Optical cable pay-off device for optical fiber telecommunication construction

A pay-off device and optical cable technology, which is applied in the directions of transportation and packaging, delivery of filamentous materials, thin material processing, etc., can solve problems such as difficult bending of optical cables, long-distance tensioning, and damage to internal optical fibers, etc., to achieve Protect the state of pay-off requirements, reduce labor, and avoid the effects of springback and bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing:

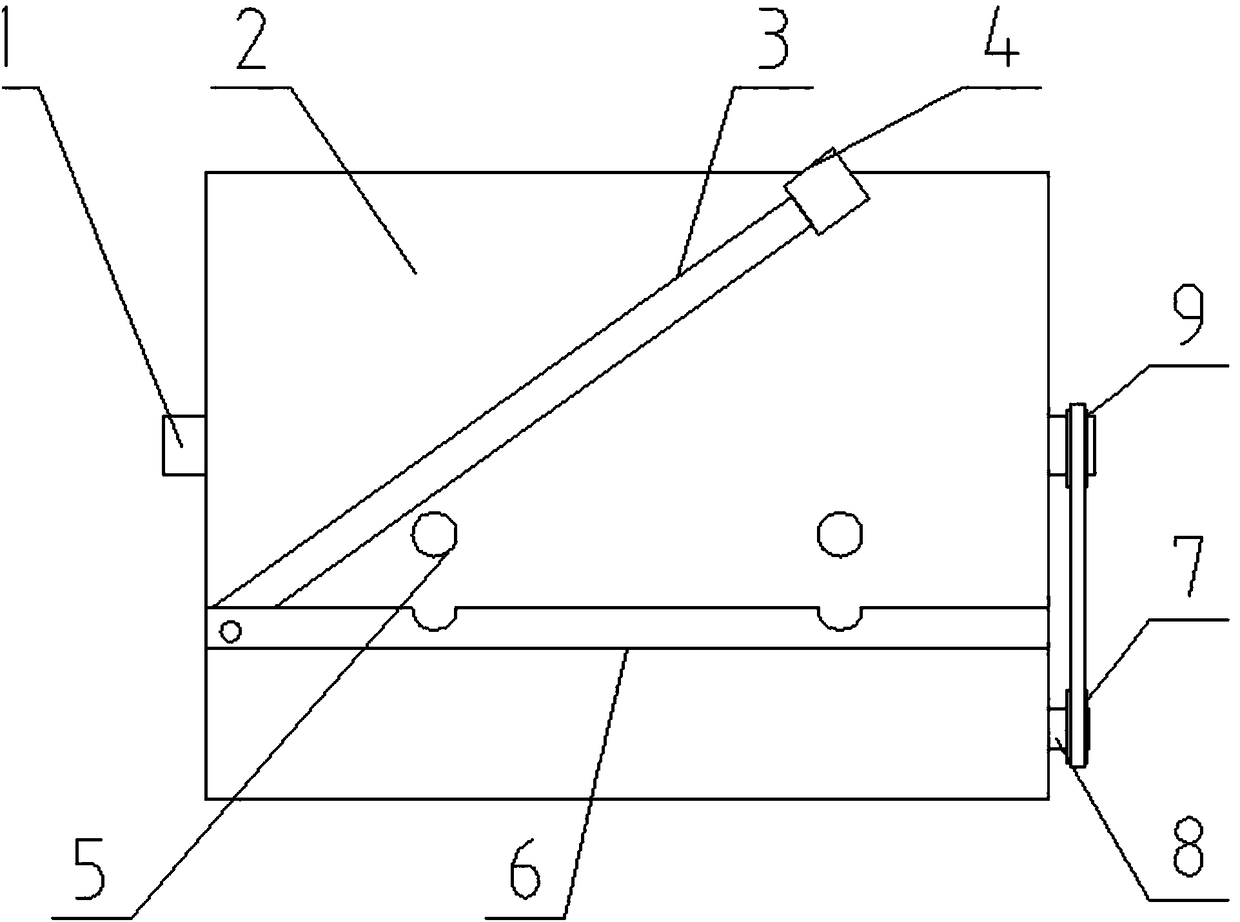

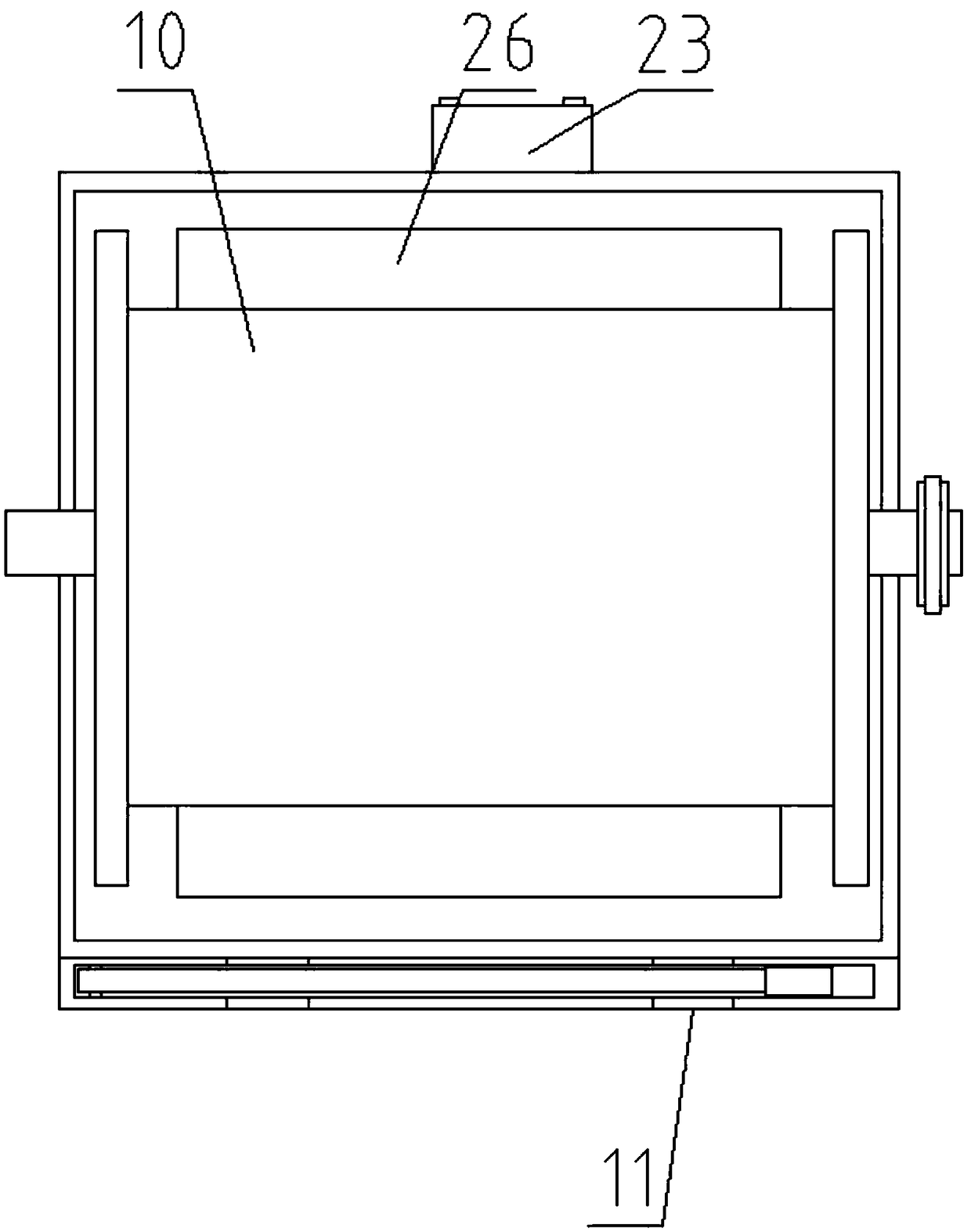

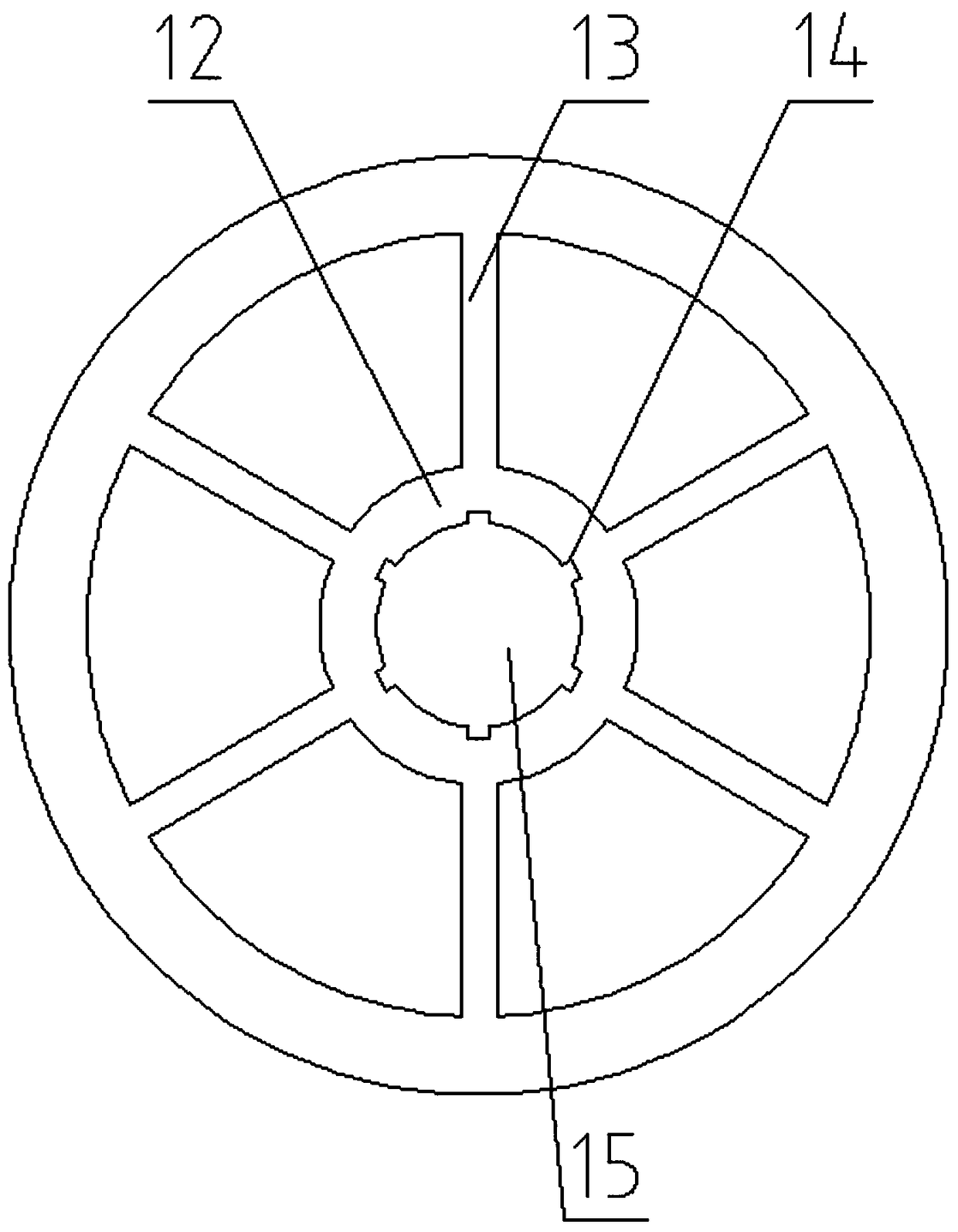

[0025] Such as Figure 1-Figure 5 As shown, an optical cable pay-off device for optical fiber telecommunication construction includes a main shaft 1, a pay-off box 2, a cutter 3, and a mounting frame 21. The main shaft 1 is arranged in the pay-off box 2, and one end of the main shaft 1 is arranged There is a driven wheel 9, a reel 10 is arranged on the outer side of the main shaft 1, a hub 12 is arranged at both ends of the reel 10, a support frame 13 is arranged on the outer side of the hub 12, and a central hole 15 is arranged on the inner side of the hub 12, The outer side of the central hole 15 is provided with a slotted hole 14, and the bottom of the reel 10 is provided with a motor 26, and one end of the motor 26 is provided with a transmission shaft 8, and one end of the transmission shaft 8 is provided with a driving wheel 7. A control box 23 is arranged at the rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com