Cable processing winding machine

A winding machine and cable technology, which is applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc., can solve the problems of inconvenient use, messy winding, and inability to guide the cable, so as to improve the winding power and prevent Knotted, stability-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

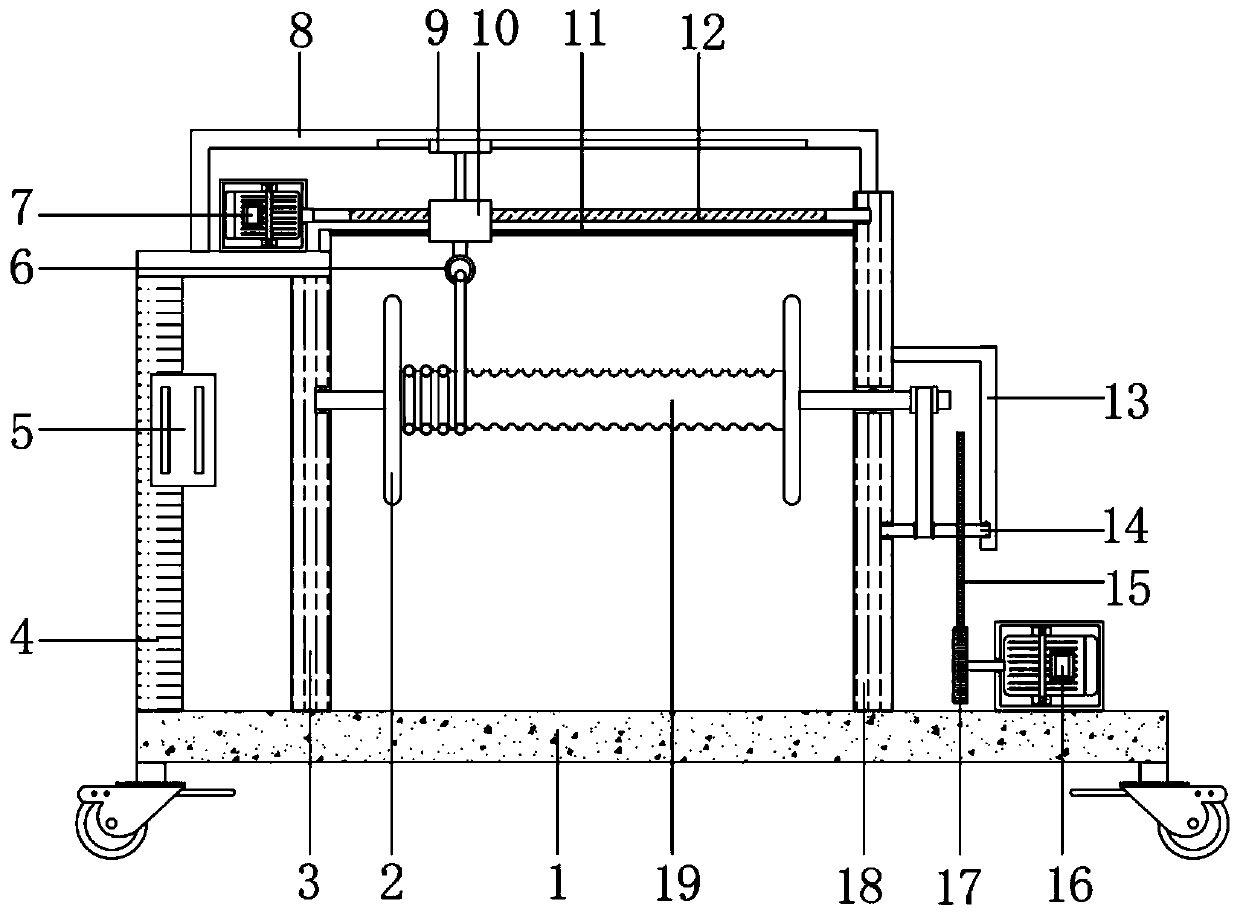

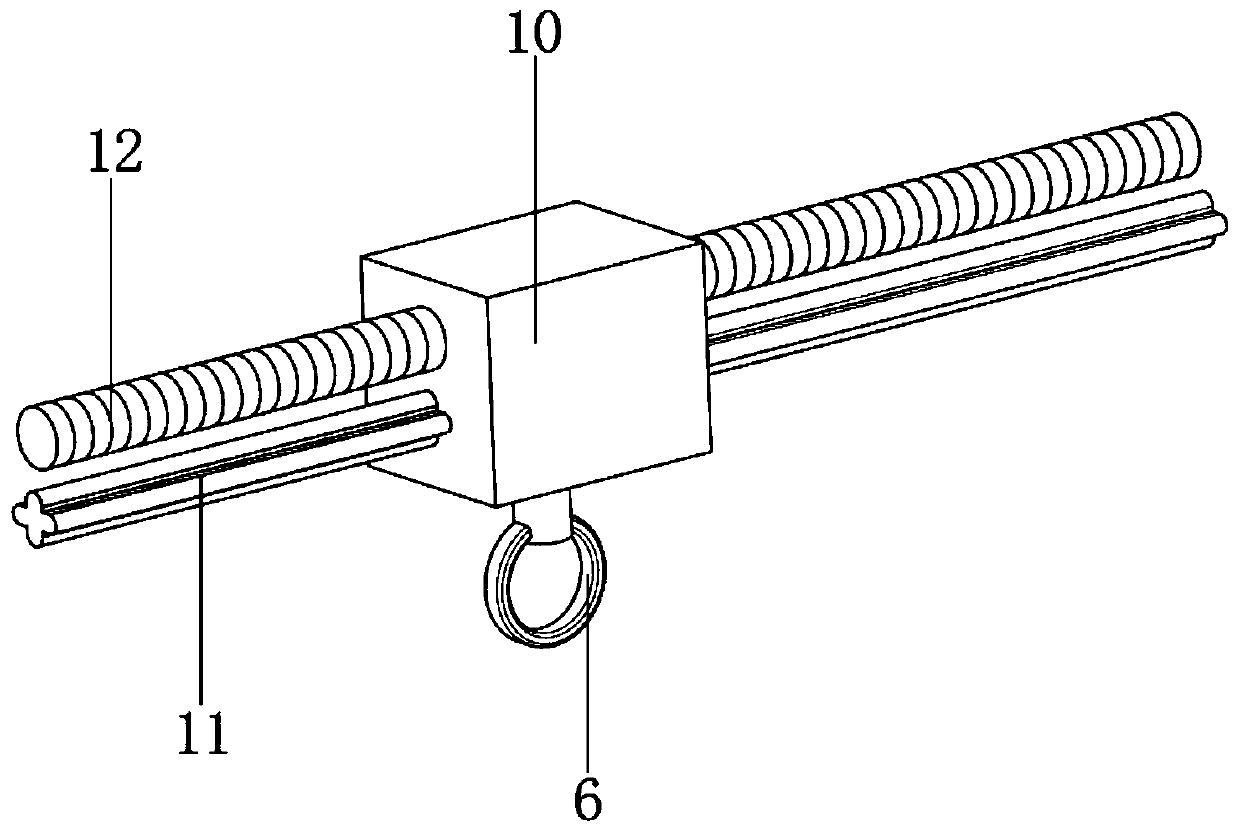

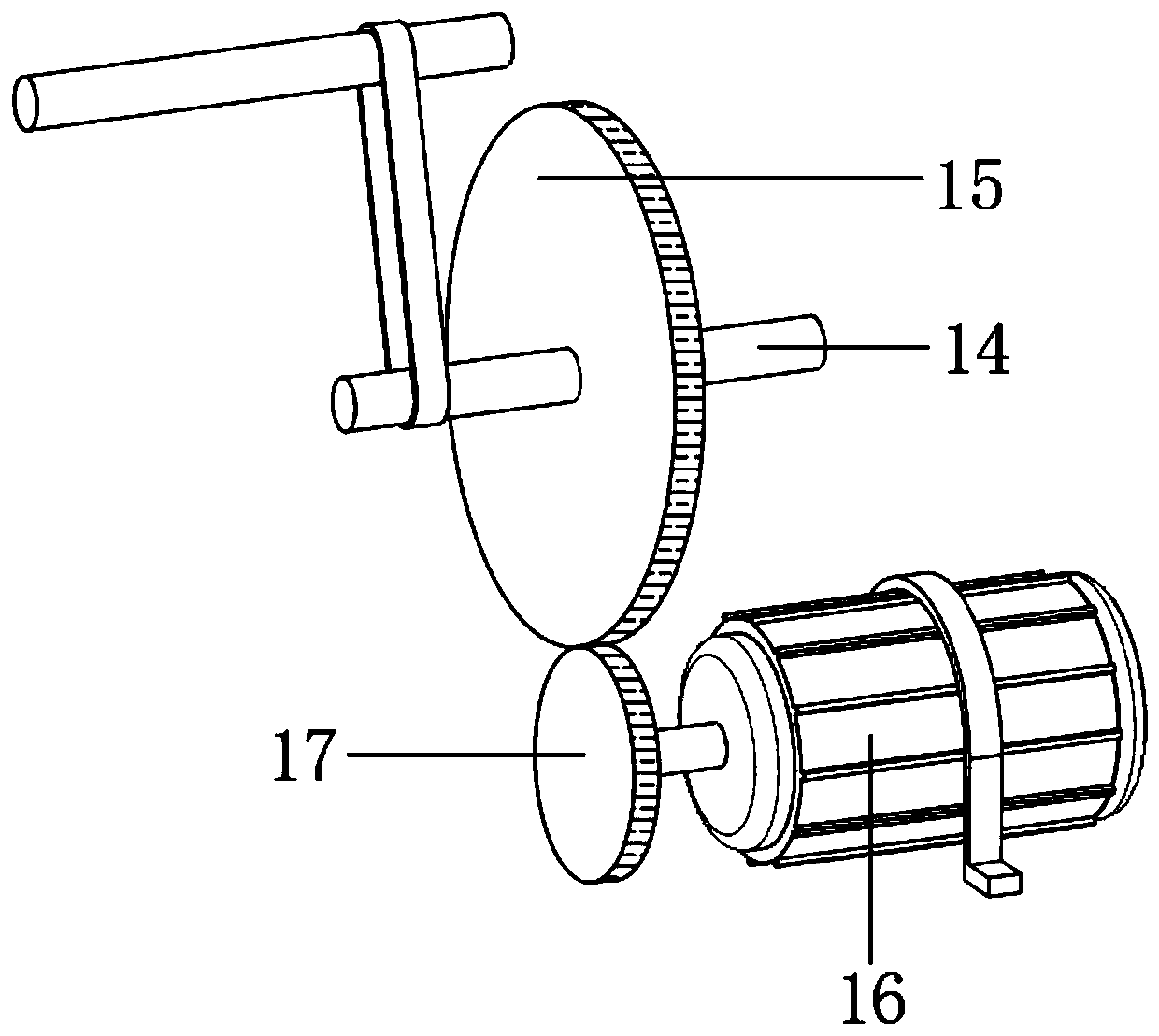

[0027] refer to Figure 1-3 , a cable processing and winding machine, including a base 1 with brake wheels fixed at the four corners of the bottom by bolts, and vertically arranged side braces one 3 and two side braces 18 are respectively welded on both sides of the top of the base 1, and the side braces The opposite side of one 3 and side brace plate 2 18 is connected with the same take-up roller 19 through bearing rotation, and the side of base 1 close to side brace plate 2 18 is equipped with a driving mechanism, and the base 1 is close to side brace plate 1 3. One side is welded with a column 4, and the top of the column 4 and the side support plate-3 are welded with the same mounting plate, and the mounting plate is equipped with a reciprocating movement mechanism, and the reciprocating movement mechanism includes a forward and reverse motor fixed to the mounting plate by bolts 7. The output shaft of the forward and reverse motor 7 is connected to the screw rod 12 through...

Embodiment 2

[0036] refer to figure 1 , a cable processing and winding machine, compared with Embodiment 1, this embodiment also includes a mounting plate and a side support plate 2 18 equipped with a strengthening mechanism, and the strengthening mechanism includes a fixing frame 8 welded to the mounting plate and the side support plate 2 18 , the fixed frame 8 has a chute, the chute is slidably connected with a T-shaped slide bar 9, and the end of the T-shaped slide bar 9 is welded to the top of the moving block 10.

[0037] Working principle: When in use, the mutual cooperation between the fixed frame 8 and the T-shaped sliding rod 9 is used to effectively improve the stability of the moving block 10 when it moves back and forth through its position-limiting effect, which is beneficial to the cable winding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com