Patents

Literature

110results about How to "Improve pay-off efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

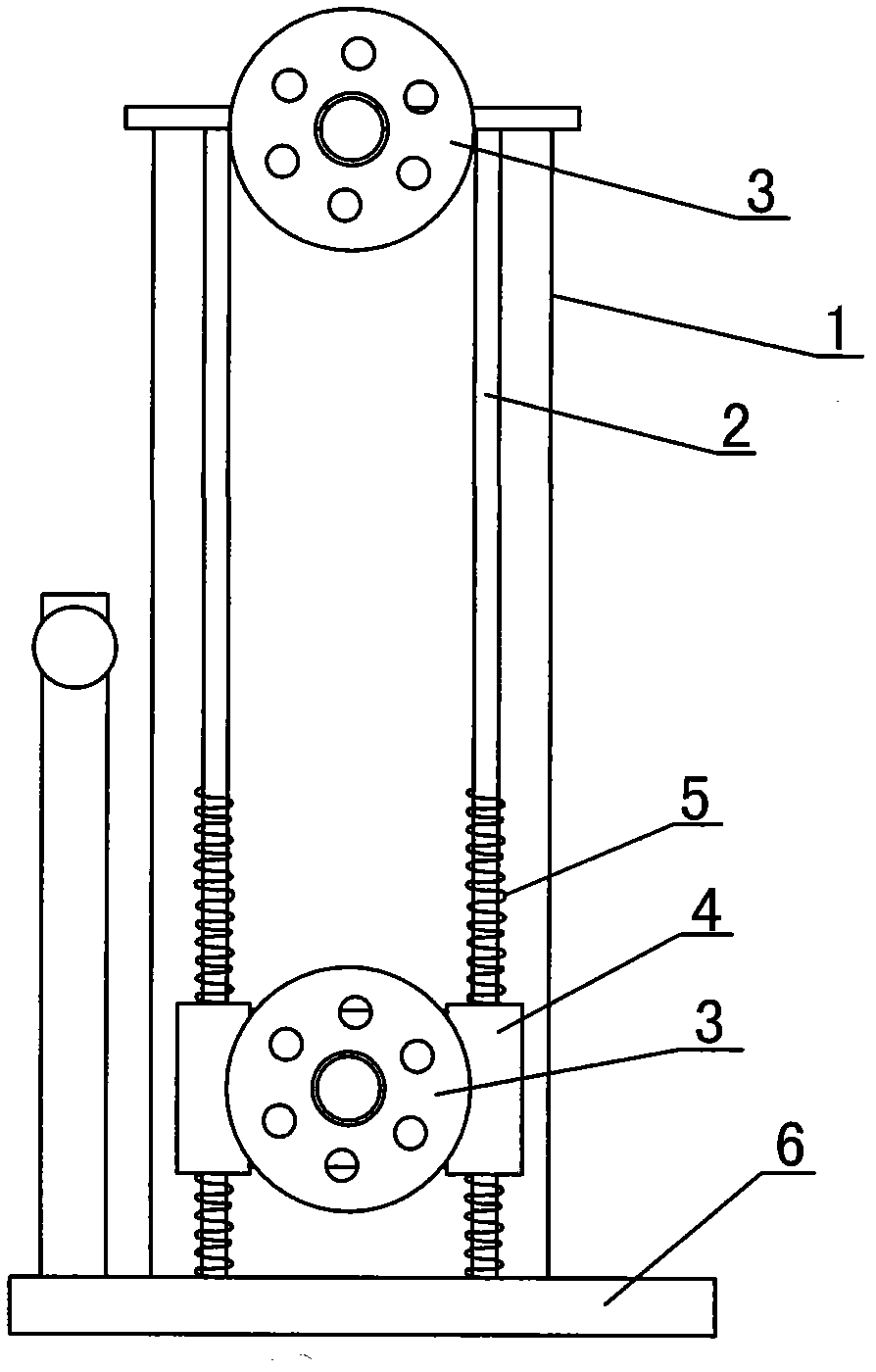

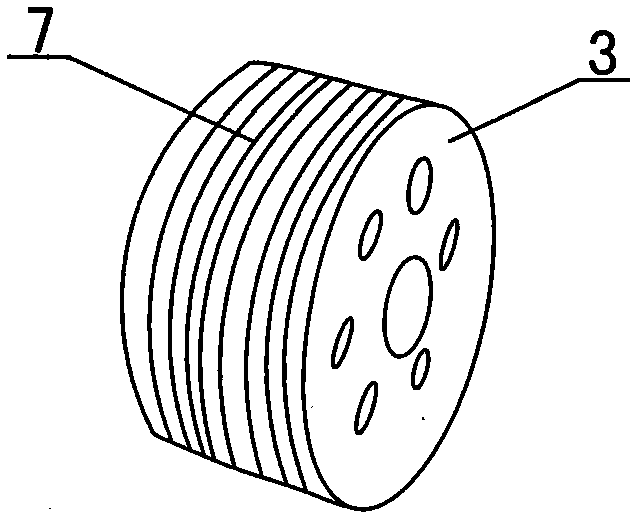

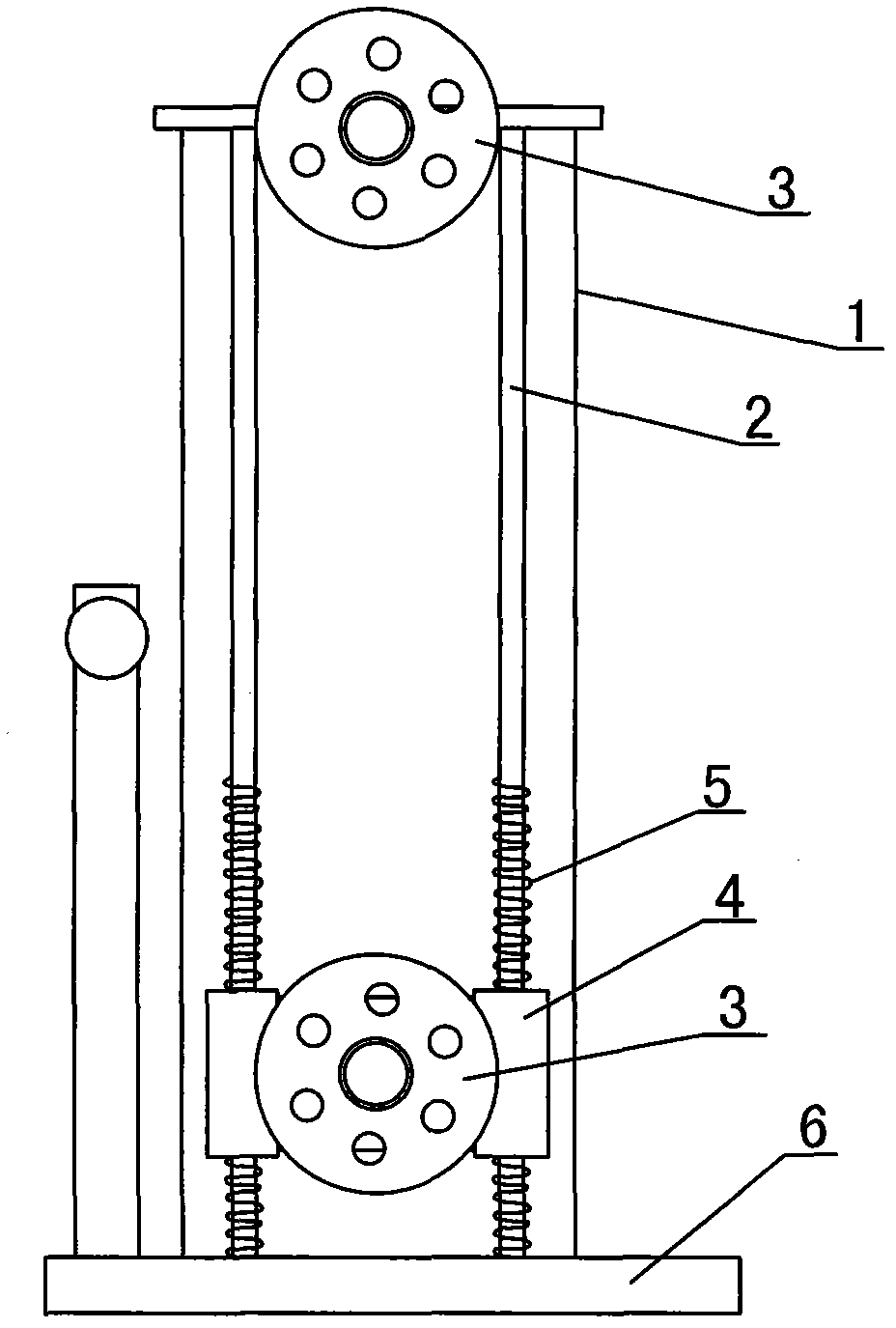

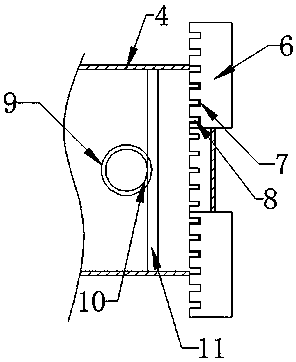

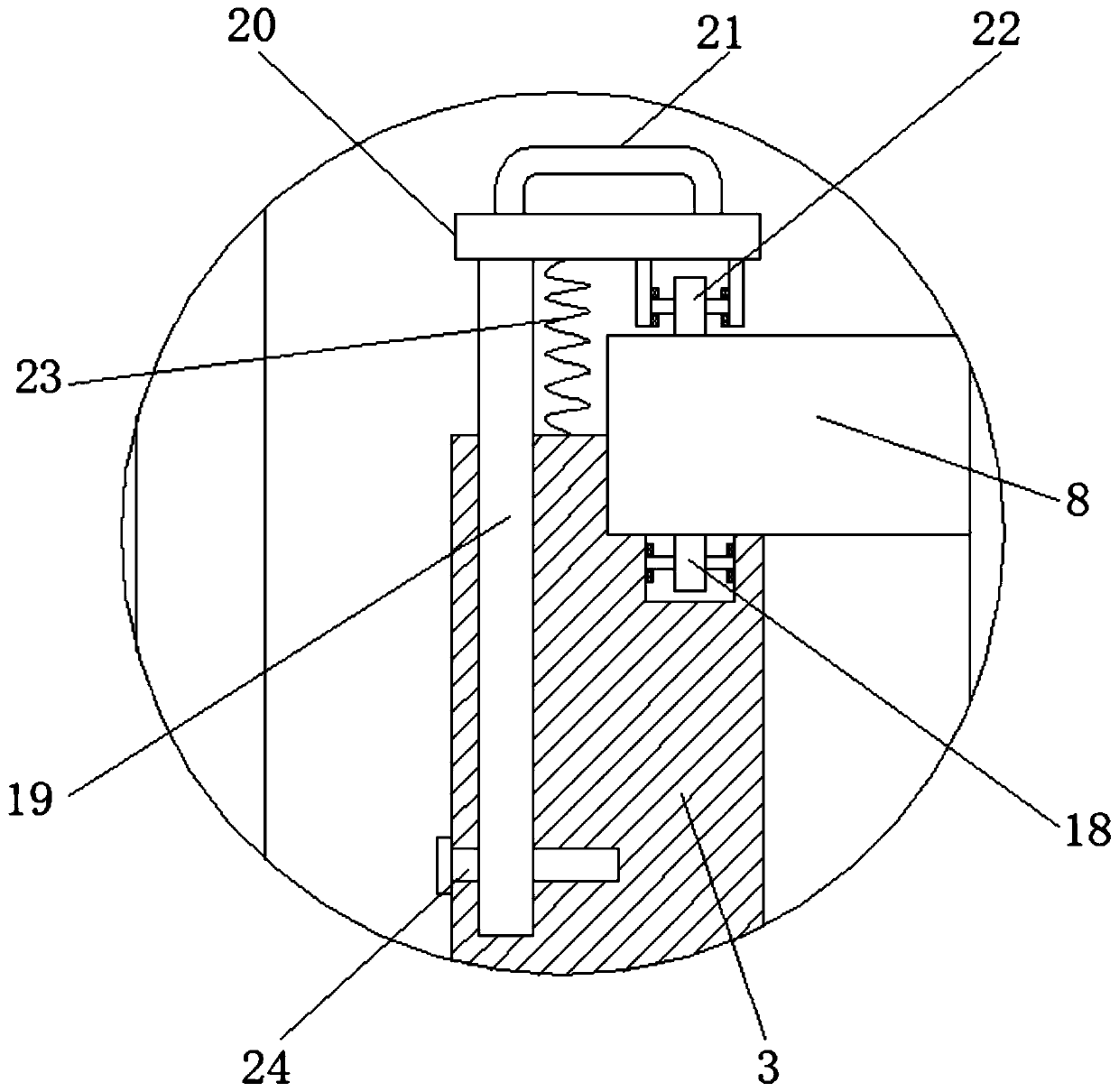

Tension adjusting device

InactiveCN102060212APrevent looseningAvoid phenomena such as uneven winding densityFilament handlingEngineeringPulley

The invention provides a tension adjusting device which comprises a bracket, two slide rods and two slide wheels, wherein the base of the bracket is vertically provided with the two metal slide rods, a movable fixed baffle plate is arranged between the two metal slide rods, the front end of the fixed baffle plate is connected with one slide wheel, and the top end of the bracket is simultaneously provided with the other slide wheel; and the two slide rods which are arranged at the upper side and the lower side of the position of the fixed baffle plate are respectively sheathed with a spring. The tension adjusting device has the beneficial effects that by adopting a top and bottom double-slide wheel structure, a certain tension can be constantly kept during winding and unwinding a cable, the phenomena that a cable coil is loosened, the cable winding thickness is uneven and the like during winding can be avoided, the cable winding efficiency or the wire unwinding efficiency can be improved.

Owner:正裕电器配件(昆山)有限公司

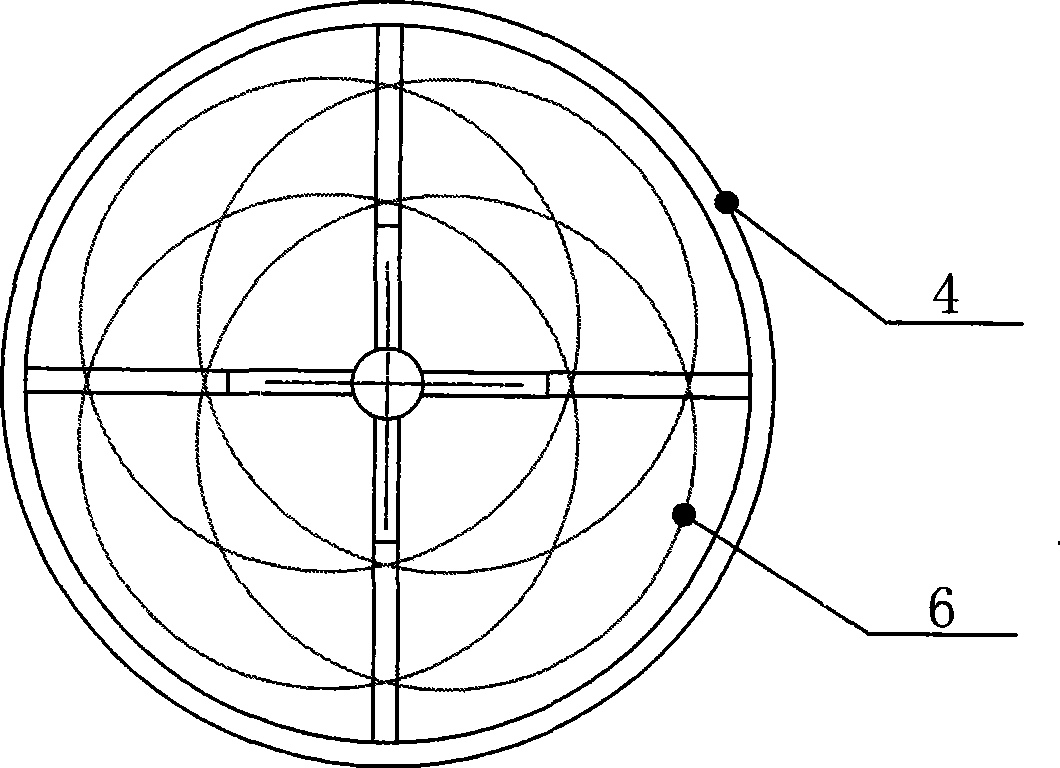

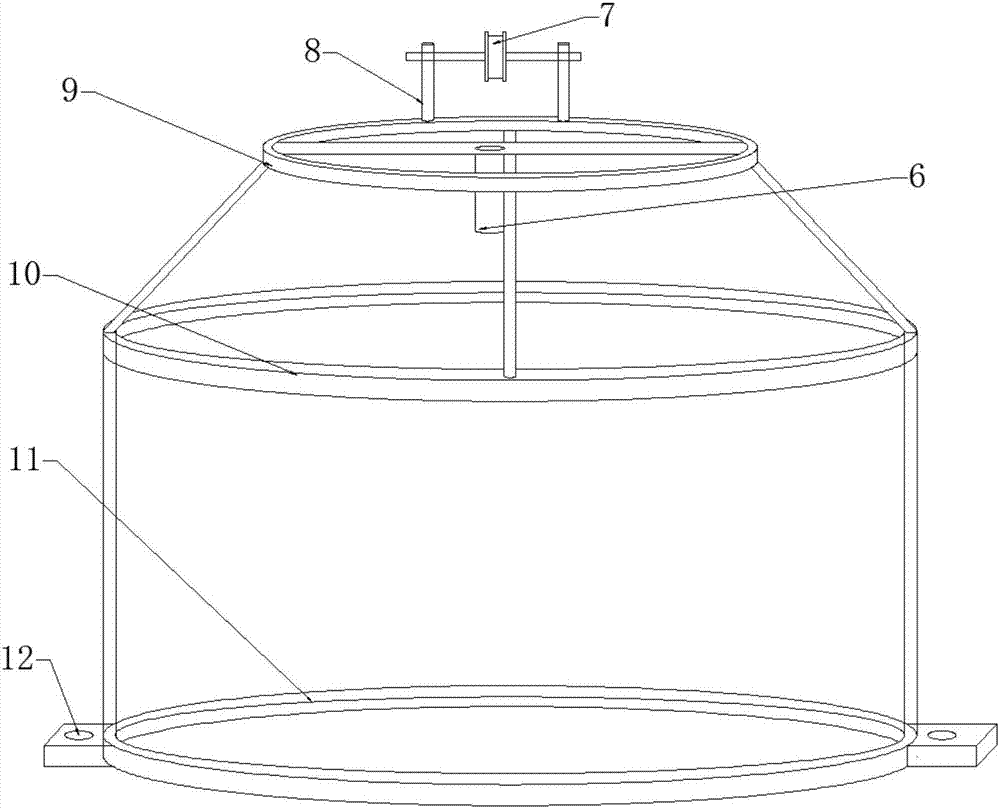

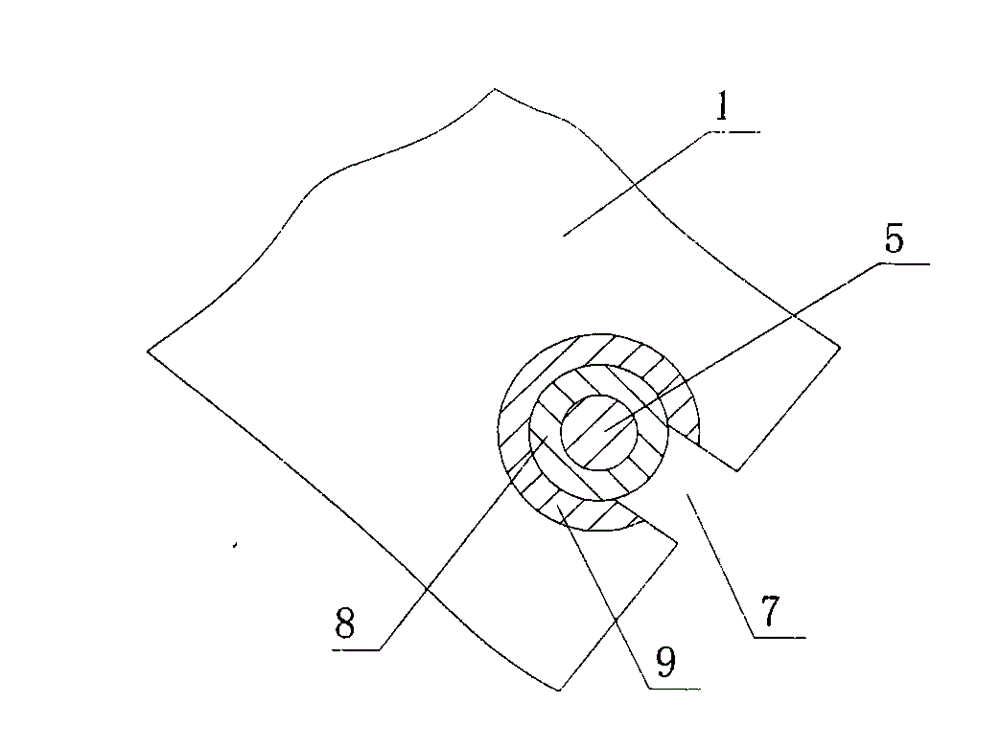

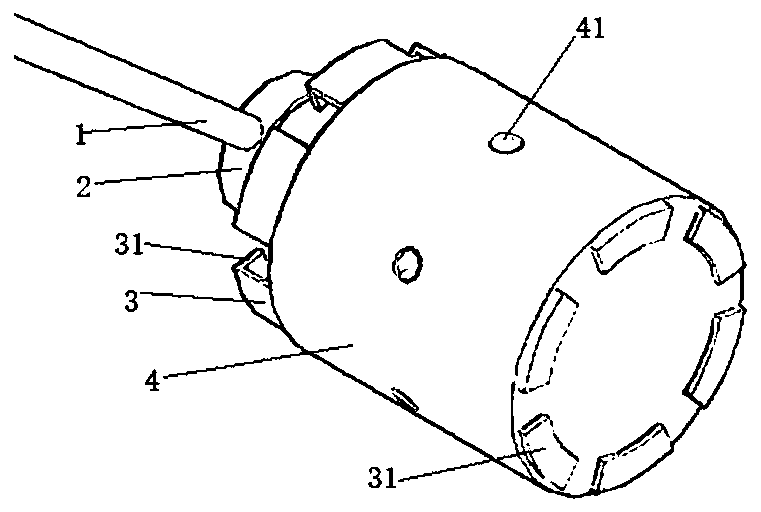

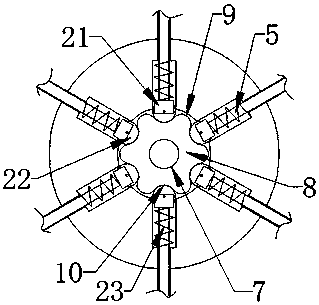

Quincunx wire unloading device

Disclosed is a plum blossom shape wire-unloading device used in steel wire production, which comprises a trunk frame, an upper rotary table, a wire cover, a wire frame and a lower rotary table, the upper rotary table is mainly composed of a fixed seat, a bearing and a rotating disc, a take-up stand is positioned on the lower rotary table, the lower rotary table is driven by a variable-frequency motor, the upper rotary table is connected with the trunk frame and falls on the upper end of the wire frame, the wire frame is placed on the lower rotary table, and an eccentric distance is retained between the center of rotation of the wire frame and the center of the upper rotary table for realizing the plum blossom shape taking-up and paying-off of steel wires. The lapped steel wires will not slide off and foul up easily through the device, the pay-off speed of the next procedure is increased, and the gross weight of the plum blossom shape take-up wires can be increased by 30 percent on the wire frame with the same size.

Owner:GUIZHOU AEROSPACE NANHAI ELECTROMECHANICAL

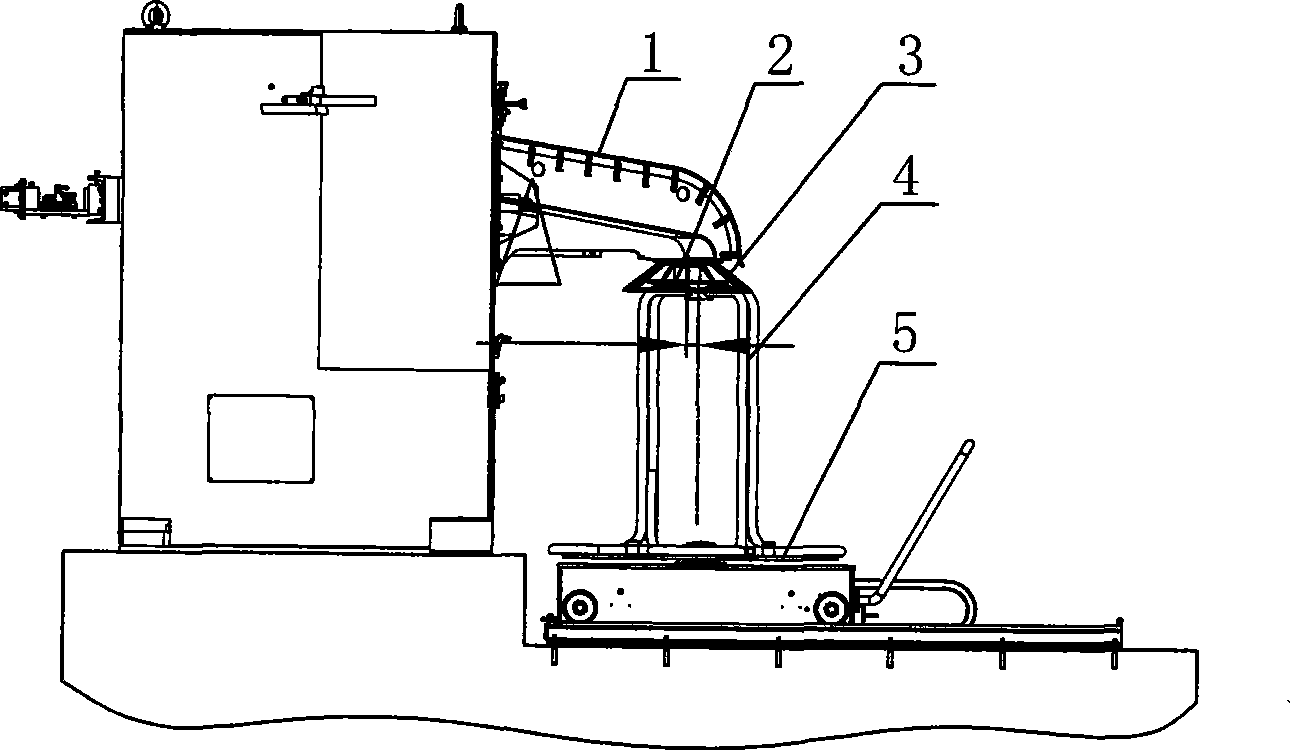

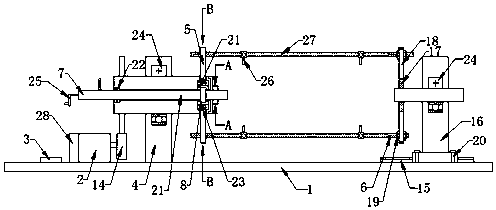

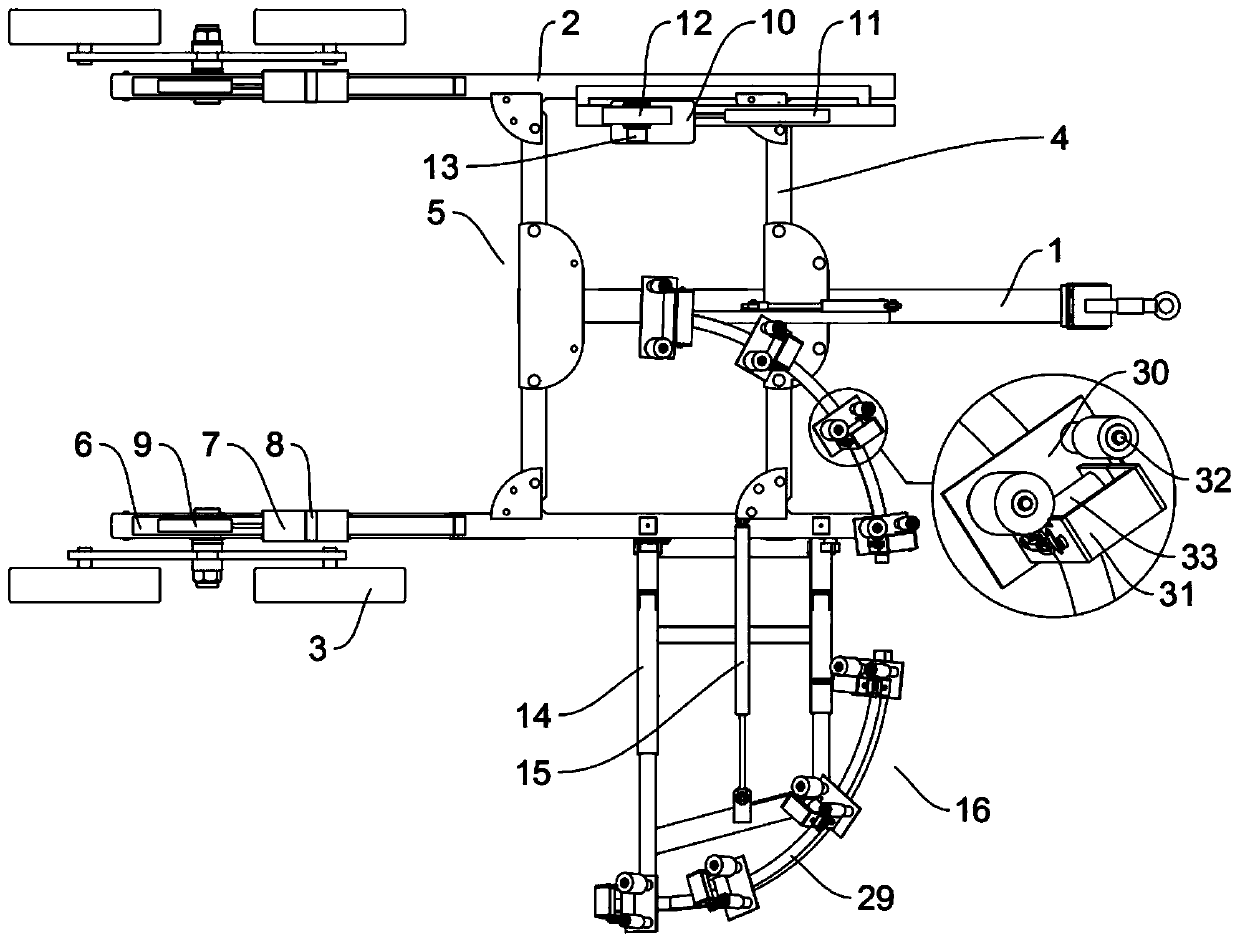

Electric overhead line laying traction machine and construction method

ActiveCN111162485AReduce security risksAvoid leaningApparatus for overhead lines/cablesApparatus for laying cablesEngineeringControl theory

The invention relates to an electric overhead line laying traction machine and a construction method. The electric overhead line laying traction machine comprises a lifting cross rod, clamping devices, fixed traction devices and a driving device, the clamping devices are symmetrically arranged at the left end and the right end of the lifting cross rod, the fixed traction devices are connected to the upper portion of the middle of the lifting cross rod, and the driving device is arranged in front of the lifting cross rod. According to the invention, when the overhead line is installed, usually,a worker needs to hold the free end of a single overhead line by hand to climb the upper end of a telegraph pole to install and tighten the line. A plurality of overhead lines need to be placed on asingle telegraph pole, so that the worker needs to climb to the upper end of the telegraph pole for multiple times, potential safety hazards of the personnel are easily caused in the climbing processfor multiple times due to the fact that the overhead lines are heavy, meanwhile, the pole body of the telegraph pole is likely to incline due to climbing for multiple times, and the paying-off efficiency of the single telegraph pole is low.

Owner:汉锐工程有限公司

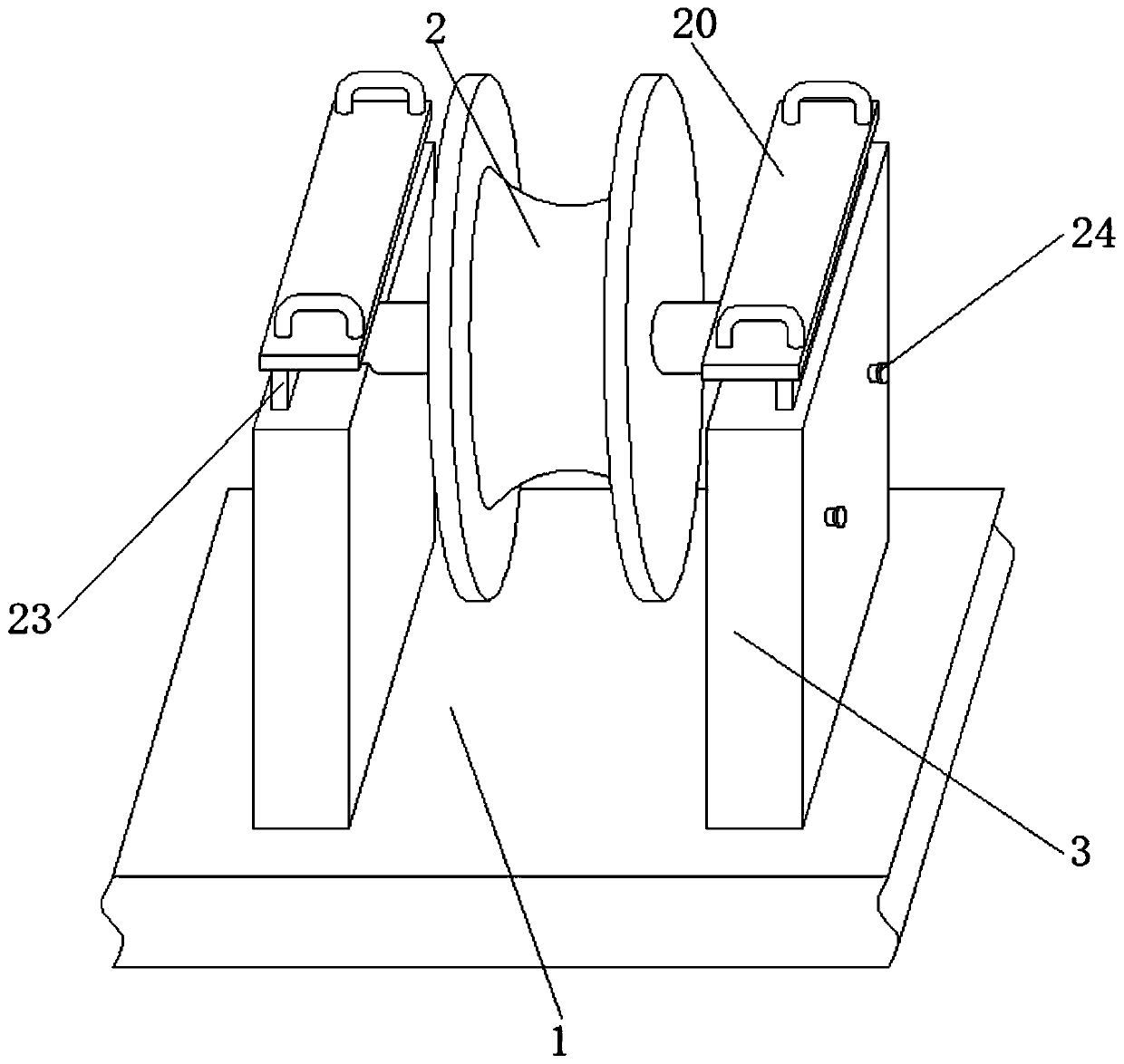

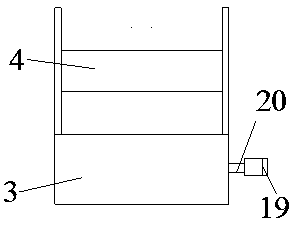

Multi-tray take-up reel of classified winding displacement

InactiveCN108910625APracticalImprove pay-off efficiencyFilament handlingApparatus for laying cablesEngineeringConductor Coil

Owner:合肥甘来智能科技有限公司

Paying-off device of cable paper lapping machine

The invention relates to a paying-off device of a cable paper lapping machine. The paying-off device comprises a base, a crimping barrel for storing a cable, and an electric motor, wherein the base is symmetrically provided with support plates; each support plate is provided with a mounting hole; the crimping barrel is arranged in the mounting hole of each support plate through a rotating shaft; the rotating shaft is provided with a speed sensor; the speed sensor is electrically connected to a control instrument; the control instrument is electrically connected to a magnetic controller; the rotating shaft is connected to the electric motor; and the magnetic controller is connected to the electric motor. The speed sensor is arranged to detect a paying-off speed and deliver the paying-off speed to the control instrument and the magnetic controller, and the electric motor is controlled to drive the rotating shaft to rotate at a uniform speed so as to prevent a released cable from being too loose or too tight, so that the paying-off efficiency is therefore improved.

Owner:昆山市线缆机械厂

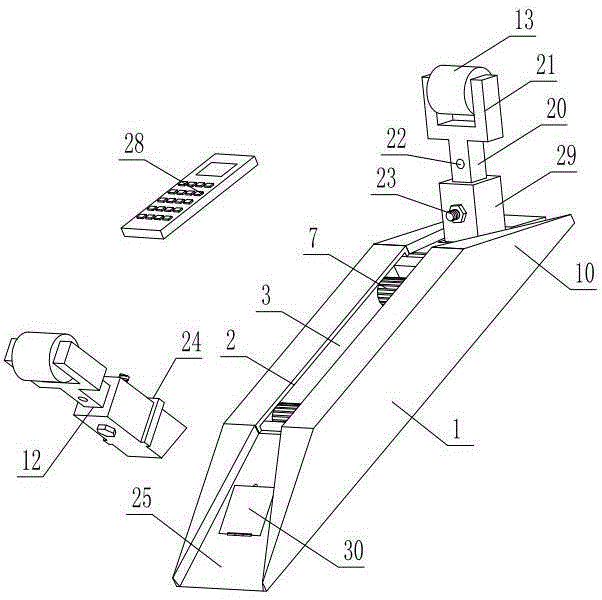

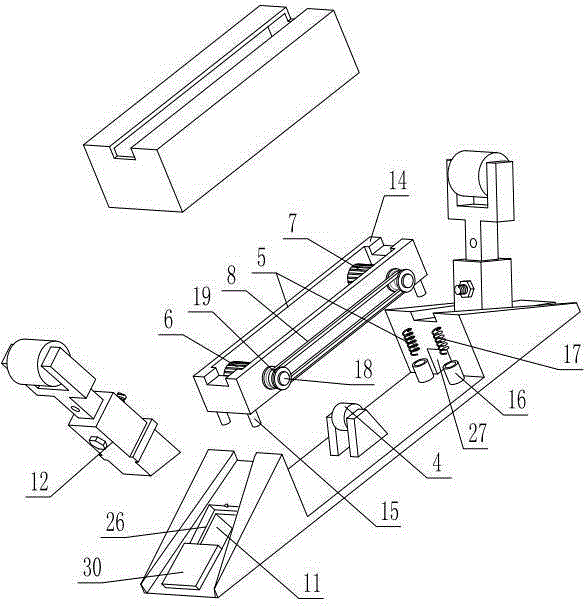

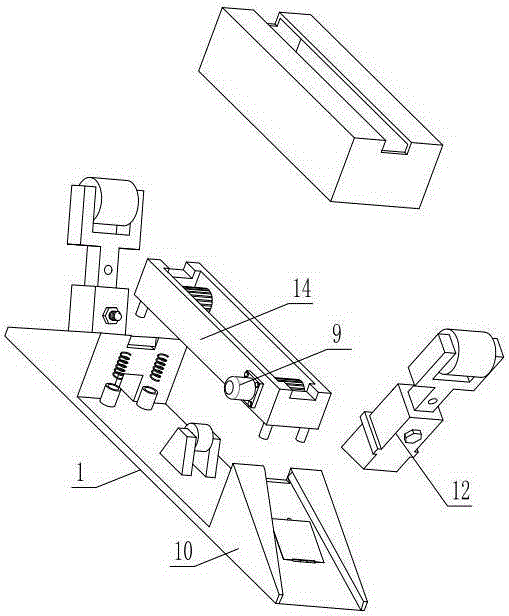

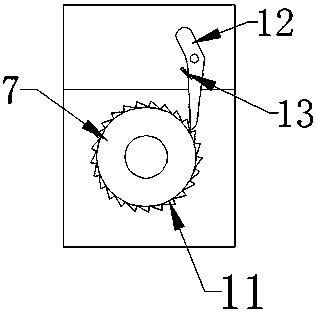

Cable tray paying-off device

ActiveCN106356767AReduce in quantityImprove payout and laying qualityArrangements using take-up reel/drumApparatus for laying cablesCable trayEngineering

The invention discloses a cable tray paying-off device. The cable tray paying-off device comprises a base. A groove extending back and forth along the length direction of the base is arranged in the upper portion of the base, a cavity communicated with the groove is arranged in the base, a carrying roller is mounted in the middle portion of the cavity through a rotating shaft extending left and right, a front driving wheel and a back driving wheel are respectively mounted at the front end and the back end of the carrying roller in the cavity through a positioning device, the outer periphery top of each of the front driving wheel and the back driving wheel is slightly higher than that of the carrying roller, the front driving wheel is in transmission fit with the back driving wheel through a belt, a motor in transmission fit with the front wheel is further mounted in the cavity, the front and back ends of the base is respectively provided with a sloping desk, each of the sloping desks is provided with a vertically-penetrating through hole, a positioning rod is inserted in the through hole, and a roller is mounted at the upper end of the positioning rod. The cable tray feeding device is reasonable in structure, free from overturning of a cable tray, capable of realizing paying off by only rolling the cable tray and simple and laborsaving in operation, at most one person is enough to stay with the cable tray during paying off, and paying-off efficiency can be greatly improved.

Owner:STATE GRID SHANDONG ELECTRIC POWER COMPANY WEIFANG POWER SUPPLY +1

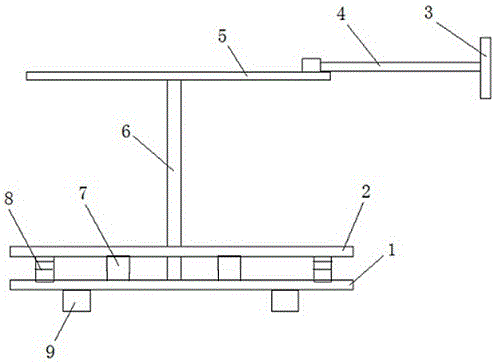

Automobile wire harness pay-off rack

InactiveCN107324126APlay the role of guidingImprove pay-off efficiencyFilament handlingCircular discProduction line

The invention discloses an automobile wire harness pay-off rack, and relates to the technical field of production equipment of automobile production lines. The automobile wire harness pay-off rack comprises a support table and a pay-off rack body, wherein a circular-disc-shaped groove is formed in the support table; a rotating disc is mounted in the groove; a through hole is formed in the center position of the groove; a rotating motor is mounted at the lower end of the support table through a fastening plate; a gear set is arranged at the driving end of the rotating motor; a driving shaft on the gear set passes through the through hole and is connected with a mounting groove in the center position of the rotating disc; clamping grooves are formed in the upper end of the rotating disc; a support plate is supported in the clamping grooves; a vertical rod perpendicular to the support plate is arranged at the center position of the support plate; and first circular rings, second circular rings and third circular rings are arranged on the pay-off rack body in sequence from bottom to top. The automobile wire harness pay-off rack is high in pay-off efficiency, and free from the phenomena of knotting and intertwining during the pay-off process.

Owner:WUHU BOKANG ELECTRICAL

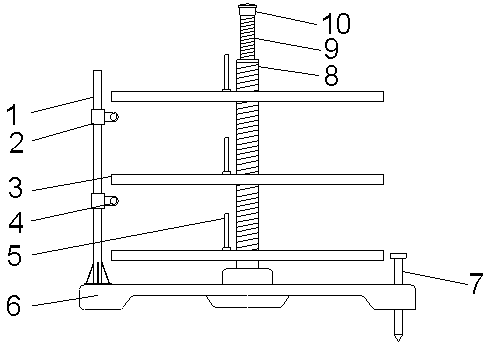

Portable cable dereeling plate

The invention belongs to the technical field of electricity and specifically provides a portable cable dereeling plate. The portable cable dereeling plate comprises a base plate which is supported on the ground; a fixing shaft which is straight up is fixed in the middle part of the base plate; a rotating plate which sleeves the fixing shaft is arranged on the base plate; a plurality of rollers which can rotate along the upper surface of the base plate are arranged on the lower surface of the rotating plate; a detachable top plate on which a rotating handle is fixed is connected to the upper end of the fixing shaft. The portable cable dereeling plate is simple in structure, convenient to mount and small in size; the rollers below the rotating plate can reduce the resistance in dereeling; the rotating handle can assist reeling and dereeling, so that the manpower can be saved, the dereeling speed can be controlled, and as a result, the dereeling efficiency can be increased.

Owner:牛永杰

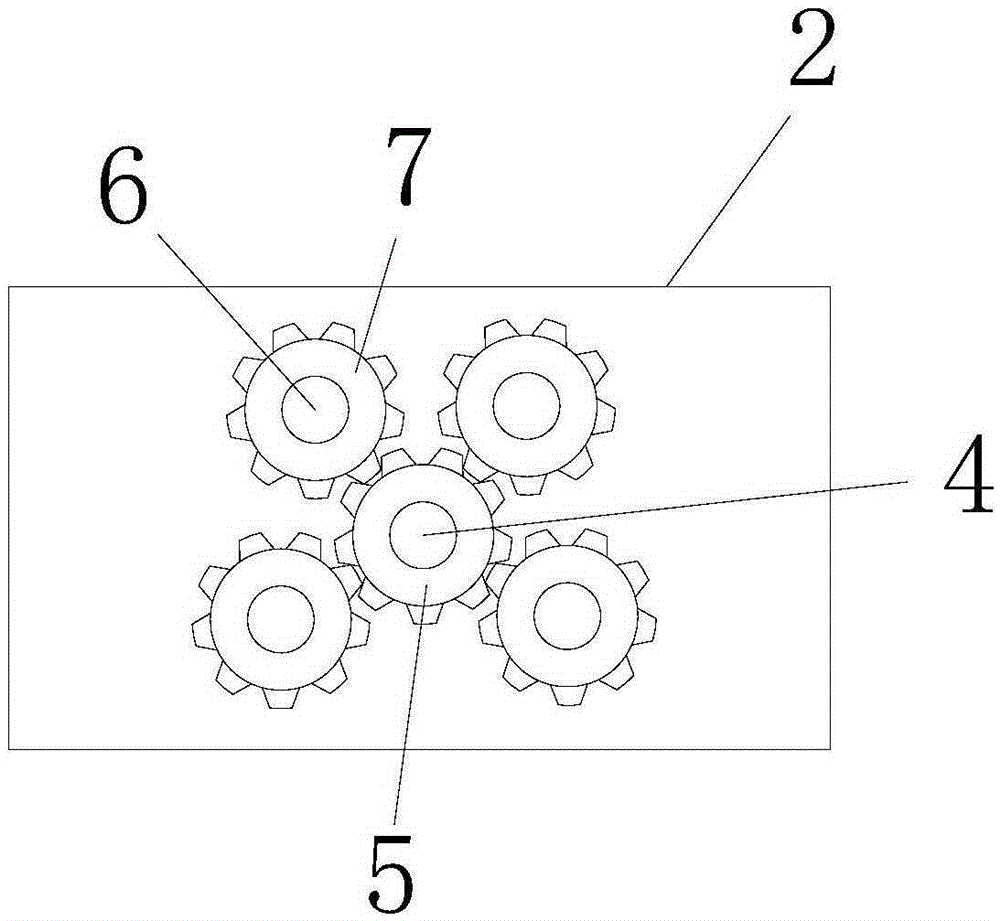

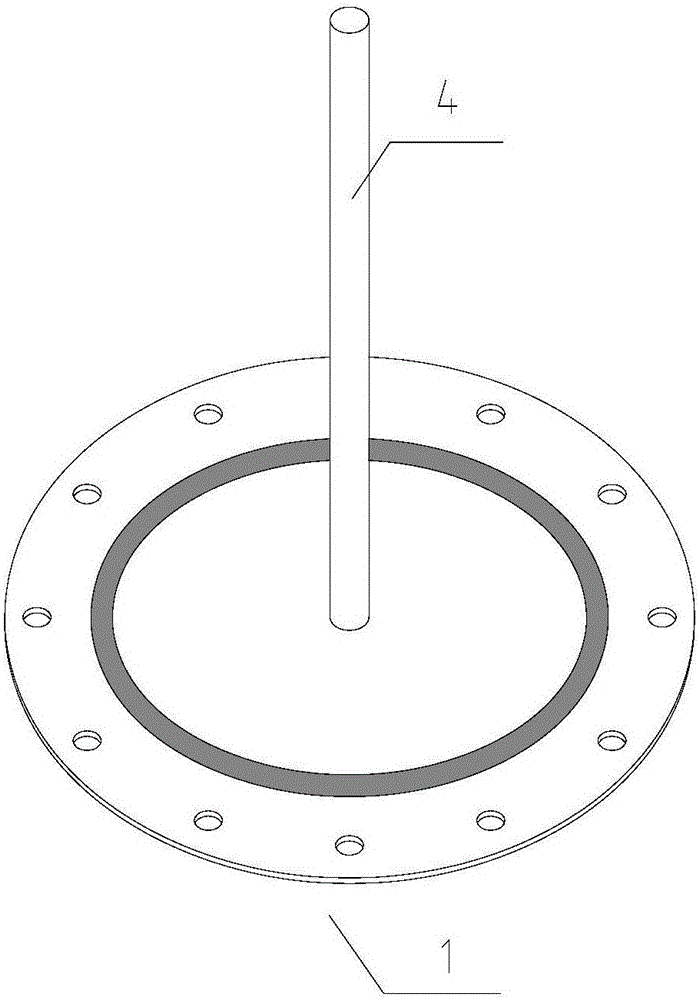

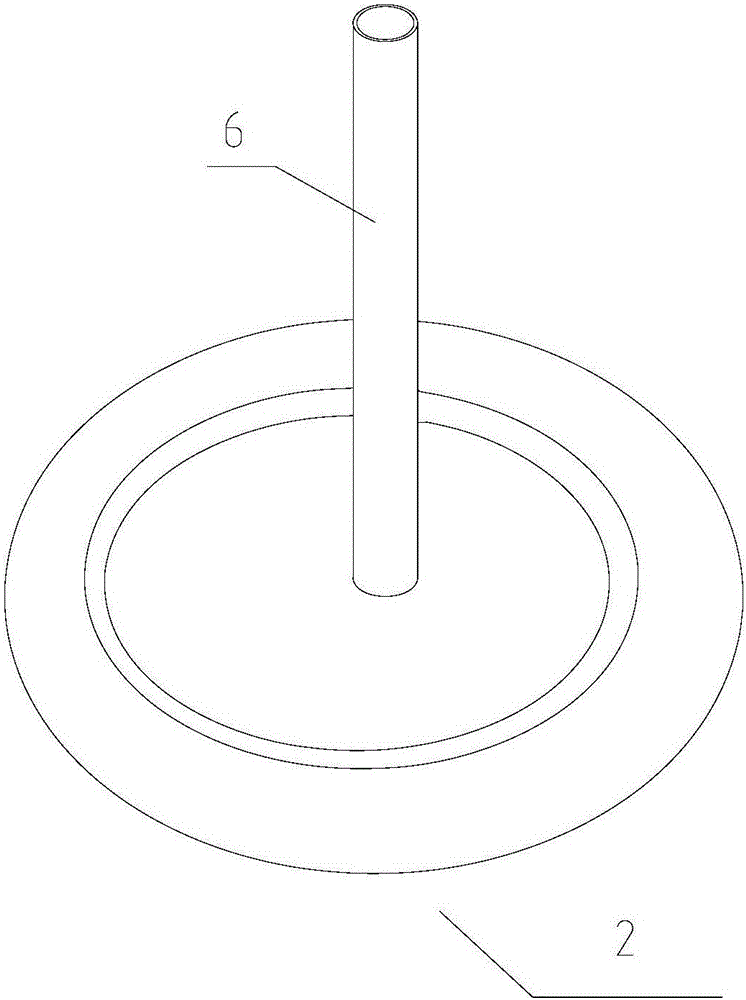

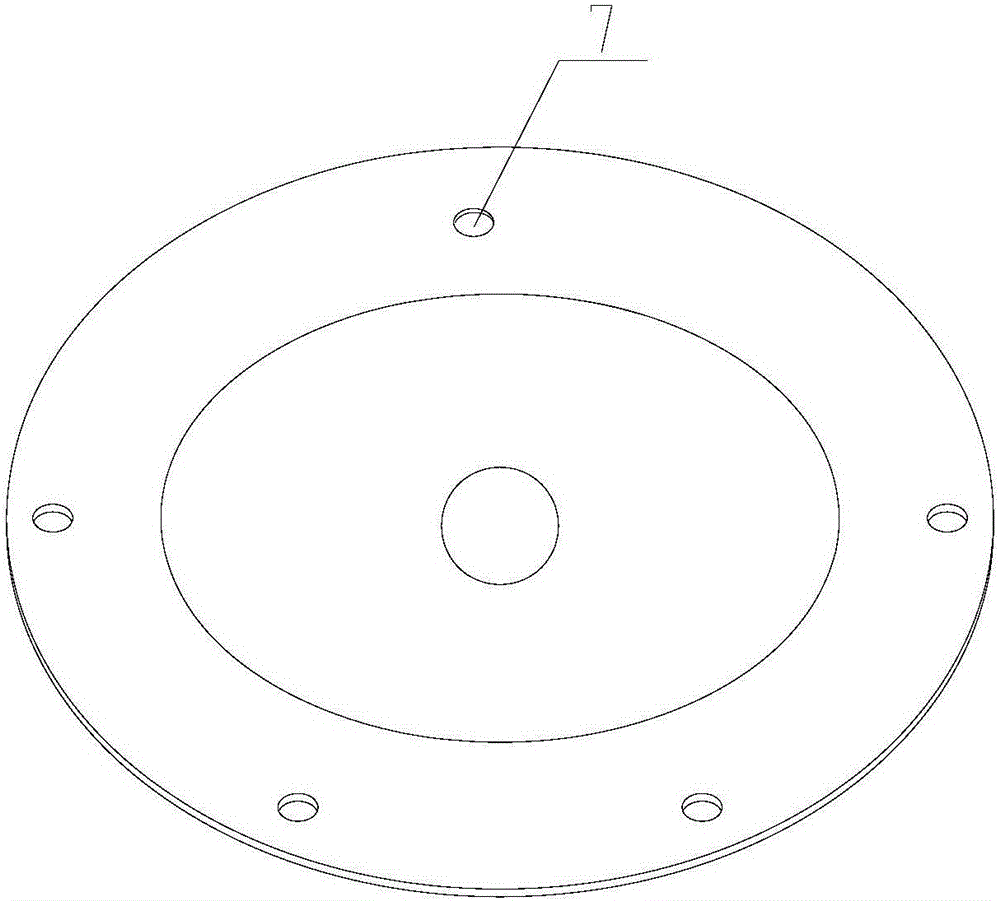

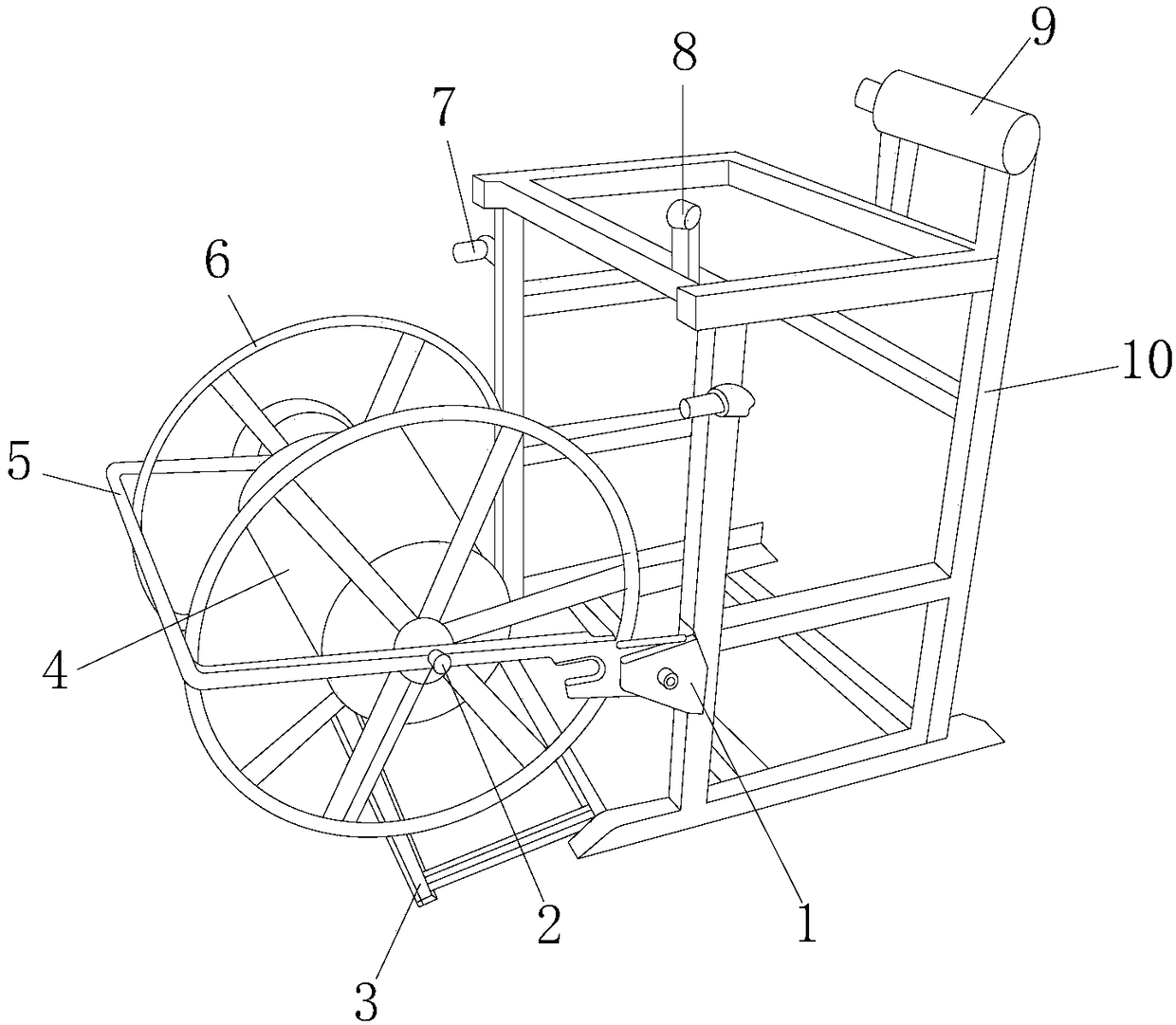

Textile rack

The invention discloses a textile rack. The textile rack comprises a base (2) with a cavity (1), a motor (3), a driving rotary shaft (4), a driving rotary gear (5), multiple driven rotary shafts (6) and multiple driven rotary gears (7), wherein the motor is arranged inside the base; the driven rotary shafts are vertically arranged on the top end surface of the base; one end of the driving rotary shaft is connected with a rotary shaft of the motor; the other end of the driving rotary shaft penetrates through the top end surface of the base and vertically outwards extends; the outer wall of the driving rotary shaft is sleeved with the driving rotary gear; the outer walls of the driven rotary shafts are sleeved with the driven rotary gears; teeth of the driven rotary gears can be engaged with teeth on the driving rotary gear. The textile rack is small in occupied space, and can increase the weaving speed and improve the textile production efficiency.

Owner:WUHU KANGDAOER TEXTILE SCI

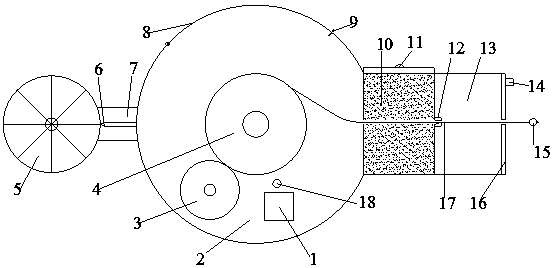

Optical cable pay-off device for optical fiber telecommunication construction

The invention discloses an optical cable pay-off device for optical fiber telecommunication construction. The optical cable pay-off device comprises a spindle, a pay-off box, a cutting knife and a mounting frame. The spindle is arranged in the pay-off box. A driven wheel is arranged at one end of the spindle. A winding wheel is arranged on the outer side of the spindle. Wheel hubs are arranged atthe two ends of the winding wheel. Supporting frames are arranged on the outer side of the wheel hubs. Center holes are formed in the inner sides of the wheel hubs. Slotted holes are formed in the outer sides of the center holes. A motor is arranged under the winding wheel. A transmission shaft is arranged at one end of the motor. A driving wheel is arranged at one end of the transmission shaft. Acontrol box is arranged on the rear portion of the pay-off box. A forward rotation button is arranged on the surface of the control box. A reverse rotation button is arranged on one side of the forward rotation button. The optical cable pay-off device has the beneficial effects that workloads of manual pay-off are reduced, the pay-off efficiency is improved, meanwhile, and rebound and bending ofoptical cables are avoided. The pay-off required state is protected, economic losses are reduced, meanwhile, the optical cable pay-off device is provided with a cutting device, and cutting is facilitated.

Owner:YANGTZE UNIVERSITY

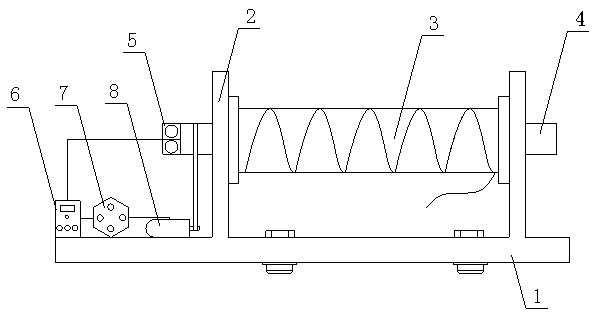

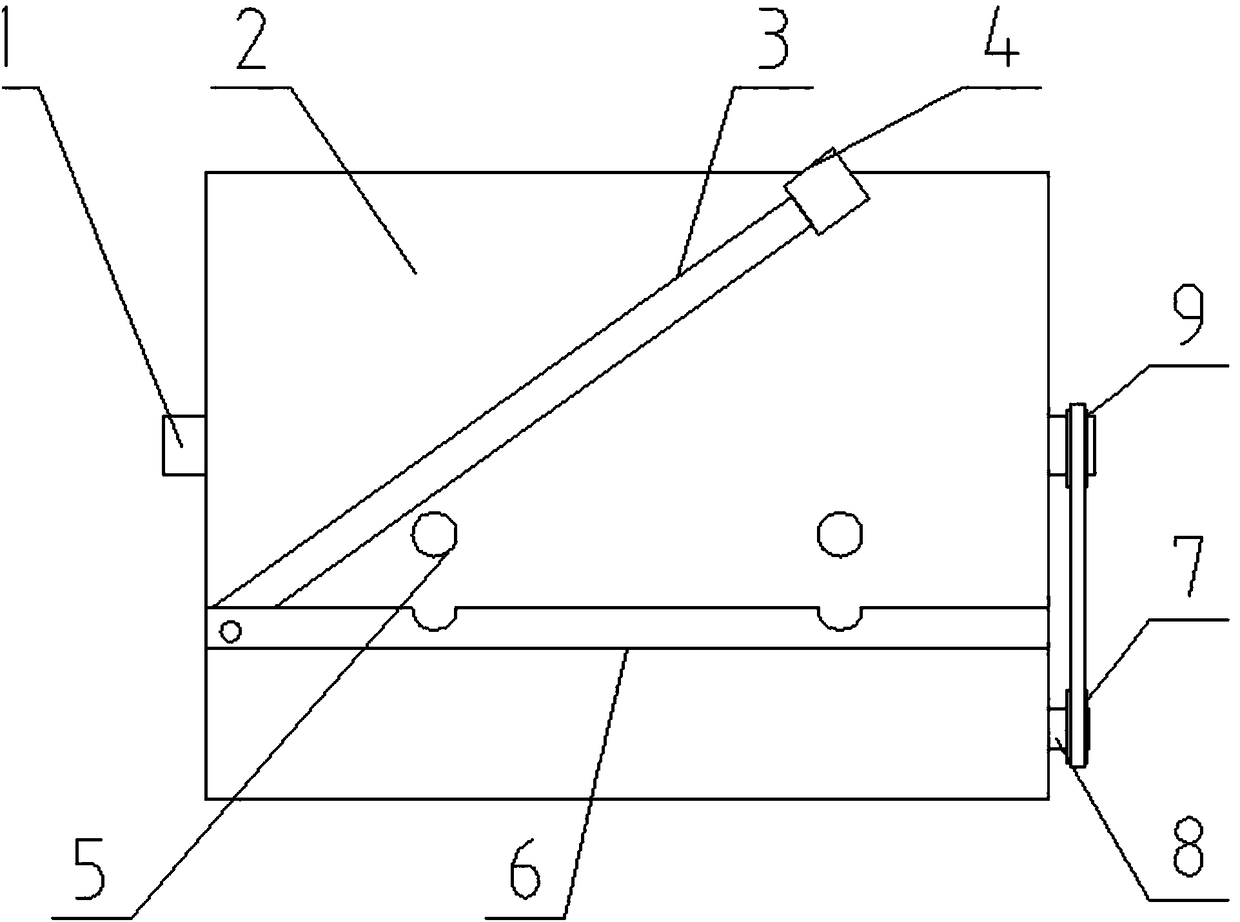

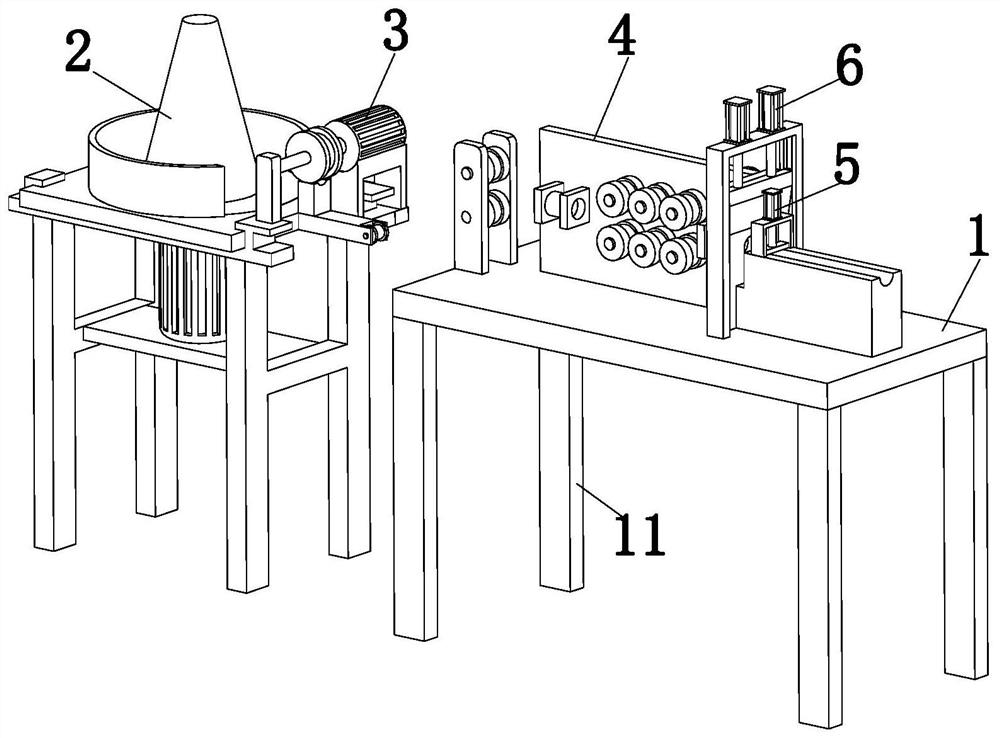

Flexible fireproof flame-retardant cable processing and cutting device

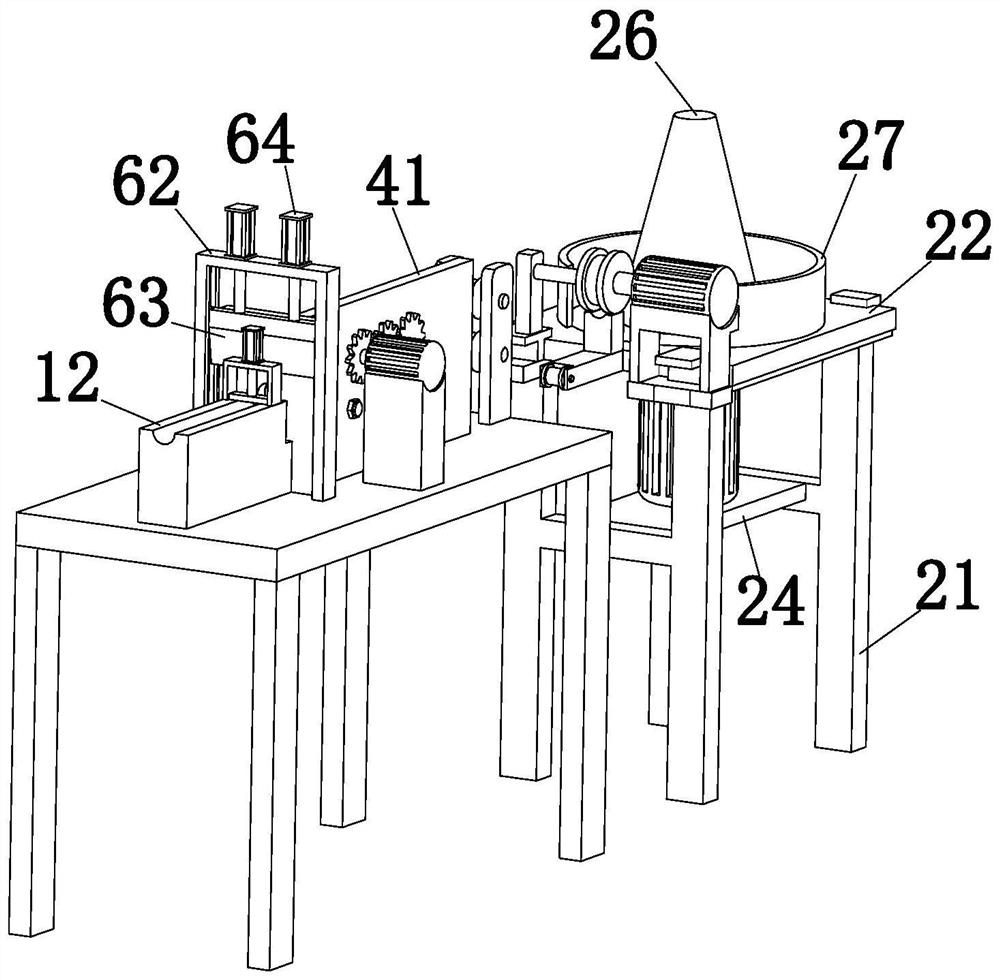

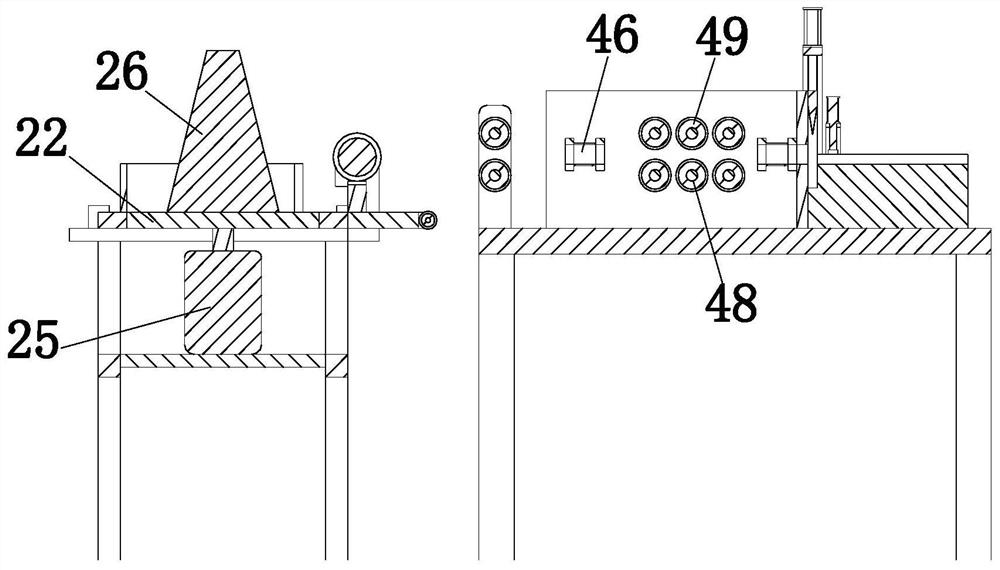

InactiveCN111816373AExact lengthImprove cutting efficiencyApparatus for feeding conductors/cablesStructural engineeringElectric cables

The invention discloses a flexible fireproof flame-retardant cable processing and cutting device. The invention belongs to the technical field of cable processing cutting equipment. The device comprises a machining table, a pay-off device, a wire feeding device, a flattening device, a fixing device and a cutting device. The machining table is arranged on the ground. Four supporting legs which aresymmetrical in pairs are arranged at the bottom of the machining table. A discharging groove seat is arranged at the top of the machining table; scales are arranged on the two side walls of the discharging groove base. The pay-off device is arranged beside the machining table, the wire feeding device is installed on the pay-off device, the flattening device is transversely arranged at the top of the machining table, the fixing device is arranged at the top of the discharging groove base, and the cutting device is arranged between the flattening device and the fixing device. According to the cable cutting device, the pay-off device, the wire feeding device, the flattening device, the fixing device and the cutting device can work synchronously, the cutting efficiency is improved, the lengthof a cut cable is more accurate, and the cutting effect can be guaranteed.

Owner:梁波

Cable pay-off device

InactiveCN102916370ASimple structureImprove pay-off efficiencyApparatus for overhead lines/cablesLocking mechanismEngineering

Owner:高密胜鑫交通工程有限公司

Novel control cable pay-off frame

InactiveCN105692321ALarge diameterIncreased load-bearing capacityFilament handlingEngineeringThreaded rod

The invention discloses a new control cable pay-off frame, which is used to control the release of cable coils on a cable reel, and is characterized in that it includes a fixed chassis and a rotating disk sleeved on the fixed chassis; the central welding of the fixed chassis There is a drill rod used to put the cable reel; the center of the rotating disk is provided with a cylindrical hollow rod for passing through the drill rod; the bottom of the rotating disk is equipped with a plurality of Rotary wheels, each of which is fixed by a screw. The invention adopts a portable design, which is convenient for on-site use and portability; simple and convenient assembly, saving time; capable of laying out cables of different types; durable and convenient for maintenance.

Owner:XUANCHENG POWER SUPPLY COMPANY OF STATE GRID ANHUI ELECTRIC POWER +1

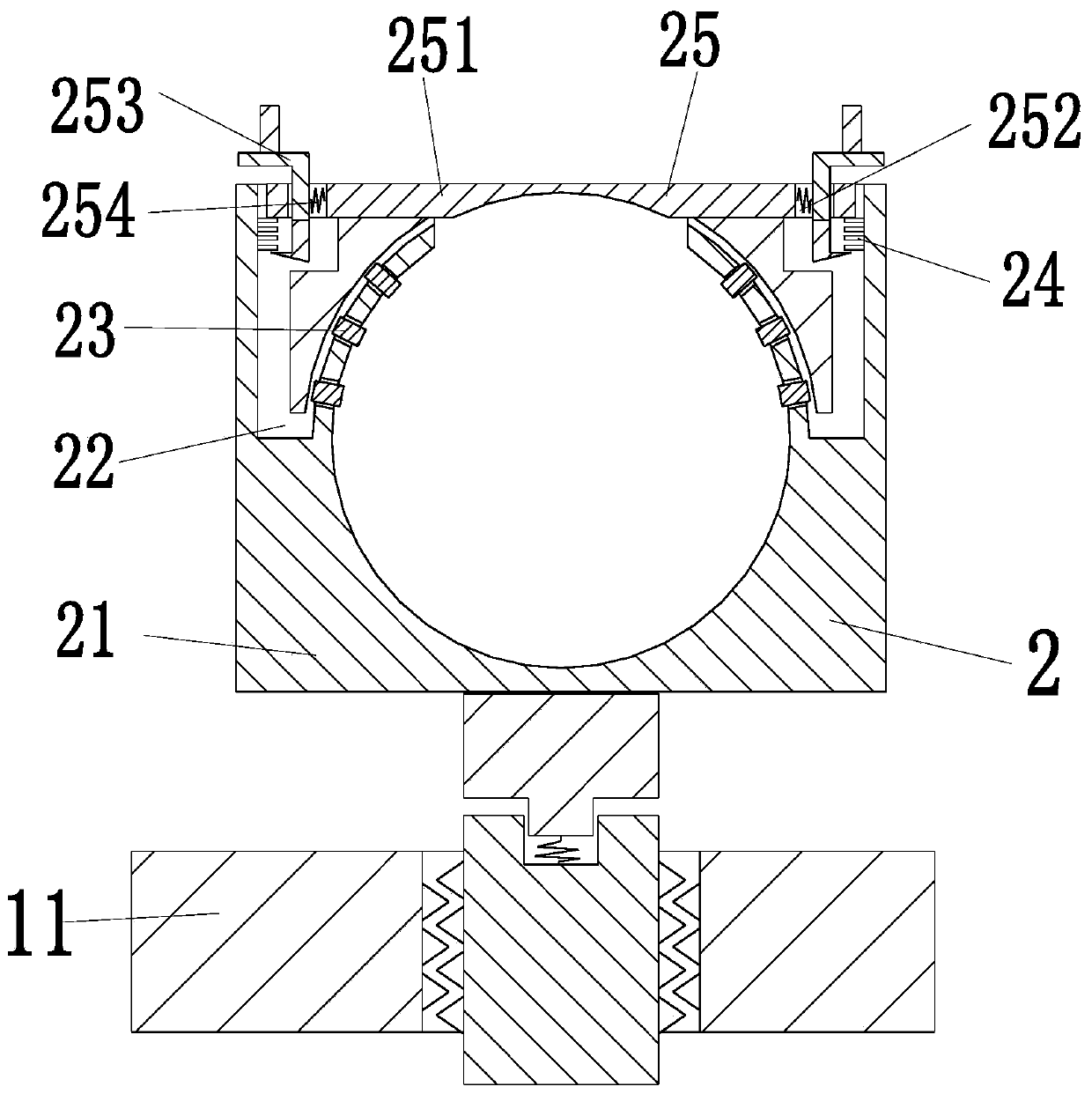

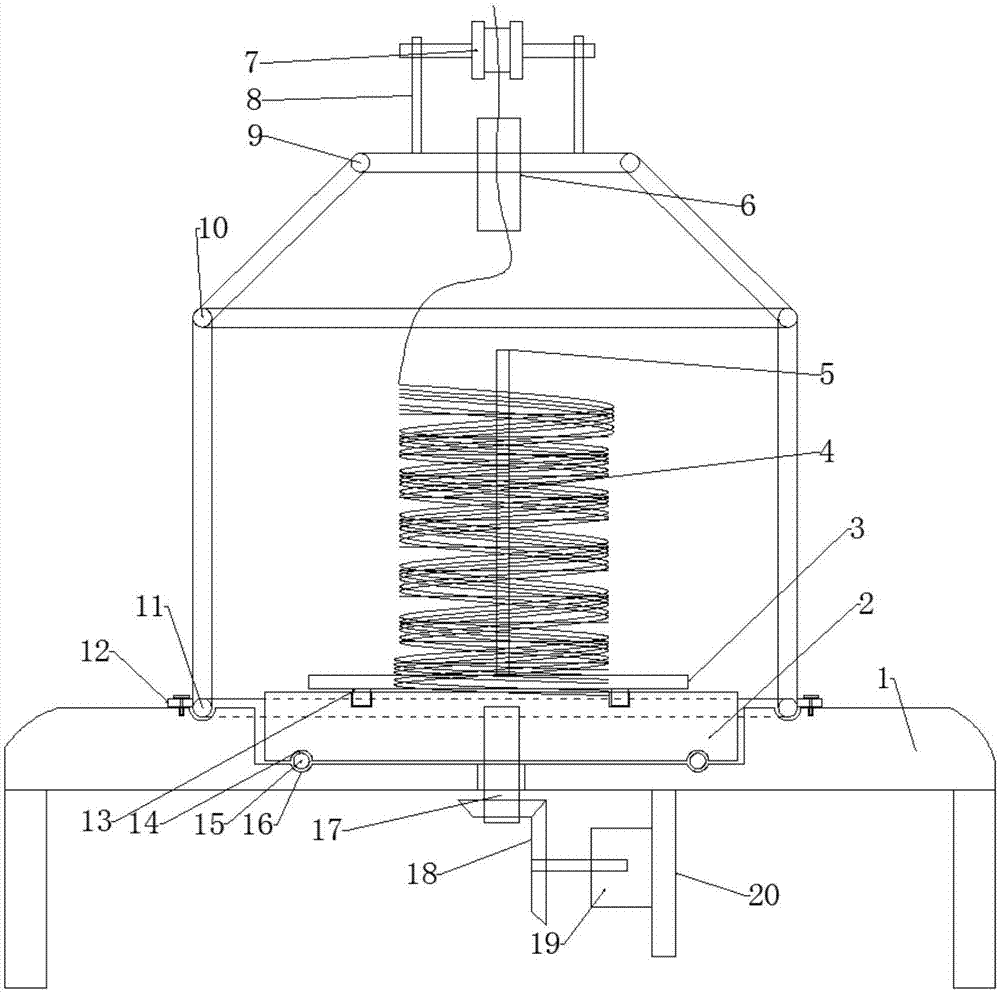

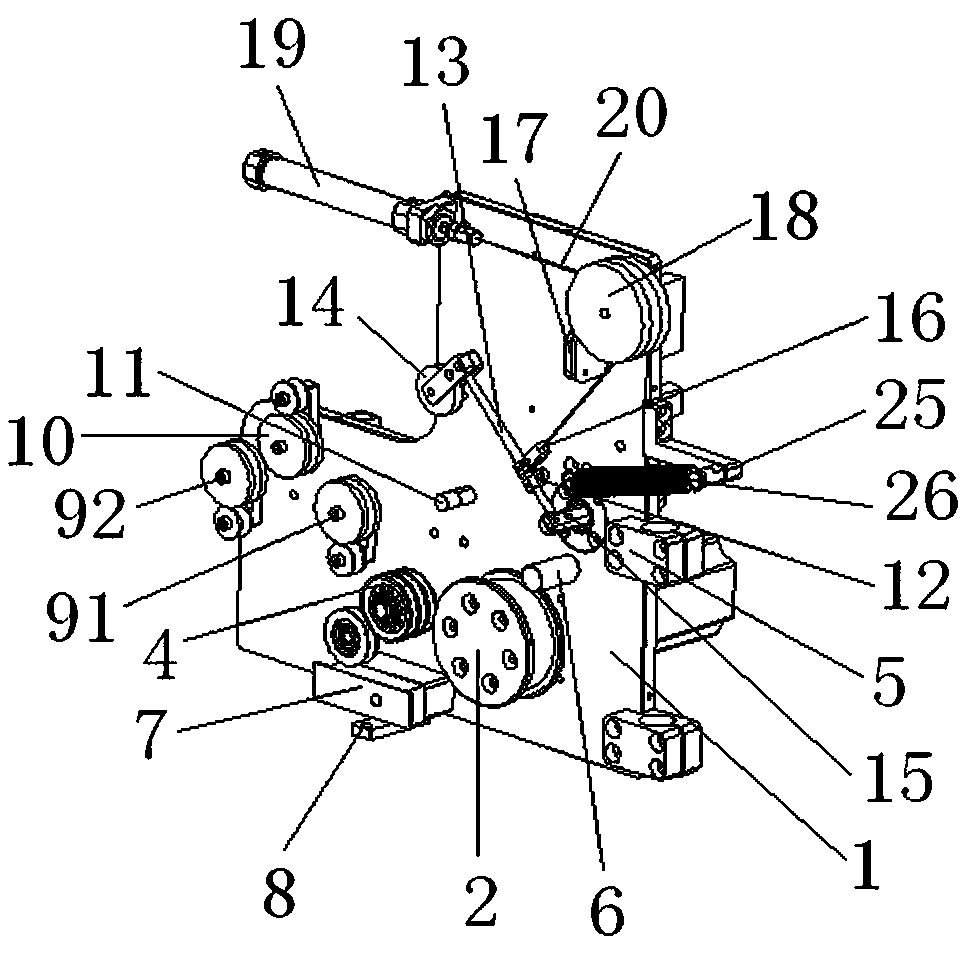

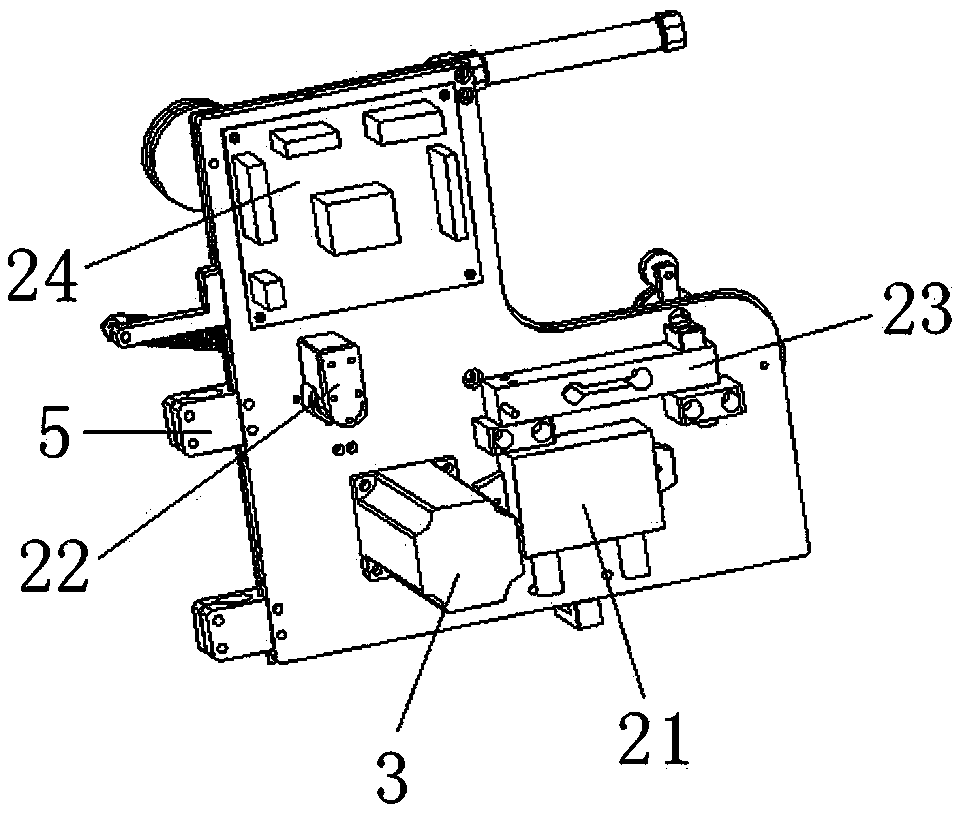

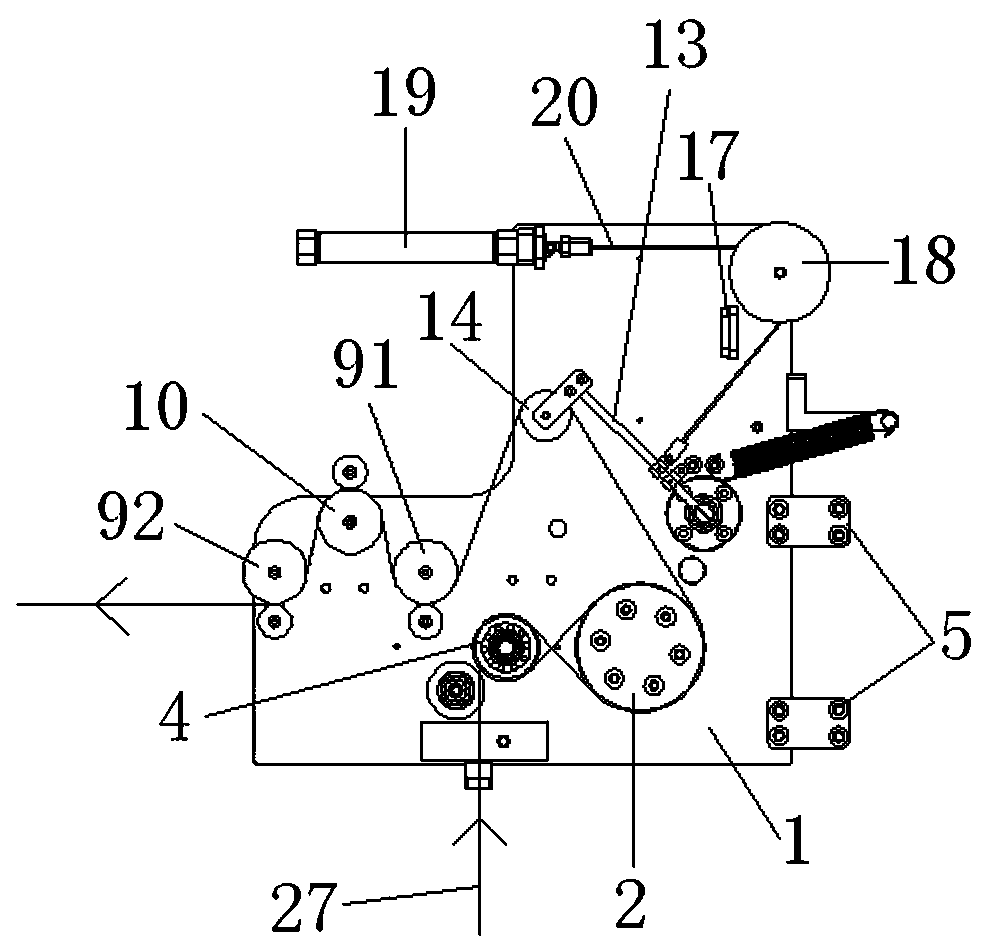

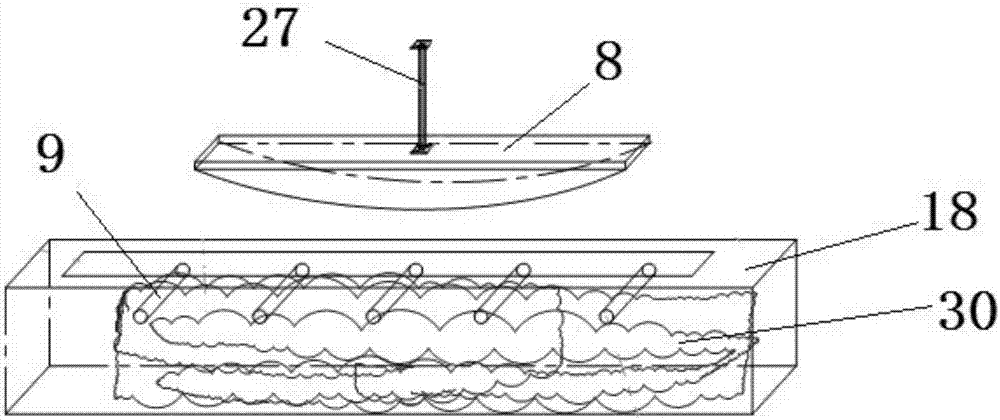

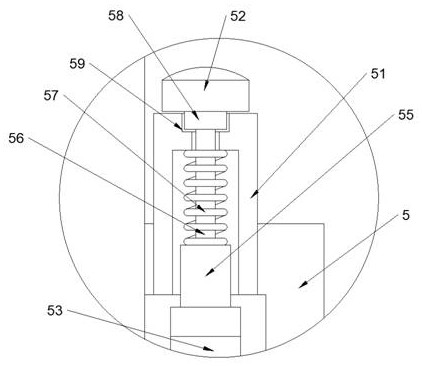

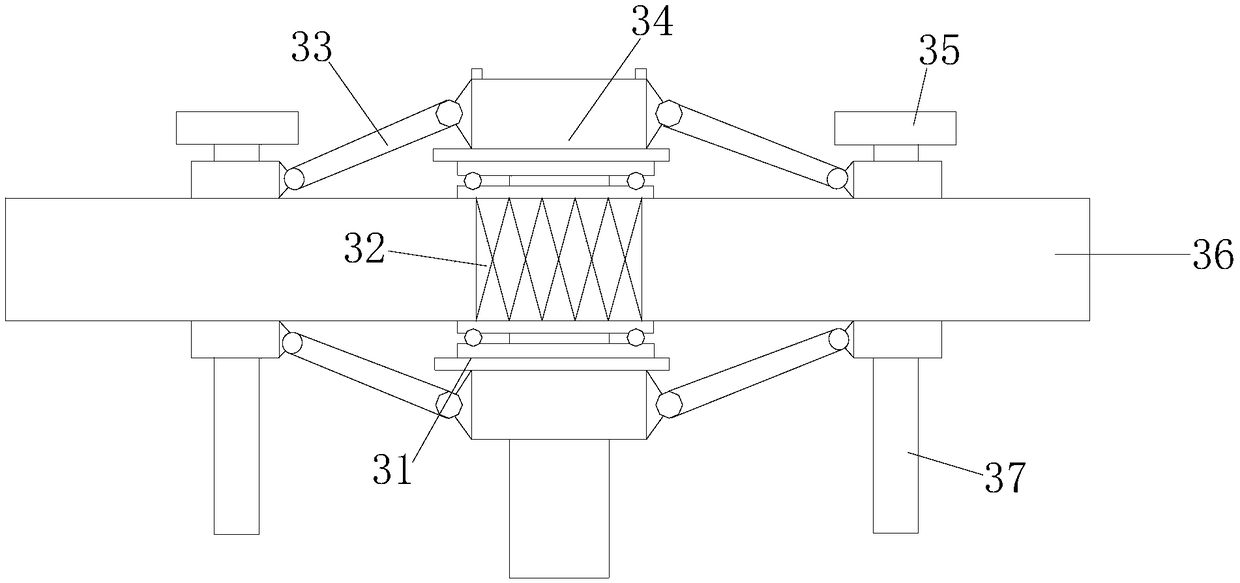

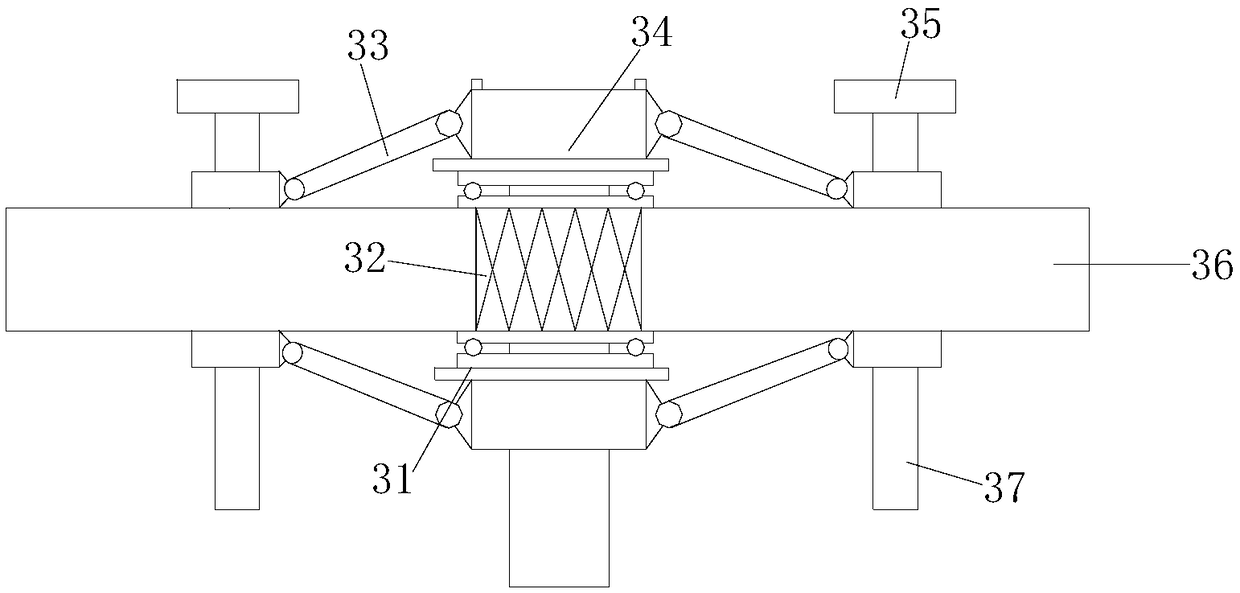

Dynamic balance automatic servo tension device

ActiveCN110065849AImprove the winding effectMake sure the tension is constantFilament handlingWinding machineDynamic balance

The invention provides a dynamic balance automatic servo tension device. The tension device comprises a tension driving wheel, a servo motor, an input thread passing wheel, a machine fixing base, a thread blocking shaft, wool felt, a thread inlet nozzle, an output thread passing wheel, a tension thread passing wheel, a tension rod limiting column, a reset spring pulling base, a tension rod, a tension wheel, a tension rod rotating shaft, a tension rod thread connector, a tension rod limiting block, a steel wire rope passing wheel, a steel wire rope, an air cylinder, a tension controller, an angle sensor, a tension sensor and a CPU controller. According to the tension device, dynamic paying-off can be realized, and it is ensured that the paying-off tension is constant and the paying-off angle is constant. The tension device has the advantages of being high in paying-off efficiency, good in paying-off effect, good in winding effect and capable of ensuring uniform tightness in the windingprocess. The overall structural design solves the problems that a traditional winding machine conducts passive paying-off, and paying-off speed losses, unstable tension, non-uniform winding tightnessof the winding machine and poor winding effects are likely to occur in the paying-off process.

Owner:DONGGUAN ZONGHENG ELECTROMECHANICAL SCI & TECH

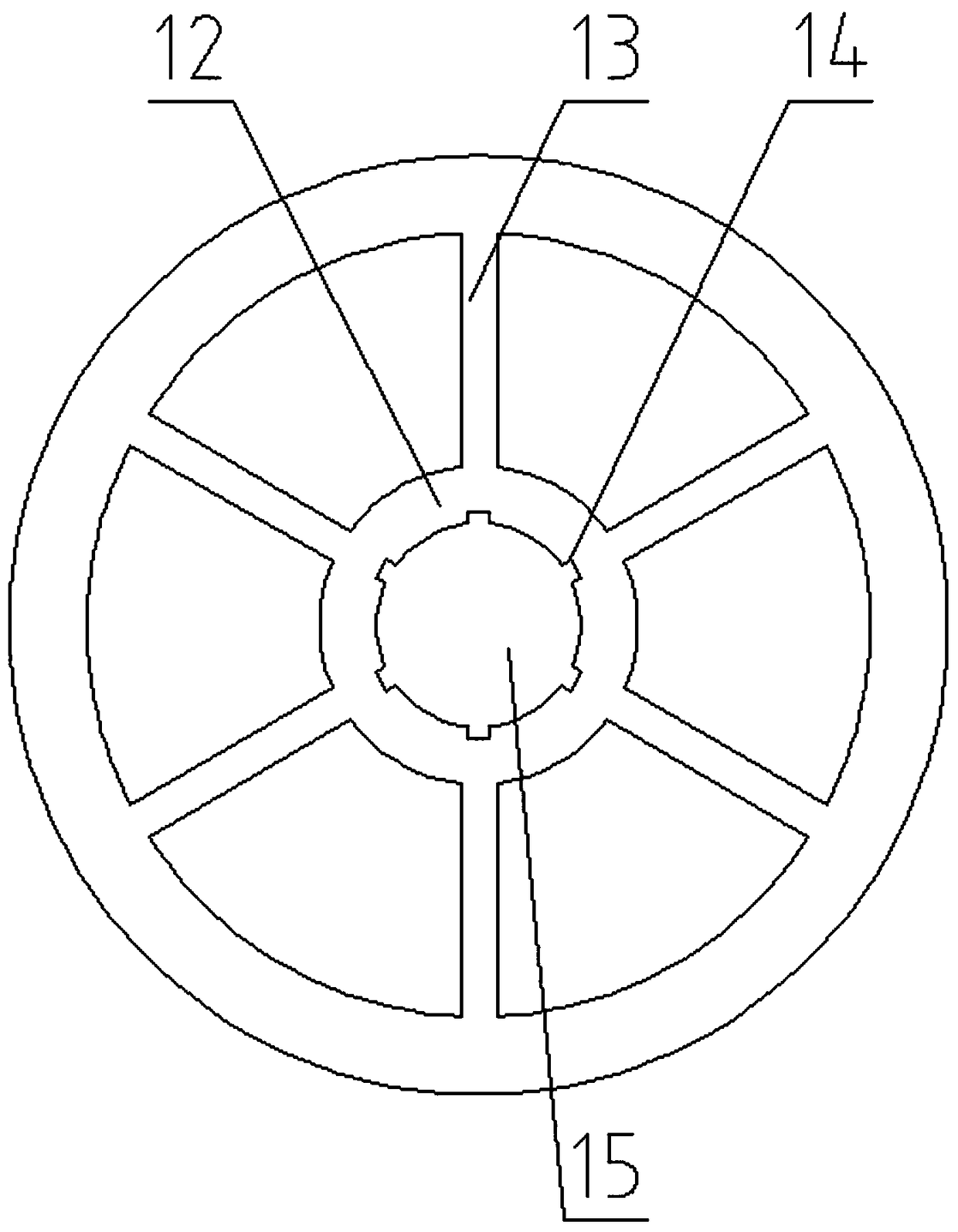

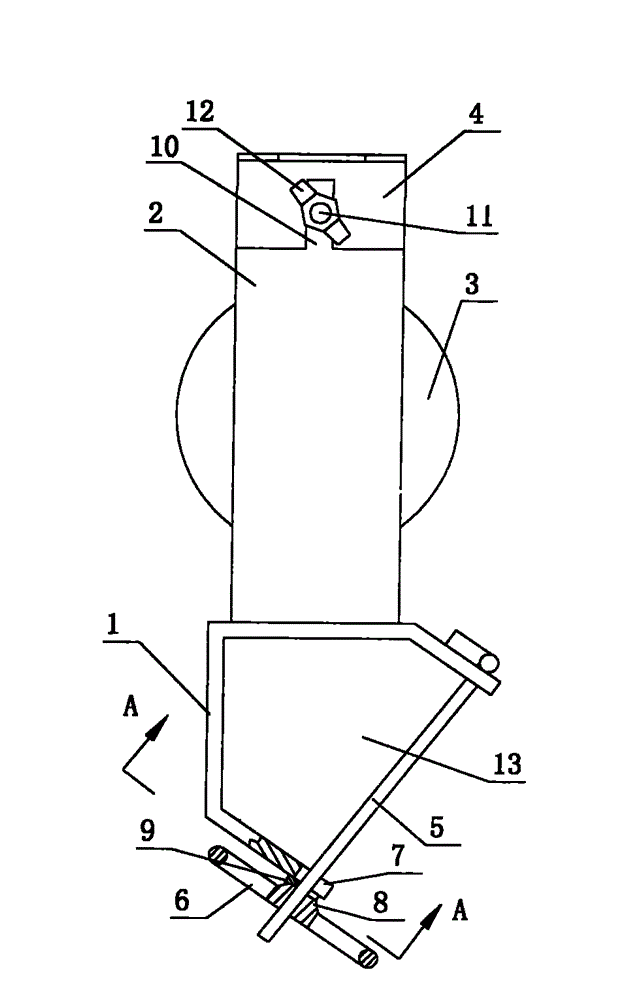

Steel bar spacing setting-out tool and setting-out method

ActiveCN110616905AEasy to operateImprove pay-off efficiencyBuilding material handlingRebarEngineering

The invention discloses a steel bar spacing setting-out tool and a setting-out method. The tool comprises an operation rod, a mandrel, a roller and sponge used for adsorbing a marking liquid, whereinthe roller sleeves the mandrel with a gap; the sponge is filled between the mandrel and the roller; penetrating outer dotting holes are uniformly formed in the outer circle of the roller in the circumferential direction; clamping grooves are distributed in the end surface of the roller; a movable baffle is placed in each clamping groove in an insertion manner; penetrating inner dotting holes are formed in each movable baffle; each outer dotting hole corresponds one movable baffle; the inner dotting holes and the outer dotting holes can be aligned and staggered by adjusting the insertion-placement positions of the movable baffles; the bottom of the operation rod is rotationally connected with a part located outside the roller, of the mandrel; and the operation rod is capable of pushing theroller to roll when the roller is transversally placed. The steel bar spacing setting-out tool and the setting-out method are simple to operate, high in setting-out efficiency and setting-out quality,wide in practicability, and low in cost.

Owner:CHINA FIRST METALLURGICAL GROUP

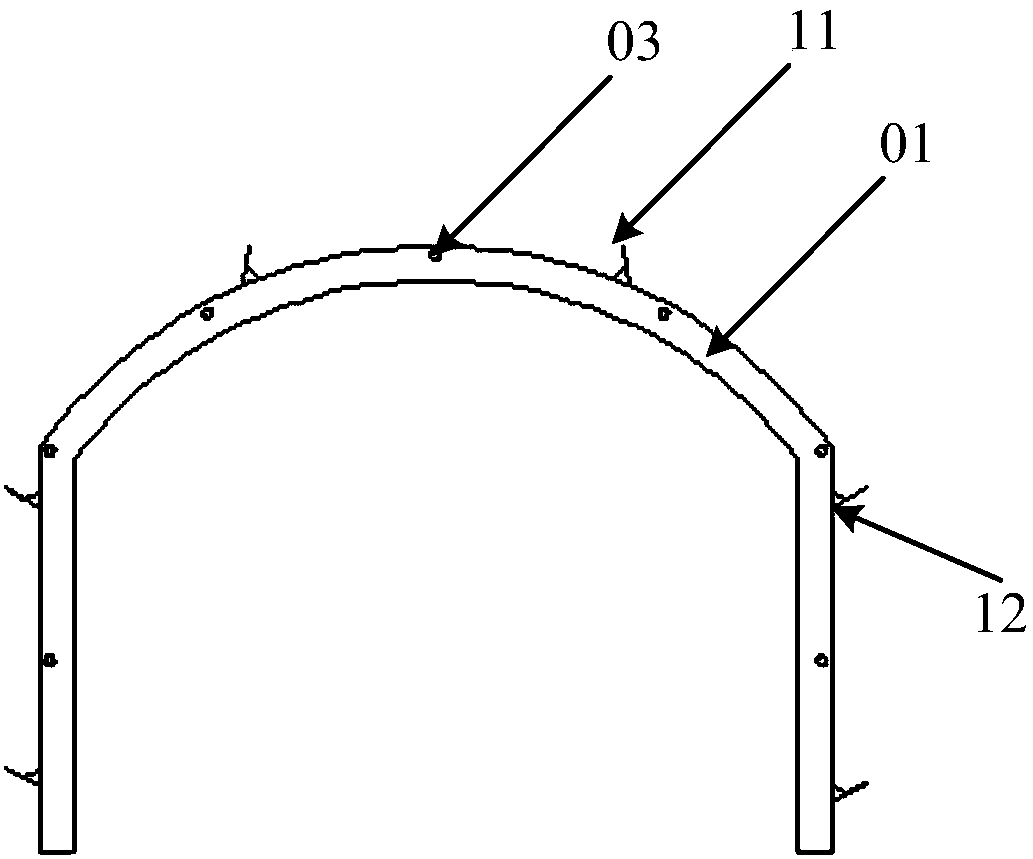

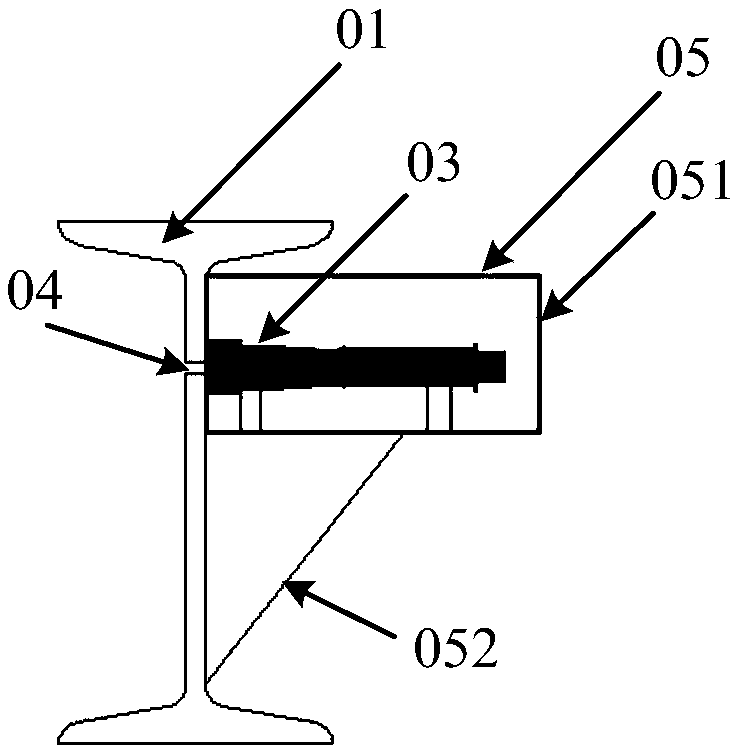

Pay-off device and method

ActiveCN107687842AEasy to makeEasy to operateReference line/planes/sectorsLaser transmitterOptoelectronics

The invention provides a pay-off device and method. The pay-off device comprises a first arching and a plurality of first laser transmitters, wherein the first arching has an outer contour which is the same as that of a target tunnel and is arranged at the outer side of an excavation section; the first laser transmitters are arranged on the first arching at intervals and are used for transmittingfirst laser to the excavation section to form a projection of the contour of the target tunnel. The pay-off device provided by the invention is simple to manufacture and measurement pay-off operationis convenient and has small working amount and high efficiency.

Owner:STATE GRID CORP OF CHINA +3

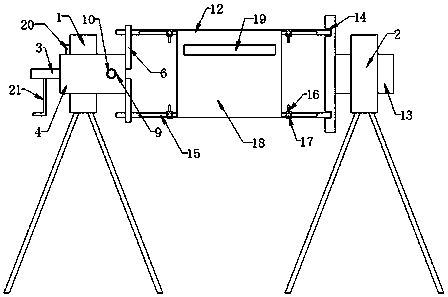

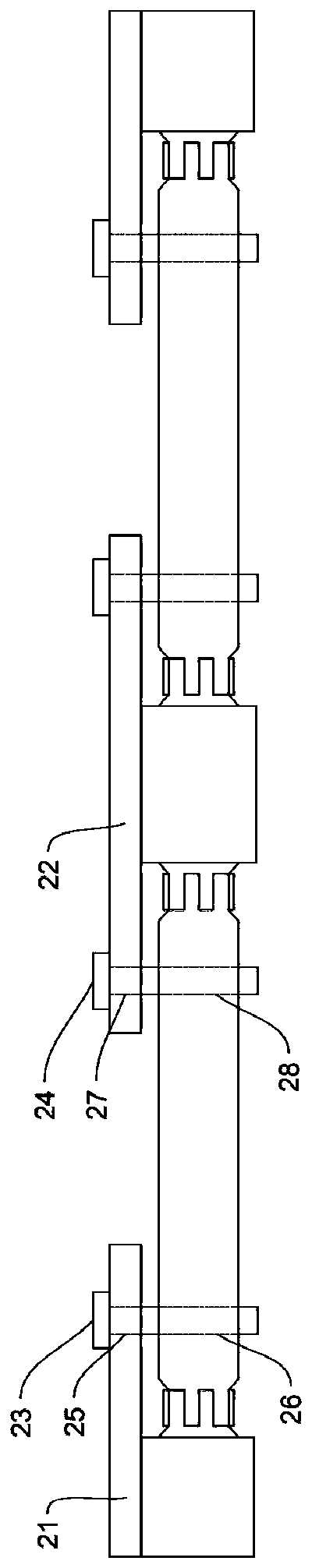

Power cable taking-up and paying-off machine

ActiveCN108163646AIncrease spacingGuaranteed stabilityApparatus for overhead lines/cablesBobbinPower cable

The invention discloses a power cable taking-up and paying-off machine. The power cable taking-up and paying-off machine comprises a rack. The rack is provided with a motor and a controller which areconnected. The power cable taking-up and paying-off machine is characterized in that the rack is rotationally provided with a left base, the left base is provided with a plurality of sliding rods in asliding manner, and the sliding rods are provided with supporting rods; the left base is further provided with an adjusting rod in a sliding manner, the adjusting rod is provided with an adjusting block, the adjusting block is provided with shoring teeth and clamping grooves, the shoring teeth and the clamping grooves are arranged in a staggered manner, and the clamping grooves are matched with the sliding rods; the adjusting rod and the left base are further provided with a ratchet and a pawl which are matched with each other, and a tension spring is connected between the pawl and the left base; and a transmission gear connected with the motor is arranged on the outer circumference of the left base. According to the power cable taking-up and paying-off machine, the size of a bobbin can be adjusted according to needs, accordingly, one paying-off device can meet the paying-off requirement of multiple specifications of cables, and the universality and the paying-off efficiency of the device are greatly improved.

Owner:中国电建集团河北工程有限公司

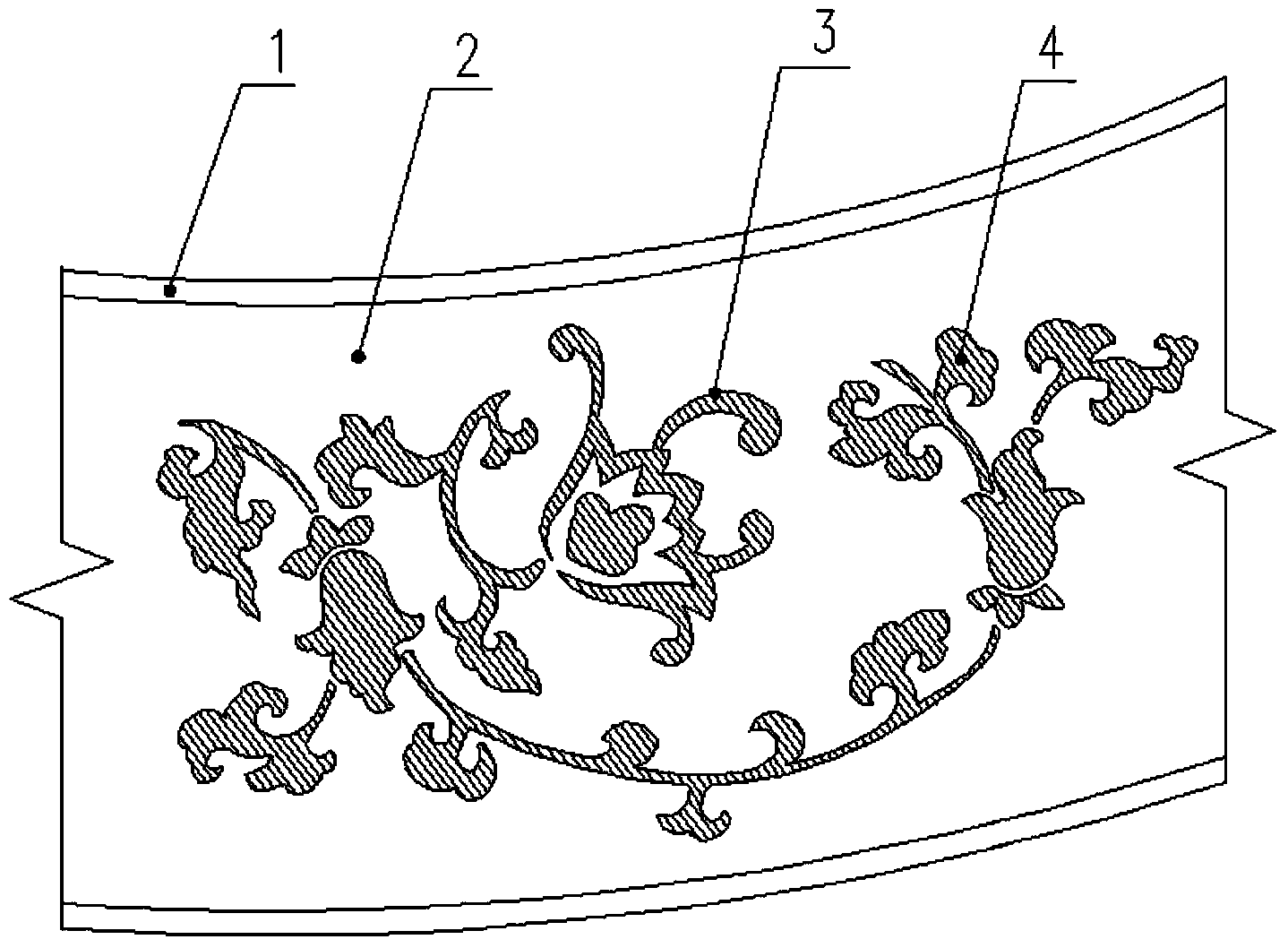

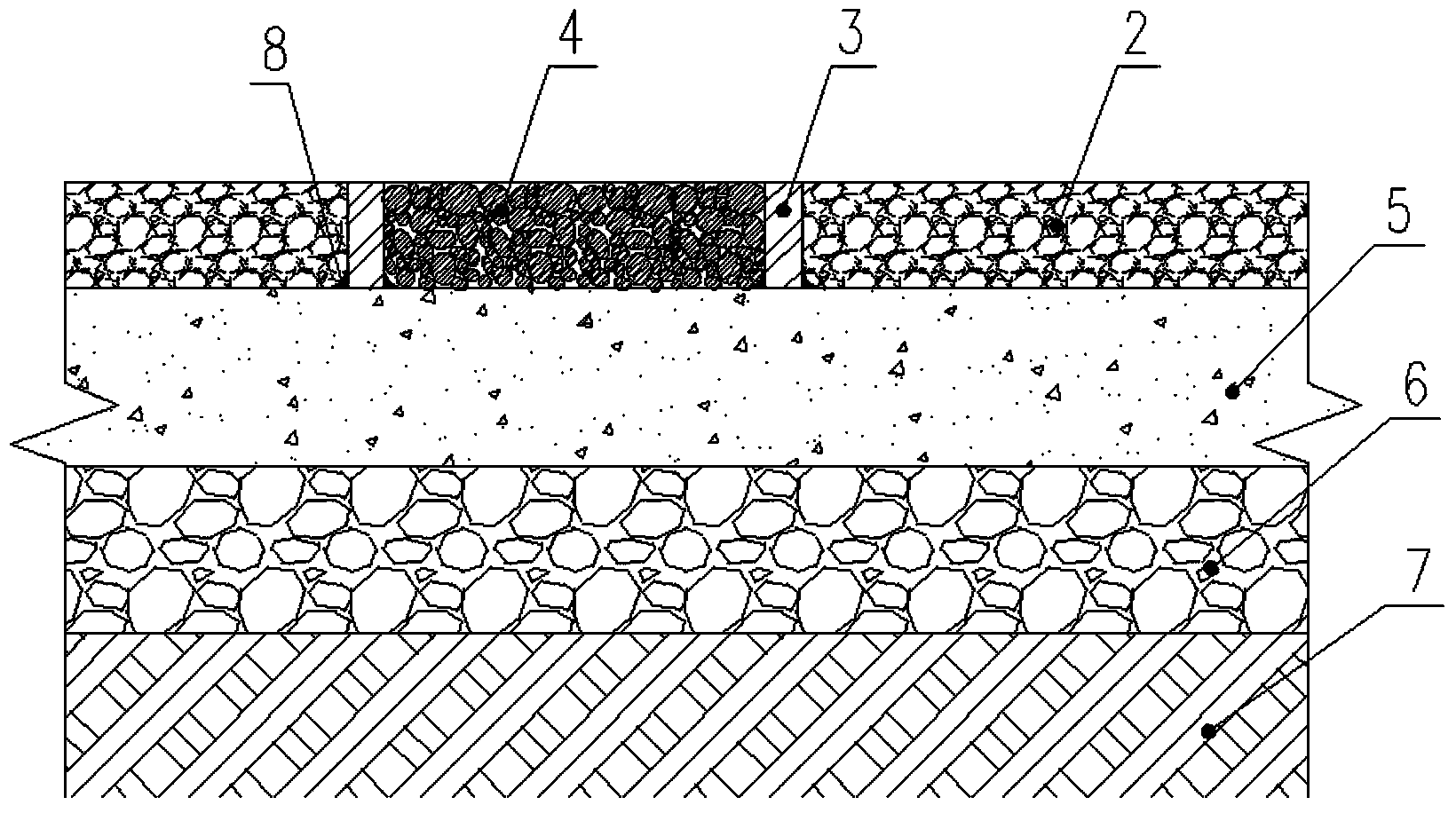

Pavement and contraction method for crushed aggregate pattern

ActiveCN103924498AImprove the efficiency of pay-offPrecise stakeoutSidewalk pavingsAcute angleExtension method

The invention relates to a pavement and contraction method for a crushed aggregate pattern. The pavement and contraction method adopts a technological process of preparing materials, treating a base layer, constructing and setting out, erecting a pattern framework, paving the crushed aggregate pattern, protecting a pattern finished product, and paving other parts outside the pattern. According to the pavement and contraction method for the crushed aggregate pattern, a sample extension method in a construction flow is used for setting out so that the setting-out efficiency is improved, the setting-out is accurate and the construction efficiency is improved; the step of erecting the pattern framework has a good fixing and molding effect on the pattern; an acute angle is fine and a decorative pattern is fine and smooth; the construction quality is obviously improved. Furthermore, the method is simple to operate; the requirements on skills of constructors are low and the potential of popularizing and applying is great.

Owner:HUAYUAN LANDSCAPE ARCHITECTURE CO LTD

Pay-off ink-fountain device for masonry wall and use method of pay-off ink-fountain device

ActiveCN107351052AOvercoming the problem of repeatedly rewinding the lineGuaranteed to proceed normallyOther workshop equipmentStructural engineeringIndustrial engineering

The invention discloses a pay-off ink-fountain device for a masonry wall and a use method of the pay-off ink-fountain device. The device includes an end-portion balance board, an ink-fountain pull box and an ink-fountain main box; the end-portion balance board is connected with three chalk lines, the ink-fountain pull box is provided with five placement grooves, a fixed type pull box cabinet is installed in the middle placement groove, the other four placement grooves are each internally provided with two movable pull box cabinets, and line through holes are formed in the fixed type pull box cabinet and the movable pull box cabinets. 240 mm wall lines can be placed in the pay-off ink-fountain device, 120 mm wall lines can also be placed in the device, the problem that a secondary masonry structure requires repeated line releasing is solved, the pay-off deviation value is reduced, the pay-off efficiency is high, the precision is reliable, errors caused by paying off are reduced, paying off work of all walls of the secondary masonry structure can be completed without replacing equipment, the workload of paying off is reduced, the progress of the project is sped up, and it is ensured that the later-period masonry construction is normally conducted.

Owner:THE THIRD CONSTR & ENG OF CCFED

Bidirectionally-adjustable cable pay-off device

ActiveCN103910233AAvoid overall overturningEnable mobilityFilament handlingProduction lineEngineering

Owner:安徽华上电缆科技有限公司

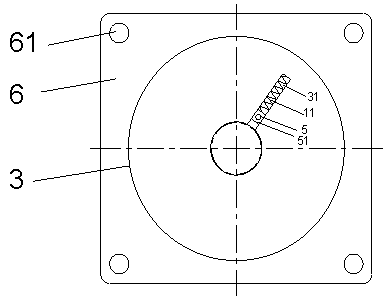

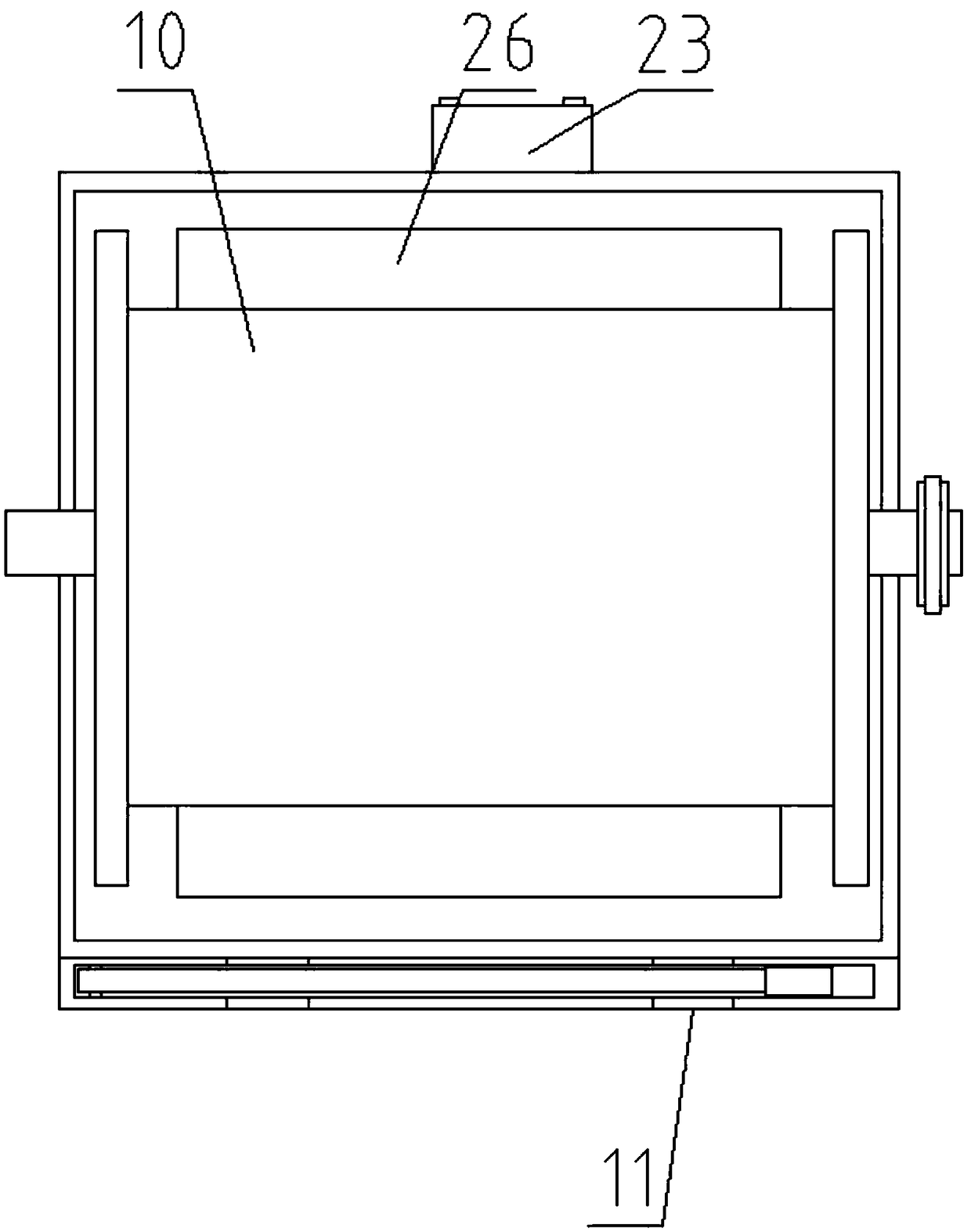

Cable winding and unwinding device

The invention discloses a cable winding and unwinding device. The device comprises a left base and a right base, wherein a rotating disc is arranged on the left base in a rotating mode, and the rotating disc is connected with sliding blocks which are arranged in a sliding mode through an Archimedes spiral groove; the rotating disc is further connected with an adjusting gear through a transmissiongear; and supporting rods are arranged on the sliding blocks. According to the cable winding and unwinding device, the rotating disc is driven to rotate through rotation of the adjusting gear, and then the sliding blocks are driven to move, so that the size of a wire cylinder formed by the supporting rods is changed, a set of equipment can meet the unwinding requirements of multiple coils, time for replacing the wire cylinder and the quantity of equipment needing to be carried are reduced, and working efficiency is improved.

Owner:浙江品创知识产权服务有限公司

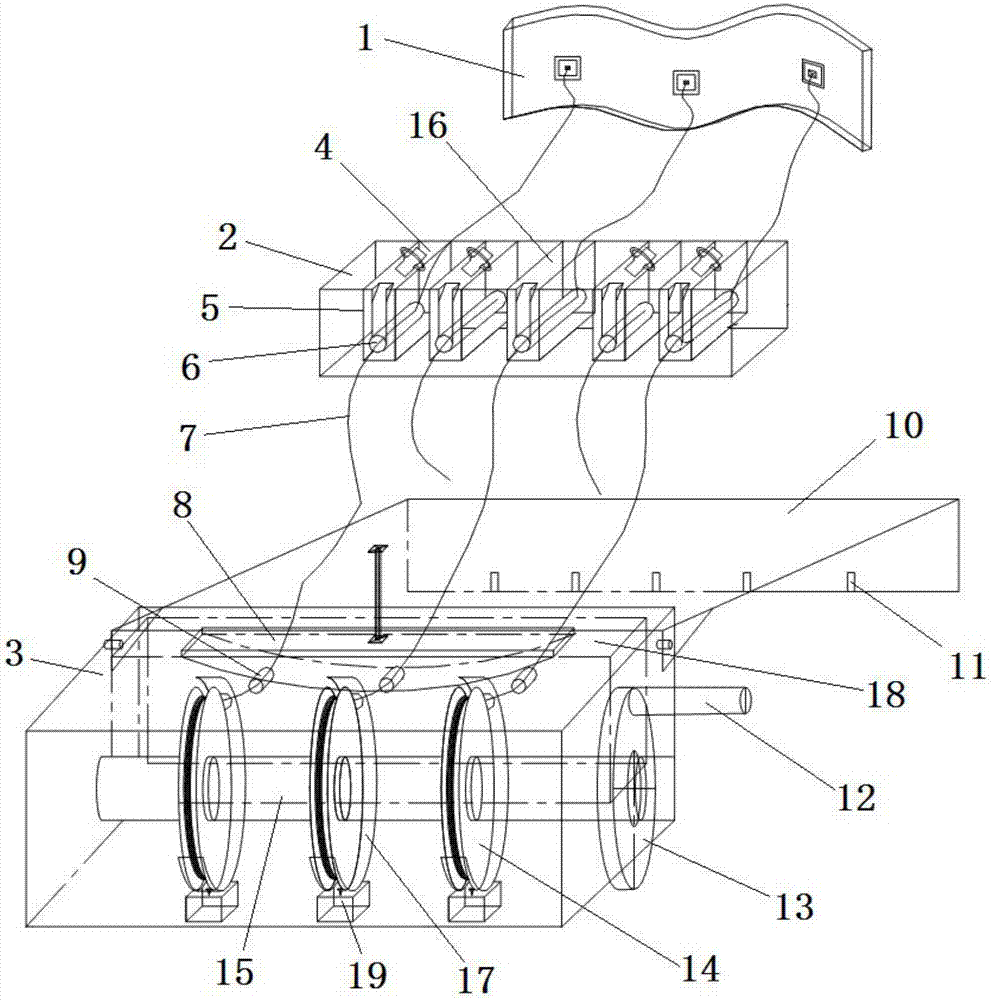

Aerial projection paying-off method for special-shaped building

ActiveCN113203401AReduce the number of wiringReduce difficultyMeasuring points markingReference line/planes/sectorsMeasuring instrumentConstruction engineering

The invention discloses an aerial projection paying-off method for a special-shaped building, which comprises a laser projection instrument, a measuring instrument, a marking device and a laser vertical instrument. The construction paying-off process comprises the steps of S1, manufacturing a projection film, specifically, according to a construction drawing, engraving the axis and component side lines which need to be used as reference to coincide and contour lines or control lines of special-shaped components and structures which need to be paid off on the film in etching mode together, and ensuring that the light can only project a construction line needing to be paid off. The construction line is released in a projection mode, the number of reserved floor pay-off holes and the number of released control lines are reduced, and the plane pay-off difficulty and workload of the special-shaped building are greatly reduced by projecting the contour lines or the control lines of the components and the structures at a time; and the positions of the components and the structures on the floor plane are determined by adopting a reference control line overlapping mode, so that the investment of manpower and pay-off equipment is reduced, the pay-off efficiency is improved, and the construction period is shortened.

Owner:THE FOURTH OF CHINA EIGHTH ENG BUREAU

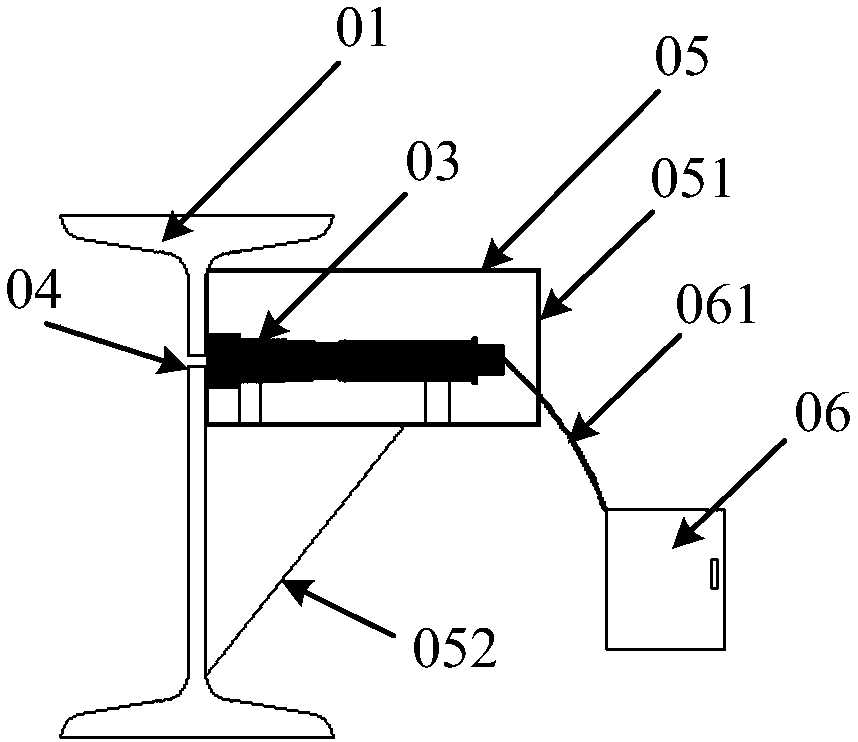

Cable one-way transportation locking structure for high mountain cable erection

ActiveCN112047178AImprove pay-off efficiencyImprove structural strengthFilament handlingStructural engineeringMechanical engineering

The invention discloses a cable one-way transportation locking structure for high mountain cable erection. The cable one-way transportation locking structure comprises a fixing frame, a first mountingcylinder is fixedly connected to one side of the fixing frame, a limiting wheel is rotatably connected to the interior of the first mounting cylinder, a second mounting cylinder is fixedly arranged at the top end of the first mounting cylinder in a penetrating mode, and a connecting block is arranged in the second mounting cylinder; and a clamping block is fixedly connected to the bottom end of the connecting block, the clamping block is a cylinder with one side provided with an inclined plane, the clamping block is clamped in a tooth groove in the outer side of the limiting wheel, the two sides of the tooth groove are perpendicular to the outer surface of the limiting wheel, and a spring is arranged between the top end of the connecting block and the top end of the interior of the secondmounting cylinder. According to the cable one-way transportation locking structure for the high mountain cable erection provided by the invention, the clamping block is additionally arranged betweenthe tooth groove in the outer side of the limiting wheel, when the limiting wheel rotates, the vertical face of one side of the clamping block makes contact with one side of the tooth groove, under the action of the clamping block, limiting of the tooth groove and locking of one-way rotation of the limiting wheel are completed, workers do not need to always crank a rotating handle and limit one-way rotation of a wire coil, and the hands of the workers are liberated.

Owner:国网河南省电力公司桐柏县供电公司

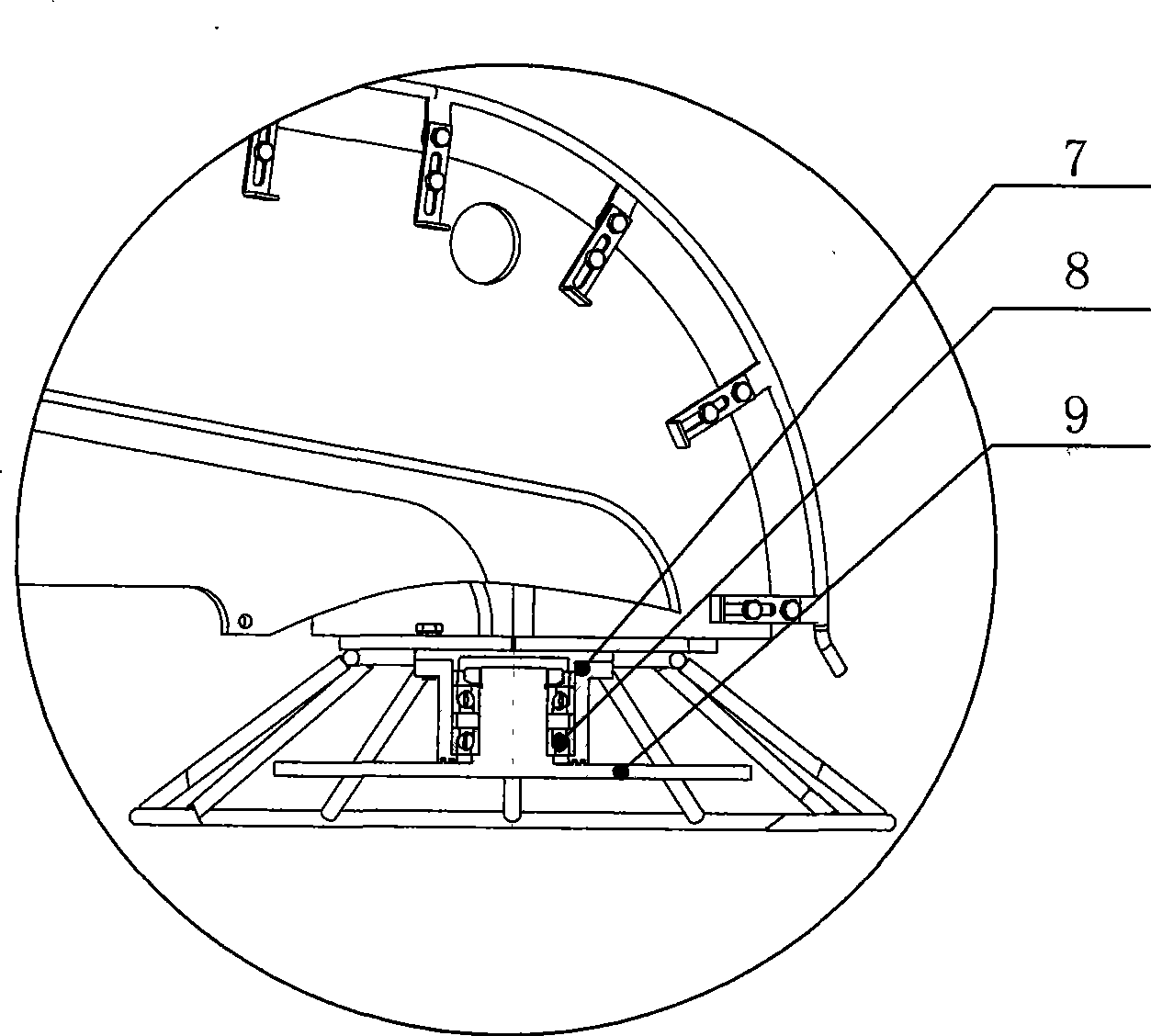

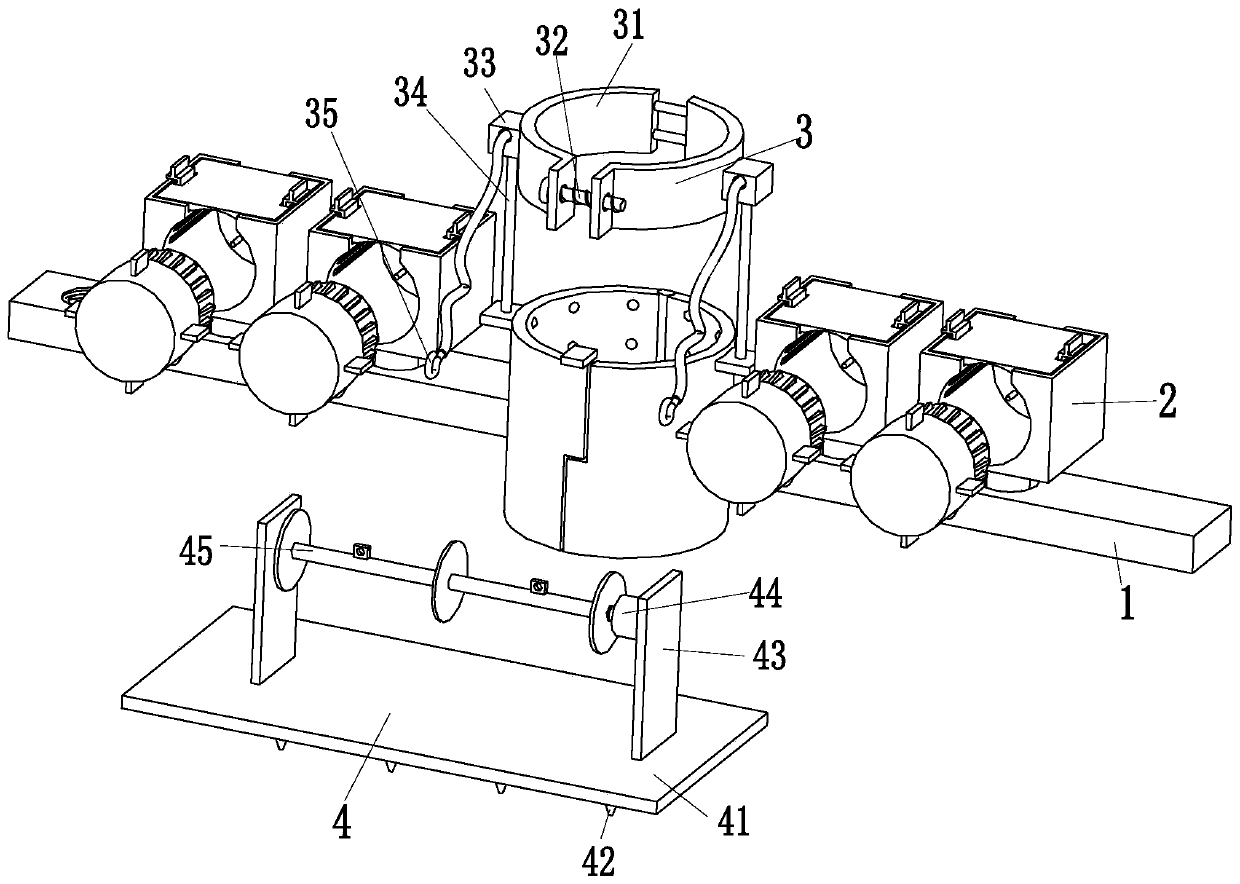

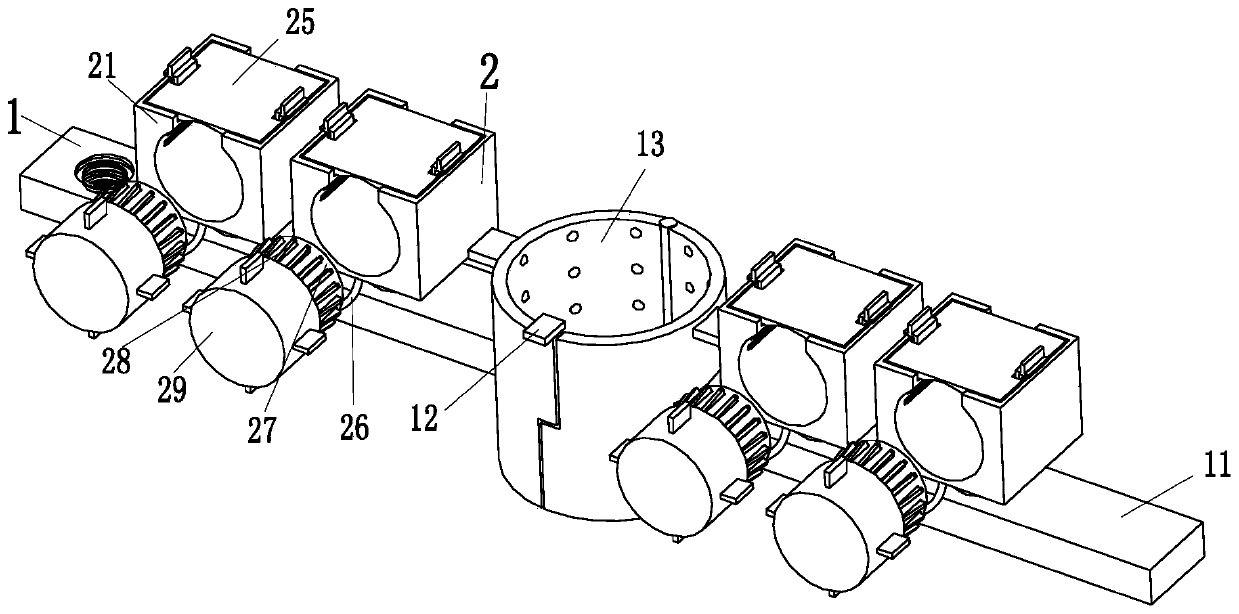

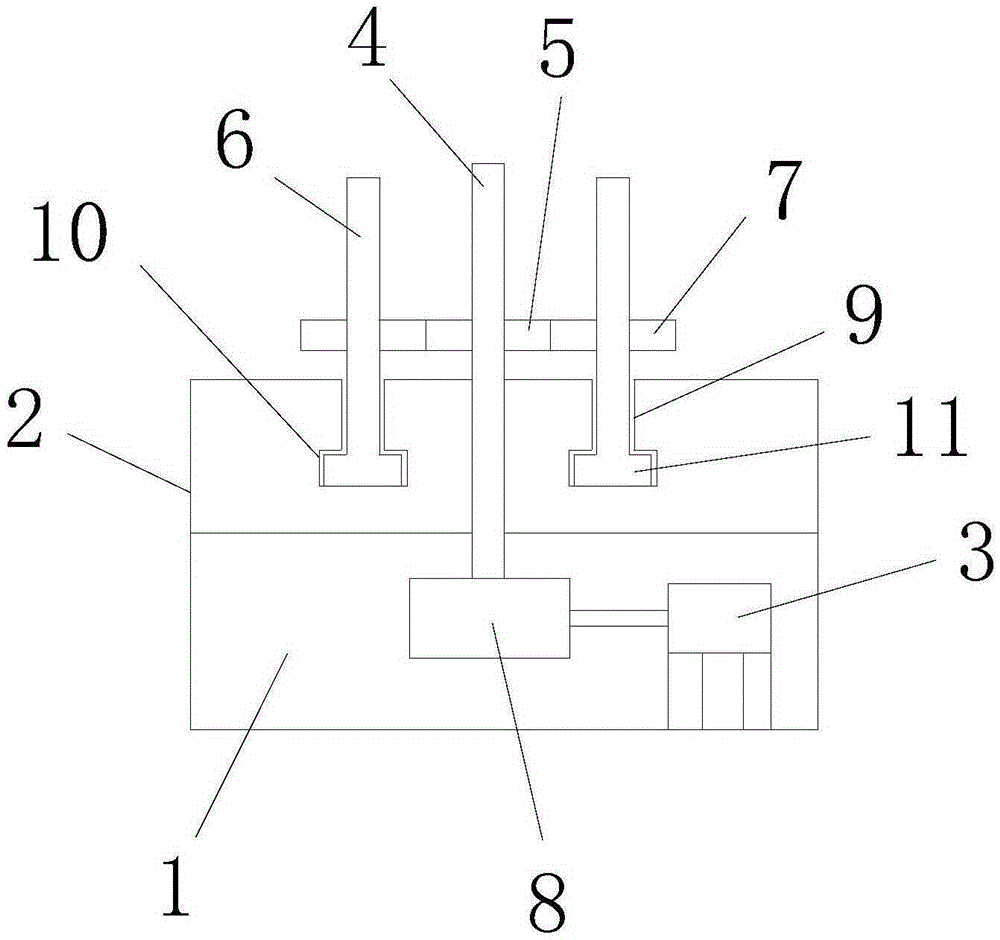

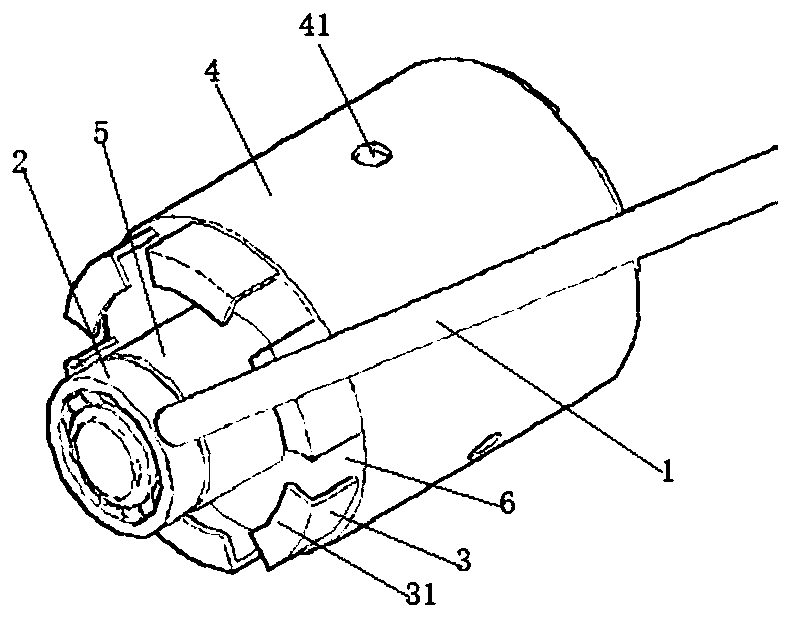

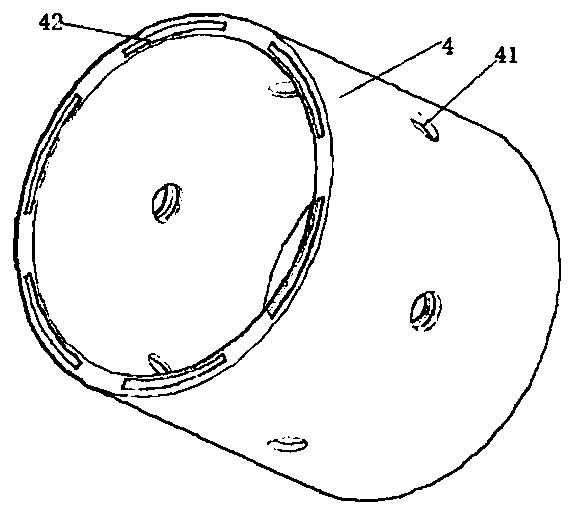

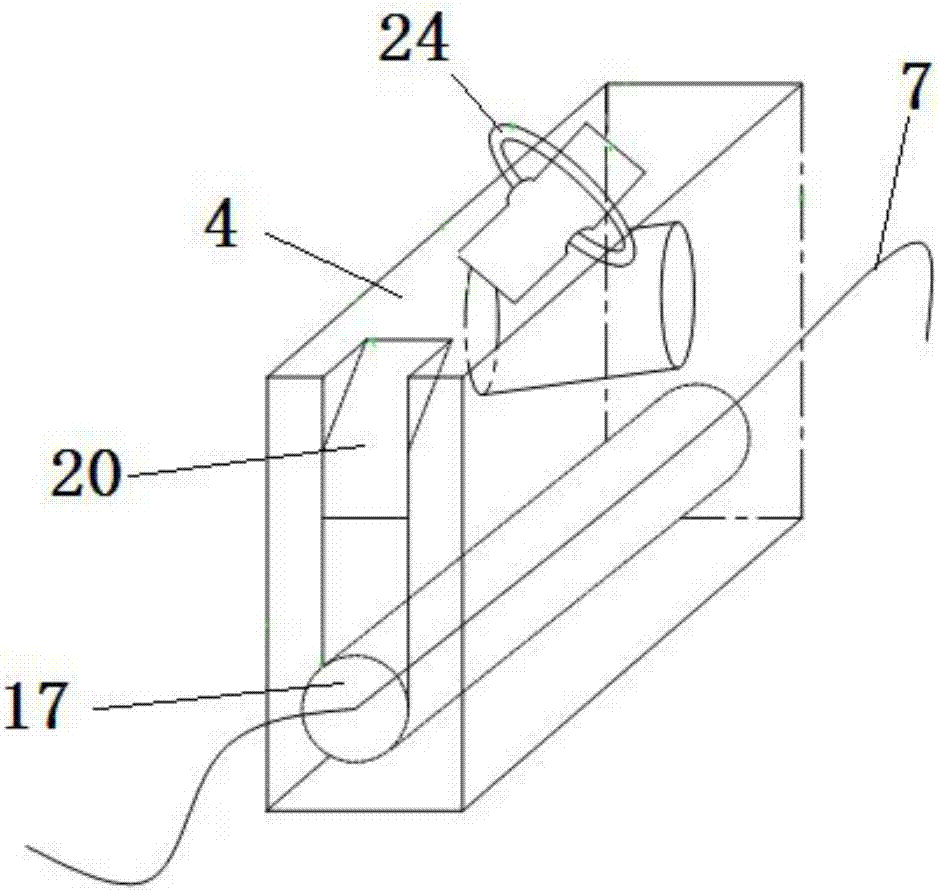

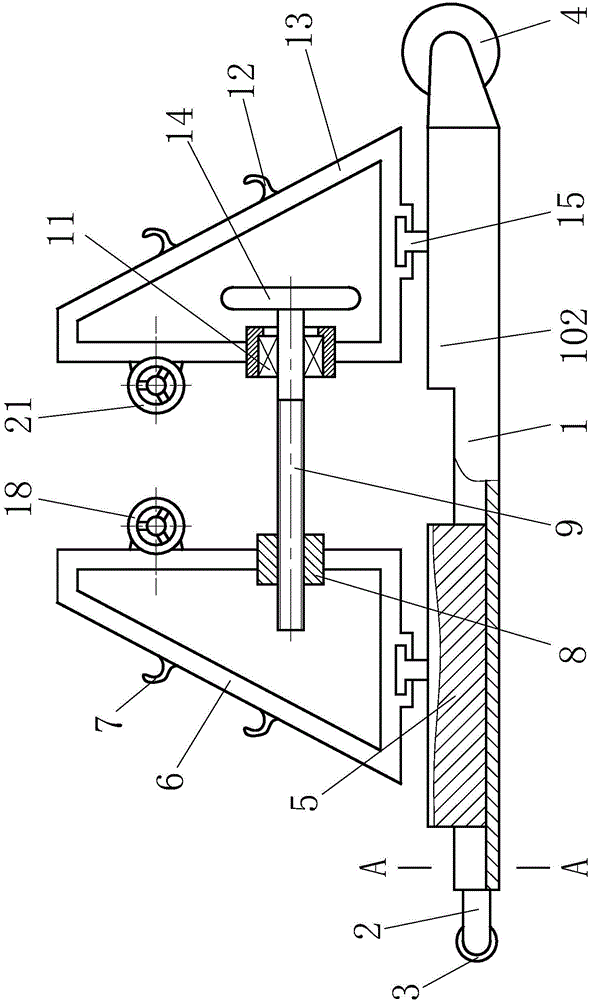

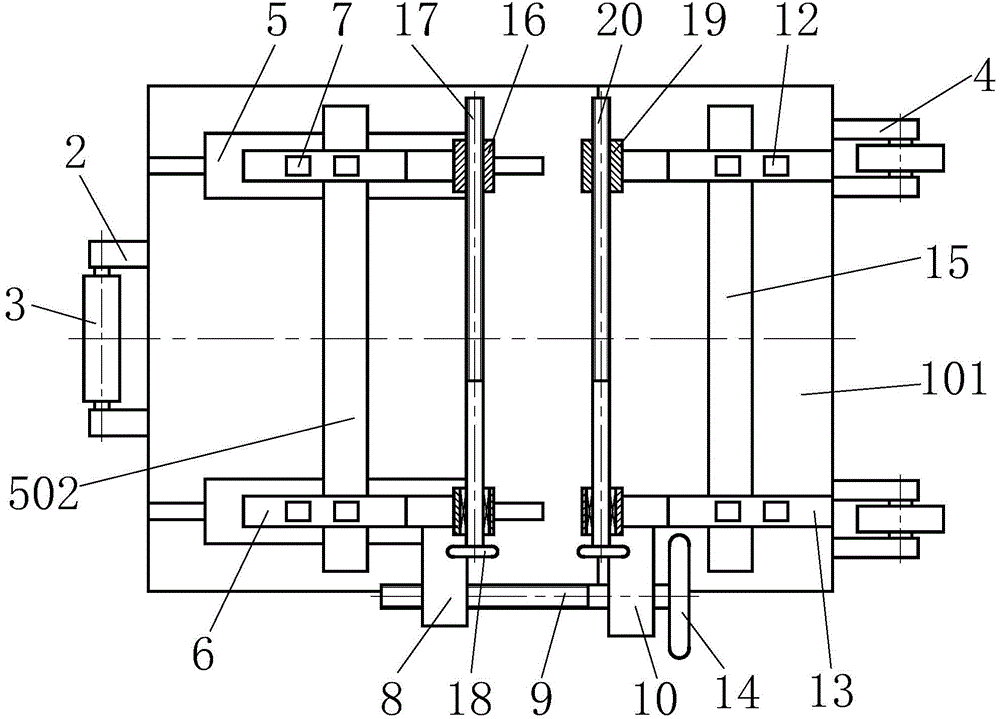

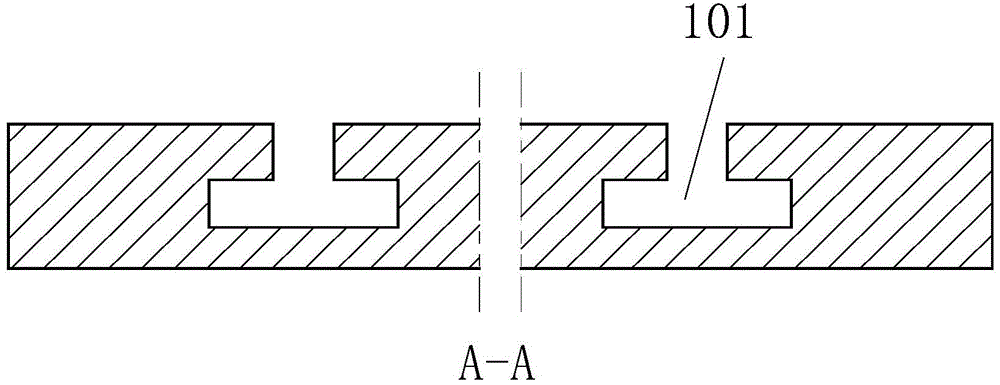

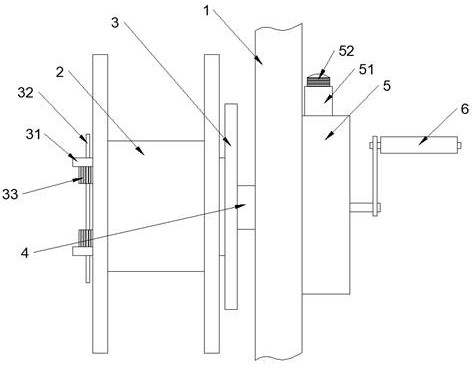

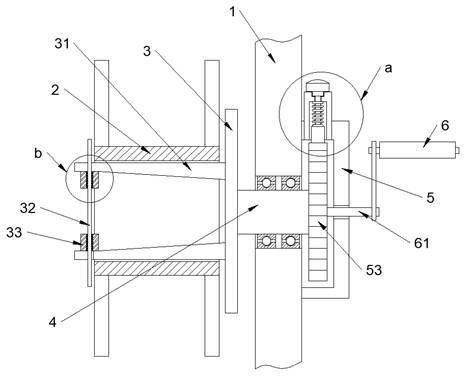

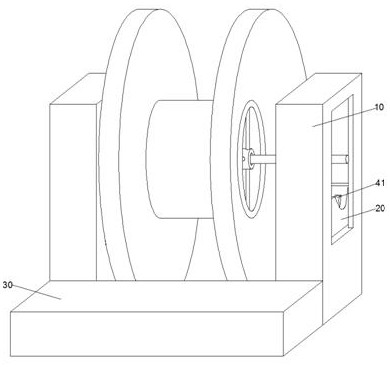

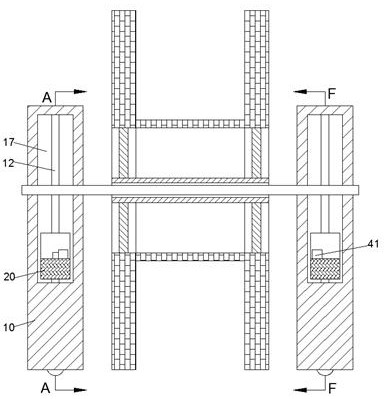

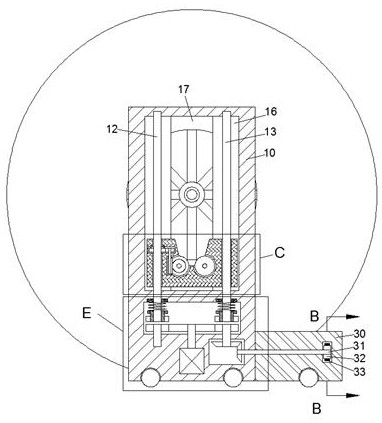

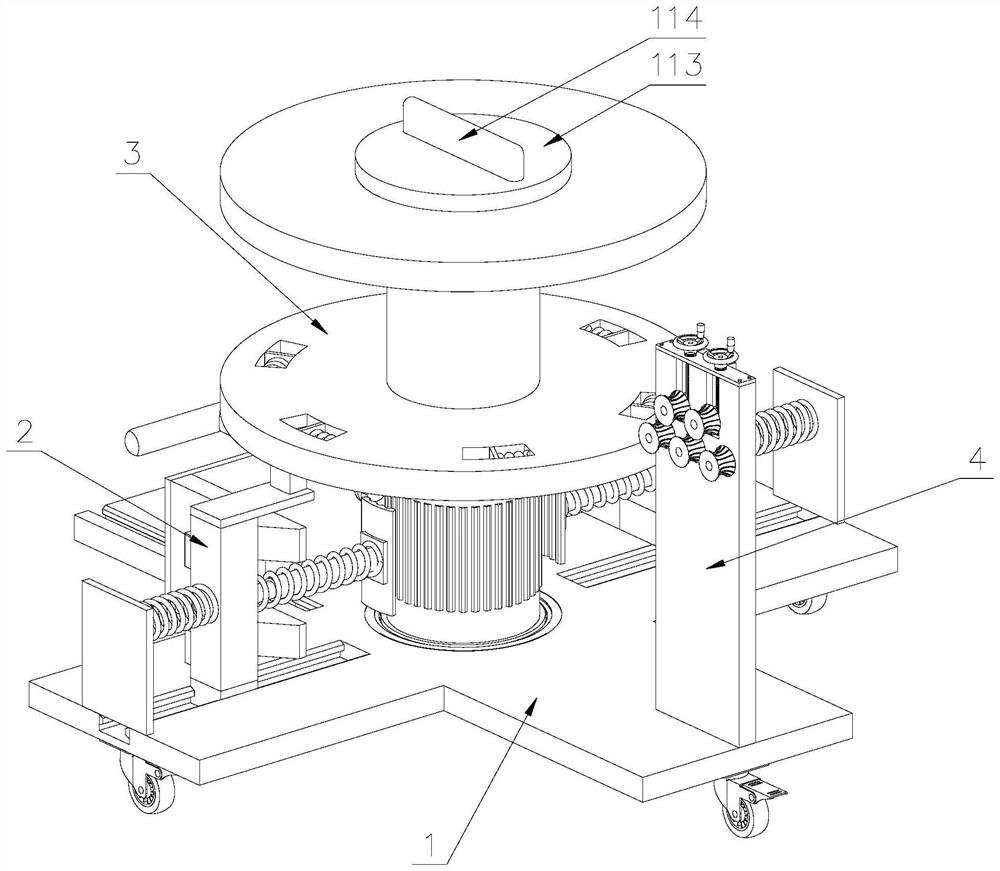

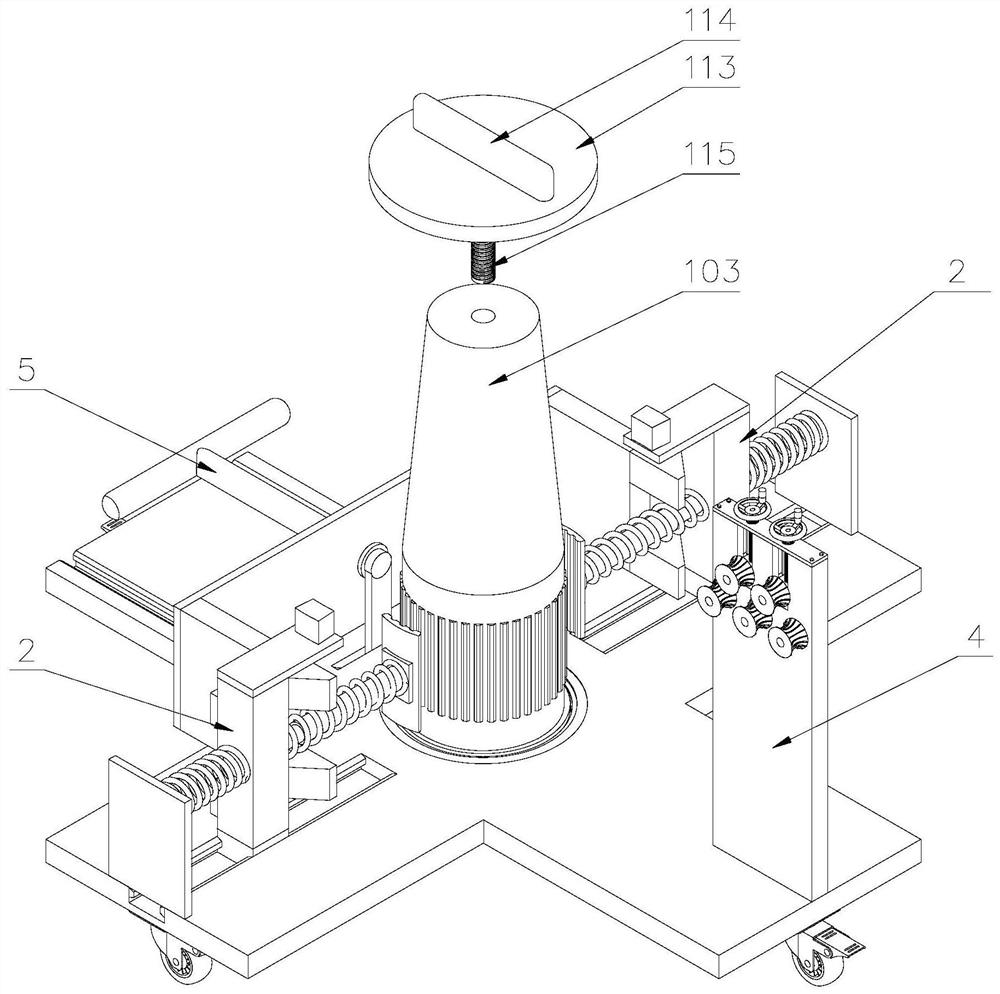

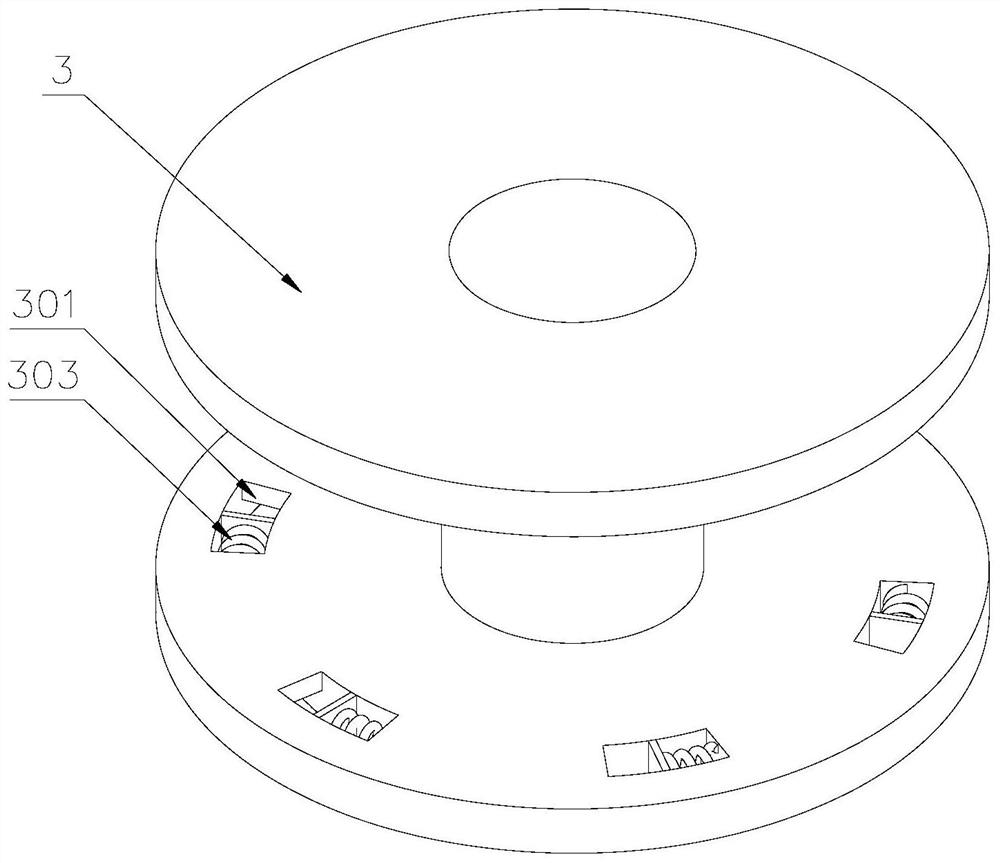

Cable multi-head active pay-off rack

The invention discloses a cable multi-head active pay-off rack. The cable multi-head active pay-off rack comprises two main box bodies, the main box bodies are arranged in a bilateral symmetry mode, synchronous transmission box bodies fixed to the front end surfaces of the main box bodies are arranged on the front sides of the main box bodies, lifting mechanisms are arranged in the main box bodies, clutch mechanisms are arranged on the lower sides of the lifting mechanisms, and a pay-off rotating mechanism is further arranged in the lifting mechanism on the left side. A cable reel is lifted by lifting seats which simultaneously ascend and descend on the two sides, the cable reel is prevented from toppling due to inclination of the gravity center, and meanwhile, the pay-off rack can be suitable for the cable reels with different diameters; the cable reel can be conveniently installed on a pay-off reel through a U-shaped center shaft clamping cavity, and the pay-off efficiency is improved; meanwhile, manual pay-off is replaced by the pay-off rotating mechanism, so that the work amount of a worker is greatly reduced; meanwhile, the pay-off rack has a self-locking function, so that the cable reel can stop rotating when the pay-off rack is suddenly powered off, and the pay-off safety is improved.

Owner:厦门峻百冶贸易有限公司

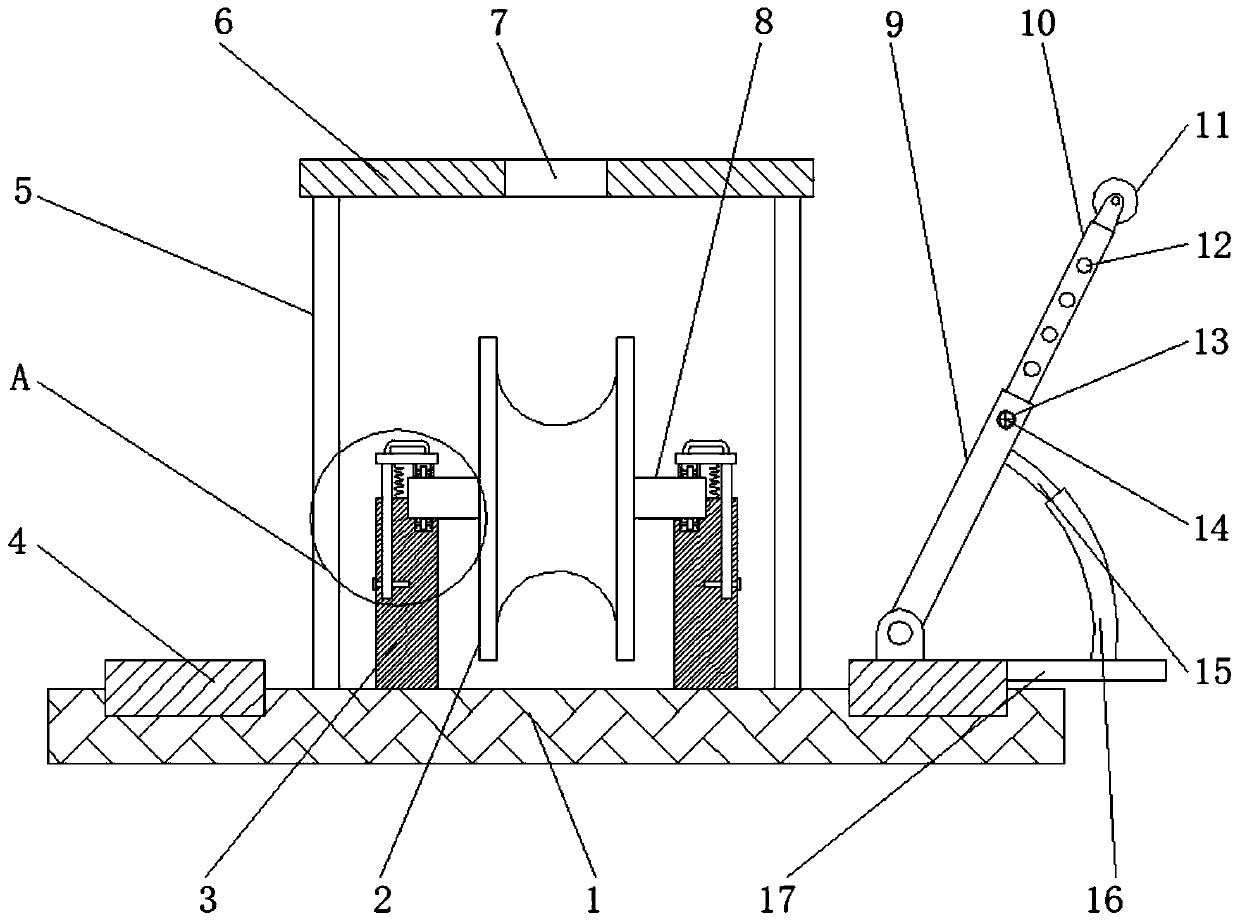

Vertical cable pay-off rack with braking function

ActiveCN111668759AImprove pay-off efficiencyReduce labor intensityArrangements using take-up reel/drumArrangements using spring-loaded loopControl theoryElectric cables

The invention discloses a vertical cable pay-off rack with a braking function, which is characterized in that a plurality of universal wheels are arranged on the lower portion of a base, first slidinggrooves are formed in the left side and the right side of the base, and first sliding blocks are arranged in the first sliding grooves; the upper portion of the base is movably connected with a rotating shaft through a bearing, a winding roller is installed on the rotating shaft, and multiple clamping holes are formed in the lower portion of the winding roller; braking devices are symmetrically arranged on the two sides of the rotating shaft, each braking device comprises a stand column fixedly installed on the corresponding first sliding block, a first inserting rod arranged in the stand column, a first sleeve arranged outside the first inserting rod in a sleeving mode, a transverse plate arranged at the top of the first sleeve and a clamping block which is arranged at one end of the transverse plate and matched with the corresponding clamping hole, and a first spring is arranged in each stand column. The braking devices are arranged on the two sides of the base, after a cable is paid off to the needed length, the braking devices brake the winding roller in time, the paying off of the redundant cable is avoided, the labor intensity of workers for taking up the cable is reduced, and the cable paying-off efficiency is improved.

Owner:STATE GRID SHANDONG ELECTRIC POWER CO PINGYUAN POWER SUPPLY CO

Pay-off device for submarine communication cable laying

ActiveCN110970835AEasy to replaceEasy to removeApparatus for laying cablesSlide plateElectric cables

The invention discloses a pay-off device for submarine communication cable laying. The pay-off device comprises a bottom plate, and vertical rods are arranged at the four corners of the outer wall ofthe top of the bottom plate correspondingly. A top plate is arranged on the outer walls of the tops of the vertical rods, and a pay-off opening is formed in the outer wall of the top of the top plate.Vertical plates are welded to the positions, close to the two sides, of the outer wall of the top of the bottom plate. A clamping groove is formed in the outer wall of one side of each vertical plate, a rotating shaft is rotatably connected to the inner wall of each clamping groove, a pay-off roller is arranged on the outer wall of the rotating shaft, a fixing groove is formed in the inner wall of the bottom of each clamping groove, lower rolling wheels are rotatably connected to the inner wall of the fixing grooves through pin shafts, and a sliding groove is formed in the outer wall of the top of the vertical plate. The inner wall of the sliding groove is slidingly connected with a sliding board. According to the pay-off device, the rotating shaft on the pay-off roller can be rapidly taken down from the vertical plate, so that the pay-off roller is more convenient to replace, the pay-off efficiency of the device is effectively improved, a cable does not rub the underwater position ofthe cable, the protection effect on the cable is achieved, and the use effect is better.

Owner:WEIZHUO PETROTECH (BEIJING) LTD

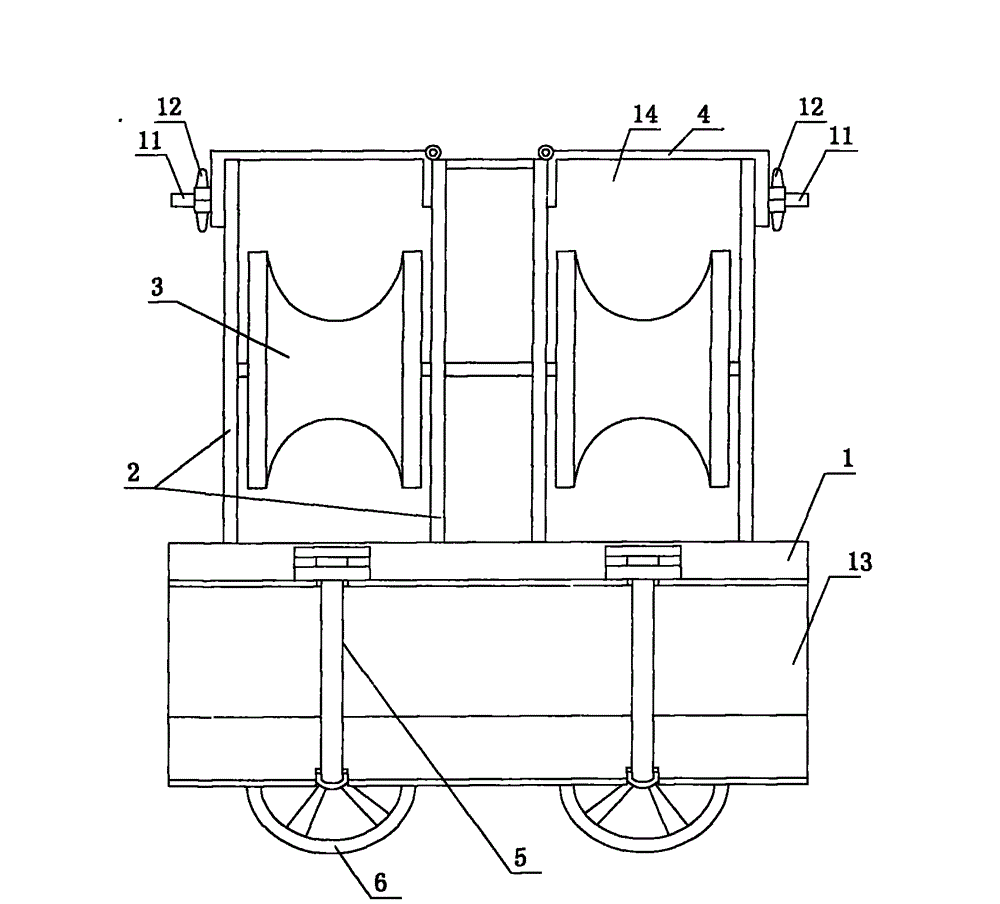

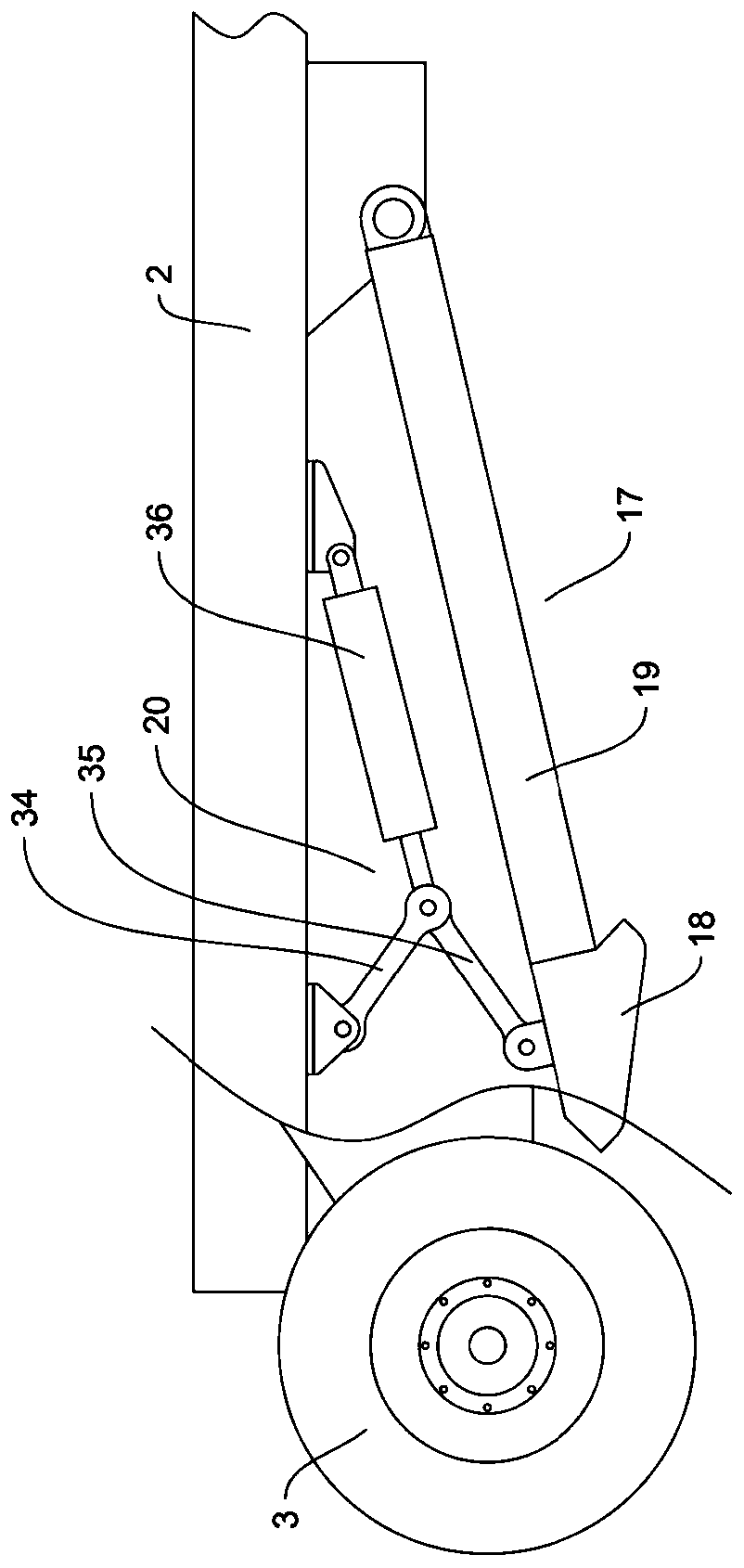

Cable uncoiling vehicle

InactiveCN109994964AAchieve mechanical liftEffective rotationBraking element arrangementsApparatus for laying cablesDrive wheelVehicle frame

The invention discloses a cable uncoiling vehicle. The cable uncoiling vehicle includes a traction frame and is characterized in that side frames are disposed on both sides of the traction frame, a linkage bar is disposed between the side frames and the traction frame, two ends of the linkage bar are respectively hinged with the traction frame and the side frames, a positioning mechanism is disposed on the hinging portion of the linkage bar, support rods are fixedly arranged on the side frames, a support base is slidably disposed on the support rods, a shaft groove is arranged on the support base, the side frame on one side of the traction frame is provided with a driving seat in a sliding mode, driving wheels are arranged on the driving seat, a brake mechanism is arranged on the bottom ofthe side frames, and the brake mechanism is composed of a brake block, a brake lever and a hydraulic driving mechanism. Compared with the prior art, the cable uncoiling vehicle is advantaged in thatthe cable uncoiling vehicle can be contracted and folded as a whole, is convenient for transporting and mounting, has the good braking effect, saves cost, can realize convenient installation of a cable reel and has high uncoiling efficiency.

Owner:XUZHOU HUABANG SPECIAL VEHICLE

Convenient setting-out device for angle measurement

ActiveCN108827256AImprove storage efficiencyReduce pollutionSurveying instrumentsAngles/tapers measurement gaugesEngineeringMechanical engineering

The invention relates to a convenient setting-out device for angle measurement. The convenient setting-out device comprises a power storage group, a wire box, a wire reel holder, an angle scale, a pointer, a rotating belt shaft, a wire box cover, an ink storage box, a dirt collecting box, a wire and a driving assembly, wherein the power storage group is embedded in the wire box; the wire reel holder is installed in the wire box; the angle scale is fixedly mounted at the tail end of the rotating belt shaft; the pointer is fixedly installed at the middle part of the rotating belt shaft; the direction of an arrow points to the angle scale; the front end of the rotating belt shaft is fixedly connected with the center line of the wire box, and the rear end of the rotating belt shaft is movablyconnected with the angle scale; the wire box cover is movably installed on the wire box and is fixed with the wire box by buckles; one end of the ink storage box is connected with the wire box, and the other end of the ink storage box is connected with the dirt collecting box; and one end of the dirt collecting box is fixedly connected with the ink storage box, and the other end of the dirt collecting box is internally threaded. According to a technical scheme in the invention, the convenient setting-out device is compact and ingenious in design, can accurately measure a setting-out angle during setting out, improves setting-out efficiency and precision, reduces contamination of ink storage sponge by dust and other impurities, and improves the storage efficiency of an ink wire.

Owner:NANJING CHEM CONSTR

Paying-off device for wire of excessively small diameter

InactiveCN109368374AReduce tensionTension drop and stabilityFilament handlingNitrile rubberEngineering

The invention discloses a paying-off device for a wire of an excessively small diameter. The paying-off device for the wire of the excessively small diameter structurally comprises locking pieces, a rotating shaft, a tension adjusting device, a paying-off disk, a loading and unloading frame, rotating wheels, locking bolts, a wire outlet hole, a traction guide roller and a paying-off body. When thepaying-off device for the fine wire starts to pay off the wire with the diameter smaller than 0.05 mm, the pressure and friction force between the paying-off disk and a tray are reduced, so that theconstraint borne by the paying-off disk during rotation is reduced; when paying-off is stopped, the pressure and friction force between tension wheels and a tension disk are increased, the rotating wheels are controlled through nitrile rubber mats, the tension disk assists the tray to adjust the speed of the paying-off disk, so that the paying-off disk and the rotating wheels evenly reduce the paying-off speed until stop, the tension change degree during paying off is reduced, the quality and yield of the wire are guaranteed, and the production efficiency and the paying-off efficiency of the wire are improved.

Owner:泉州台商投资区五季网络有限公司

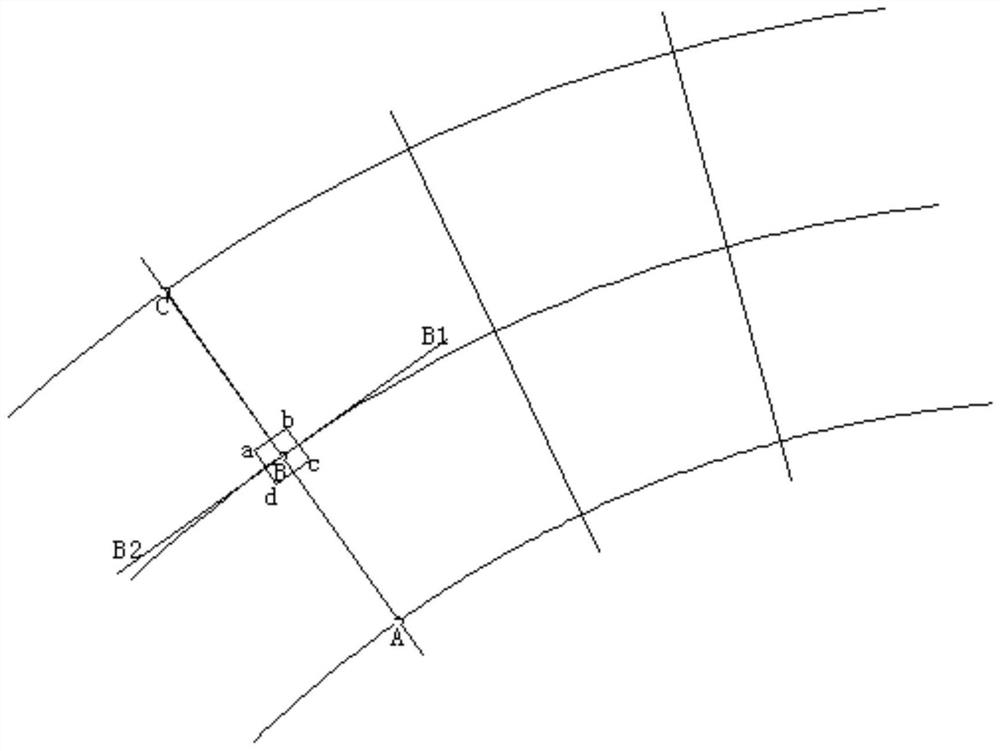

Rapid paying-off method for warp and weft axis net square column

InactiveCN111827697AAvoid heavy workloadImprove pay-off efficiencyBuilding material handlingMarking outStructural engineering

The invention discloses a rapid paying-off method for a warp and weft axis net square column. The method comprises the steps that coordinates of intersection points A and C of the minimum radius weftand the warp where the square column center point B is positioned and the maximum radius weft and the warp where the square column center point B is positioned are determined according to positioningcoordinates of a building design drawing; according to the coordinates of A and C, A and C are measured and marked on a construction site through a total station, and the warp AC is made; according tothe distance between A or C and B in the building design drawing, B is measured and marked along the warp AC with the point A or C as the starting point; a straight line segment B1B2 which passes through B and is perpendicular to the warp AC is made on the construction site, and the straight line segment B1B2 coincides with the tangent line of the weft where B is positioned; and square column side lines are paid off according to the size relation between the four side lines of the square column and the tangent lines of the warp where B is positioned and the weft where B is positioned. According to the rapid paying-off method, the paying-off efficiency is improved, and the paying-off cost is reduced.

Owner:WUHAN YIYE CONSTR ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com