Dry electrode and manufacturing method thereof

A dry electrode and electrode column technology, applied in the field of EEG measurement, can solve the problems of large thermal noise, unfavorable EEG signal acquisition, small contact area, etc., to achieve good contact and avoid bad contact effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The principle and spirit of the present invention will be described below with reference to several exemplary embodiments shown in the accompanying drawings. It should be understood that these embodiments are given only to enable those skilled in the art to better understand and implement the present invention, but not to limit the scope of the present invention in any way.

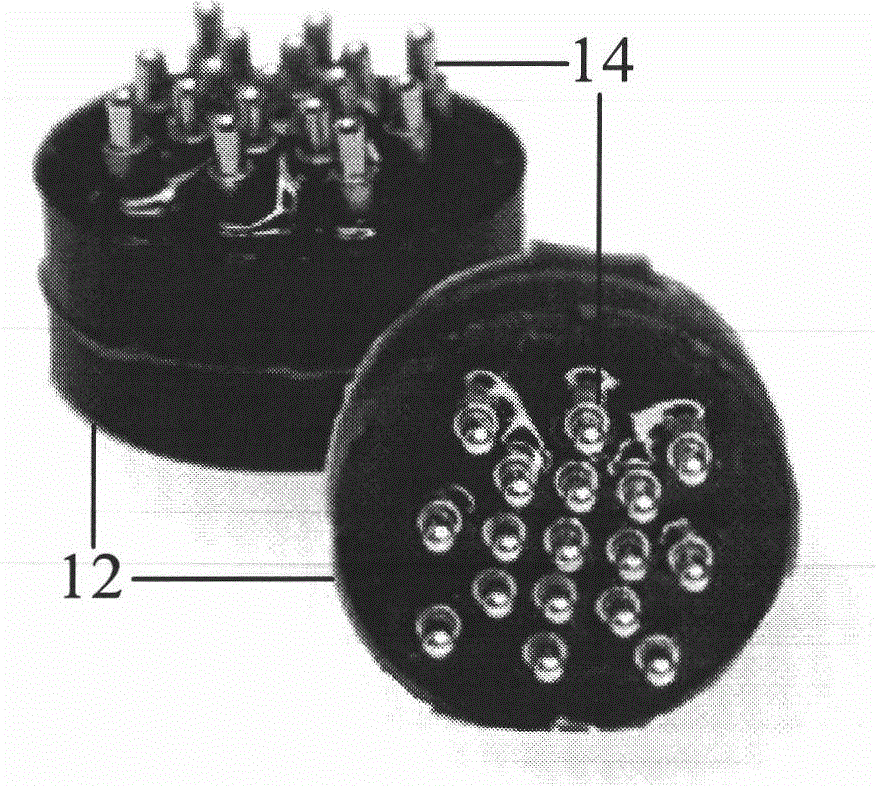

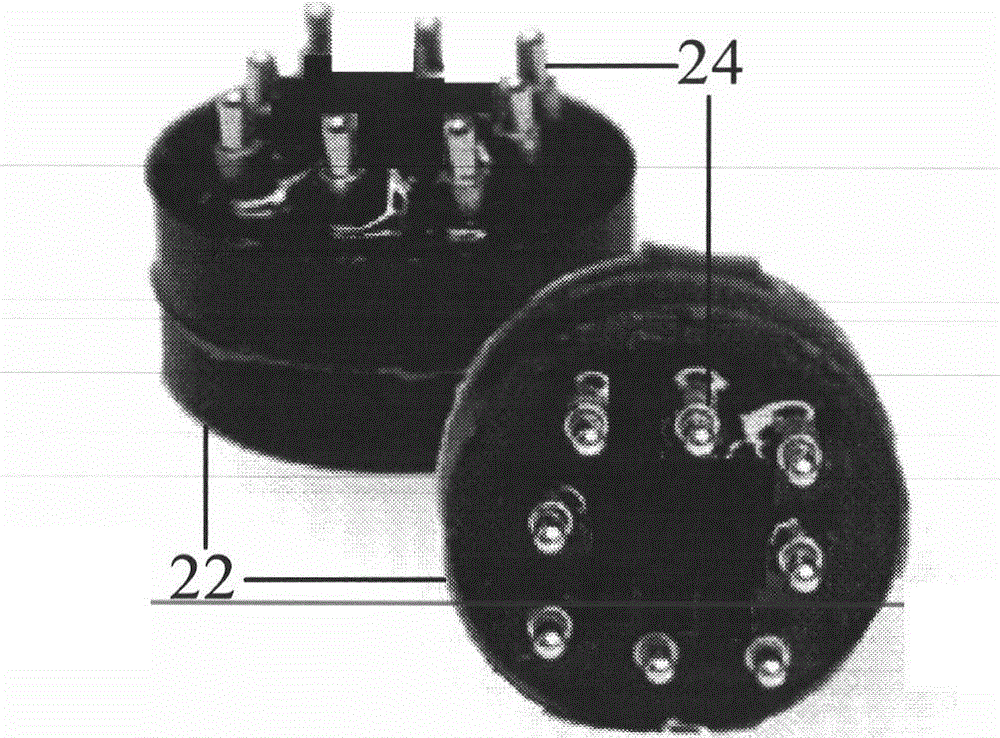

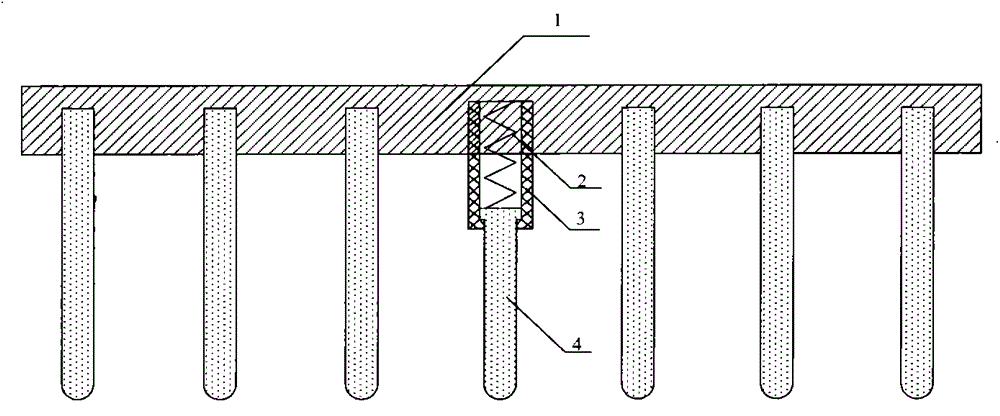

[0038] image 3 is a sectional view illustrating a dry electrode according to an embodiment of the present invention. Wherein, the substrate 1 is generally used as a part of the above-mentioned dry electrode seat, and a conduit 2 is fixed on one side; an elastic member 3 is installed in the conduit 2, and the elastic member 3 can be a variety of springs, shrapnel, etc. well known to those skilled in the art. A component that can generate elastic force through deformation, wherein the elastic coefficient of the elastic component 3 is associated with the position of the conduit 2 on the substrate 1;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com