Patents

Literature

120results about How to "Improve take-up efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

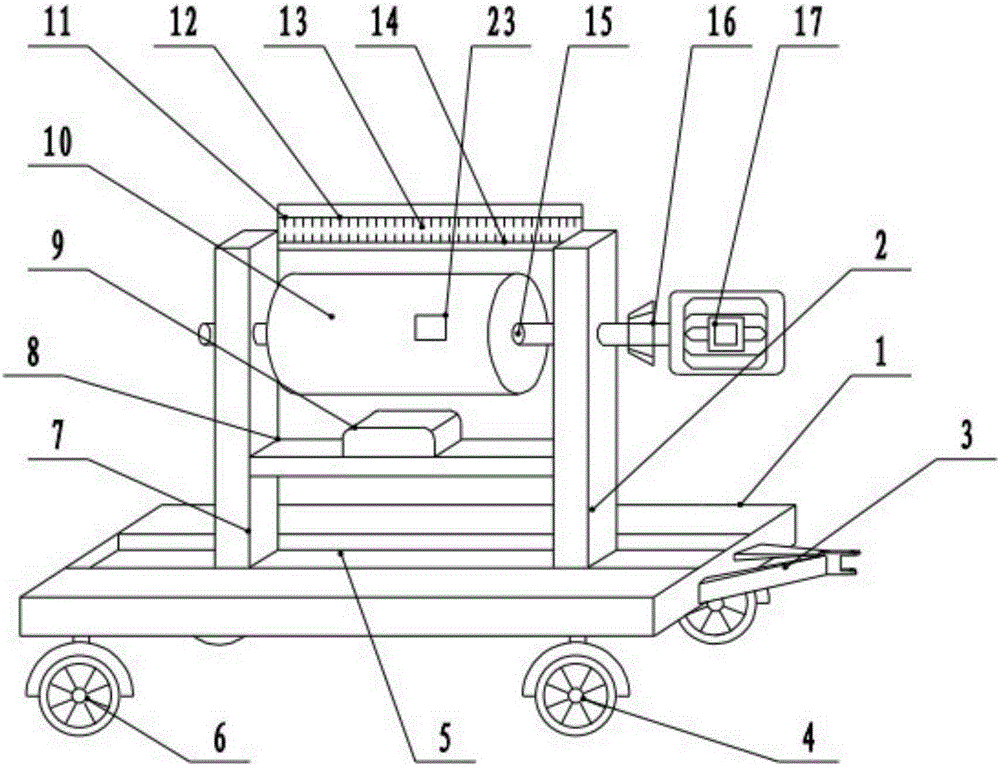

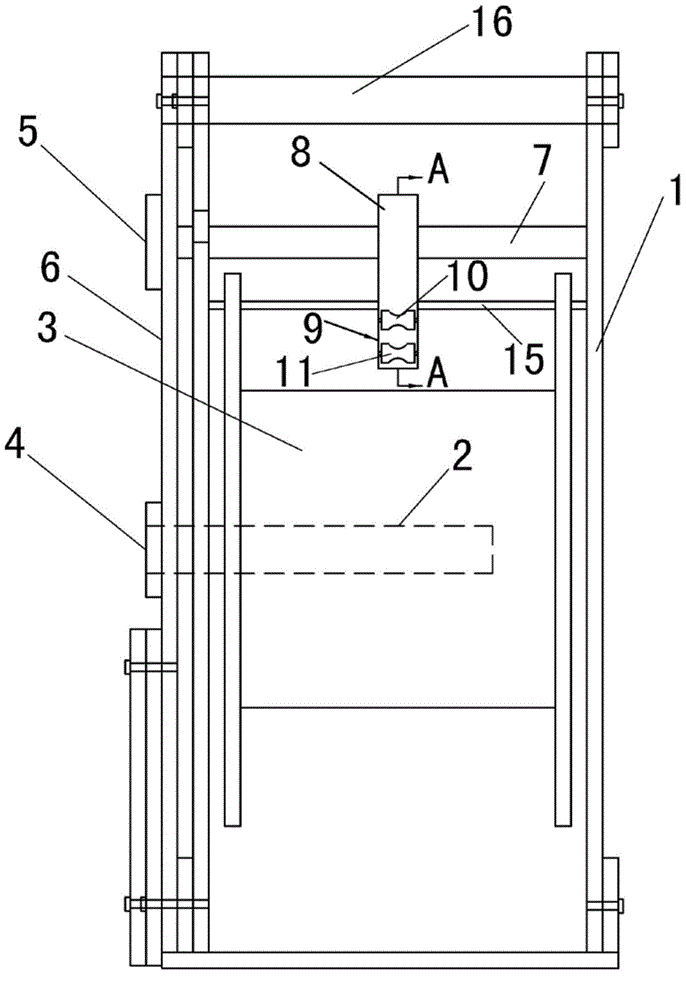

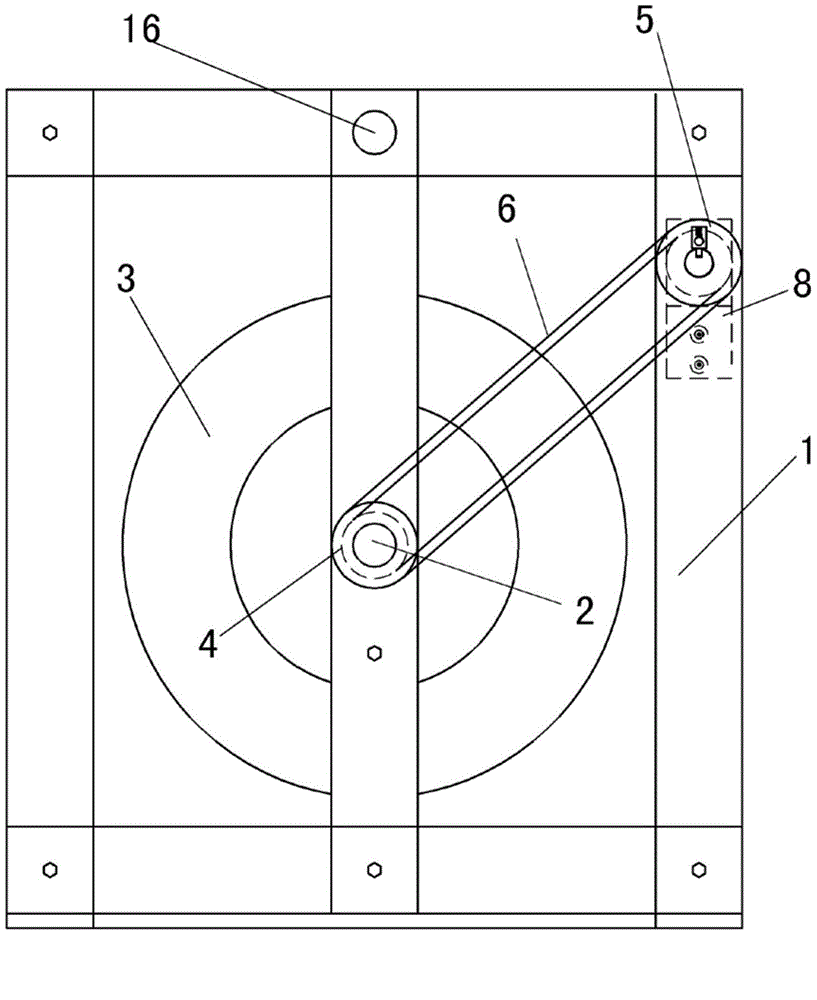

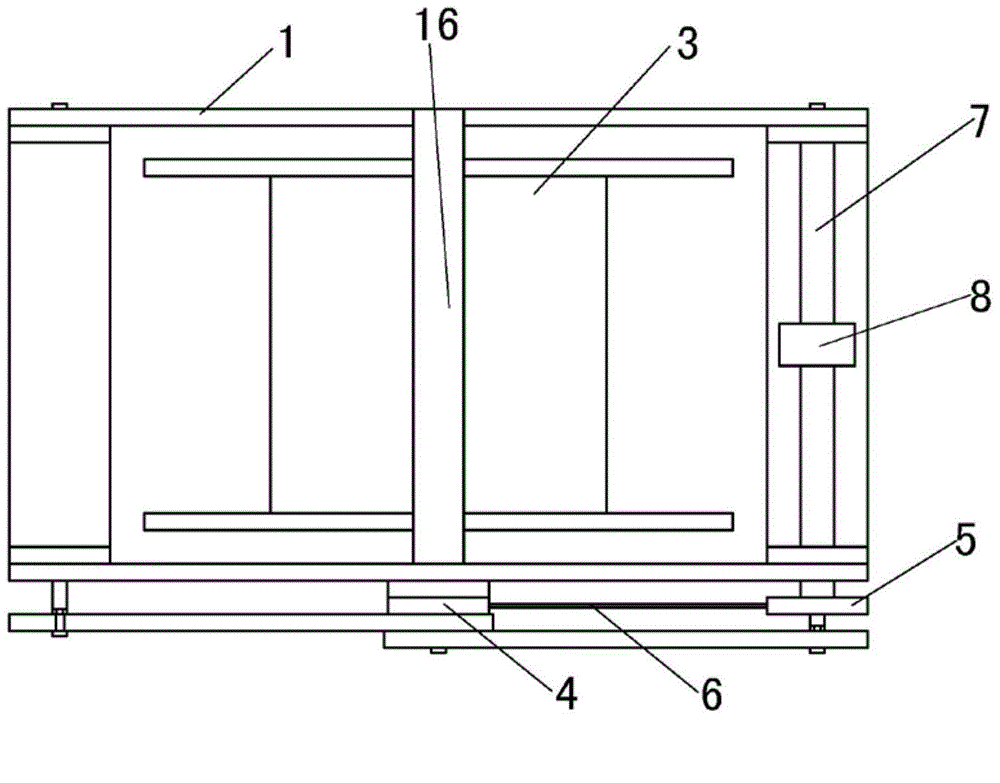

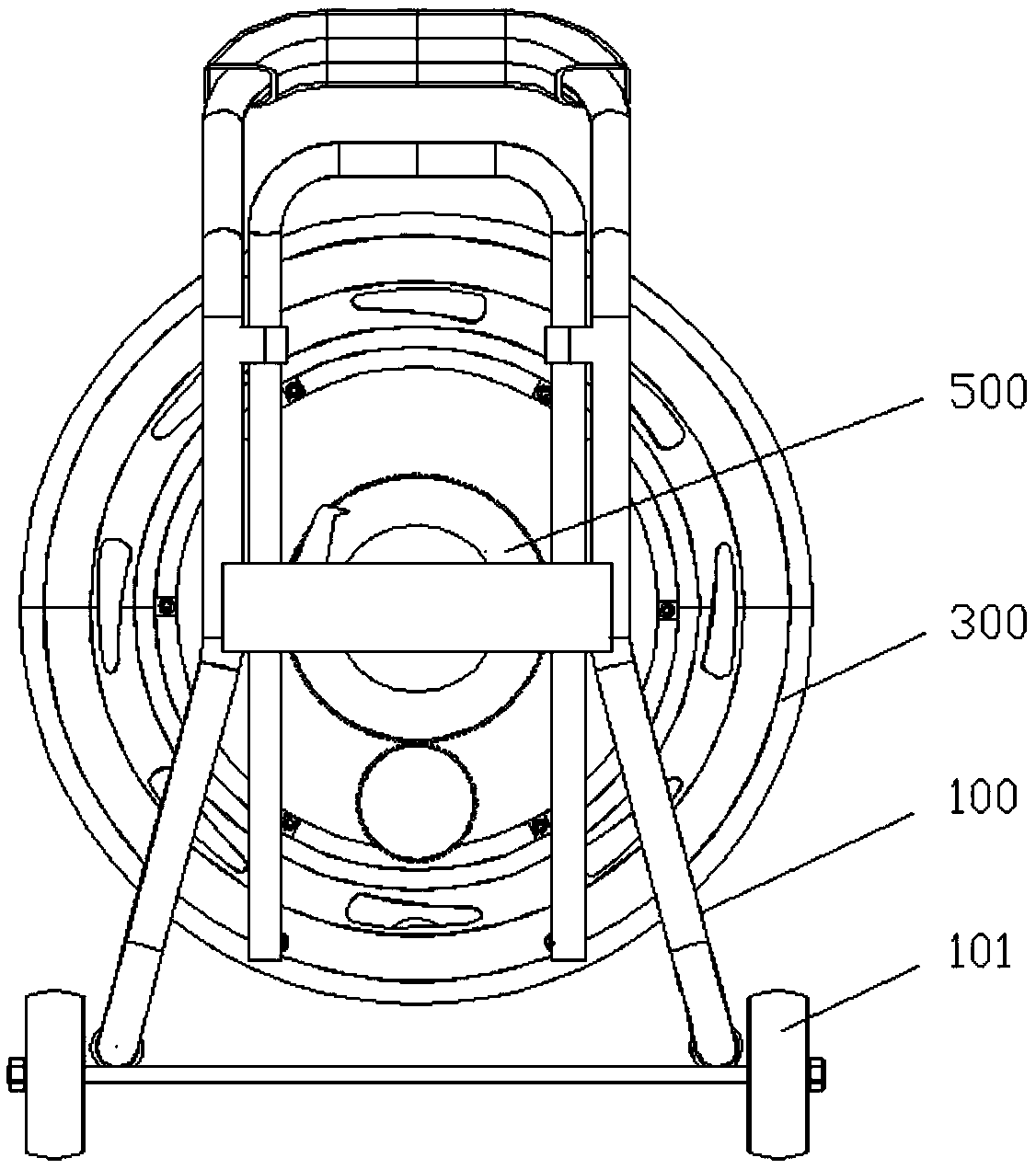

Automatic wire take-up device for electric power industry

The invention discloses an automatic wire take-up device for electric power industry and belongs to the technical field of power equipment. The automatic wire take-up device comprises a support device and a wire take-up device, wherein the support device comprises a support base and a support frame; a slideway is arranged on the support base; the bottom of the support frame is embedded in the slideway; the support frame comprises a support stand column and a support plate; a motor I is arranged on the support plate; the wire take-up device comprises a reel, a rotation shaft and a motor II; two ends of the rotation shaft are fixed on the support stand column respectively; one end of the rotation shaft is connected with the motor II. The automatic wire take-up device is simple in structure, convenient to operate and high in wire take-up efficiency; the motor II drives the support device to move in a reciprocating manner to uniformly wind cables on the reel; a draft gear is arranged to facilitate movement of the automatic wire take-up device.

Owner:STATE GRID CORP OF CHINA +1

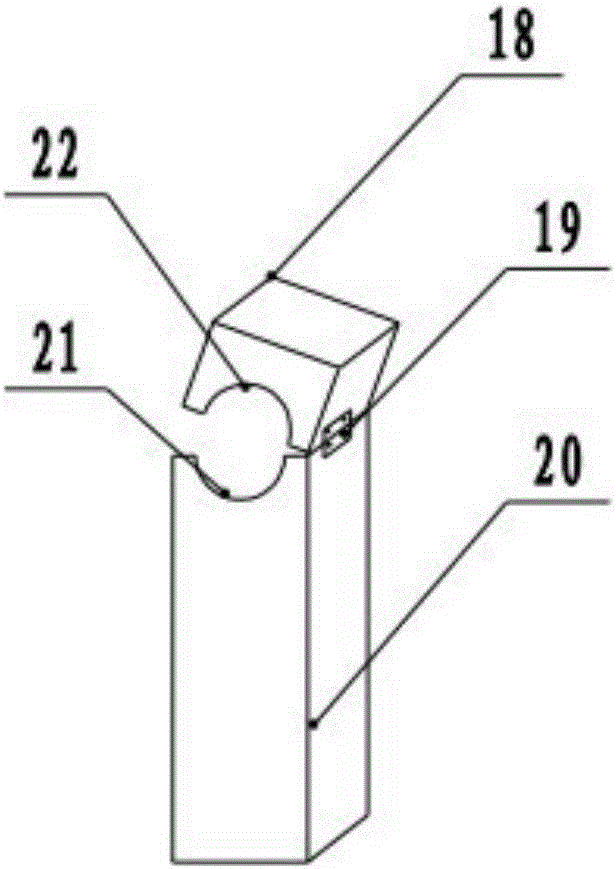

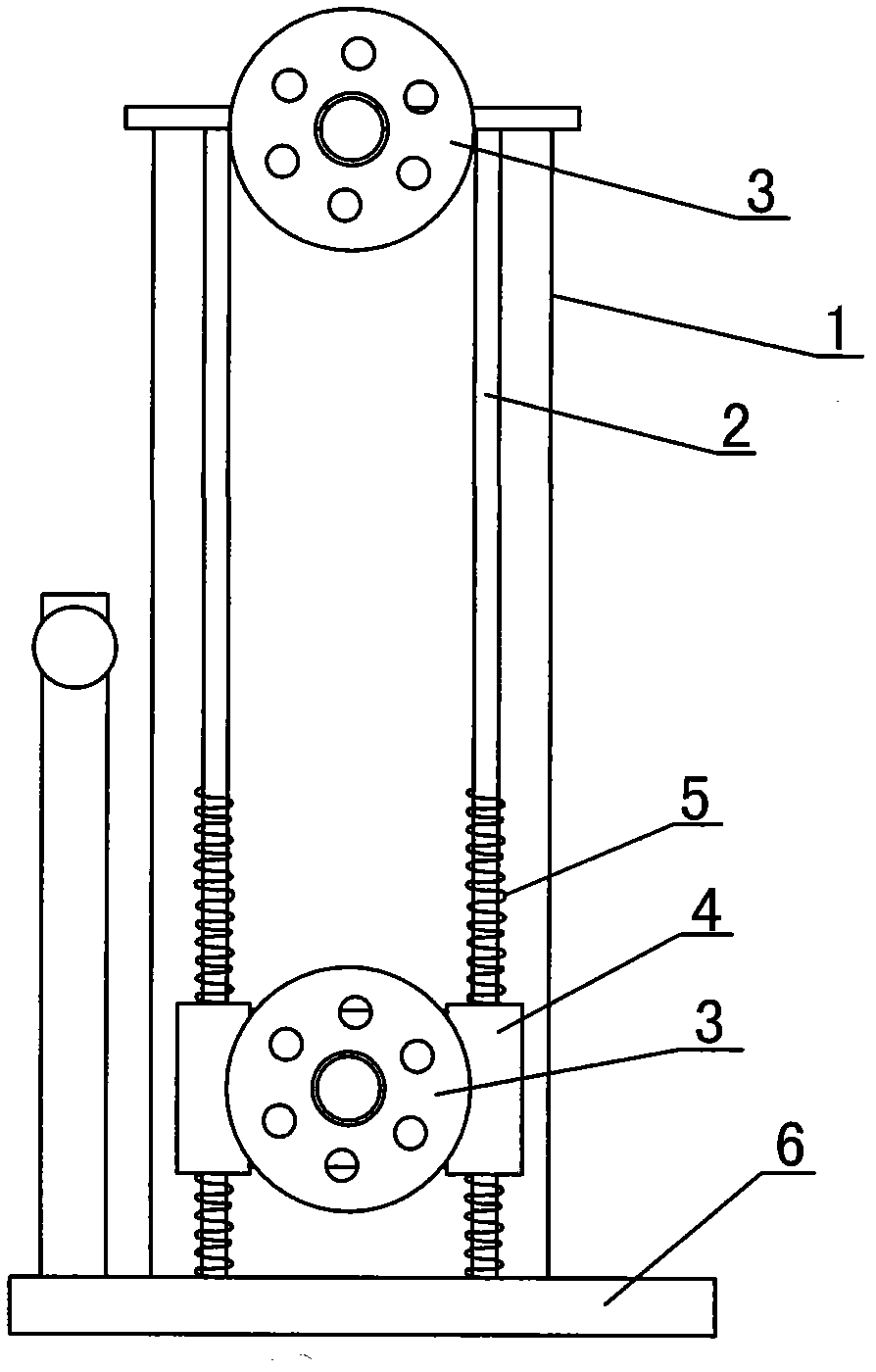

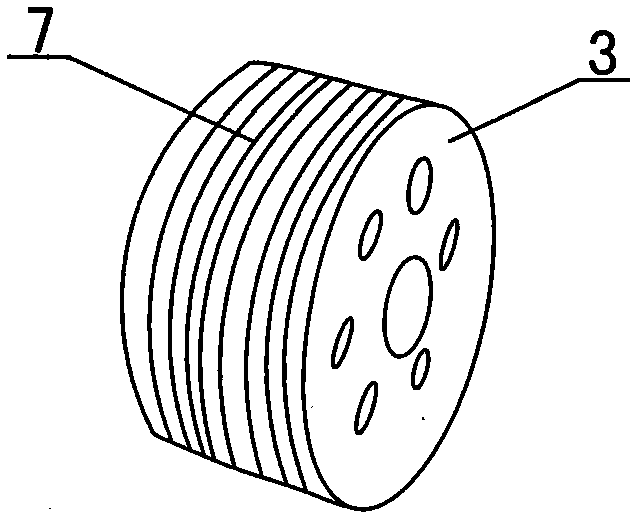

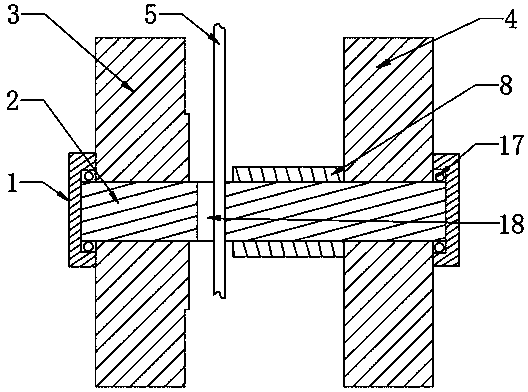

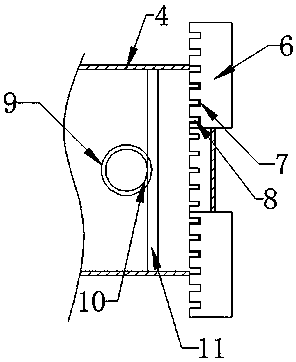

Tension adjusting device

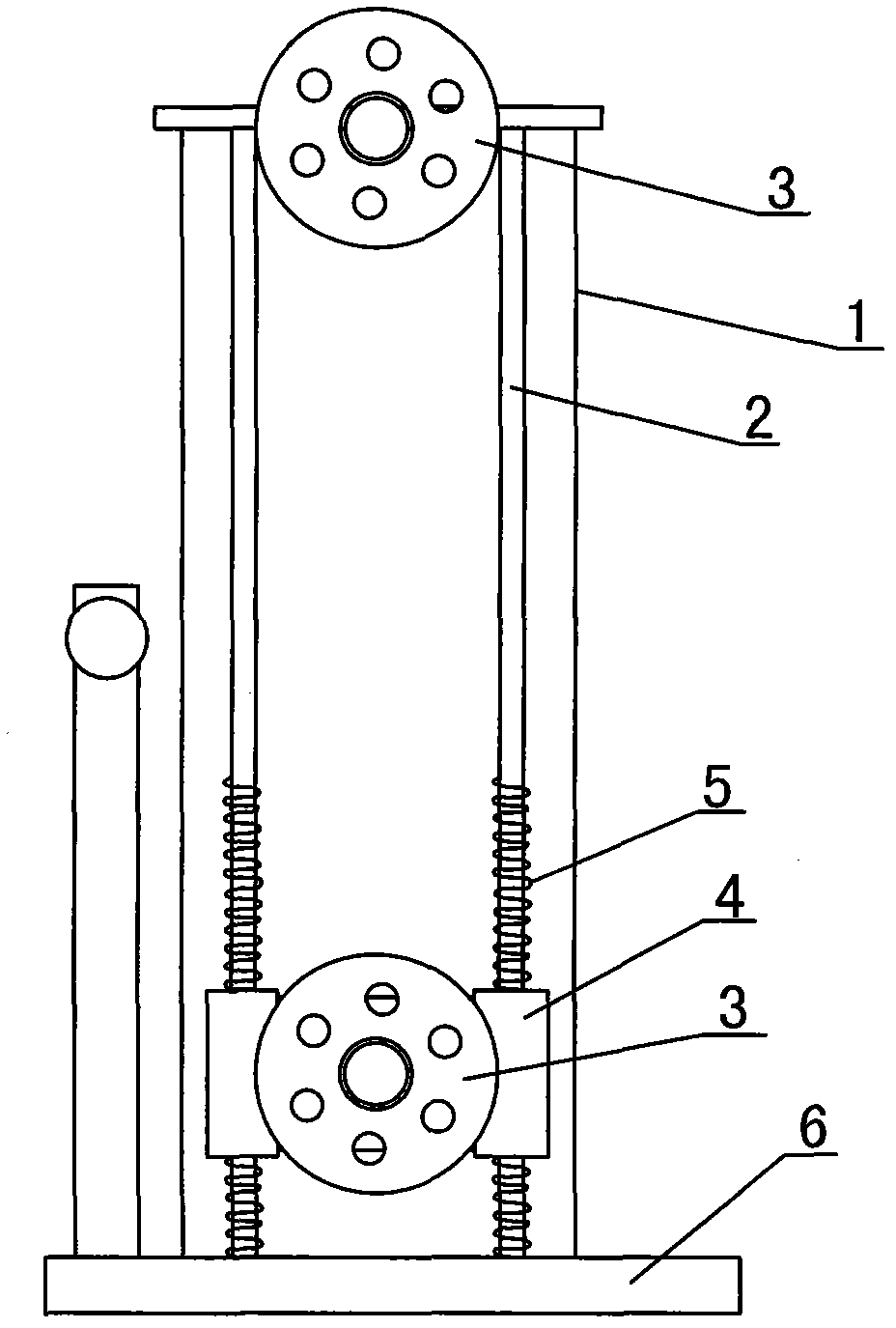

InactiveCN102060212APrevent looseningAvoid phenomena such as uneven winding densityFilament handlingEngineeringPulley

The invention provides a tension adjusting device which comprises a bracket, two slide rods and two slide wheels, wherein the base of the bracket is vertically provided with the two metal slide rods, a movable fixed baffle plate is arranged between the two metal slide rods, the front end of the fixed baffle plate is connected with one slide wheel, and the top end of the bracket is simultaneously provided with the other slide wheel; and the two slide rods which are arranged at the upper side and the lower side of the position of the fixed baffle plate are respectively sheathed with a spring. The tension adjusting device has the beneficial effects that by adopting a top and bottom double-slide wheel structure, a certain tension can be constantly kept during winding and unwinding a cable, the phenomena that a cable coil is loosened, the cable winding thickness is uneven and the like during winding can be avoided, the cable winding efficiency or the wire unwinding efficiency can be improved.

Owner:正裕电器配件(昆山)有限公司

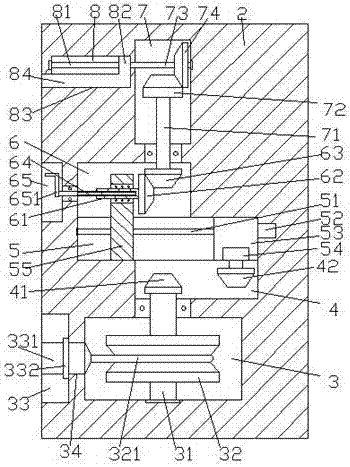

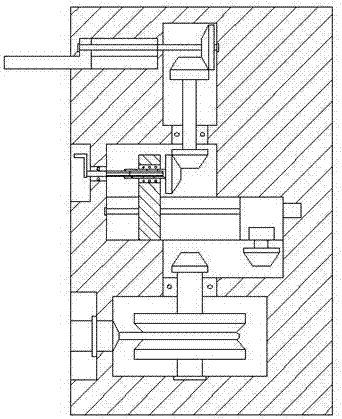

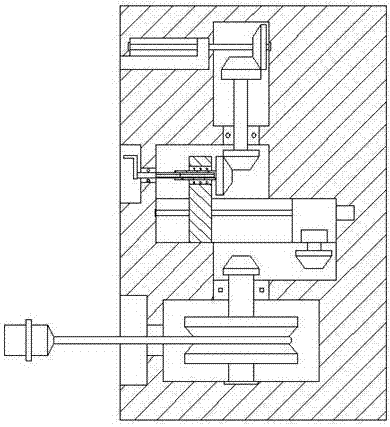

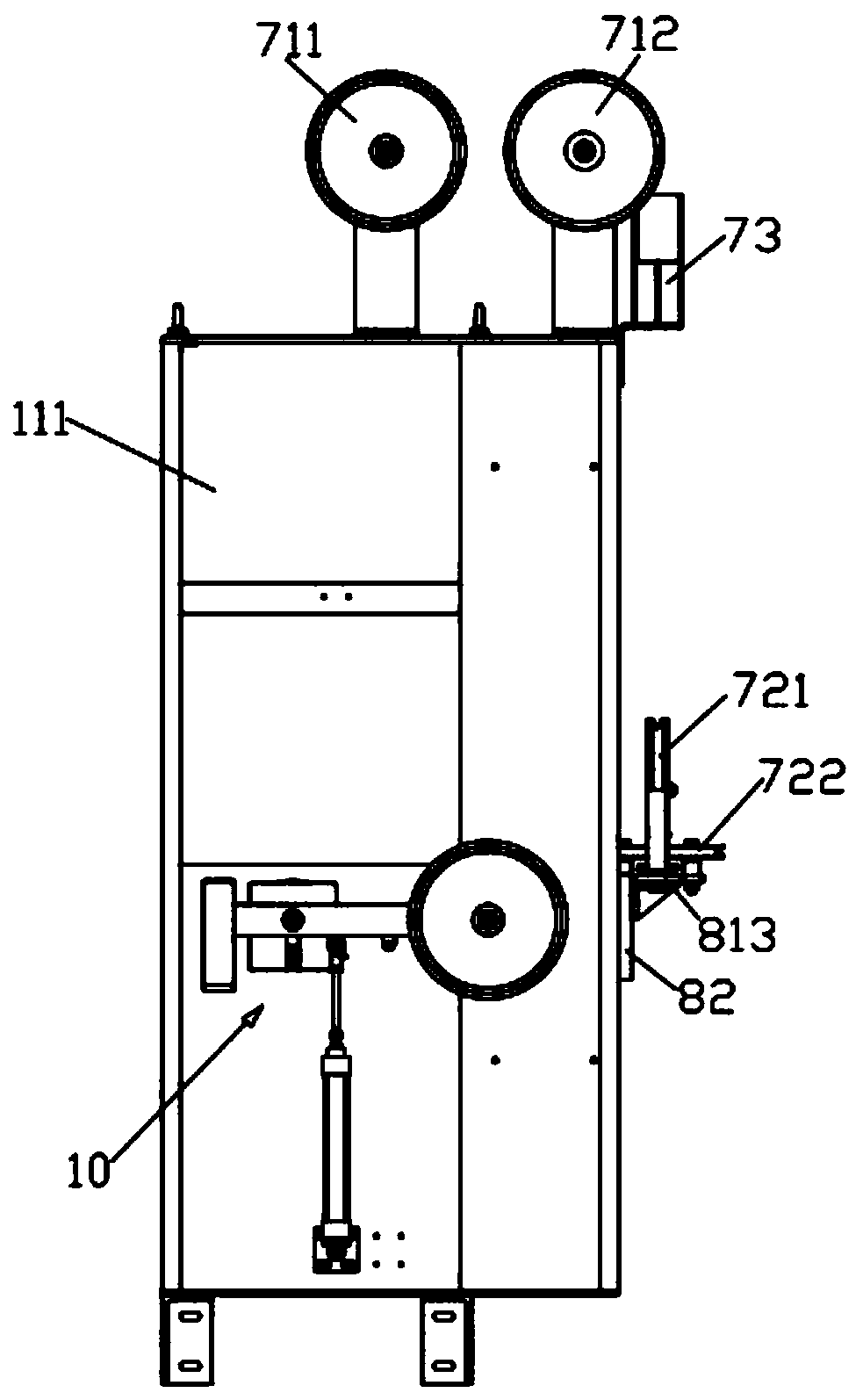

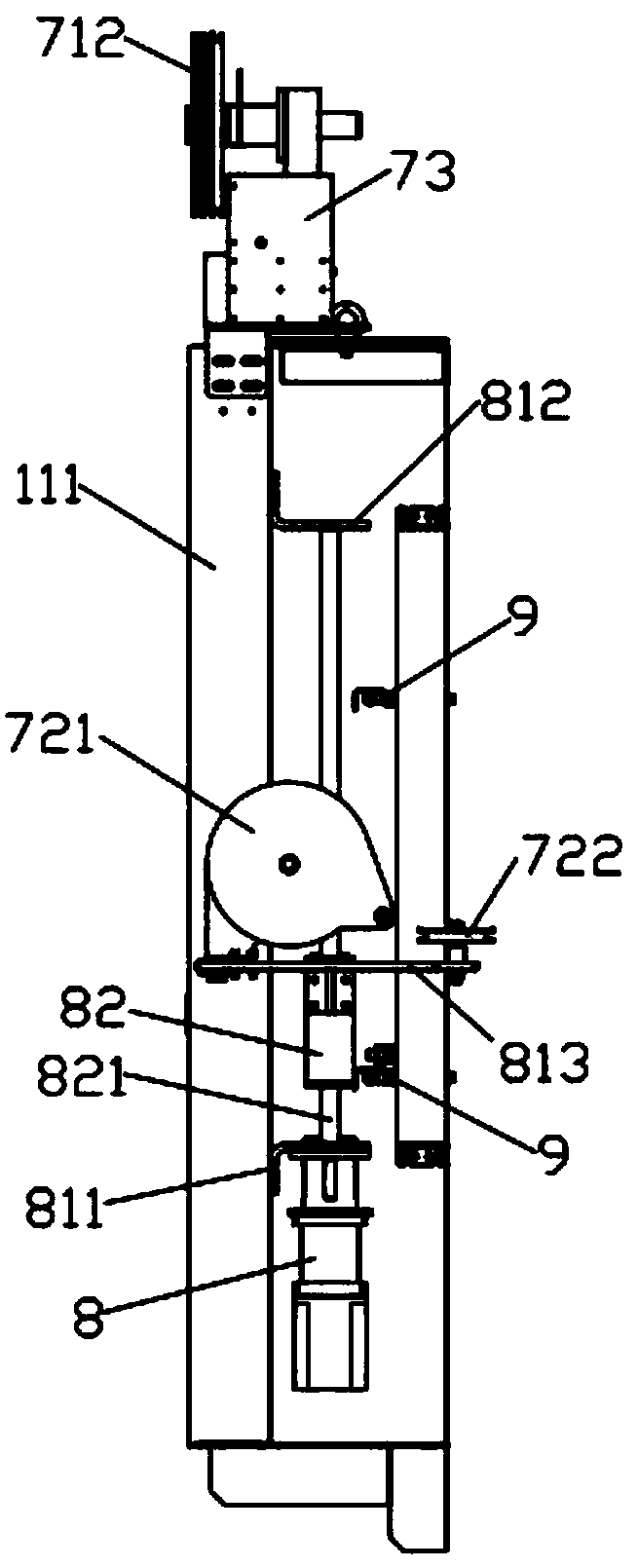

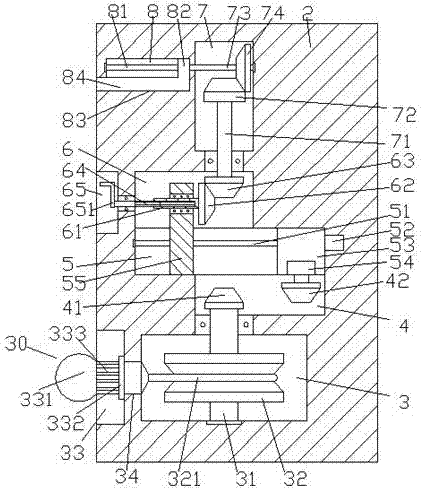

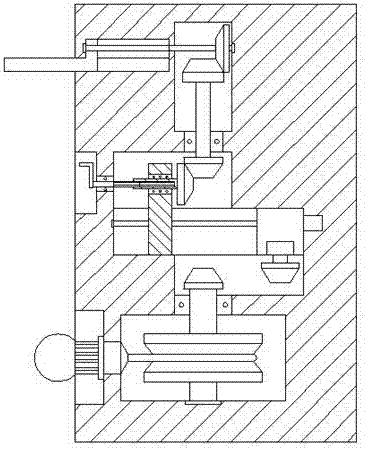

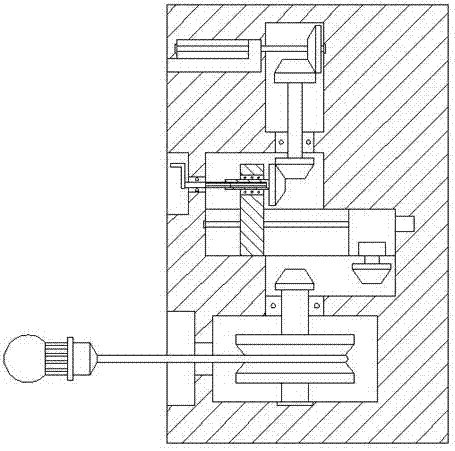

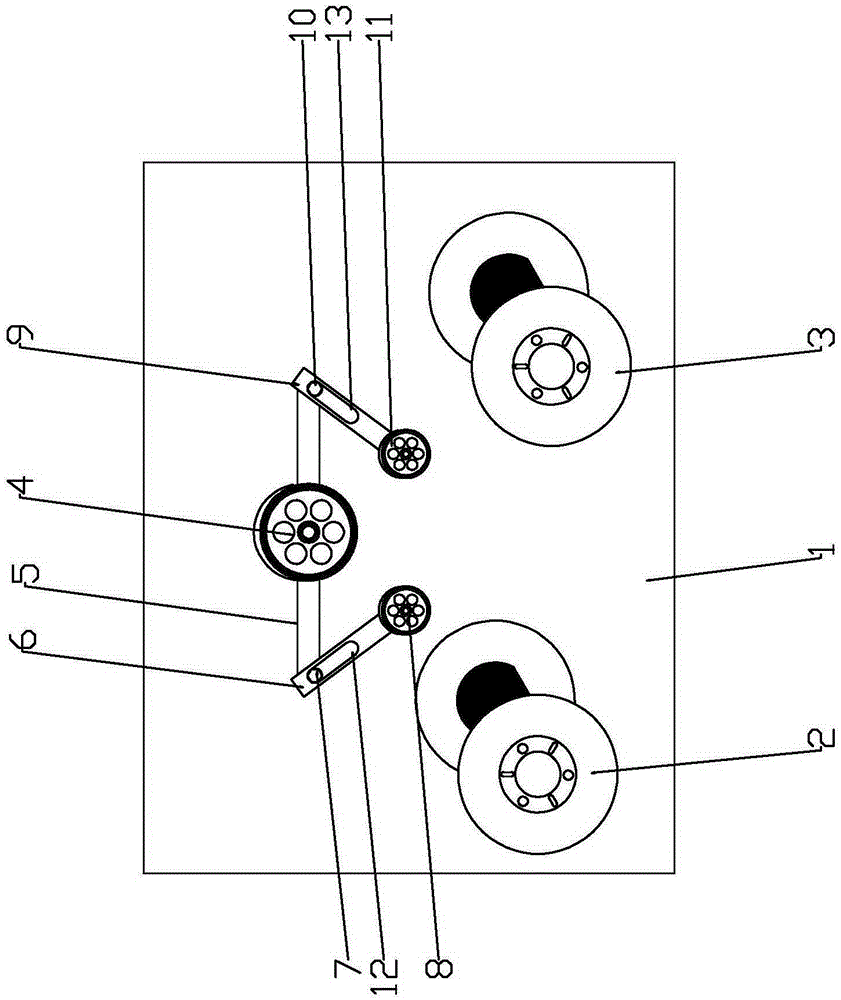

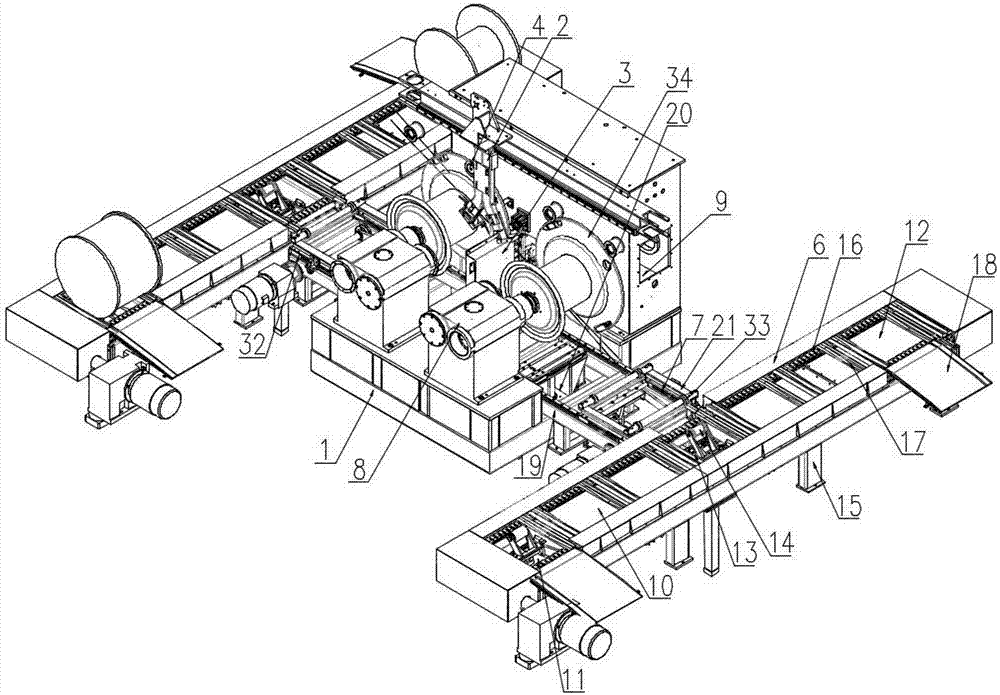

Semi-automatic wire take-up machine

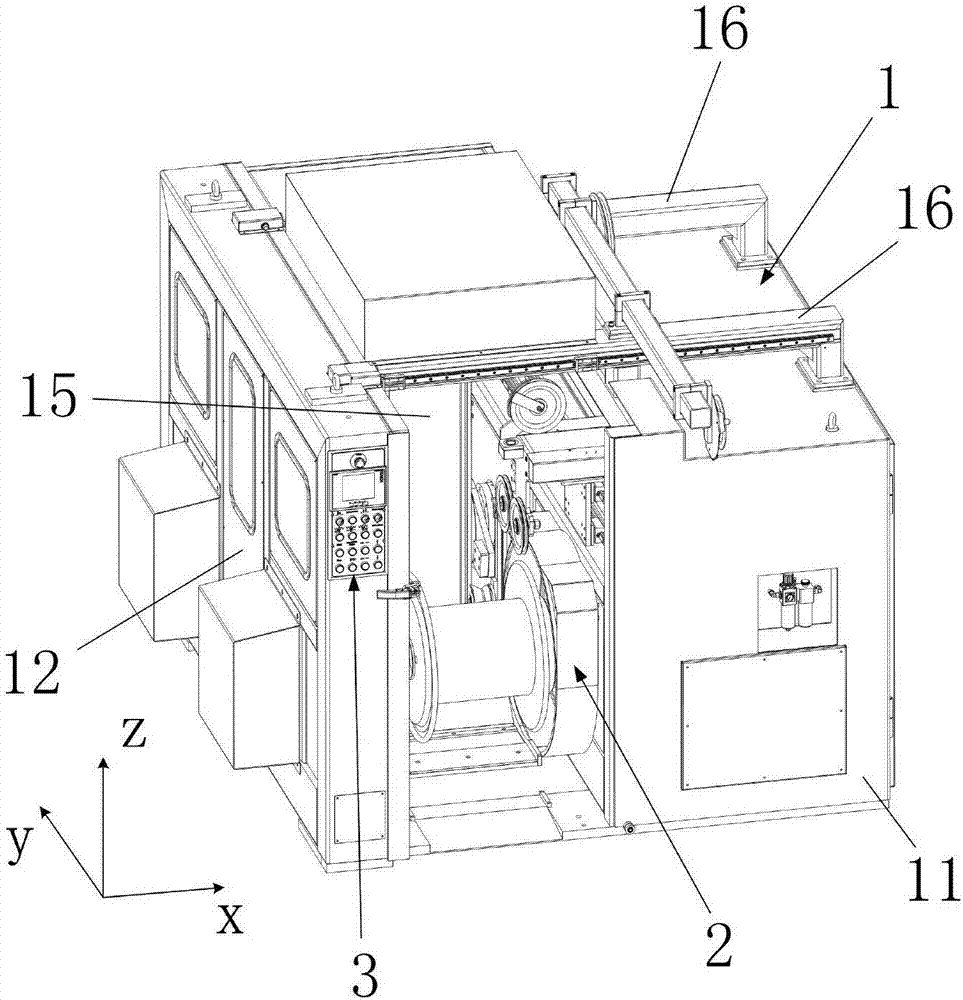

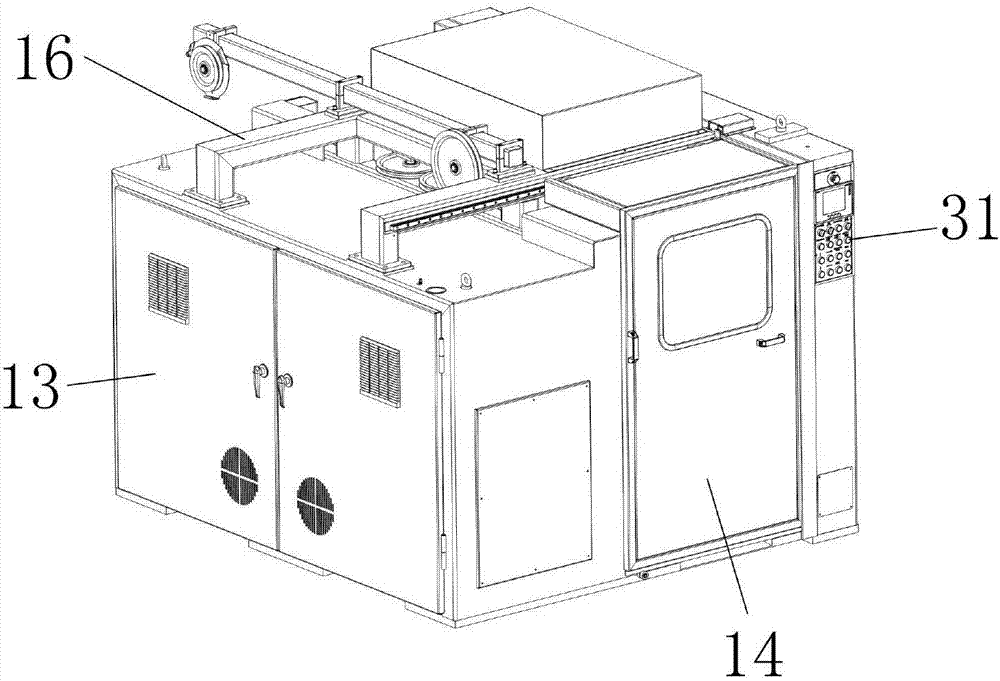

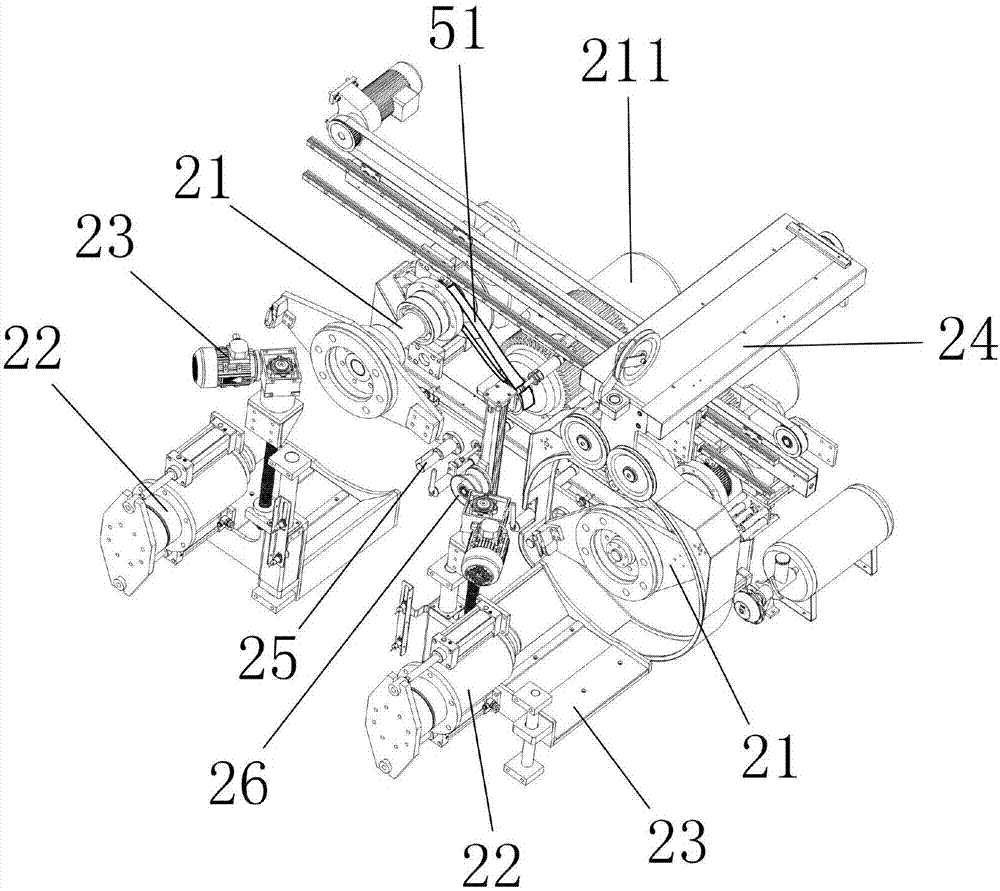

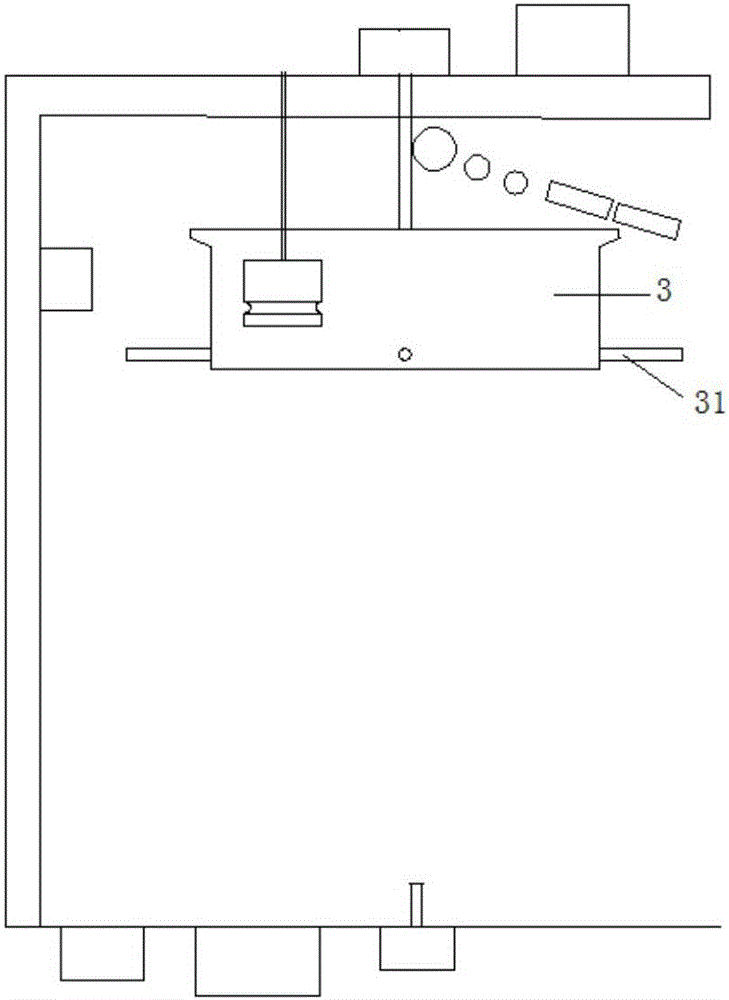

The invention relates to a semi-automatic wire take-up machine. The semi-automatic wire take-up machine comprises a case and a wire take-up assembly located inside the case. The wire take-up assembly comprises two driving wire take-up mechanisms, two driven wire take-up mechanisms, two lifting mechanisms, a wire arrangement mechanism, two wire cutting mechanisms and a wire capturing mechanism, wherein the two driving wire take-up mechanisms are separated from each other; the two driven wire take-up mechanisms are separated from each other; the two lifting mechanisms are separated from each other; the driving wire take-up mechanisms are aligned with the driven wire take-up mechanisms; the lifting mechanisms are located between the driving wire take-up mechanisms and the driven wire take-up mechanisms; the wire capturing mechanism is located between the two driving wire take-up mechanisms; the wire cutting mechanisms are located between the lifting mechanisms and the wire capturing mechanism; and the wire arrangement mechanism is located above the two lifting mechanisms. As for the semi-automatic wire take-up machine of the structure, while one wire coil is replaced, a wire of another wire coil can be taken up, and the wire take-up efficiency is greatly improved.

Owner:东莞市金技机械有限公司

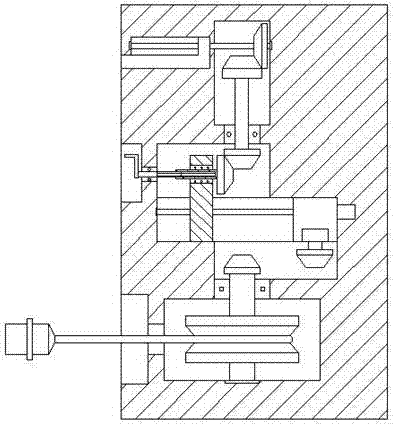

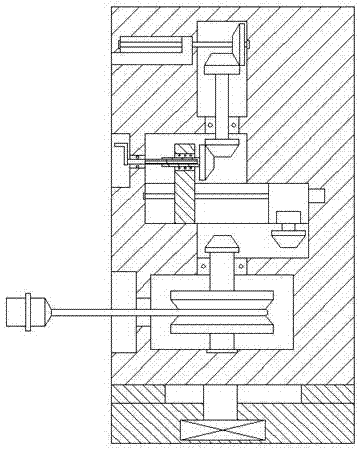

New energy car charging device capable of automatically controlling winding up

InactiveCN106891771AManually controlled automatic scalingManually control the take-up workCharging stationsElectric vehicle charging technologyAutomatic controlNew energy

The invention discloses a new energy car charging device capable of automatically controlling winding up. The new energy car charging device comprises a charging pile body, and a sliding groove is transversely formed in the middle position in the charging pile body. A first cavity is formed in the position, above the left side of the sliding groove, of the charging pile body, and a second cavity is formed in the position, below the right side of the sliding groove, of the charging pile body. A winding up cavity is formed in the position, at the bottom of the second cavity, of the charging pile body, a transmission cavity is formed in the position above the right side of the first cavity, and a first screw is arranged in the sliding groove. The right side end of the first screw is in power connection with a first motor, a movable rod upwards extending and a movable block arranged on the right side of the movable rod are connected to the first screw in a threaded fit mode, the upwards-extending section of the movable rod extends into the first cavity, and an inner spline shaft is connected into the movable rod in a rotating fit mode. A first conical wheel is fixedly arranged at the right side end of the inner spline shaft, the inner spline shaft is internally connected with an external spline shaft in a matched mode, and a second conical wheel is connected to the position above the right side of the first conical wheel in an engaged mode. The new energy car charging device is simple in structure and convenient to operate, rainwater is prevented from falling into the charging pile body, and working efficiency and safety are improved.

Owner:深圳龙电华鑫控股集团股份有限公司

Oil-coating conductive wire support for enameled wires

PendingCN109335844AWind evenlyPrevent disconnectionFilament handlingEngineeringMechanical engineering

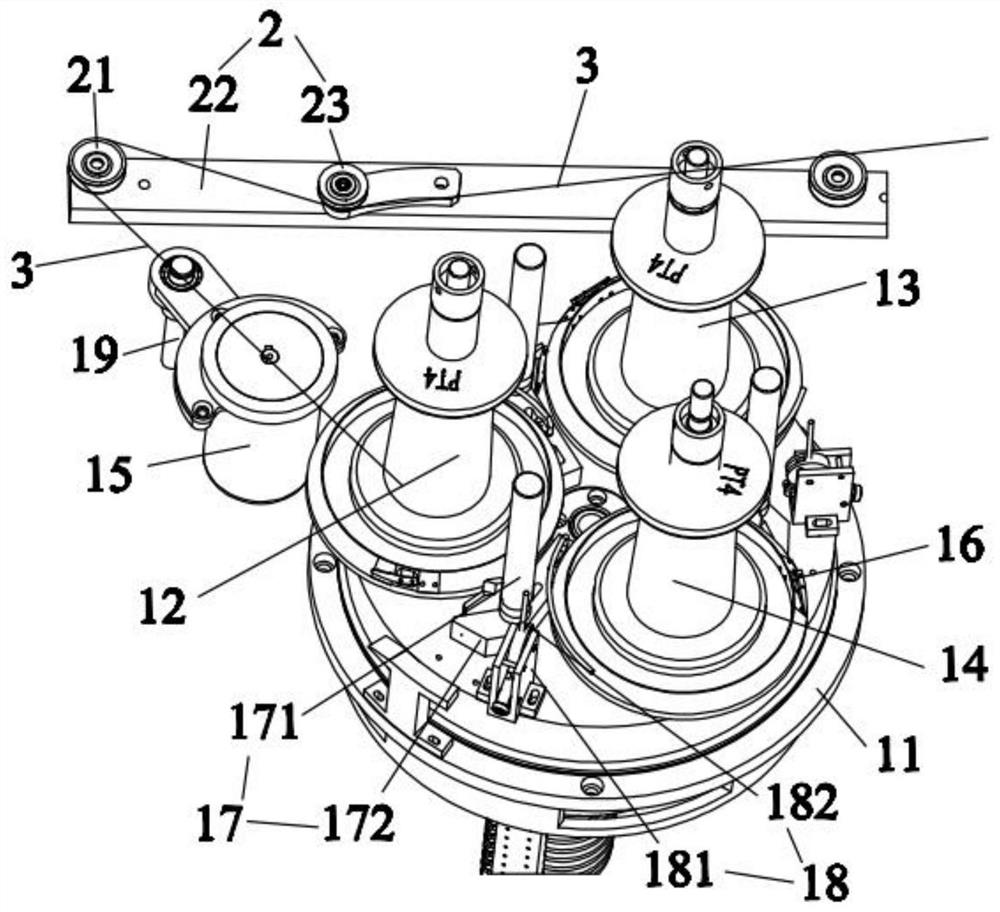

The invention provides an oil-coating conductive wire support for enameled wires. The oil-coating conductive wire support for the enameled wires comprises a support, a first wire crossing wheel and asecond wire crossing wheel which are installed on the upper part of the support, a tension swing rod mechanism installed on the lower part of the support, a wire arrangement servo motor installed on the side part of the support, a screw rod driven by the wire arrangement servo motor, a nut seat used in a manner of matching with the screw rod, a wire arrangement guide block connected with the nut seat, a first wire arrangement wheel and two second wire arrangement wheels which are installed on the wire arrangement guide block, and a felt oil-coating mechanism installed on the side part of the support. According to the oil-coating conductive wire support for the enameled wires, the oil-coated enameled wires can be stably and orderly arranged, so as to be uniformly wound on take-up discs; andin addition, winding tension for the enameled wires is flexibly detected through the tension swing rod mechanism and a winding speed is flexibly adjusted in time, so that the enameled wires can be wound under constant tension and at a constant speed, the case of breakage of the enameled wires is prevented, the winding uniformity for the enameled wires is ensured, and the winding efficiency for the enameled wires is increased.

Owner:WUXI JUYI TONGCHUANG TECH CO LTD

Bridge equipment

ActiveCN106906755AManually controlled automatic scalingManually control the take-up workBridge erection/assemblyArrangements using take-up reel/drumEngineering

The invention discloses bridge equipment. The bridge equipment comprises a machine body, wherein a sliding groove is formed at the center inside the machine body; a first empty groove is formed in the machine body above the left side of the sliding groove; a second empty groove is formed in the machine body below the right side of the sliding groove; a containing groove is formed in the machine body at the bottom of the second empty groove; a force transmission chamber is arranged above the right side of the first empty groove; the sliding groove is internally provided with a first screw rod; the right end of the first screw rod is connected with a first driving machine; a spiral thread on the first screw rod is matched and connected with a vertical rod which extends upward and a sliding block arranged on the right side of the vertical rod; an upward extending section of the vertical rod stretches into the first empty groove and the inner part of the vertical rod is rotatably matched and connected with an inner spline shaft; a first gear is fixedly arranged on the right end of the inner spline shaft; the inner part of the inner spline shaft is matched and connected with an outer spline shaft; and a second gear is engaged and connected with the upper side of the right side of the first gear. The bridge equipment disclosed by the invention is simple in structure and convenient to operate; automatic take-up work can be realized and the bridge equipment has a rain-proof function; and the working efficiency is improved, wastes of electric supply are reduced and the utilization cost is relatively low, so that the bridge equipment is suitable for popularization and application.

Owner:浦江晨风新材料科技有限公司

Automatic wire winding equipment

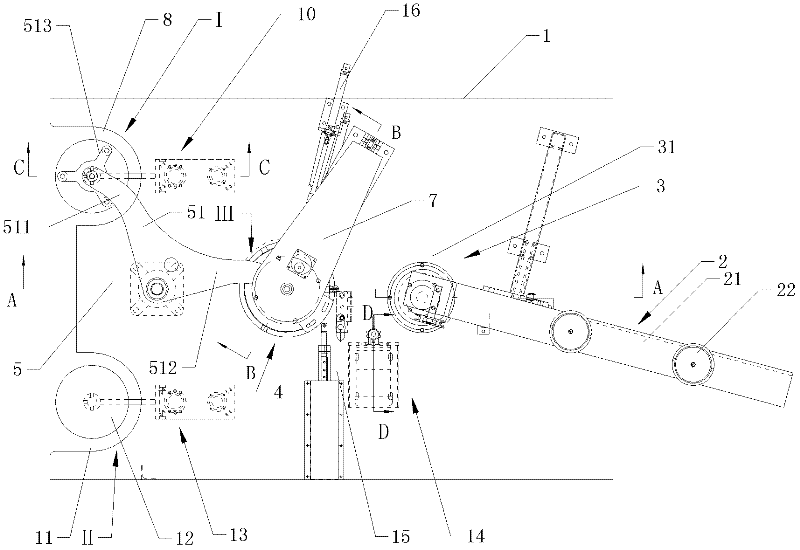

The invention discloses automatic wire winding equipment which comprises a wire winding mechanism, a clamping mechanism, a wire conveying mechanism and a cutting mechanism. The wire winding mechanismis used for axially moving to clamp a wire coil, drives the wire coil to pivot and can be in constant-speed reciprocating displacement along the direction of axis integrally when driving pivoting, theclamping mechanism comprises a first side away from the wire winding mechanism and a second side close to the wire winding mechanism, and the wire coil is clamped and sent to the wire winding mechanism from the first side through the clamping mechanism; the wire conveying mechanism is close to the second side and constantly conveys wires to the wire winding mechanism along the circumferential face of the outer wall of the clamped wire coil, and the cutting mechanism is used for cutting the wires. The automatic wire winding equipment can wind the wires on a calendering production line onto thewire coil orderly, efficiently and automatically.

Owner:上海颐尚电气科技股份有限公司

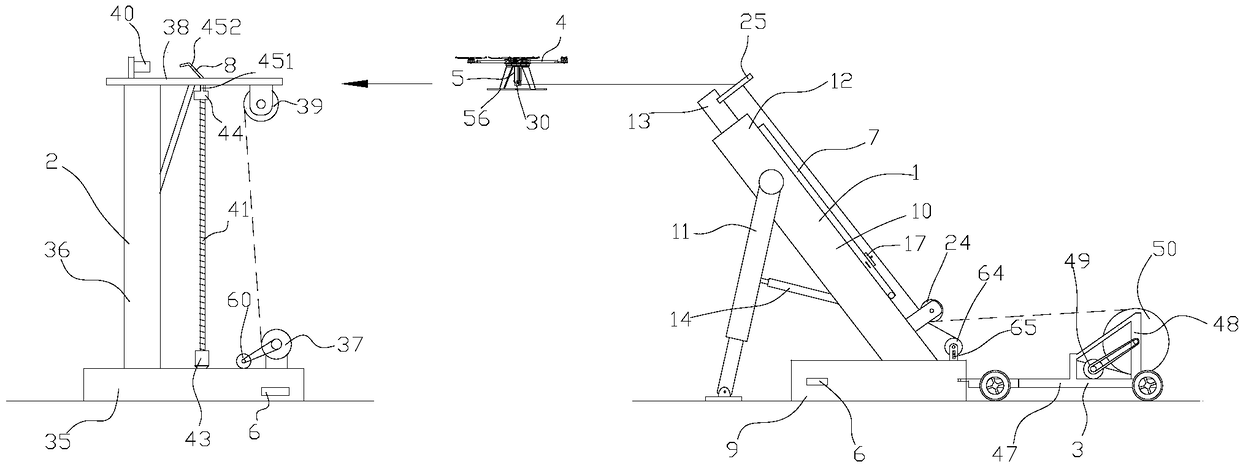

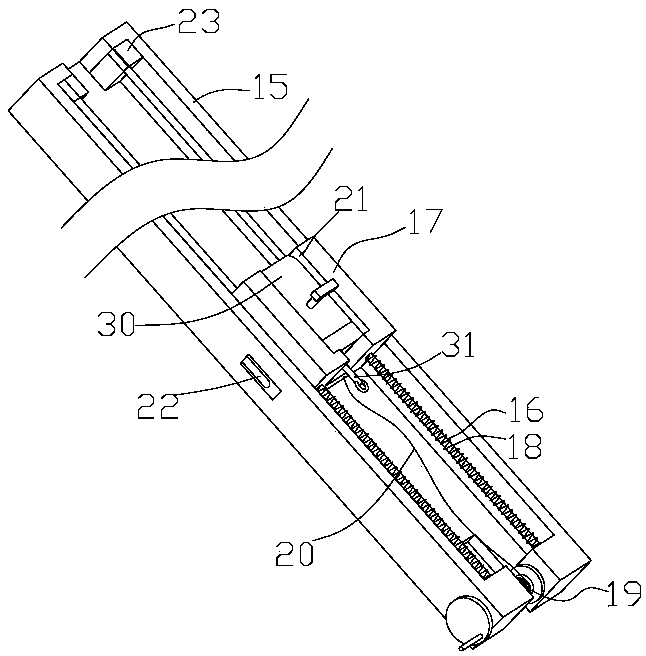

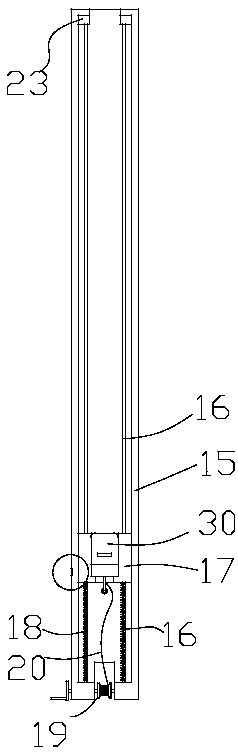

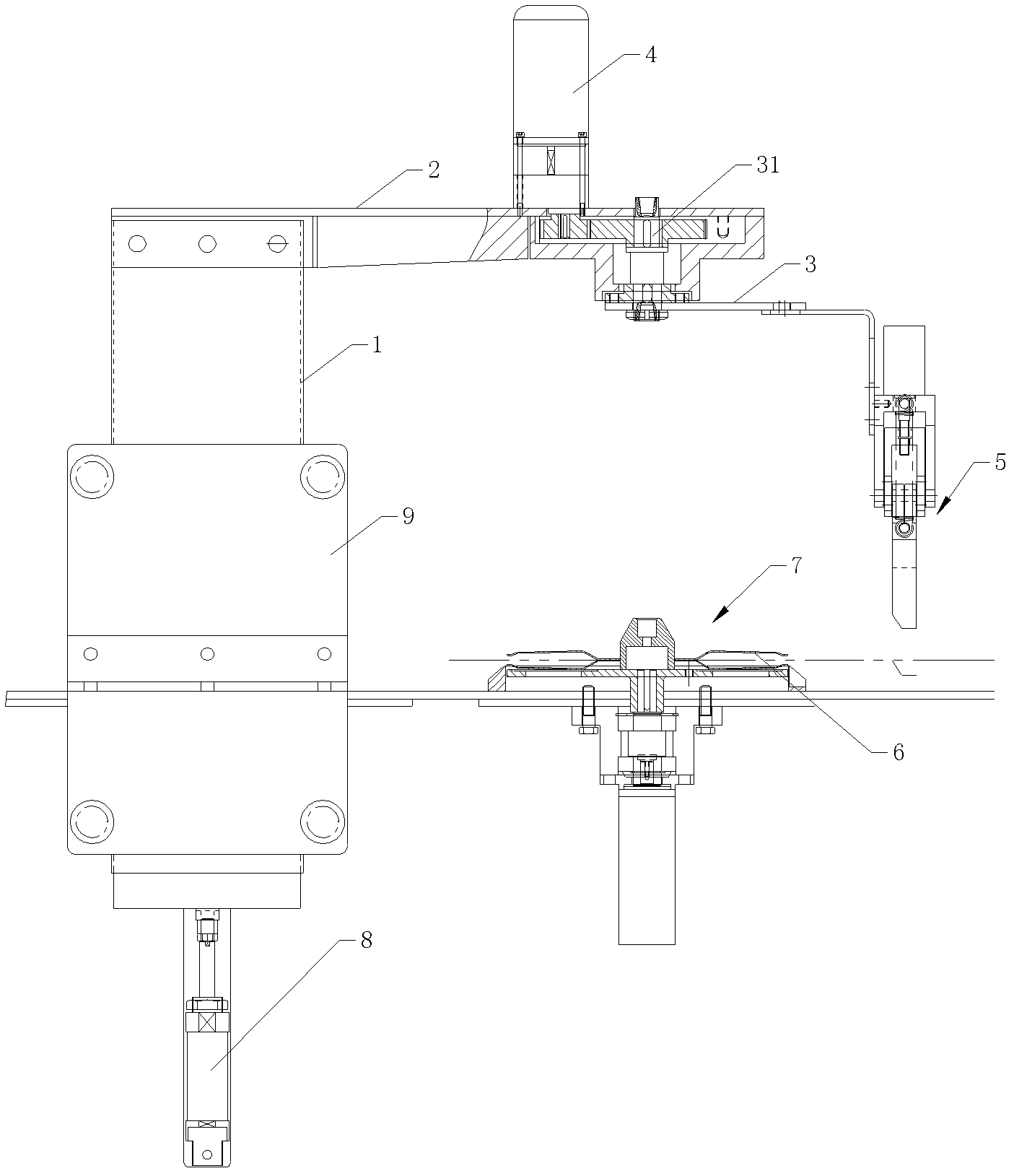

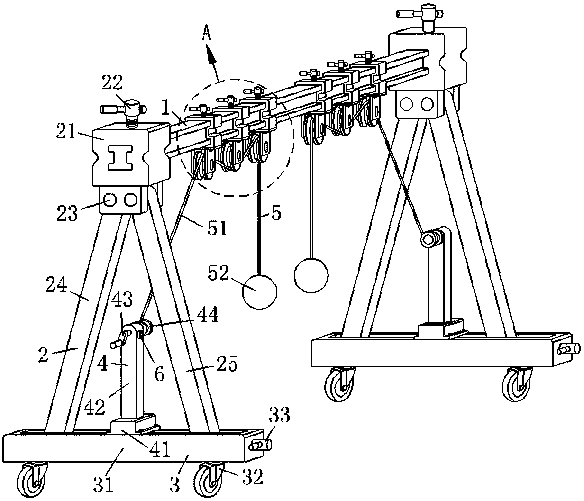

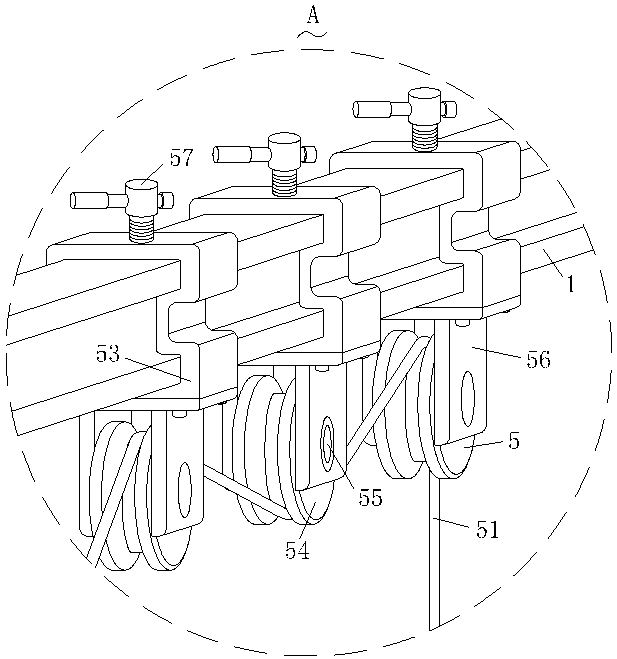

Tool for high-altitude erection

ActiveCN109449825AConvenient and fast stringing workAvoid manual erection difficultiesApparatus for overhead lines/cablesBall screwComputer module

The invention discloses a tool for high-altitude erection. The tool comprises a pay-off bracket, a take-up bracket, a pay-off roller bracket, a traction aircraft, a hang-up buckle, an ejection device,a take-up claw and a controller, wherein the pay-off bracket comprises a take-up base, a height support rod and a support foot, the middle part of a fixed rod of the pay-off bracket is provided withthe ejection device and a pressing wheel, and the take-up bracket mainly comprises a take-up base, a support rod, a landing plate, the take-up claw and a take-up roller; an electromagnet is arranged on the landing plate, and the take-up claw and a ball screw are arranged on the take-up base; the traction aircraft is connected with a traction wire through the hang-up buckle, the hang-up buckle comprises a fixed plate and a magnetic buckle, the magnetic buckle is provided with a steel needle which is detachably connected, a signal transmitting module is arranged on the landing plate, a signal searching module corresponding to the signal transmitting module is arranged on the traction aircraft, and the traction aircraft flies towards a take-up device according to signals transmitted by the signal transmitting module. The scheme of the invention can automatically realize line erection, and is convenient and fast.

Owner:FUJIAN YONGTAI CONSTR ENG CO

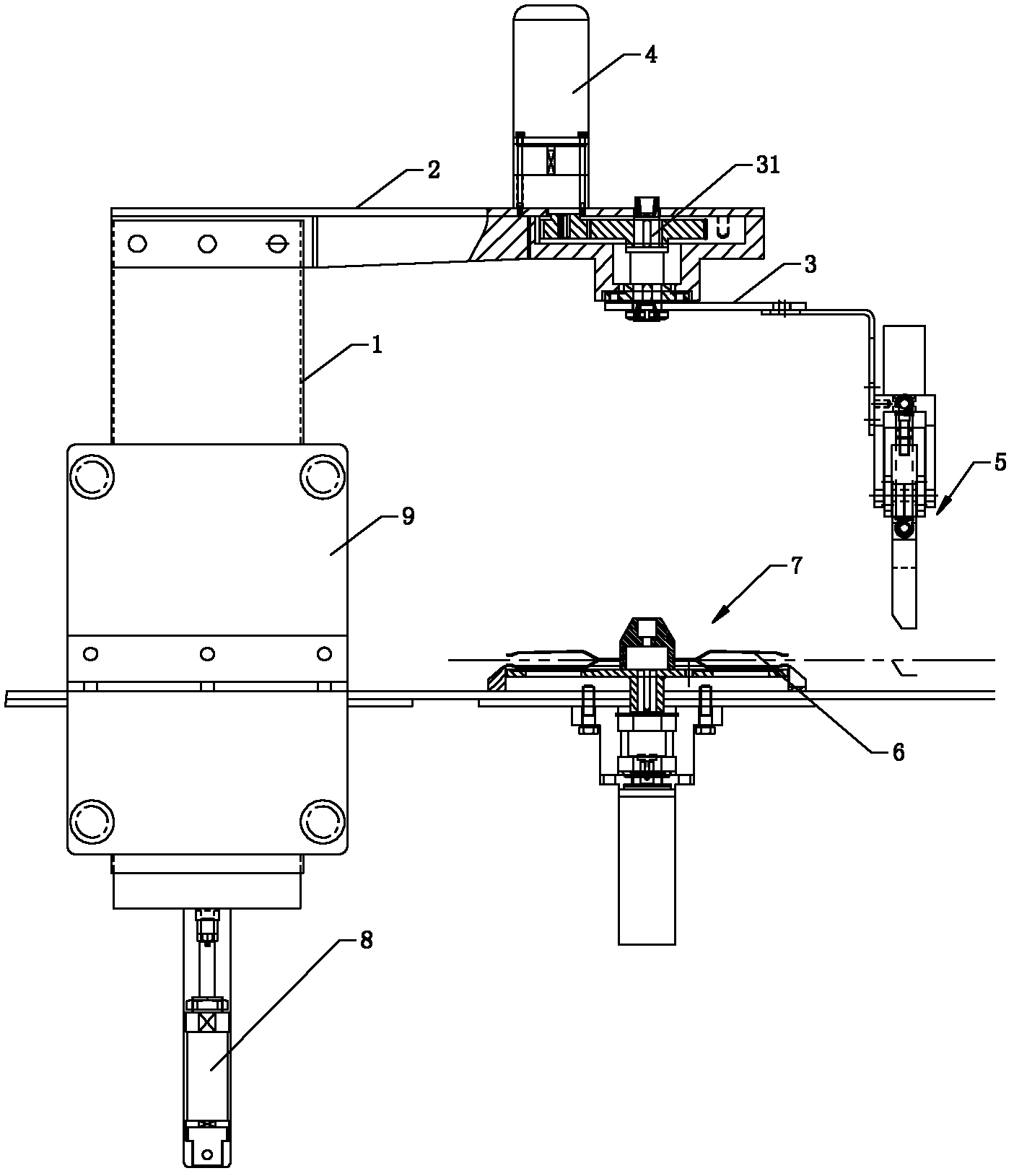

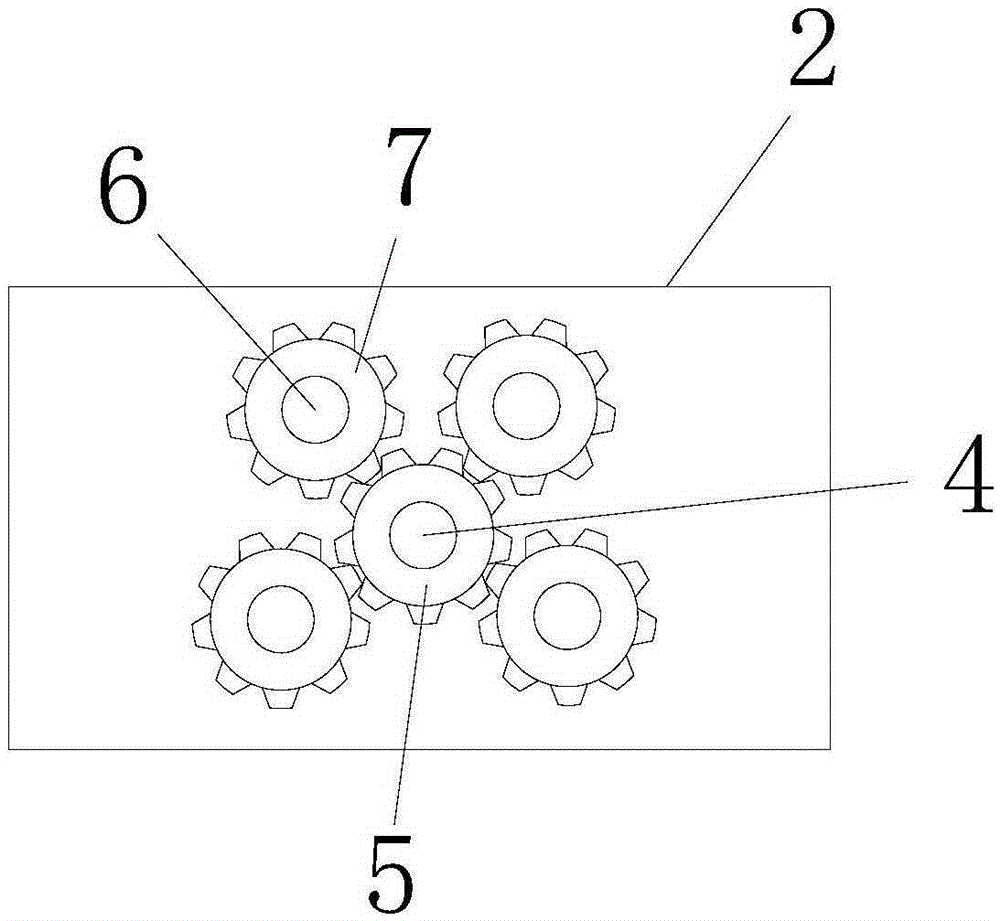

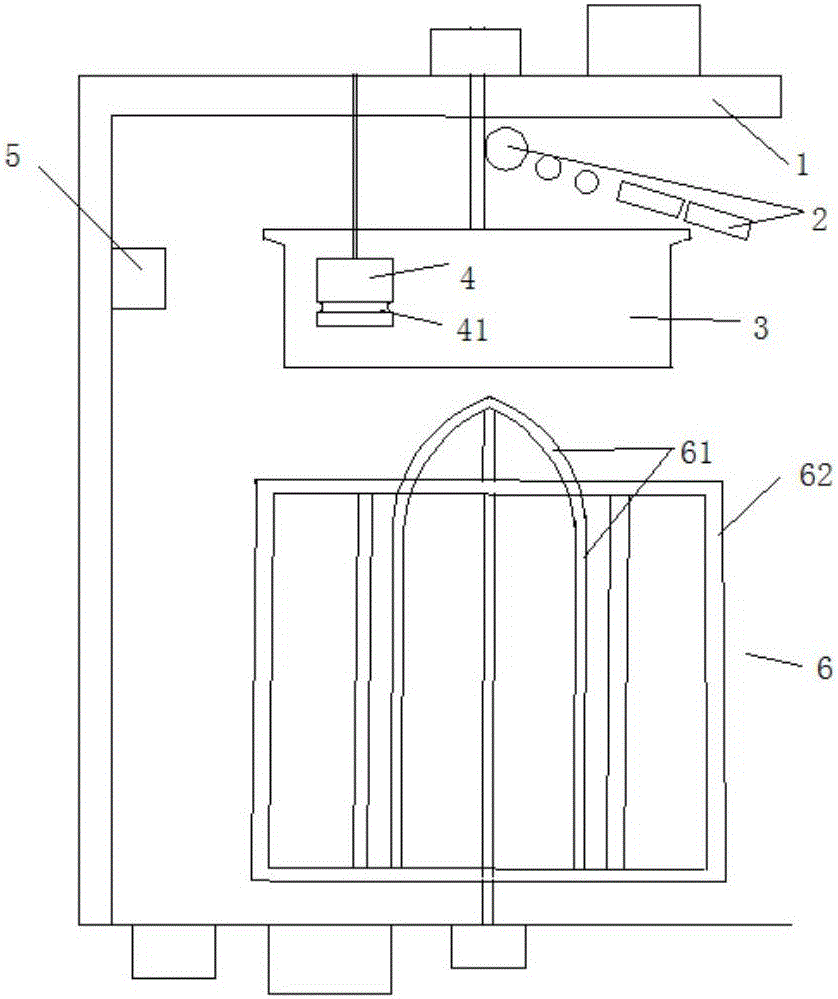

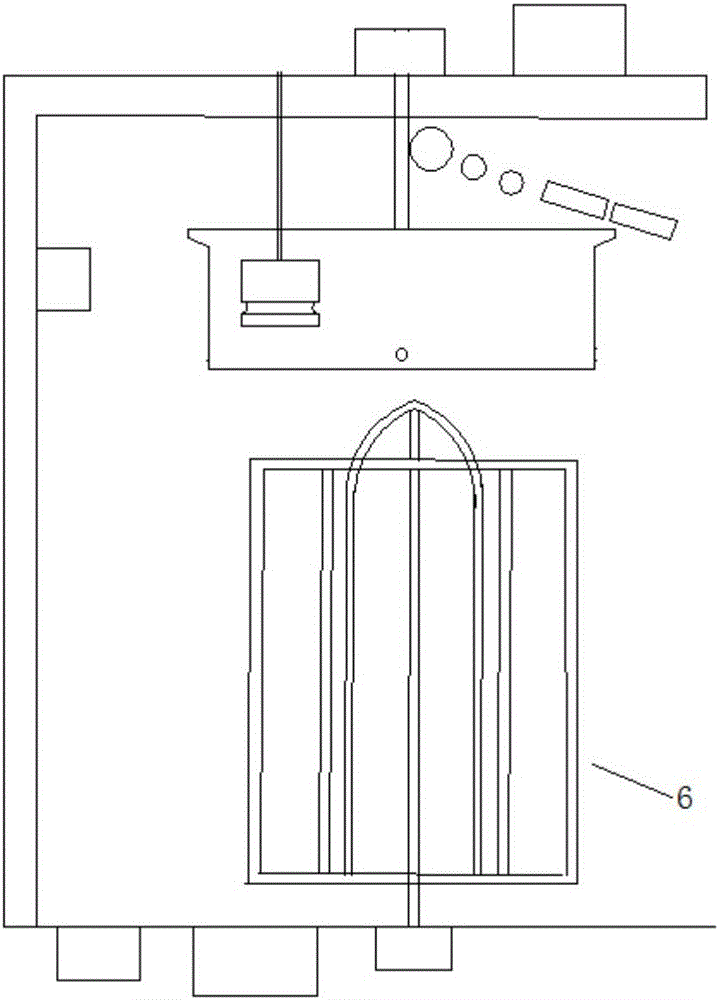

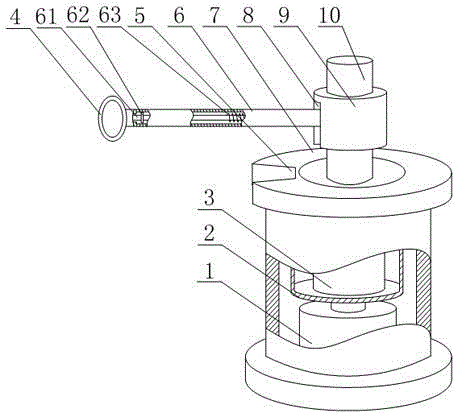

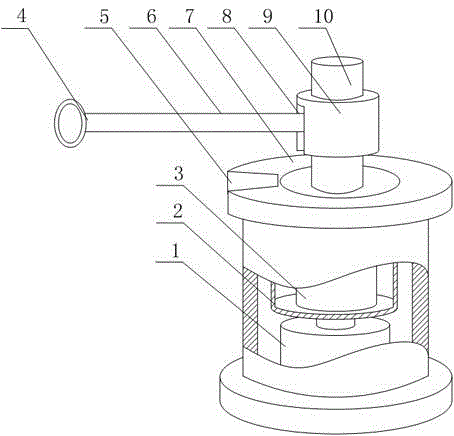

Automatic winding device of shuttle wire-unwinding machine of fishing net weaving machine

InactiveCN102633160AReduce labor intensityImprove take-up efficiencyFilament handlingEngineeringConductor Coil

The invention discloses an automatic winding device of a shuttle wire-unwinding machine of a fishing net weaving machine. The automatic winding device comprises a fixed base which is fixed on a rack, wherein the fixed base is vertically and slidingly provided with a stand column which is driven by a hoisting power device to be hoisted; the stand column is fixedly provided with a cross beam and the cross beam is rotatably provided with a rotating arm; the rotating arm is driven by a winding power device to rotate; and the lower end of the rotating arm is provided with a chuck assembly which is used for tightly clamping a fishing net wire to be wound on a shuttle of a wire-unwinding station. The automatic winding device can automatically wind the fishing net wire on the shuttle of the wire-unwinding station, replaces the manual operation and reduces the labor intensity of operators; and meanwhile, the wire-unwinding efficiency of the wire-unwinding machine is improved.

Owner:JIANGSU JIANGHAI MASCH CO LTD

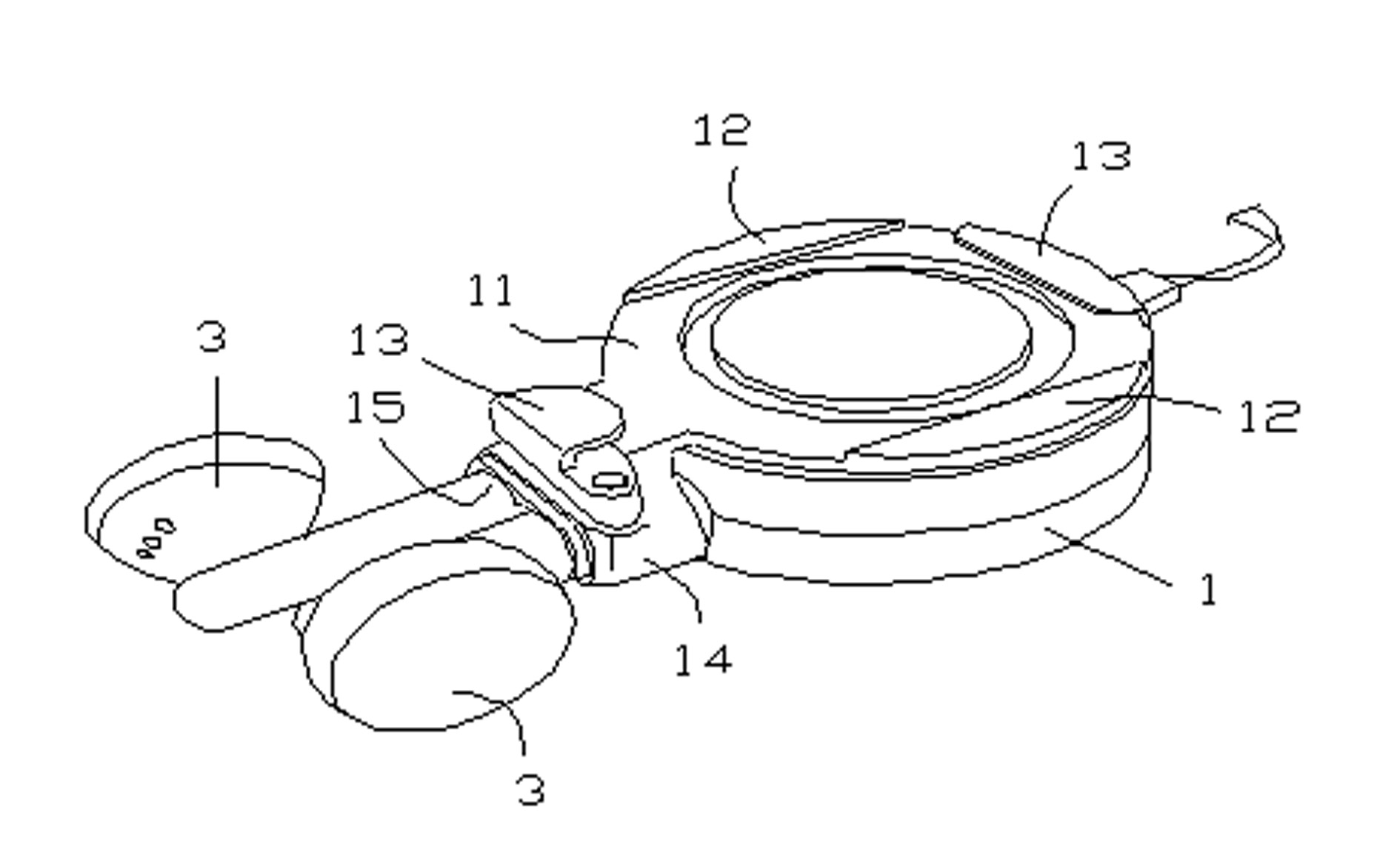

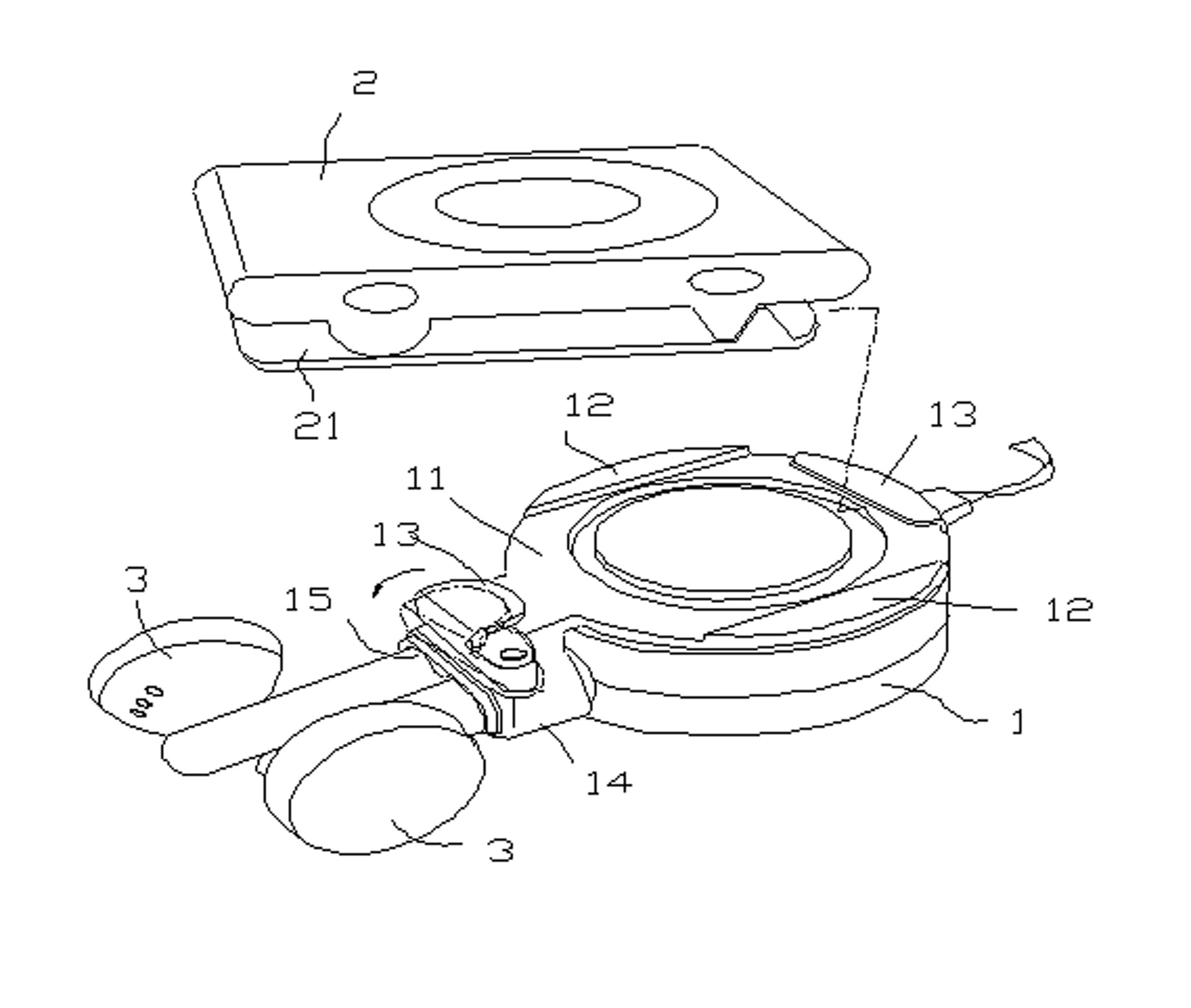

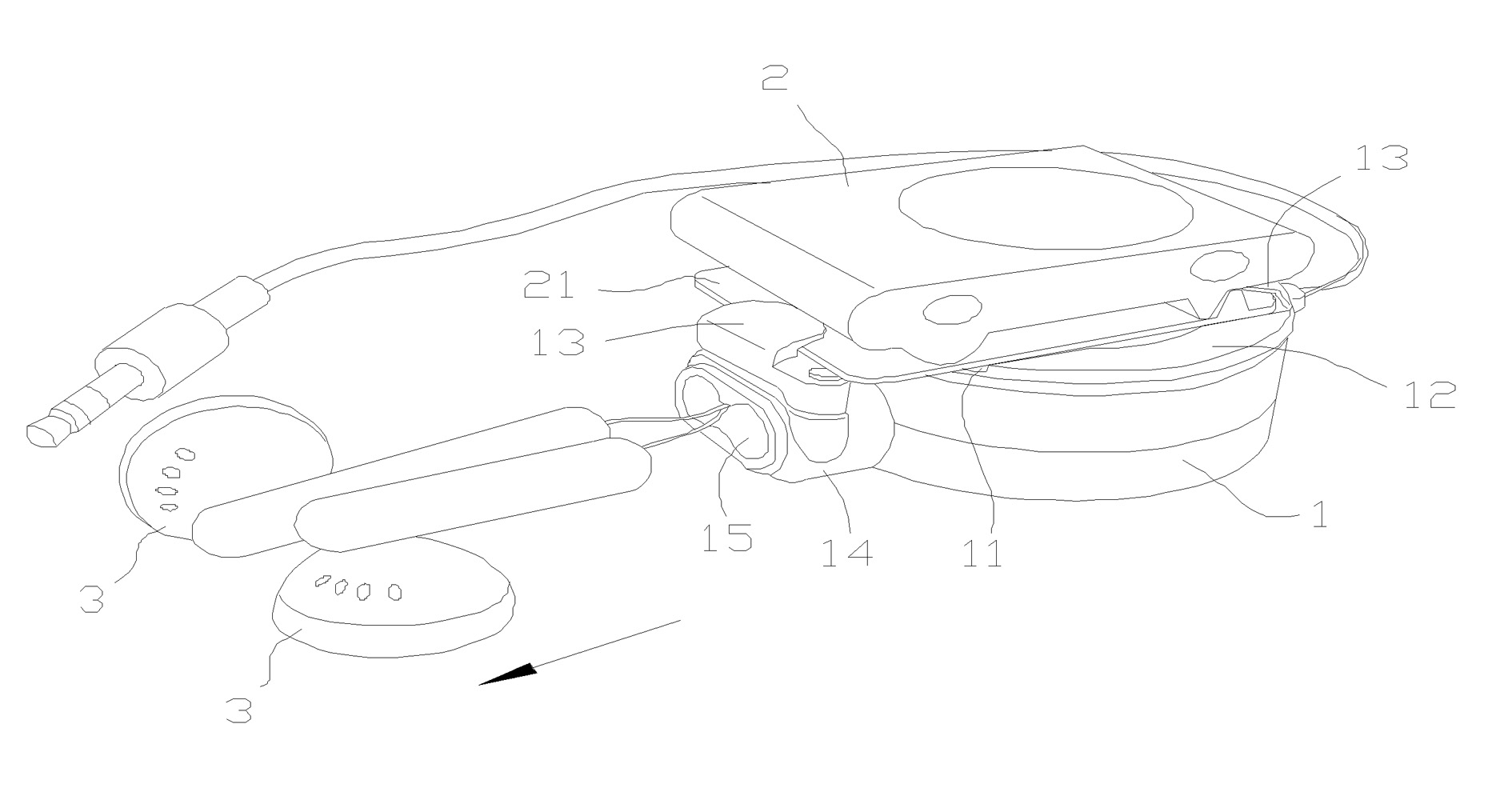

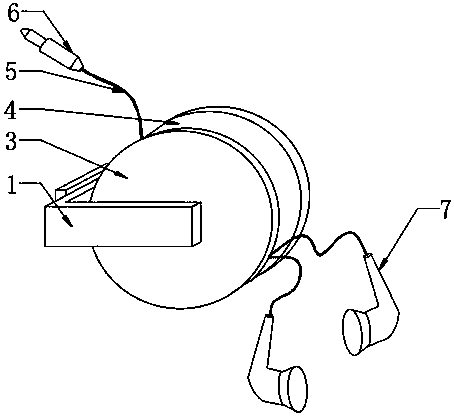

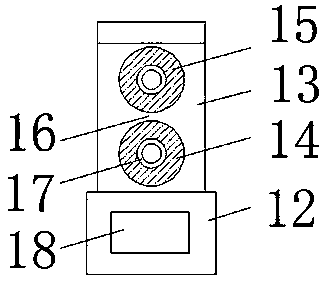

Wire take-up device for headset

InactiveCN102026059AEasy to storeImprove take-up efficiencyEarpiece/earphone attachmentsHeadphonesTower

The invention discloses a wire take-up device for a headset, which relates to the technical field of wire take-up device, in particular to a wire take-up device for taking up a headset wire. The wire take-up device disclosed by the invention comprises a wire take-up main body; a wire take-up space and a wire take-up mechanism are arranged in the main body, a tower part is extended outwards from a wire take-up opening of the main body, and the middle part of the tower part is provided with a hollow accommodating groove communicated with the wire take-up opening, after the headset wire is completely taken up, the wire end of the headset can be accommodated in the accommodating groove so as to position the headset; an external side face of the main body is provided with a holding groove, and a back panel of a corresponding player can just be embedded and fixed in the holding groove, so that the player and the wire take-up main body are connected together; and the holding groove is defined by a combination of bumps and hooks on the side face of the main body, and at least one hook has an openable and recoverable trend. The device disclosed by the invention has the advantages of simple structure, is easy to process and manufacture, and has low cost, is easy in installation and removal of the player.

Owner:DONGGUAN ZHONGQIANG IND

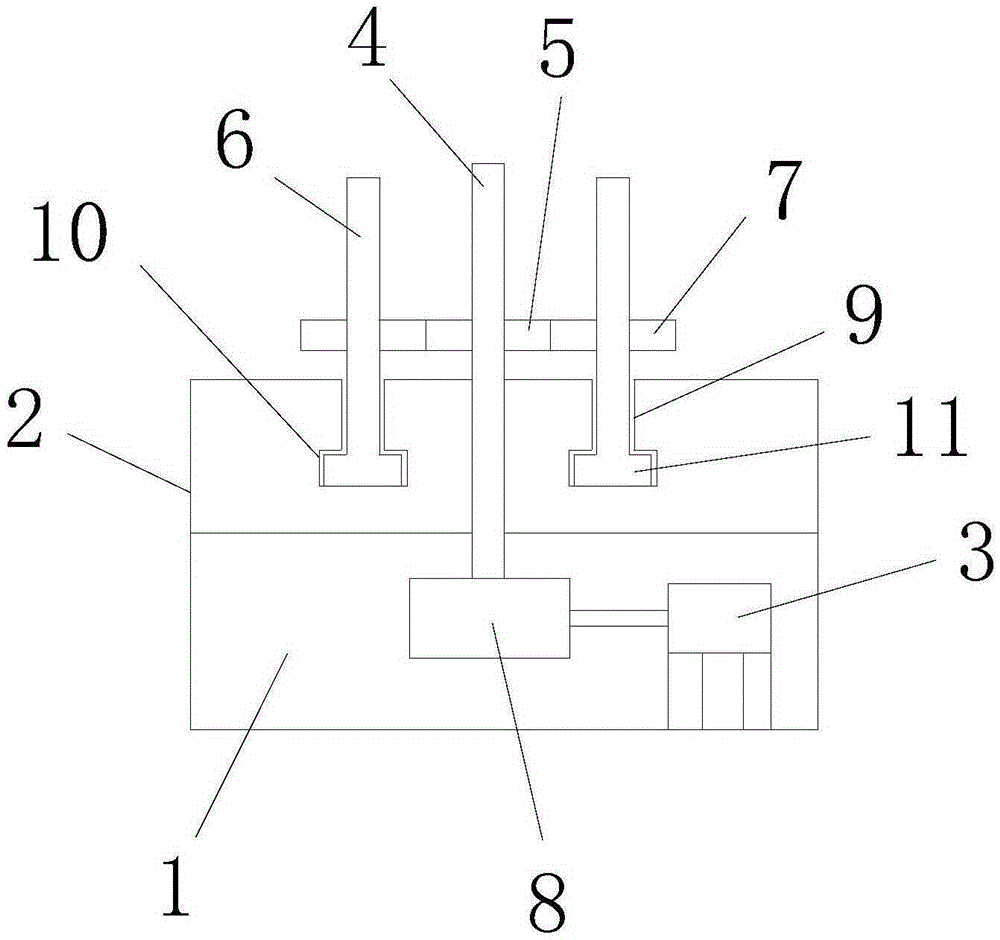

Textile rack

The invention discloses a textile rack. The textile rack comprises a base (2) with a cavity (1), a motor (3), a driving rotary shaft (4), a driving rotary gear (5), multiple driven rotary shafts (6) and multiple driven rotary gears (7), wherein the motor is arranged inside the base; the driven rotary shafts are vertically arranged on the top end surface of the base; one end of the driving rotary shaft is connected with a rotary shaft of the motor; the other end of the driving rotary shaft penetrates through the top end surface of the base and vertically outwards extends; the outer wall of the driving rotary shaft is sleeved with the driving rotary gear; the outer walls of the driven rotary shafts are sleeved with the driven rotary gears; teeth of the driven rotary gears can be engaged with teeth on the driving rotary gear. The textile rack is small in occupied space, and can increase the weaving speed and improve the textile production efficiency.

Owner:WUHU KANGDAOER TEXTILE SCI

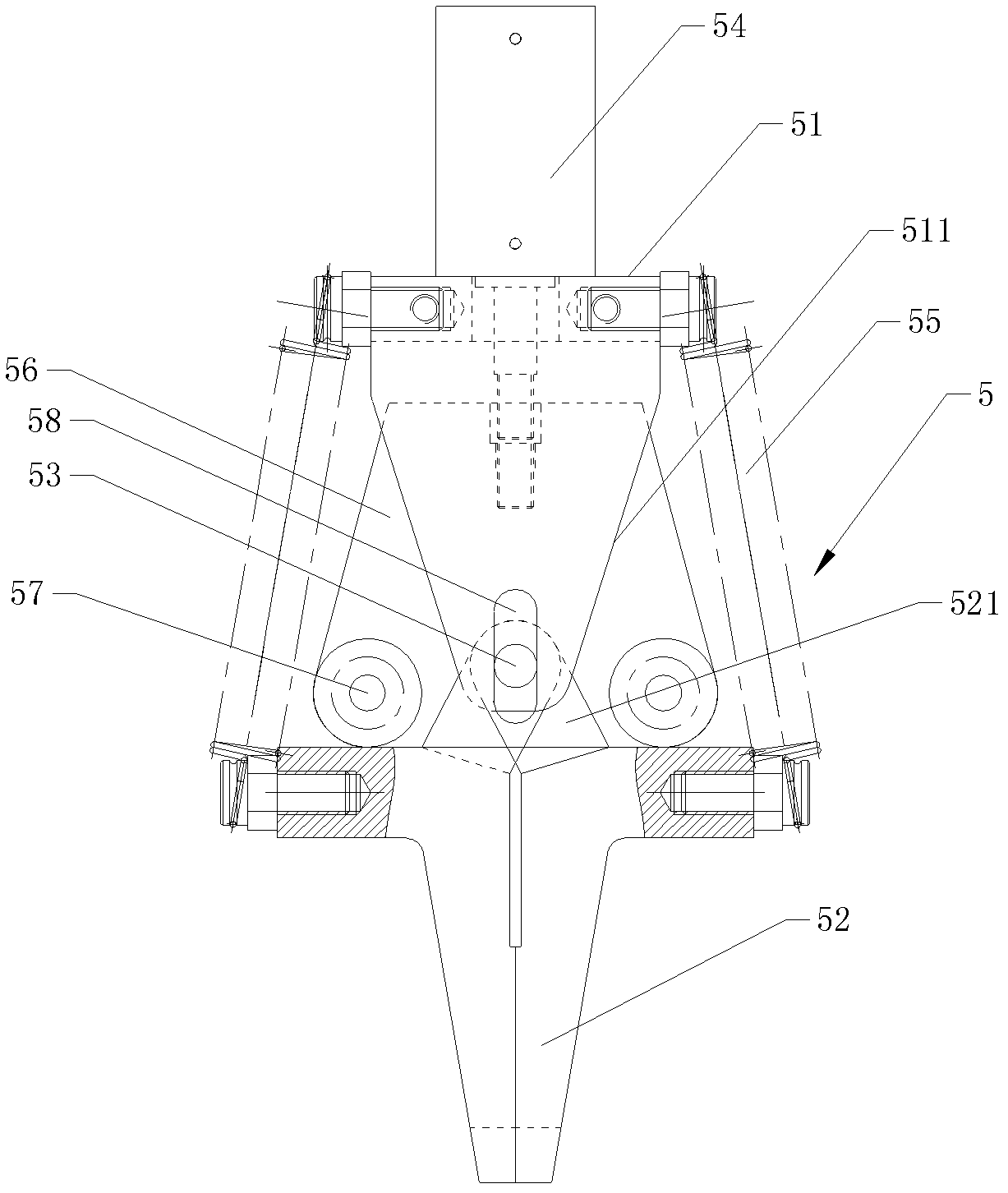

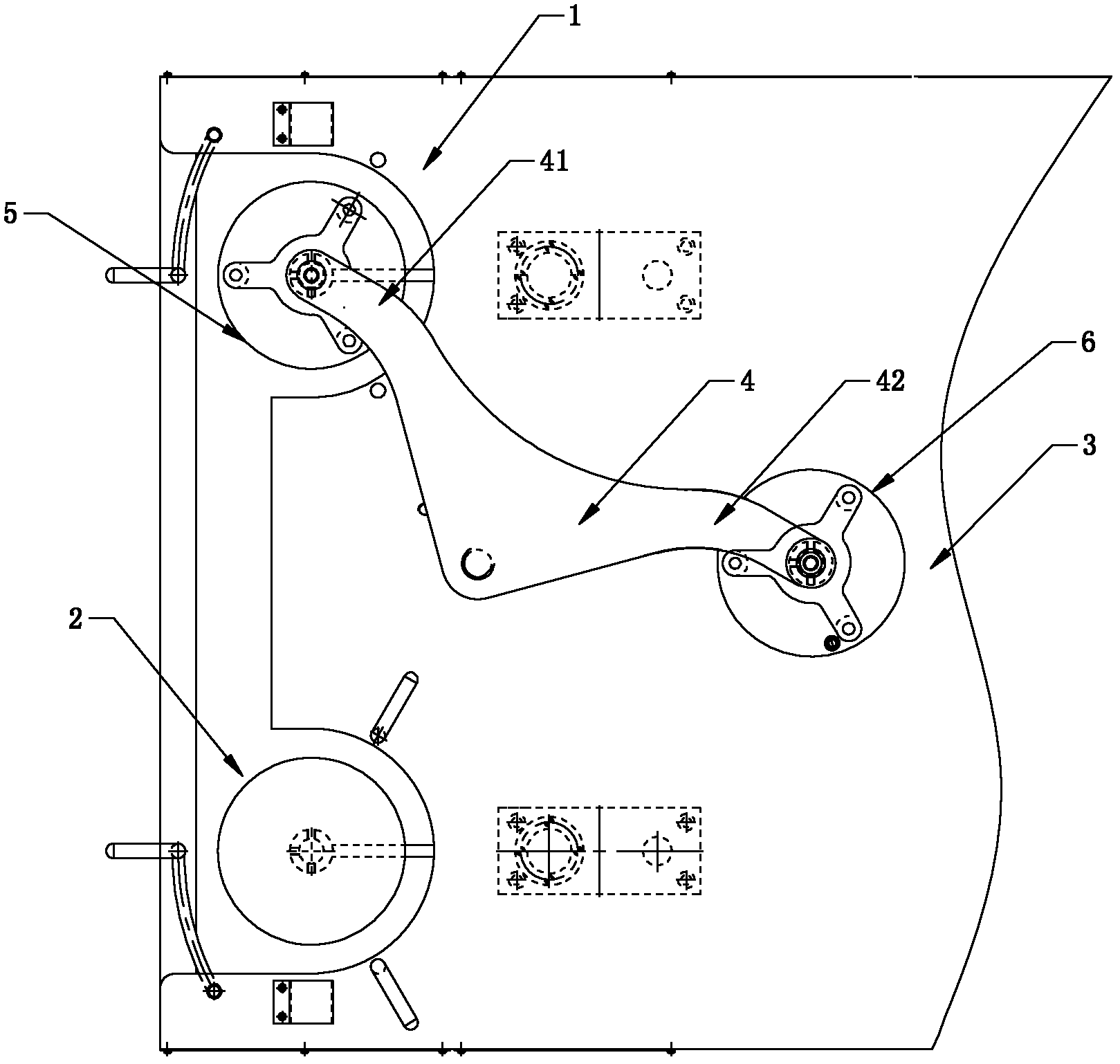

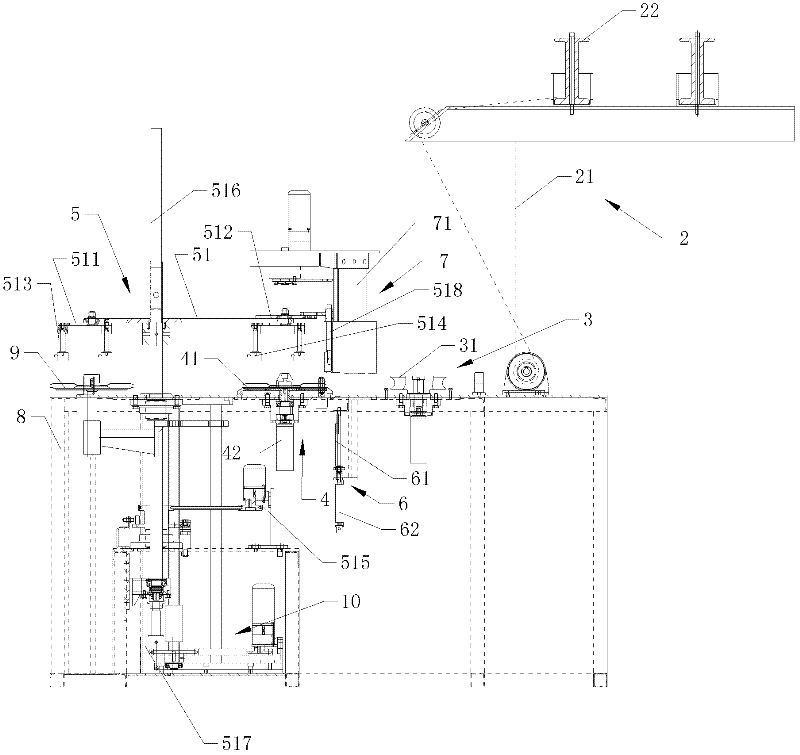

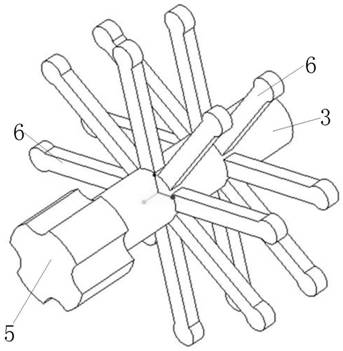

Shuttle plate replacing device for shuttle plate coiling machine of fishing net loom

InactiveCN102633162AUniform adsorption capacityNot easy to fall offFilament handlingIsoetes triquetraEngineering

The invention discloses a shuttle plate replacing device for a shuttle plate coiling machine of a fishing net loom. The device is characterized in that a blank plate placing station used for placing a blank plate, a full plate placing station used for placing a full plate and a coiling station used for coiling are arranged on the coiling machine; the blank plate placing station, the full plate placing station and the coiling station are distributed at three peaks of an equilateral triangle; the shuttle plate replacing device comprises a rotating claw which is rotatably mounted on a frame; therotating center of the rotating claw is the center of the equilateral triangle; the rotating claw is provided with a first claw part and a second claw part; a first adsorbing device which is used foradsorbing and conveying the blank plate on the blank plate placing station to the coiling station is mounted on the first claw part; a second adsorbing device which is used for adsorbing and conveying the full plate on the coiling station to the full plate placing station is mounted on the second claw part; and the rotating claw is driven by a shuttle plate replacing driving device to deflect back and forth. According to the invention, the blank plate and the full plate on the shuttle plate replacing device can be automatically replaced, so that the coiling efficiency of the shuttle plate coiling machine is increased and the manpower resource is saved.

Owner:JIANGSU JIANGHAI MASCH CO LTD

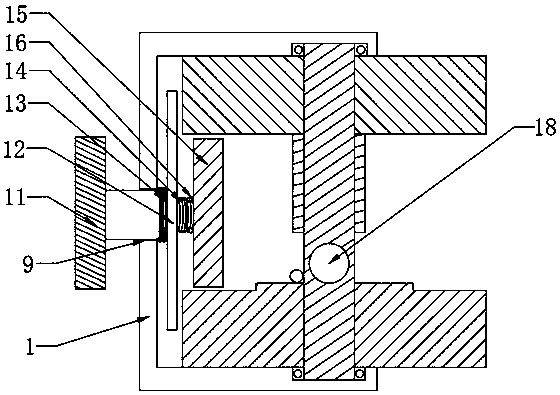

Inverted take-up device and inverted take-up method

Owner:NANTONG HUIFENG ELECTRONICS TECH

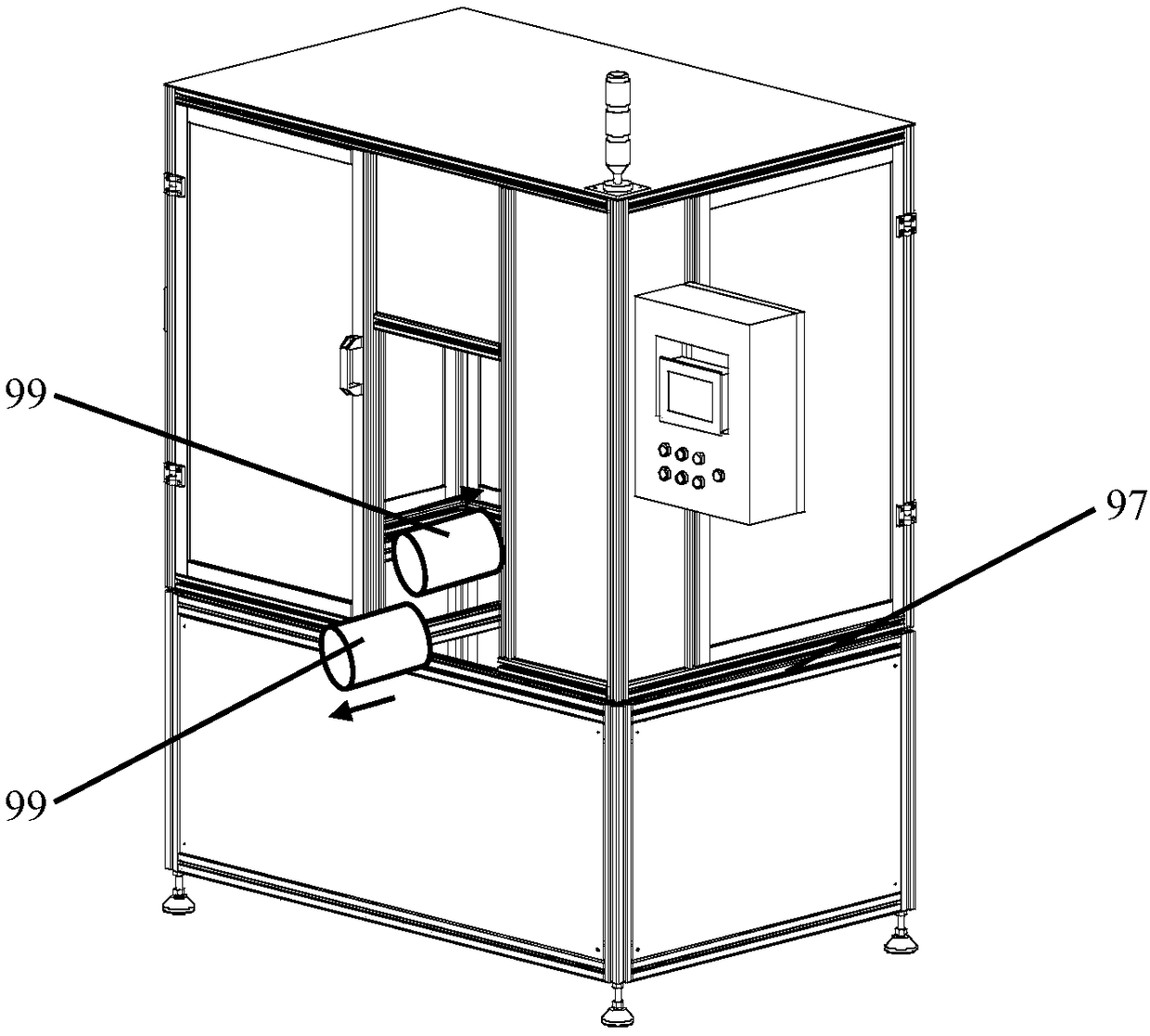

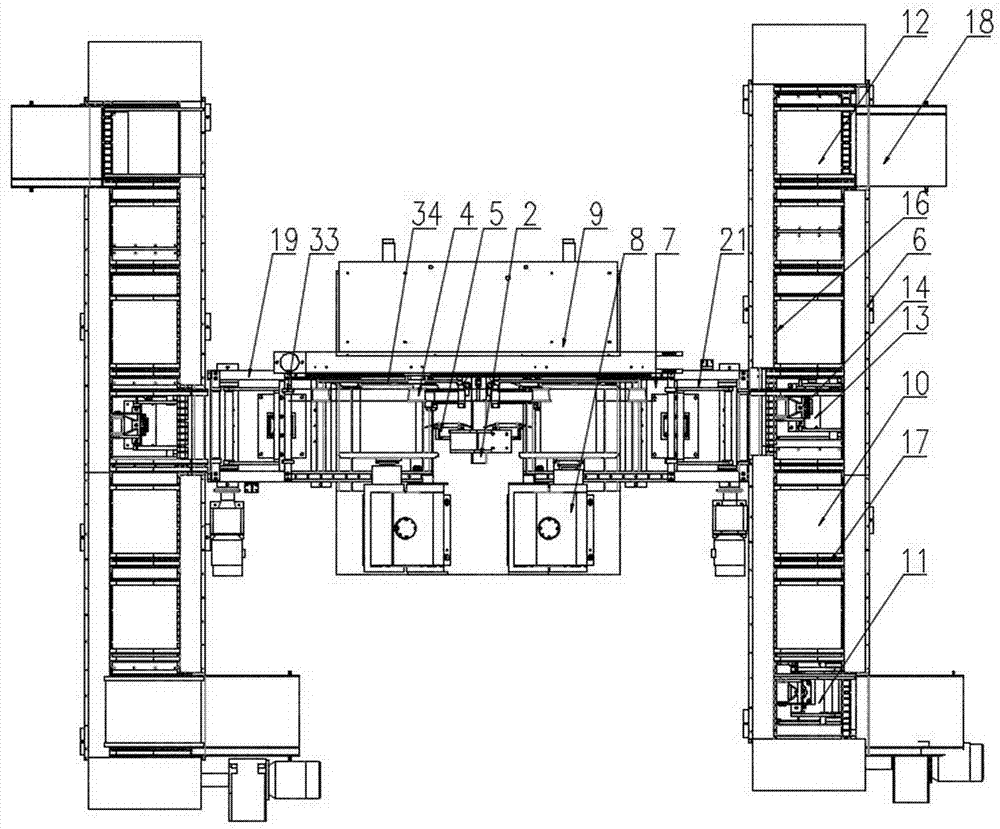

Three-shaft horizontal rotary full-automatic take-up device

PendingCN112693963ARealize automatic take-upImprove take-up efficiencyFilament handlingSynchronous motorWire cutting

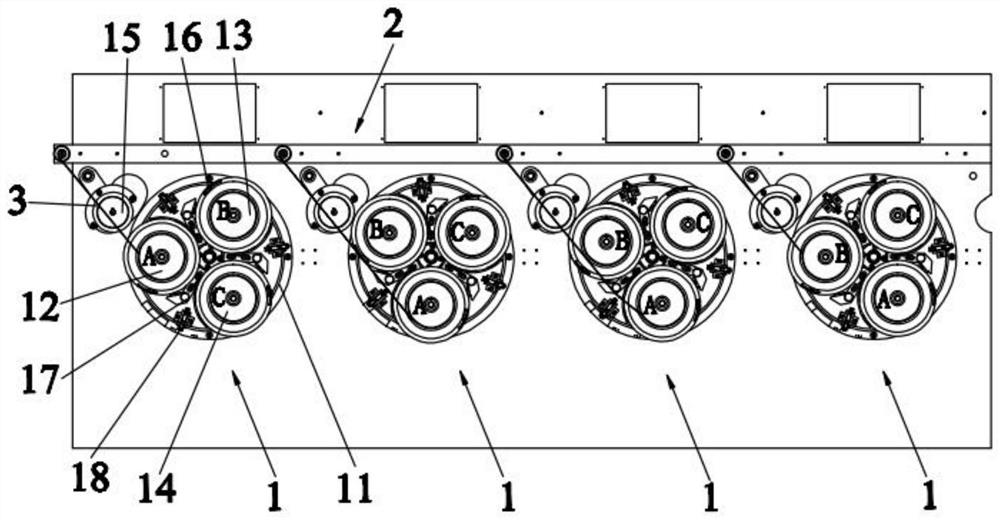

The invention relates to the technical field of take-up equipment, and specifically relates to a three-shaft horizontal rotary full-automatic take-up device comprising at least one reel changing mechanism and wire arranging mechanisms corresponding to the reel changing mechanisms. Each reel changing mechanism comprises a rotary disc, a take-up reel A, a take-up reel B, a take-up reel C and a synchronous motor, and each take-up reel A, the corresponding take-up reel B and the corresponding take-up reel C are arranged on the corresponding rotary disc in a triangular structure. Wire clamping devices are arranged on the circumferential edges of the take-up reels A, the take-up reels B and the take-up reels C correspondingly, a wire cutting mechanism is arranged between every two adjacent take-up reels of each take-up reel A, the corresponding take-up reel B and the corresponding take-up reel C, a wire shifting mechanism is arranged on the edge, corresponding to the corresponding wire cutting mechanism, of each rotary disc, and each synchronous motor is arranged on one side of the corresponding rotary disc. Each wire arranging mechanism is provided with at least one wire arranging wheel, and each wire arranging wheel obliquely corresponds to one rotary disc. The take-up reels A, the take-up reels B and the take-up reels C cooperate with one another, automatic reel changing of automatic take-up is achieved, the take-up efficiency is improved, the structure is simple, and the mass production cost is lower.

Owner:佛山市顺德区盛永机械有限公司

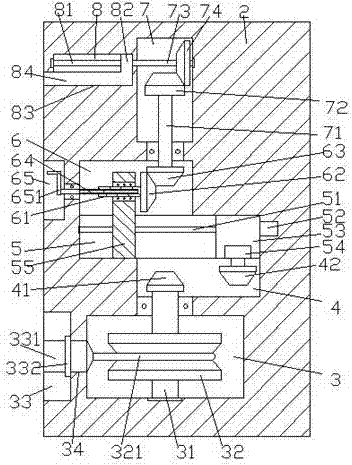

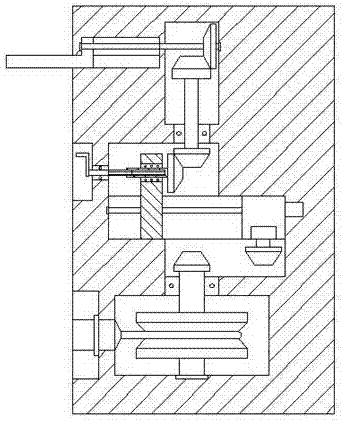

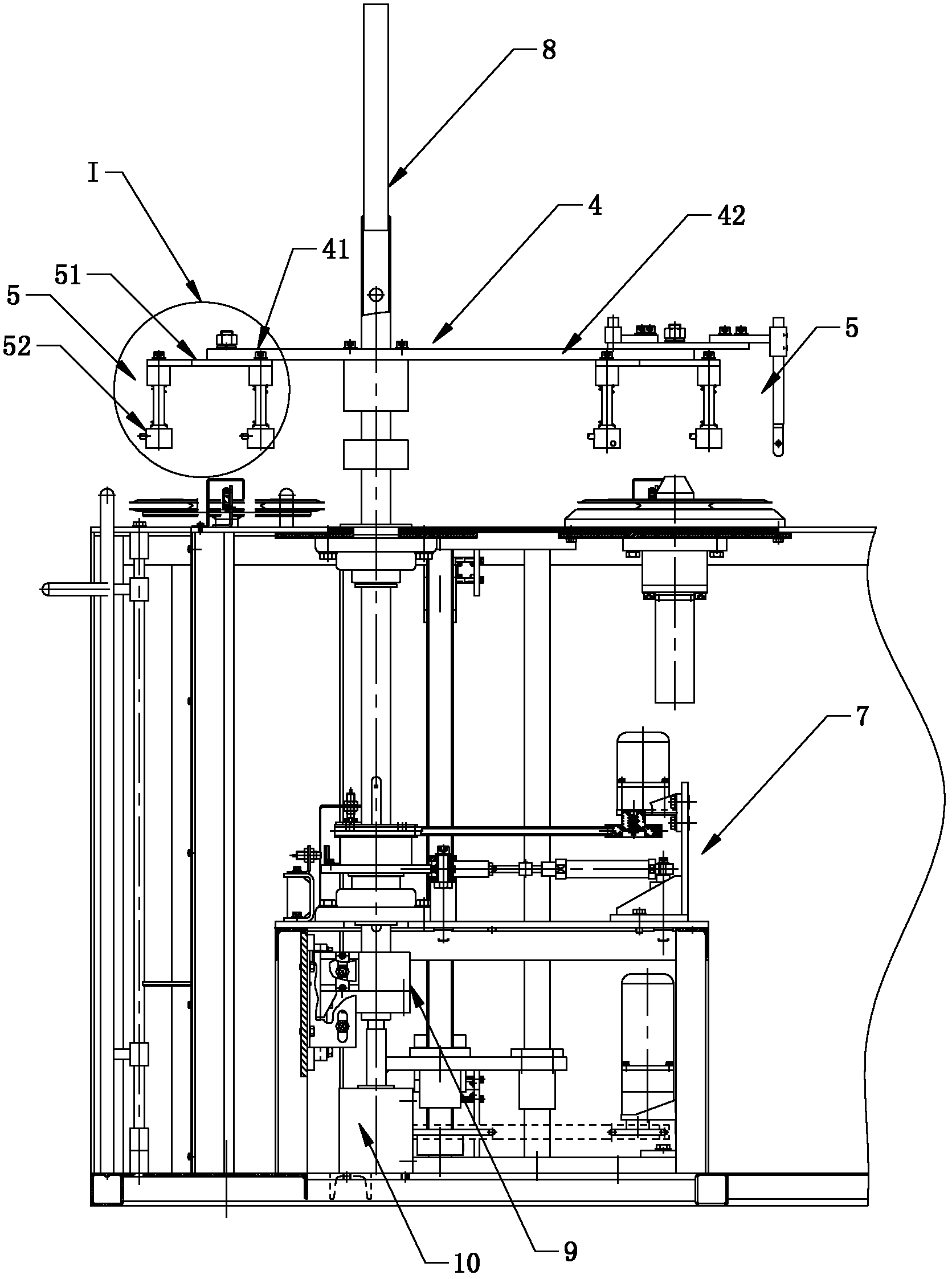

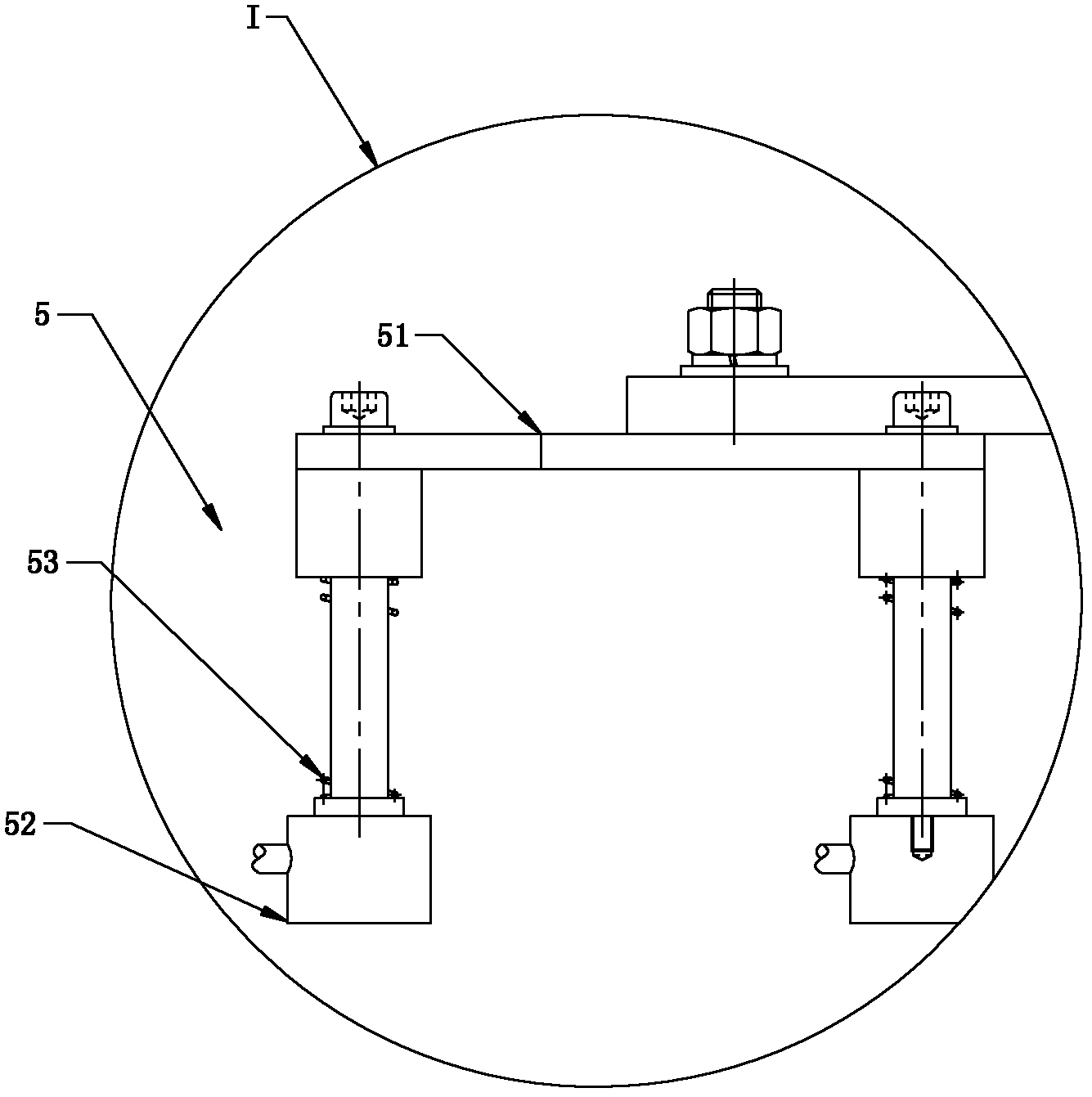

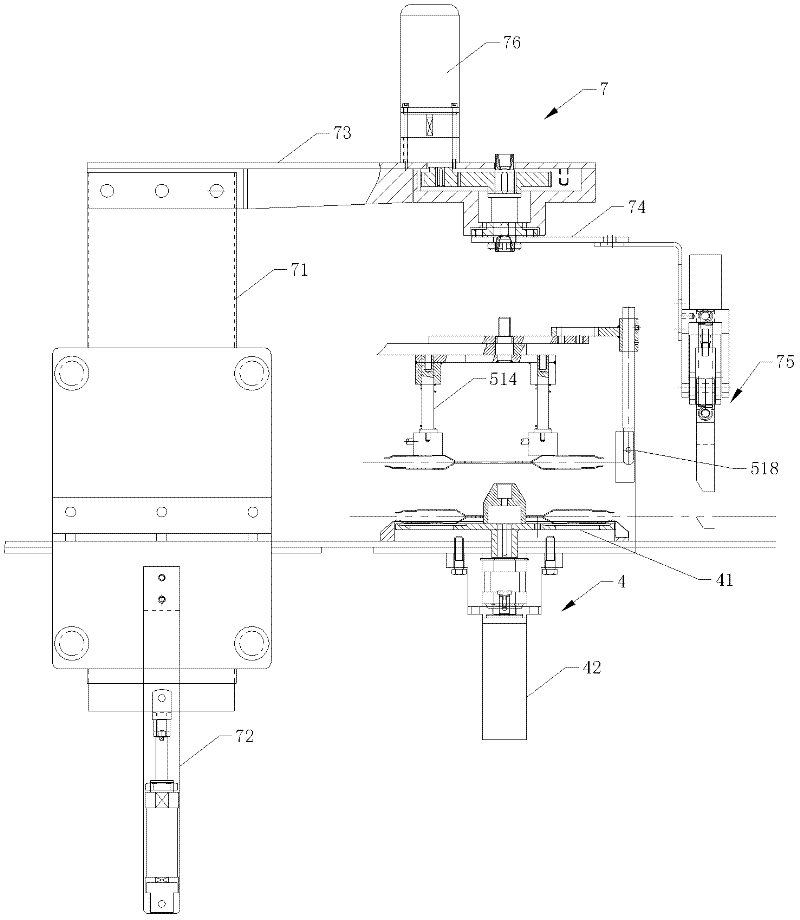

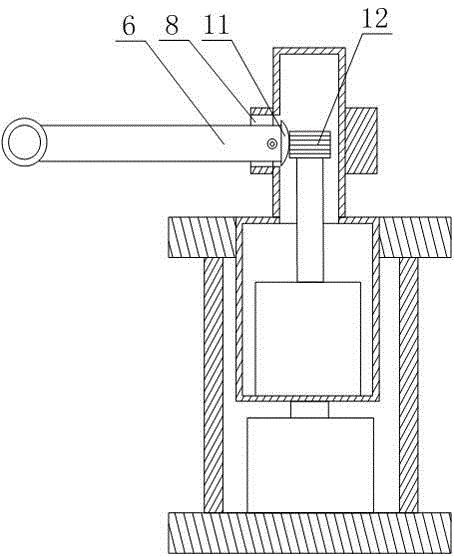

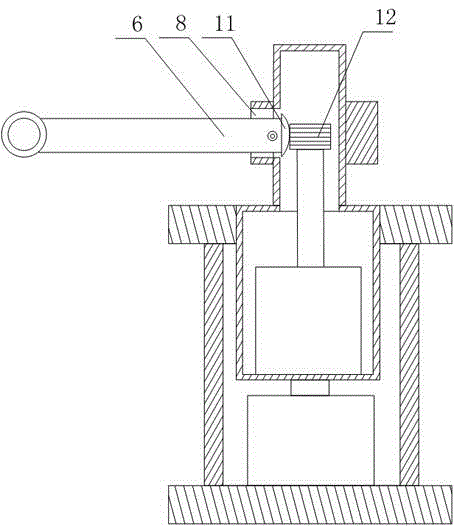

Automatic take-up machine of fishing-net weaving machine shuttle reel

InactiveCN102642744AAvoid the uneven tightness of the winding lineHigh degree of automationFilament handlingIsoetes triquetraEngineering

The invention discloses an automatic take-up machine of a fishing-net weaving machine shuttle reel, which comprises a stander, a lead device and a traction device as well as an empty reel holding station for holding an empty reel, a full reel holding station for holding a full reel and a take-up station for take-up, wherein the empty reel holding station, the full reel holding station and the take-up station are arranged on the stander and are distributed on three peaks of an equilateral triangle, and the take-up station is located on the downstream of the traction device; and the automatic take-up machine also comprises a take-up device, a shuttle reel rotating and replacing device, a cutting-off device for cutting off a fishing-net line on the upstream of the take-up station and a winding device for clamping the end of the cut-off fishing-net line to be wound on the shuttle reel. The automatic take-up machine of the fishing-net weaving machine shuttle reel has high automation degree, the fishing-net line is free from being manually cut and wound, the take-up efficiency can be improved, and the labor can be saved.

Owner:JIANGSU JIANGHAI MASCH CO LTD

Earphone for facilitating wire take-up

The invention discloses an earphone for facilitating wire take-up. The earphone comprises an earphone storage main body, a front roller is movably connected to the front side in the earphone storage main body through a rotating shaft, a rear roller is movably connected to the rear side in the earphone storage main body through the rotating shaft, an earphone wire is twined on an annular side faceof the rotating shaft, an earphone plug is electrically connected to the top of the earphone wire, and an earplug is electrically connected to the bottom of the earphone wire. The earphone provided bythe invention is provided with the earphone storage main body, the rotating shaft, the front roller, the rear roller, the earphone wire, the earphone plug, the earplug, a winding block, a first through hole, a pull rod, a pull head, a locking plate, a first spring, an expansion link, a holding plate and a second spring, by means of the cooperative use of the components, the problem that wire take-up cannot be performed quickly and conveniently after the existing earphone is used, resulting in mutual twining of the earphone wires is solved, the earphone for facilitating wire take-up has the advantages of being fast and convenient to take up the wires, being convenient for a user to quickly take up the wires and improving the wire take-up efficiency.

Owner:郑州率众电子科技有限公司

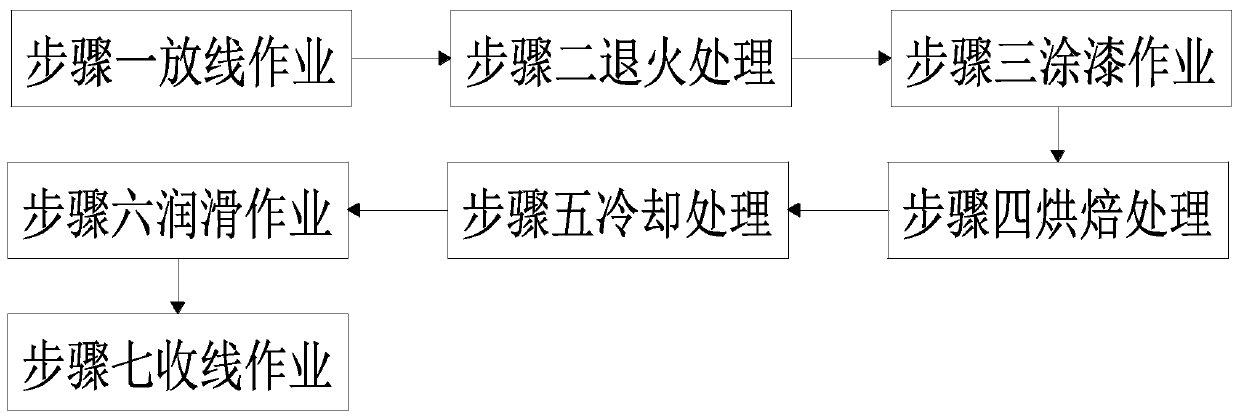

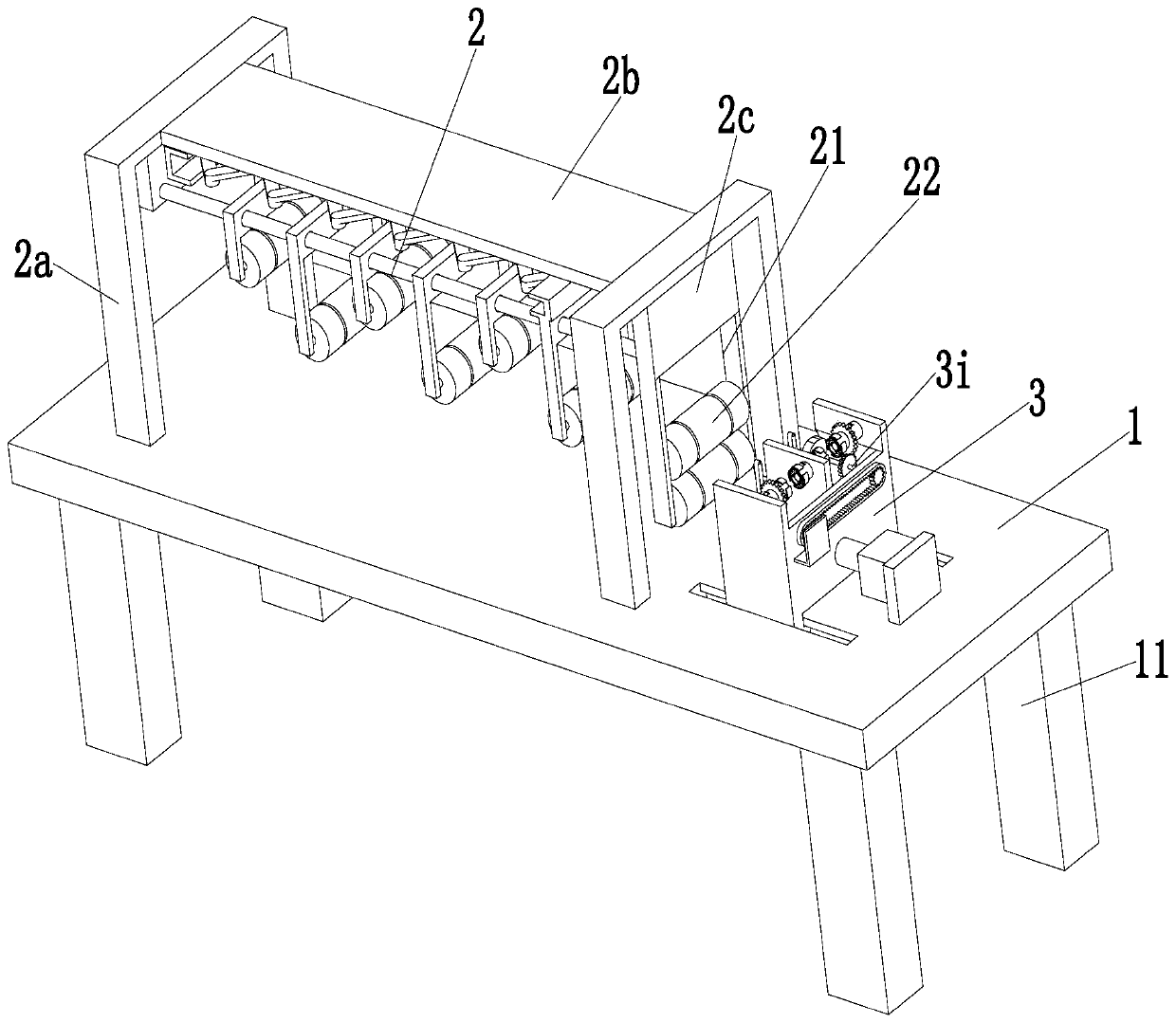

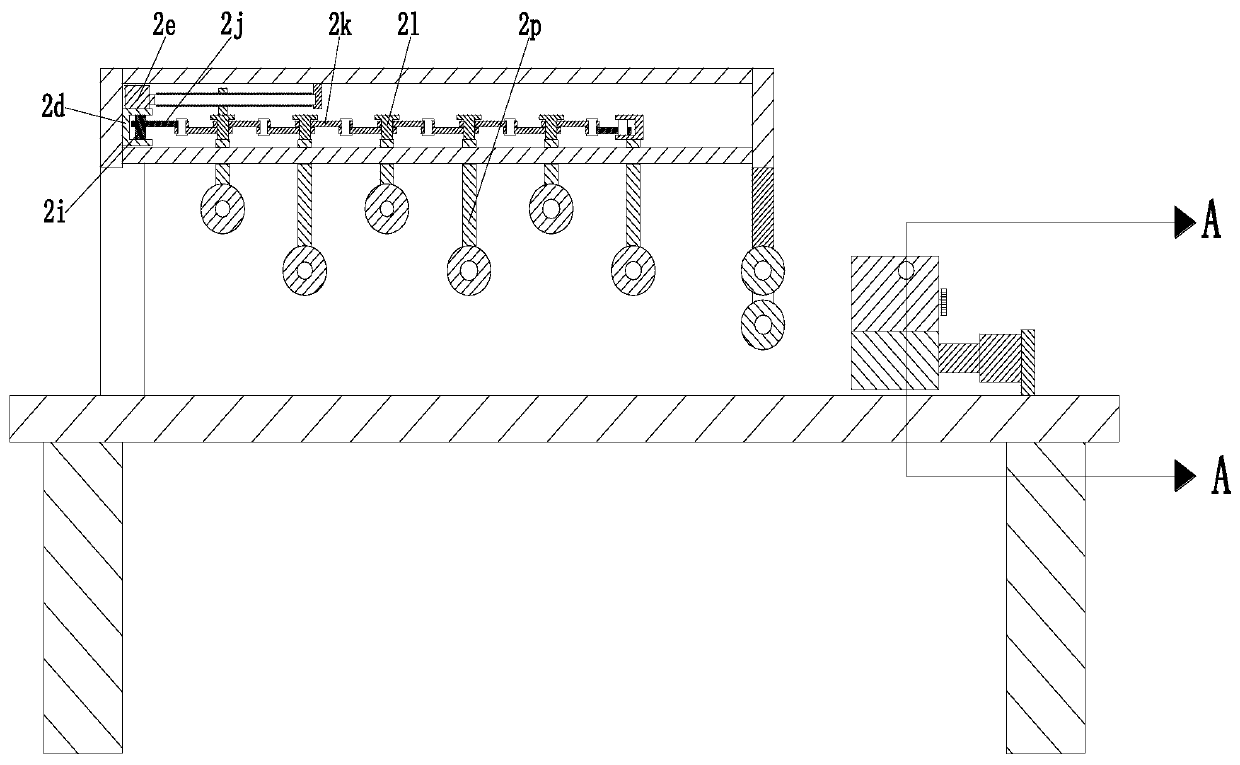

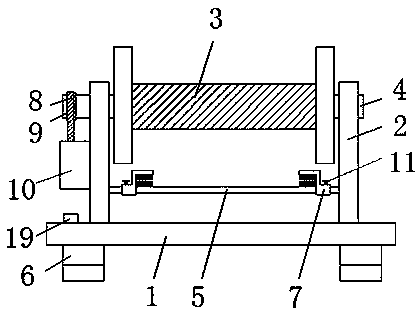

Enameled wire manufacturing and processing process

InactiveCN111403123AEven and stable take-up operationImprove take-up efficiencyFilament handlingInsulating conductors/cablesMachining processMechanical engineering

The invention relates to an enameled wire manufacturing and processing process. The process mainly comprises the following steps: paying-off operation, annealing treatment, painting operation, bakingtreatment, cooling treatment, lubricating operation, take-up operation and the like. The used enameled wire take-up equipment comprises a bottom plate, a stretching device and a take-up device. The provided process can solve the following problems existing in winding of existing enameled wires: a) when a traditional enameled wire winding mechanism is used for winding an enameled wire, several rearcircles of wires are pressed on several front circles of wires, the enameled wires collapse suddenly when reaching a certain height to make the rear circle of wires pressed under the front circle ofwires, so that use is affected, wire winding operation needs to be conducted again frequently, and time and labor are wasted; and b) when the traditional enameled wires are wound, the first batch of wires and the second batch of wires are often arranged in a crossed shape, gaps of the enameled wires on a wire disc are large, the wire capacity of the wire disc is reduced, and the enameled wires aredisordered in appearance.

Owner:盛珊瑜

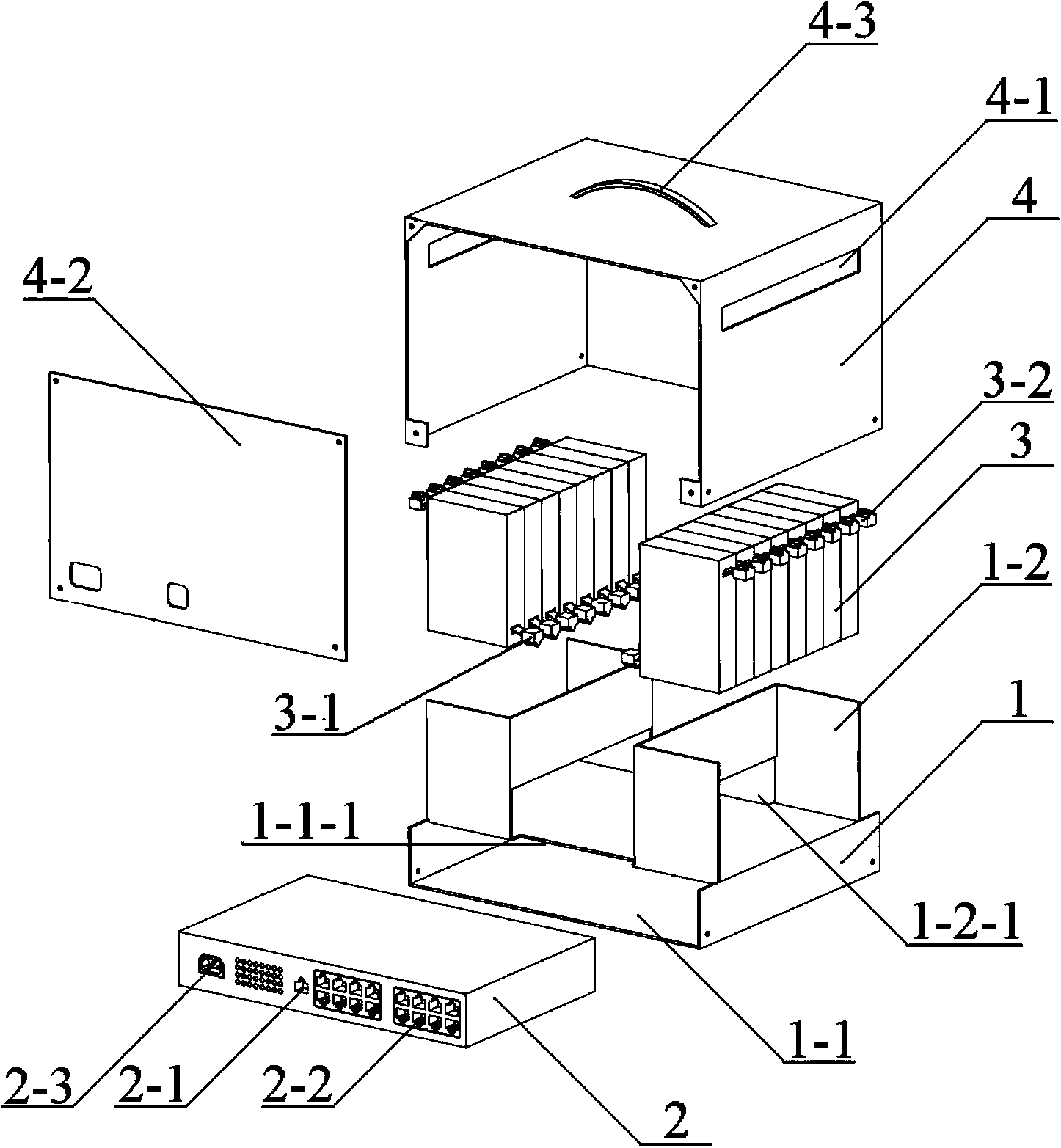

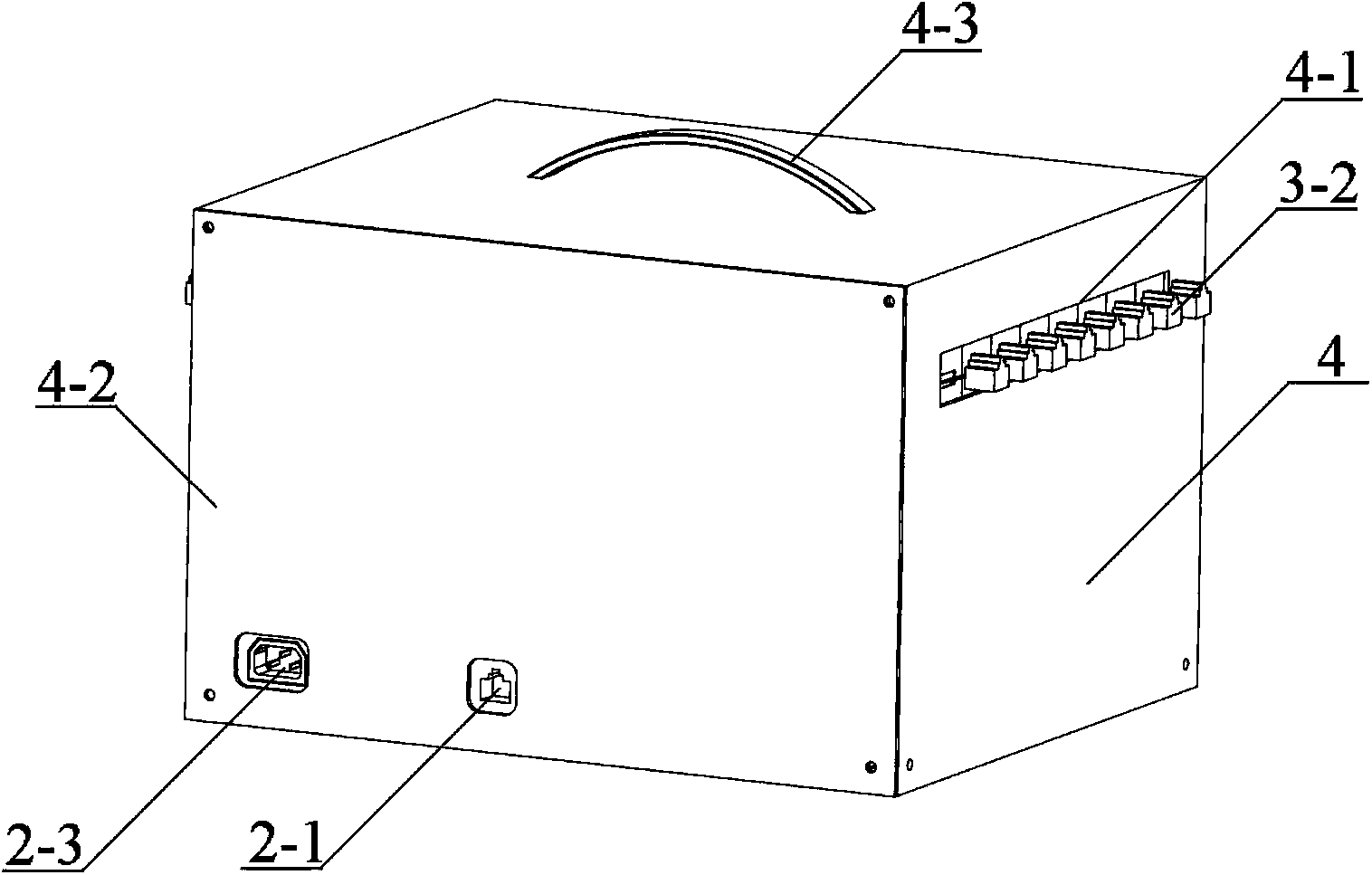

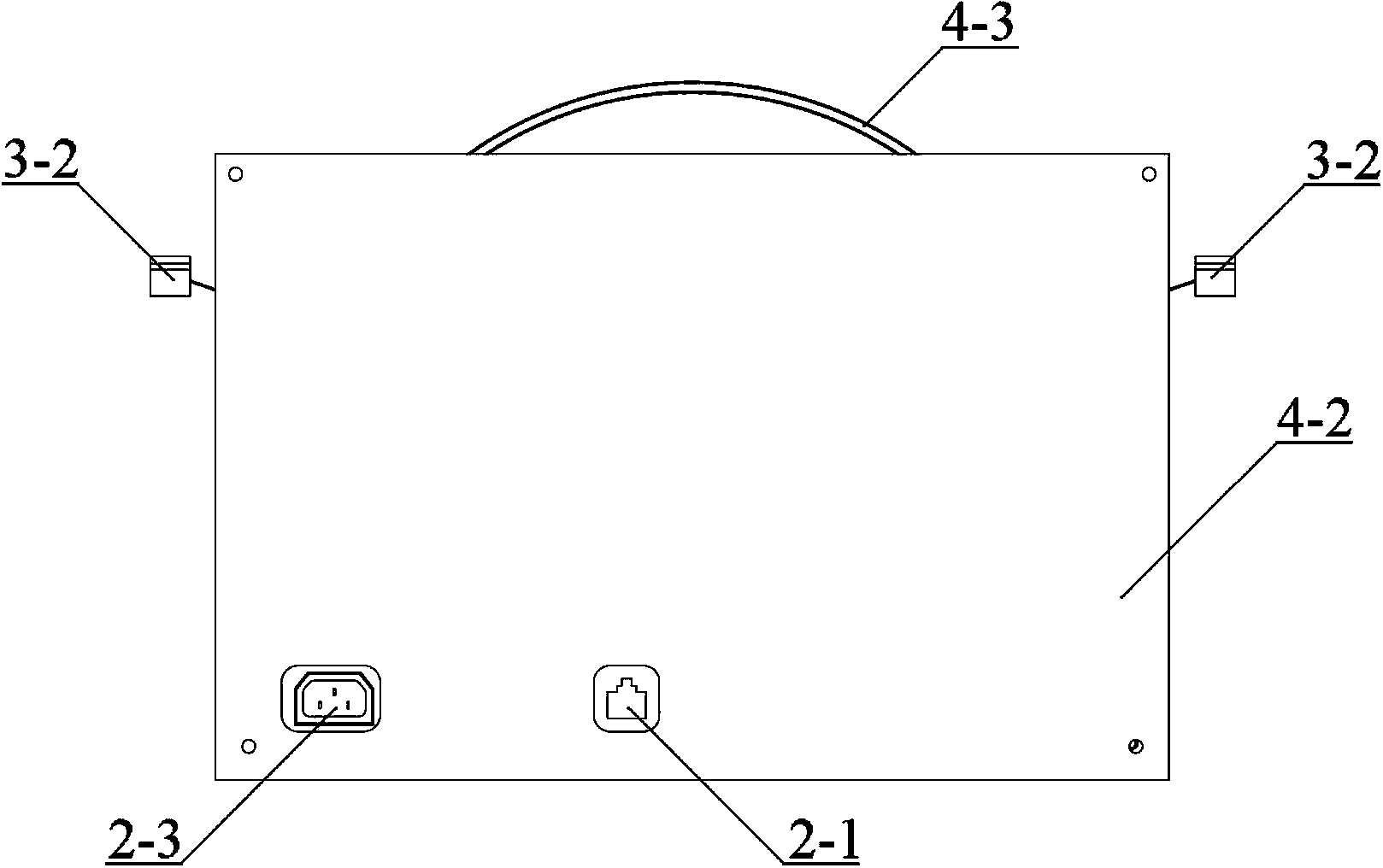

Portable network cabling box

ActiveCN103457811ARealize free expansionAchieve lockingData switching detailsData switching by path configurationLocking mechanismNetwork output

The invention relates to a portable network cabling box which comprises a base, a switchboard, a cable box and a box body. The switchboard is fixedly installed on the base through a switchboard installing groove in the base and provided with a network input interface, a network output interface and a power interface. The cable box is fixedly installed on the base through the cable box arranged on an upper cover plate on the switchboard installing groove. A network cable retraction mechanism and a network cable locking mechanism are arranged inside the cable box, a network cable is evenly wound on the network cable retraction mechanism, an input crystal head at one end of the network cable penetrates a groove of rear cover plate on the cable box installing groove and a groove of the upper cover plate on the cable box installing groove to be connected with the network output interface, and an output crystal head at the other end of the network cable penetrates a cable box output and then extends out of windows arranged on the two side walls. The problems of low working efficiency and nonstandard cabling during temporary local area network building are solved, and the portable network cabling box is convenient to carry and simple in use.

Owner:STATE GRID CORP OF CHINA +2

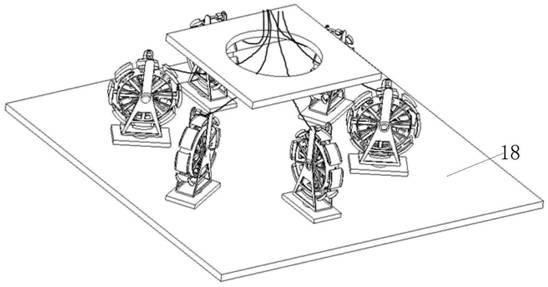

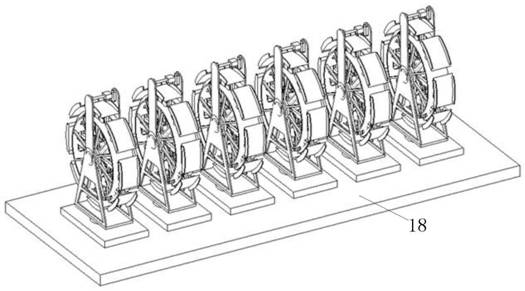

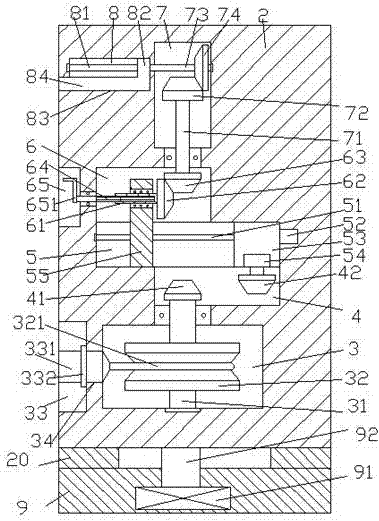

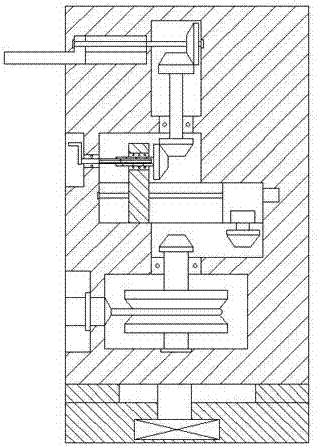

Pipeline take-up and payoff device and system with adjustable winding space

The invention provides a pipeline take-up and payoff device and system with adjustable winding space. The device comprises a support, a winding space adjusting mechanism, an automatic line moving mechanism, a pipeline automatic take-up and payoff mechanism and an operation and control system, the winding space adjusting mechanism can adjust the winding radius and can rotate around the support, andthe device and system have the beneficial effects that through the winding space adjusting mechanism capable of adjusting the winding radius, storage needs of different scales of pipelines can be met, the function of automatic winding displacement and automatic pipeline take-up and payoff can be achieved, space and manpower are saved, modular and expandability characteristics are achieved, fine managing of pipelines in equipment can be achieved, and equipment automation and the intelligent level can be improved.

Owner:BEIJING INST OF RADIO MEASUREMENT

Novel bridge equipment

InactiveCN107161811AReduce electricity wasteImprove take-up efficiency and stabilityInternal rotationEngineering

The invention discloses a new type of bridge equipment, which comprises a machine body. A slide groove is arranged at the center of the inside of the machine body. A first empty groove is arranged in the body above the left side of the slide groove, and a second empty groove is arranged in the body below the right side of the slide groove. slot, the body at the bottom of the second empty slot is provided with an accommodating slot, the upper right side of the first empty slot is provided with a force transmission cavity, the sliding slot is provided with a first screw rod, and the right end of the first screw rod is connected with the first driving machine Connection, the helical thread on the first screw rod is connected with an upwardly extending vertical rod and a sliding block arranged on the right side of the vertical rod, the upward extending section of the vertical rod extends into the first empty slot and the internal rotation is connected with an internal spline shaft , the right side end of the inner spline shaft is fixed with a first gear, the inner spline shaft is fitted with an outer spline shaft, and the upper right side of the first gear is meshed with a second gear; the present invention is simple in structure and easy to operate. It can realize automatic wire take-up work and has its own rainproof function, which improves work efficiency, reduces waste of mains electricity, and has low use cost, which is suitable for popularization and use.

Owner:浦江县速达进出口有限公司

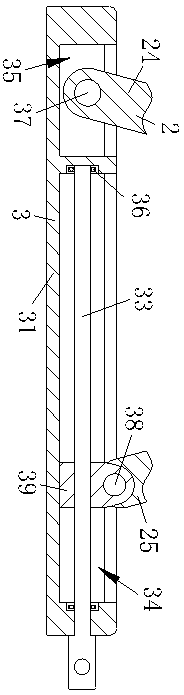

Lifting wire speed detection device based on DSP

PendingCN110713116AEasy to fixEasy to disassembleBase supporting structuresBraking devices for hoisting equipmentsControl theoryMechanical engineering

The invention relates to the field of speed detection devices, in particular to a lifting wire speed detection device based on a DSP. The lifting wire speed detection device comprises I-shaped steel,a supporting mechanism, a fixing mechanism, a control mechanism, a detection mechanism, an adjusting mechanism and a fastening mechanism. Due to installation of the supporting mechanism, the I-shapedsteel can be conveniently fixed and supported; under the effect of the fastening mechanism, the I-shaped steel and the supporting mechanism can be more stable; due to fixing of the fixing mechanism onthe supporting mechanism, the supporting mechanism can conduct height adjustment, meanwhile, moving and carrying are facilitated, and therefore the application range of the supporting mechanism is wider; under the effect of the control mechanism, the detection mechanism is driven, and therefore detection work is completed; and under the adjustment of the adjusting mechanism, the control mechanismis used more flexibly and conveniently, and the detection precision value and multi-adaptive detection are greatly improved.

Owner:江西中船航海仪器有限公司

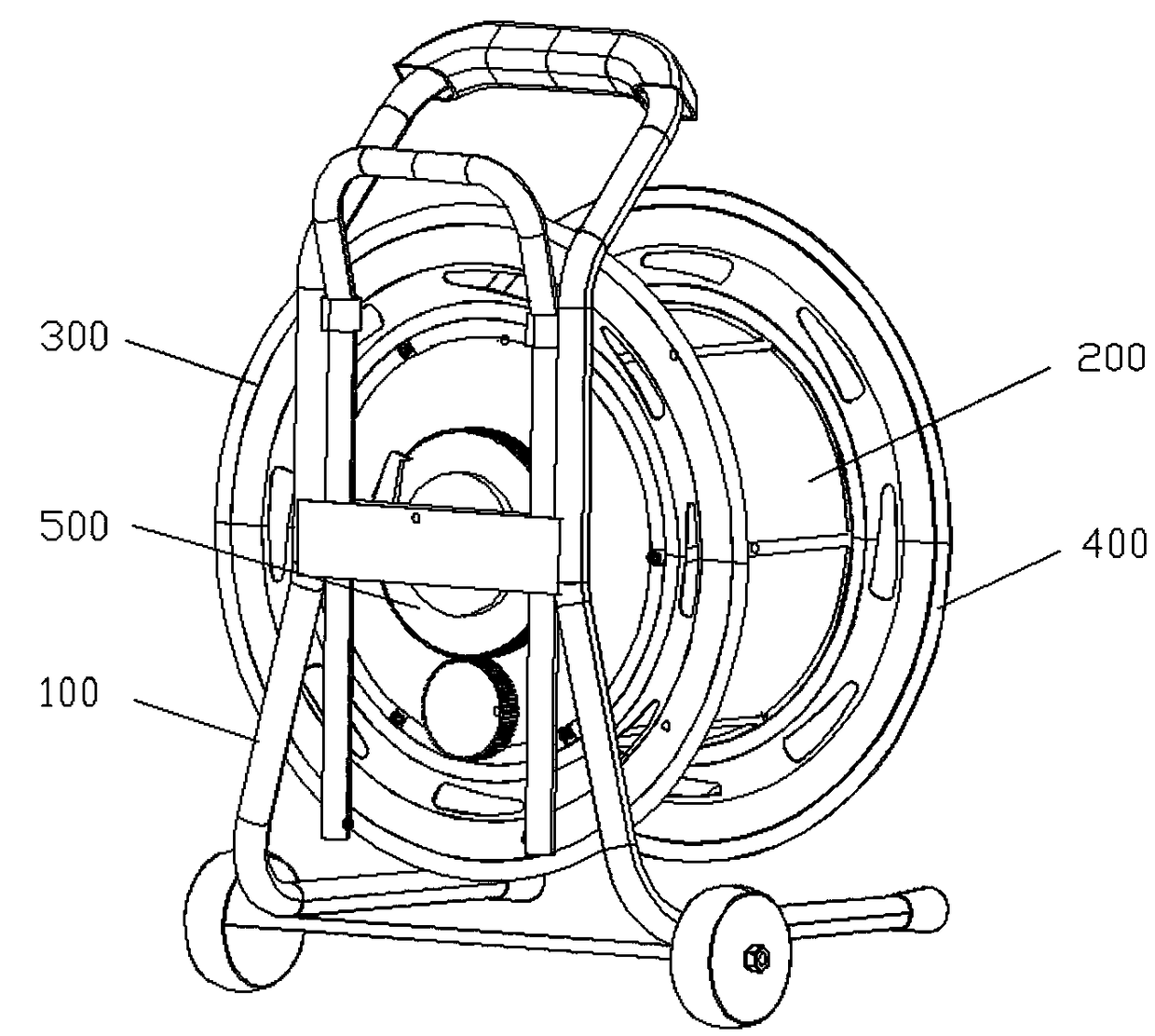

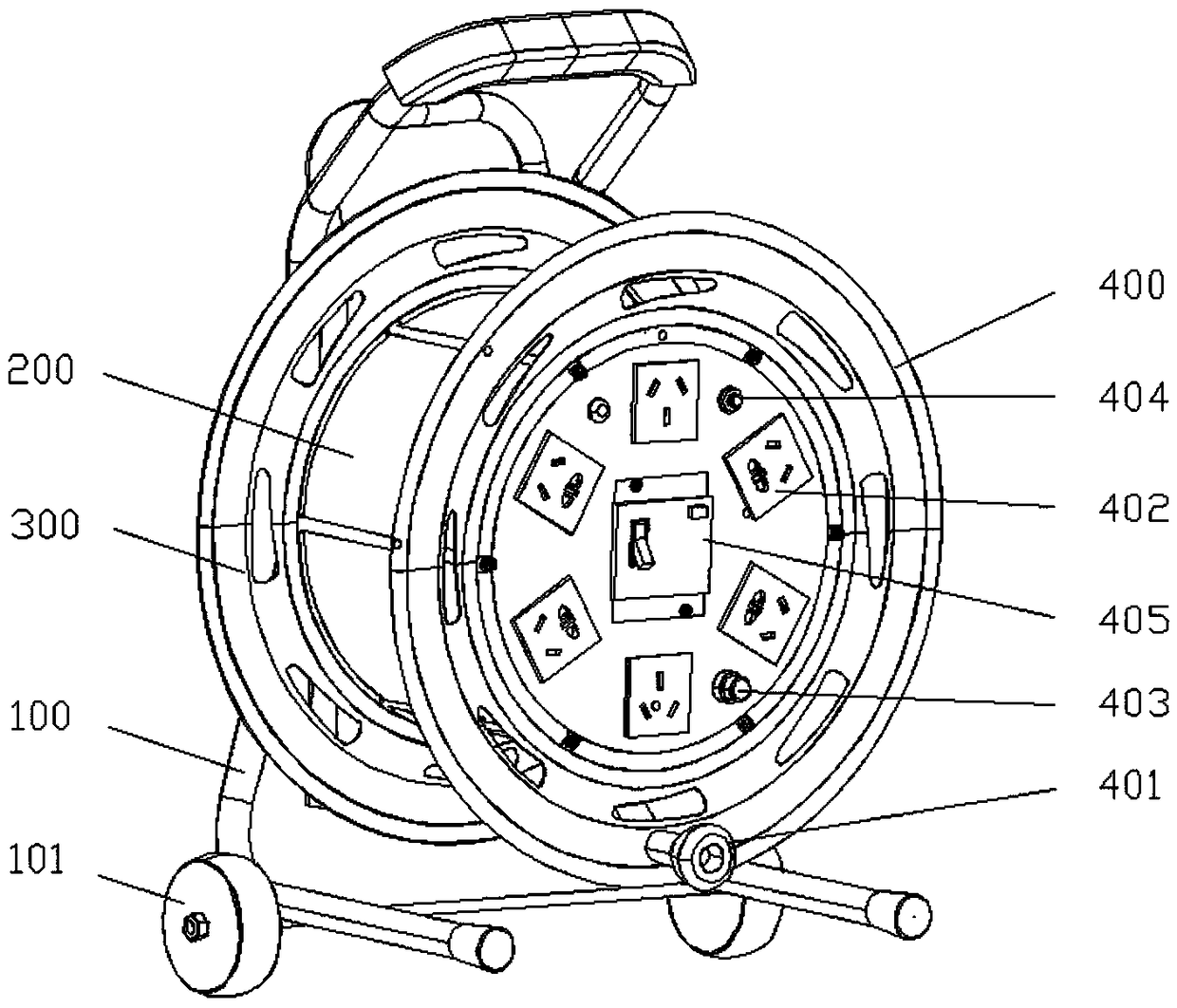

Multi-plug automatic winding displacement digital display power disc

ActiveCN104362473AMonitor voltage status in real timeReduce the risk of low voltage electric shockFlexible lead accommodationLow voltageVoltmeter

The invention discloses a multi-plug automatic winding displacement digital display power disc which comprises a rack body. The rack body is provided with an automatic winding displacement device, multifunctional pluggable type plugs, a digital display voltmeter, overheat protectors and a leakage protector. The automatic winding displacement device comprises a fixing shaft, a power disc body, two chain wheels, a chain, a reciprocating lead screw and a nut. The overheat protectors are all arranged in the power disc body. The multifunctional pluggable type plugs, the digital display voltmeter and the leakage protector are all arranged on the power disc body. The power disc body is arranged on the fixing shaft in a sleeving mode. The fixing shaft is sleeved with the first chain wheel, the second chain wheel is arranged at the end of the reciprocating lead screw, and the two chain wheels are in transmission through the chain. The reciprocating lead screw is sleeved with the nut, a cable guide mechanism is arranged below the nut, and the cable penetrates through the cable guide mechanism and then is wound on the power disc body. The multi-plug automatic winding displacement digital display power disc has the advantages of being capable of improving the take-up and pay-off efficiency of the power disc body, safe to use, high in reliability, capable of lowering the low voltage electric shock risks of workers and the like.

Owner:STATE GRID CORP OF CHINA +2

LED lamp

ActiveCN106895375AReduce electricity wasteImprove take-up efficiency and stabilityGas-tight/water-tight arrangementsLight fasteningsGyrationAgricultural engineering

The invention discloses an LED lamp which comprises a shell, wherein a sliding chute is formed in the middle part in the shell; a first trough body is arranged at a position, which is located above the left side of the sliding chute, in the shell; a second trough body is arranged at a position, which is located below the right side of the sliding chute, in the shell; an accommodating cavity is formed in a position, which is located at the bottom of the second trough body, in the shell; a transmission cavity is formed above the right side of the first trough body; a first spiral rod is arranged in the sliding chute; the right side end of the first spiral rod is connected with a first motor; the first spiral rod is in threaded fit with an upwards extending vertical column and a sliding block arranged on the right side of the vertical column; the upwards extending section of the vertical column penetrates into the first trough body, and is internally connected with an internal spline shaft in a gyration cooperation manner; a first tooth-shaped wheel is fixedly arranged at the right side end of the internal spline shaft; the internal spline shaft is internally connected with an external spline shaft in a cooperation manner; and a second tooth-shaped wheel is connected above the right side of the first tooth-shaped wheel in a hinged manner. The LED lamp is simple in structure and convenient to operate, can realize automatic take-up work, has a rain prevention function, can reduce waste of mains supply and improve the construction efficiency, is relatively low in use cost, and is suitable for being popularized and used.

Owner:盐城明钰科技有限公司

Automatic electric wire winding plate

The invention provides an automatic electric wire winding plate, and relates to the technical field of electric wire plates. The automatic electric wire winding plate comprises a support, a wire winding roller, a first baffle plate and an automatic wire winding assembly, wherein the wire winding roller is connected onto the support; the first baffle plate is connected to the inner side end of thewire winding roller; one end of the automatic wire winding assembly is connected onto the support; the other end of the automatic wire winding assembly is connected onto the first baffle plate; and the automatic wire winding assembly can drive the first baffle plate to rotate so as to enable the first baffle plate to drive the wire winding roller to automatically wind a wire. The technical problems that in the prior art, a movable electric wire plate adopts a manual wire winding manner, so that the physical power of operating personnel is wasted, the wire winding efficiency is low, and the wire is winded disorderly are solved. According to the automatic electric wire winding plate provided by the invention, the automatic wire winding assembly is connected between the first baffle plate andthe wire winding roller and is utilized for driving the first baffle plate to move, so that the wire winding roller is driven to wind the wire automatically, the wire winding efficiency is high, andthe wire is winded in order.

Owner:GUANGDONG POWER GRID CO LTD +1

Three-direction-adjustable wire distributing and winding device

Owner:WUXI XINHONGYE WIRE & CABLE

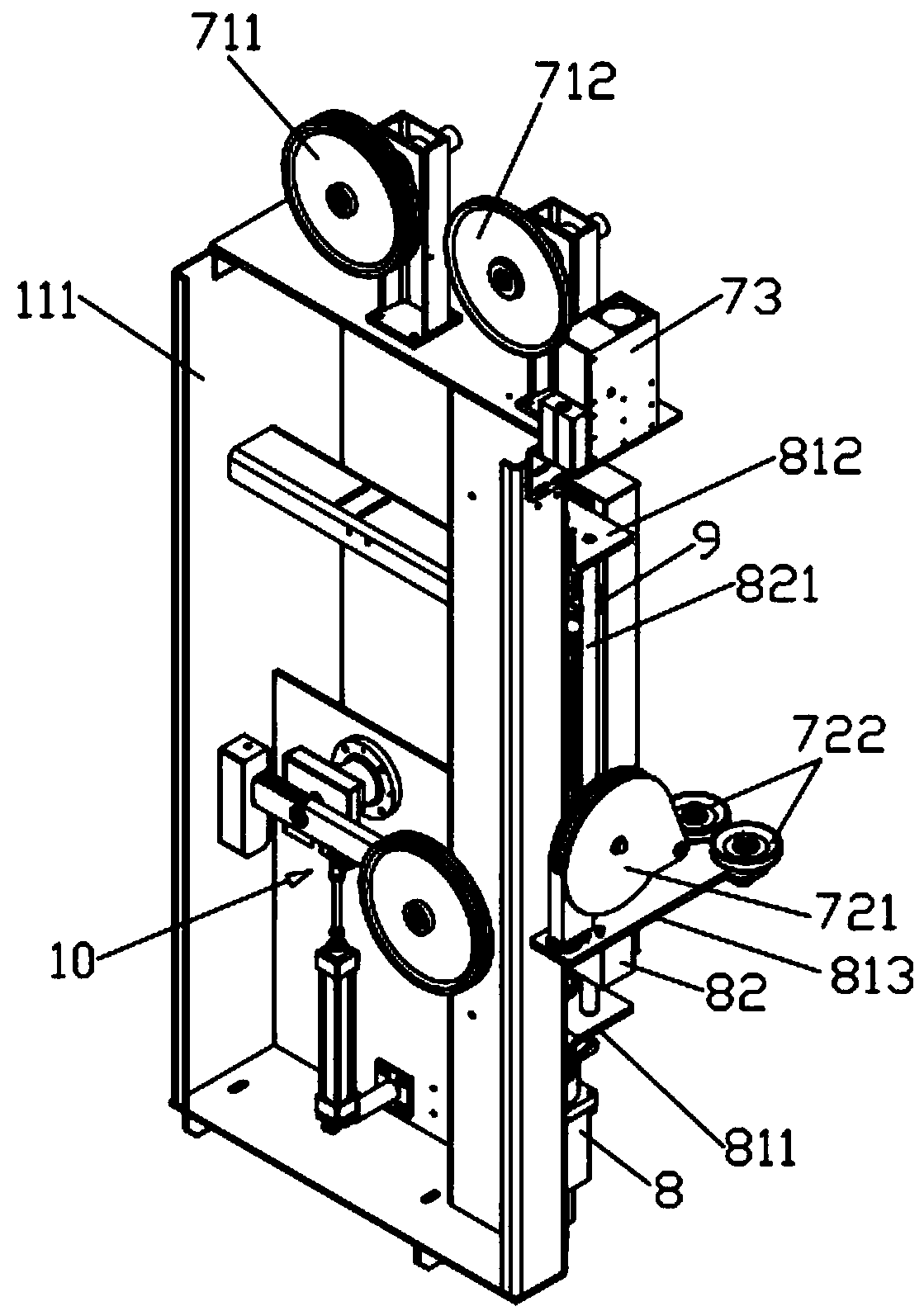

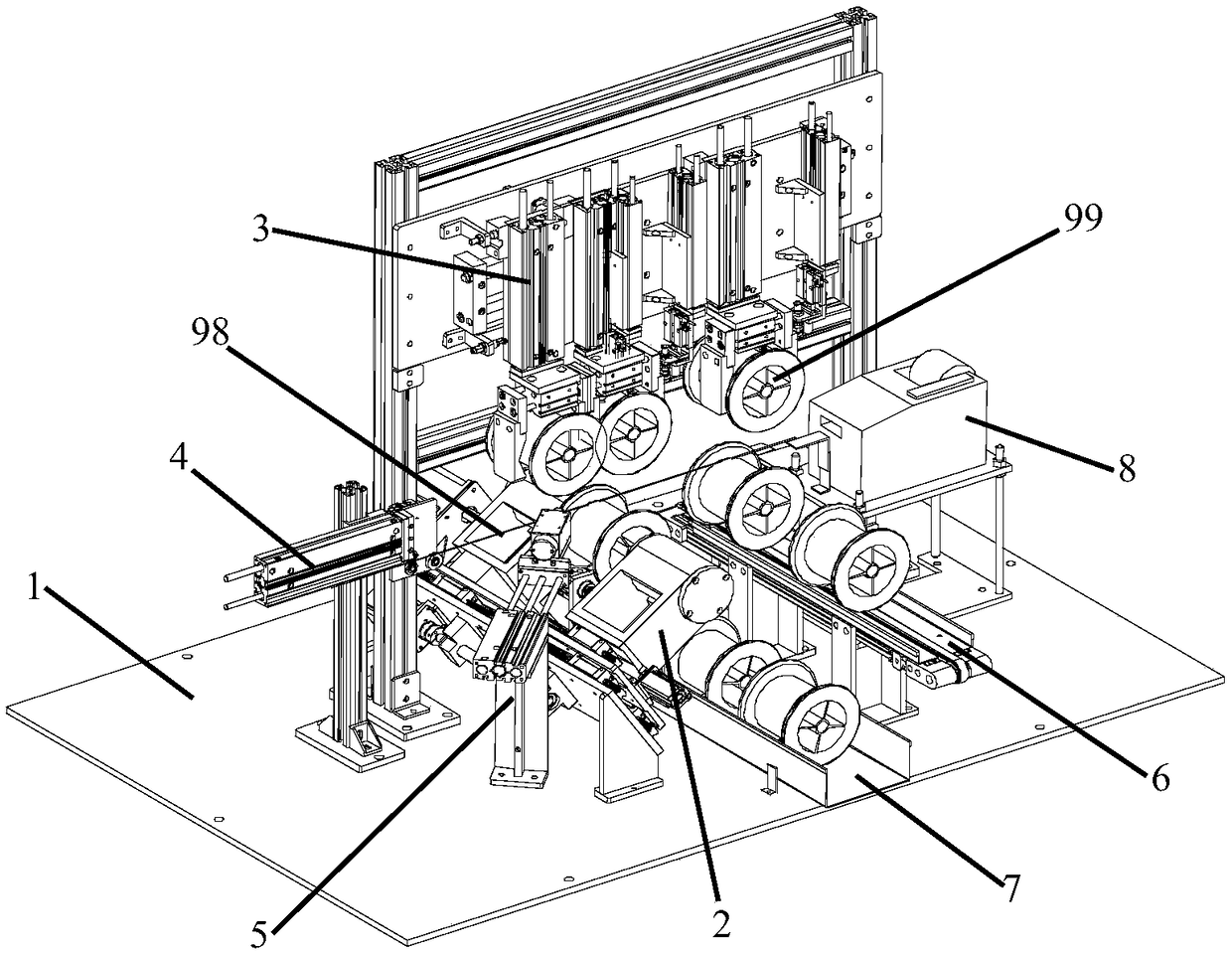

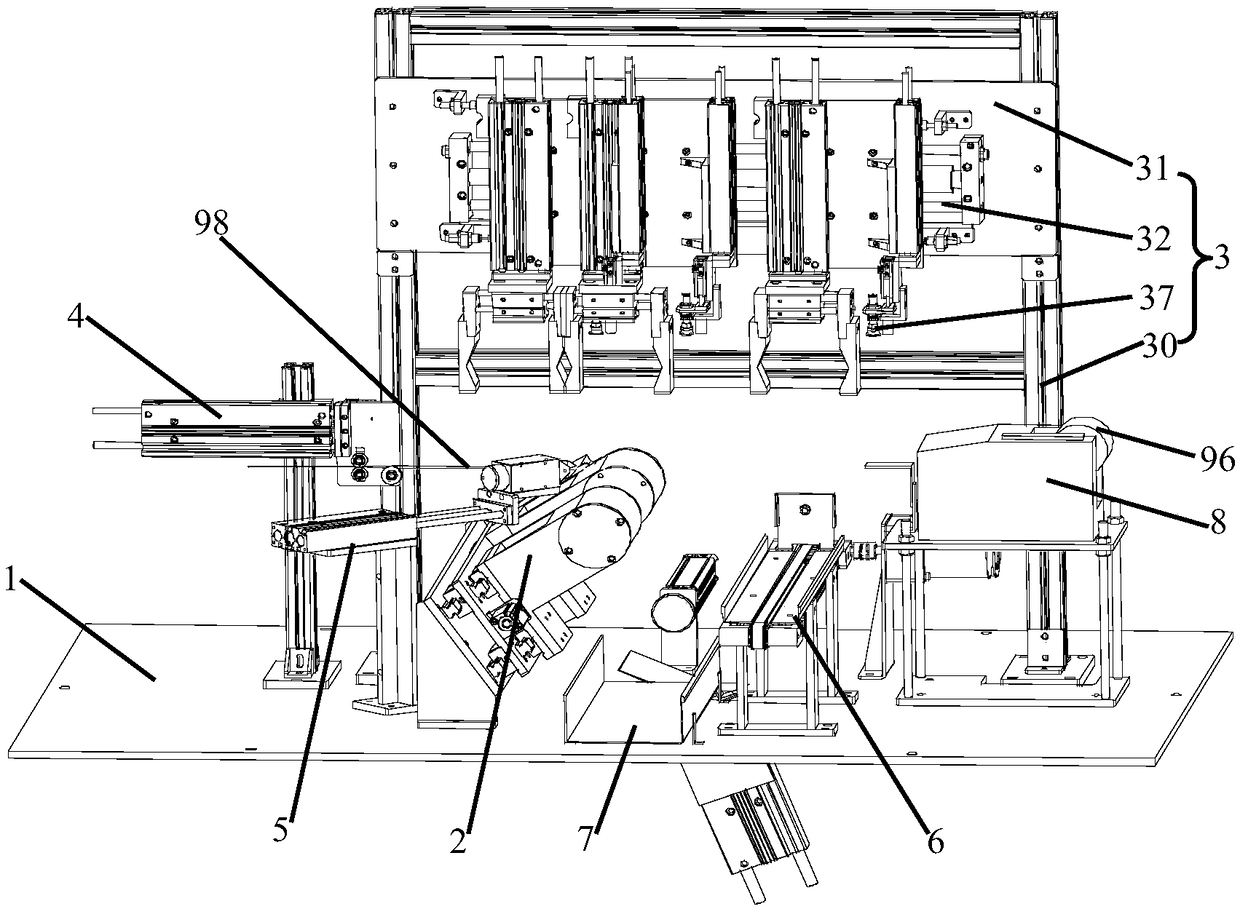

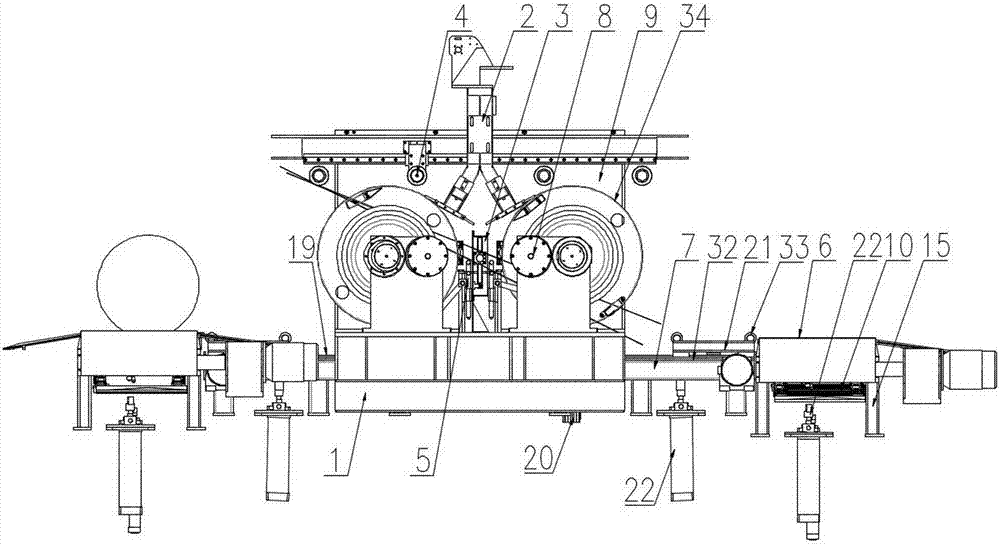

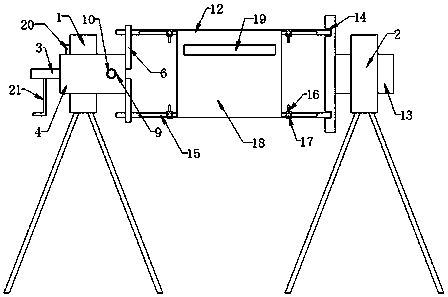

Full-automatic dual-coil continuous take-up machine

PendingCN107377671AImprove continuityImprove take-up efficiencyMechanical engineeringFully automated

The invention discloses a full-automatic dual-coil continuous take-up machine, which comprises a rack. The rack is equipped with wire coil automatic puller devices, an automatic wire arrangement device, an automatic wire catching device, an automatic wire dragging device and a cutting device. There are two wire coil automatic puller devices, which are symmetrically arranged on the rack. The automatic wire arrangement device and the automatic wire dragging device are both arranged above the rack. The automatic wire catching device is arranged at the central section between the two wire coil automatic puller devices. The cutting device is arranged at the lower part between the two wire coil automatic puller devices. Two sides of the rack are provided with two symmetrical automatic coil transport devices and two symmetrical automatic coil swapping devices. The automatic coil swapping devices are arranged between the wire coil automatic puller devices and the automatic coil transport devices. Without shutdown, automatic coil transport and swapping and continuous take-up can be realized, and the purpose of raising take-up efficiency is achieved.

Owner:伊东新(德阳)线缆设备有限公司

Central tube type ADSS (All-Dielectric Self-Supporting) optical fiber cable take-up machine

The invention discloses a central tube type ADSS (All-Dielectric Self-Supporting) optical fiber cable take-up machine which comprises a cable tray and a motor, wherein the output end of the motor is connected with a positioning cylinder, the positioning cylinder is internally provided with an air cylinder, the upper end surface of the positioning cylinder is fixedly connected with a rotating cylinder communicated with the interior of the positioning cylinder, and the output end of the air cylinder is provided with multiple annular teeth; one end of a guide rod is provided with fan-shaped teeth matched with the annular teeth, the guide rod is internally provided with a cavity, and the tail end of the top rod is connected with the inner wall of the cavity by virtue of a spring; the inner wall, which is close to one side of a guide ring, of the cavity is provided with an annular bulge, and the movable end of the top rod is fixedly provided with a limiting block which is matched with the annular bulge; the guide ring can limit an optical fiber cable, the optical fiber cable is prevented from bouncing during a moving process; meanwhile, by virtue of the up-and-down movement of the guide rod, the swing range of the optical fiber cable can be buffered, after the optical fiber cable enters into the cable tray, a relatively stable state of the cable tray is ensured, distribution of each layer of the optical fiber cable on the cable tray is more uniform, and the two adjacent loops of optical fiber cable can be closely attached together.

Owner:成都亨通光通信有限公司

Cable winding and unwinding device

The invention discloses a cable winding and unwinding device. The device comprises a left base and a right base, wherein a rotating disc is arranged on the left base in a rotating mode, and the rotating disc is connected with sliding blocks which are arranged in a sliding mode through an Archimedes spiral groove; the rotating disc is further connected with an adjusting gear through a transmissiongear; and supporting rods are arranged on the sliding blocks. According to the cable winding and unwinding device, the rotating disc is driven to rotate through rotation of the adjusting gear, and then the sliding blocks are driven to move, so that the size of a wire cylinder formed by the supporting rods is changed, a set of equipment can meet the unwinding requirements of multiple coils, time for replacing the wire cylinder and the quantity of equipment needing to be carried are reduced, and working efficiency is improved.

Owner:浙江品创知识产权服务有限公司

Optical cable take-up machine with anti-jumping function

The invention discloses an optical cable take-up machine with an anti-jumping function. The optical cable take-up machine with the anti-jumping function comprises a cable reel and a motor, wherein the output end of the motor is connected with a positioning drum, the upper end of the positioning drum penetrates through the upper end surface of the cable reel, an air cylinder is installed in the positioning drum, a rotary drum communicated with the internal portion of the positioning drum is fixedly arranged on the upper end surface of the positioning drum, a rectangular notch is formed in the side wall of the rotary drum, a guide rod is hinged in the notch, a plurality of annular teeth are arranged on the output end of the air cylinder, sector-shaped teeth matched with the annular teeth are arranged at one end of the guide rod, and a guide ring is installed at the other end of the guide rod. by limiting an optical cable through the guide ring, the optical cable can be prevented from jumping during movement, the upward and downward movement of the guide rod can buffer the oscillating amplitude of the optical cable, the optical cable is guaranteed to be kept in a relatively stable state after the optical cable enters the cable reel, the optical cable at each layer on the cable reel is enabled to be more uniformly distributed, two adjacent turns of optical cable can be closely fit together, the space on the cable reel is effectively utilized and the take-up efficiency of the optical cable is improved.

Owner:成都亨通光通信有限公司

Cotton yarn take-up device

InactiveCN108529326APrevent the phenomenon of winding disorderImprove take-up efficiencyFilament handlingYarnEngineering

The invention discloses a cotton yarn take-up device which comprises a take-up base and a take-up roll. Two support arms are fixedly welded on the upper side of the take-up base and are perpendicularto the take-up base, the take-up roll is arranged on the support arms via a rotary shaft and is parallel to the take-up base, a motor is fixedly arranged on a side of the corresponding support arm, agear is welded at an end of the rotary shaft, the motor is connected with the gear by a chain, a take-up slide bar is fixedly arranged between the lower sides of the support arms, restraint blocks sleeve the take-up slide bar and comprise restraint seats and restraint arms, two auxiliary take-up rods are fixedly arranged on a side of each restraint arm, and upper restraint auxiliary rolls and lower restraint auxiliary rolls are movably mounted on the auxiliary take-up rods. The cotton yarn take-up device has the advantages that cotton yarns can be restrained by the restraint blocks, accordingly, cotton yarn take-up chaotic phenomena can be prevented, and the cotton yarn take-up efficiency can be improved.

Owner:响水县嘉亿纺织有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com