Embossing device used for printing with continuous imprinting

An embossing and control device technology, applied in the general parts of printing machinery, printing, printing presses, etc., can solve the problems of paper crushing, unsatisfactory continuity, etc., to achieve difficult sliding, ensure the embossing effect, and good continuity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

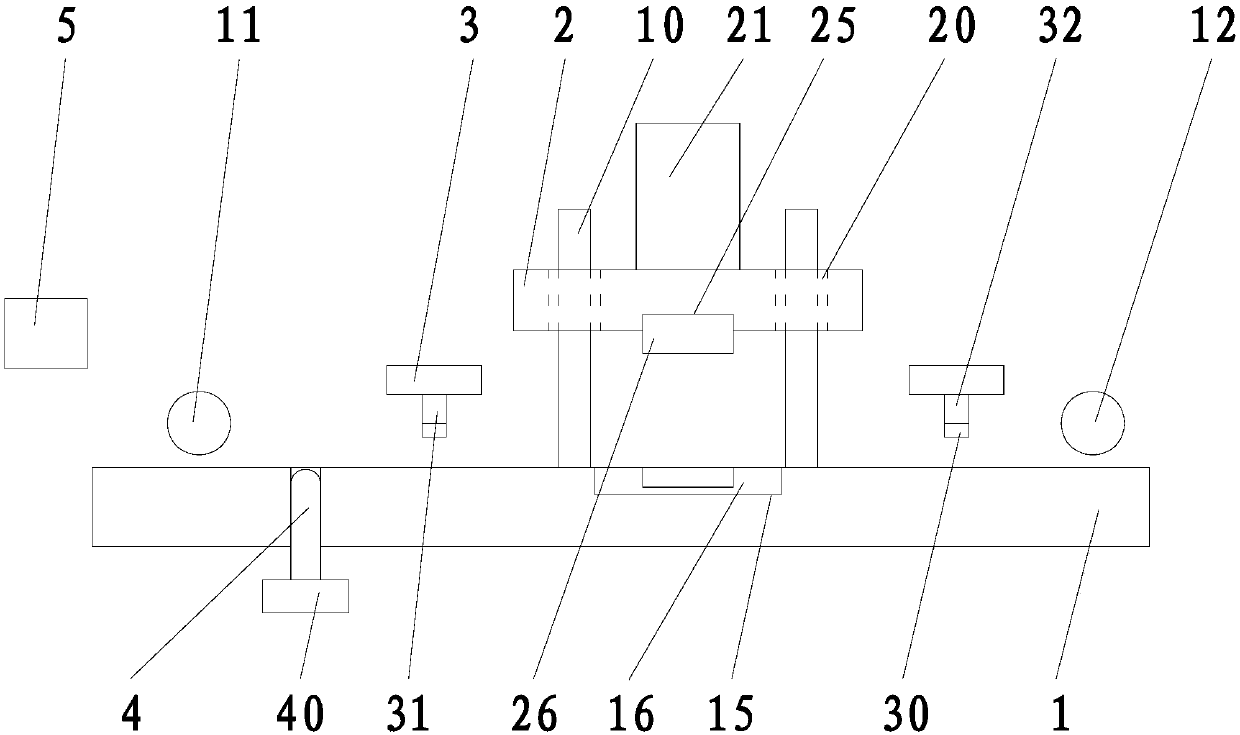

[0015] refer to figure 1 , a printing embossing device for continuous embossing of the present invention, comprising a conveying table 1, a first conveying roller 11, a second conveying roller 12, a first pressing plate 31, a second pressing plate 32, a pressing plate 2, a control Device 5, the top of the conveying table 1 is sequentially provided with a first conveying roller 11, a first pressing plate 31, a pressing plate 2, a second pressing plate 32, and a second conveying roller 12 along the conveying direction of the paper, and the pressing plate 2. A detachable embossing die 26 with heating function is fixed on the bottom, and a concave die 16 matching the embossing die 26 is arranged on the conveying table 1. The concave die 16 is located directly below the embossing die 26. The top of the pressing plate 2 is connected with a first pressing device 21, the top of the first pressing plate 31 and the second pressing plate 32 are connected with a second pressing device 3, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com