Nonlinear rolling tension control process

A tension control, non-linear technology, applied in the direction of winding strips, thin material handling, transportation and packaging, etc., can solve the problems that the tension control method is not very suitable, the winding effect cannot meet the technical requirements, etc. The roll effect is improved, the pass rate is improved, and the winding effect is neat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

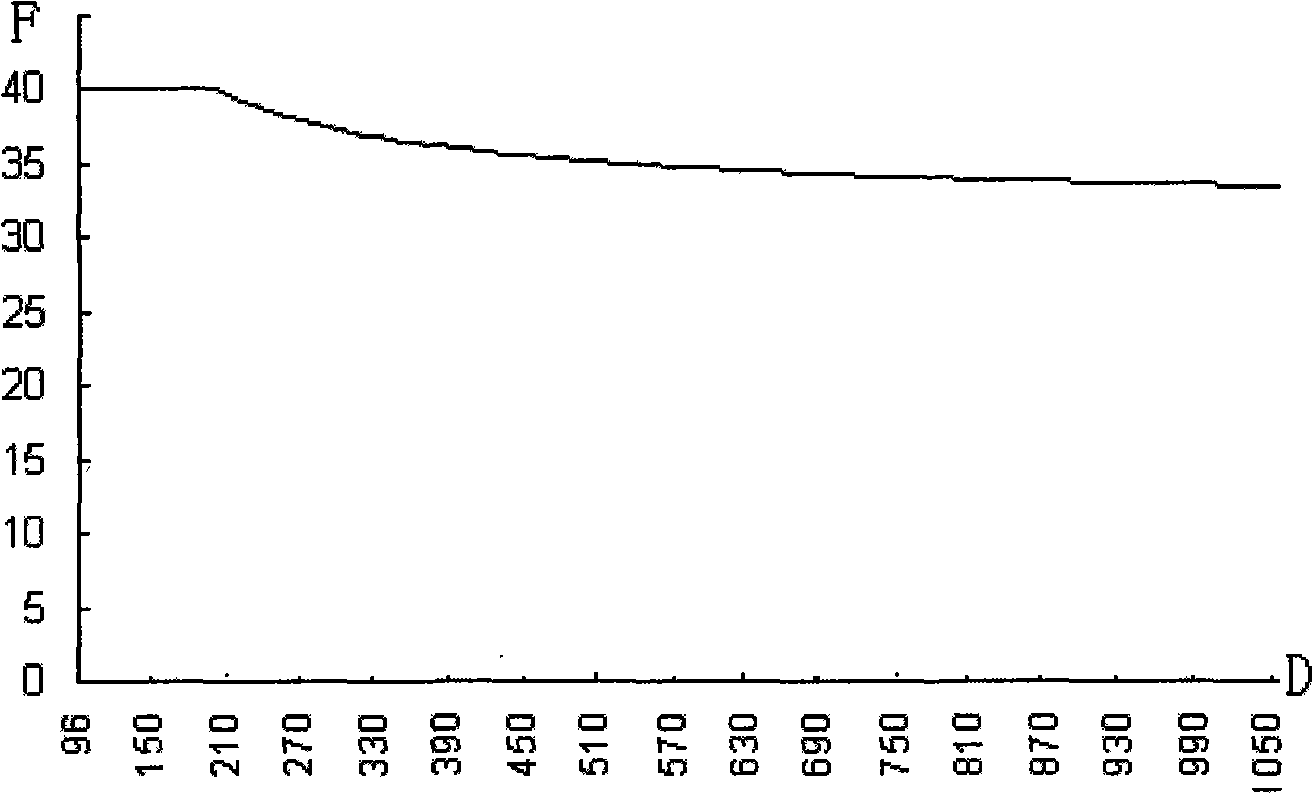

[0039] As shown in Table 1, four kinds of materials are selected, and the initial winding data of the four groups of materials are respectively set, and then their respective functional expressions are obtained from the functional relationship (5) between tension and winding diameter, and each group of materials is obtained Corresponding Tension vs. Coil Diameter Curves image 3 , Figure 4 , Figure 5 and Figure 6 .

[0040] Table 1 sets the initial data for the four materials

[0041] group

D. 0 (mm)

f 0 (kg)

K

First group

PET

200

40

0.2

Second Group

OPP

300

30

0.4

The third group

PE

400

25

0.5

Fourth group

Aluminum foil and PE

500

20

0.8

[0042] The first set of expressions: F = 40 [ 1 - 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com