Automatic wire arrangement device

A technology of automatic wire arrangement and take-up device, which is applied in the directions of transportation and packaging, thin material handling, and conveying filamentous materials, etc. It can solve the problems of non-compactness, uneven winding of enameled wires, etc., and achieve uniform arrangement and density and winding effect. Good, quality-improving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the implementations shown in the drawings, but it should be noted that these implementations are not limitations of the present invention, and those of ordinary skill in the art based on the functions, methods, or structural changes made by these implementations Equivalent transformations or substitutions all fall within the protection scope of the present invention.

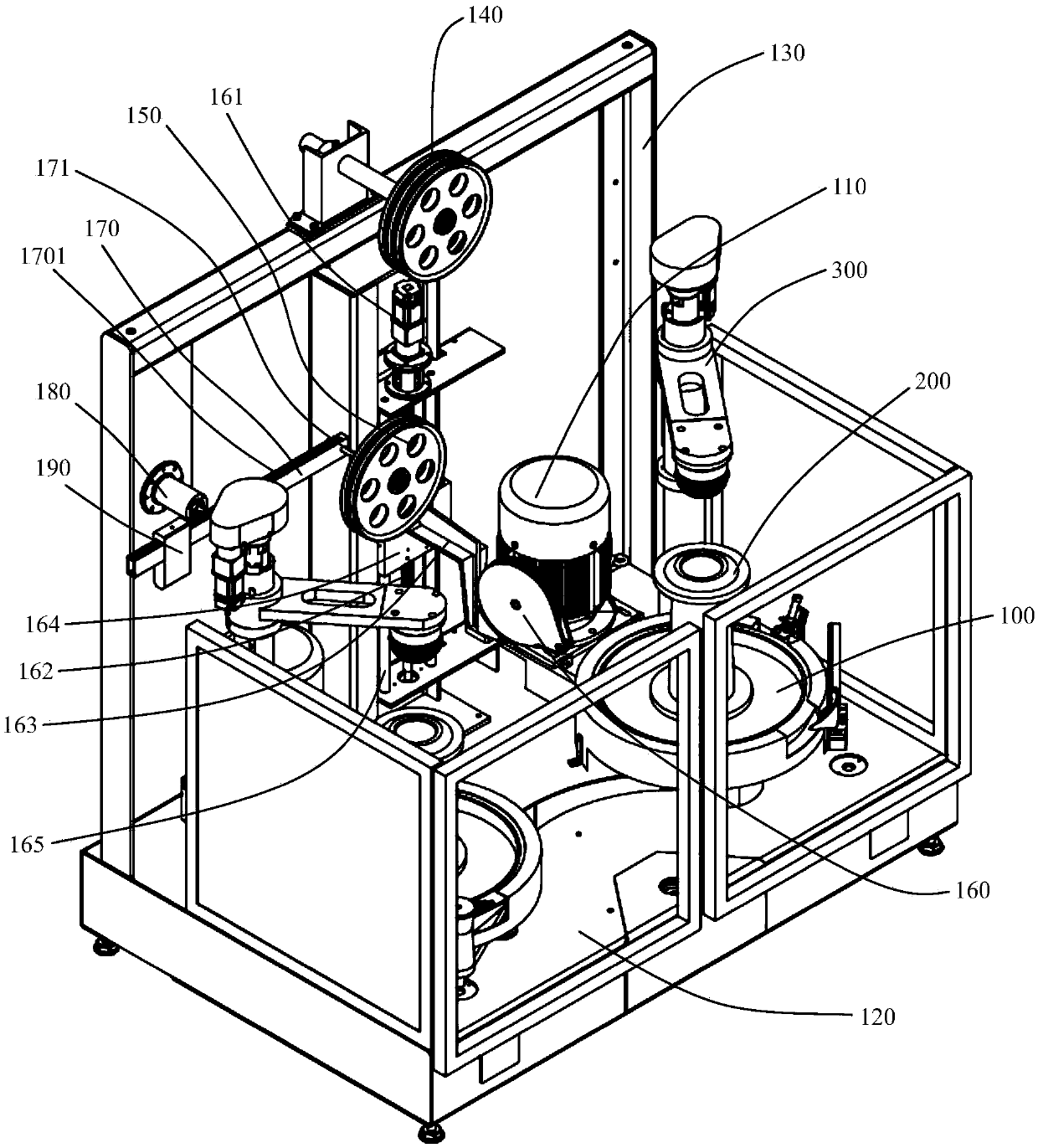

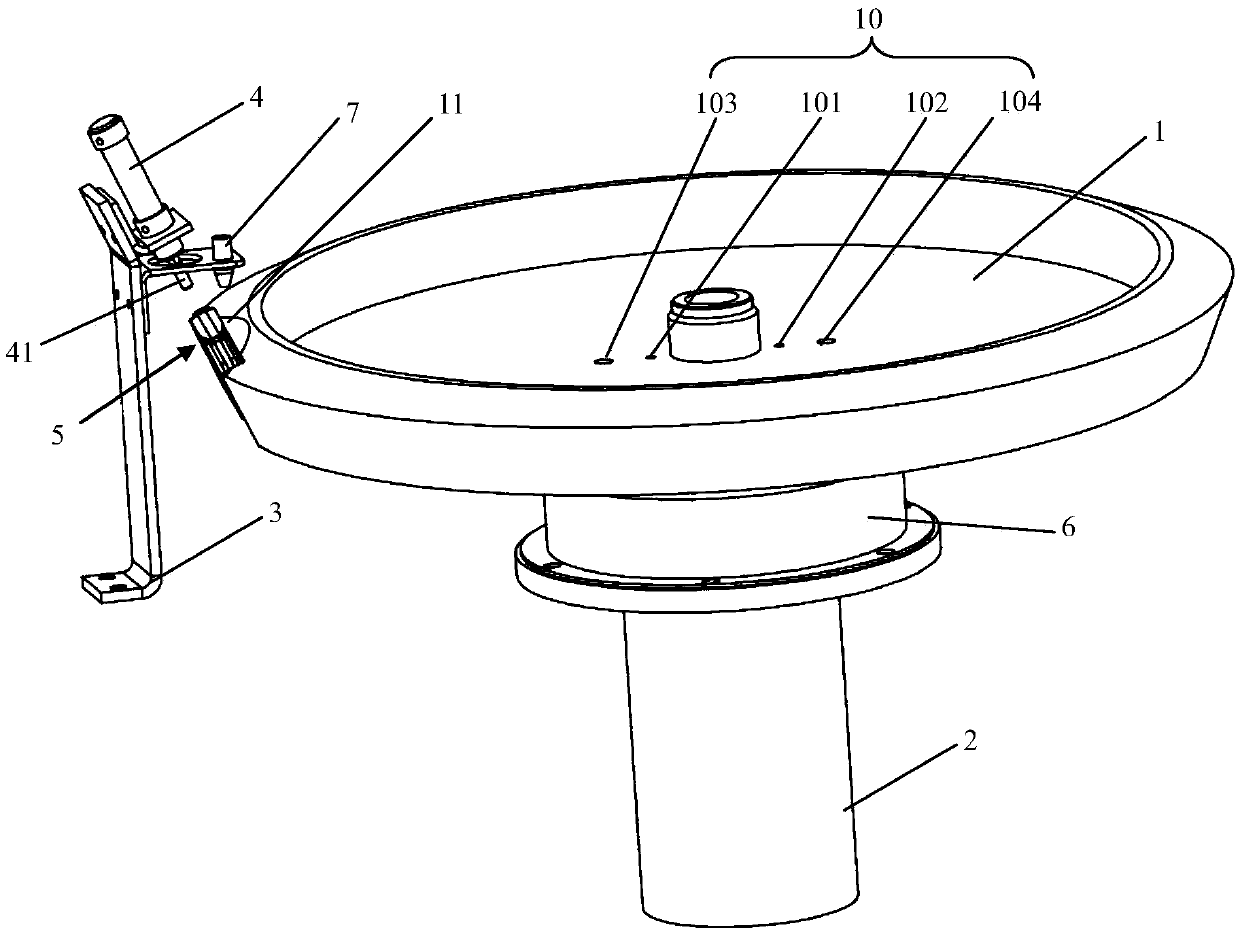

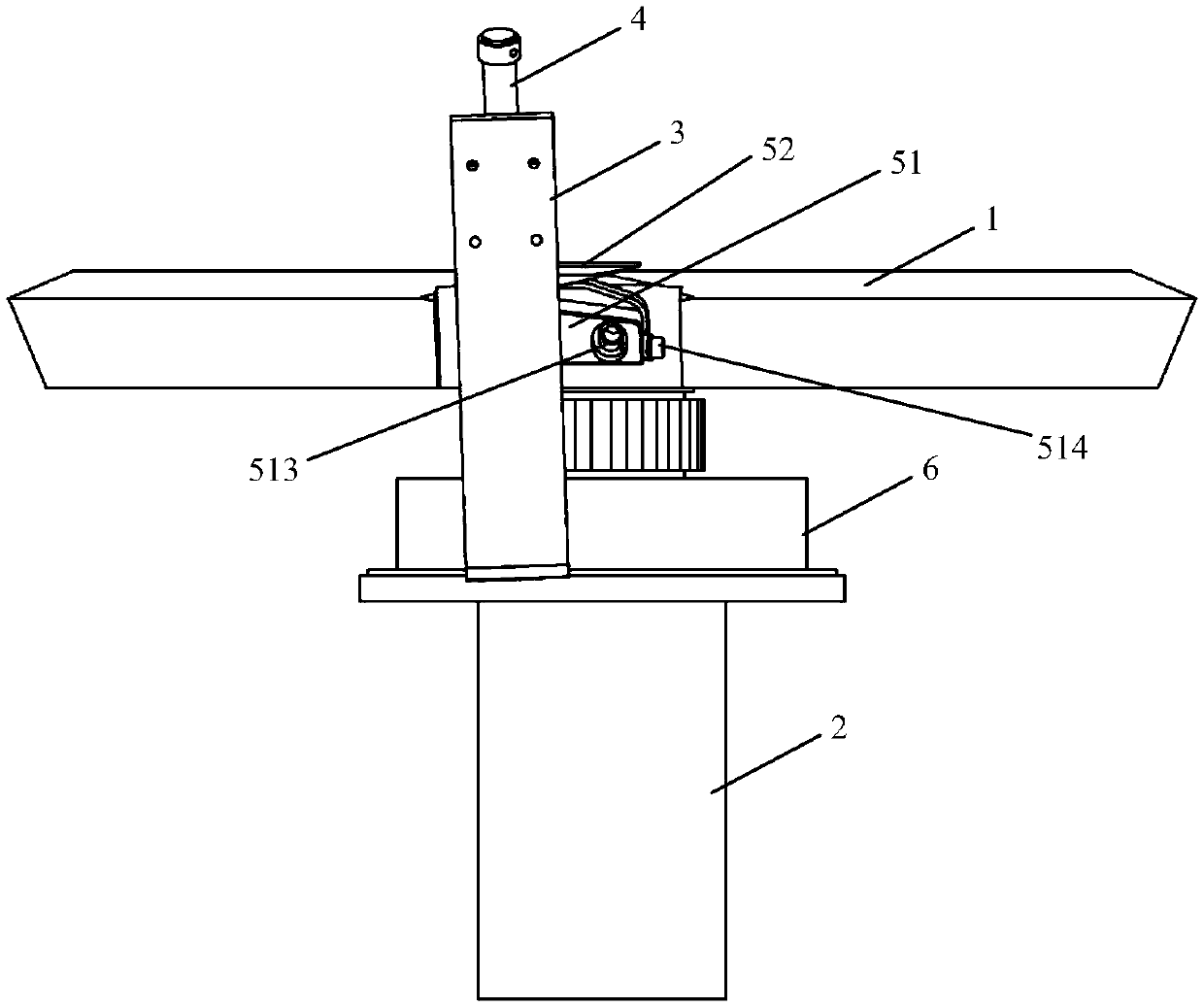

[0022] Please refer to Figure 1 to Figure 5 A specific implementation of the automatic cable arrangement device of the present invention is shown. Such as figure 1 As shown, the automatic cable arrangement device includes: a base 120, a frame body 130, two wire take-up devices 100 and a drive motor 110 for driving the wire take-up device 100 to rotate on the base 120, and the first wire connected to the frame body 130 A guide wheel 140 and a second guide wheel 150, a guide rod 165 and a screw rod 162 that are vertically arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com