Inverted take-up device and inverted take-up method

An inverted wire take-up device, which is applied in the field of inverted wire take-up devices, can solve problems such as low wire take-up efficiency and inconvenient production, reduce the probability of damage or breakage, simplify the replacement process, improve wire take-up efficiency and The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

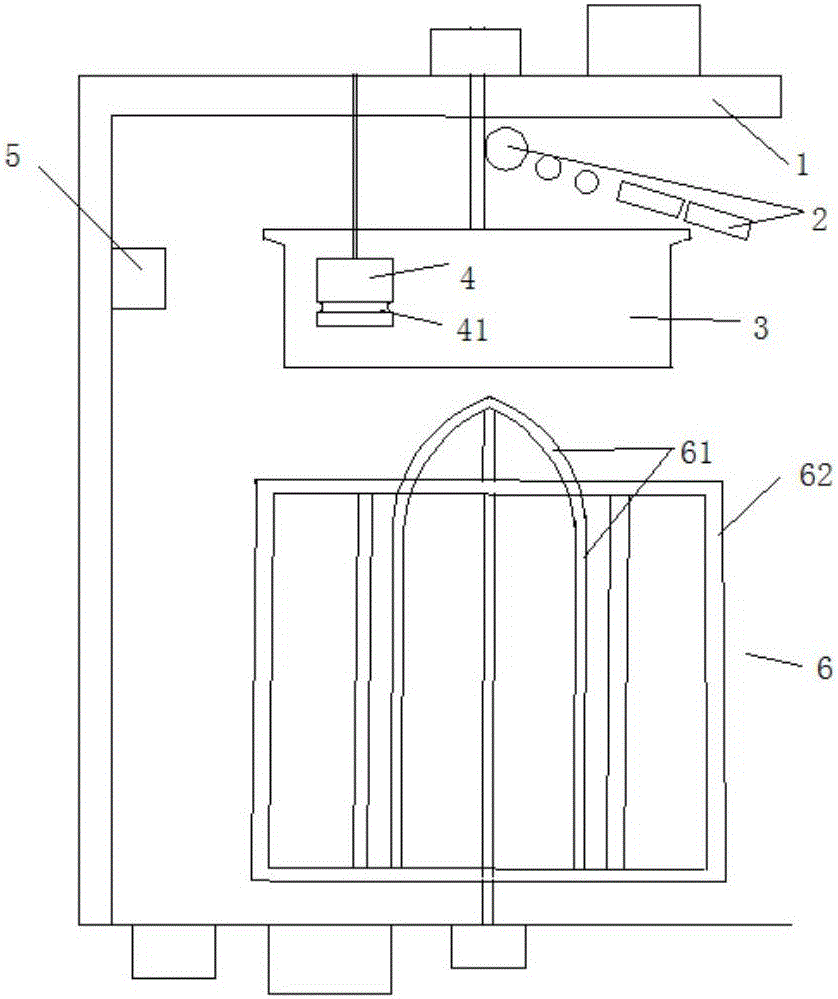

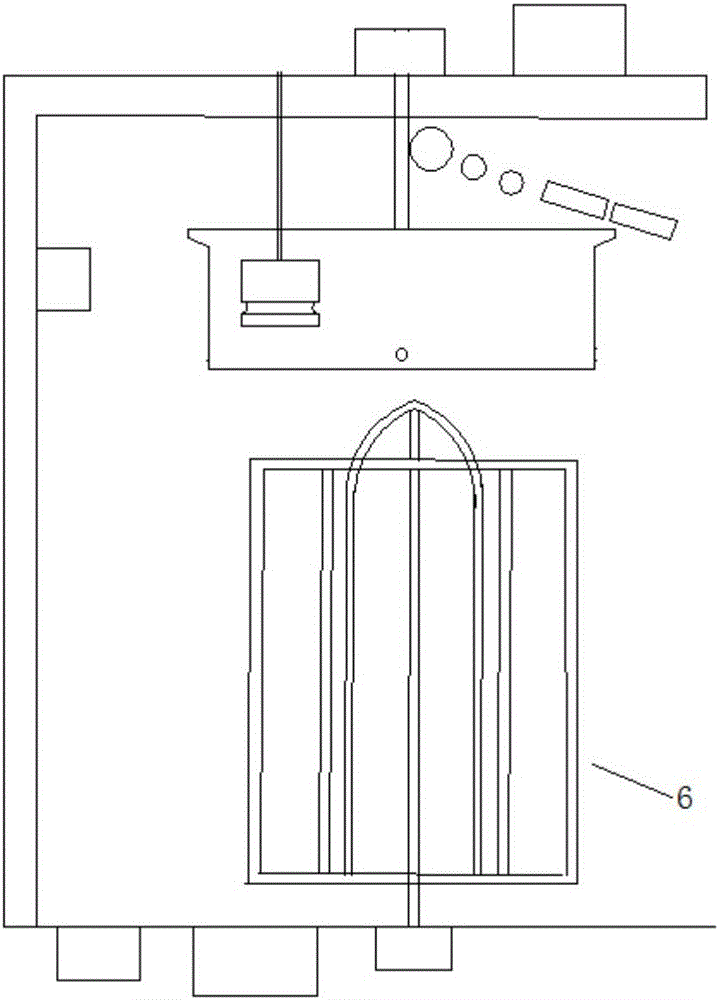

[0056] This embodiment provides an inverted wire take-up device, comprising:

[0057] Rack 1;

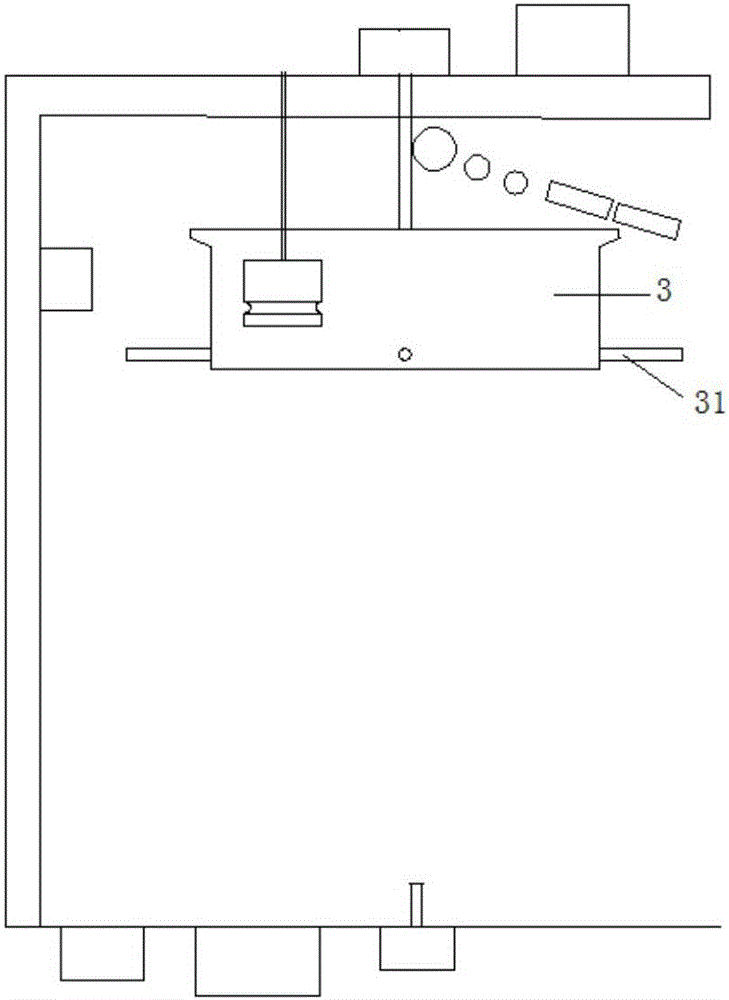

[0058] Winding reel 3, rotatable setting;

[0059] The first motor is used to drive the winding reel 3 to rotate;

[0060] The wire device 2 is used to guide the external wire into the winding reel 3, wind it on the winding reel 3, and drive the wire to fall;

[0061] The take-up basket 6 is rotatably arranged directly below the winding reel 3;

[0062] The second motor is used to drive the take-up basket 6 to rotate, and is not linked with the first motor;

[0063] The controller independently controls the actions of the first motor and the second motor.

[0064] In the above-mentioned inverted take-up device, the winding reel 3 and the take-up basket 6 are respectively driven by the first motor and the second motor, the first motor and the second motor are not set in linkage, and are independently controlled by the controller, The rotation speed of the take-up basket can be a...

Embodiment 2

[0080] This embodiment provides a method for taking up a wire by an inverted wire take-up device, which includes the following steps:

[0081] S1: Drive the external wire into the winding reel 3 and wind it on the winding reel 3;

[0082] S2: drive the winding reel 3 to rotate;

[0083] S3: driving the take-up basket 6 to rotate independently of the winding reel 3;

[0084] S4: The wire is lowered from the winding reel 3 into the take-up basket 6 .

[0085] The take-up basket 6 rotates independently of the winding reel 3, so that the rotating speeds of the winding reel 3 and the take-up basket 6 can be controlled and adjusted separately, so the speed of the take-up basket 6 can be set to be greater than the speed of the winding reel 3, that is It is possible to make the coil diameter of the wire coiled in the wire basket 6 smaller than the wire coil diameter falling from the winding reel 3, the greater the rotation speed of the wire basket 6, the smaller the coil diameter of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com