Steel bar spacing setting-out tool and setting-out method

A technology for steel bar spacing and tools, which is applied in the field of steel bar spacing setting-out tools and its setting-out, can solve problems affecting construction progress, low efficiency, and increasing construction costs, achieving low cost, high setting-out efficiency, and accelerated construction period Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

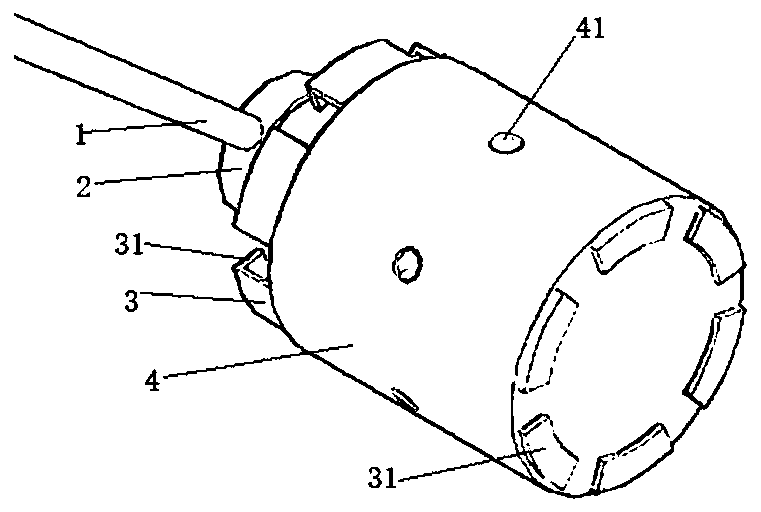

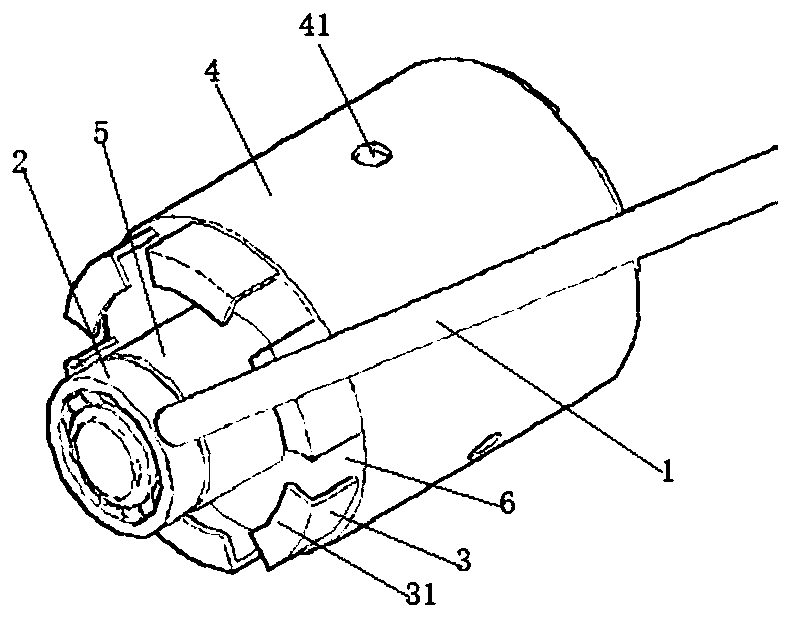

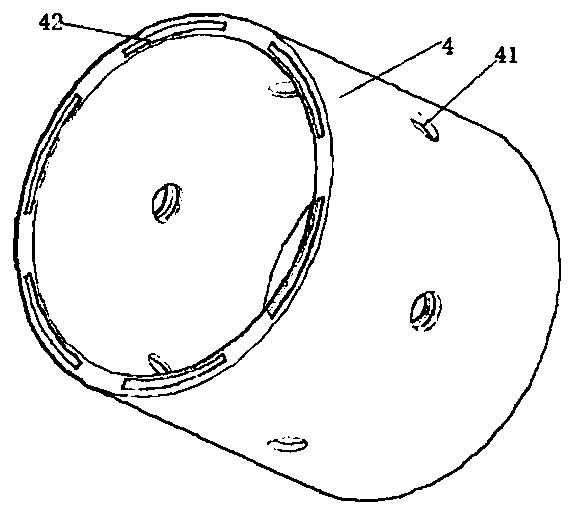

[0033] Such as Figure 1 to Figure 6 As shown, a wire spacing tool for steel bars includes an operating rod 1, a mandrel 5, a roller 4 and a sponge 6 for absorbing the marking liquid. The roller 4 is sleeved on the mandrel 5 with a gap, and the sponge 6 is filled between the mandrel 5 and the Between the rollers 4, the outer circle of the rollers 4 is evenly opened with a through hole 41 along the circumferential direction, and the end faces of the rollers 4 are distributed with card slots 42, and the movable baffles 3 are inserted in the card grooves 42, and the movable baffles 3 are There are through inner dotting holes 32, and each outer dotting hole 41 corresponds to a movable baffle 3. Adjusting the insertion position of the movable baffle 3 can make the inner dotting holes 32 and the outer dotting holes 41 aligned and staggered. 1. The bottom is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com