Bridge equipment

A technology for equipment and bridges, applied in the field of bridge equipment, can solve the problems of inconvenient retraction and release of power supply lines of wiring boards, increased use costs, and difficulties in power supply connection, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

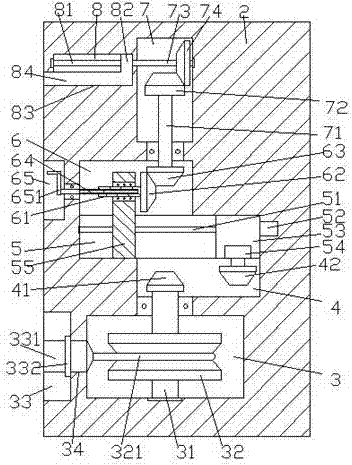

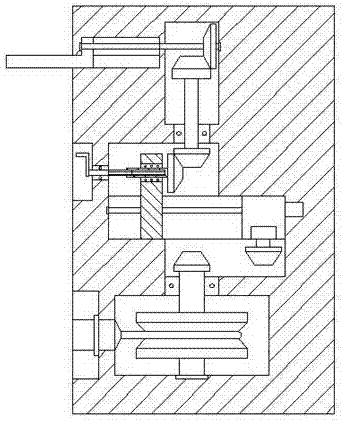

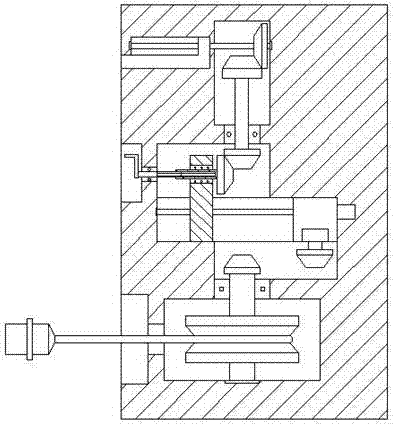

[0019] Such as Figure 1-Figure 5 As shown, a bridge device of the present invention includes a body 2, a slide groove 5 is provided at the center of the inside of the body 2, and a first empty groove 6 is provided in the body 2 above the left side of the slide groove 5, The body 2 below the right side of the sliding groove 5 is provided with a second empty groove 4, and the body 2 at the bottom of the second empty groove 4 is provided with an accommodation groove 3, and the right side of the first empty groove 6 A power transmission cavity 7 is arranged on the upper side, and a first screw rod 51 is arranged in the sliding groove 5, and the right end of the first screw rod 51 is connected with the first driving machine 52, and the upper screw rod 51 is screwed. The vertical rod 55 extending upwards and the sliding block 53 arranged on the right side of the vertical rod 55 are connected by thread fit. The upward extending section of the vertical rod 55 extends into the first e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com