A new energy vehicle charging device with automatic control of wire take-up

A technology for new energy vehicles and charging devices, which is applied in electric vehicle charging technology, electric vehicles, charging stations, etc., can solve the problems of charging piles that do not have automatic winding wires, accidents, and shortening of wire life, so as to improve the winding speed. Efficiency and stability, reduction of utility power waste, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

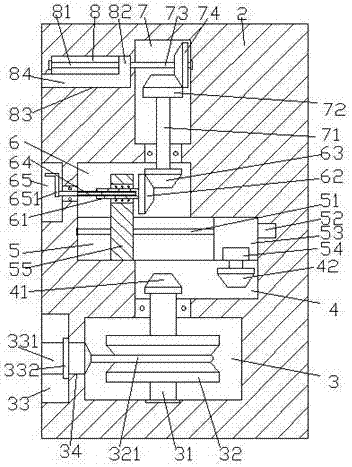

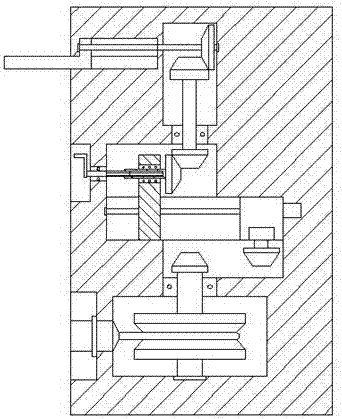

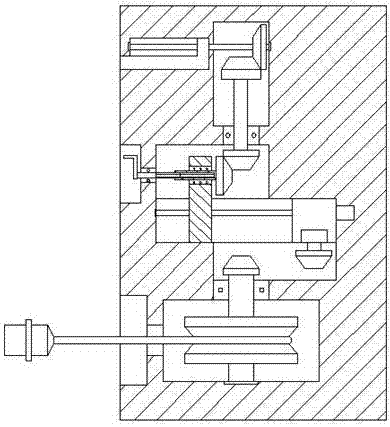

[0020] Such as Figure 1-Figure 5 As shown, a charging device for new energy vehicles with automatic control of wire take-up according to the present invention includes a charging pile body 2, and a sliding groove 5 is horizontally arranged at the middle position inside the charging pile body 2, and the upper left side of the sliding groove 5 is A first cavity 6 is provided in the charging pile body 2, a second cavity 4 is provided in the charging pile body 2 below the right side of the sliding groove 5, and a second cavity 4 is provided in the bottom of the second cavity 4. The charging pile body 2 is provided with a wire take-up chamber 3, a transmission chamber 7 is provided above the right side of the first chamber body 6, a first screw 51 is provided in the sliding groove 5, and a first screw 51 is provided on the right side of the first screw 51. end is connected with the power of the first motor 52, and the first screw rod 51 is threadedly connected with an upwardly ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com