Optical cable take-up machine with anti-jumping function

A wire take-up and functional technology, applied in the direction of conveying filamentous materials, thin material handling, transportation and packaging, etc., can solve the problems of increasing the damage of optical fibers, looping, damage to optical cables, etc. The probability of the disc, the increase of the contact area, and the effect of improving the efficiency of the wire take-up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

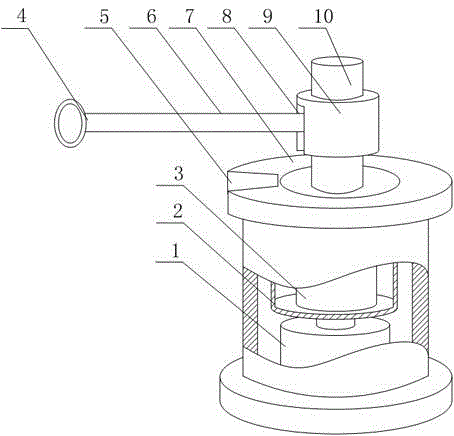

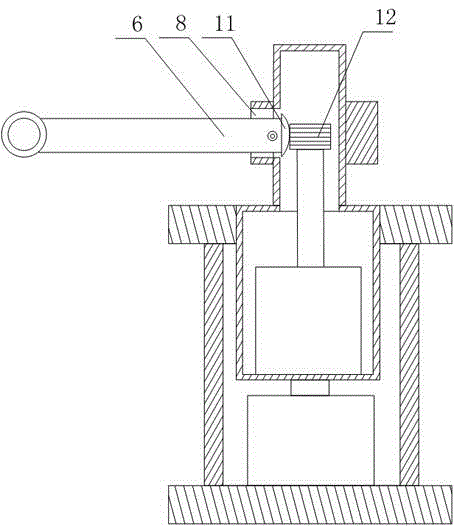

[0021] Such as figure 1 and figure 2 As shown, this embodiment includes a hollow cable reel 7 and a motor 1 fixed in the cable reel 7, the output end of the motor 1 is connected with a positioning cylinder 2, the upper end of the positioning cylinder 2 penetrates the upper end surface of the cable reel 7, and A cylinder 3 is installed in the positioning cylinder 2, and a rotating cylinder 10 communicating with it is fixed on the upper end surface of the positioning cylinder 2. The side wall of the rotating cylinder 10 is provided with a rectangular gap, and is hinged in the gap. There is a guide rod 6, a plurality of annular teeth 12 are arranged on the output end of the cylinder 3, one end of the guide rod 6 is provided with sector teeth 11 matched with the ring teeth 12, and a guide ring 4 is installed at the other end of the guide rod 6; it also includes The fixed block 9 fixed on the outer wall of the rotating cylinder 10 has a movable groove 8 communicating with the gap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com