Oil-coating conductive wire support for enameled wires

A wire support and enameled wire technology, which is applied in the field of wire take-up machines, can solve the problems of enameled wires being easily broken, uneven enameled wires, and increased tension of enameled wires, and achieve the effects of preventing wire breakage, improving wire take-up efficiency, and ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the embodiments shown in the drawings, but it should be noted that these embodiments are not a limitation of the present invention, and those of ordinary skill in the art make functional, method, or structural improvements based on these embodiments. Equivalent changes or substitutions fall within the protection scope of the present invention.

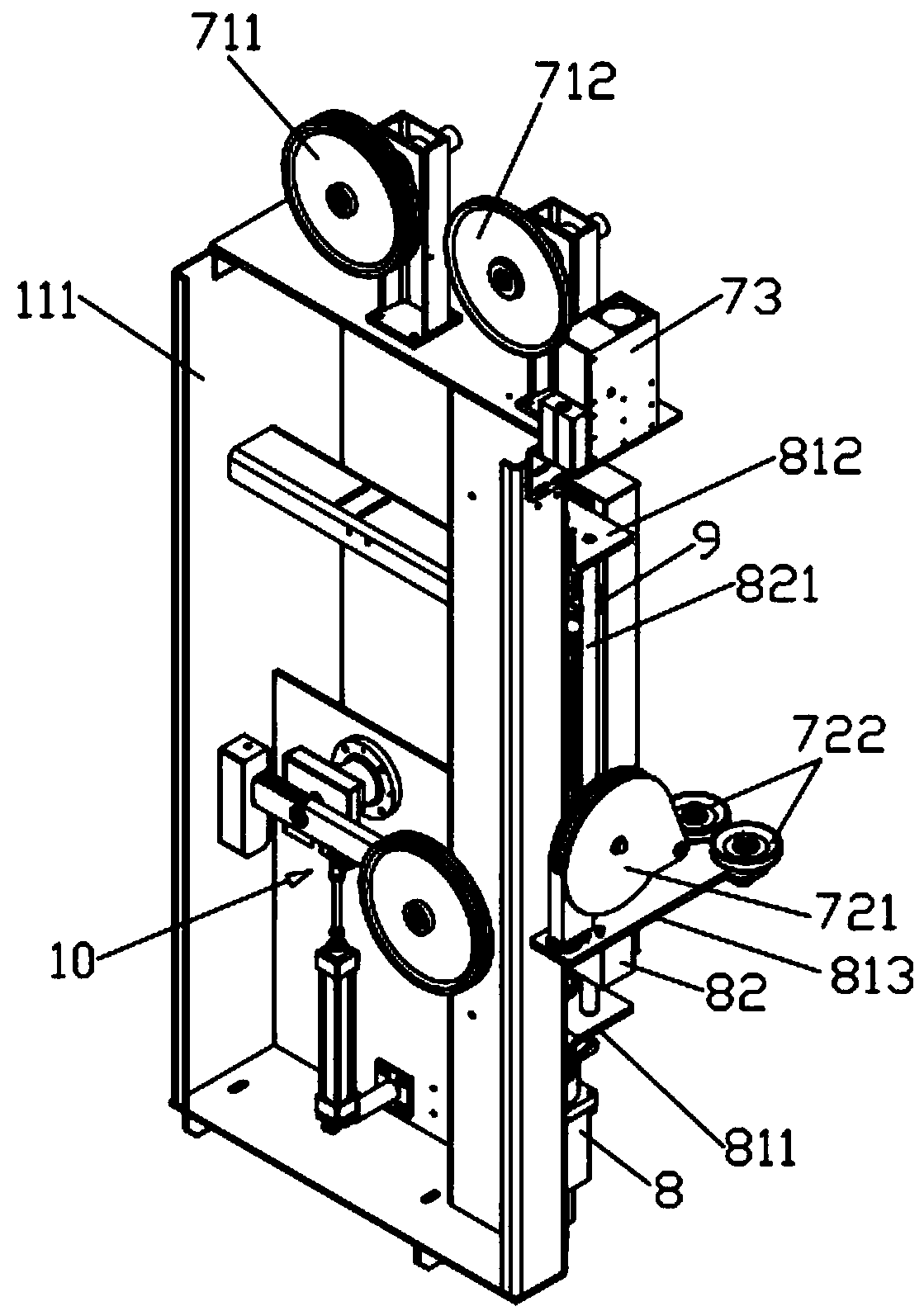

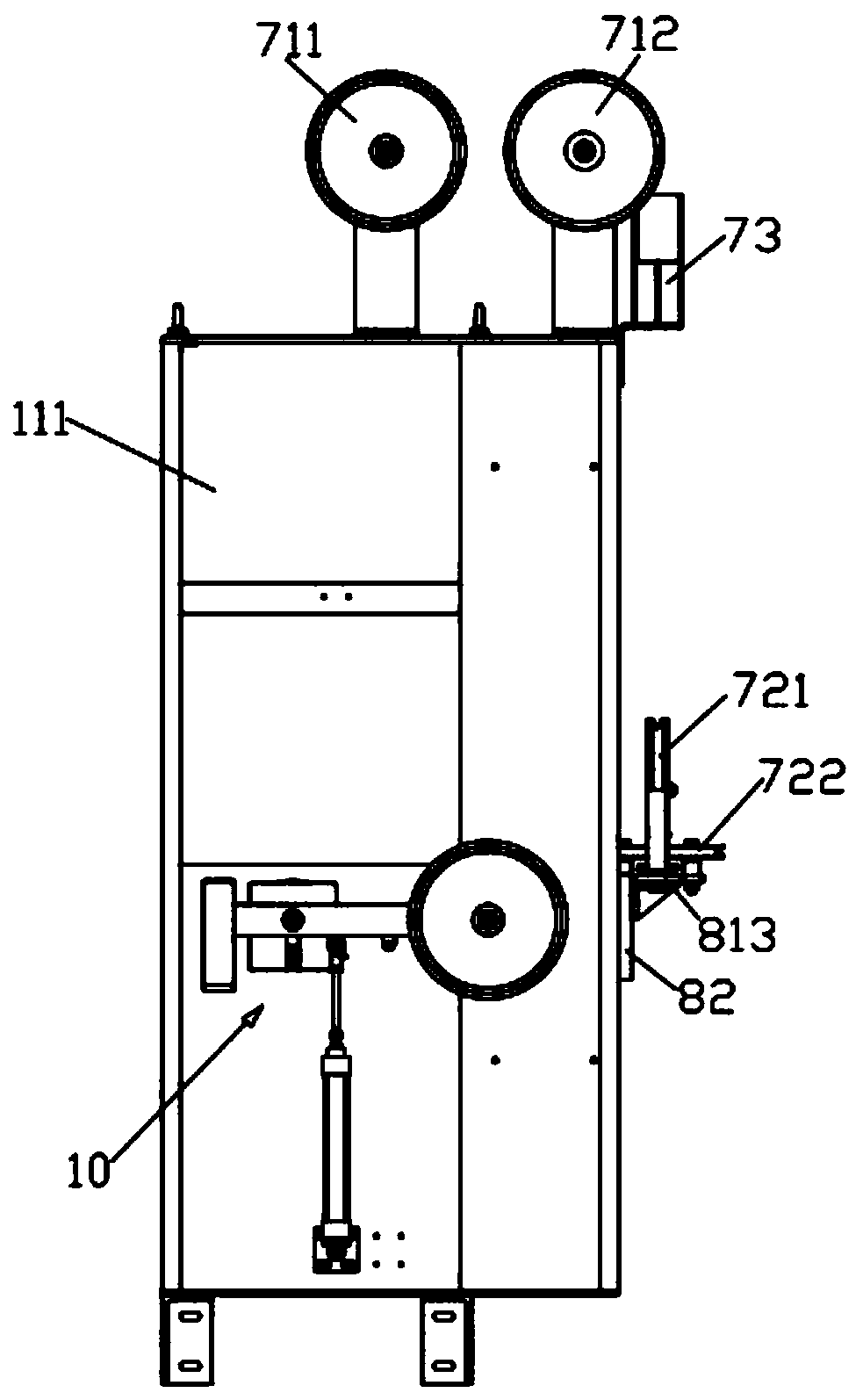

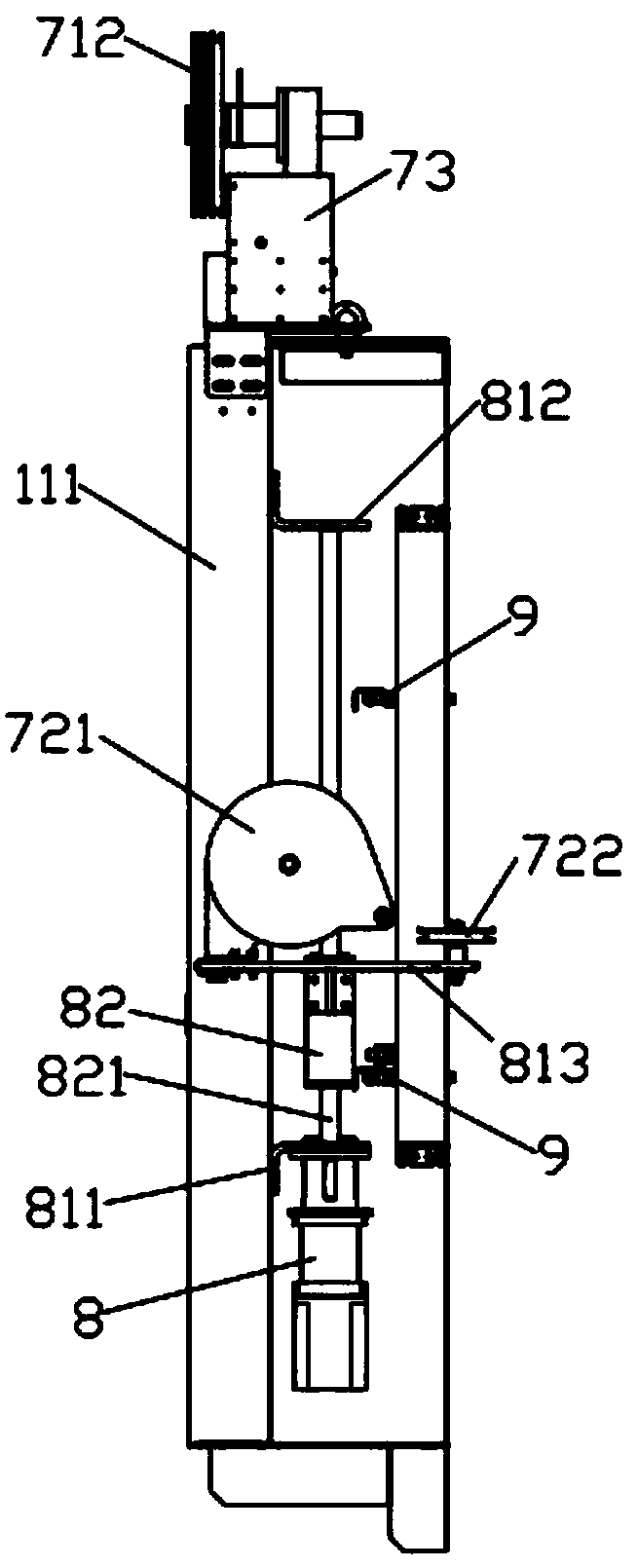

[0028] Such as Figure 1-4 The illustrated oil-coated wire support for enameled wire includes a support 111, a first thread passing wheel 711 and a second thread passing wheel 712 mounted on the upper part of the support 111, and a tension swing lever mechanism 10 mounted on the lower part of the support 111, mounted on the side of the support 111 Part of the arranging servo motor 8, a threaded rod (not shown) driven by the arranging servo motor 8, a nut seat (not shown) used with the threaded rod, a platoon guide block 82 connected to the nut seat, installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com