Cable tray paying-off device

A pay-off device and cable reel technology, which is applied to cable laying equipment and the layout of reels/photosensitive drums, can solve the problems of pickup trucks being unable to transport, increasing difficulty, and occupying space for production vehicles. The effect of improving the quality of pay-off and laying and saving quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

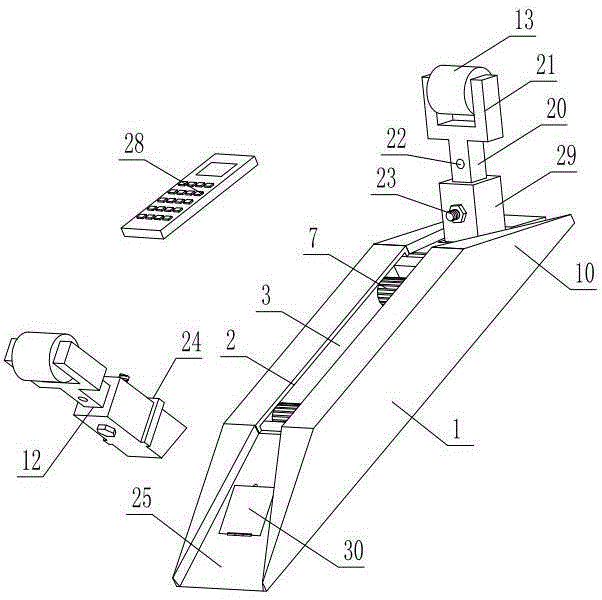

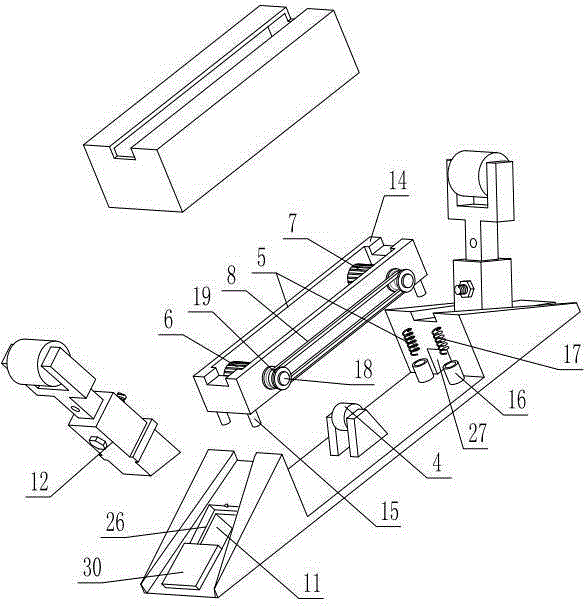

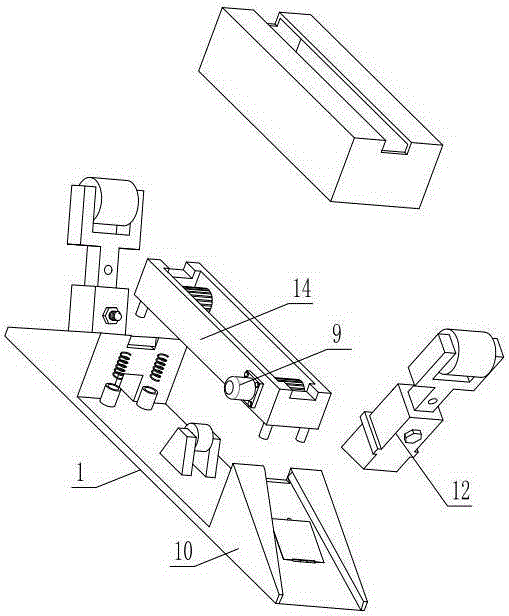

[0025]As shown in the figure, the cable reel pay-off device includes a base 1, the upper part of the base is provided with a groove 2 extending forward and backward along the length of the base, the base is provided with a cavity 3 communicating with the groove, and the middle part of the cavity is Load bearing wheels 4 are installed in the rotating shaft extending left and right, and front drive wheels 6 and rear drive wheels 7 are respectively installed at the front and rear ends of the load wheels by positioning device 5 in the cavity. The top of the outer periphery of the load-bearing wheel is slightly higher, and the front drive wheel and the rear drive wheel are driven and matched by a belt 8, and a motor 9 matched with the front drive wheel is also installed in the cavity, and an inclined platform 10 is fixed at the front and rear ends of the base respectively. , the inclined platform is provided with a through-hole 11 that runs up and down, and a positioning rod 12 is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com