Tension adjusting device

A tension adjustment and sliding bar technology, which is used in transportation and packaging, transportation of filamentous materials, thin material handling, etc., can solve problems such as low wire take-up or pay-off efficiency, loose wire spools, and uneven cable winding density. , to improve the efficiency of take-up or pay-off and avoid loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

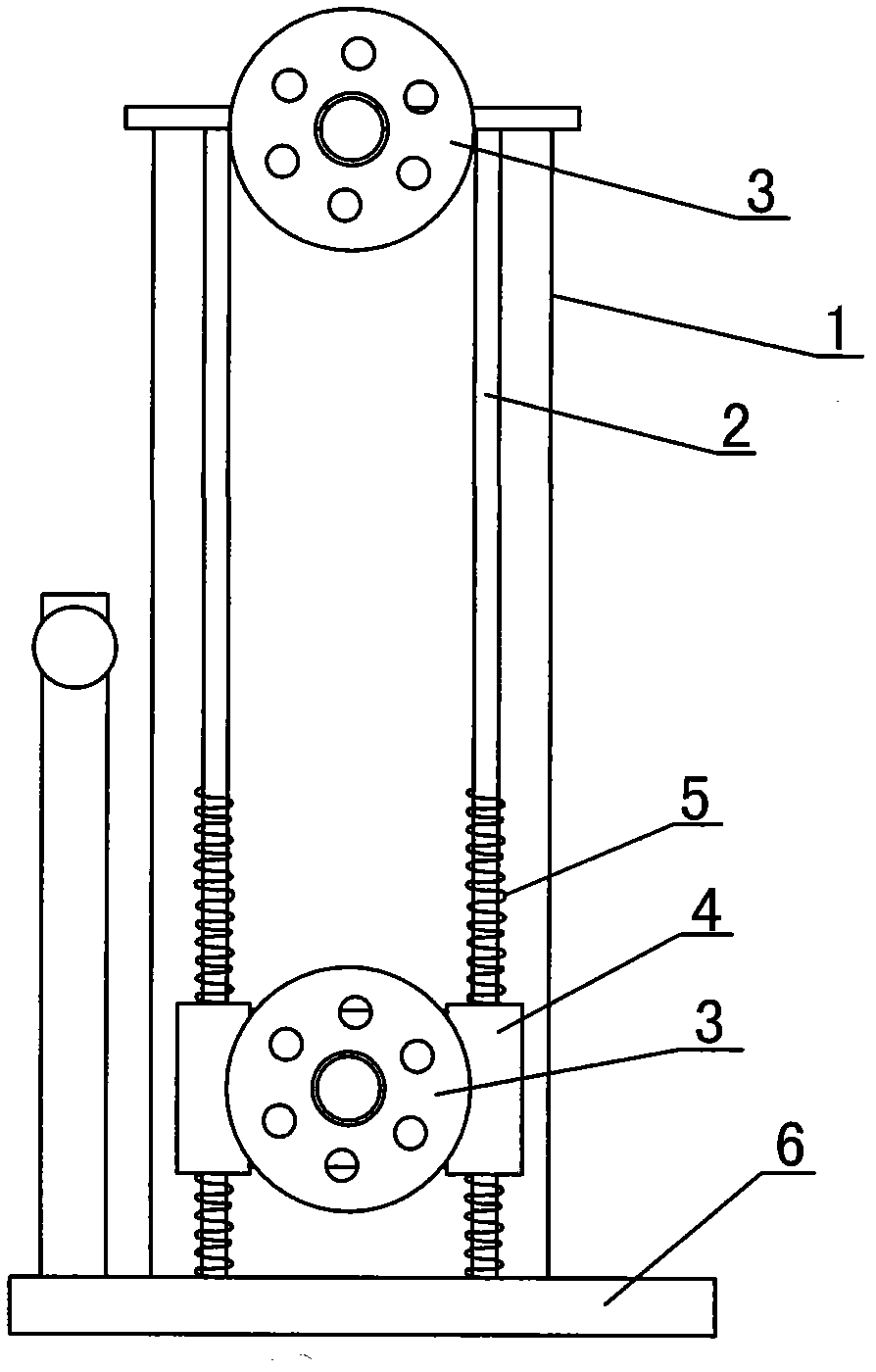

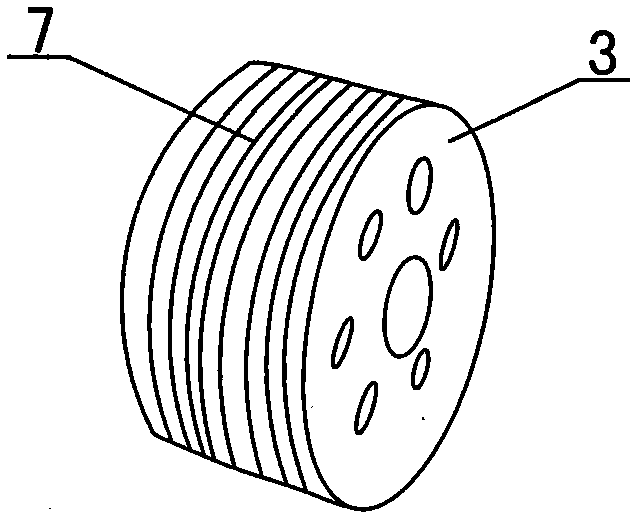

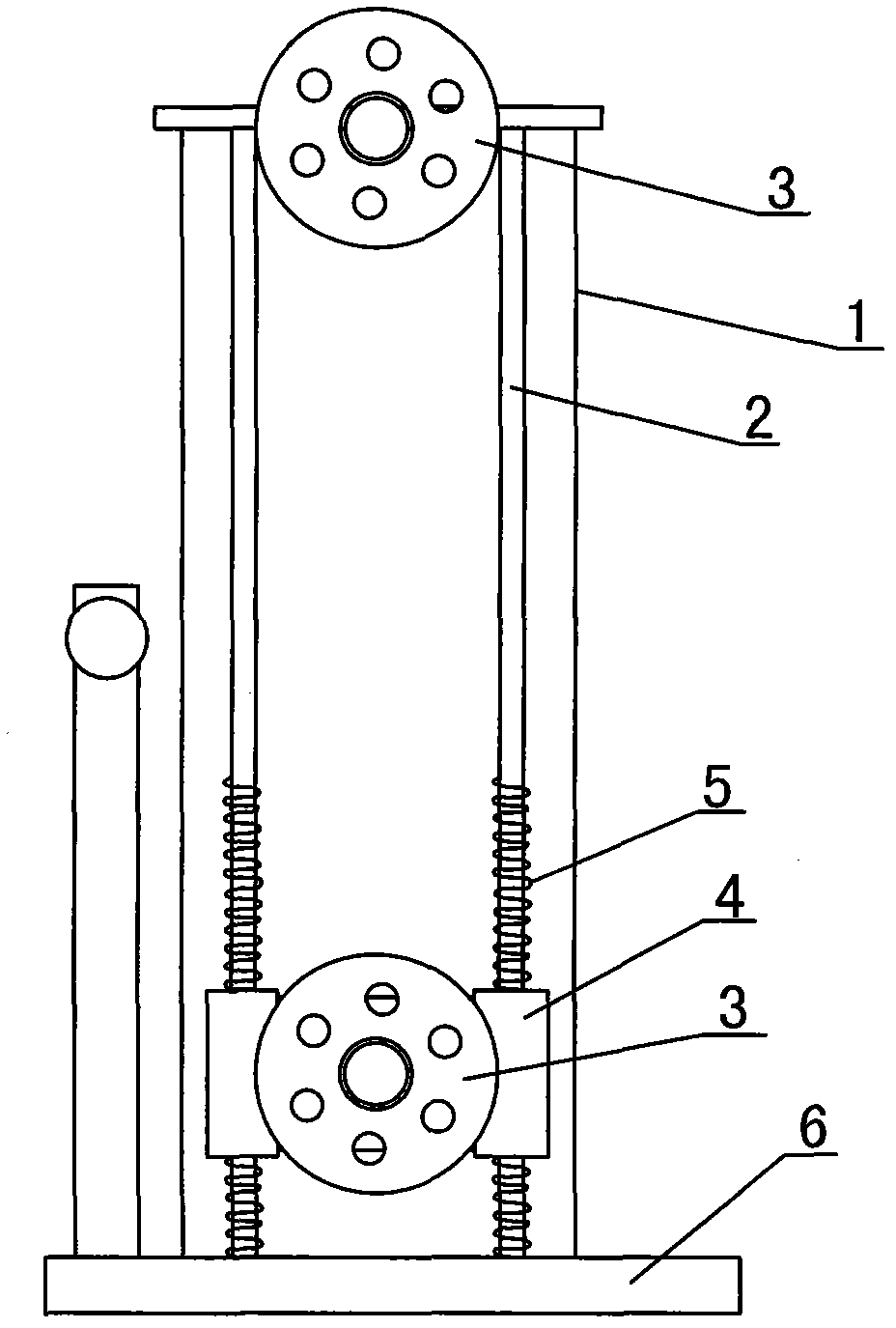

[0012] Such as Figure 1-2 As shown, the tension adjustment device of the present invention includes a bracket 1, a slide bar 2, and a pulley 3. Two metal slide bars 2 are vertically arranged on the base 6 of the support 1, and movable bars 2 are installed between the metal slide bars 2. The fixed baffle 4, the front end of the fixed baffle 4 is connected to the pulley 3 and a pulley 3 is installed on the top of the bracket 1 at the same time; the upper and lower sides of the fixed baffle 4 are respectively covered with springs 5 on the sliding bars 2 to strengthen the longitudinal direction of the pulley 3 Elasticity, while being convenient to automatically adjust the tension when the cable passes through, a number of wire slots 7 are evenly opened on the outer cylindrical surface of the pulley 3. Through the configuration of the pulley structure, a certain tension can be kept constant during the retracting and unwinding process, which can avoid the phenomenon of loosening ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com