Quincunx wire unloading device

A plum blossom and winding technology, which is applied in the field of plum blossom wire unloading device, can solve the problems of affecting the unwinding speed of the next process, reducing work efficiency, and the steel wire is easy to be disordered.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

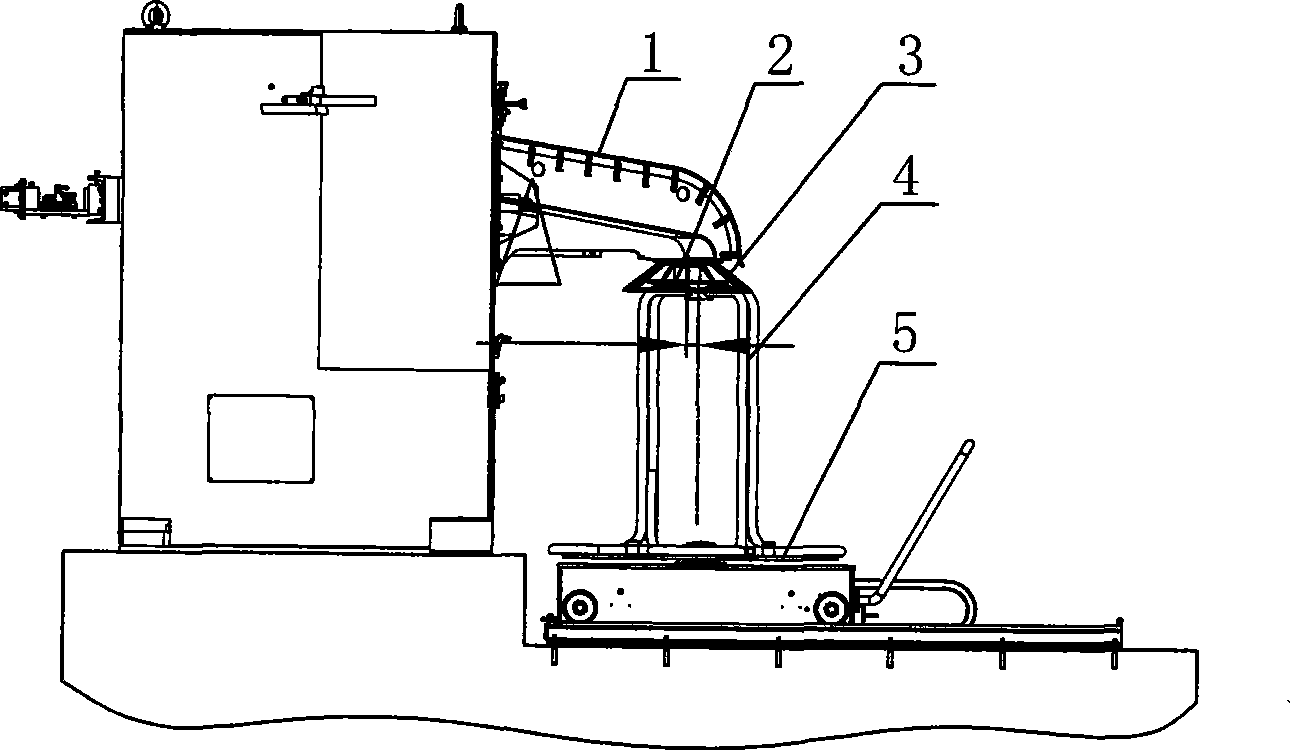

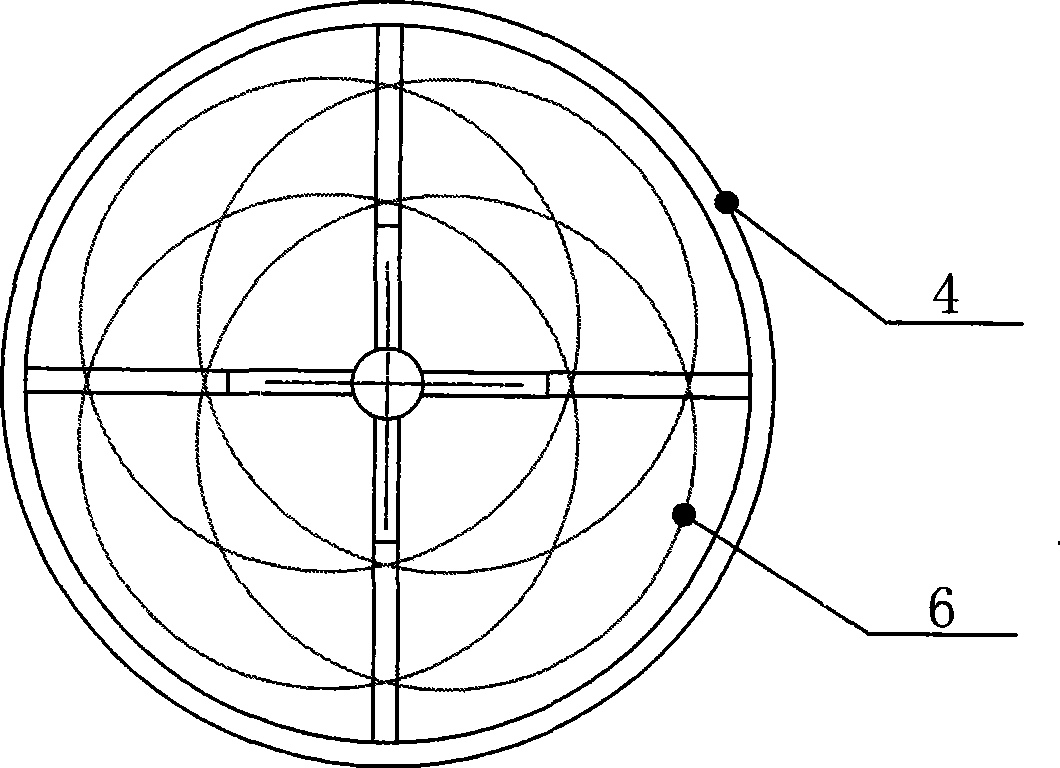

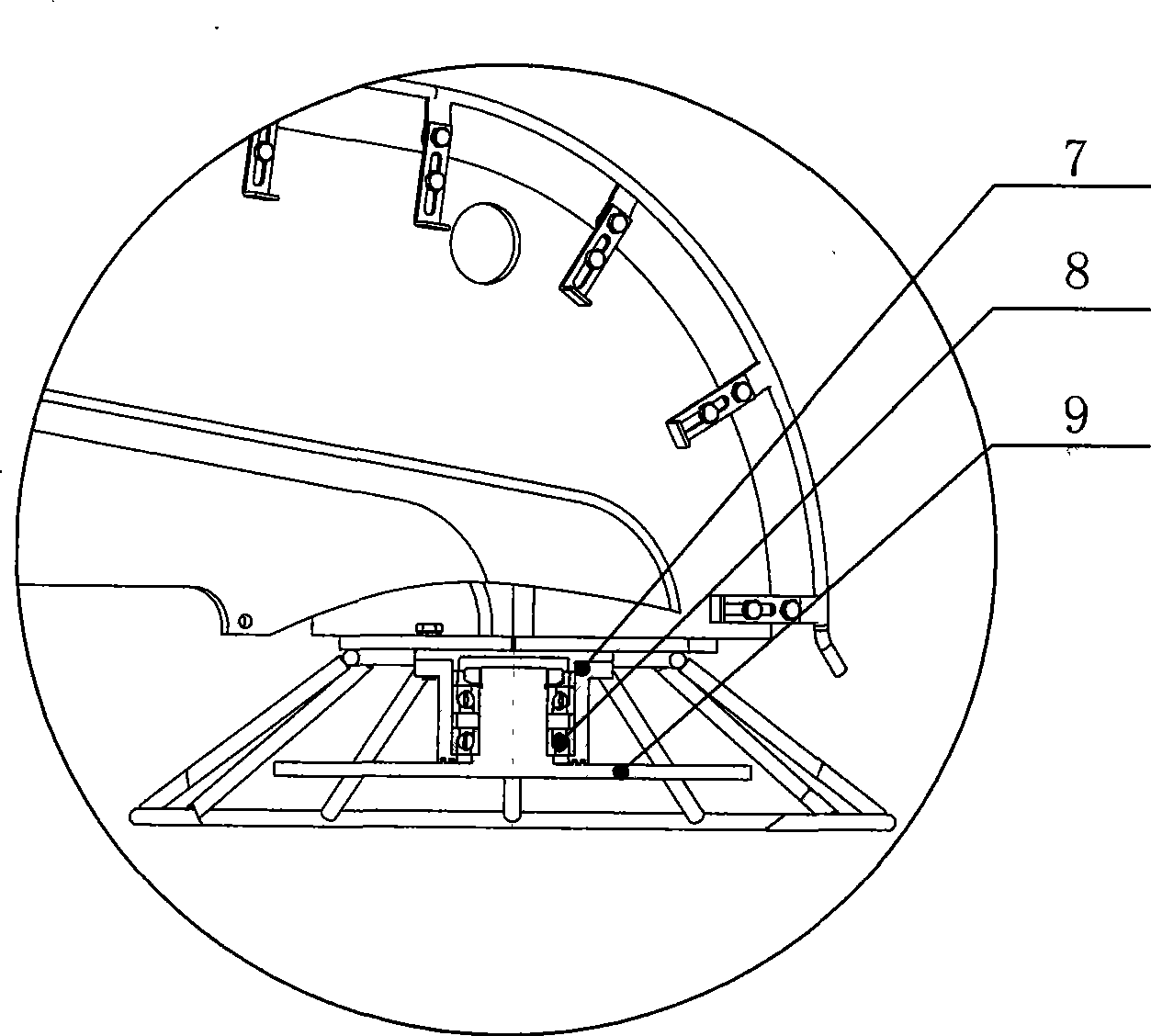

[0008] The specific embodiment of the plum blossom wire unloading device of the present invention will be described in detail with reference to the accompanying drawings. The structure of the upper turntable 2 mainly consists of a fixed seat 7, a bearing 8, and a rotating disk 9. The take-up frame 4 is positioned on the lower turntable 5, and the lower turntable 5 is driven to rotate by a frequency conversion motor, and the rotating speed can be determined according to the take-up speed. The upper turntable 2 is connected with the elephant trunk frame 1 and is pressed down on the upper end of the line shelf 4. The line shelf 4 is positioned on the lower turntable 5. The rotation center of the line shelf 4 and the rotation center of the upper turntable 2 have a certain eccentricity. The eccentricity of the upper and lower turntables realizes the plum blossom-shaped wire take-up of the steel wire. The steel wire slides down continuously through the elephant trunk frame 1, passes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com