Automatic wire winding equipment

A wire take-up device and automatic technology, applied in the field of automatic wire take-up equipment, to achieve high accuracy and improve the efficiency of wire take-up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The present invention is described in detail below in conjunction with the accompanying drawings:

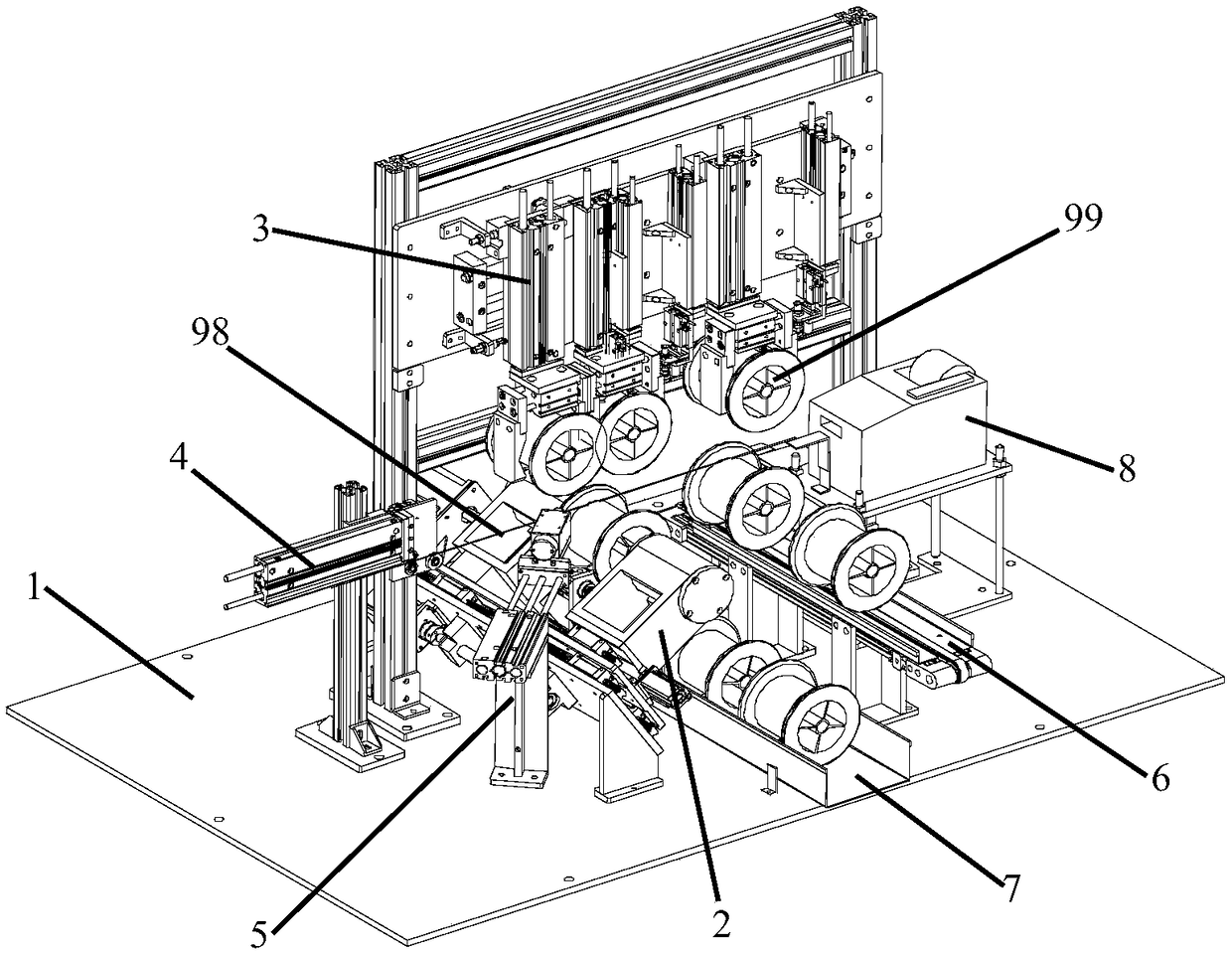

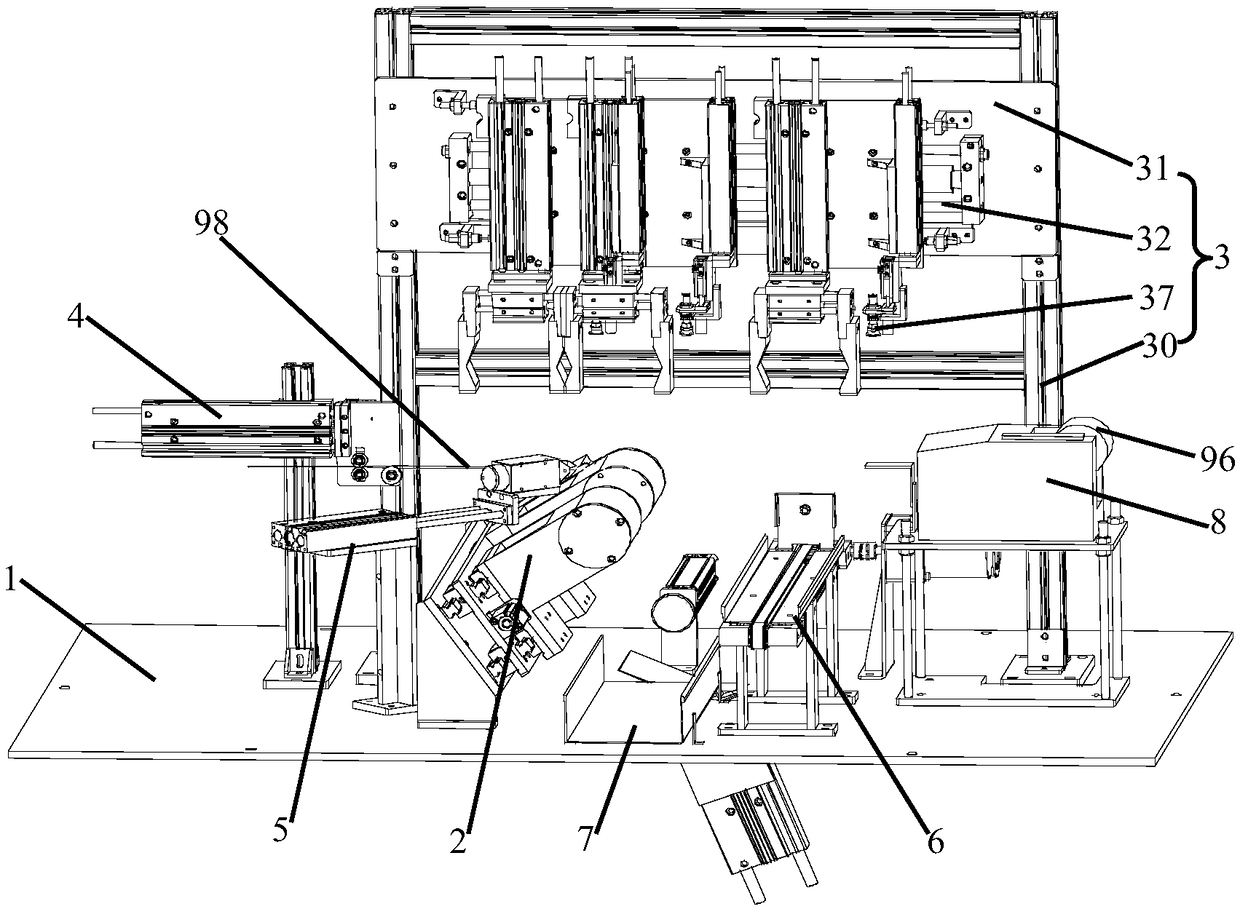

[0065] combine Figure 1 to Figure 4 As shown, the present invention firstly discloses an automatic wire take-up device comprising: a basic installation surface 1, preferably a base plate as the basic installation surface;

[0066] The winding mechanism 2 is installed on the basic installation surface 1 to clamp the bobbin 99 in the axial direction. The winding mechanism 2 drives the bobbin 99 to rotate, and the winding mechanism 2 drives the shaft. At the same time of rotation, the whole mechanism can move back and forth at a constant speed along the axis direction;

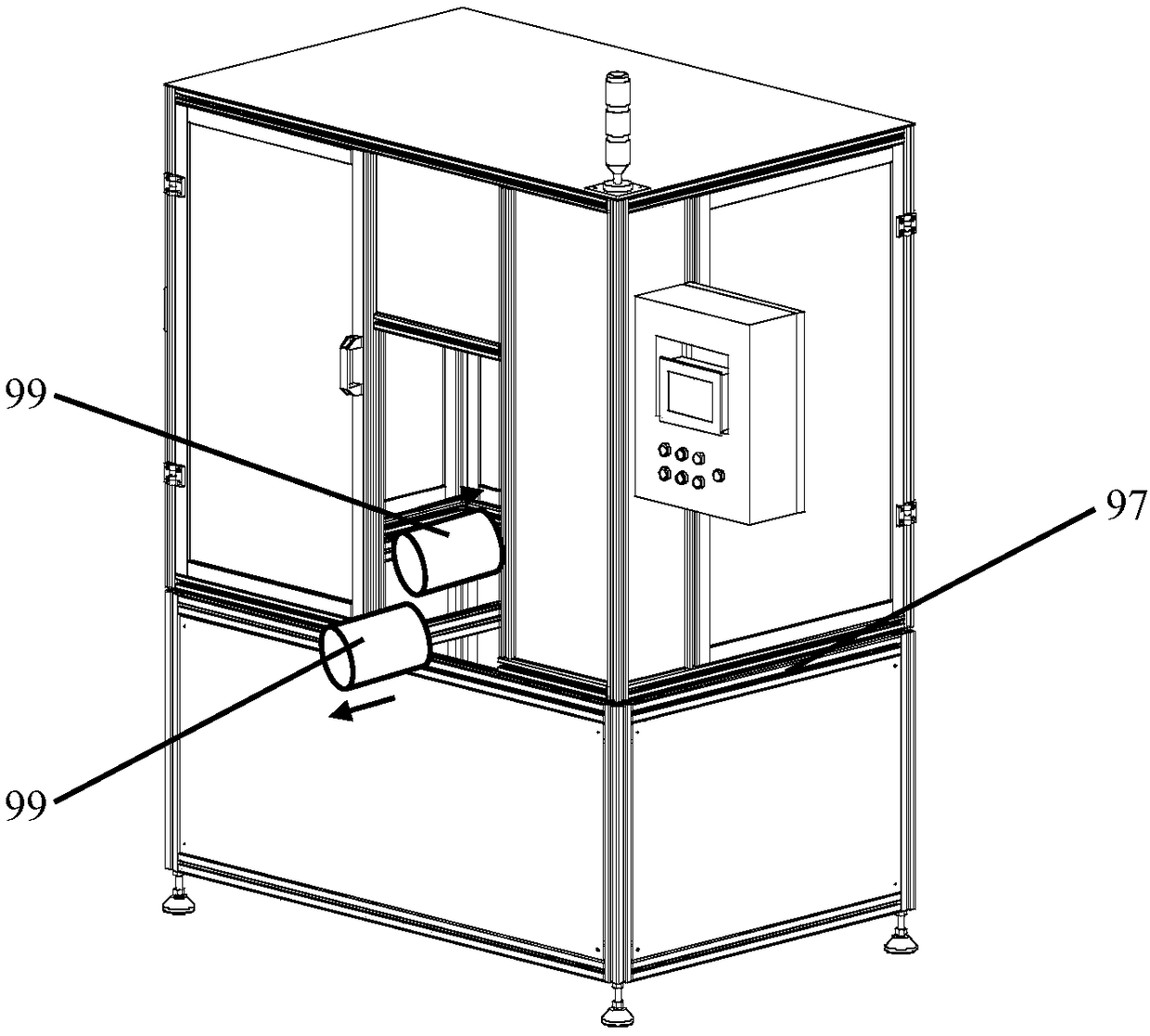

[0067] The clamping mechanism 3 is mounted on the base mounting surface 1 and includes a first side away from the winding mechanism 2 and a second side adjacent to the winding mechanism 2 , and the bobbin 99 passes through the The clamping mechanism 3 is clamped to the winding mechanism 2 from the first s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com