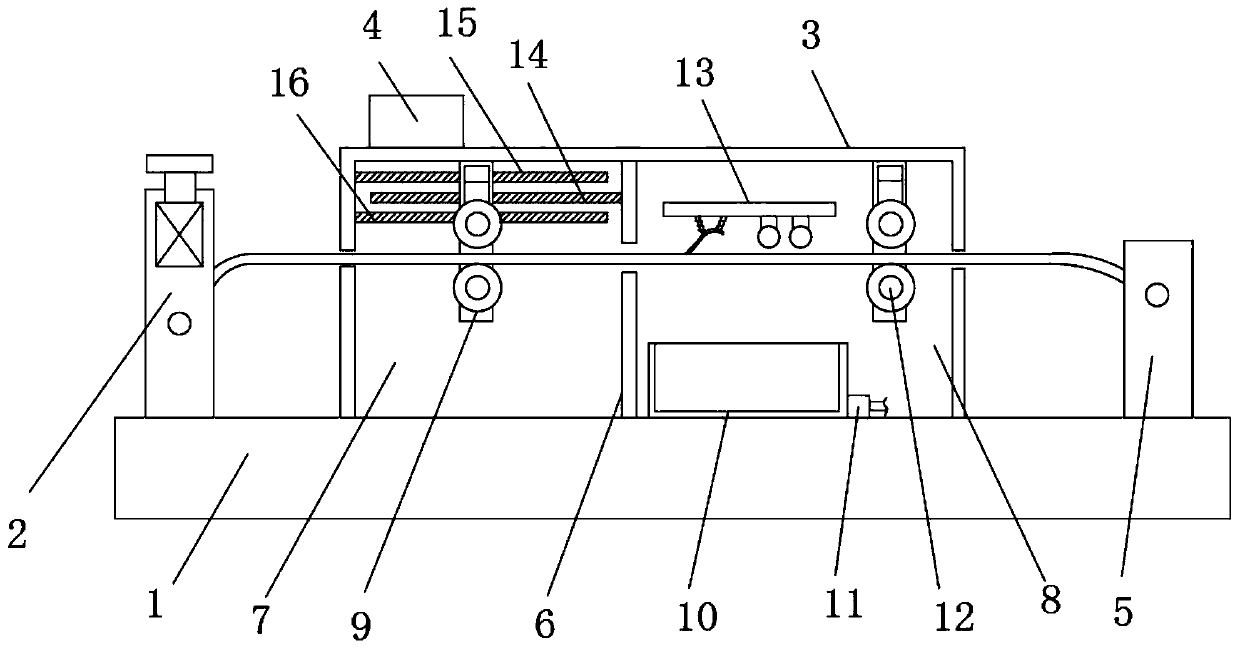

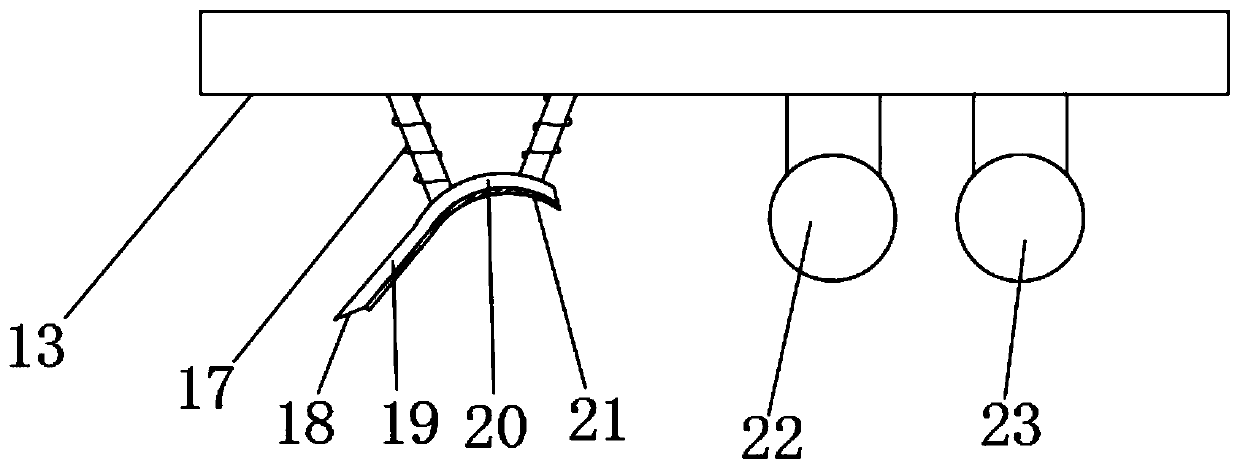

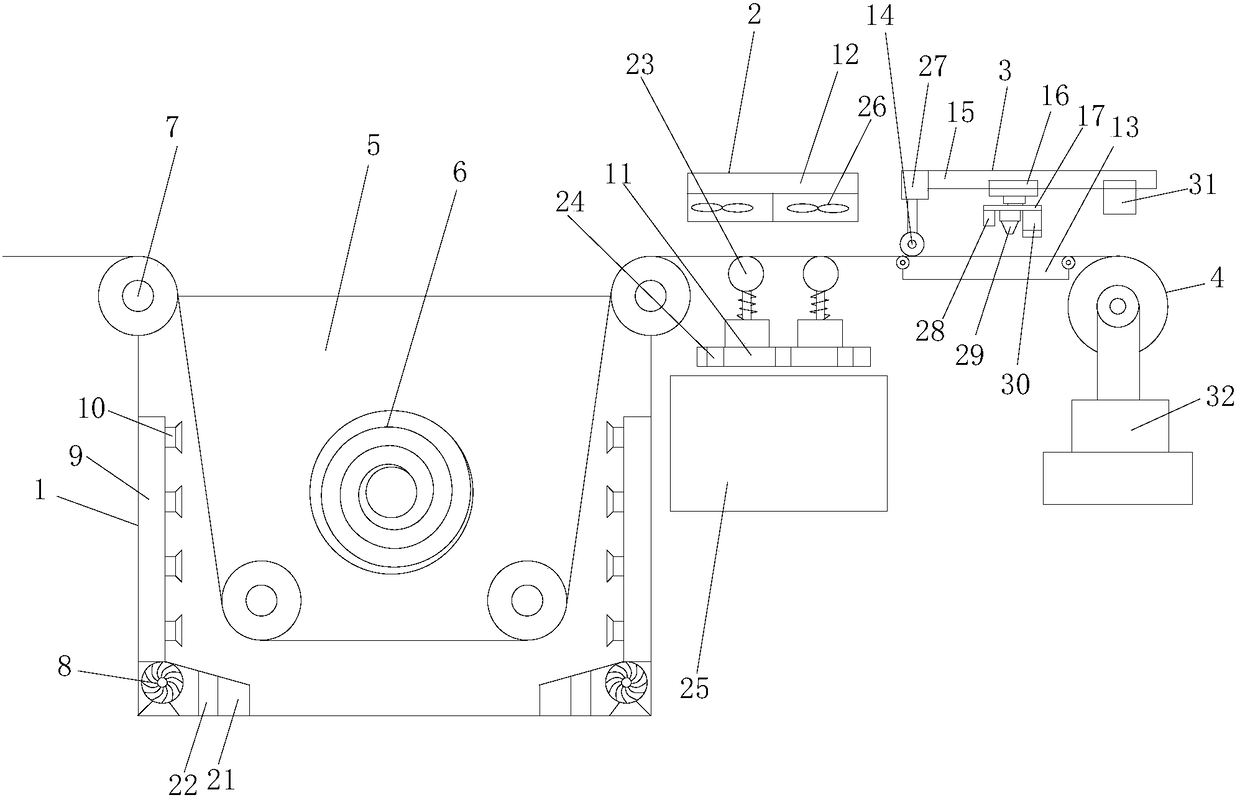

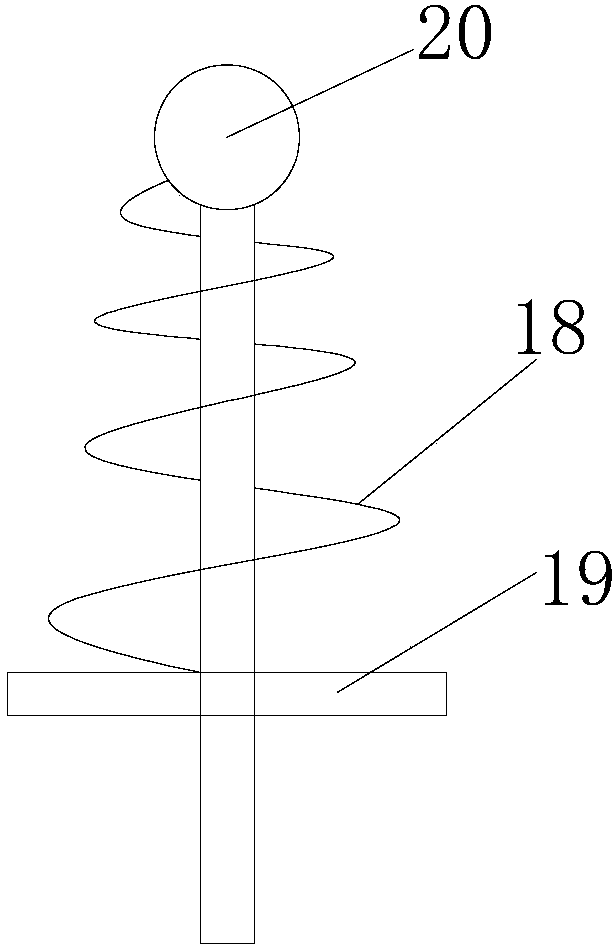

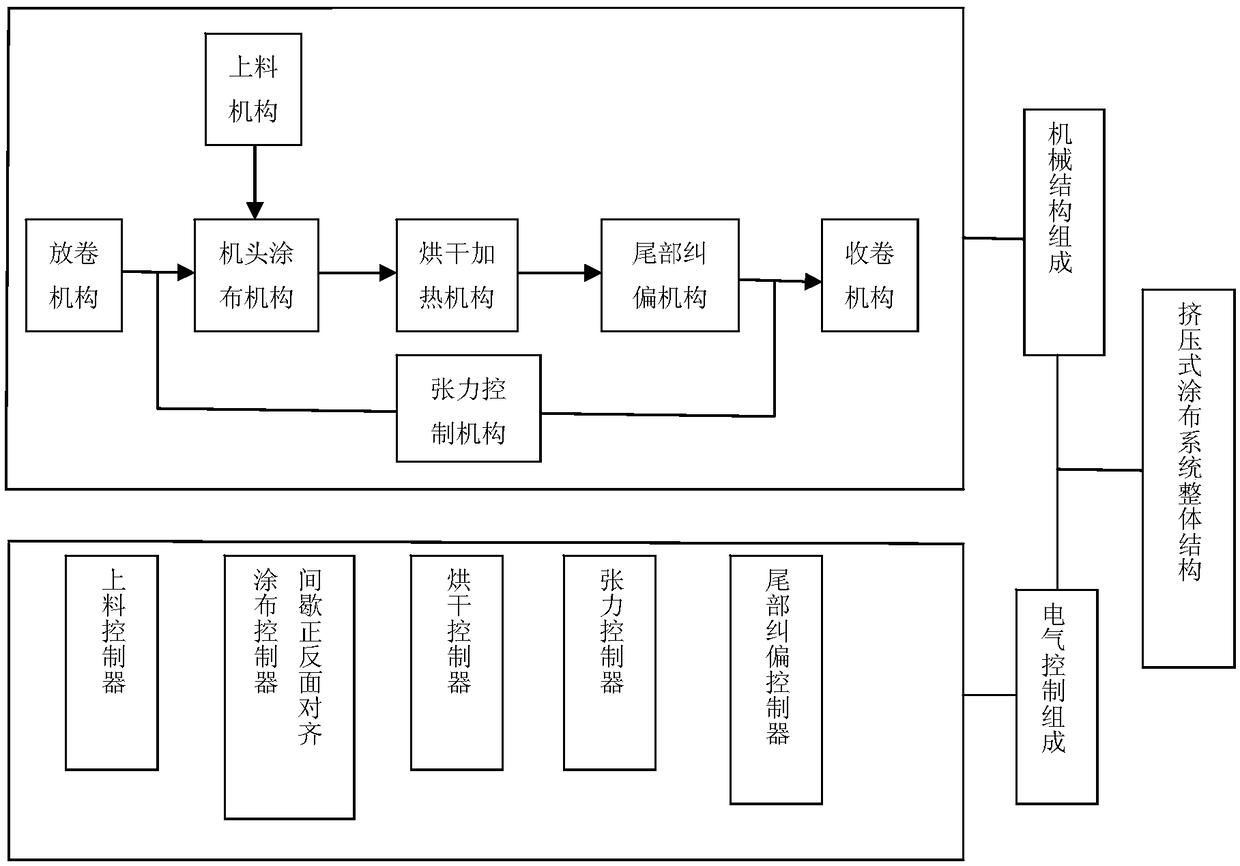

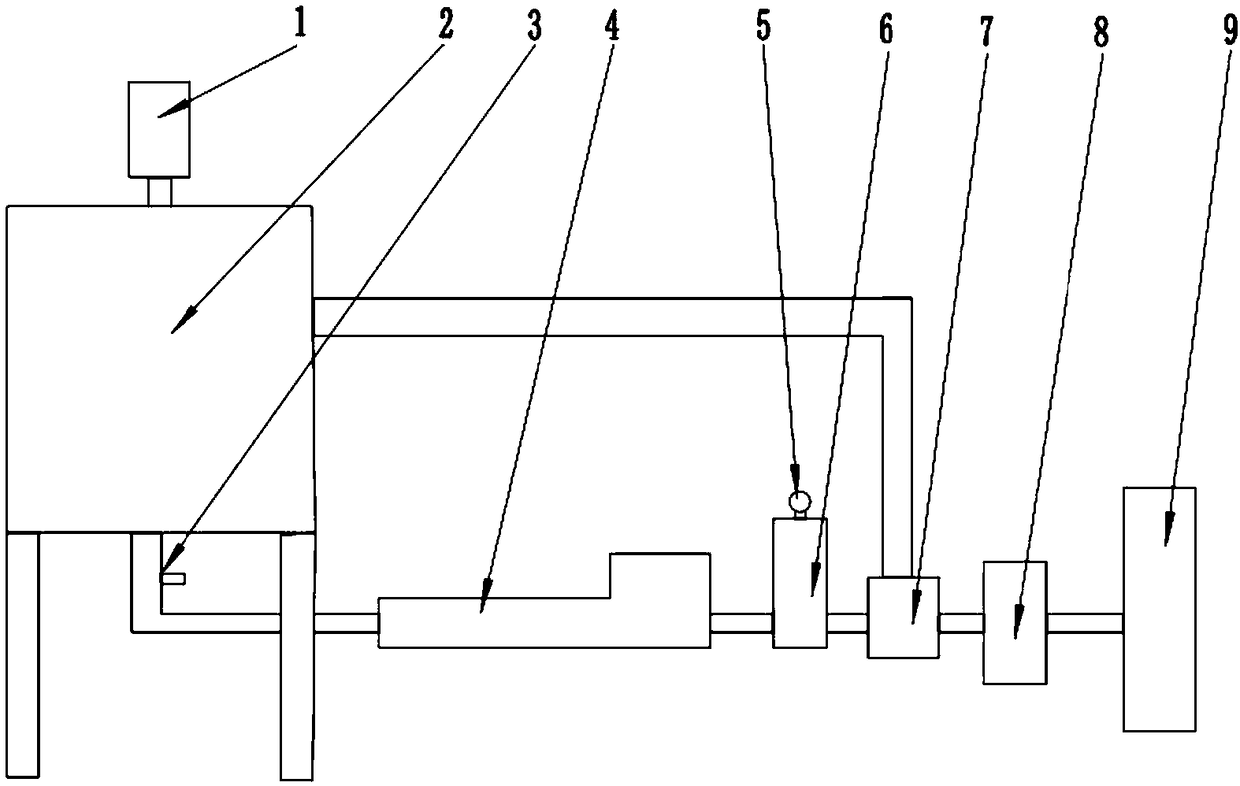

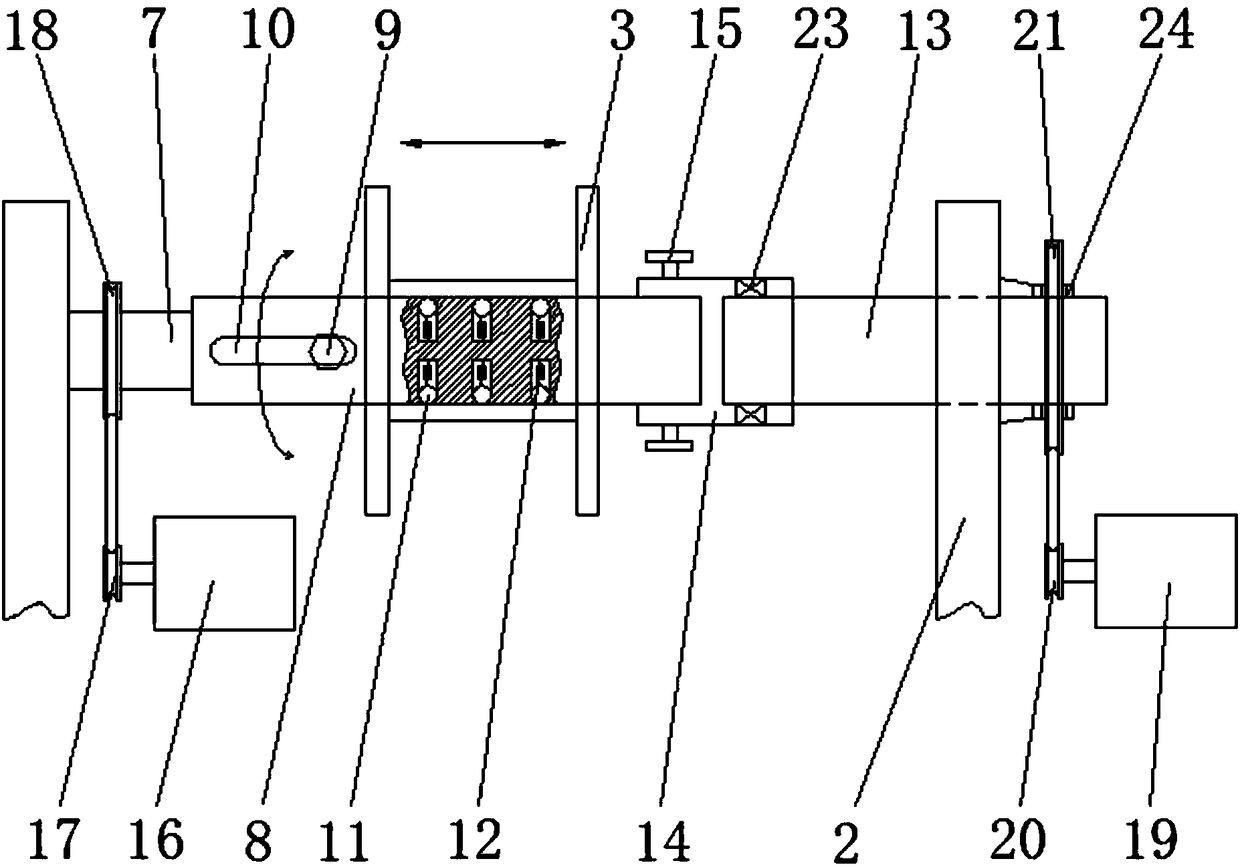

Extrusion type coating system of power lithium battery base band

ActiveCN108816645AFull dispersionFull homogenizationPretreated surfacesCoatingsCoating systemEngineering

The invention discloses an extrusion type coating system of a power lithium battery base band. The extrusion type coating system of the power lithium battery base band comprises an unwinding mechanism, a feeding device, a machine head coating device, a tension control device, a drying heating device, a tail deviation rectifying device and a winding mechanism. The unwinding mechanism releases the base band at a constant speed. The feeding device provides a stable sizing agent. The machine head coating device disperses the sizing agent to be uniform and discharges and coats the sizing agent to the base band along the position of a gap of an outlet of an extrusion mold head. The drying heating device dries the wet sizing agent coated to the base band. The winding mechanism winds the coated and dried base band. The tail deviation rectifying device can guarantee that the base band is tidy during taking up, operation of following working procedures is facilitated, and the tension control device can guarantee the best tension degree of the base band.

Owner:SOUTHEAST UNIV

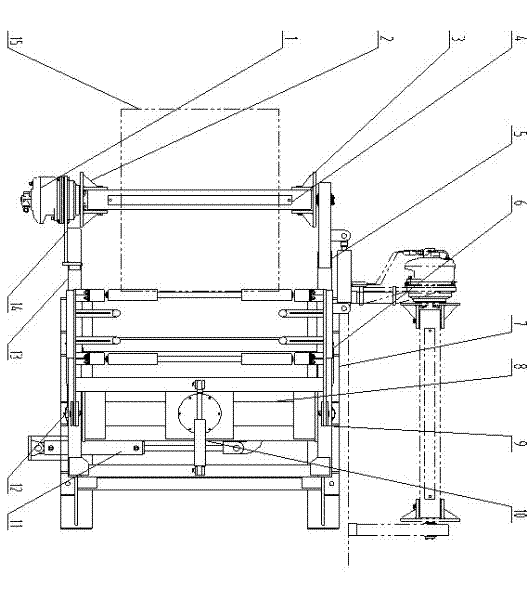

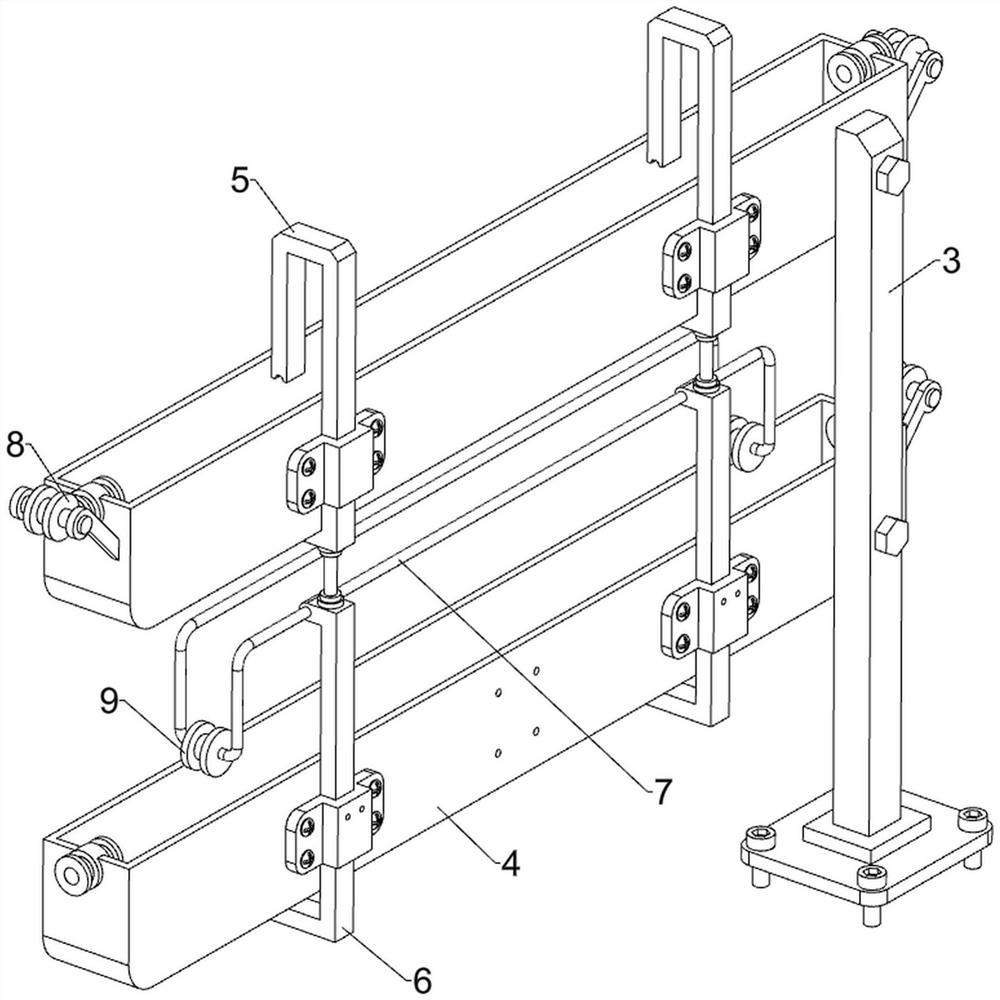

Adjusting device of steel band unwinding machine

The invention discloses an adjusting device of a steel band unwinding machine. The adjusting device comprises a base, wherein a left support column, a right support column and a bracket are separately fixedly connected to the top of the base from the left to the right, a motor is fixedly mounted at the top of the bracket, a driving gear is fixedly connected to the output end of the motor in a sleeving manner, one side of the driving gear is meshed with a driven gear, and the axis part of the driven gear is fixedly connected with one end of a first roller. By arranging the motor, a threaded column and an arc-shaped groove, the driving gear is driven by the motor to rotate, and the first roller on the driven gear is accordingly driven to rotate. By pulling clamping plates towards the two sides, a steel band is wound on the first roller. When the clamping plates are loosened, the clamping plates are gathered towards the middle due to the elasticity of springs, so that edges at the two sides of the steel band are fixed. Then, the clamping plates are clamped on chucks by rotating clamping rods, the positions of the clamping plates are fixed, and the steel band is clamped between the clamping plates. The phenomenon of untidy edges caused by the deviation of the edges of the steel band during winding is prevented.

Owner:WUXI QIANTAI METAL COMPONENTS FACTORY

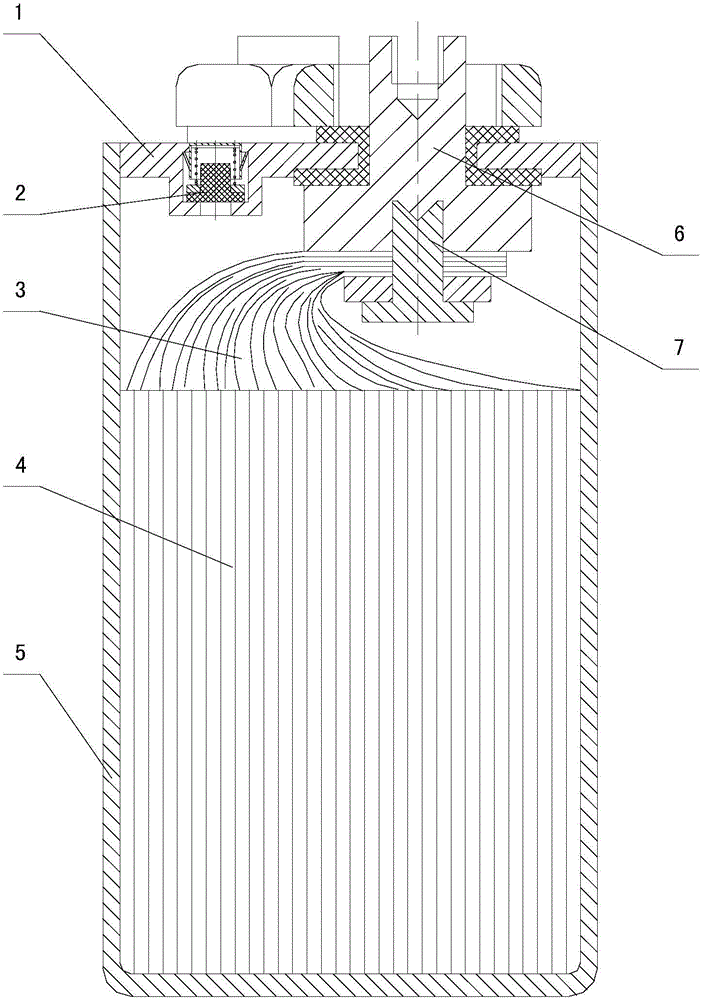

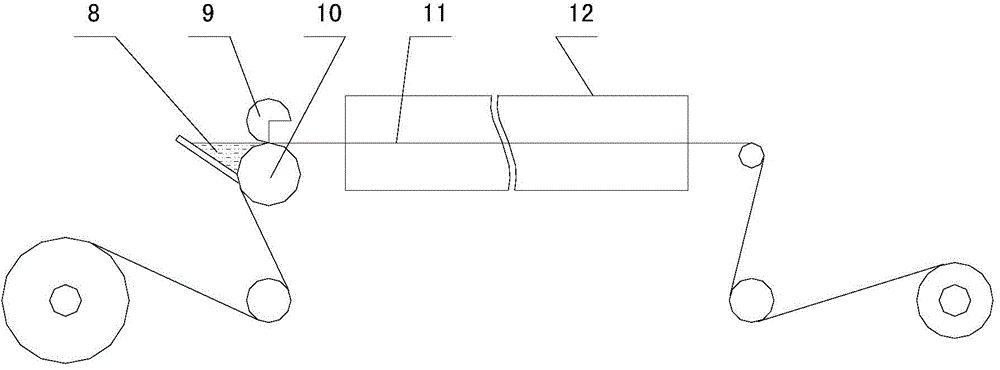

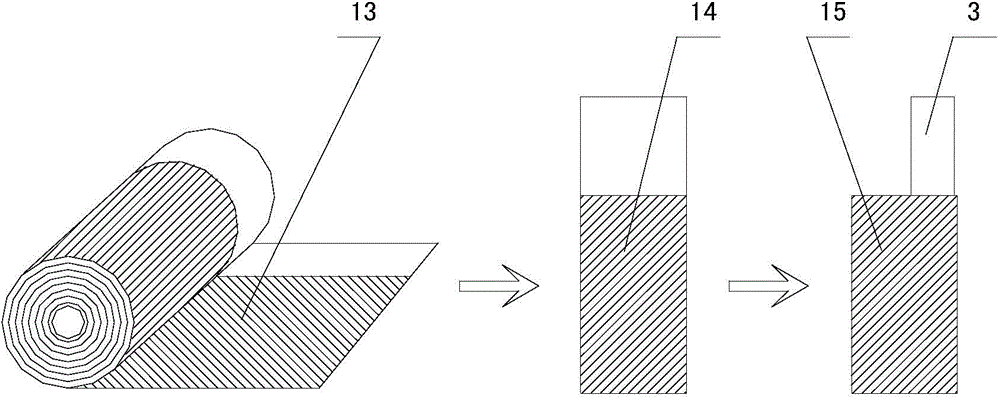

Super capacitor and manufacturing process thereof

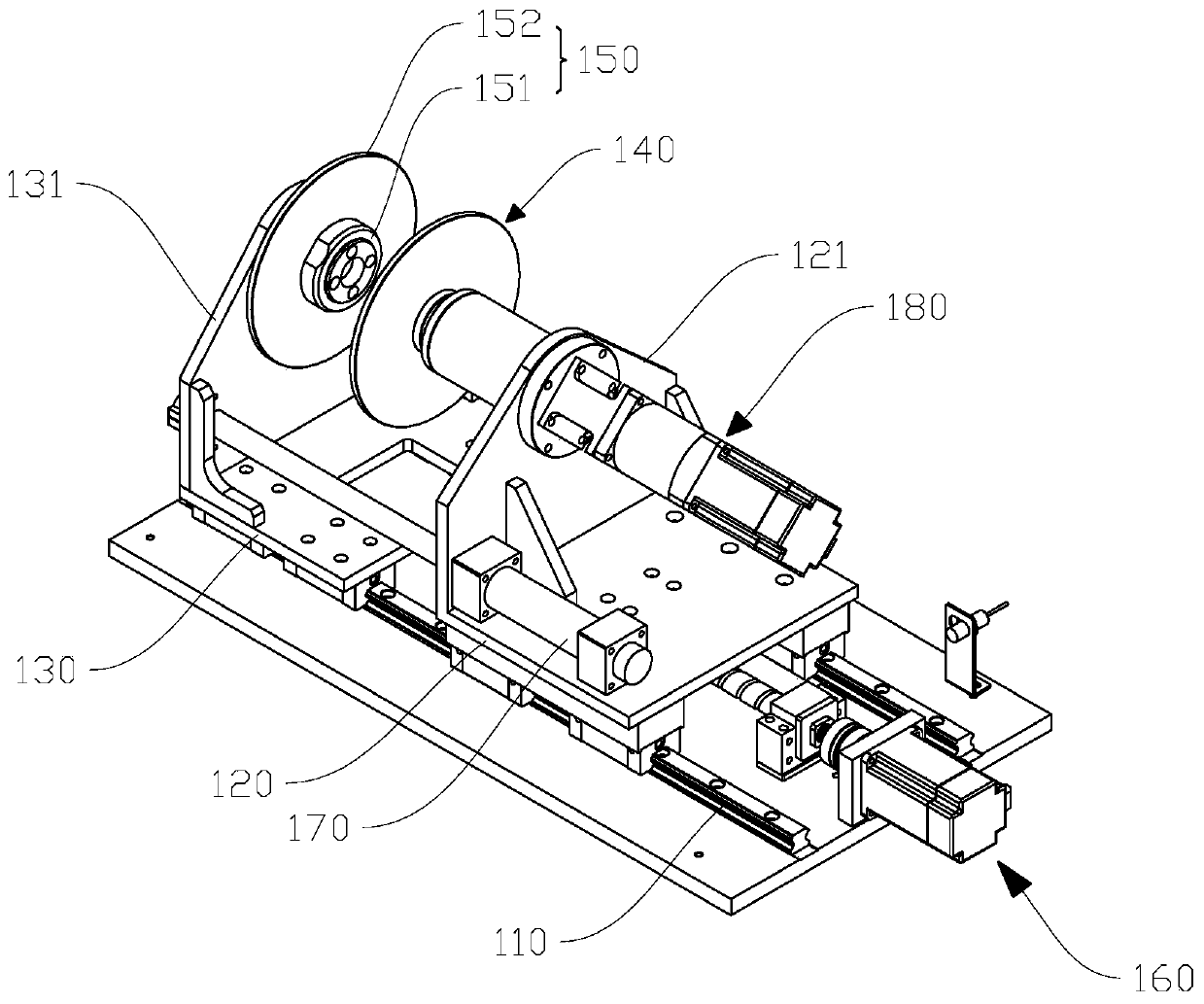

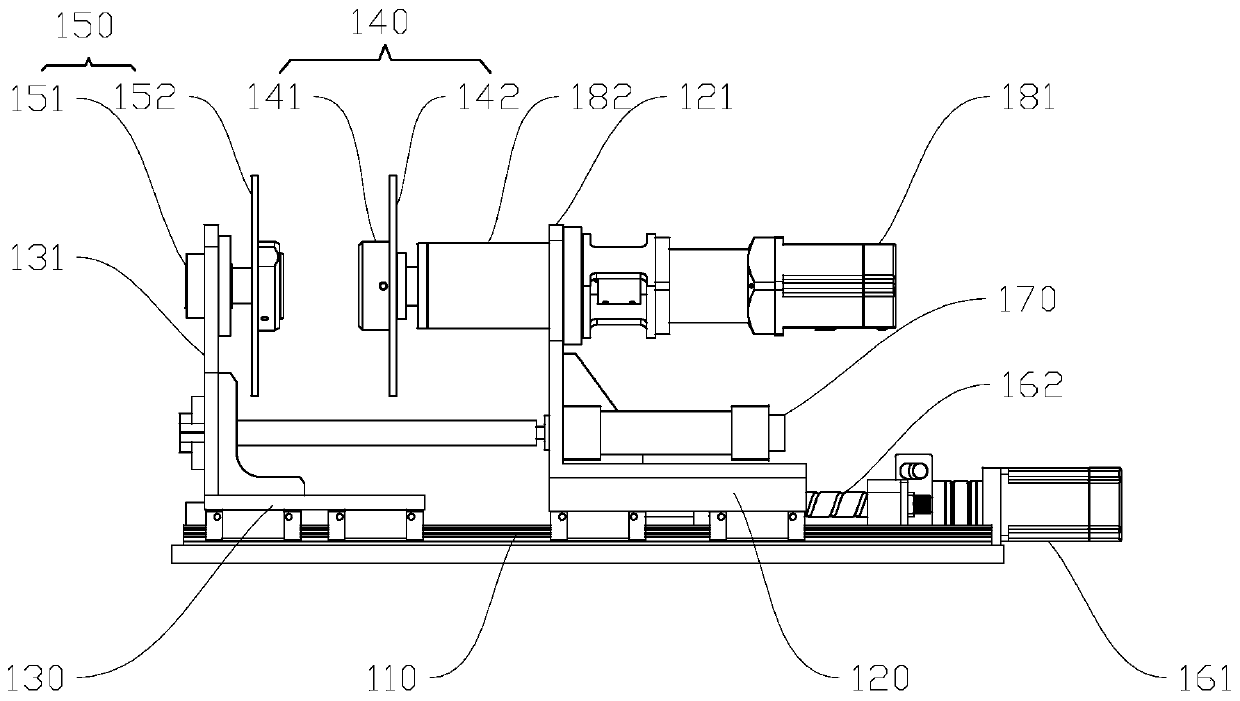

ActiveCN103606466AIncrease active spaceFactors that reduce corrosionHybrid capacitor electrodesHybrid/EDL manufactureEngineeringPole piece

The invention discloses a super capacitor. The thickness of an anode pole piece and the thickness of a cathode pole piece are different, the thickness range of the anode pole piece is 180 micrometers to 280 micrometers, and the thickness range of the cathode pole piece is 160 micrometers to 260 micrometers. The manufacturing process of the super capacitor comprises the steps: (1) material preparation, (2) the preparation of an electrode on a coating device, (3) electrode rolling, (4) the formation of pole pieces, (5) the formation of an electric core, (6) the connection of a leading-out terminal, (7) the vacuum drying of the electrical core, (8) vacuum liquid injection, and (9) safety explosion-proof. After the above structure and manufacturing process are adopted, the volume of the anode pole piece is larger than the volume of the cathode pole piece, the active space of an ion is greatly raised, the factors of electrode corrosion are reduced, the condition that a diaphragm hole is not blocked by an attachment is ensured, and the stability and the service life of the product are raised.

Owner:NINGBO CRRC NEW ENERGY TECH CO LTD

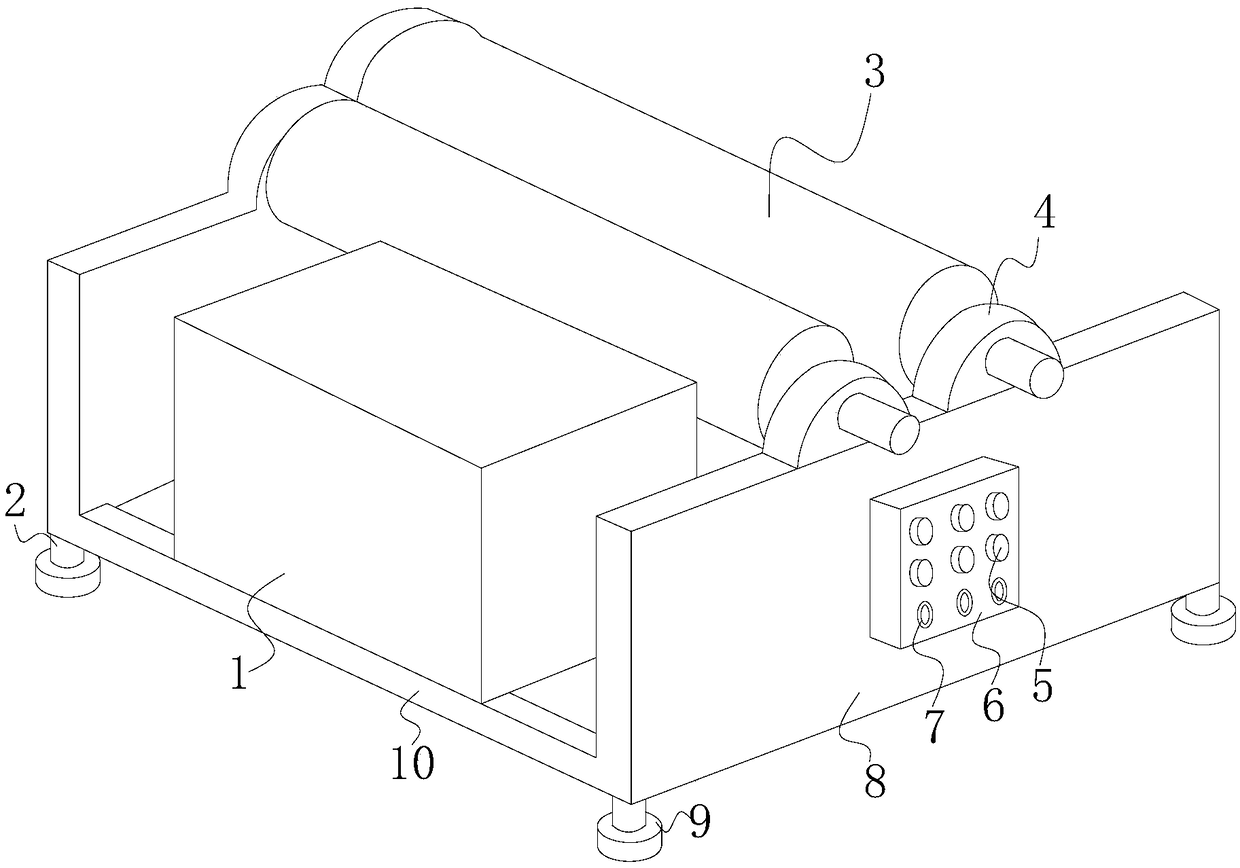

Cable processing winding machine

The invention discloses a cable processing winding machine. The cable processing winding machine comprises a base, wherein brake wheels are fixedly installed at the four corners of the bottom of the base, the two sides of the top of the base are respectively and fixedly provided with a first side supporting plate and a second side supporting plate which are vertically arranged, and the opposite sides of the first side supporting plate and the second side supporting plate are rotationally connected with the same winding roller through bearings; the sides, close to the second side supporting plate, of the base is provided with a driving mechanism, and the side, close to one side of the first side supporting plate, of the base is fixedly provided with a stand column; and the top end of the stand column and the top end of the first side supporting plate are fixedly provided with the same mounting plate, the mounting plate is provided with a reciprocating moving mechanism, and the reciprocating moving mechanism comprises a forward and reverse rotating motor fixedly mounted on the mounting plate. Under the control of a controller, by controlling the operation direction of the forward andreverse rotation motor, a lead screw and a sliding rod are matched to drive a moving block to reciprocate back and forth, and a cable is driven to move back and forth through a sleeve ring, so that the winding of the cable is tidy and orderly, and the advantage of preventing cable knotting is acheived.

Owner:惠州市鑫弘诚电子科技有限公司

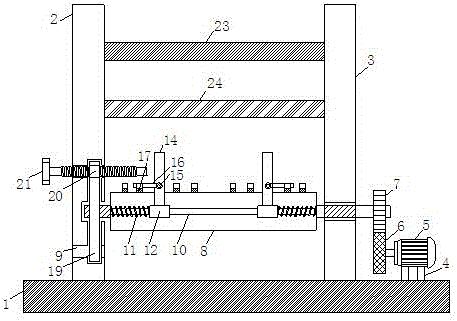

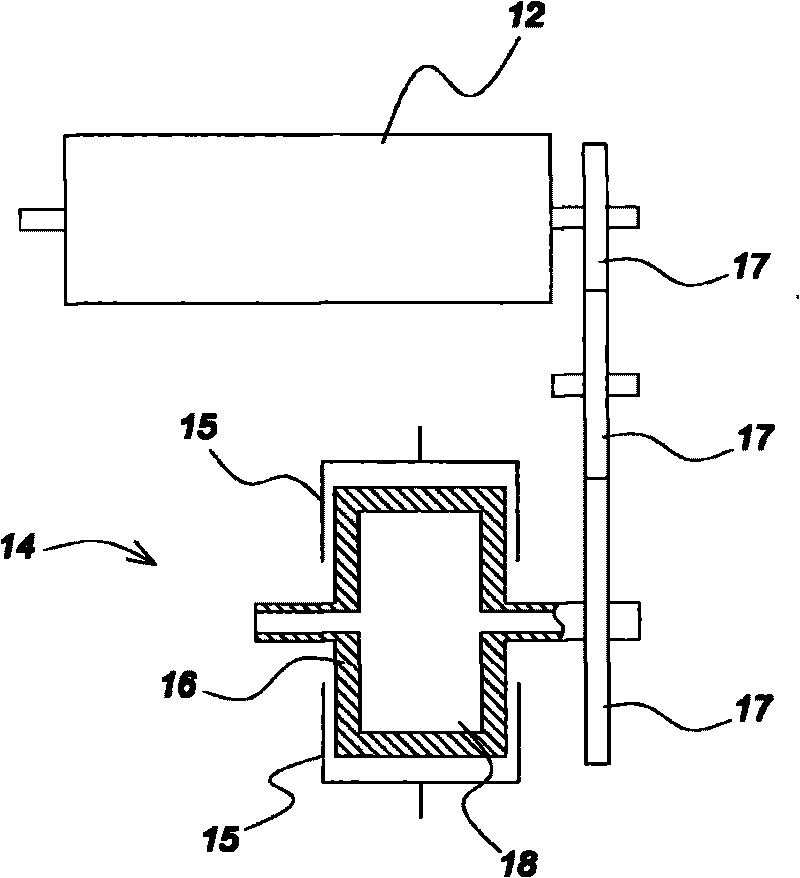

Roller type tension station applicable to rolling multiple rollers

InactiveCN101704460ANeatly rolledRewinding does not deviateWebs handlingMaterials processingMechanical engineering

The invention provides a roller type tension station which is applicable to rolling multiple rollers and can have partial tension adjusted. The tension station comprises a frame, the frame is provided with a first roller group, a second roller group and an adjusting roller group; the first roller group is composed of a first pressure roller and a first resistance roller; the second roller group is composed of a second pressure roller and a second resistance roller, and the second resistance roller drives with a first resistance device; the adjusting roller group is composed of an adjusting roller and an adjusting resistance roller; the adjusting roller is composed of an adjusting roller shaft and a plurality of rubber roller sections mounted on the adjusting roller shaft and corresponding to the width of a target steel aluminum strip; the adjusting resistance roller drives with a second resistance device; the first pressure roller, the second pressure roller and the adjusting roller are provided with pressure source. The inventive tension station rolls the rollers neatly without off-tracking or damaging target steel aluminum strip during running, has lower manufacture, use and maintenance costs than a belt tension station, and is the best option for future high-end steel aluminum plate processing equipments.

Owner:施春建

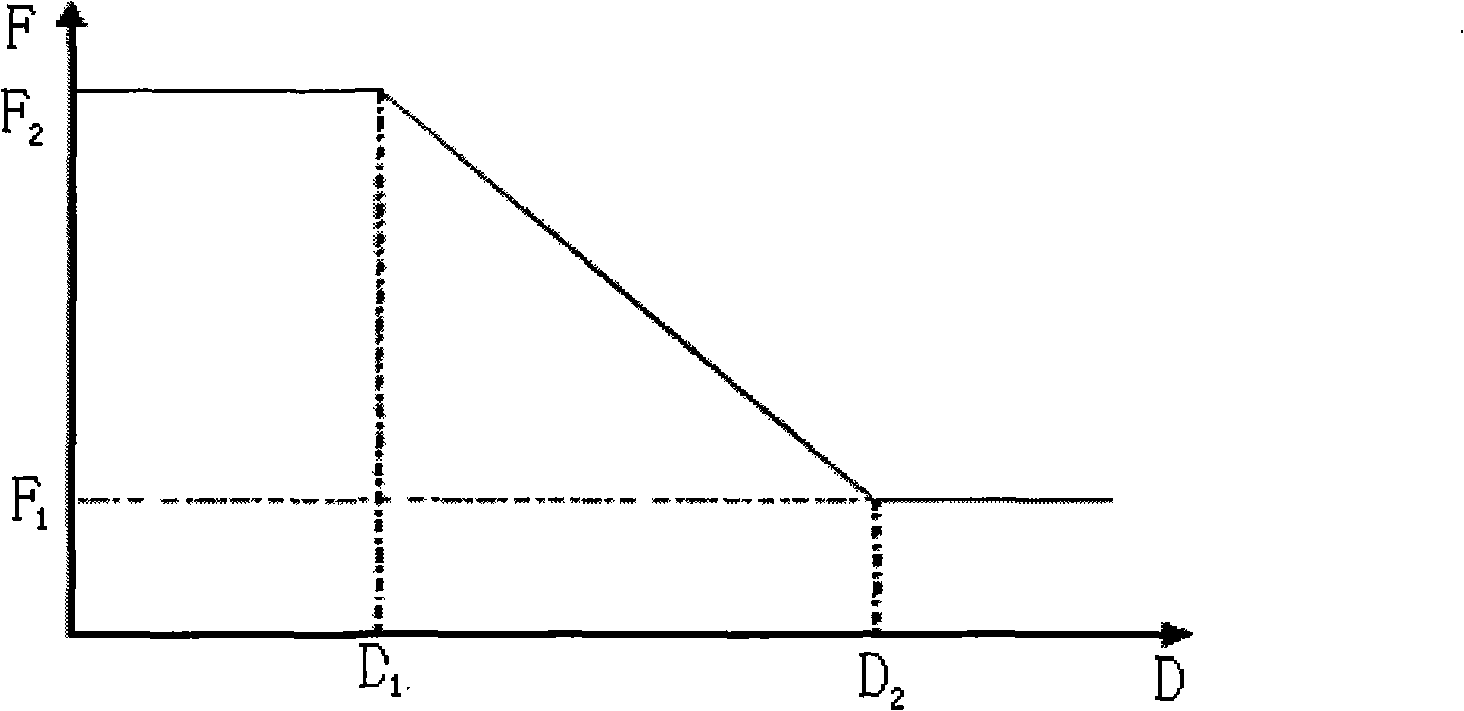

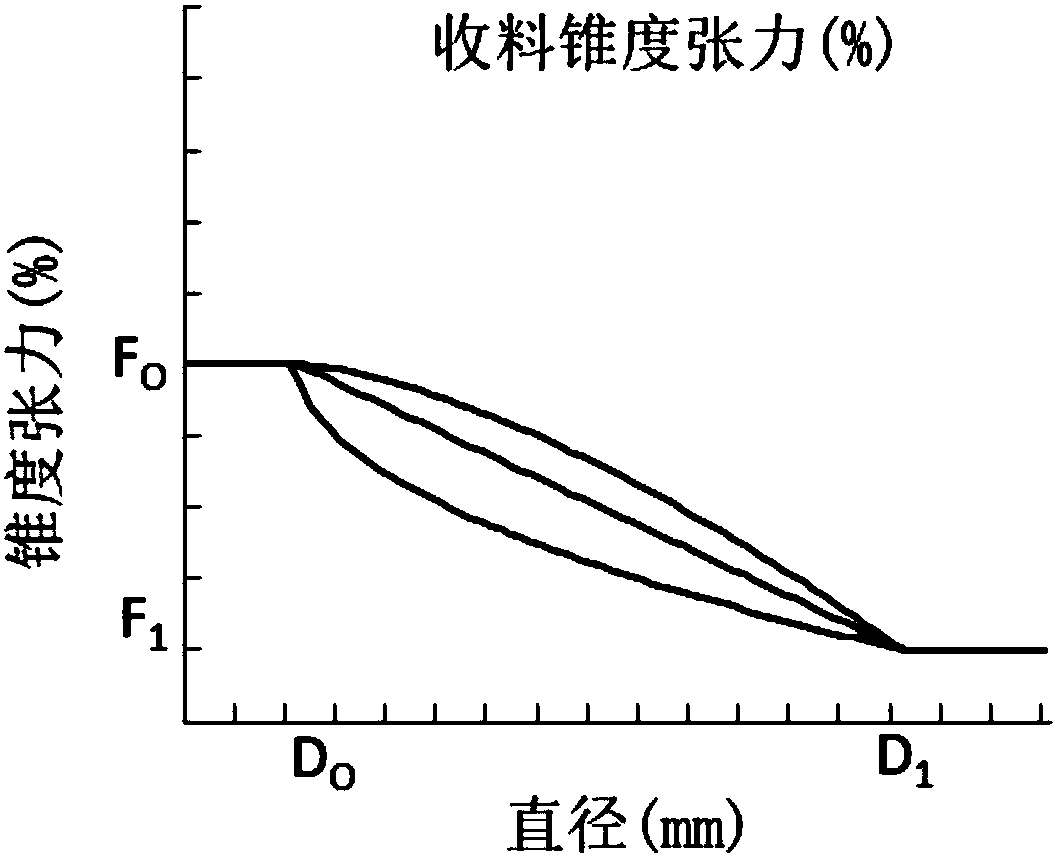

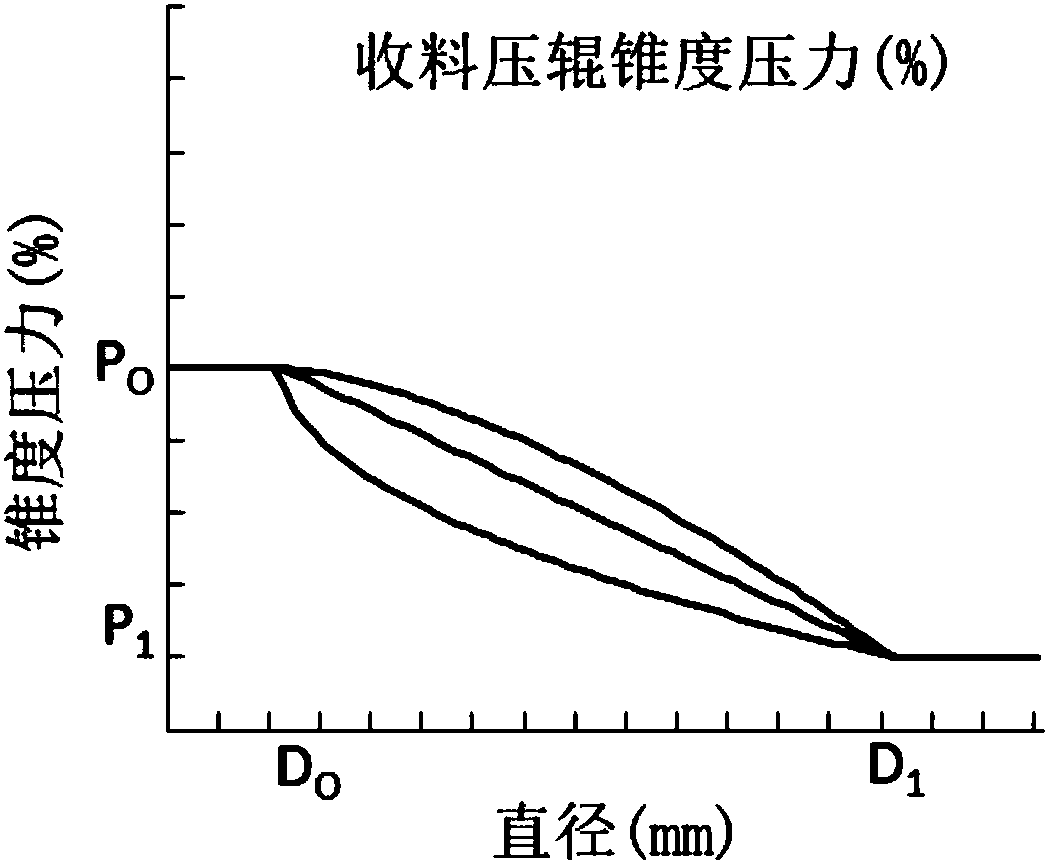

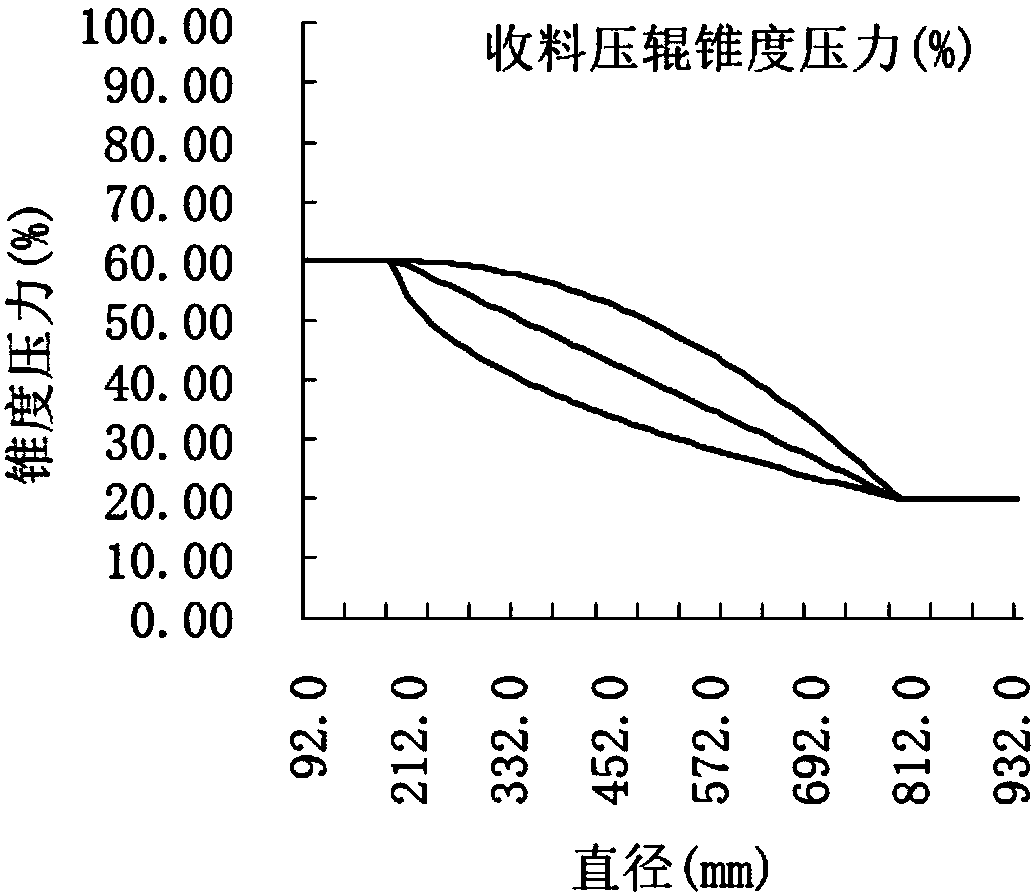

Material winding double-taper control method

ActiveCN108249189AImprove the winding effectNeatly rolledArticle deliveryWebs handlingConductor CoilMechanical engineering

The invention aims to provide a material winding double-taper control method. Taper pressure of a material winding pressing roller is controlled while taper tension is controlled during printing and composite material winding, the pressure of the material winding pressing roller is increased along with the winding diameter, the material winding taper tension and material winding pressing roller taper pressure can be simultaneously controlled through the control method with the pressure being gradually decreased in a tapered mode, and the winding quality of print materials is obviously improved.

Owner:SHAANXI BEIREN PRINTING MACHINERY

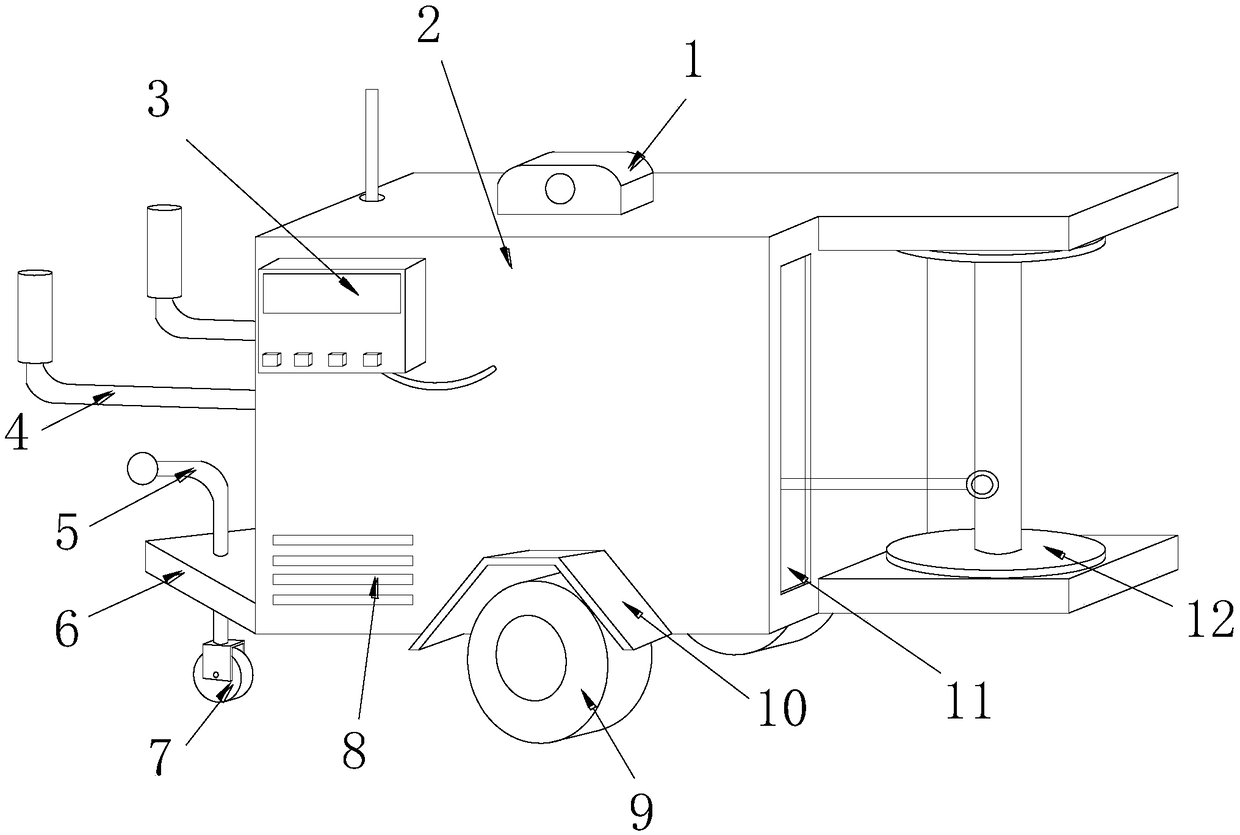

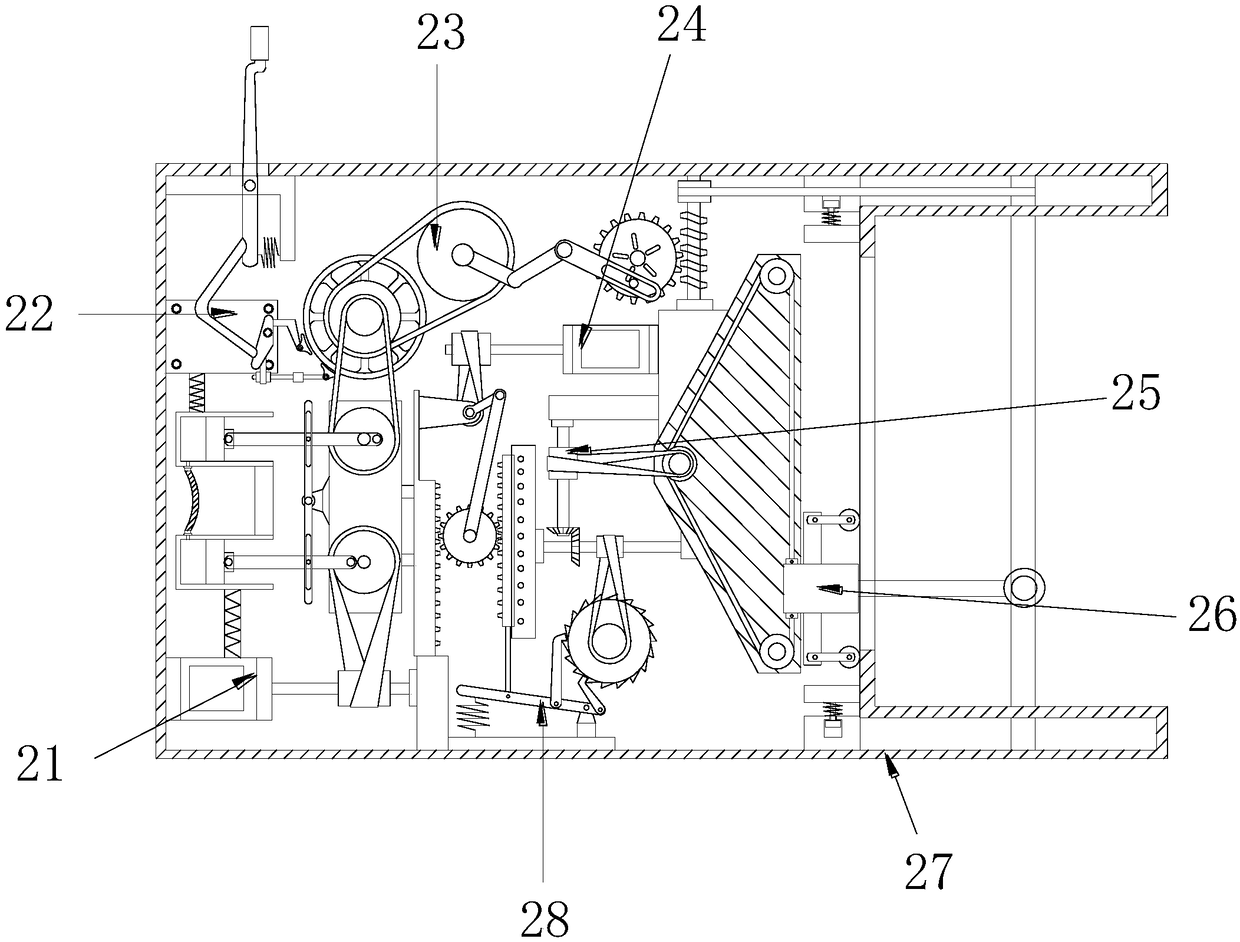

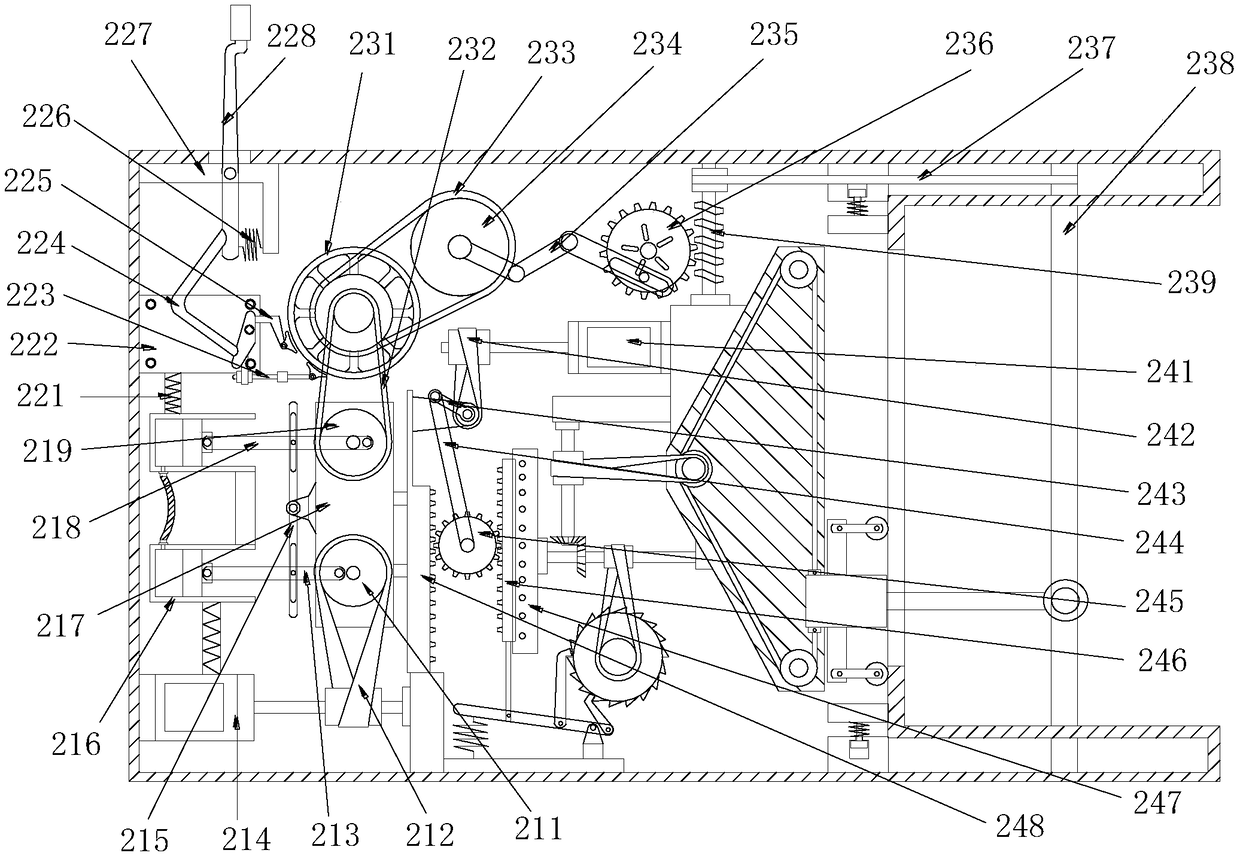

Efficient full-automatic cable taking-up and paying-off device

InactiveCN108609441AAvoid damageSlow down the winding speedPush and pullElectrical and Electronics engineering

The invention discloses an efficient full-automatic cable taking-up and paying-off device. The efficient full-automatic cable taking-up and paying-off device structurally comprises a lifting ring attached lug, a cable coiling device with a controllable rotation speed, a control panel, push-and-pull rods, a direction control rod, a control rod fixing plate, trundles, ventilation openings, trolley wheels, protective covers, an open groove and a coiling drum. The lifting ring attached lug is welded to the upper surface of the cable coiling device with the controllable rotation speed. The push-and-pull rods are embedded into the middle section of the left surface of the cable coiling device with the controllable rotation speed. The control rod fixing plate is welded to the lower end of the left surface of the cable coiling device with the controllable rotation speed. According to the efficient full-automatic cable taking-up and paying-off device, through the arranged cable coiling device with the controllable rotation speed, when the cable is taken up, if the cable bears excessively large tension, the rotation speed of a compound rotating disk 231 can be controlled, so that the taking-up speed is controlled, and the cable is prevented from being damaged; and during taking-up, the cable can be coiled into the coiling drum in tidy, and taking-up is rapid and convenient.

Owner:张晓双

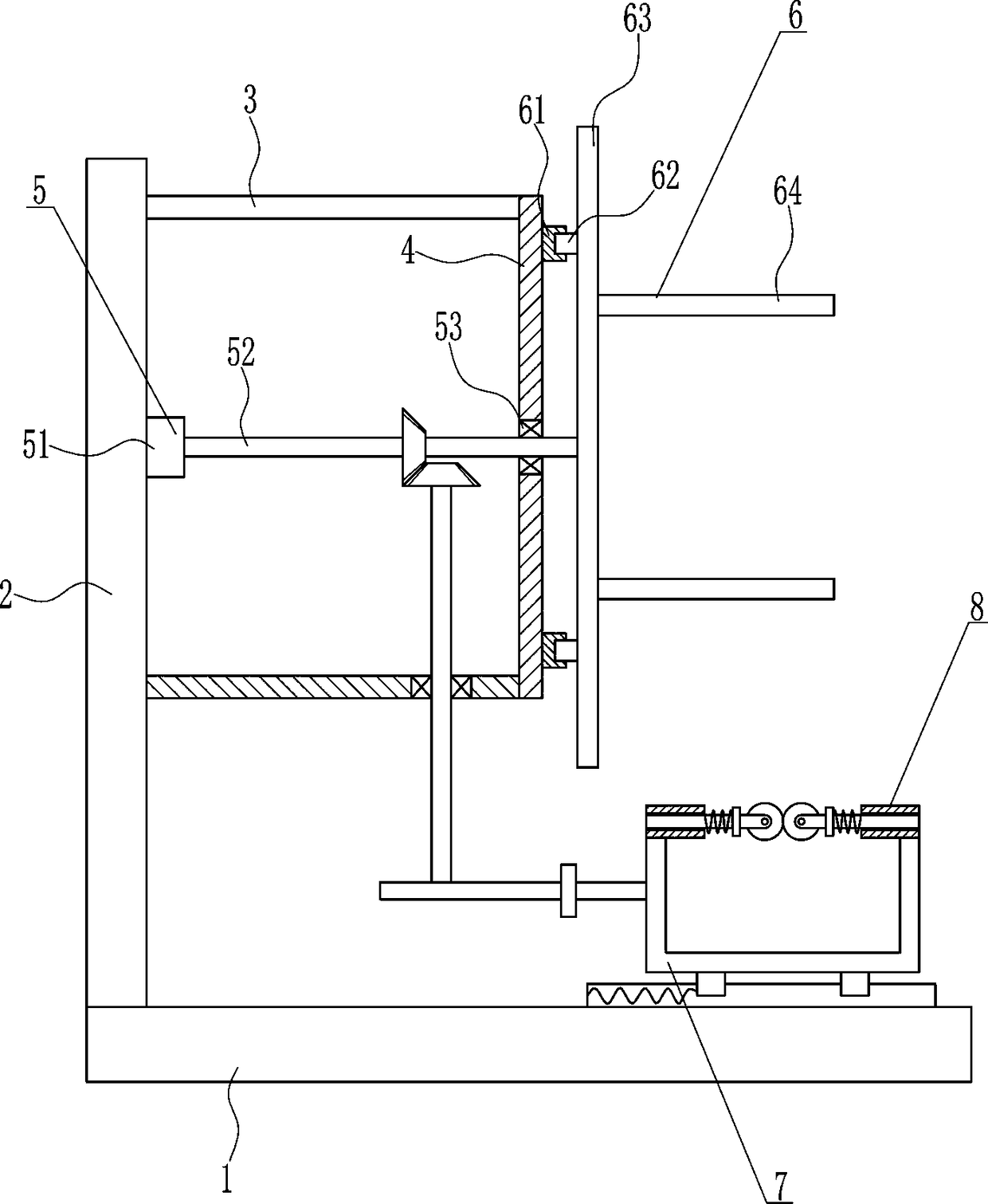

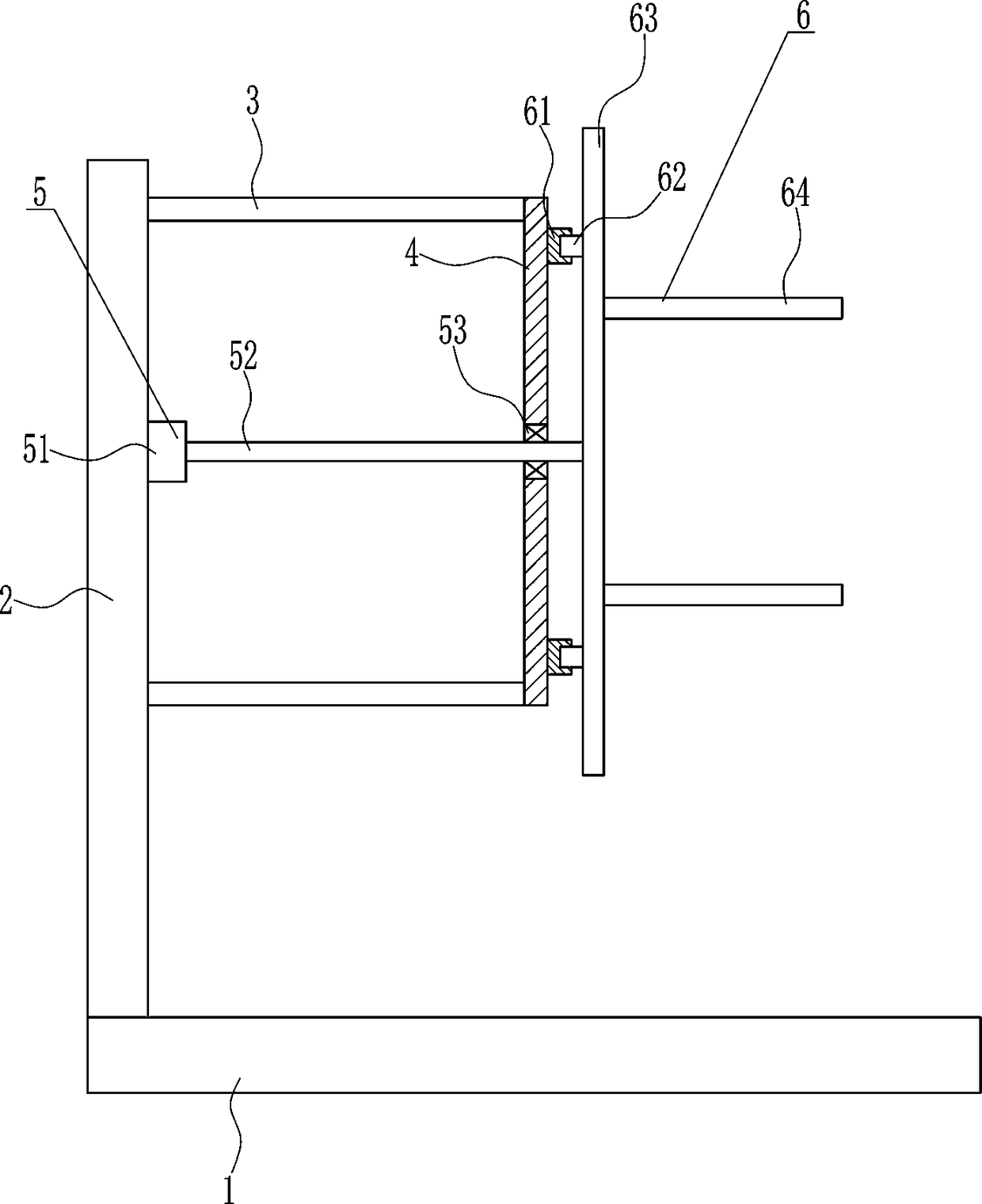

Safety cable winding device for electric power construction

The invention relates to a winding device, in particular to a safety cable winding device for electric power construction. The safety cable winding device for electric power construction has the advantages of being high in winding efficiency, orderly, time-saving and labor-saving. The safety cable winding device for electric power construction comprises a base plate and the like; a supporting plate is connected to the left end of the top of the base plate in a bolted connection mode; transverse plates are connected to the upper part and the middle part of the right side of the supporting plate; a vertical plate is connected to the ends of the upper transverse plate and the lower transverse plate in a bolted connection mode; a driving device is arranged in the middle of the right side of the supporting plate; and a winding device body is arranged on the right side of the vertical plate. According to the safety cable winding device, the driving device drives the winding device body, a moving device and a flusher to operate, the winding device body and the moving device are used for winding the safety cable in order, the flusher is used for washing away soil on the surface of the safety cable, and therefore the effects of being high in winding efficiency, orderly, time-saving and labor-saving can be achieved.

Owner:泰州市飞特尼龙绳网带有限公司

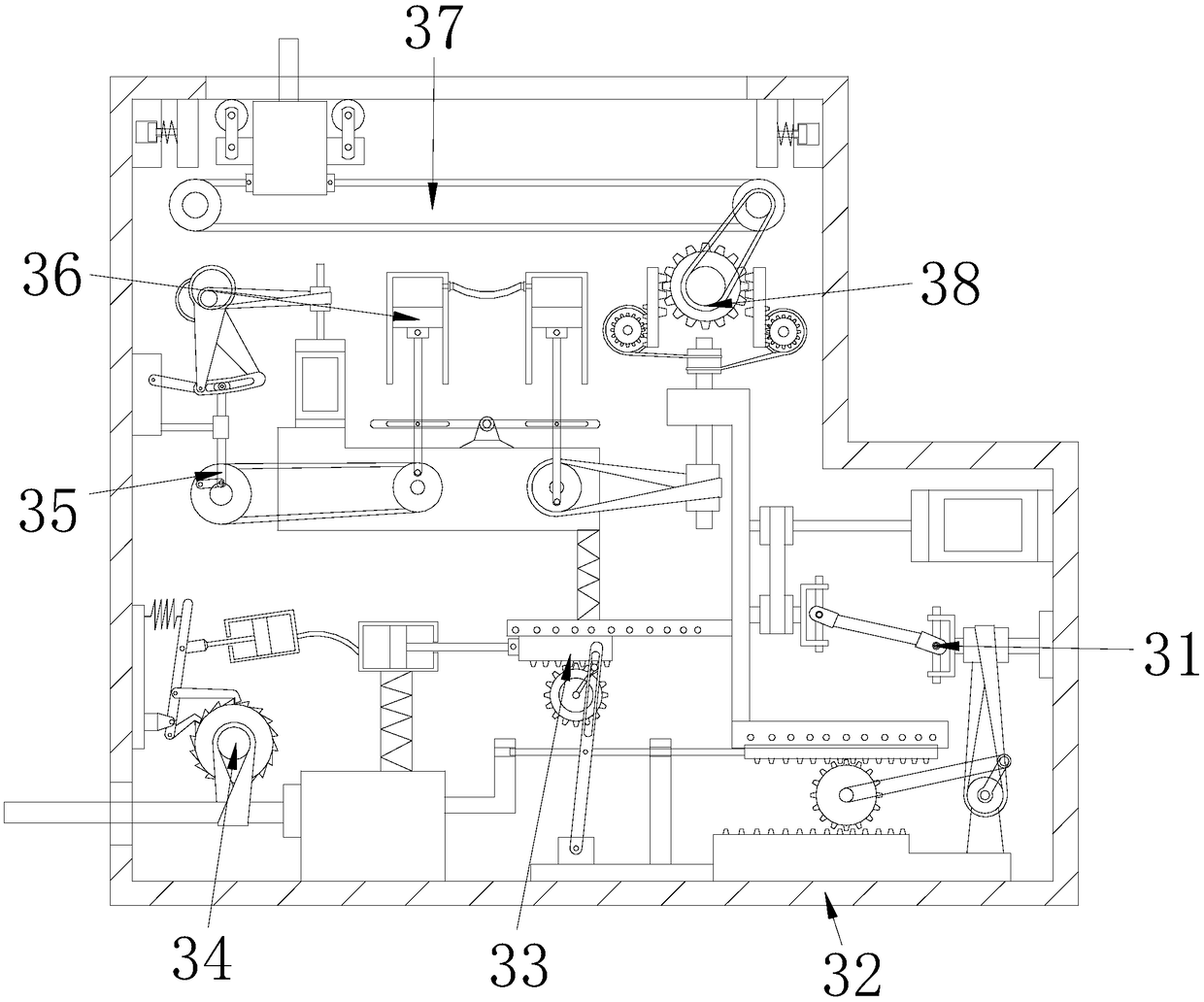

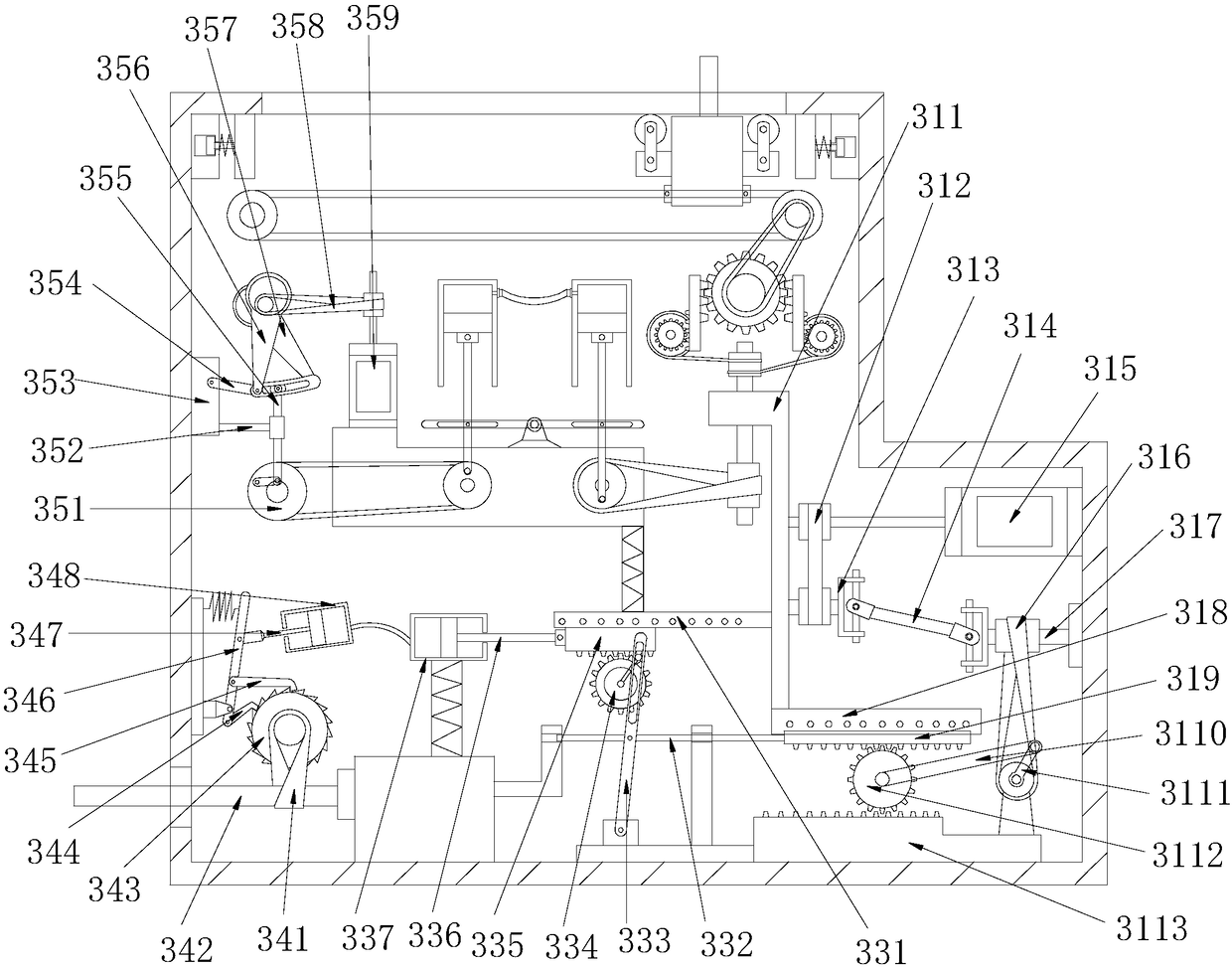

Reeling device for warp knitting machine

InactiveCN108796809AWinding levelNeatly rolledWarp knittingHeating/cooling textile fabricsEngineeringConductor Coil

The invention discloses a reeling device for a warp knitting machine. The reeling device structurally comprises a cloth reeling device, a connecting column, a winding roll, a mounting seat, a controlpanel, a control tank, indication lamps, a support frame, a support frame, anti-sliding bottom legs and a support base plate. According to the reeling device for the warp knitting machine, the cloth reeling device comprises a guiding device, a pressurizing mechanism, a starting mechanism, a transmission mechanism, an anti-meandering device, a stirring mechanism and a cooling device, so that a compression force can be applied to cloth when the cloth is reeled, the cloth can be flatly reeled, the situation that the slack cloth falls to the ground is avoided, and the cleanness of the cloth is increased; meanwhile, the cloth can be adjusted and reeled according to the width of the cloth, so that the reeled cloth is relatively order, and the reeling quality is improved; and meanwhile, the clothcan be well cooled in the working process of the winding roll, so that the situation that the cloth is deformed due to an over-high temperature, and the appearance of the cloth is influenced to a certain degree are solved.

Owner:FOSHAN XUNTUOAO TECH CO LTD

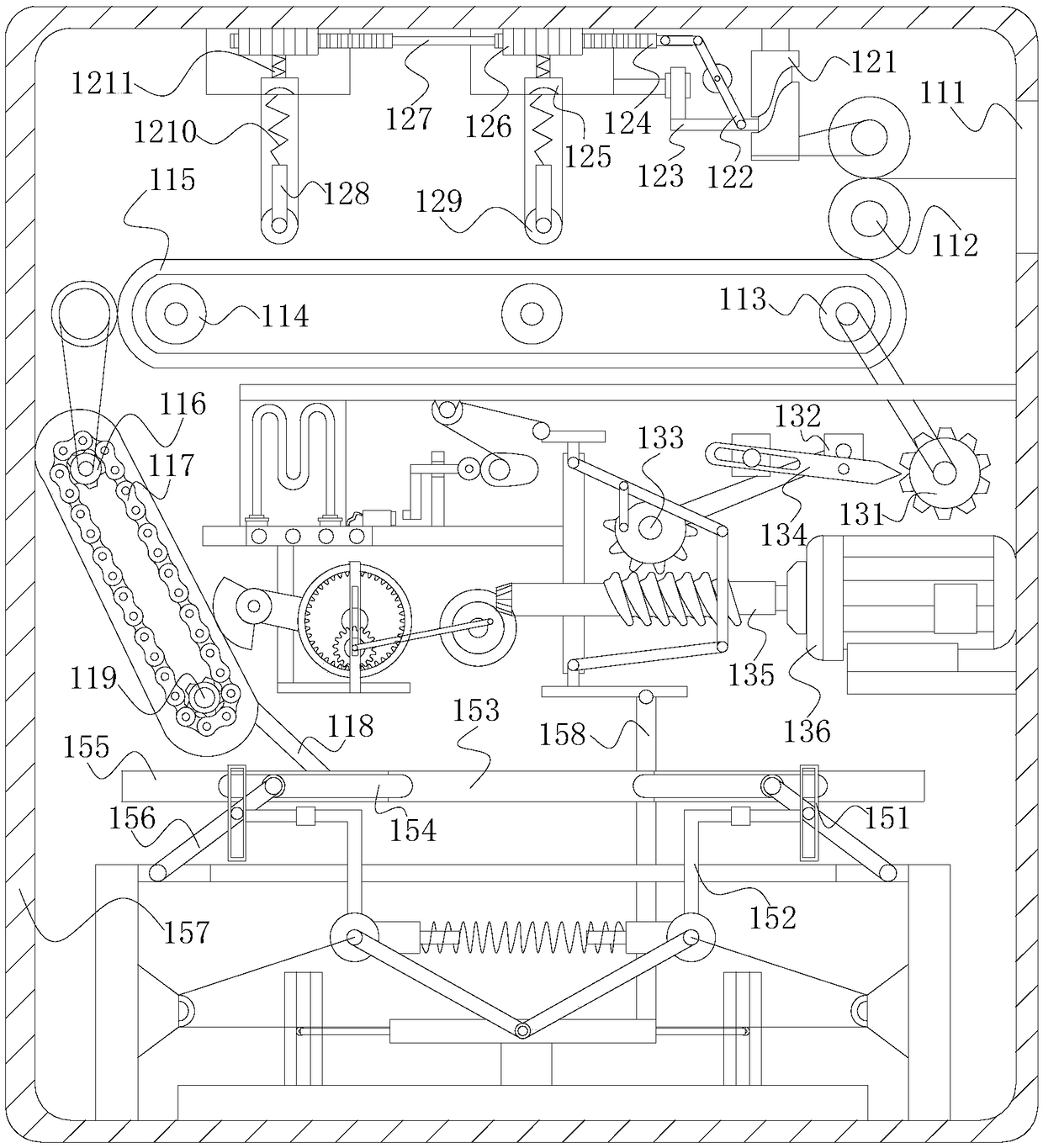

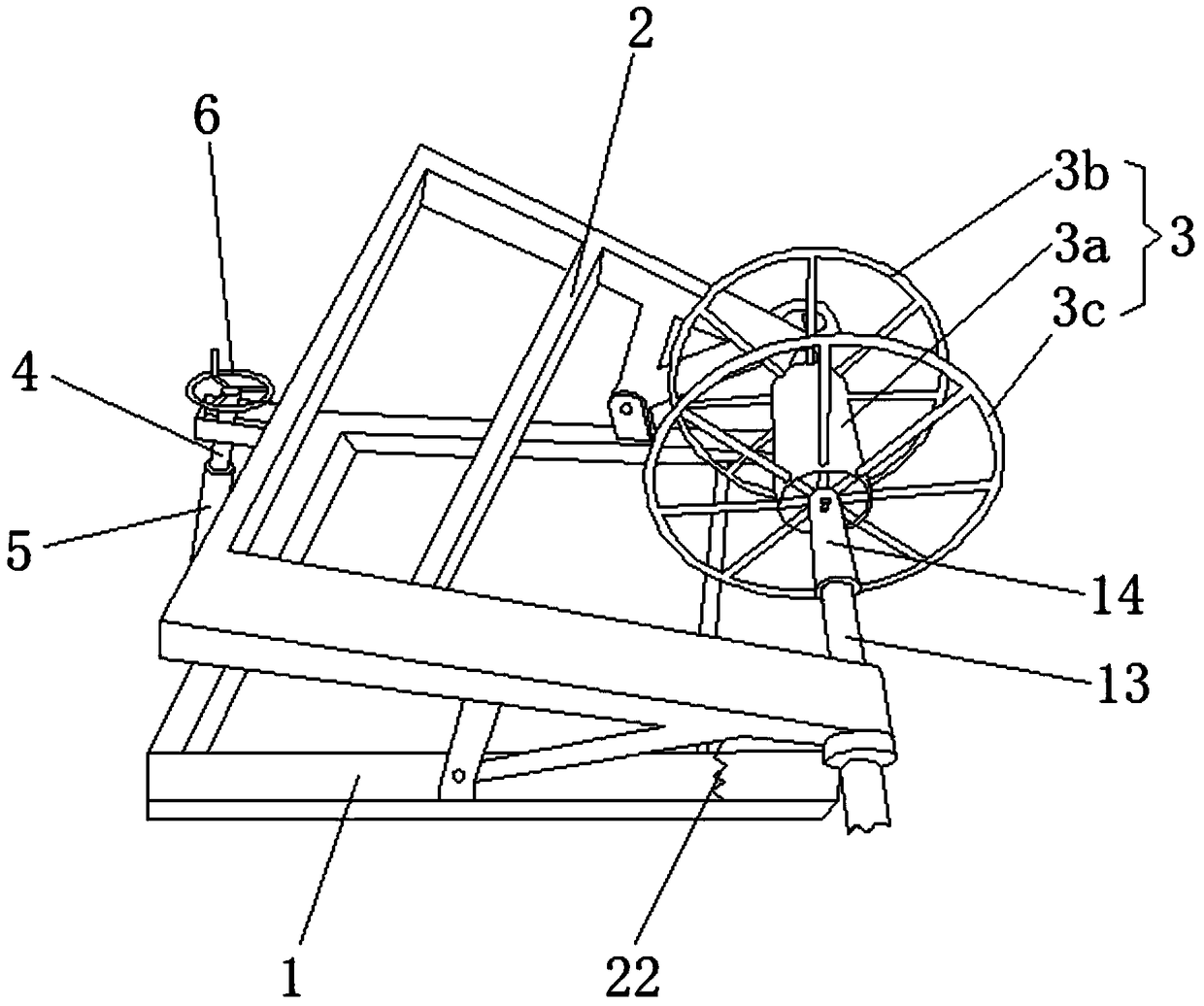

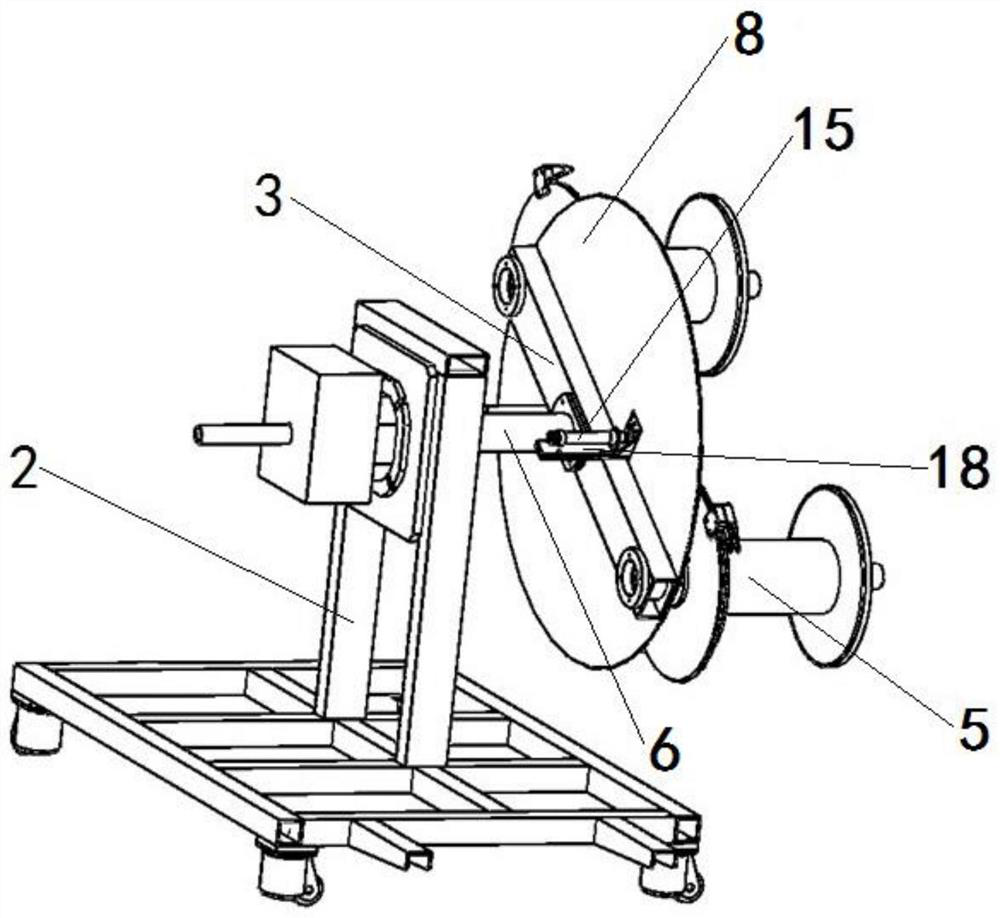

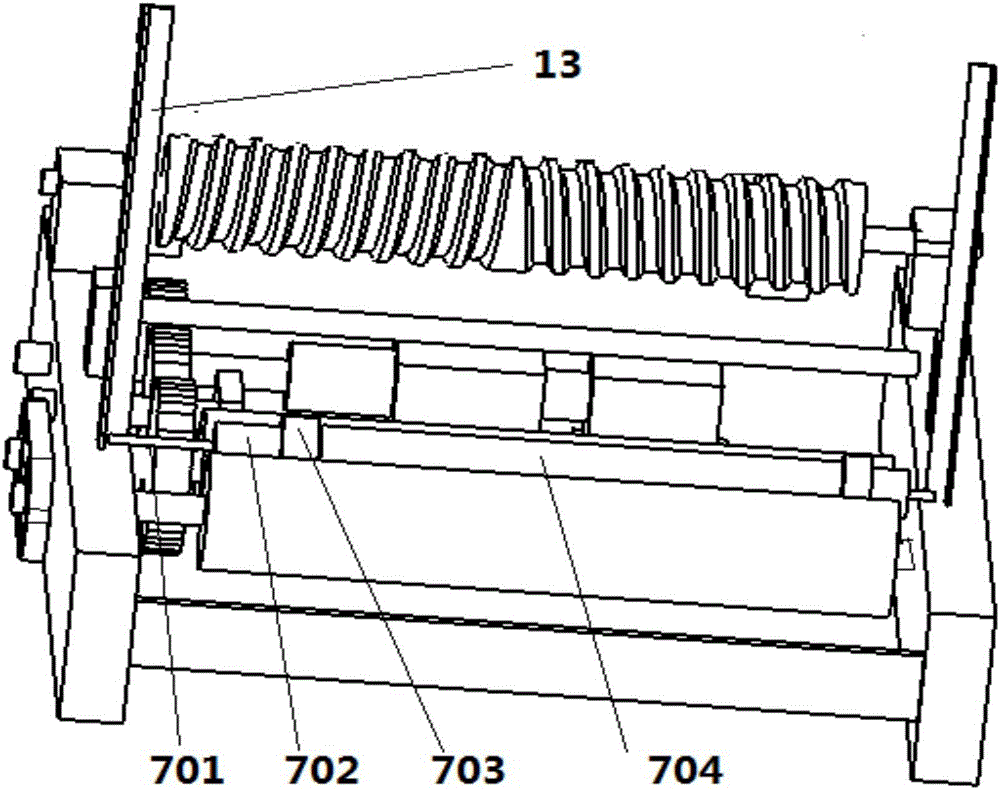

Take-up and pay-off device for belt winding mechanism of belt conveyor

The invention discloses a take-up and pay-off device for a belt winding mechanism of a belt conveyor, which belongs to the technical field of the take-up and pay-off devices. The take-up and pay-off device comprises a belt winding motor, a coupling disk I, a coupling disk II, a winding shaft, a lifting oil cylinder, a chassis, a support seat and a rotating oil cylinder, as well as a moving cantilever, a fixed cantilever, a cantilever telescopic oil cylinder, a guide device and a guide oil cylinder, wherein the support seat is mounted on the chassis and connected through the rotating oil cylinder; the fixed cantilever is mounted on the support seat and connected through the lifting oil cylinder; the fixed cantilever is connected with the moving cantilever through the cantilever telescopic oil cylinder; the belt winding motor, the coupling disk I, the coupling disk II, the winding shaft, the cantilever telescopic oil cylinder, the guide device and the guide oil cylinder are mounted on the moving cantilever; the winding shaft is connected with the moving cantilever through the coupling disk I and the coupling disk II; and the guide device is connected with the fixed cantilever through the guide oil cylinder. The take-up and pay-off device has the benefits that the take-up and pay-off device can coil a conveyor belt tidily and closely without performing any adjustment during the belt winding process and can smoothly send a belt coil onto a mine flat-bed truck after completing the belt winding.

Owner:XUZHOU WUYANG TECH

Automatic cable winding device

Owner:广西和联胜电缆有限公司

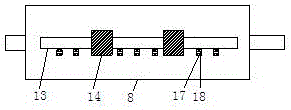

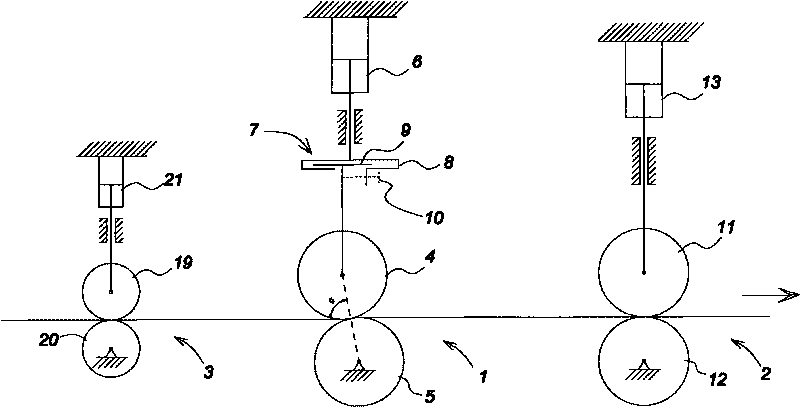

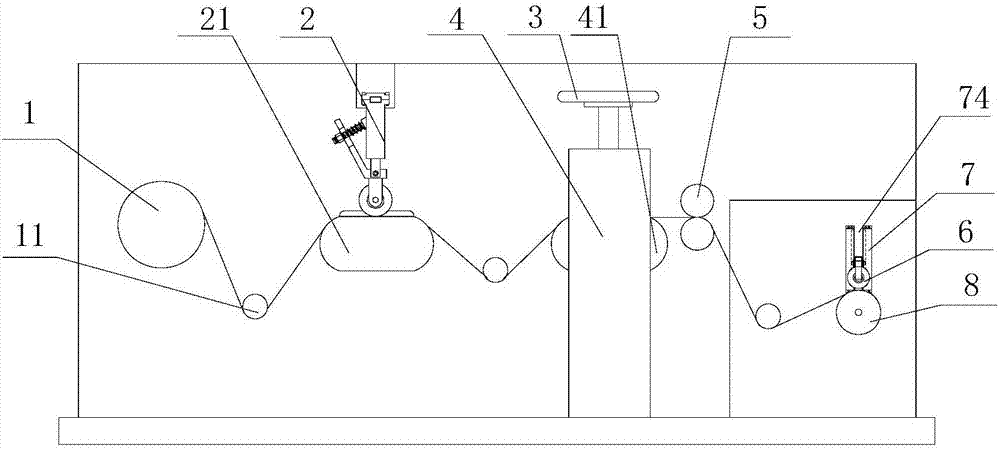

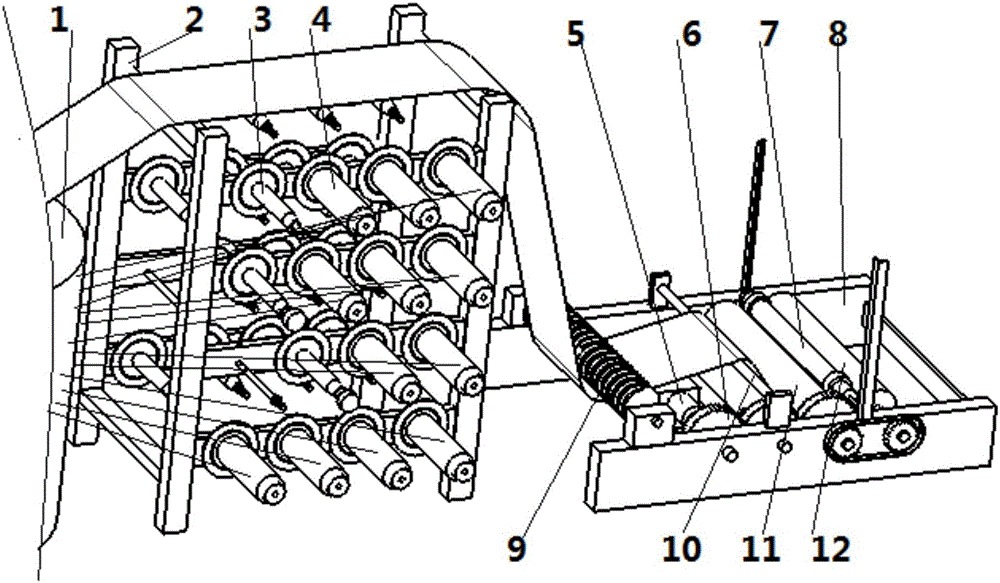

Improved trademark cutting device

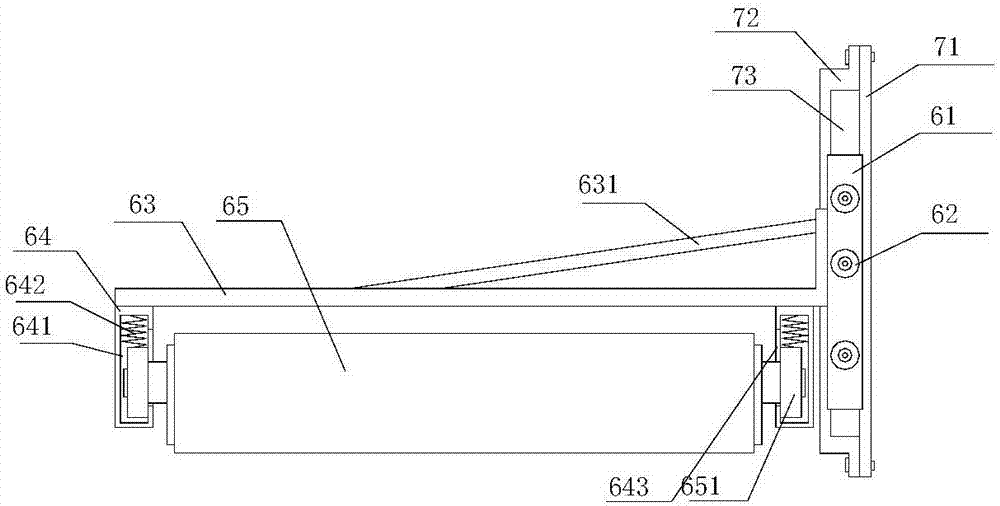

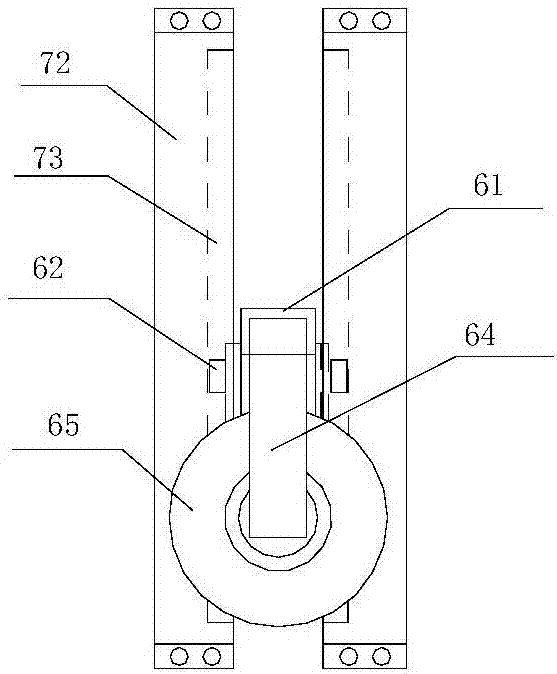

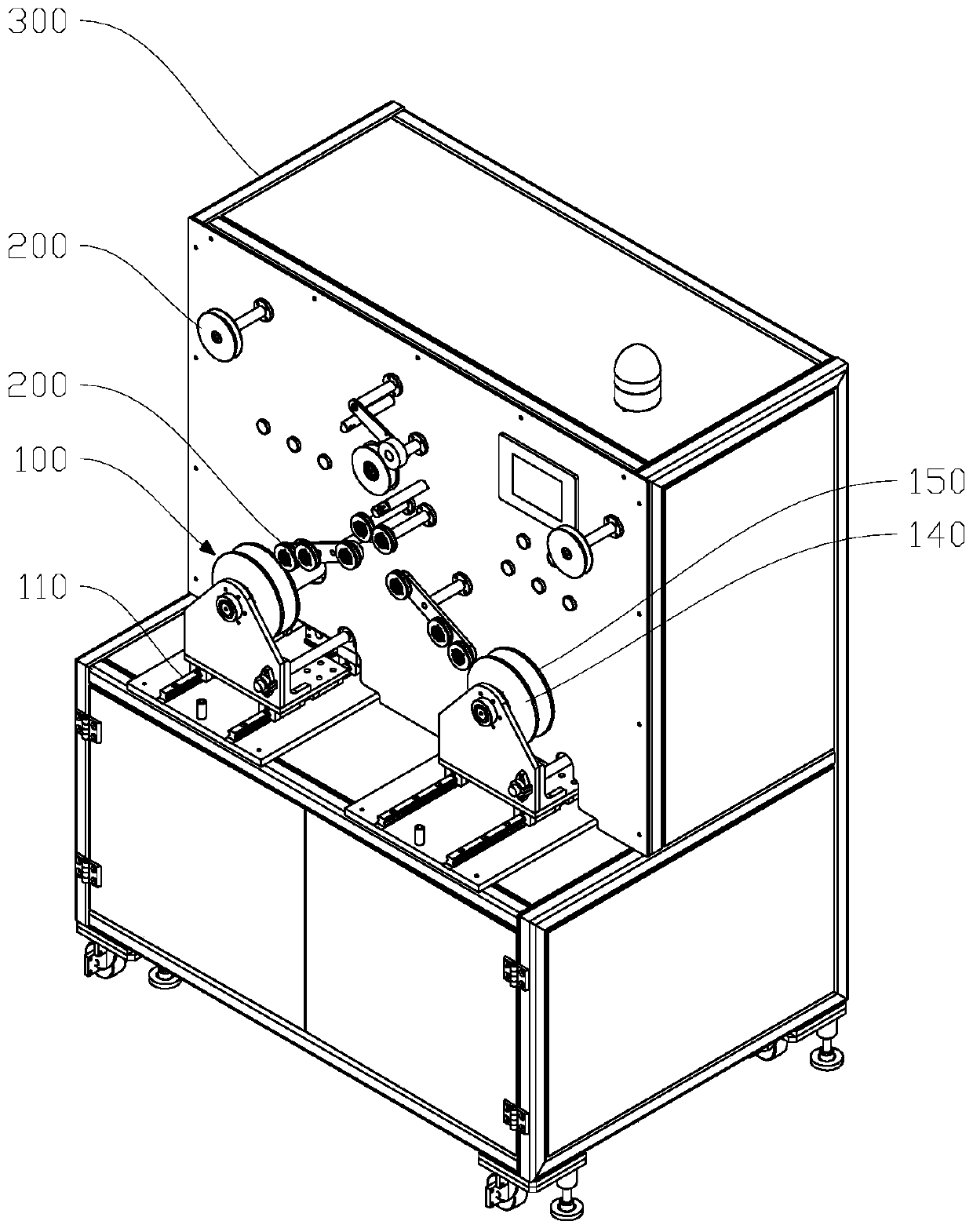

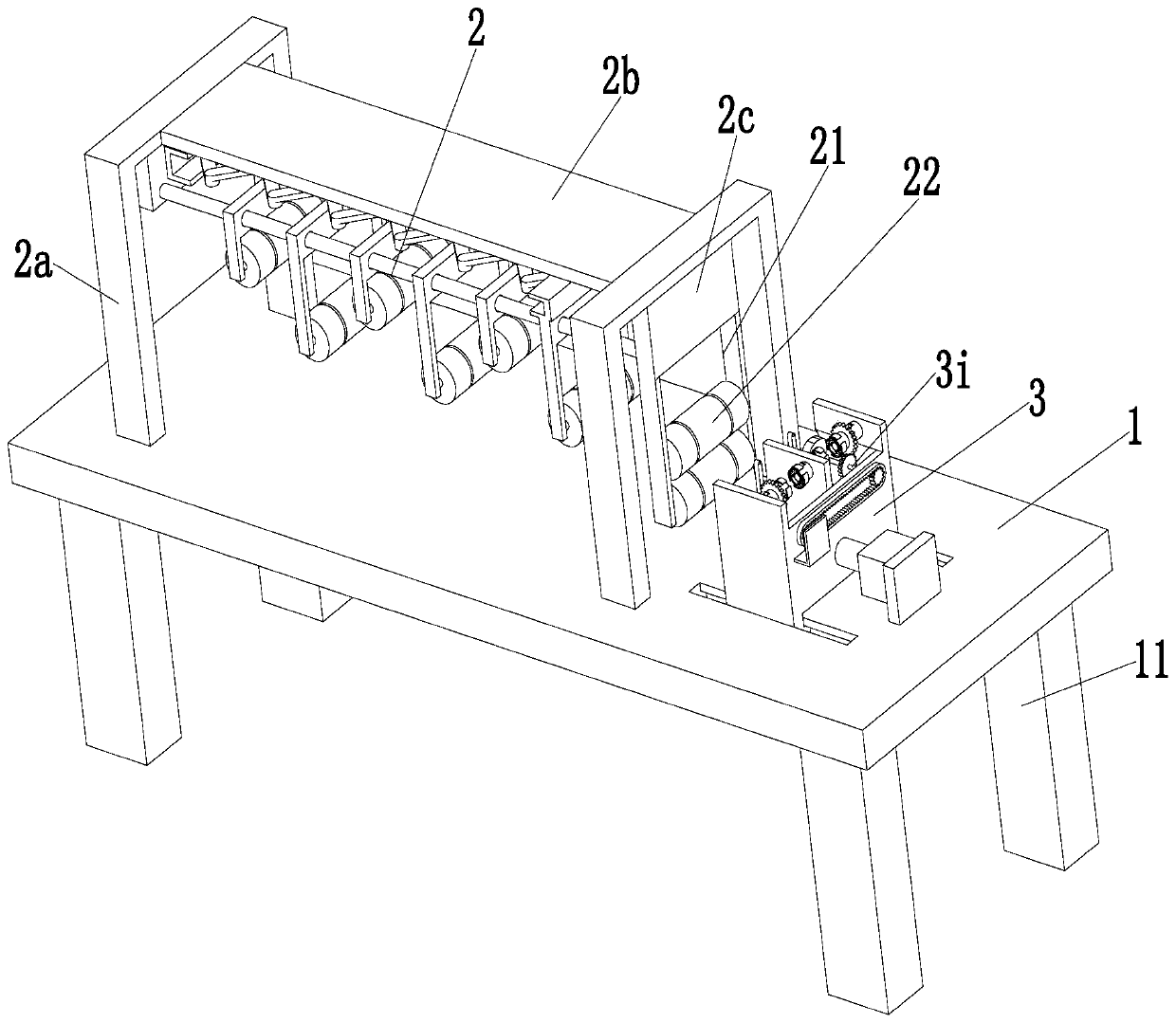

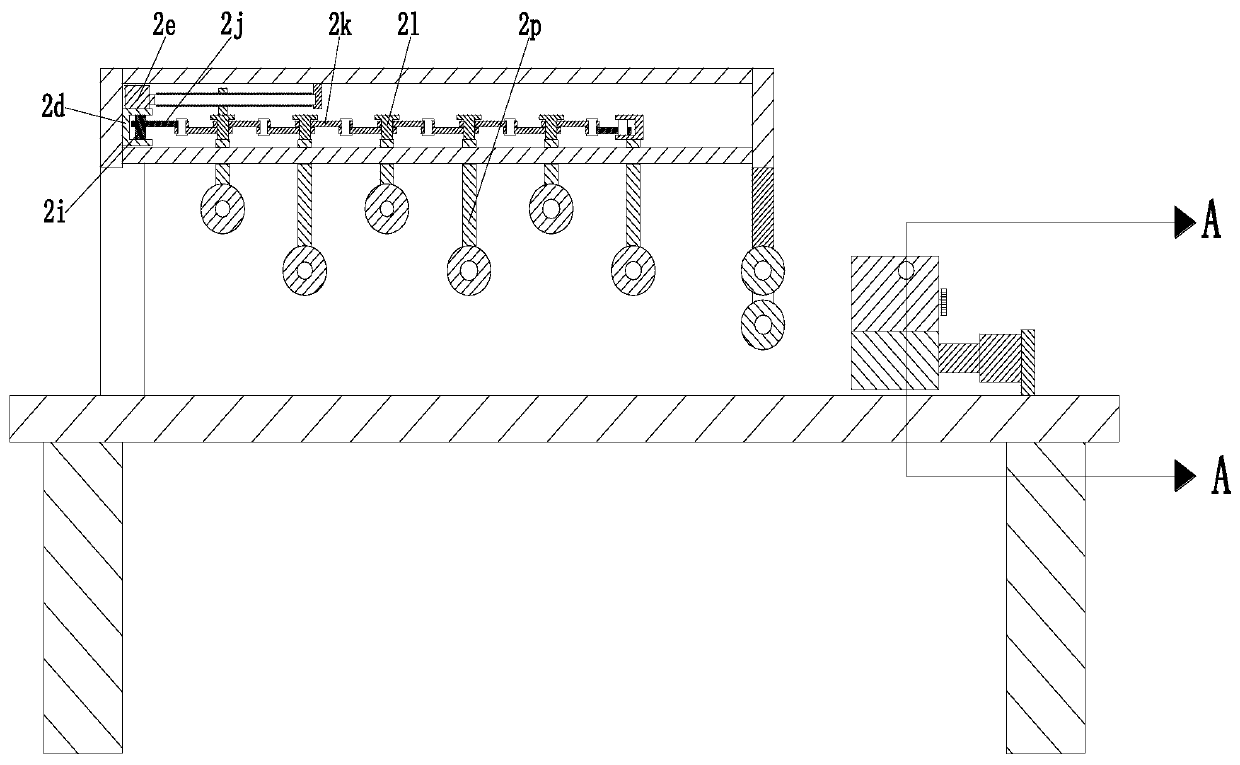

ActiveCN106966218AThe conveying process is stableAvoid wrinklesArticle deliveryWebs handlingConductor CoilMechanical engineering

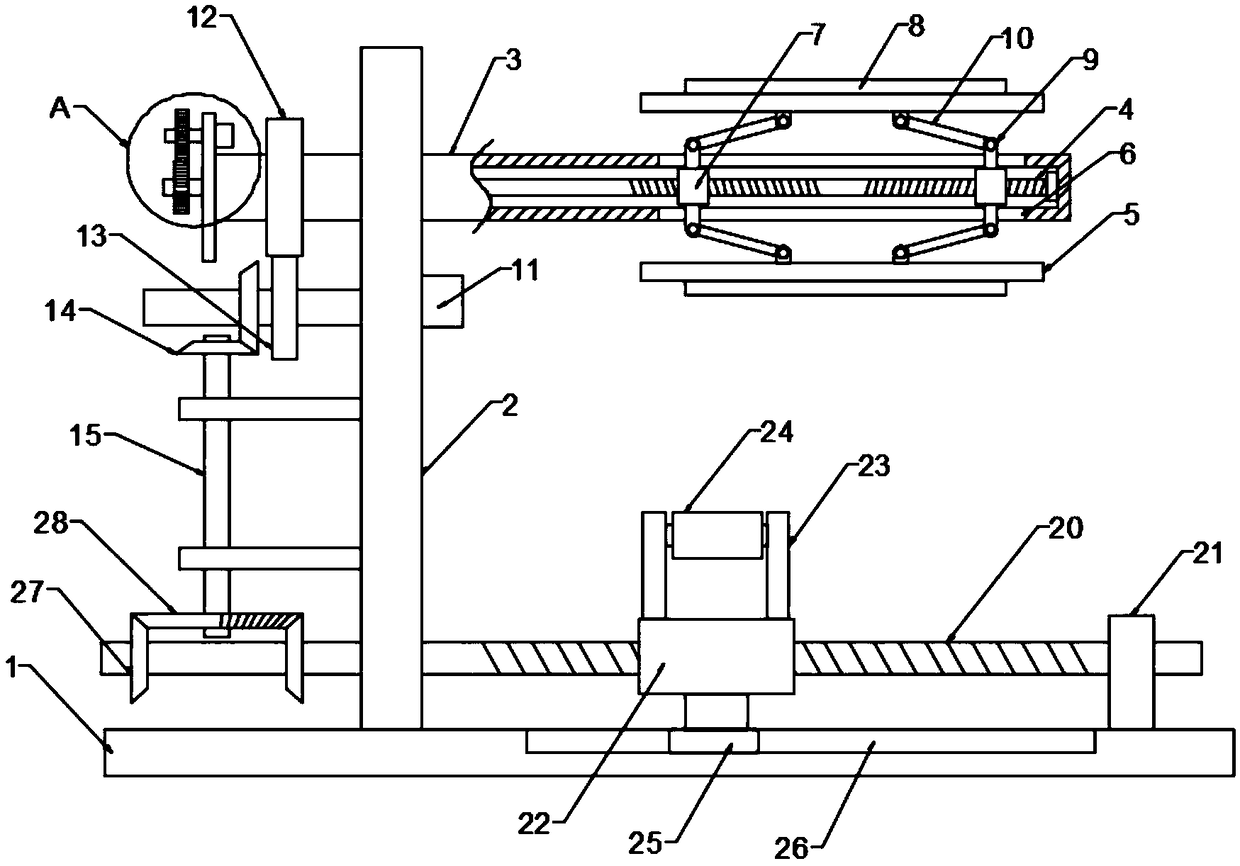

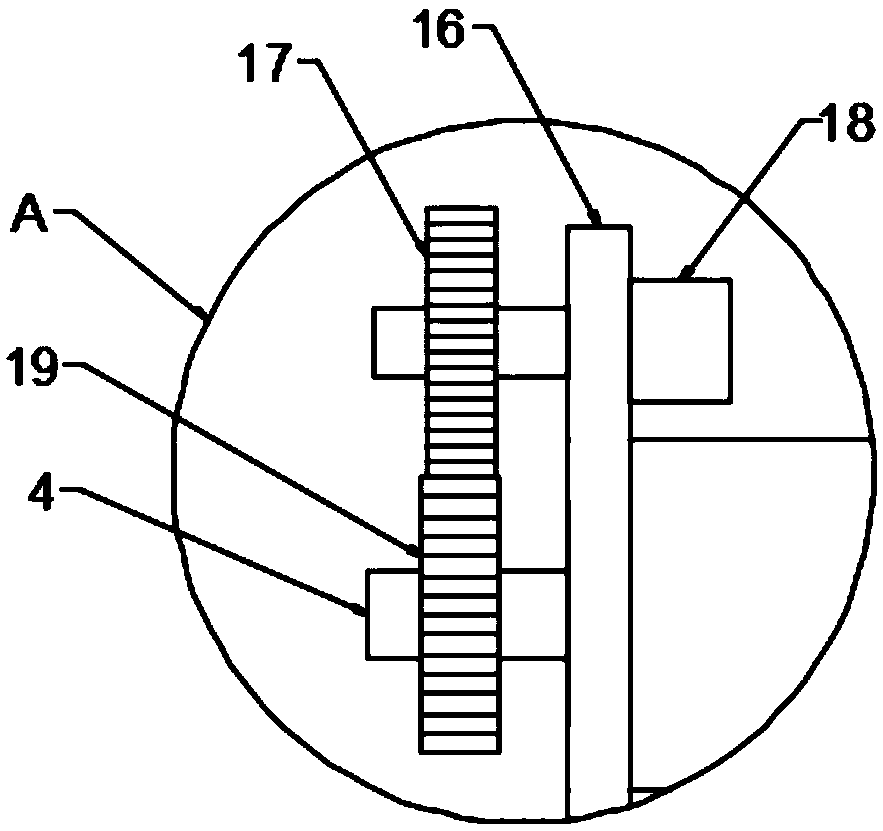

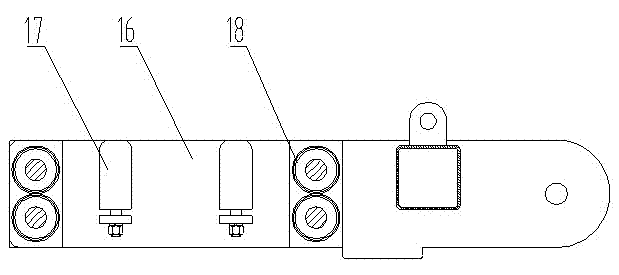

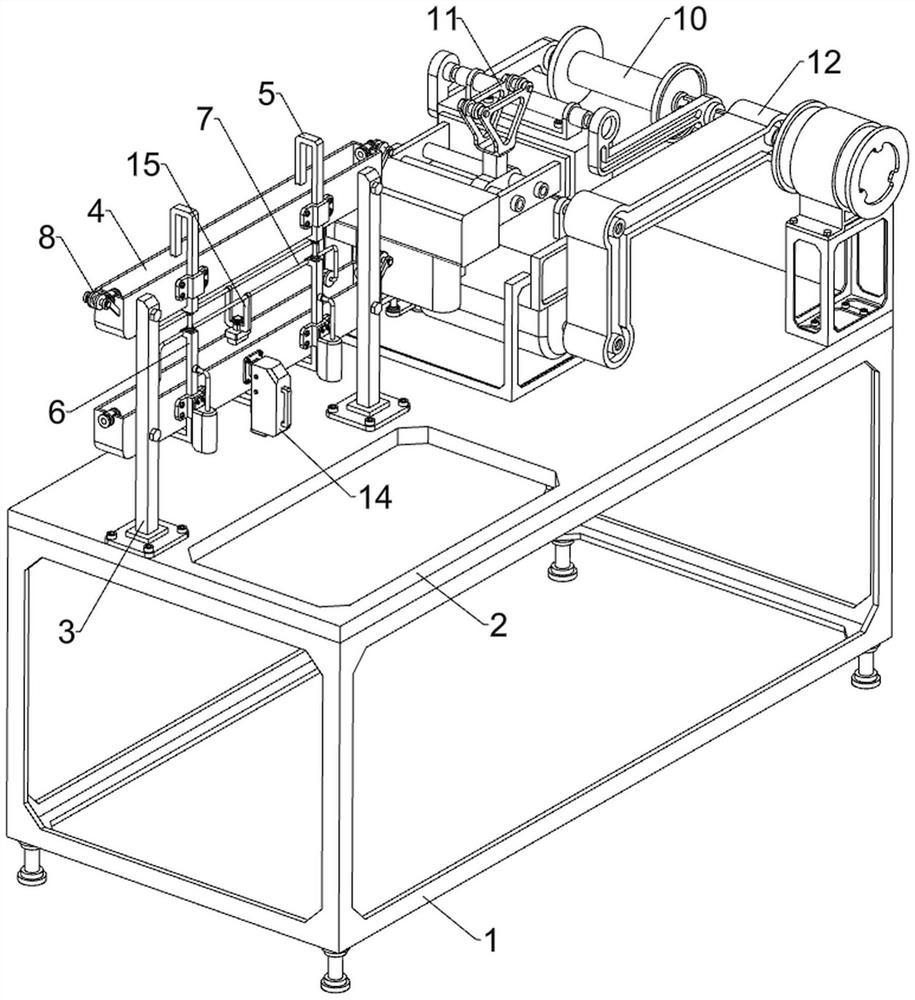

The invention discloses an improved trademark cutting device. The improved trademark cutting device comprises an unwinding device, a tape through wheel pressing device, an adjustable cutting device, an adjusting and mounting box, a conveying roller device, an auxiliary pressing roller device, an adjusting seat and a winding device, wherein a trademark tape on the unwinding device successively passes through the tape through wheel pressing device, the adjustable cutting device, the conveying roller device and the winding device under conveying of guide rollers; a plurality of pressing components are arranged at the top of the tape through wheel pressing device; an adjustable cutter frame shaft is arranged on the adjustable cutting device; a plurality of cutter components are mounted on the adjustable cutter frame shaft; the conveying roller device is matched with the winding device; the auxiliary pressing roller device is arranged above the winding device, is mounted on the adjusting seat and is capable of ensuring that the conveying process is stable and preventing trademark tapes from generating folds; buffering springs are arranged in the cutter components and are capable of reducing vibration in the cutting process; a pressing roller is clung to a winding roller and is capable of ensuring that the winding process is stable.

Owner:浙江爱尔达实业有限公司

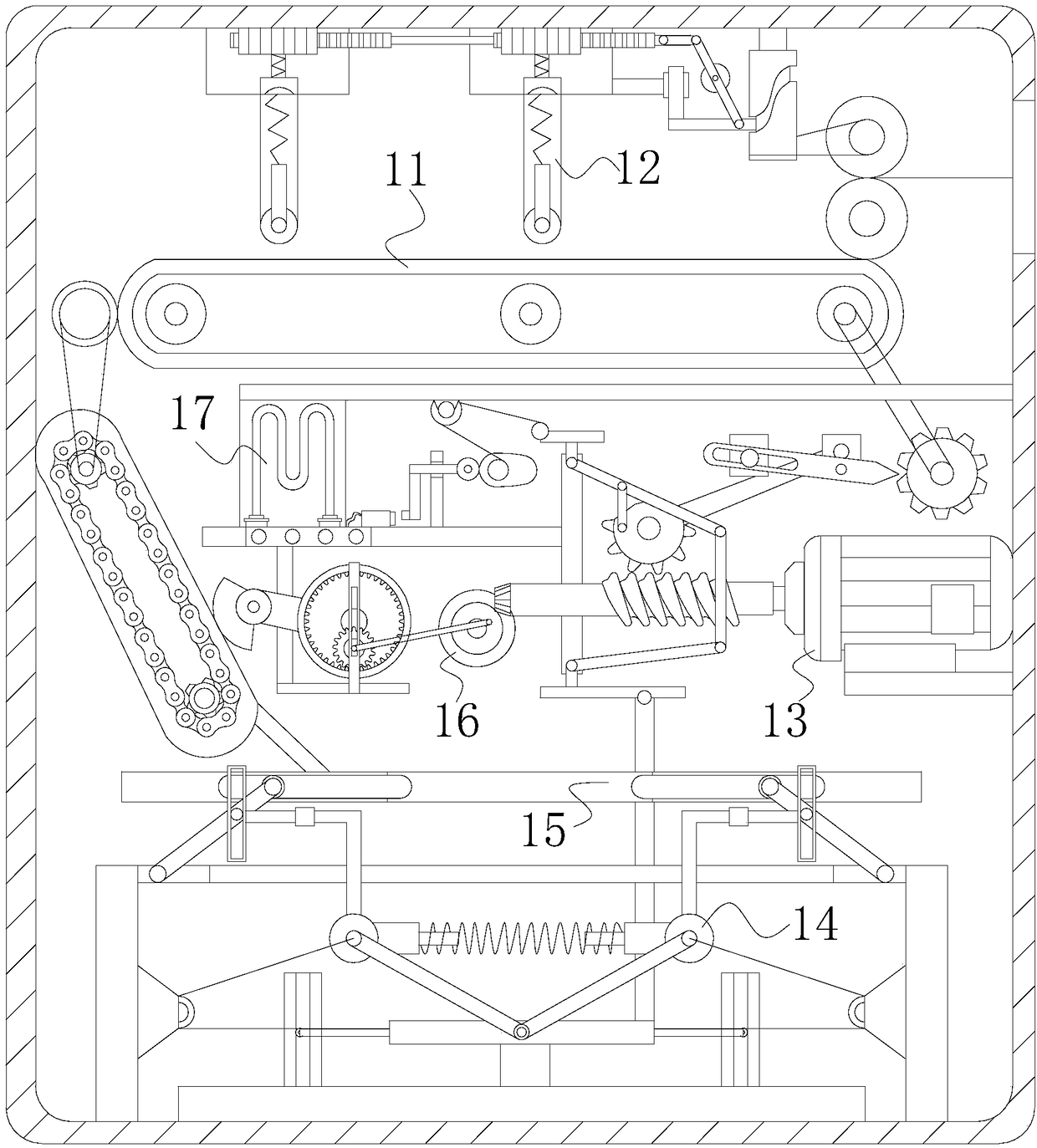

Automatic disc changing, cutting-off and winding mechanism

PendingCN112707242ASimple structureReasonable designFilament handlingMetal working apparatusWinding machineElectrical and Electronics engineering

The invention relates to the technical field of winding machines, and particularly discloses an automatic disc changing, cutting-off and winding mechanism. The automatic disc changing, cutting-off and winding mechanism comprises a rack, a supporting beam, a rotating arm, pipe shifting and cutting devices and winding discs, the supporting beam is fixed to the rack, the upper portion of the supporting beam is connected with a first rotating shaft through a bearing, the two ends of the first rotating shaft extend out of the supporting beam, one end of the first rotating shaft is fixedly connected with the center of the rotating arm, and the other end of the first rotating shaft is connected with a driving device; the two winding discs are symmetrically connected to the two ends of the rotating arm through bearings correspondingly, and pipe clamping pieces are arranged on the winding discs; the pipe shifting and cutting devices are arranged on the inner sides of the two winding discs; and a wire arranging device is arranged on one side of the rack. The mechanism is wide in application range; manual winding is not needed to cut off roll materials, so that the winding speed and efficiency are improved, and meanwhile, the labor intensity of workers is reduced; and the roll materials are evenly distributed in the circumferential direction of the winding discs, winding is compact, the situations that winding is disordered, and the wound roll materials are irregular and collapse are avoided, and the winding quality is improved.

Owner:江苏宝碟自动化设备有限公司

Winding mechanism and winding device

PendingCN110844706ANeatly rolledGuaranteed tensionFilament handlingControl theoryMechanical engineering

Owner:广东三绿科技有限公司

Waterproof tent cloth good in gas permeability and production device thereof

ActiveCN110566034AImprove antibacterial propertiesGood flexibilityMechanical cleaningStain/soil resistant fibresBiochemical engineeringCotton fibre

The invention discloses waterproof tent cloth good in gas permeability and a production device thereof. The tent cloth comprises a base cloth layer and a fabric layer arranged on the base cloth layer.The base cloth layer is woven from warps and wefts in an interwoven manner. The fabric layer is aramid fiber fabric. The tent cloth is manufactured through the following steps that the warps and thewefts are placed on a weaving loom to be woven, and the base cloth layer can be obtained; and impurities adhering to the surface of the aramid fiber fabric are removed. According to the waterproof tent cloth good in gas permeability and the production device thereof, the warps, composed of flax fiber containing insect and bacterium removal solvent and high-lightproof-performance fiber threads, andthe wefts, composed of bamboo charcoal fiber and cotton fiber, are woven into the base cloth layer, the flax fiber, the high-lightproof-performance fiber threads, the bamboo charcoal fiber and the cotton fiber all have good antibacterial performance, and therefore the tent cloth can effectively remove bacteria and repel mosquitoes, materials which are used are environment-friendly, and the waterproof tent cloth and the production device thereof conform to green production.

Owner:安徽嘉明新材料科技有限公司

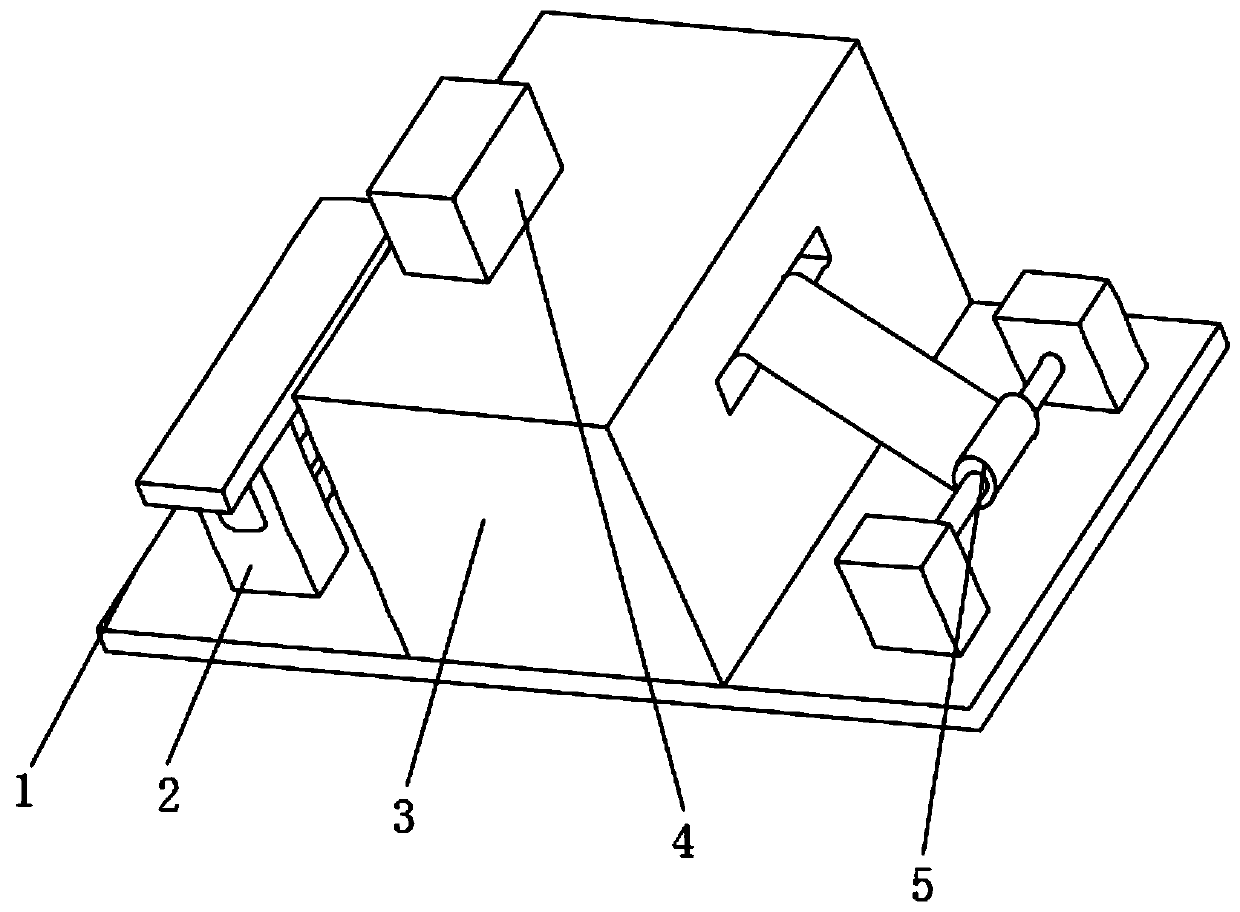

Surface layer tin plating equipment for copper wire treatment

PendingCN113957450AGood adhesionTo achieve the purpose of multifunctional integrationCopper wireWire wrap

The invention relates to tin plating equipment, in particular to surface layer tin plating equipment for copper wire treatment. The surface layer tin plating equipment for copper wire treatment integrates multiple functions, and is easy to operate and high in working efficiency. The surface layer tin plating equipment for copper wire treatment comprises a support, a base plate, supporting plates, treatment frames, pressing plates, movable plates and a frame rods, the base plate is arranged at the top of the support, the supporting plates are arranged on the left side and the right side of the left rear side of the base plate, the treatment frames are arranged on the upper portion and the lower portion between the left supporting plate and the right supporting plate, and the pressing plates are slidably arranged on the left side and the right side of the treatment frame on the upper portion; and the movable plates are slidably arranged on the lower treatment frame, the bottoms of the pressing plates are connected with the tops of the movable plates, and the frame rod is arranged on the upper portions of the movable plates. A copper wire is firstly subjected to acid pickling through the lower treatment frame so as to ensure that a tin layer and the copper wire have good adhesiveness; then the copper wire is subjected to tin plating through the upper treatment frame; and after tin plating is completed, the tinned copper wire is wound by rotating a winding reel, and the purpose of integrating multiple functions is achieved.

Owner:江西腾江铜业有限公司

Winding device for processing electric cable

The invention discloses a winding device for processing an electric cable. The winding device comprises a winding machine body. Four corners of the bottom end of the winding machine body are providedwith support legs. Two sides of the top end of the winding machine body are fixedly provided with a first support column. One side of the outer surface of the first support column is provided with a fixing block. One side of the interior of the fixing block is provided with a support rotating rod. One side of the outer surface of the first support column is fixedly provided with a first motor. Oneside of the output end of the first motor is fixedly provided with a winding plate. One side of the top end of the first support column is fixedly provided with a hydraulic cylinder. One side of theoutput end of the hydraulic cylinder is provided with a hydraulic telescopic rod. One side of the top end of the hydraulic telescopic rod is fixedly provided with a second support column. The windingdevice for processing the electric cable is capable of enabling the whole device to be more labor-saving for winding and using the electric cable, enabling the electric cable to be more tidily winded,and bringing better application prospect.

Owner:WUHU YUANKUI NEW MATERIAL TECH CO LTD

Novel winding device for electric power construction

The invention discloses a novel winding device for electric power construction. The structure of the novel winding device comprises a vent, a guide rod, an automatic cable winding device, a power cord, a control panel, a support table, bottom columns, a support frame, a bottom plate and a winding drum, wherein the vent is embedded in the upper end of the left surface of the automatic cable windingdevice, the guide rod is in clearance fit with the upper surface of the automatic cable winding device, the winding drum is movably connected to the lower end of the left surface of the automatic cable winding device, the bottom plate is fit closely to the lower surface of the automatic cable winding device, two or more bottom columns are provided and have identical shapes and sizes, the bottom columns are welded to the four corners of the lower surface of the bottom plate, and the lower end of the support frame is welded to the front surface of the automatic cable winding device. According to the novel winding device provided by the invention, by providing the automatic cable winding device, not only can a cable be automatically wound and time and labor be saved, but also a guide rod fixing seat controls the movement of the guide rod, so that the cable is wound neatly, the cable is not easy to damage, and the service life of the cable is prolonged.

Owner:福建省万宏利业投资有限公司

Spinning and winding device capable of preventing cloths from falling

InactiveCN107601115AMeet the distance adjustment needsMeet regulatory needsElectrostatic chargesWebs handlingEngineeringMechanical engineering

The invention discloses a spinning and winding device capable of preventing cloths from falling. The spinning and winding device comprises a support seat, wherein the top end of the support seat is fixedly connected with a first support rod, a static electricity eliminator, a second support rod, a first sliding seat, a third support rod and a fourth support rod from left to right; a first conveying roller is movably mounted at the upper end of the inner surface of the first support rod; a second conveying roller is movably mounted at the upper end of the inner surface of the second support rod; the outer surface of the first sliding seat is in sliding connection with a first slider. According to the spinning and winding device, limiting rollers are movably mounted at the top ends of secondsliders and can achieve the effects of limiting two sides of a winding roller, so that the phenomenon that the cloths deviate or fall off from the winding roller in the winding process can be avoided; meanwhile, through the effects of second sliding seats and the second sliders, the requirement on the adjustment of the distance between the two limiting rollers can be met; the cloths with different widths can be neatly wound; the universality of the device is improved.

Owner:李杜娟

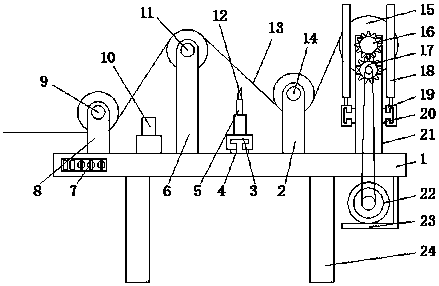

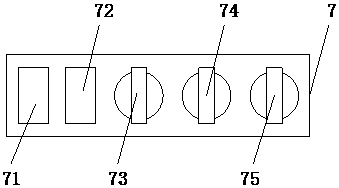

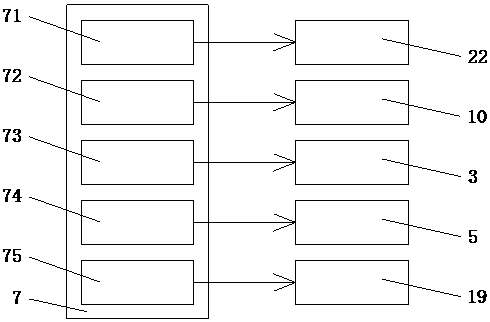

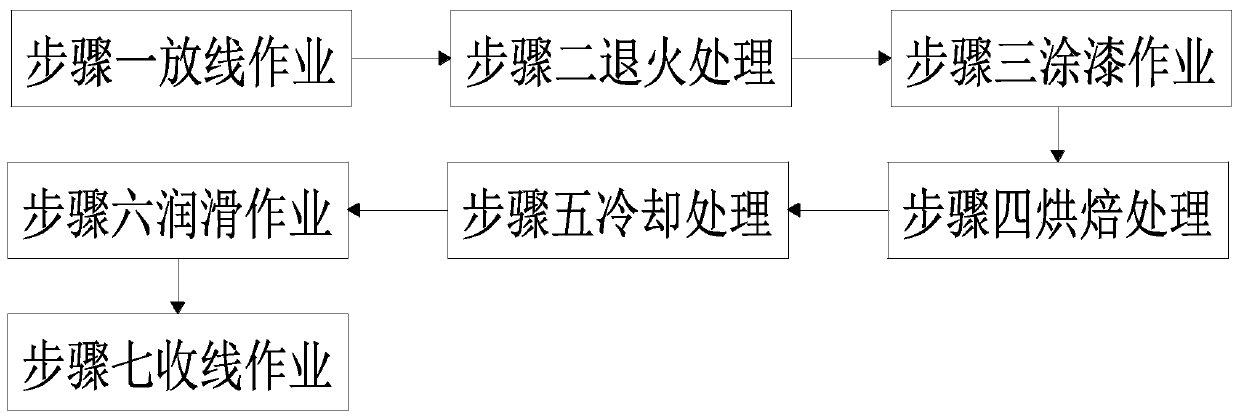

Enameled wire manufacturing and processing process

InactiveCN111403123AEven and stable take-up operationImprove take-up efficiencyFilament handlingInsulating conductors/cablesMachining processMechanical engineering

The invention relates to an enameled wire manufacturing and processing process. The process mainly comprises the following steps: paying-off operation, annealing treatment, painting operation, bakingtreatment, cooling treatment, lubricating operation, take-up operation and the like. The used enameled wire take-up equipment comprises a bottom plate, a stretching device and a take-up device. The provided process can solve the following problems existing in winding of existing enameled wires: a) when a traditional enameled wire winding mechanism is used for winding an enameled wire, several rearcircles of wires are pressed on several front circles of wires, the enameled wires collapse suddenly when reaching a certain height to make the rear circle of wires pressed under the front circle ofwires, so that use is affected, wire winding operation needs to be conducted again frequently, and time and labor are wasted; and b) when the traditional enameled wires are wound, the first batch of wires and the second batch of wires are often arranged in a crossed shape, gaps of the enameled wires on a wire disc are large, the wire capacity of the wire disc is reduced, and the enameled wires aredisordered in appearance.

Owner:盛珊瑜

Drying device for clothing fabric processing

ActiveCN109612246AEasy to dryImprove drying effectDrying gas arrangementsDrying machines with progressive movementsAgricultural engineeringThreaded rod

Owner:新昌县北联建筑工程有限公司

Gauze net winding deviation rectifying device

The invention discloses a gauze net winding deviation rectifying device. The device comprises a rack, a conveying assembly, a deviation rectifying assembly and a winding assembly, wherein the conveying assembly is arranged on the rack, the deviation rectifying assembly comprises a flattening module and a deviation rectifying module, the flattening module comprises a plurality of rotatable shaft rollers, the at least one shaft roller is opposite to the other shaft rollers in rotating direction, the deviation rectifying module is provided with a double-roller which can swing transversely, the double-roller can correct the gauze net deviating from the middle position, the winding assembly is arranged on the rack, the winding assembly is arranged at the tail end of the conveying assembly, andthe winding assembly is used for winding the flattened gauze net. According to the device, the deviation rectifying module is arranged, in the gauze net conveying process, if deviation occurs, the gauze net can be returned to the middle position through the deviation rectifying module, the gauze net can be protected against edge warping, the gauze net can be wound tidily, the flattening module isalso arranged, wrinkles are prone to generate in the conveying process of the gauze net, creases are prone to leave if the gauze net is not flattened, and work of the deviation rectifying module is not facilitated.

Owner:ANHUI HEBANG TEXTILE TECH CO LTD

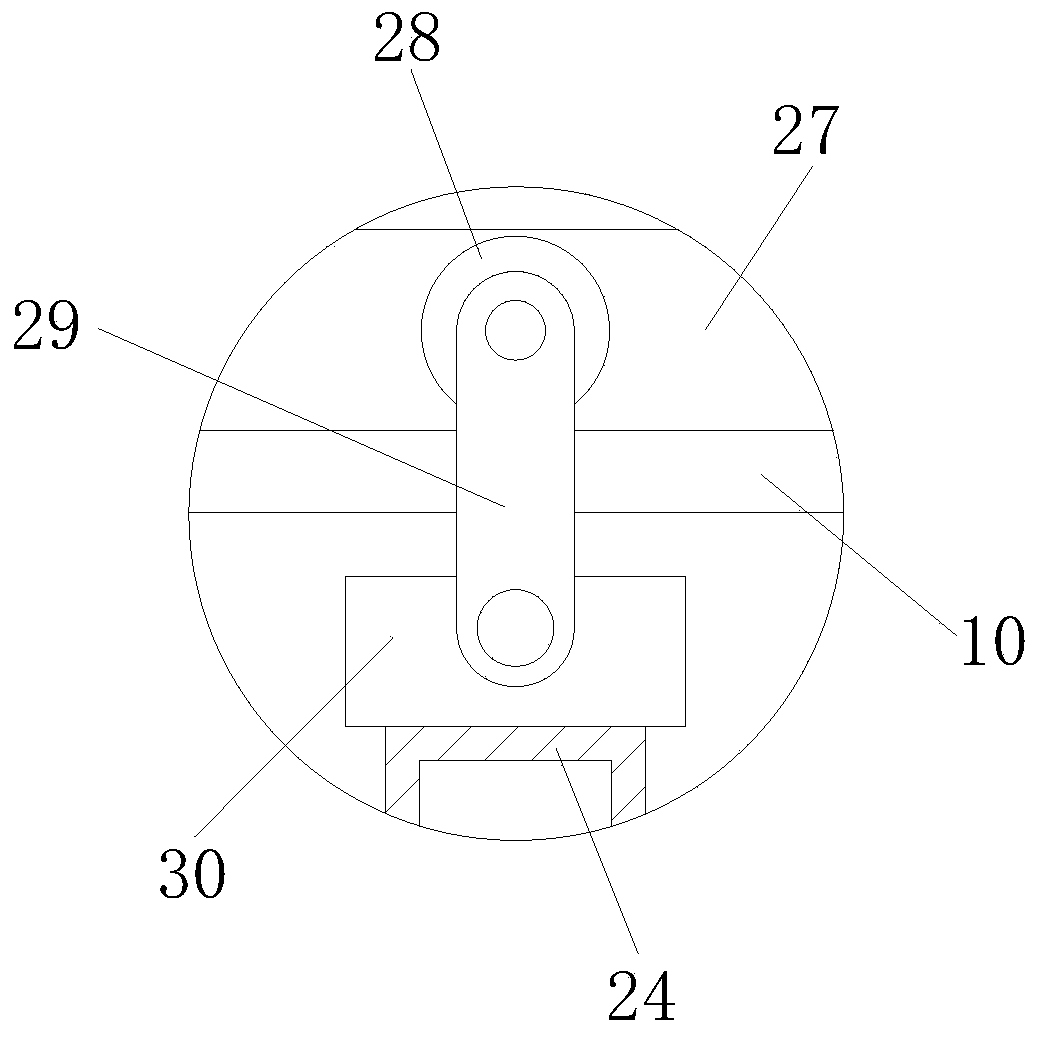

Anti-tilt television and using method thereof

ActiveCN110944132AAvoid affecting the viewing experienceEasy to fixTelevision system detailsColor television detailsLiquid-crystal displayStructural engineering

The invention discloses an anti-tilt television and a using method thereof. The anti-tilt television comprises a fixing shell, a storage battery is fixedly connected to the bottom of the left side ofan inner cavity of the fixing shell, a fixing frame is fixedly connected to the center of the bottom of the inner cavity of the fixing shell, an electric motor is fixedly connected to the top of the fixing frame, and a fan blade shell is fixedly connected to the top of the output end of the electric motor. A rotating rod, an adjusting knob, a bubble level, a driving bevel gear, a threaded sleeve,a threaded rod, a driven bevel gear, a moving cavity, a sliding wheel, a second connecting plate and a second fixing block are used in cooperation, and then the anti-tilt television solves the problems that, when an existing television is placed, due to the fact that the placing position of the existing television is not completely flat, the television is prone to inclining, a playing picture of the television inclines, watching experience of people is affected, and meanwhile when the television is placed for a long time, the surface of the liquid crystal display screen is prone to being contaminated by dust, and the playing picture is shielded.

Owner:西安微城信息科技有限公司

Winder for cloth weaving machine

InactiveCN106081716ANeatly rolledLow failure rateLoomsFilament handlingHigh volume manufacturingEngineering

The invention provides a winder for a cloth weaving machine. The winder comprises a winder body and is divided into a wound silk placement portion and a cloth winding portion, the wound silk placement portion comprises a support, multiple wound silk supporting rods are arranged on the support, the cloth winding portion comprises an underframe, a driving mechanism, a transmission mechanism and a winding mechanism, and a first guide roller and a second guide roller are arranged on the underframe; each wound silk supporting rod comprises a fixed rod and a wound silk barrel, one end of each fixed rod is provided with a thread, a fixed block is arranged at the end of each thread, each wound silk barrel is arranged on the corresponding fixed rod, each fixed rod is fixed on the support, and a limiting device is arranged on the underframe and comprises an L-shaped retaining plate fixed on the underframe. The winder is formed by further improving existing equipment, thereby being high in production efficiency, more orderly in winding, lowered in fault rate, suitable for mass production of woven bags and high in practicability.

Owner:TIANJIN XUHUIHENGYUAN PLASTIC PACKAGING CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com