Patents

Literature

43 results about "Contraction method" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The completed contract method is used to recognize all of the revenue and profit associated with a project only after the project has been completed. This method is used when there is uncertainty about the collection of funds due from a customer under the terms of a contract.

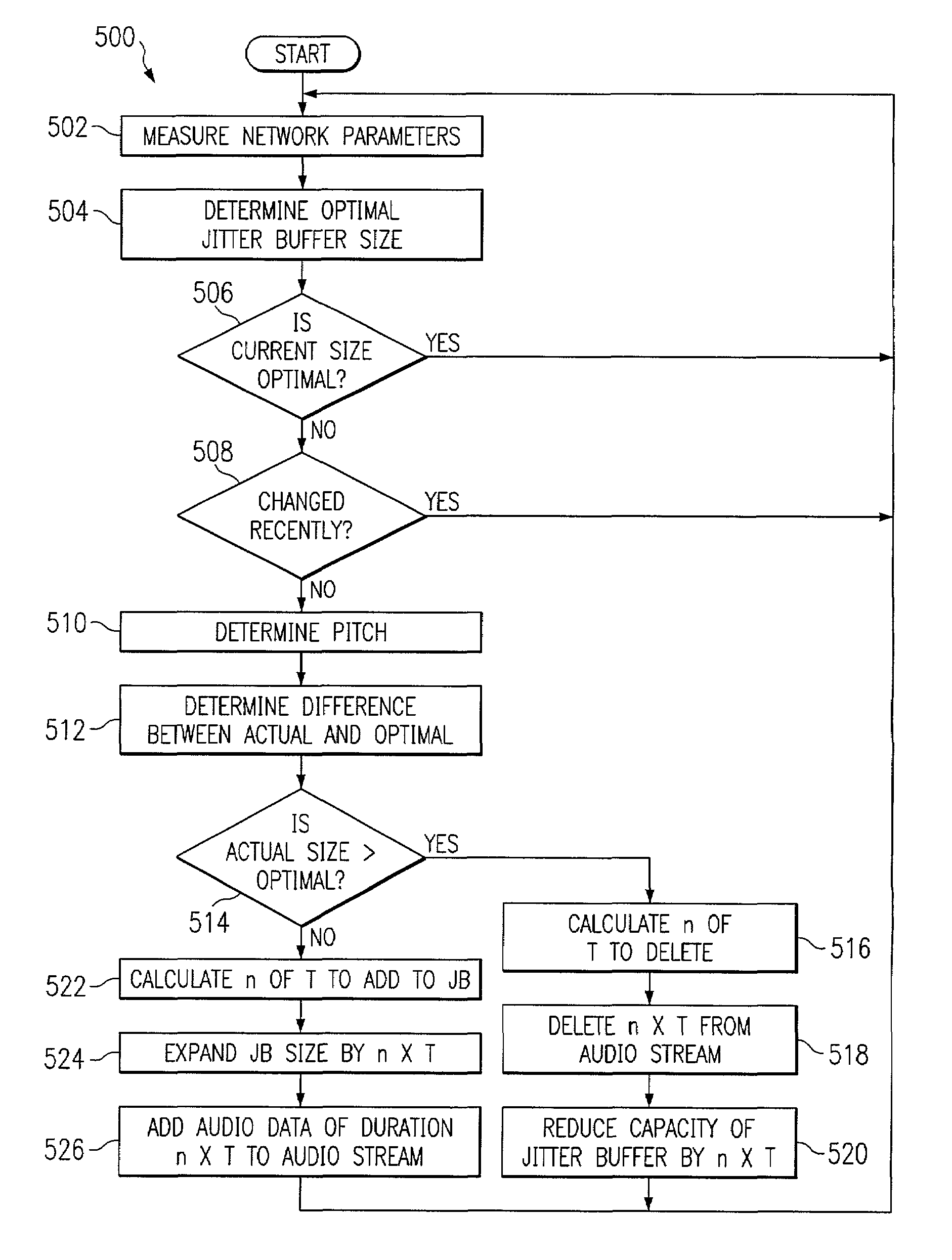

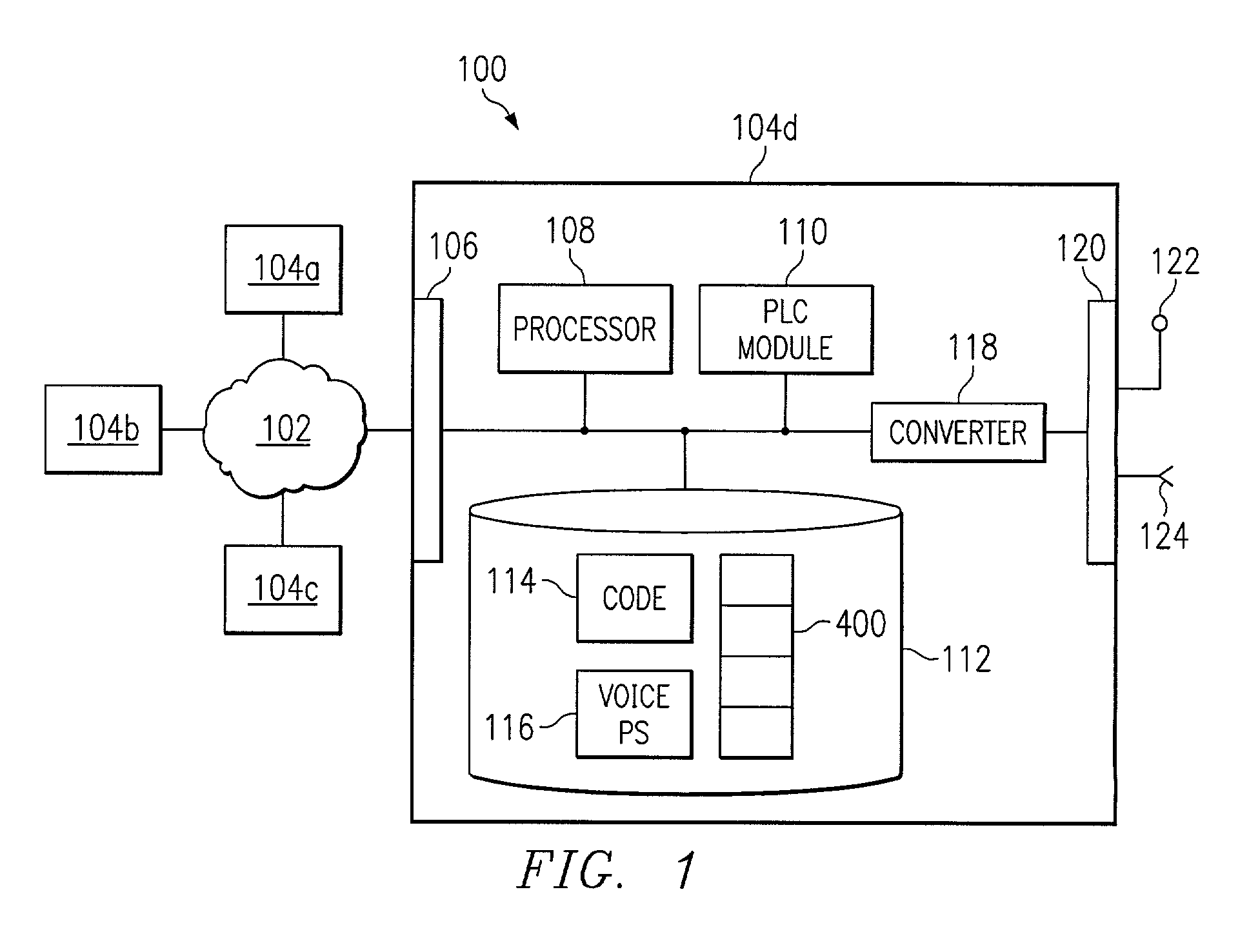

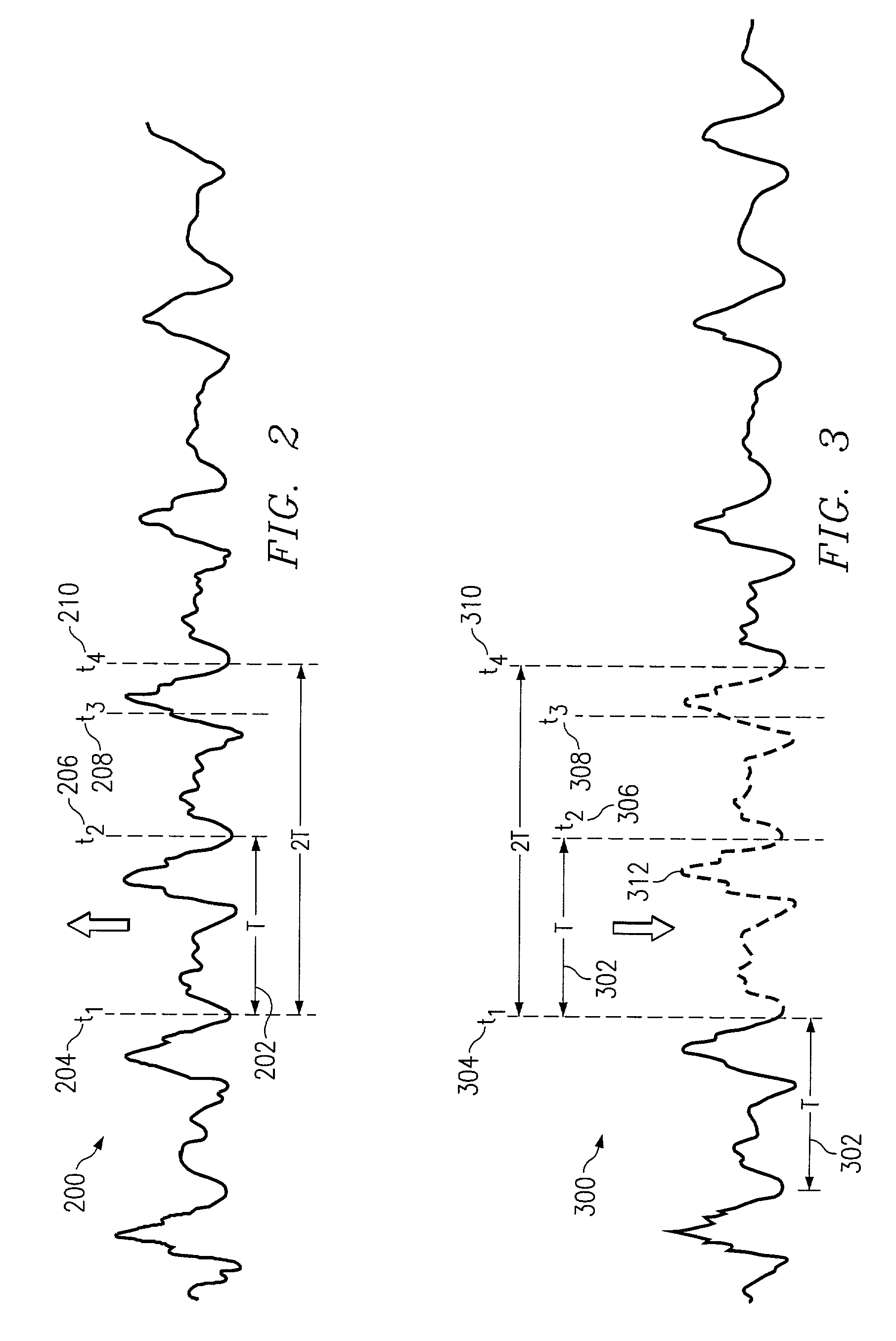

Method and apparatus for concealing jitter buffer expansion and contraction

InactiveUS7099820B1Disadvantages changingProblems changingError preventionTransmission systemsContraction methodAudio frequency

Methods for concealing audible distortions resulting from changes in jitter buffer size include receiving an audio stream, storing the audio stream in a jitter buffer, and determining a pitch period associated with the audio stream. To expand the jitter buffer, a method includes inserting additional audio data that has a duration corresponding to an integer multiple of the pitch period into the audio stream. To contract the jitter buffer, a method includes removing a portion of the audio stream having a duration corresponding to an integer multiple of the pitch period.

Owner:CISCO TECH INC

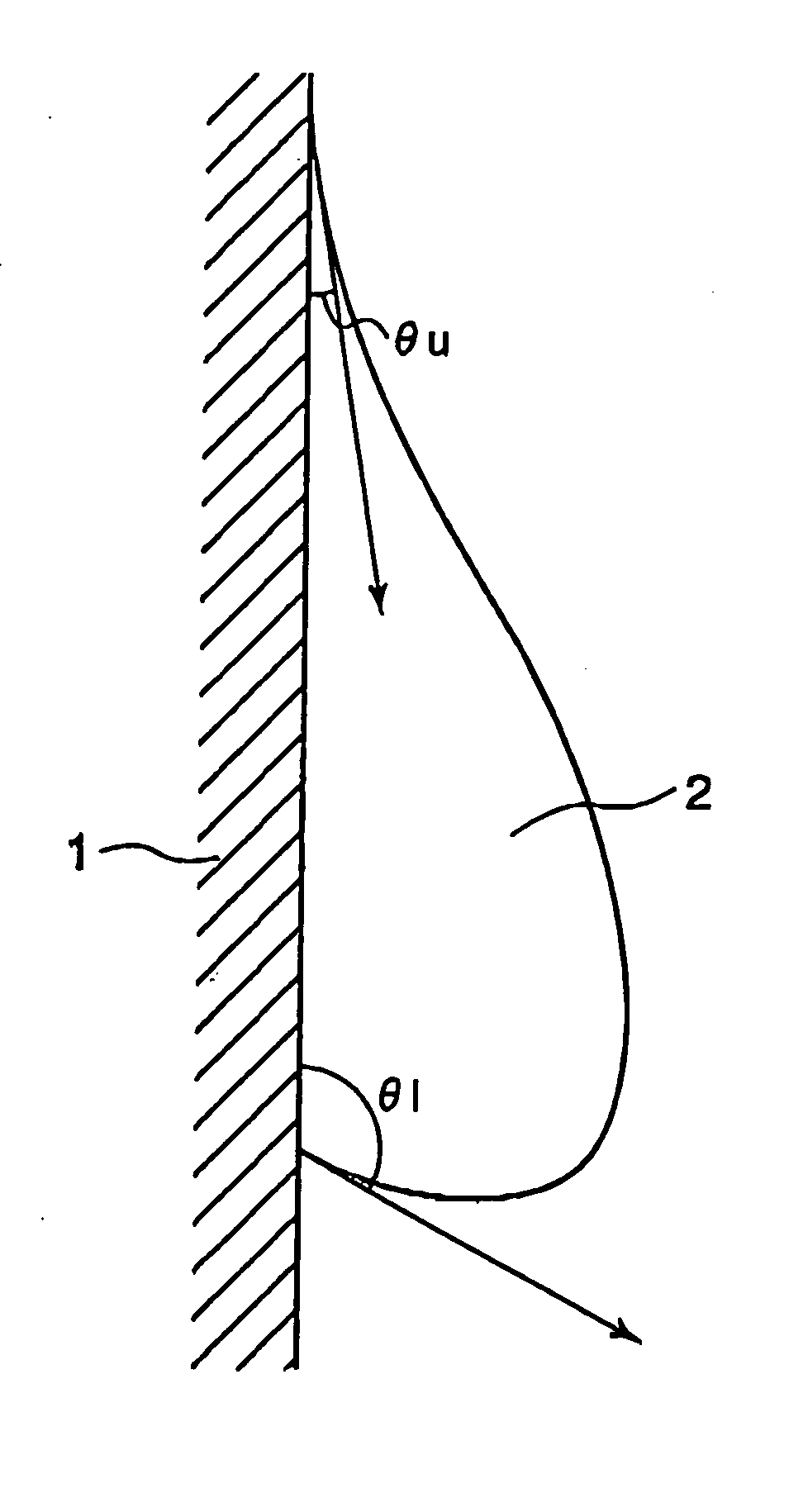

Self-cleaning member and coating composition

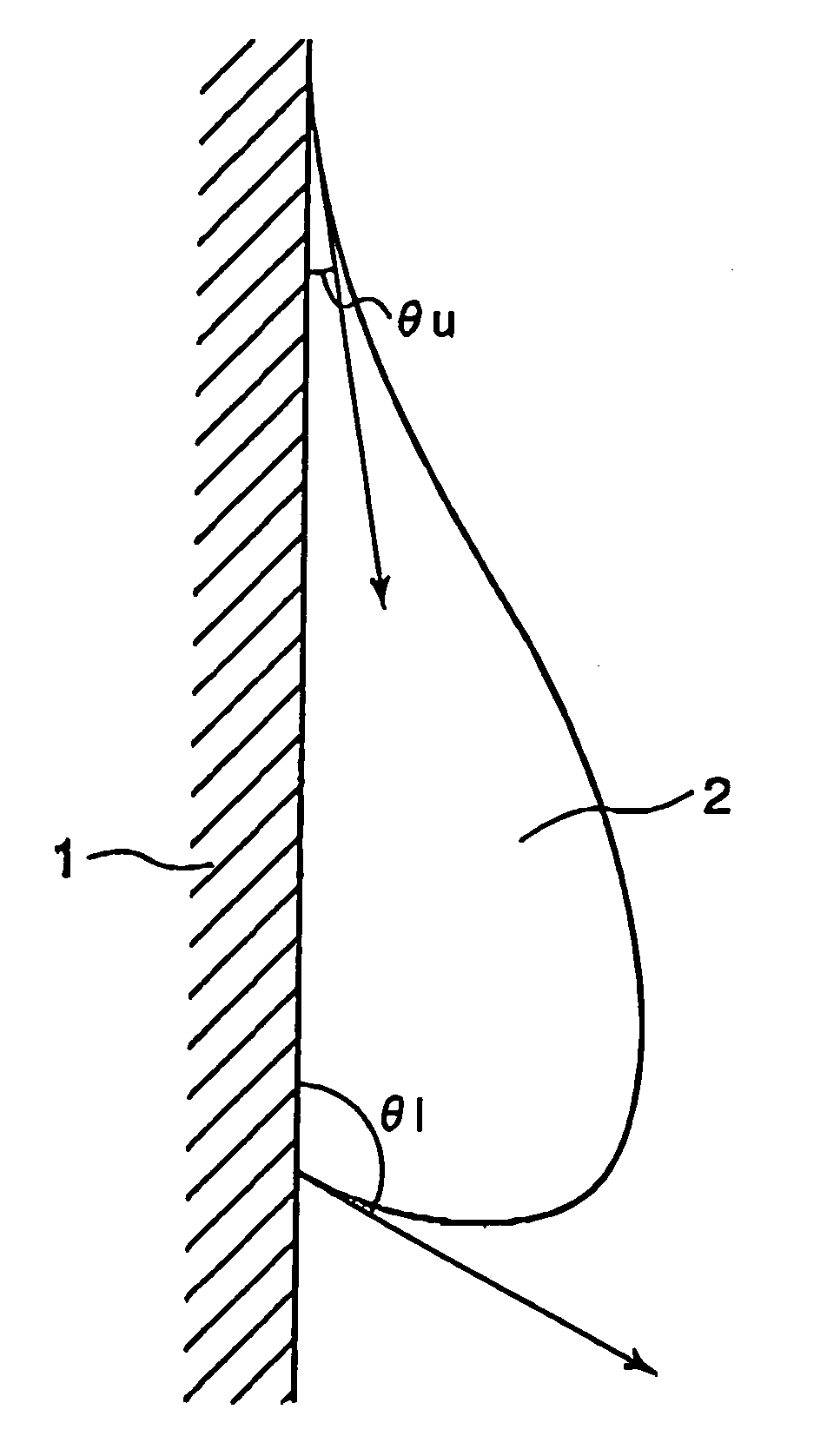

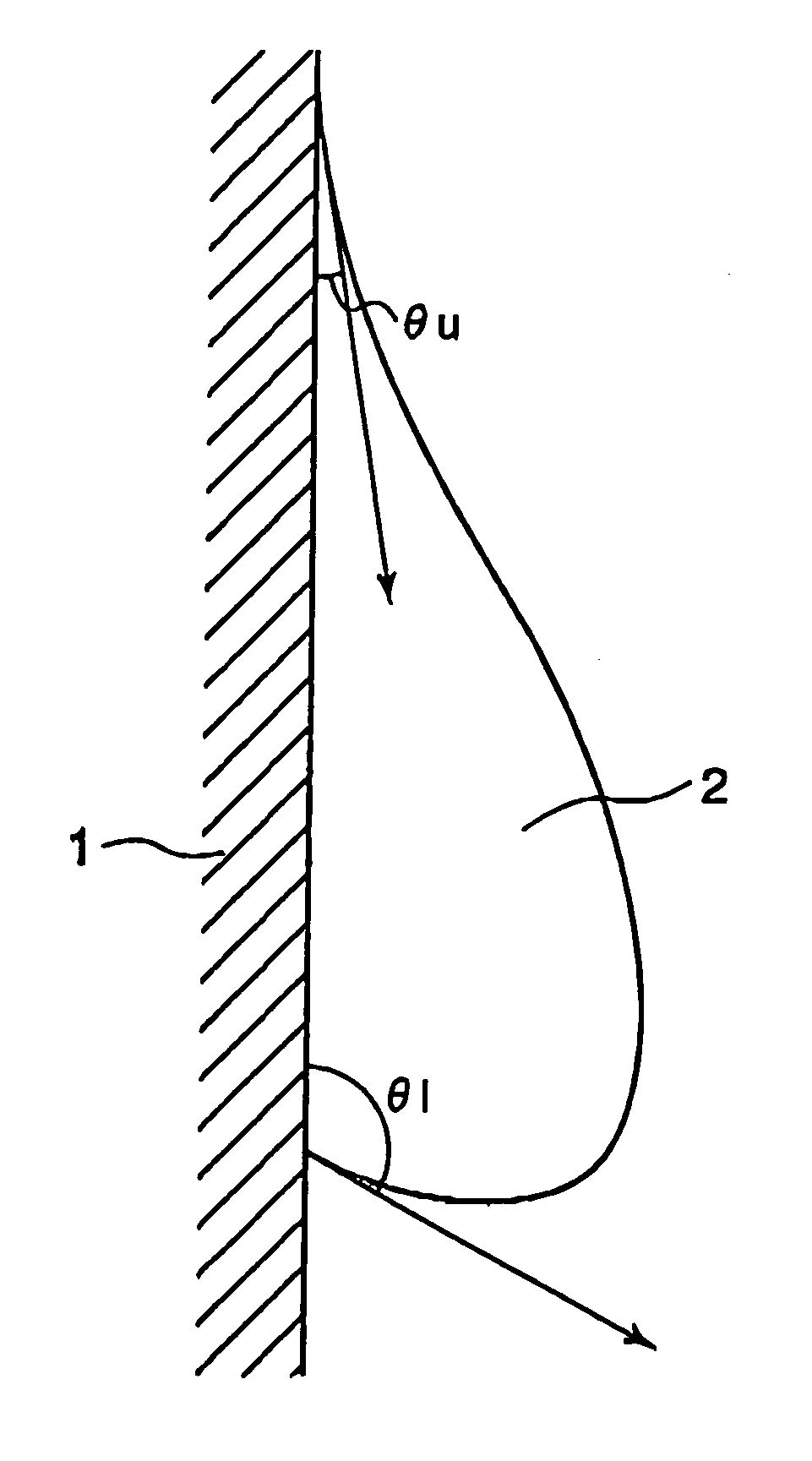

InactiveUS20100304120A1Easily washing awayEasily washed awayFouling preventionOther chemical processesHysteresisSurface layer

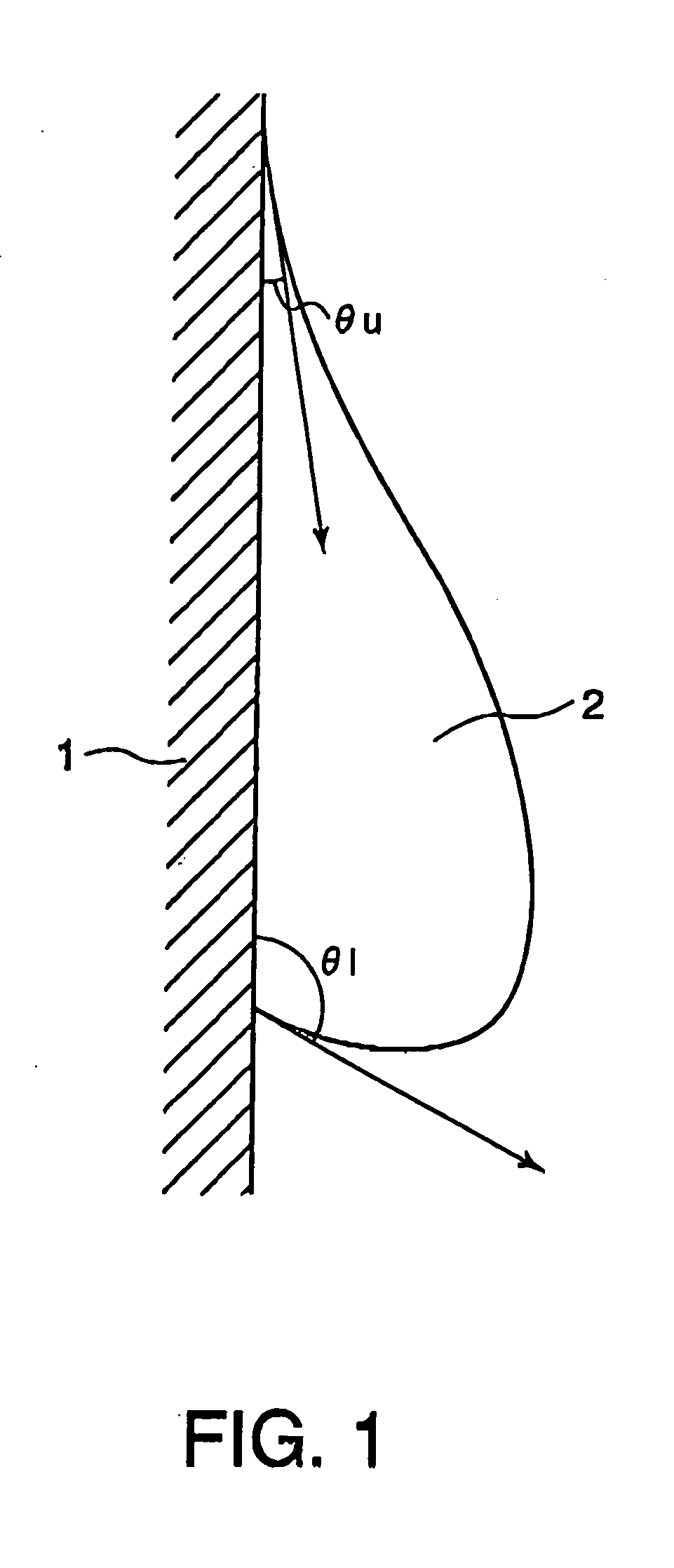

A self-cleaning member comprising a member having a porous surface is disclosed. The member has a contact angle hysteresis Δθ (=θa−θr), which is a difference between an advancing contact angle θa and a receding contact angle θr measured by a dynamic contact angle measurement with an extension / contraction method, of 80 degree or more at the surface layer and a receding contact angle θr of 25 degree or less, is capable of forming a water film on the surface by water provided and of allowing an ionic or reactive contaminant to be washed away without fixation.

Owner:TOTO LTD

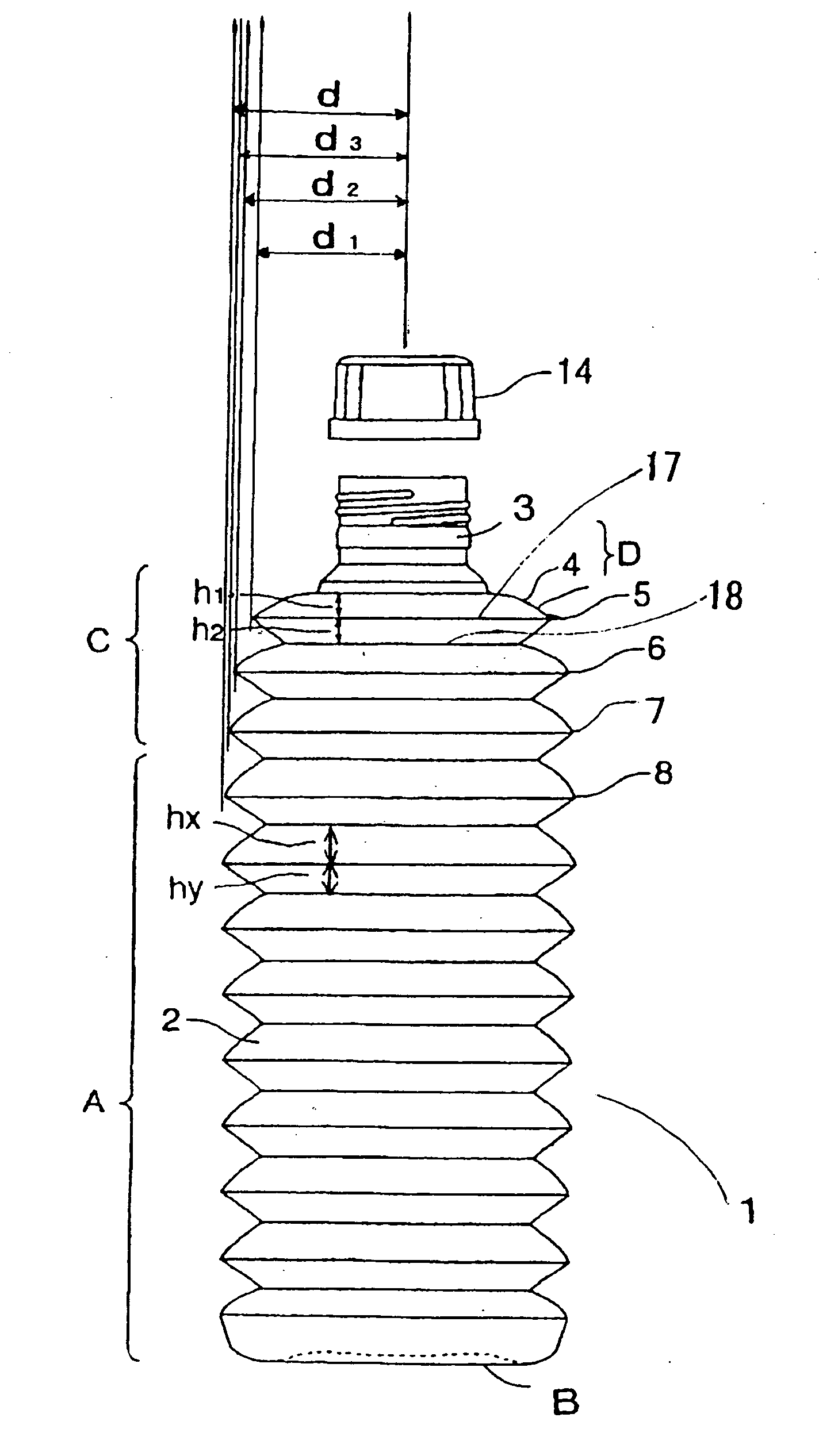

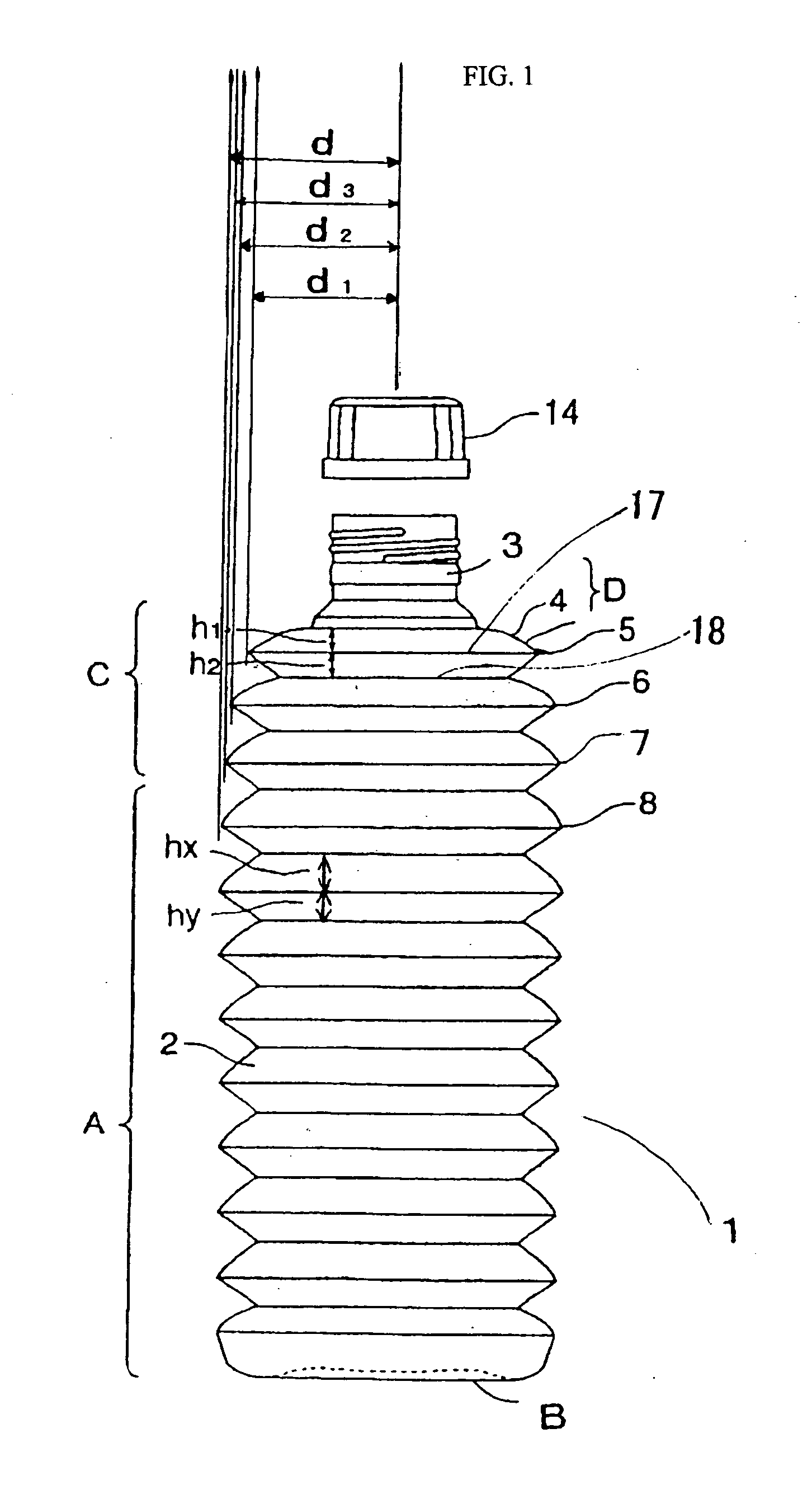

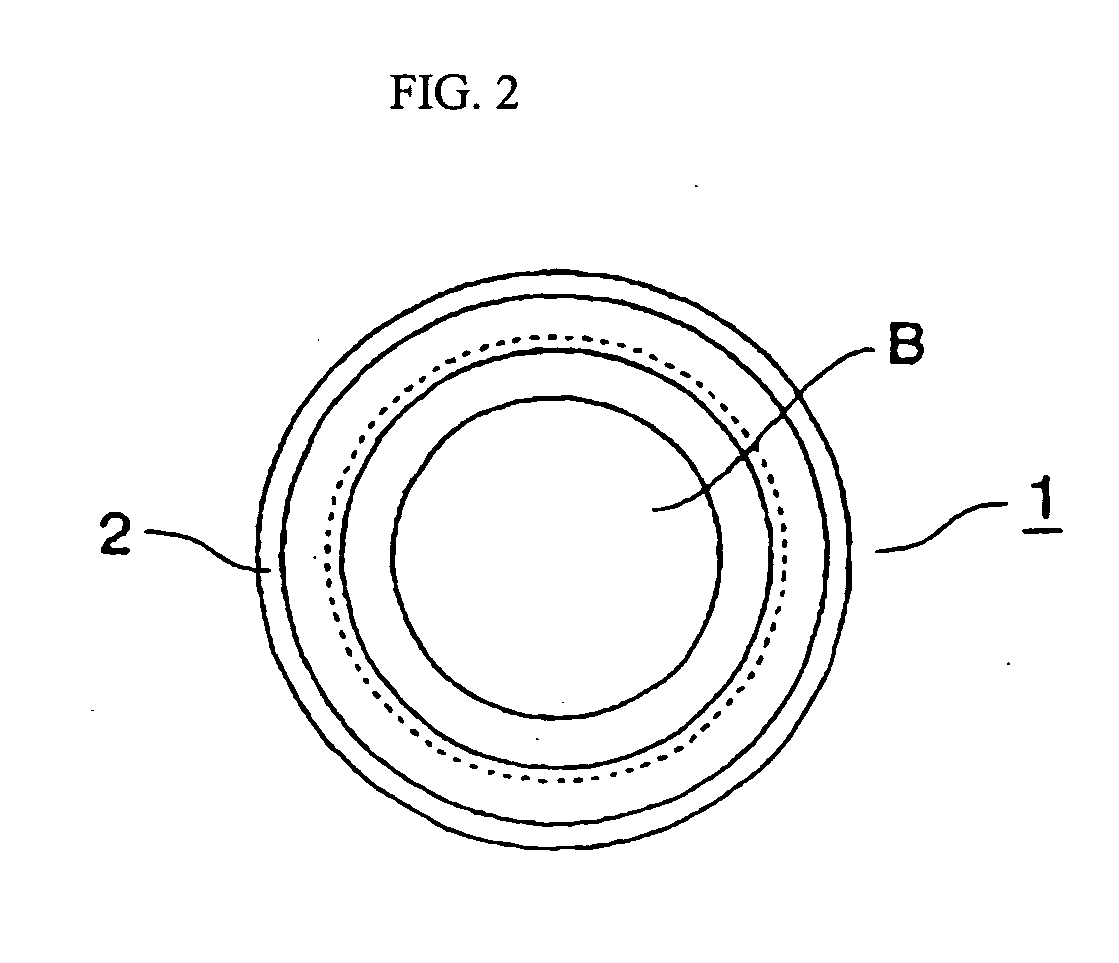

Container capable of keeping a lengthwise contracted state and contraction method thereof

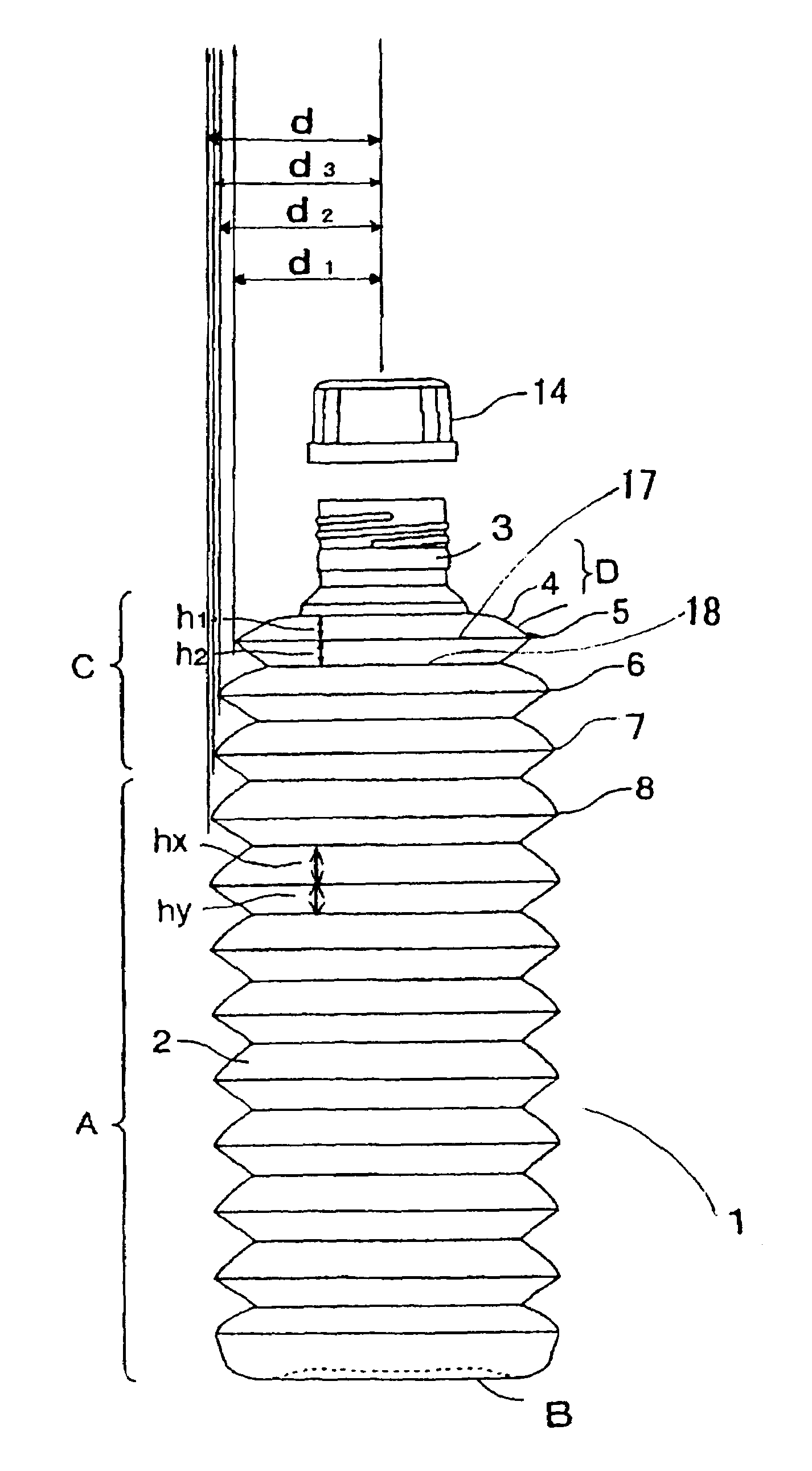

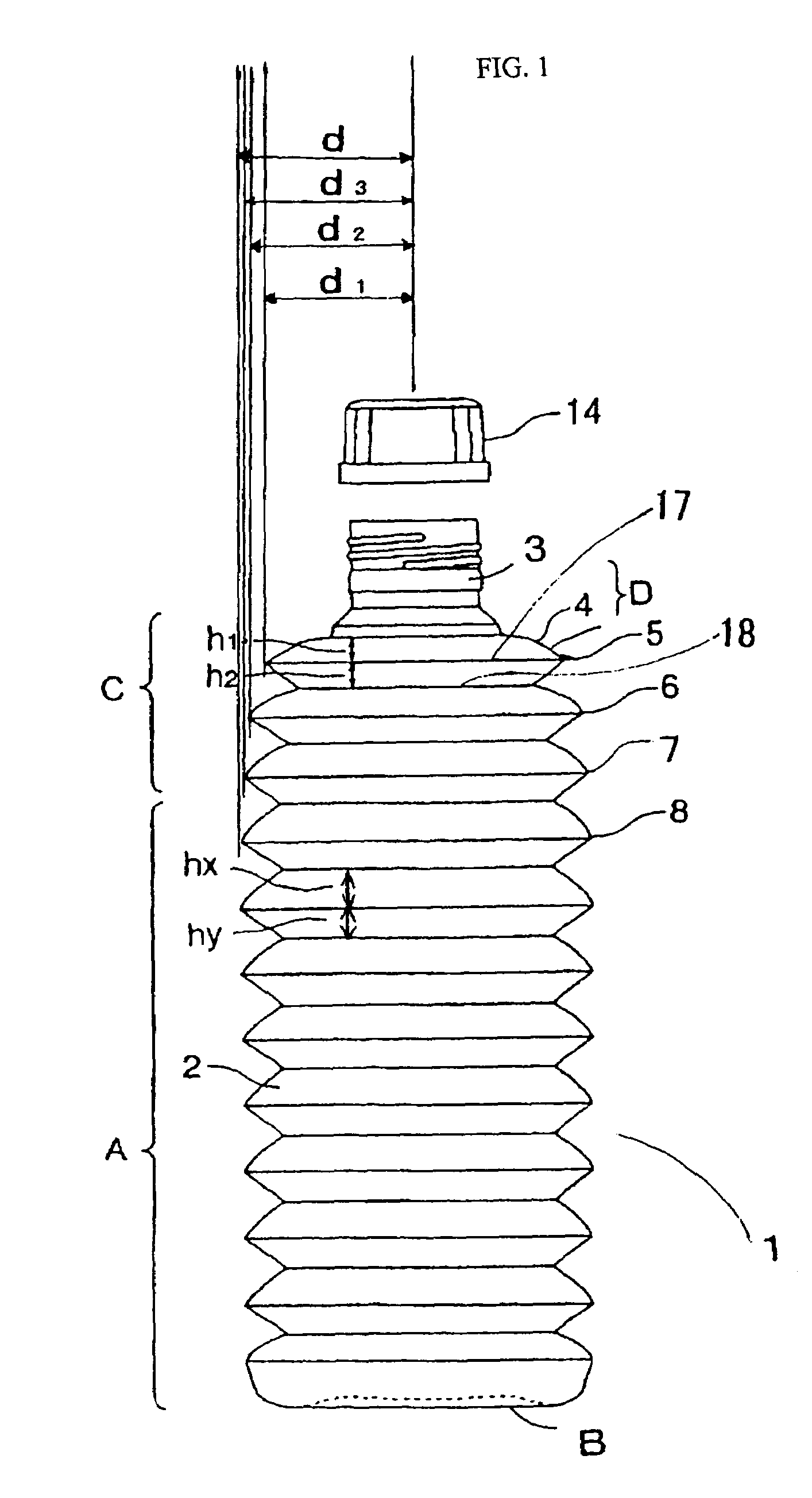

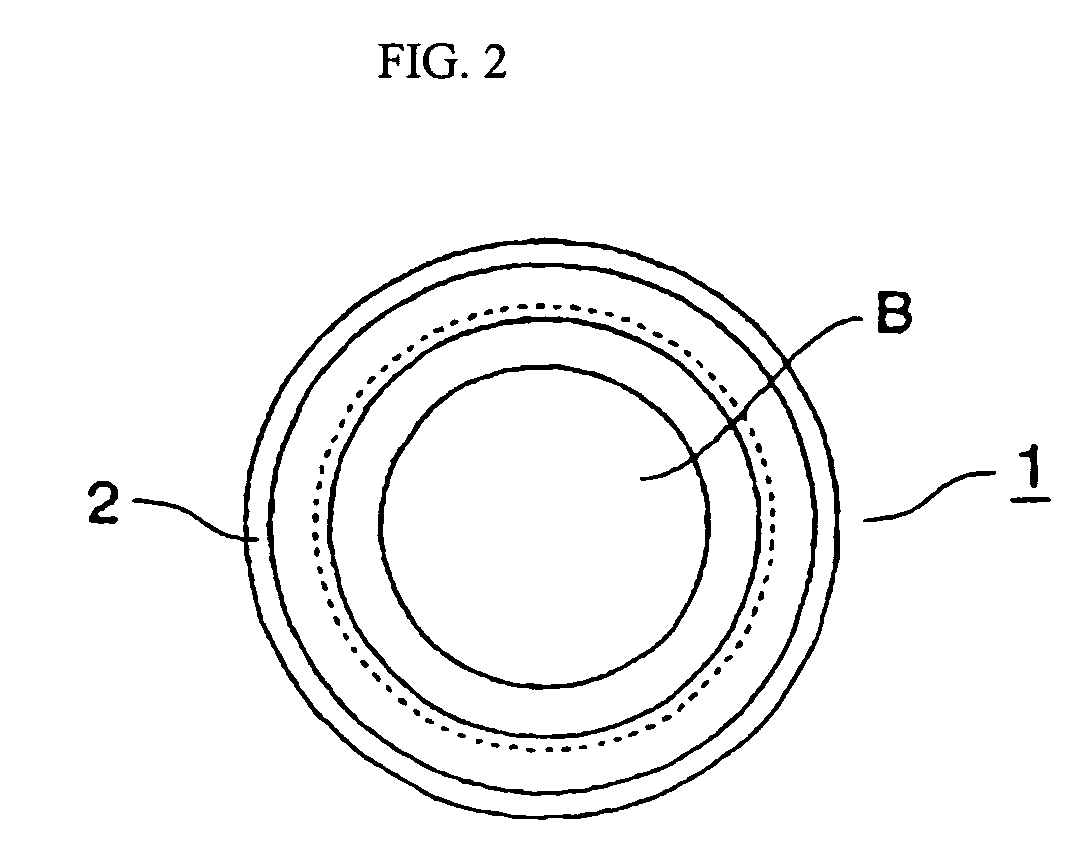

InactiveUS7108151B2Reduce capacityIncrease the number ofBottlesLarge containersContraction methodMineral water

To extremely reduce the capacity of a container body when juice or mineral water in a container body is drunk up and the container body is discarded. The container body includes: a top tap; a small width in a height direction at a bottom; and a horizontal bellows formed on the whole or part in a longitudinal direction of the container body, except the top tap, and the width in the height direction.

Owner:GOHSHO CO LTD

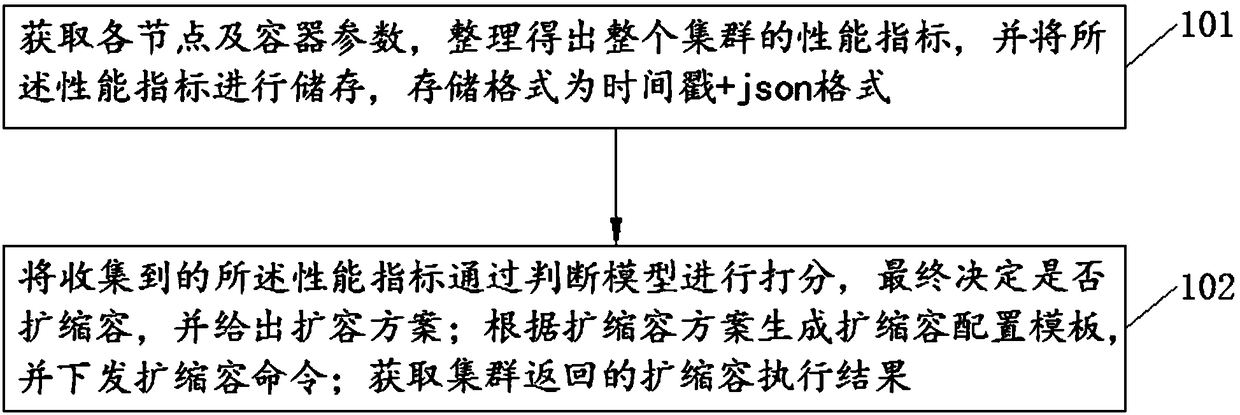

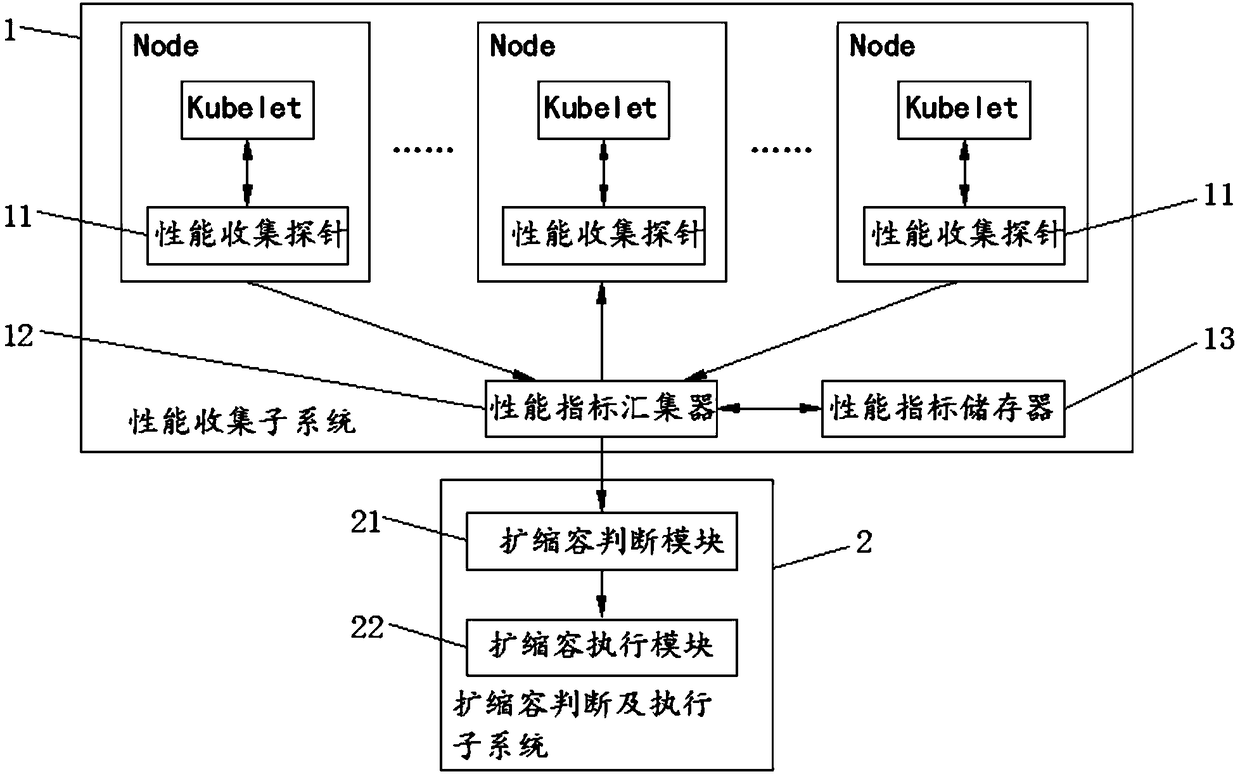

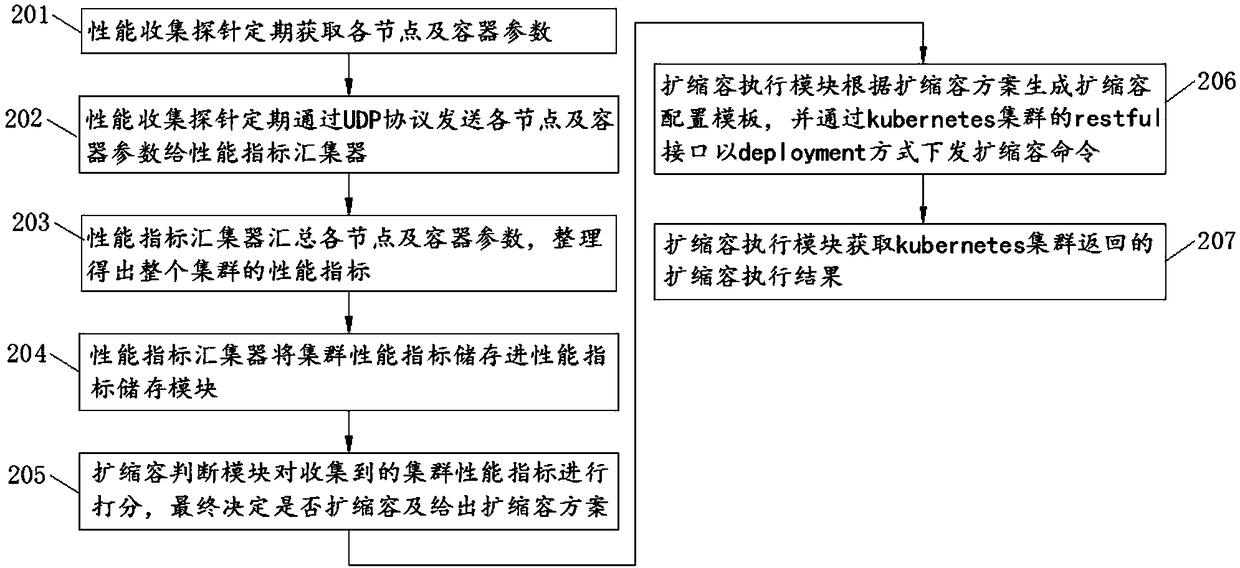

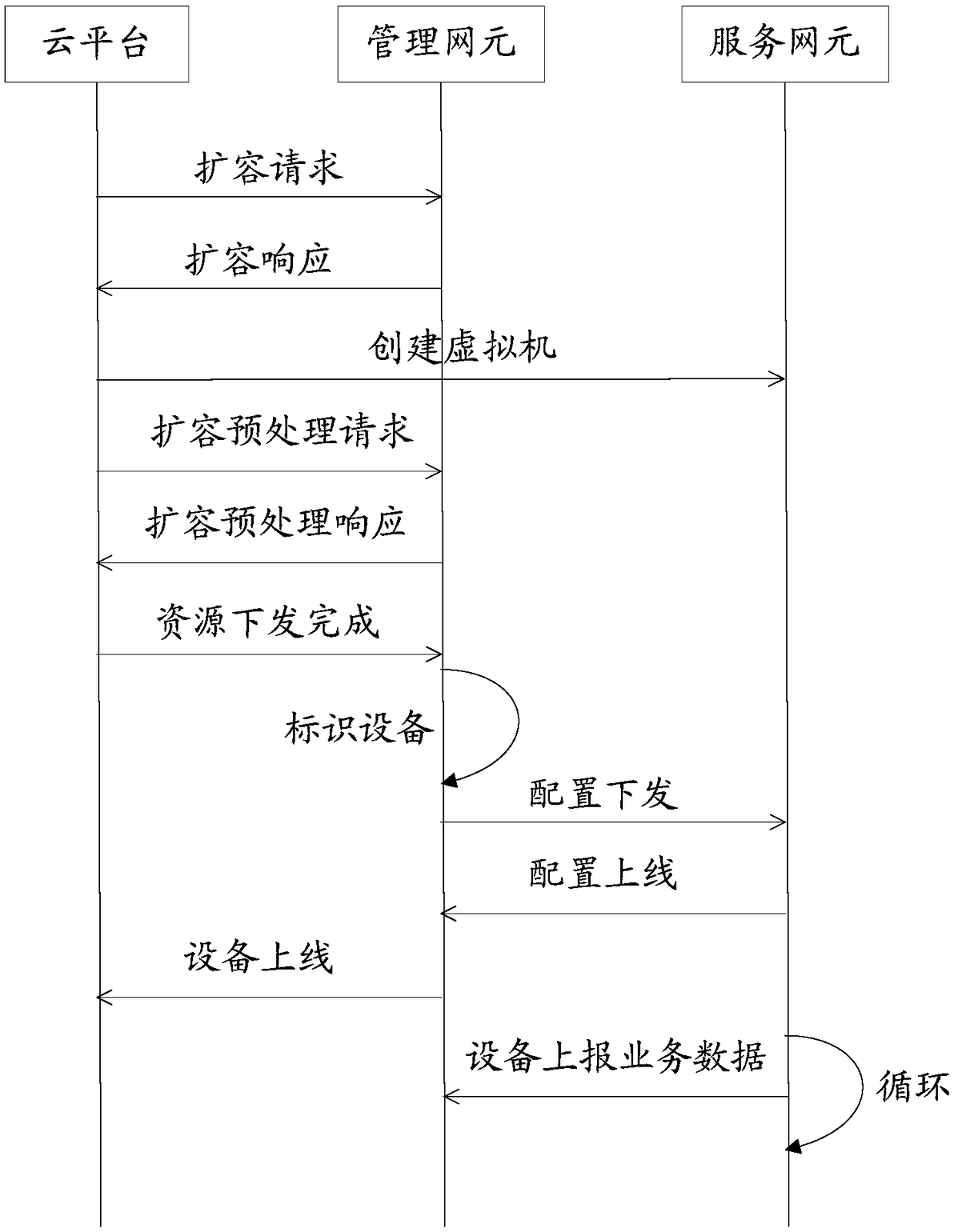

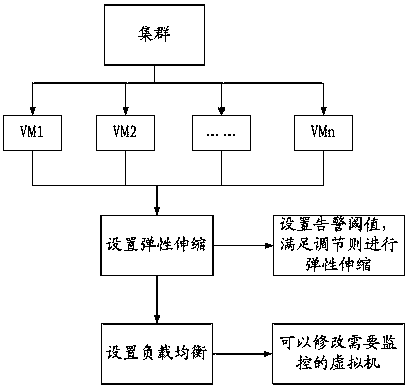

Feedback type automatic capacity expansion and contraction method and system based on cluster performance

InactiveCN108469989AQuickly respond to business needsSolve poor targetingResource allocationNODALTimestamp

Owner:GUANGZHOU VCMY TECH CO LTD

Container capable of keeping a lengthwise contracted state and contraction method thereof

InactiveUS20050017015A1Reduce capacityIncrease the number ofBottlesLarge containersContraction methodEngineering

To extremely reduce the capacity of a container body when juice or mineral water in a container body is drunk up and the container body is discarded. The container body includes: a top tap; a small width in a height direction at a bottom; and a horizontal bellows formed on the whole or part in a longitudinal direction of the container body, except the top tap, and the width in the height direction.

Owner:GOHSHO CO LTD

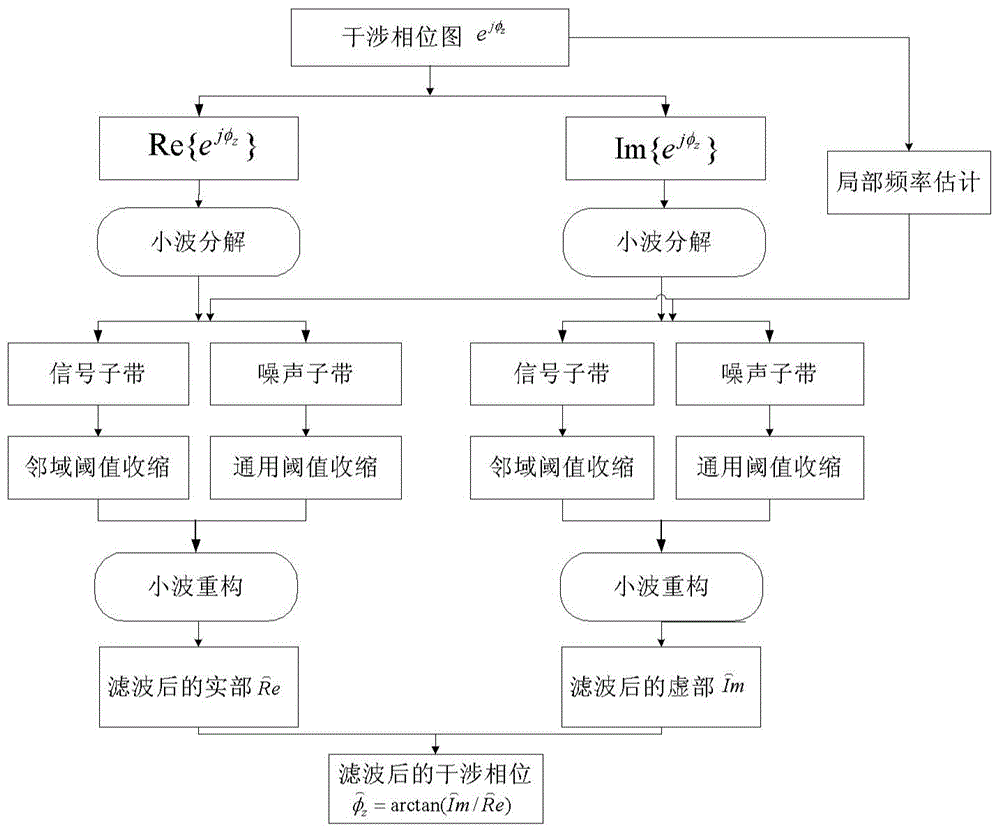

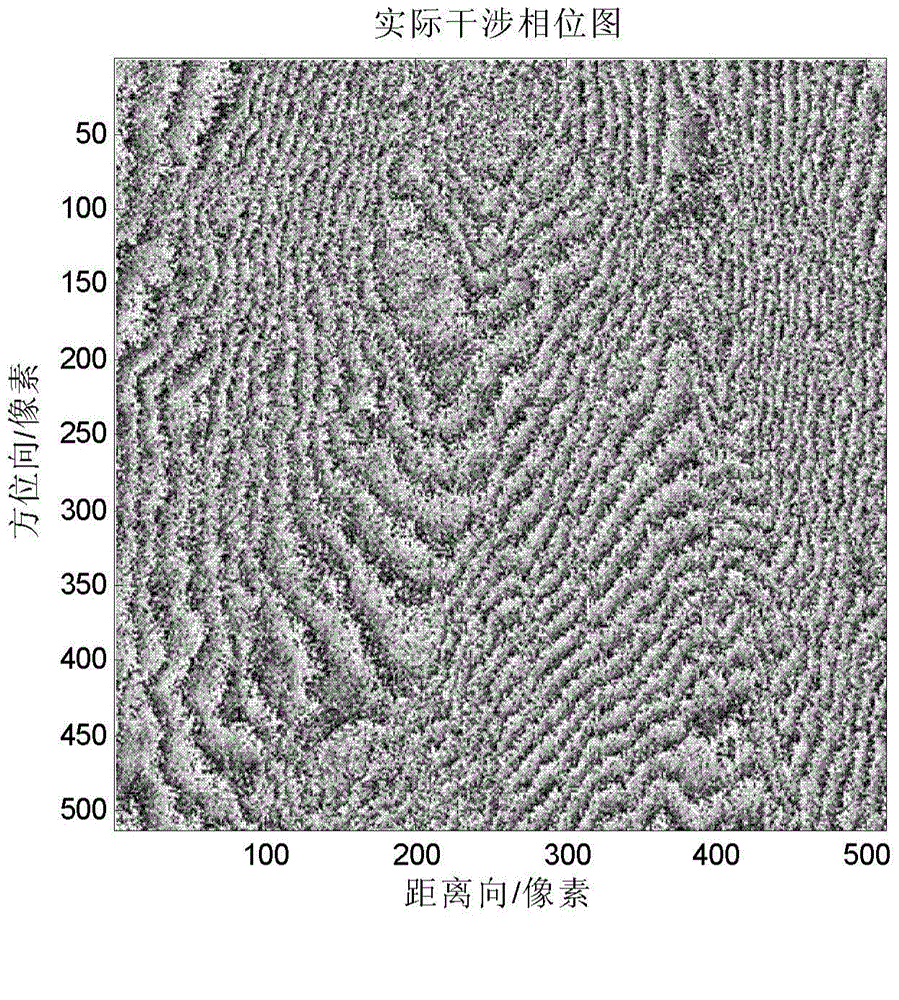

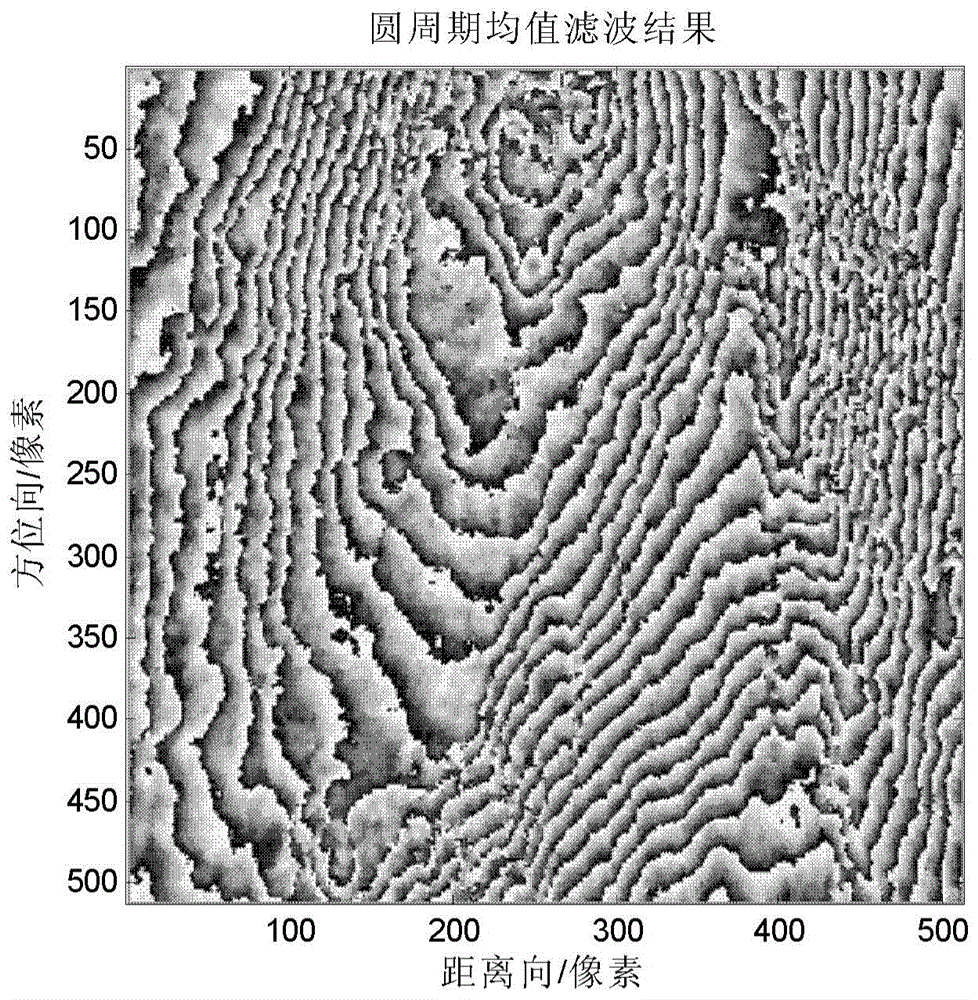

Wavelet domain InSAR interferometric phase filtering method combined with local frequency estimation

ActiveCN104459633ANot destroyedImprove denoising effectRadio wave reradiation/reflectionContraction methodInterferometric phase

The invention provides a wavelet domain InSAR interferometric phase filtering method combined with local frequency estimation. According to the wavelet domain InSAR interferometric phase filtering method, local frequency estimation is utilized for distinguishing a useful information sub-band and a noise sub-band in a wavelet coefficient of a complex domain interferometric phase, a threshold value contraction method and a neighbourhood threshold value contraction method have the advantages of being good in denoising effect and strong in detail keeping capacity respectively, the advantages are utilized for carrying out neighbourhood threshold value contraction on the wavelet coefficient of the sub-band where the useful information is located, general threshold value contraction is carried out on the wavelet coefficients of the other sub-bands, and therefore noise is filtered out as much as possible, meanwhile, the detail information of interference fringes is kept not damaged, high-precision interferometric phase filtering is achieved, and conditions are provided for high-precision interferometric measurement.

Owner:济钢防务技术有限公司

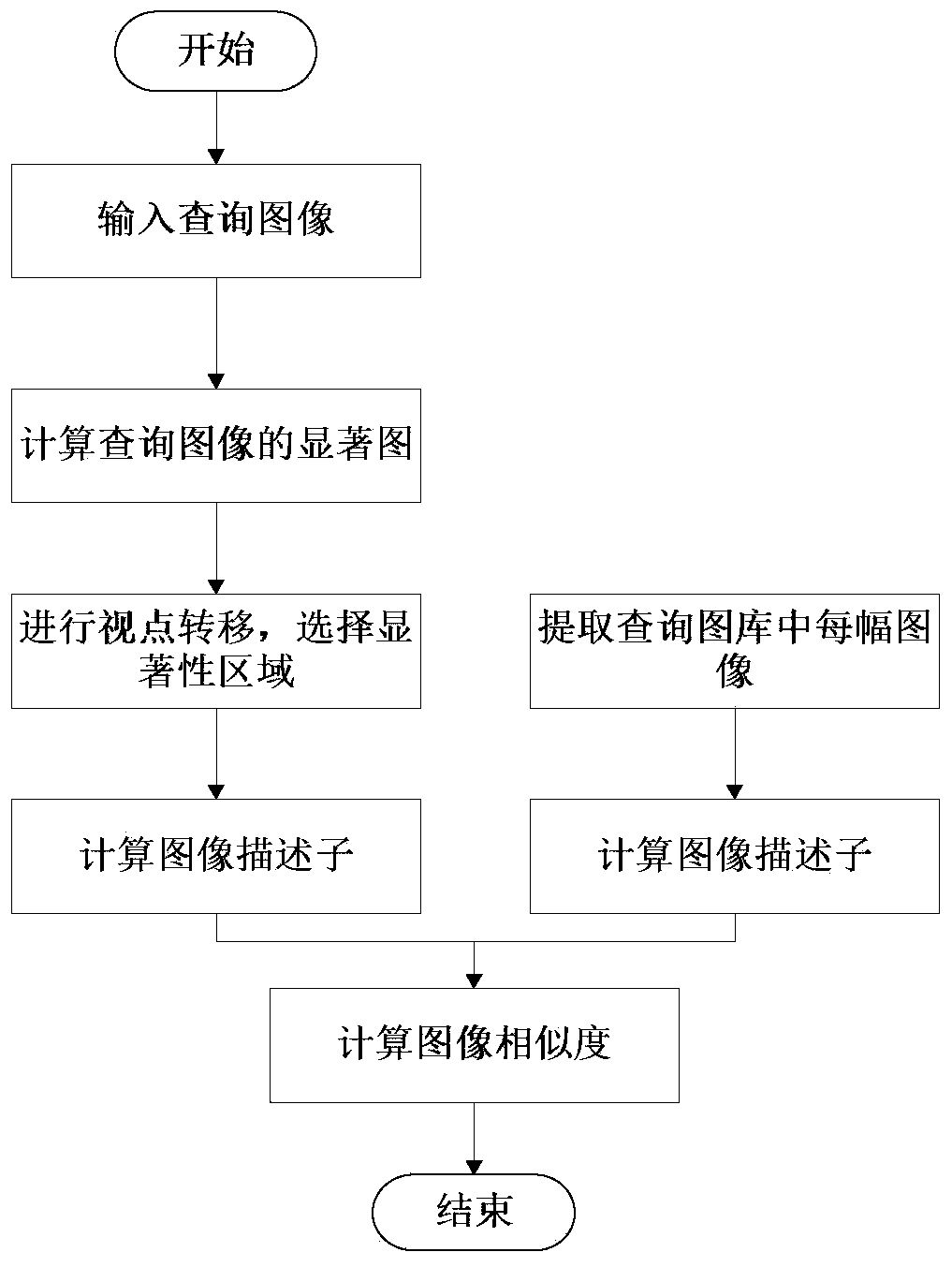

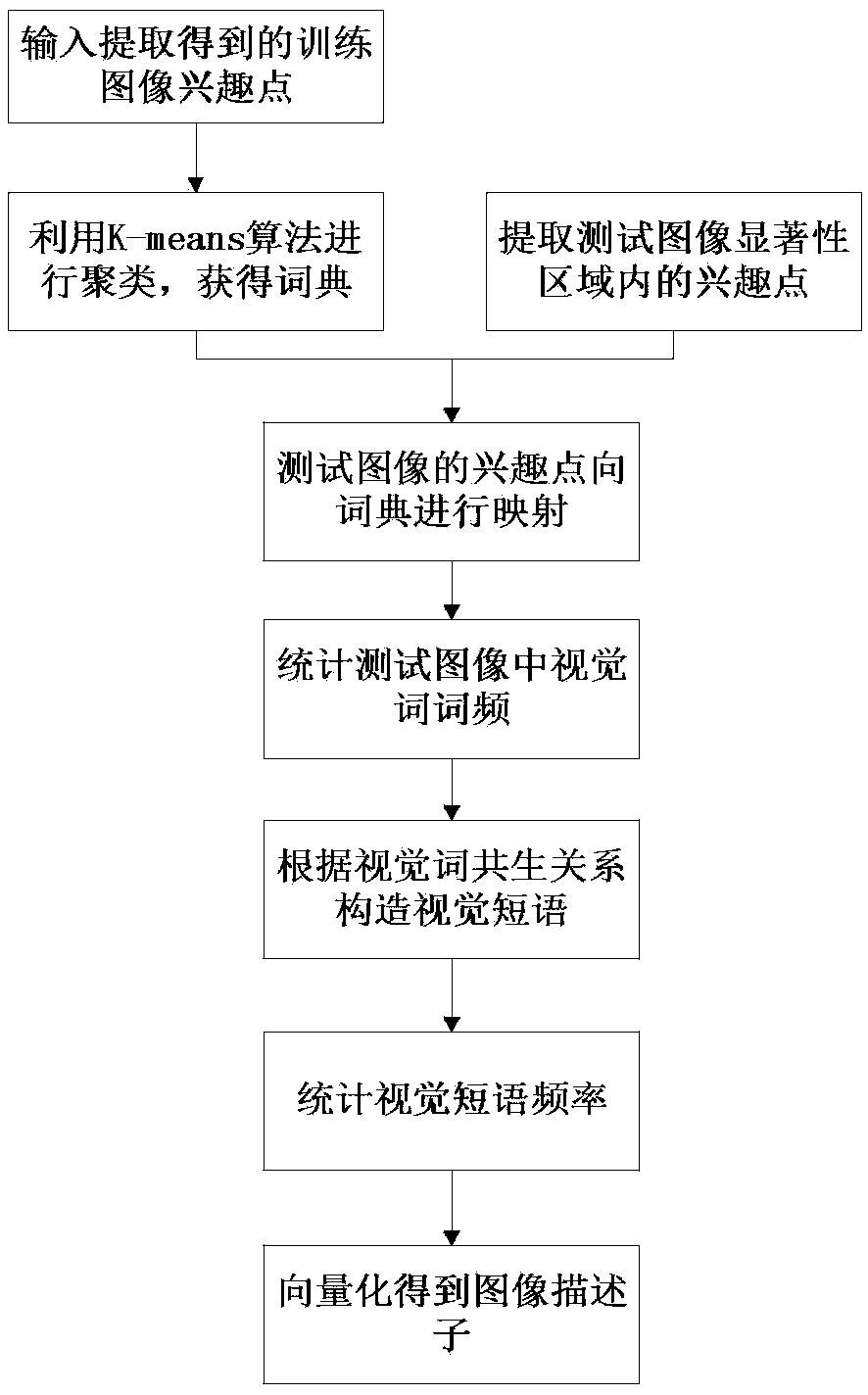

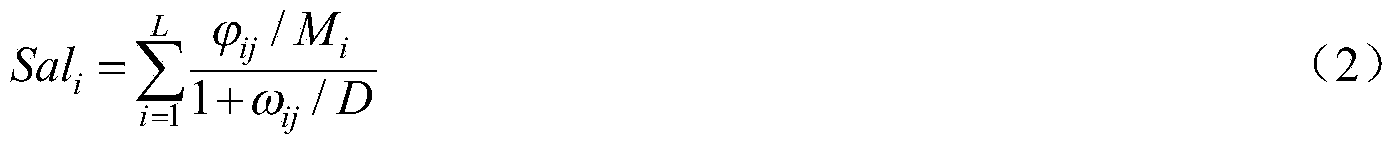

Visual saliency and visual phrase combined image retrieval method

ActiveCN103838864AReduce noiseComplies with understandingSpecial data processing applicationsSaliency mapContraction method

The invention relates to a visual saliency and visual phrase combined image retrieval method. The method includes the first step of inputting a query image, the second step of calculating the saliency image of the query image, the third step of extracting a saliency region of the query image, the fourth step of extracting visual words in the saliency region of the query image and constructing visual phases, the fifth step of obtaining the image descriptor of each image, and the sixth step of calculating the image similarity between the query image and images in an image library, carrying out sorting on the images in the image library according to image similarity values and returning the corresponding image as a query result according to requirements. Through the method, the image region is restrained by introducing the visual saliency on the basis of a typical 'bag of words' model, the noise of image expression is reduced, and the expression of the images in a computer accords with understanding of human to image semantics more, so the method has the good retrieval effect. According to the method, the visual phases are constructed through region constraints between the visual words; compared with other visual phase contraction methods, the method has the advantage of being high in speed.

Owner:BEIJING UNIV OF TECH

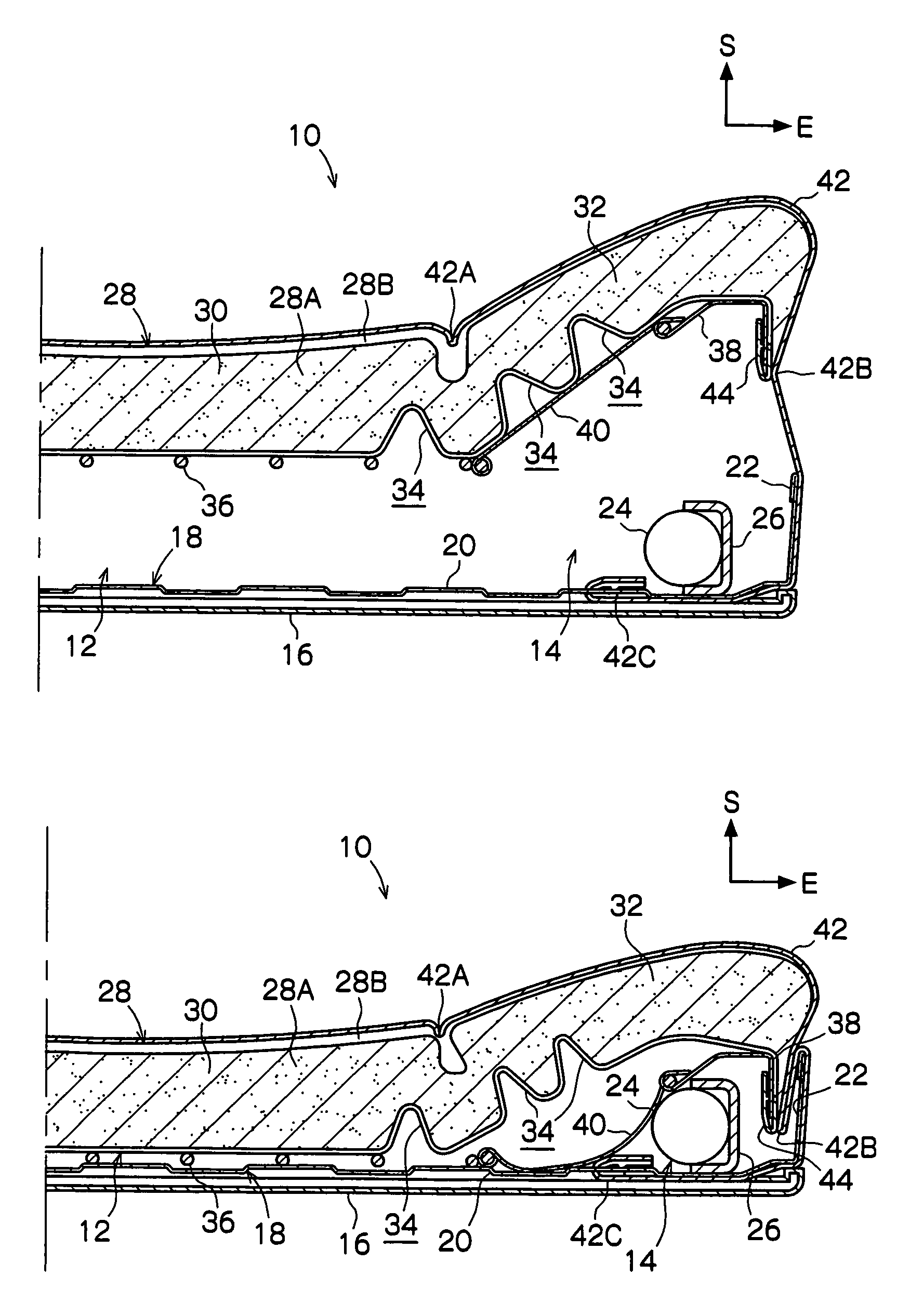

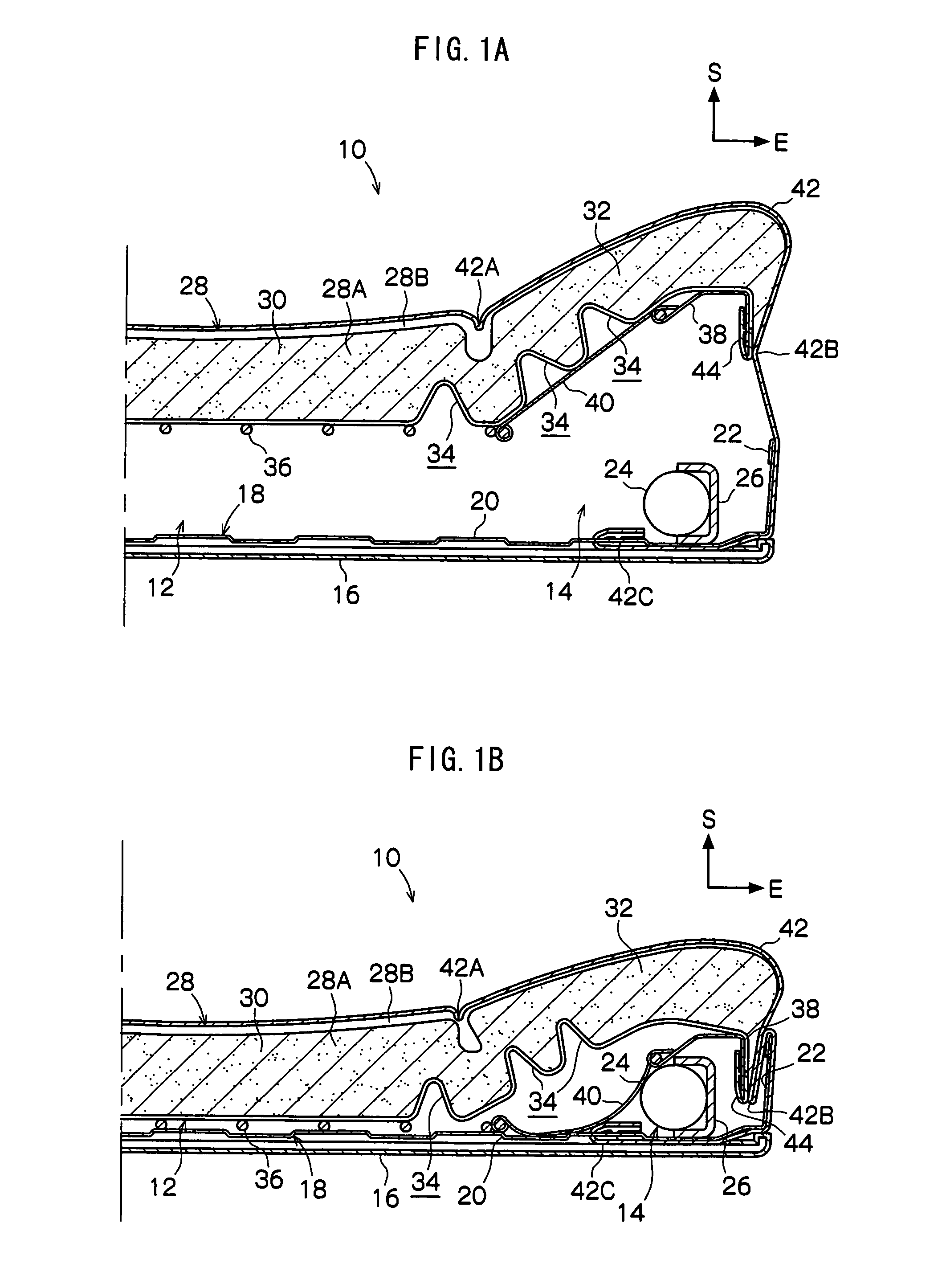

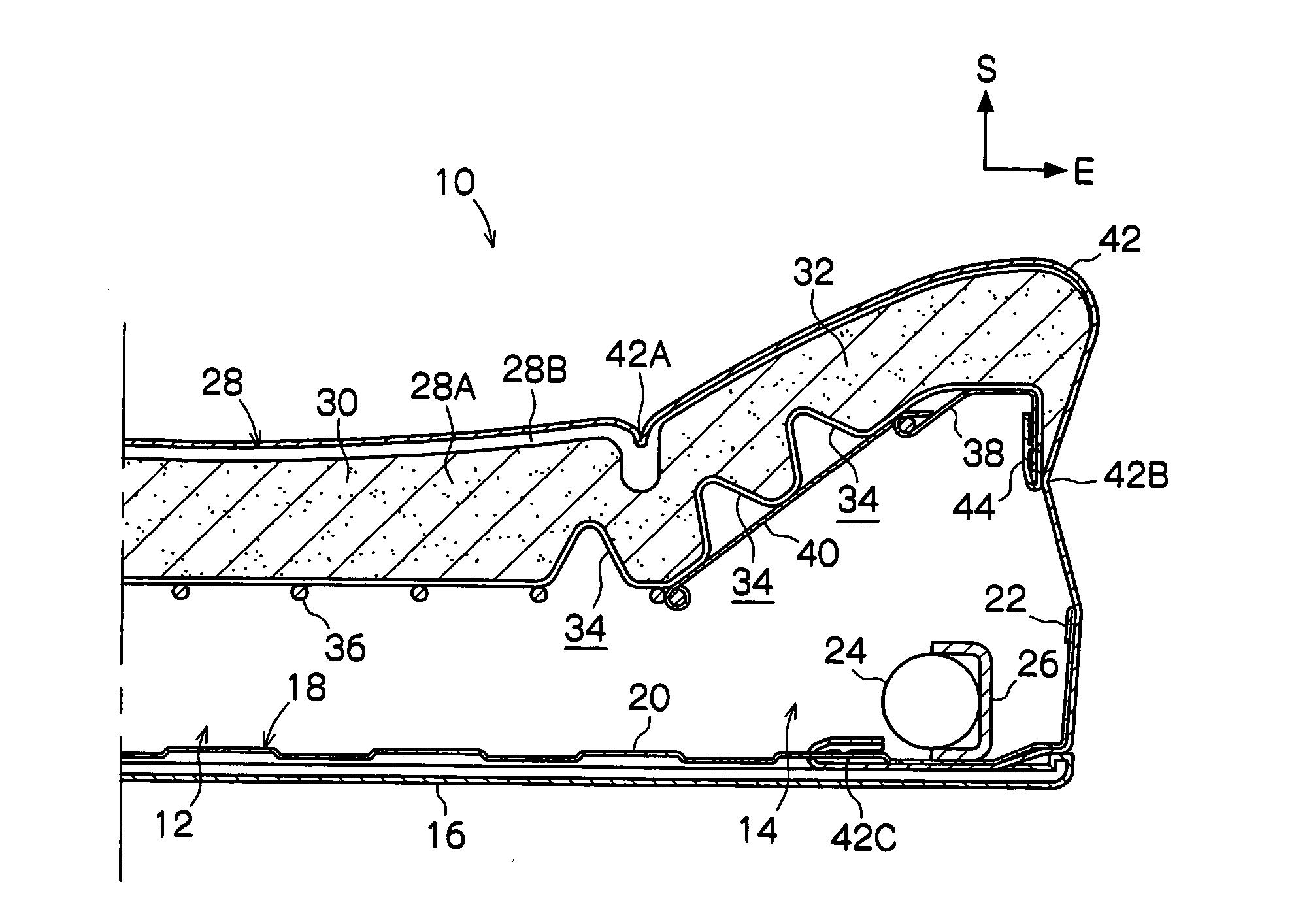

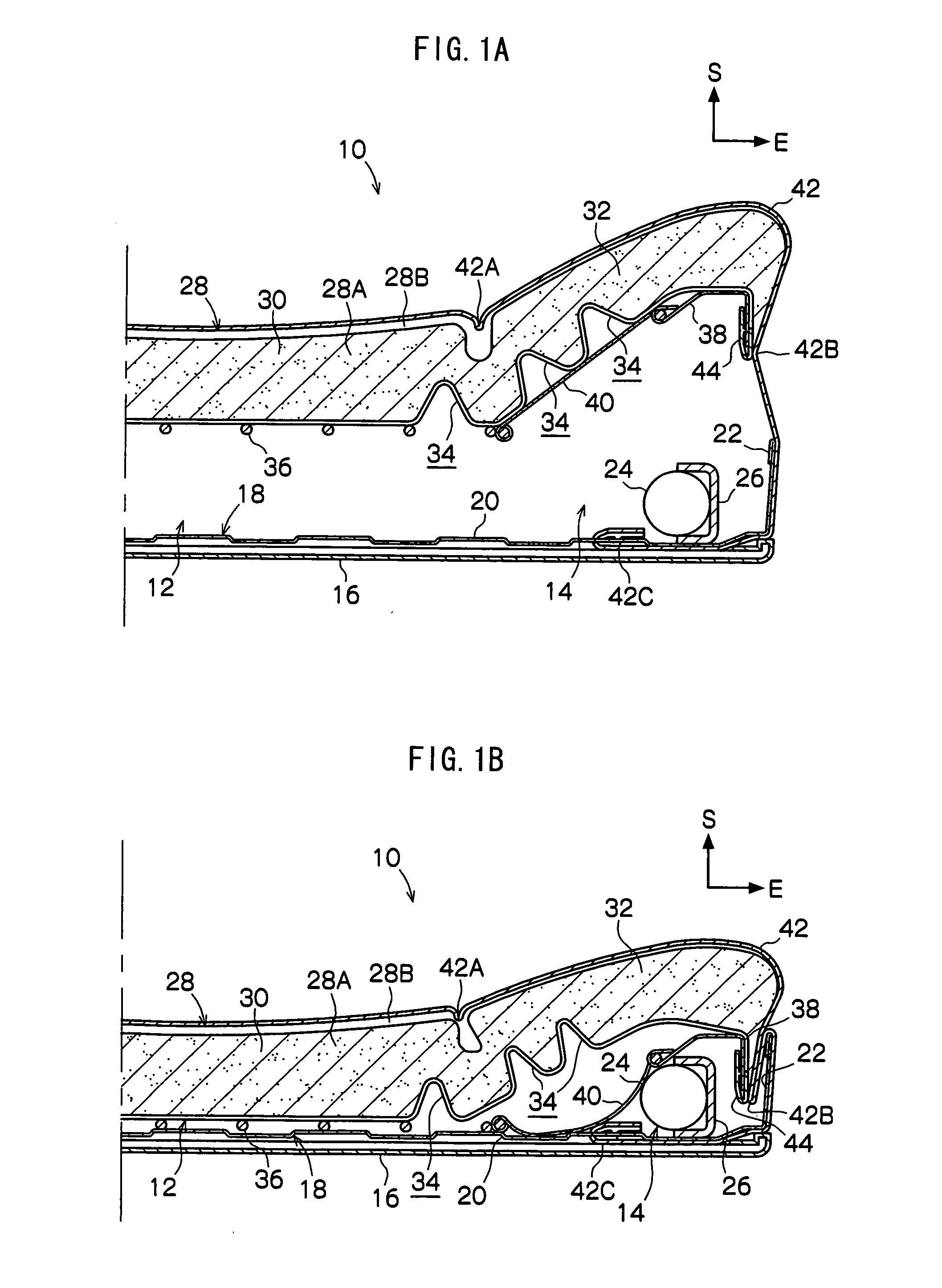

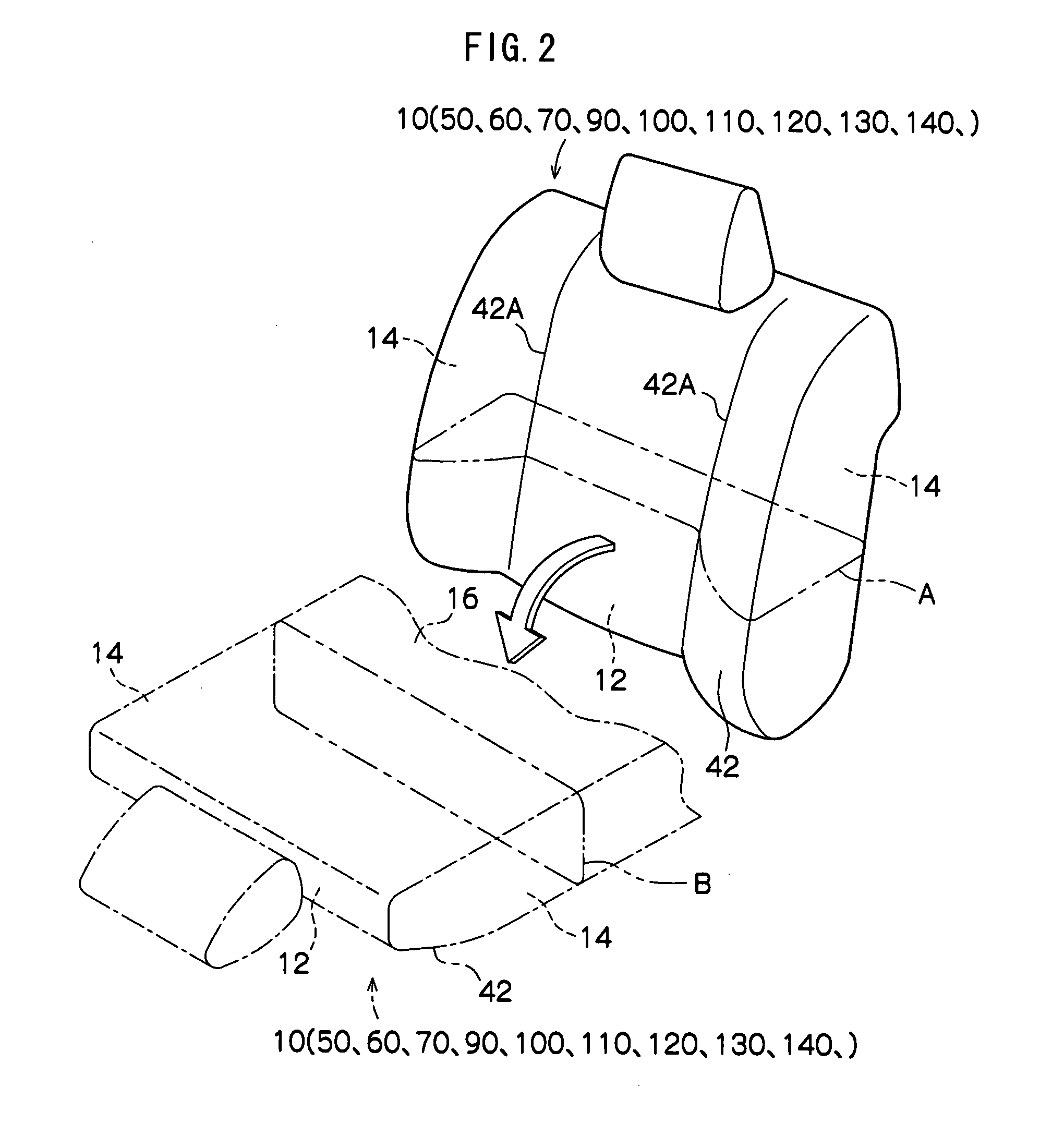

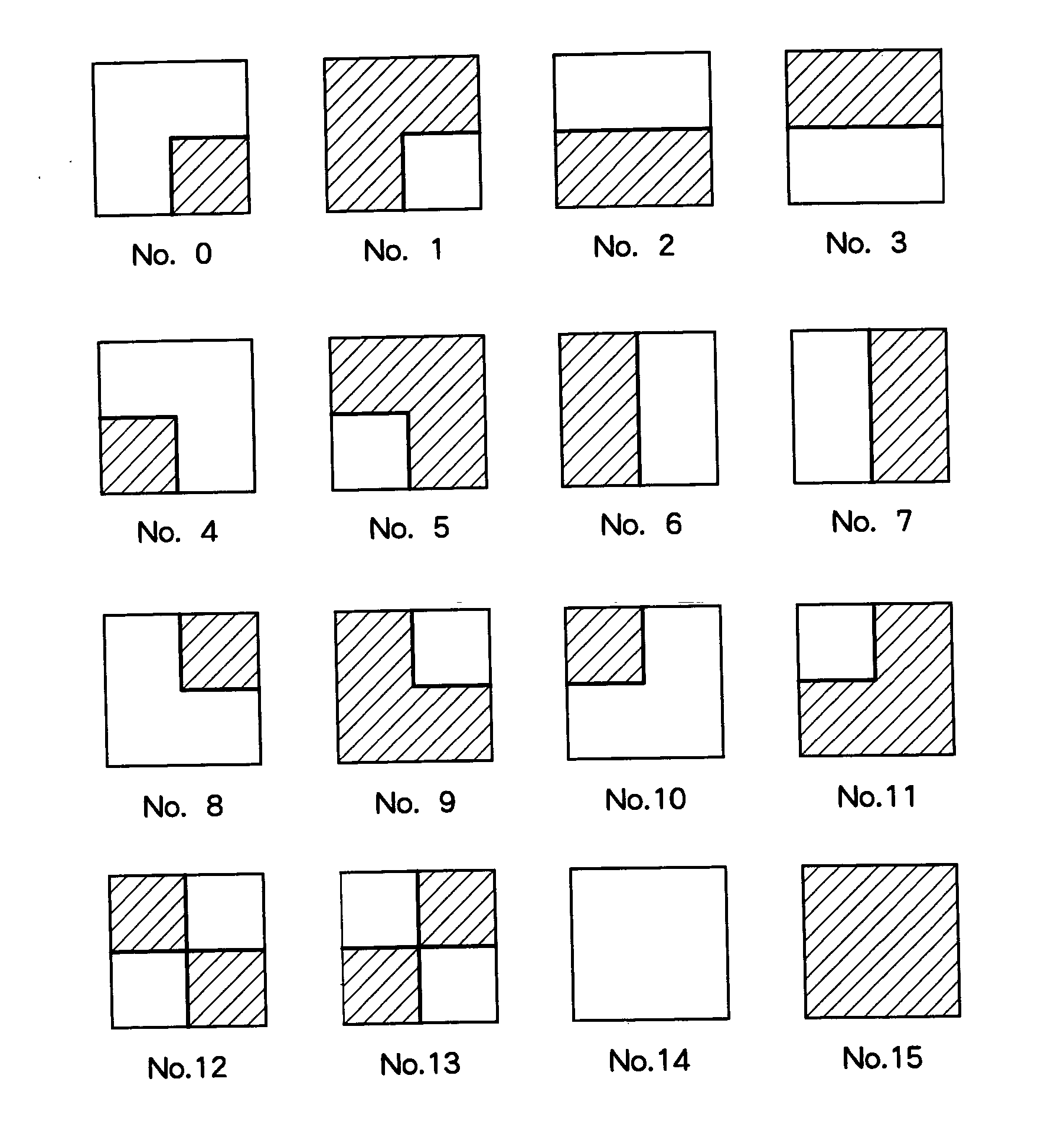

Seat structure and seat contraction method

ActiveUS8231174B2Inhibition of relaxationStoolsAdjustable chairsContraction methodBiomedical engineering

Owner:TOYOTA JIDOSHA KK +1

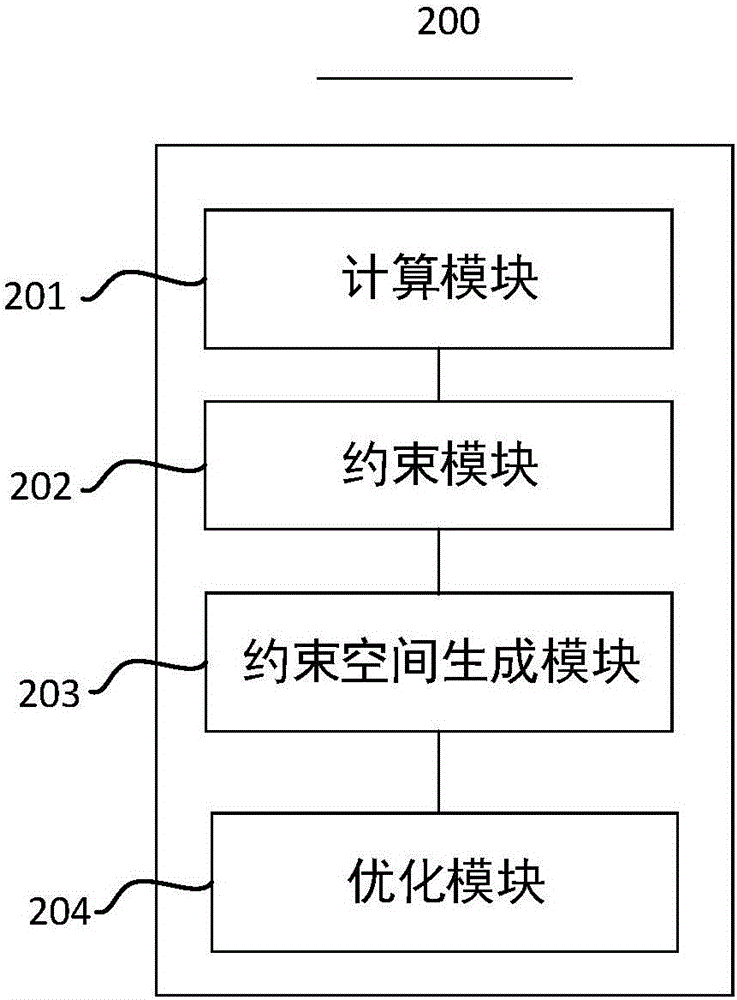

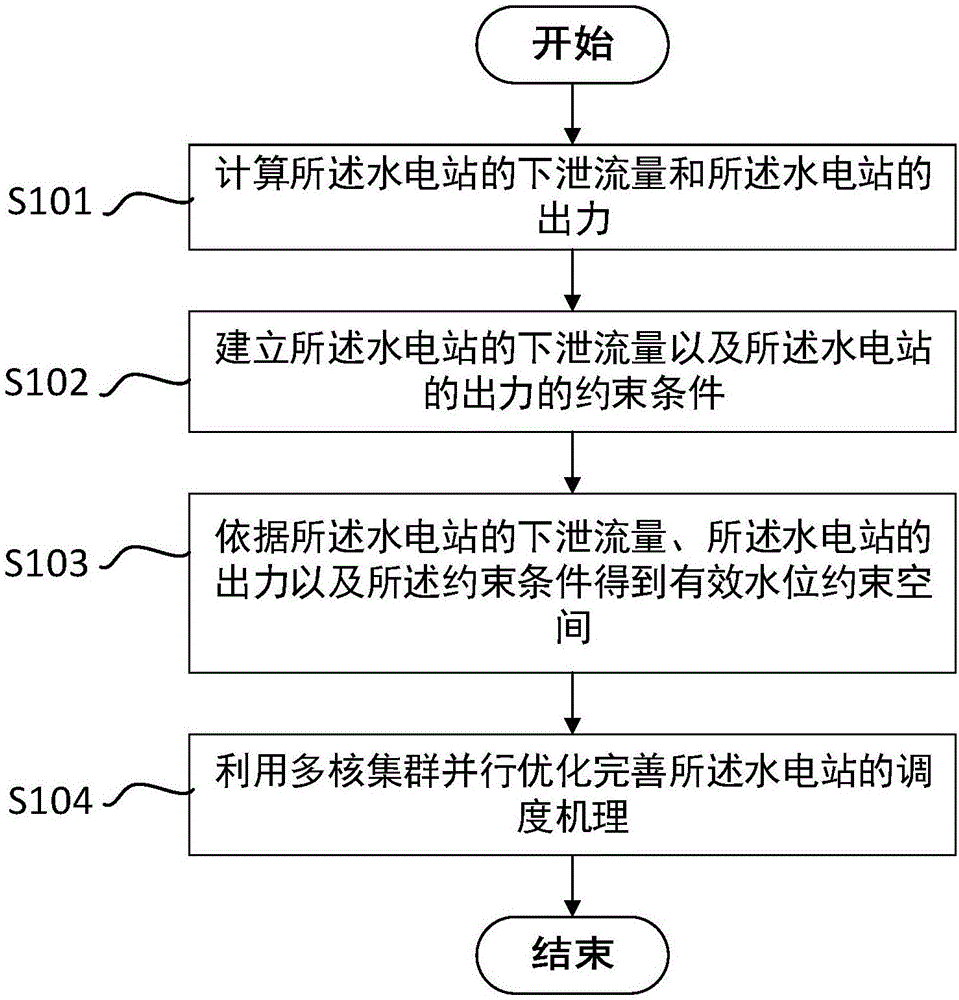

Method and device for realizing optimization scheduling of watershed cascade hydropower station

ActiveCN106373030AImprove search efficiencyImprove practicalityResourcesSystems intergating technologiesContraction methodDecomposition

The embodiment comprises a method and a device for realizing optimization scheduling of a watershed cascade hydropower station and aims to carry out optimization scheduling of a watershed cascade hydropower system. The system comprises at least one hydropower station, the device comprises a computing module, a constraint module, a constraint space generation module and an optimization module. Optimization scheduling model processing is a point of penetration, a water level constraint space contraction method is utilized to contract the water level traversal space, the cascade hydropower system is partitioned on the basis of a large-scale system decomposition coordination idea, coordination optimization is carried out, on the condition that an algorithm optimization mechanism is not changed, an optimization problem is considered, searching optimization efficiency is improved, and relatively good practicality is realized.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

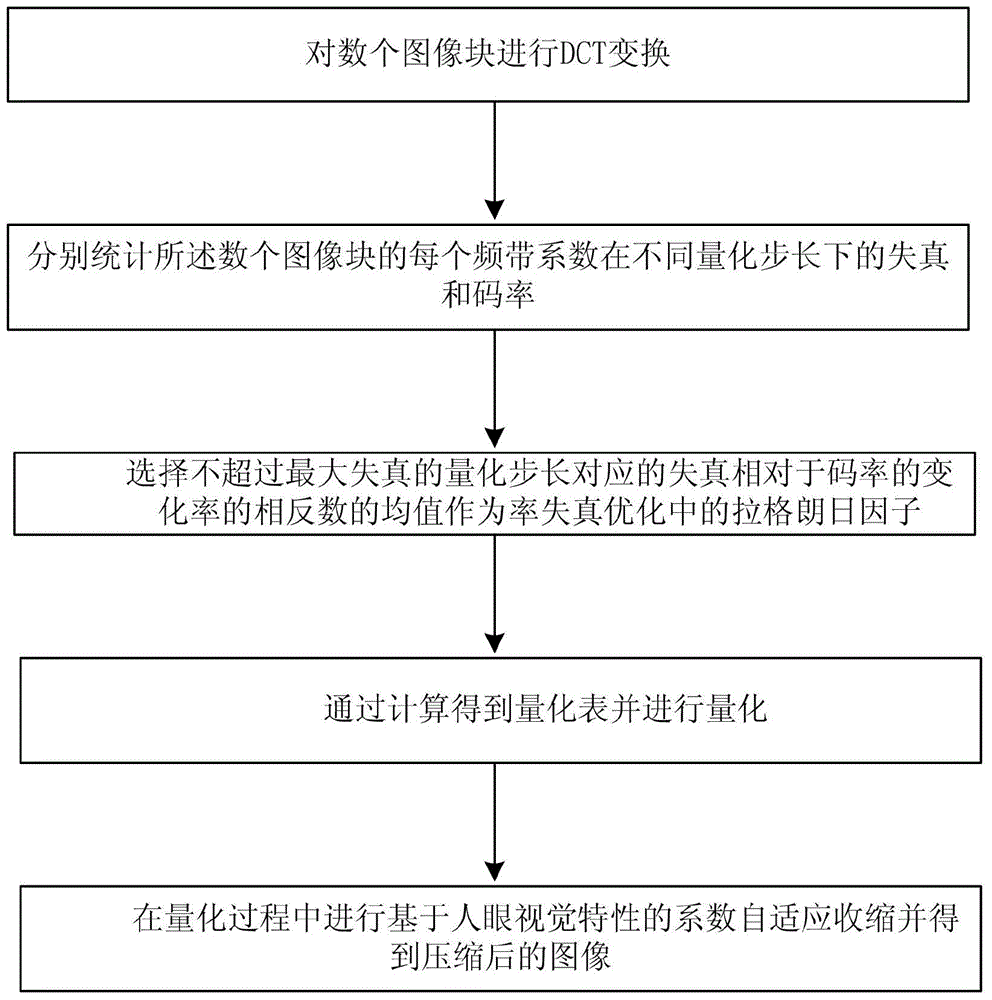

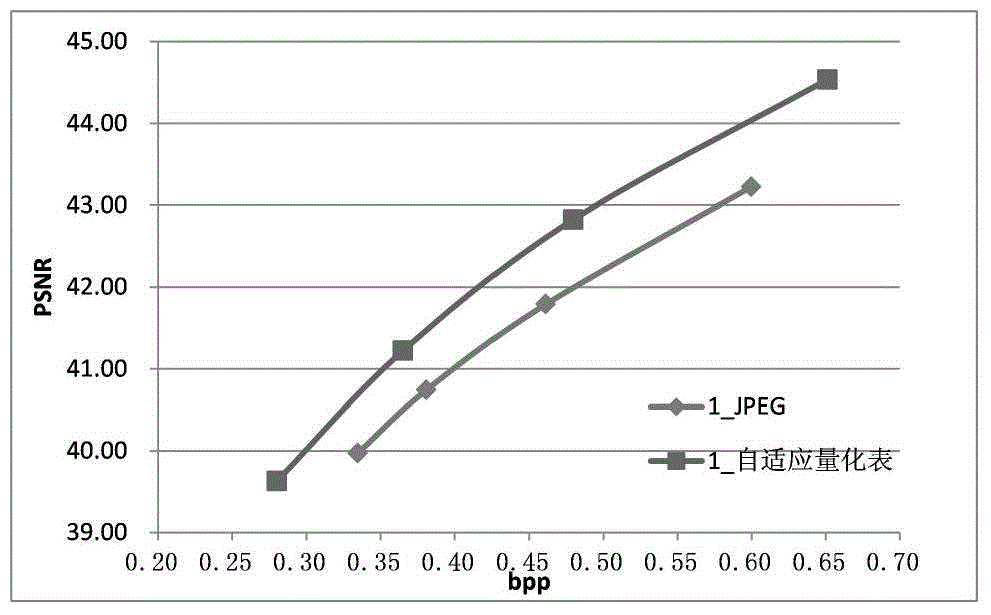

Image coding method

The embodiment of the invention discloses an image coding method, comprising the steps as follows: coding an image via a quantization table computing method optimized by rate-distortion and a region adaptive coefficient contraction method based on a human visual system. The image coding method of the invention could be used for coding the image via the quantization table computing method optimized by rate-distortion and the region adaptive coefficient contraction method based on the human visual system so as to reduce size of an image file under the condition that the subject quality of compression images is the same.

Owner:PEKING UNIV

Seat structure and seat contraction method

ActiveUS20090302652A1Inhibition of relaxationStoolsAdjustable chairsContraction methodBiomedical engineering

When a seat (10) is to be stowed, a seat pad (28) is moved toward a seat (10) reverse side, pad side portions (32) are rotated toward the seat (10) reverse side with respect to a pad center portion (30), and a center portion (12) and side portions (14) of the seat (10) are contracted. Here, interlockingly with contraction of the side portions (14), a skin (42) is bent and folded in at portions covering distal ends of vertical walls (22) of a wall panel (18) and at second fixing portions (42B). Due thereto, slack of the skin (42) at seat (10) lateral direction end surfaces can be taken in.

Owner:TOYOTA JIDOSHA KK +1

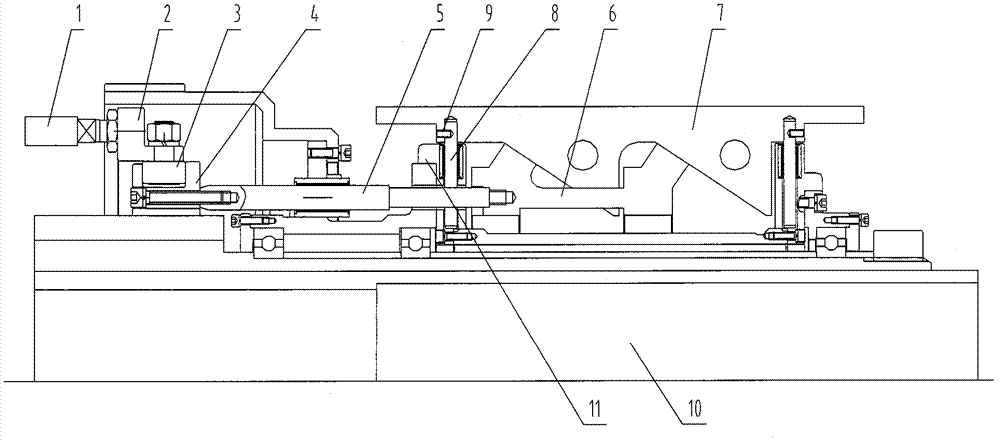

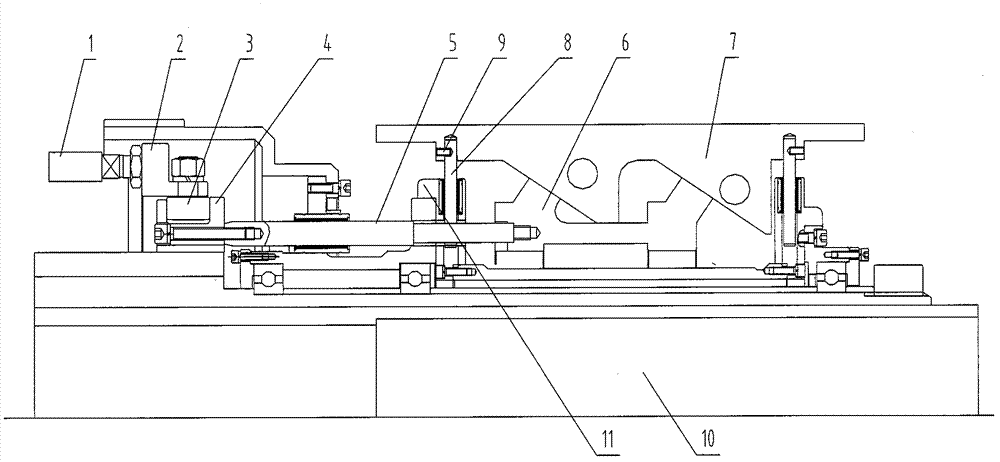

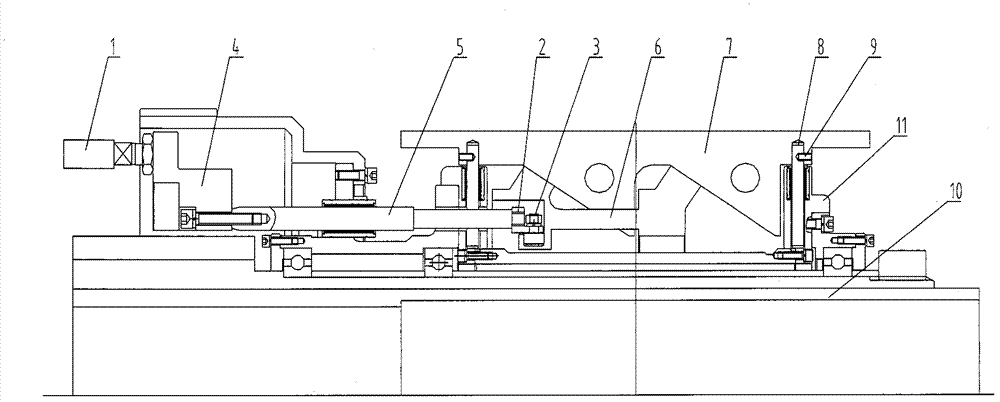

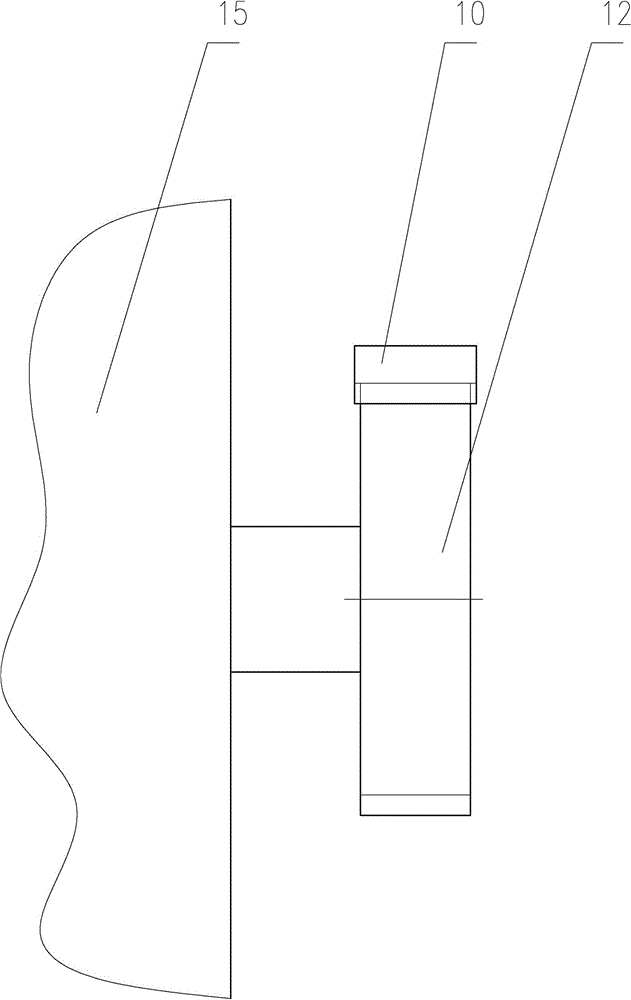

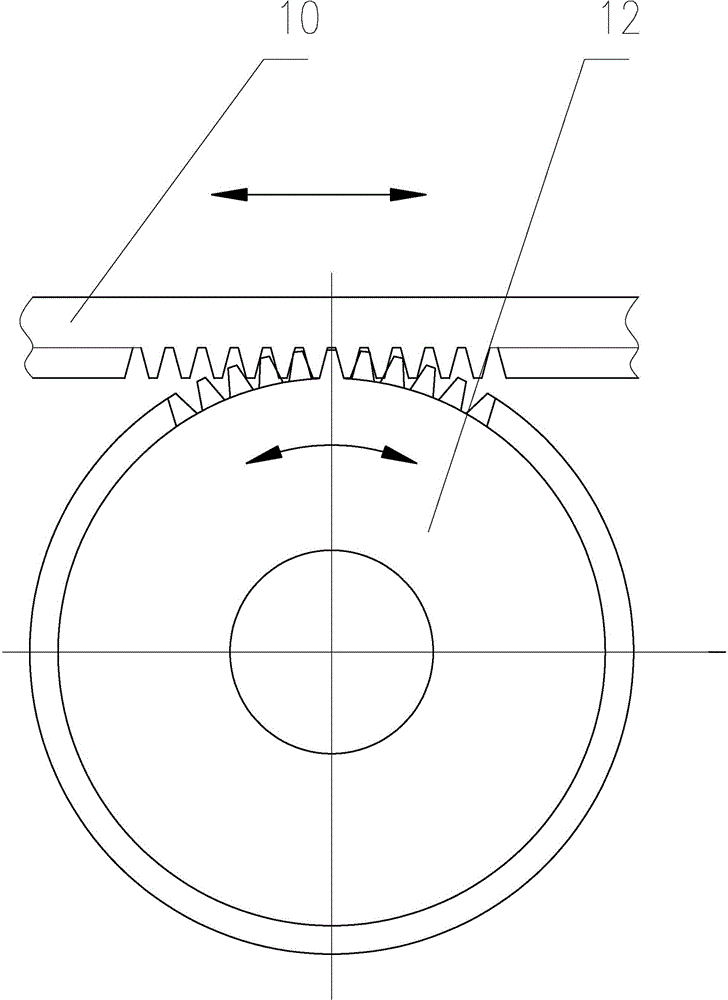

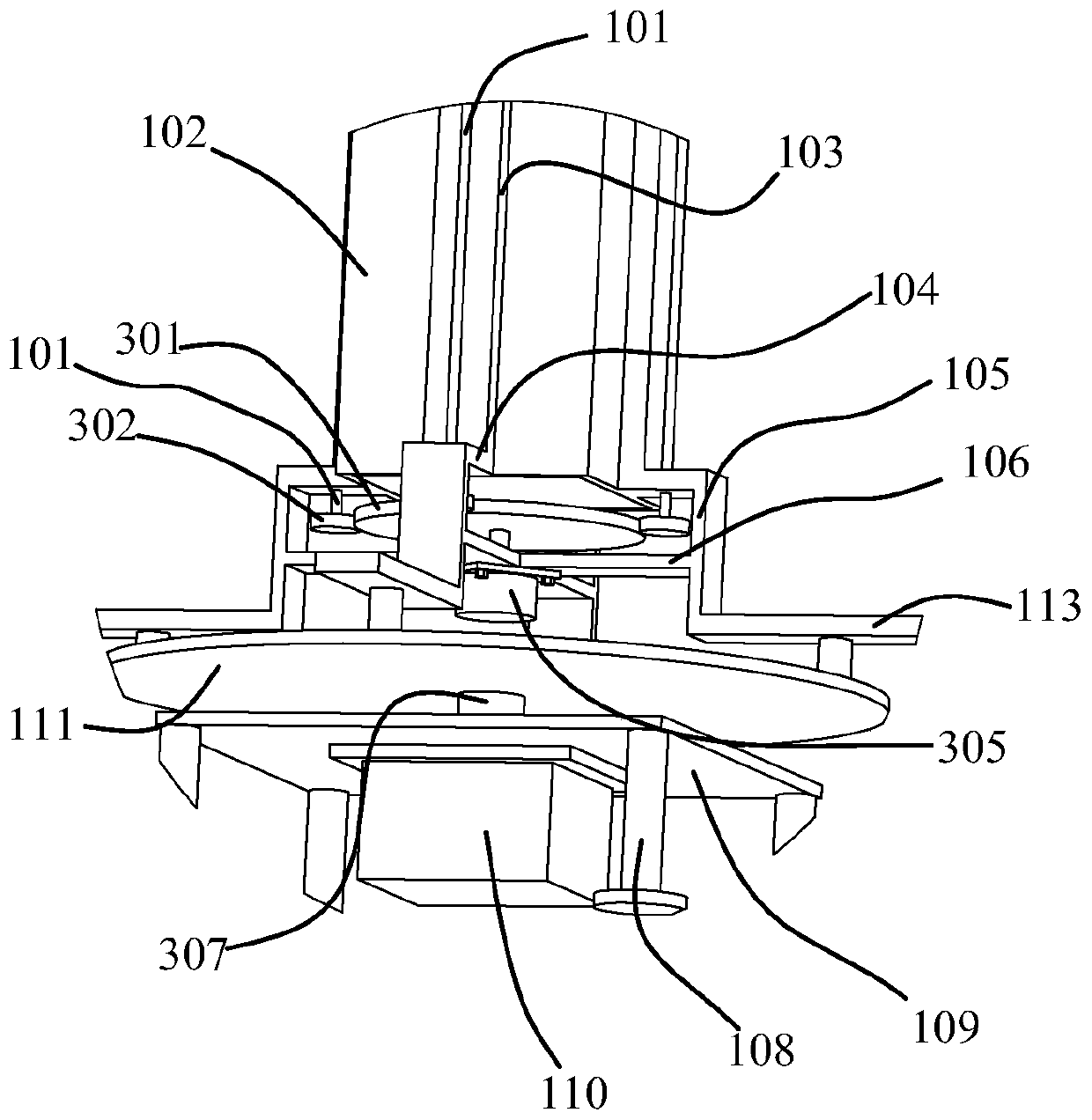

Tire building machine belt layer drum and radial expansion and contraction method thereof

InactiveCN103085301AEasy to controlEasily adjustable diameter rangeTyresPush and pullContraction method

The invention relates to a tire building machine belt layer drum and a radial expansion and contraction method thereof. A servo motor is adopted as an axial driving device; with motion mode conversion, drum tile radial expansion and contraction changes are caused with a mechanical transmission mode, such that the radial expansion and contraction distance of each drum tile can be precisely controlled. Therefore, belt layer drum diameter range adjustment precision can be improved. The belt layer drum radial expansion and contraction method comprises the steps that: at least a set of drum tiles which can be radially expanded and contracted, and a conical sleeve which can be subjected to synchronous axial rotation with the drum tiles are radially sleeved on a main shaft of the belt layer drum. A thrust device driven by the servo motor is axially arranged along the main shaft. The thrust device comprises a first push rod laterally connected with the conical sleeve. The first push rod rotates synchronically under the driving of the conical sleeve, such that the first push rod can push and pull the conical sleeve along an axial direction, and drum tile radial expansion and contraction can be realized.

Owner:MESNAC

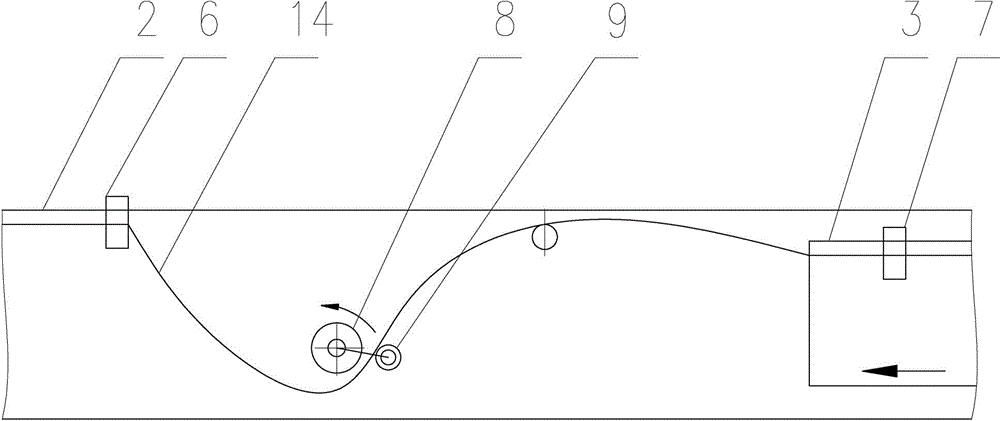

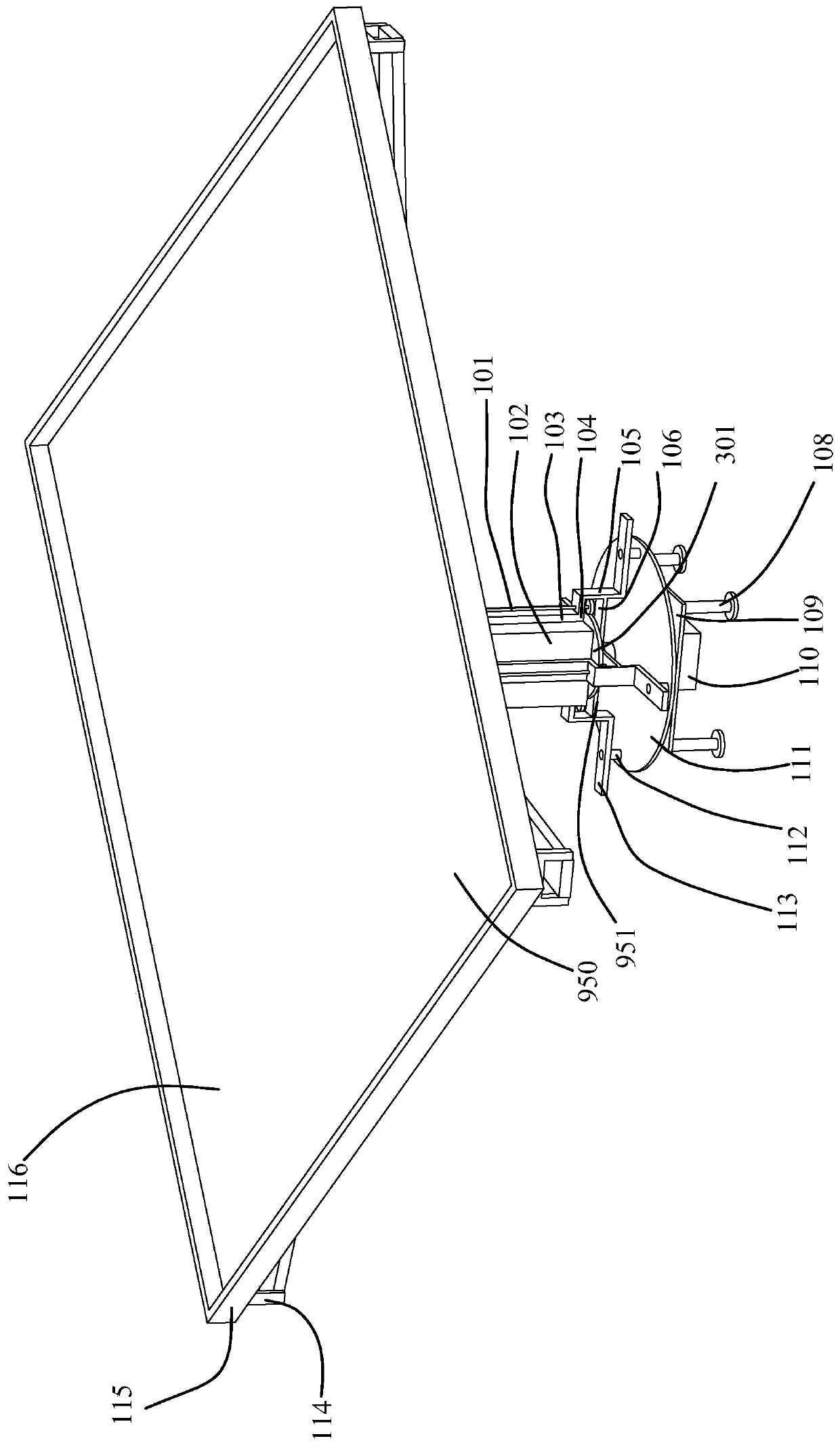

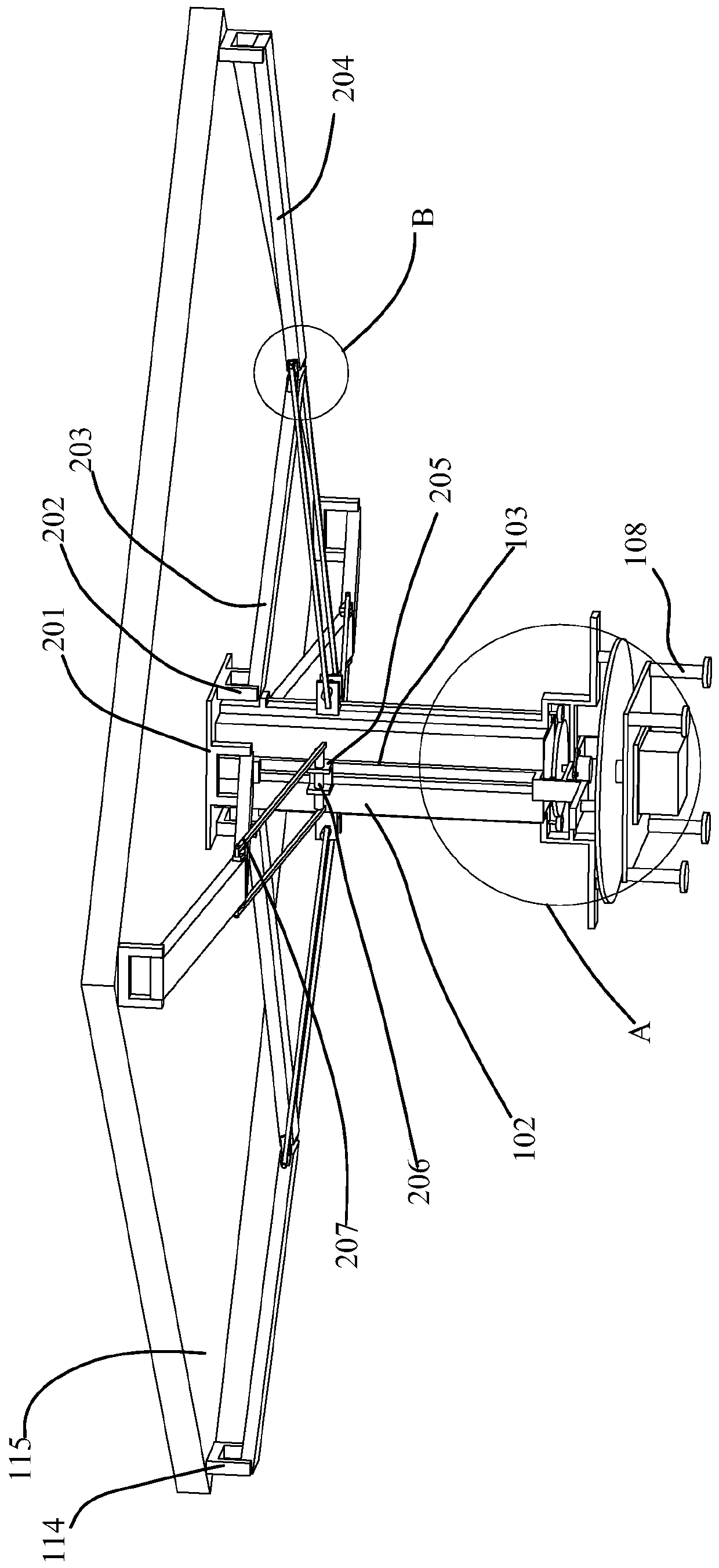

Expansion and contraction method and application of belt support of marine annular belt conveyer, belt contraction and release device and conveyer

The invention discloses an expansion and contraction method and application of a belt support of a marine annular belt conveyer for contracting and releasing a loose belt during expansion and contraction of two adjacent belt supports, a belt contraction and release device and a conveyer. The method relates to the belt, a fixed belt support and a second section belt support which can expand and contract on the fixed belt support, and is characterized in that the belt is contracted by the belt contraction and release device when the second section belt support retracts towards the fixed belt support through an expansion and contraction device; when the second section belt support extends out towards the fixed belt support through the expansion and contraction device, the belt is released by the belt expansion and contraction device. The method is reliable; the device has a simple structure; during expansion and release of the belt support, the belt in the loose state is contracted and released, the completeness of the entire marine annular belt conveyer and the reliability of the working are guaranteed.

Owner:YUANJIANG HENGSHENG MACHINERY MFG

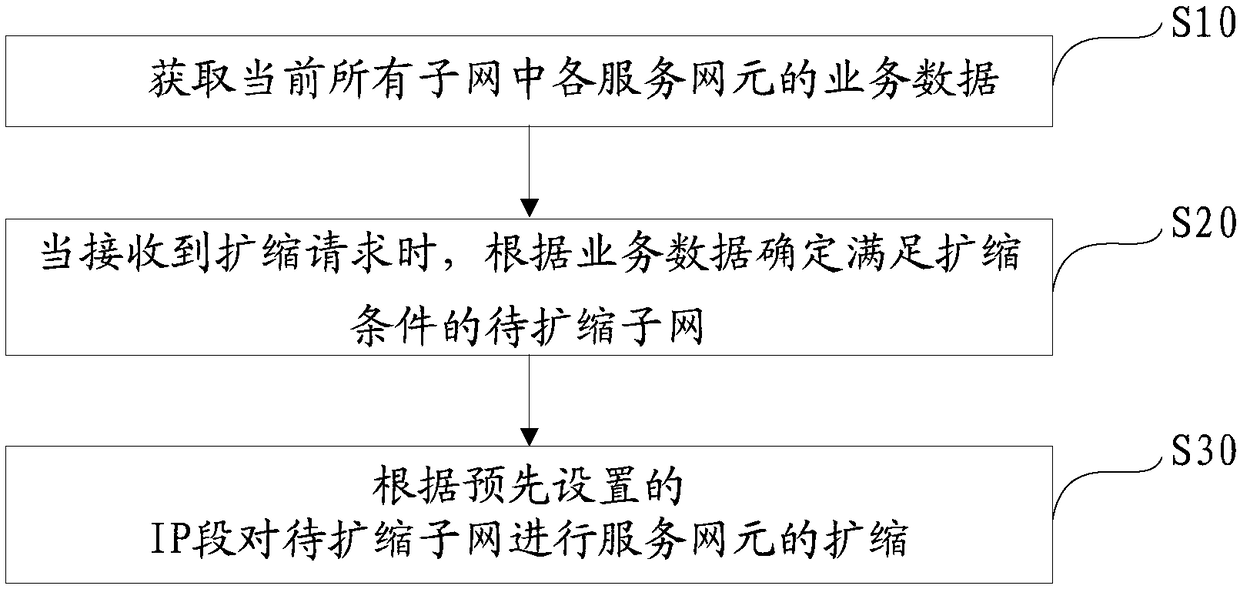

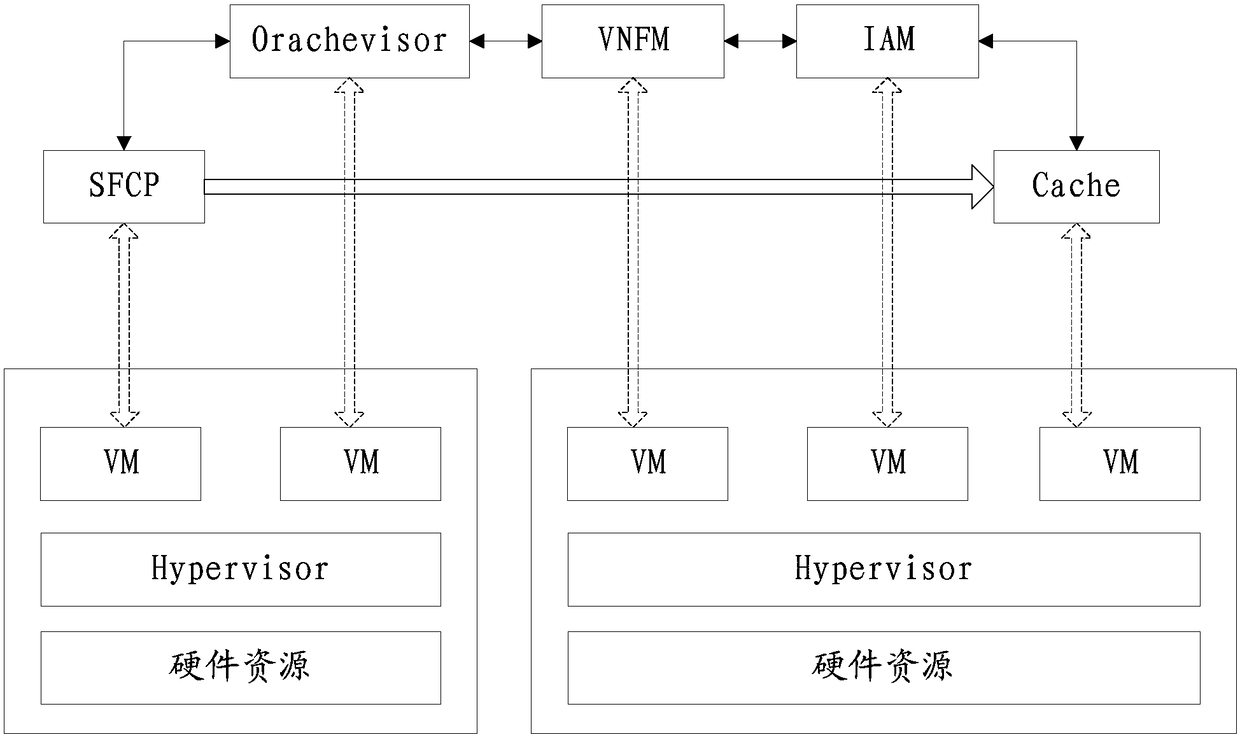

Service network element expansion and contraction method and system as well as computer readable storage medium

The invention discloses a service network element expansion and contraction method and system as well as a computer readable storage medium. The service network element expansion and contraction method comprises the following steps: acquiring service data of each service network element in all the sub networks at present; when an expansion and contraction request is received, determining a to-be-expanded or to-be-contracted sub network meeting expansion and contraction conditions according to the service data; and according to a preset IP section, performing service network element expansion and contraction on the to-be-expanded or to-be-contracted sub network. According to the scheme, the IP section of the sub network is configured in advance, when the expansion and contraction request isreceived, the to-be-expanded or to-be-contracted sub network meeting the expansion and contraction conditions is determined according to the service data of each service network element in all the sub networks at present, and the service network element expansion and contraction are performed on the to-be-expanded or to-be-contracted sub network according to the preset IP section, so that DHCP isavoided from being used for performing IP random distribution capacity expansion or random capacity contraction, and expansion and contraction better meet service requirements of the sub network.

Owner:ZTE CORP

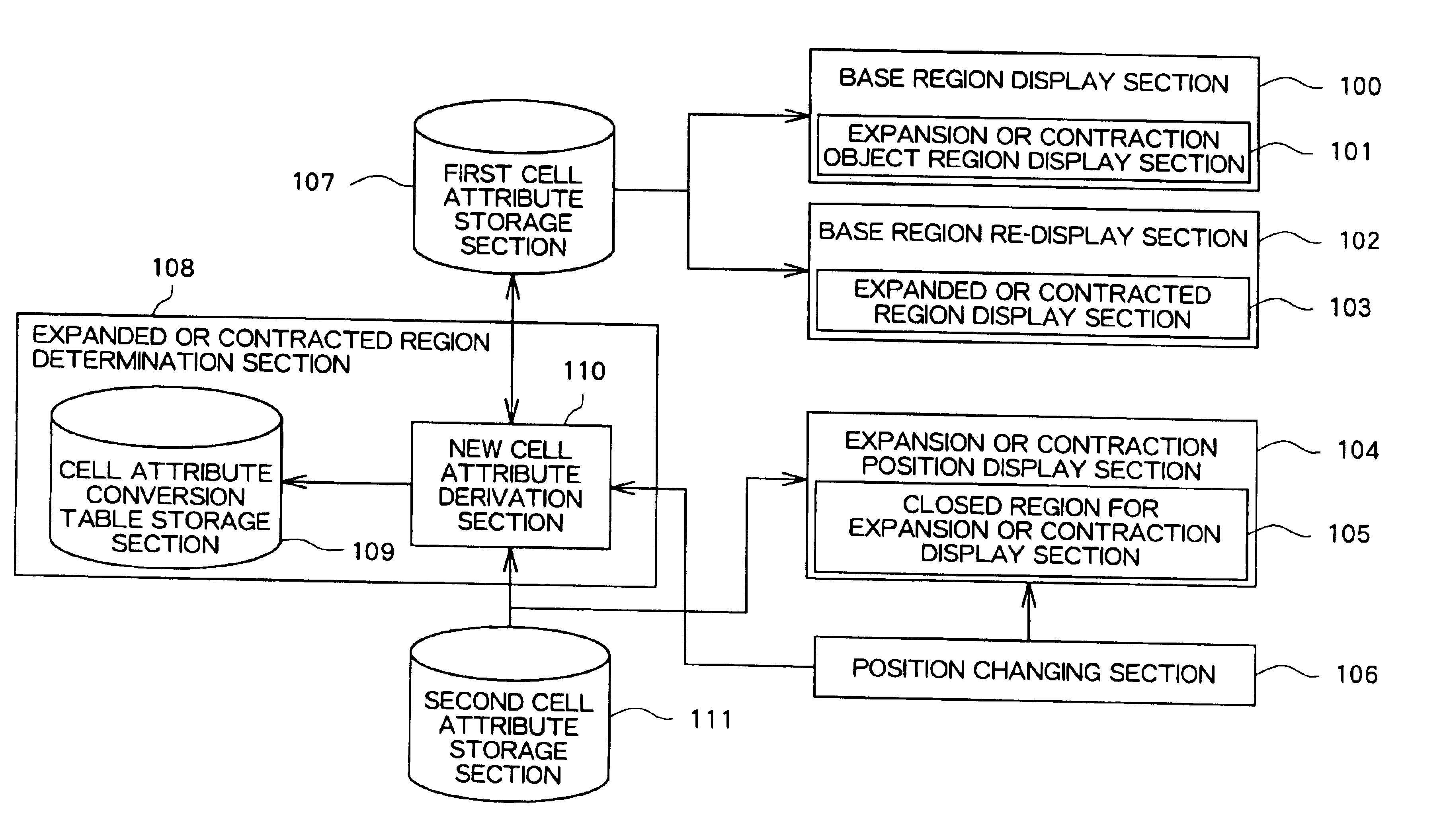

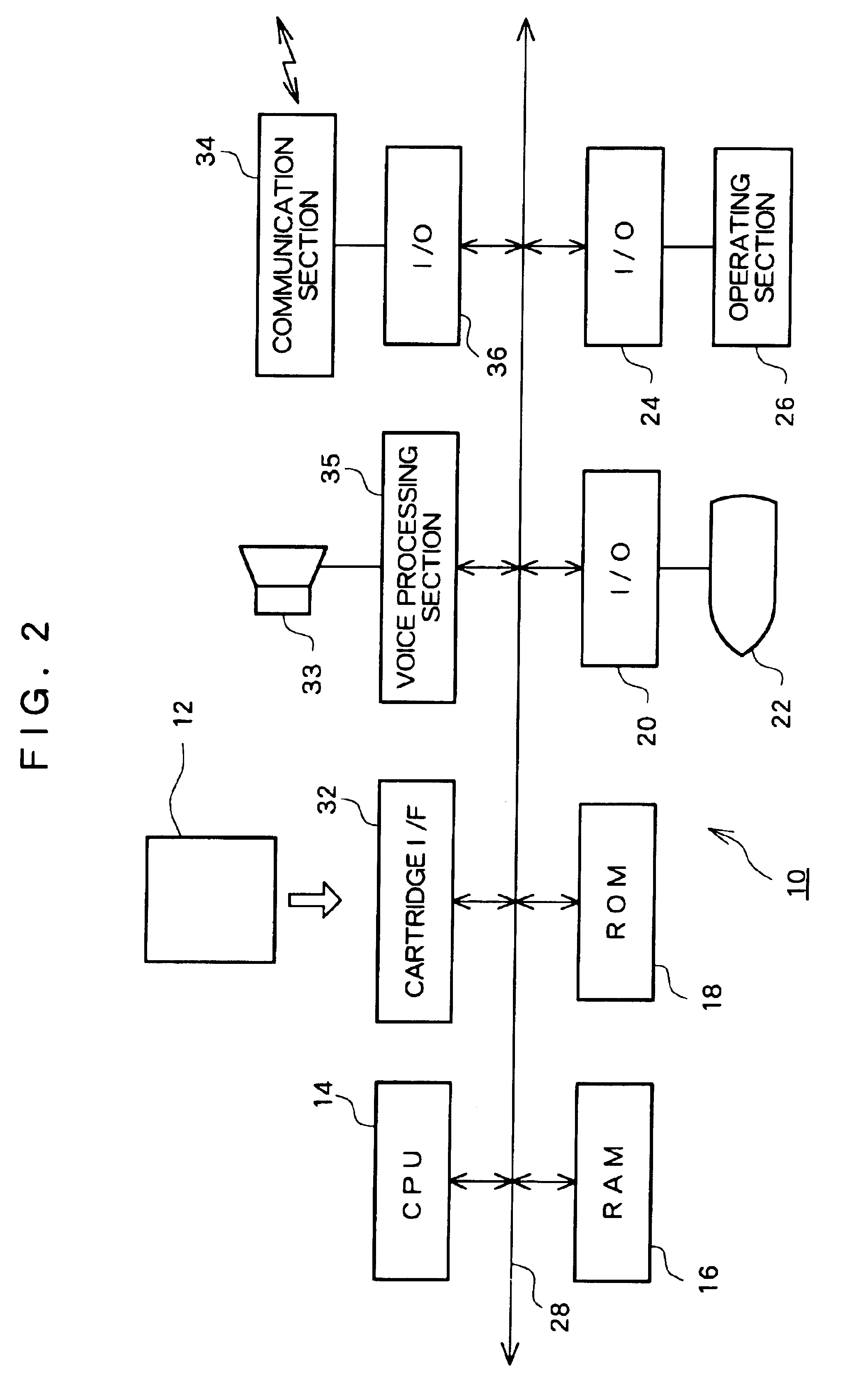

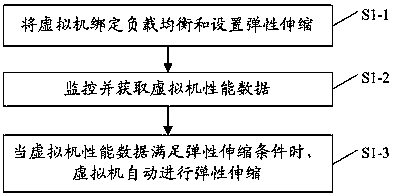

Game device, game region expansion and contraction method, game program and information storage medium

InactiveUS6932699B2Easy to operateGeometric image transformationAnimationContraction methodComputer graphics (images)

Owner:KONAMI DIGITAL ENTERTAINMENT CO LTD

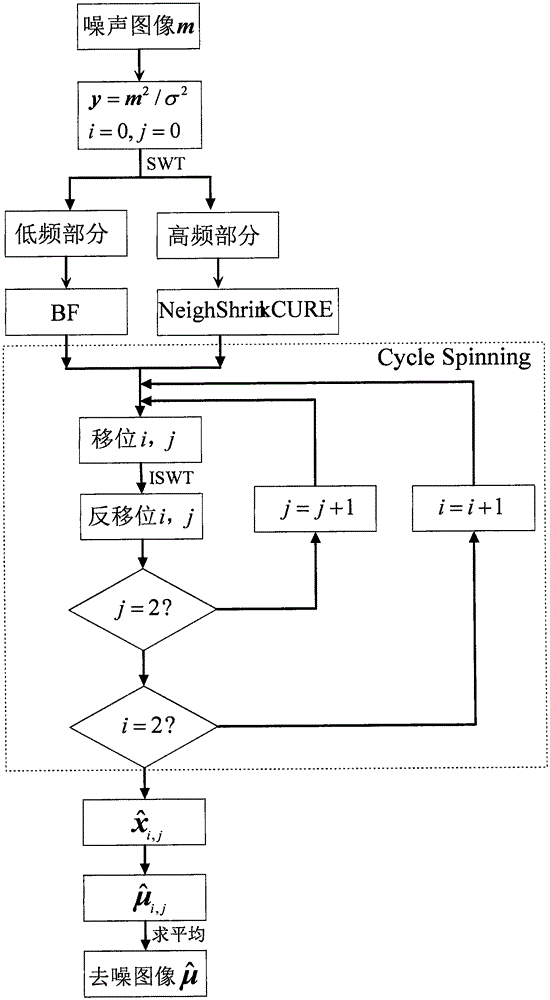

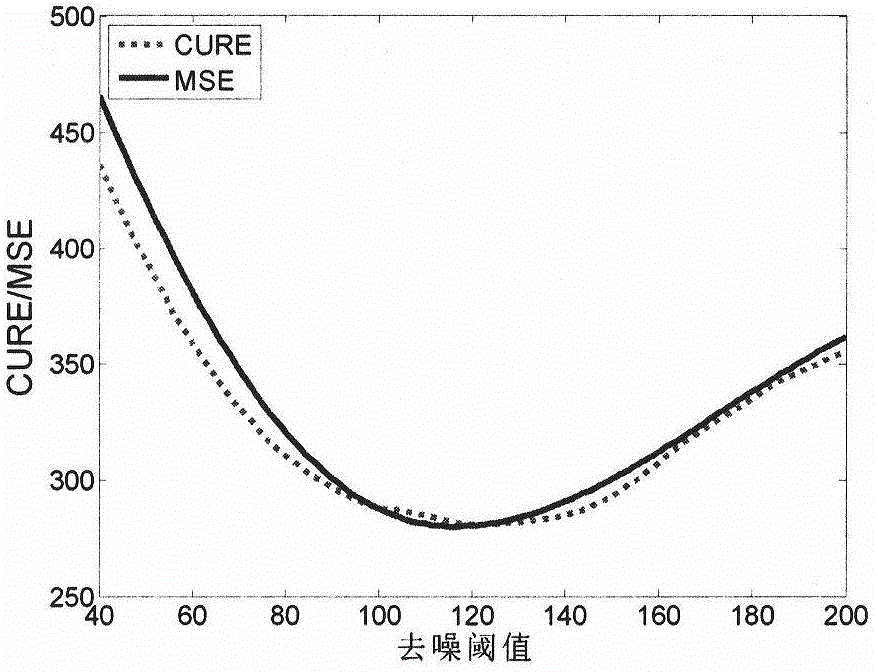

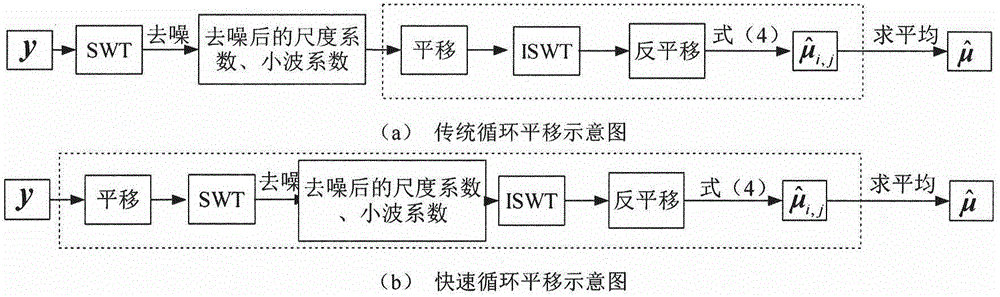

Neighborhood contraction MRI de-noising method based on Chi-square unbiased risk estimation

ActiveCN106469438AImprove denoising effectPseudo-Gibbs phenomenon suppressionImage enhancementImage analysisContraction methodHaar wavelet

The invention discloses a neighborhood contraction MRI de-noising method based on Chi-square unbiased risk estimation. The method comprises steps of: after estimating the noise standard deviation, squaring a noise image and then dividing the obtained value with the square of the noise standard variation so as to satisfy the property of the noncentral Chi-square distribution; then, carrying out stable Haar wavelet transform which has not been normalized so as to obtain high-frequency coefficient and low-frequency coefficient; deblurring the low-frequency coefficient by use of a bilateral filter; carrying out cyclic shift on the denoised wavelet coefficient on the high-efficient coefficient by use of the neighborhood contraction method based on the Chi-square unbiased risk estimation; and finally, averaging multiple shifted denoising images so as to obtain the denoised image.

Owner:ZHEJIANG NORMAL UNIVERSITY

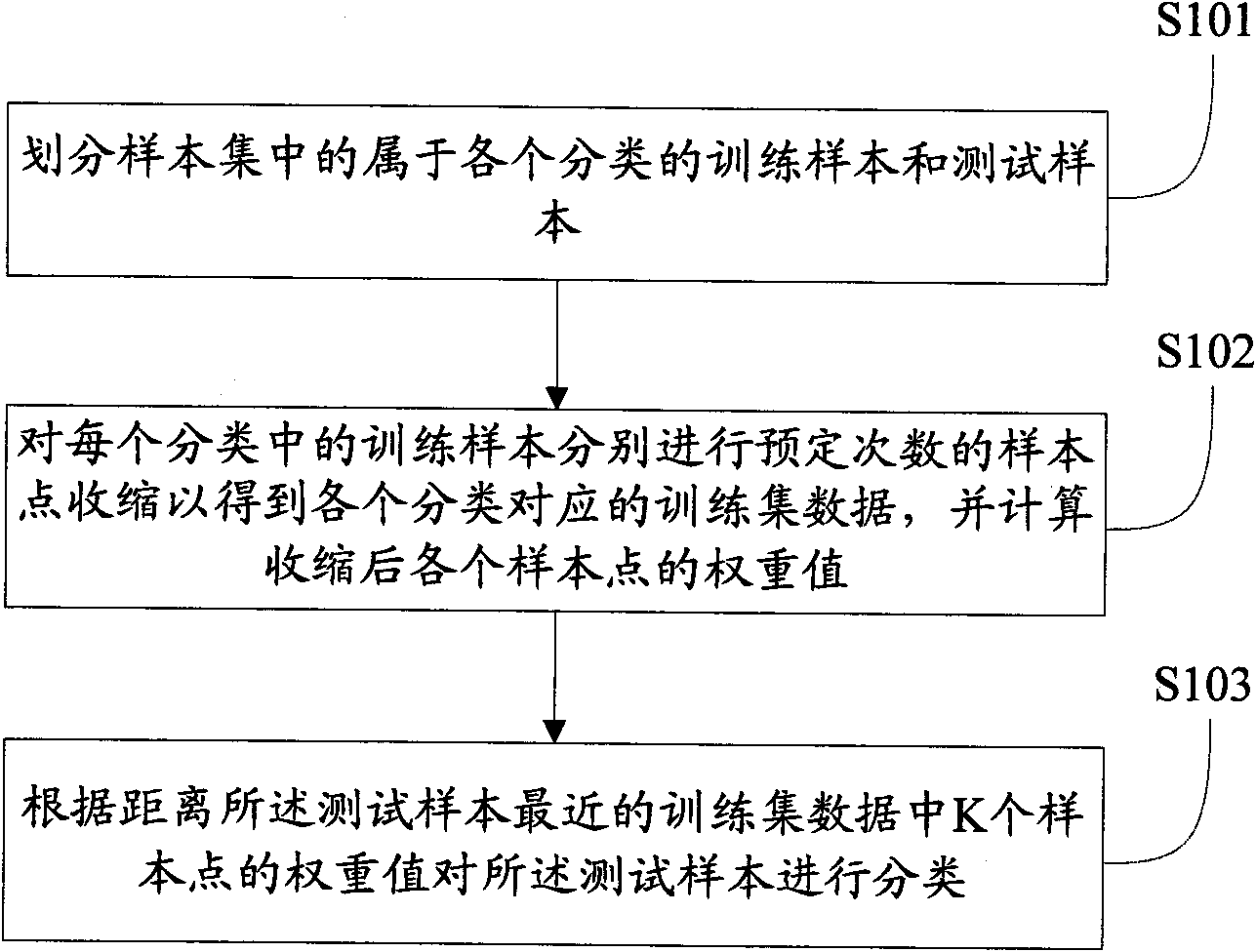

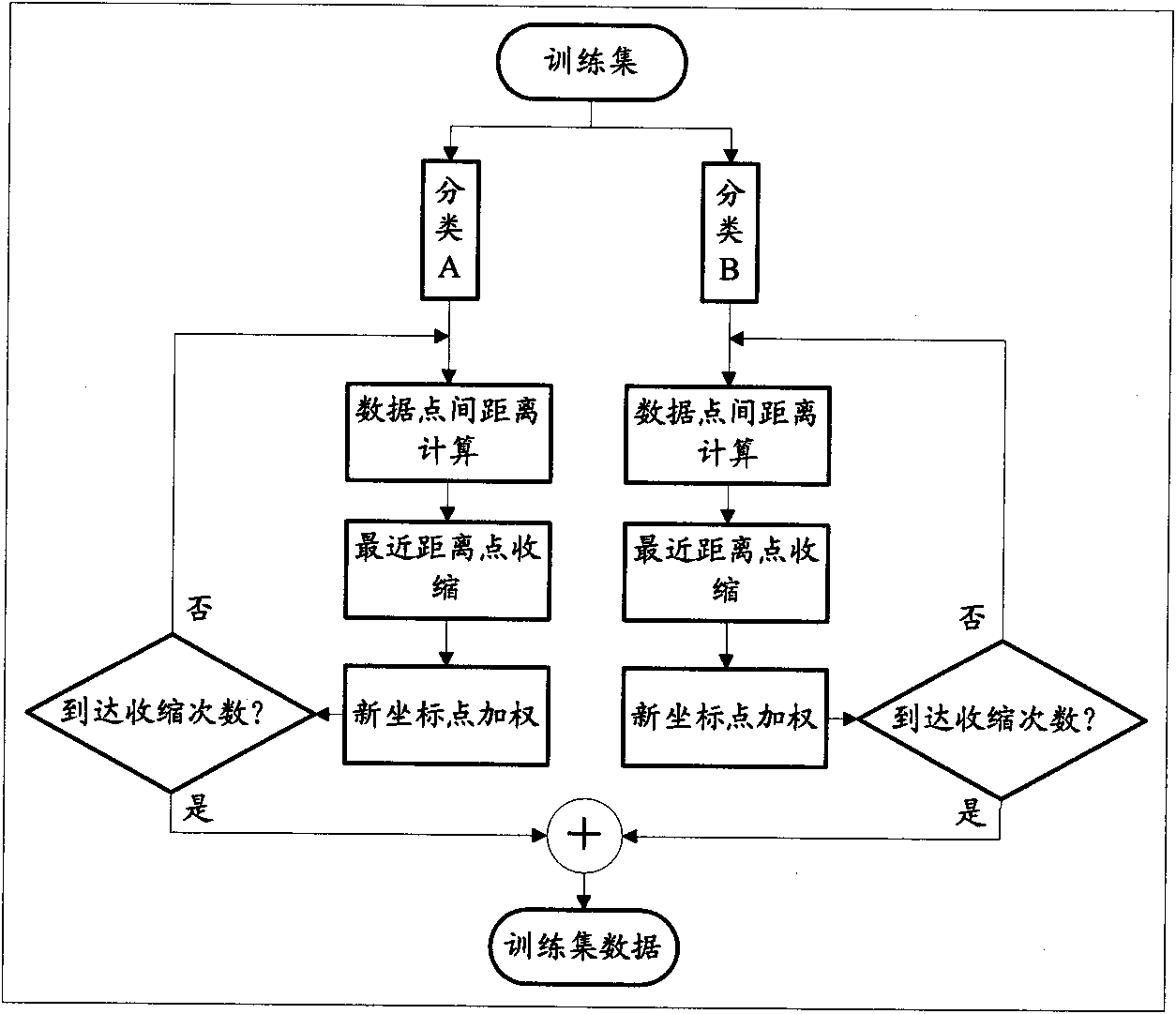

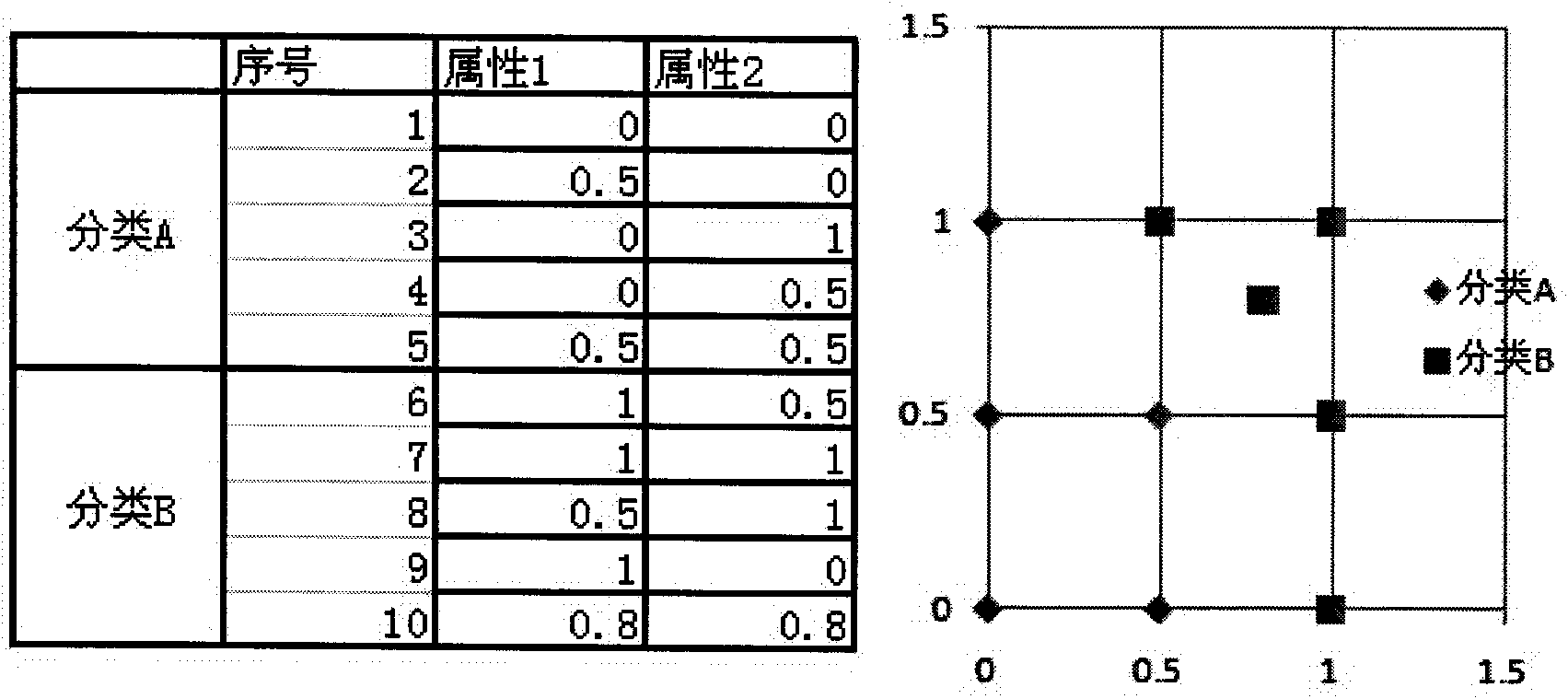

Weighting contraction method based on K near neighbor method

InactiveCN101866426AFast operationReduce operational complexityCharacter and pattern recognitionContraction methodTest sample

The invention relates to a weighting contraction method based on a K near neighbor method, which comprises the following steps that: samples are divided to intensively belong to training samples and test samples in each classification; the sample point contraction for preset times is respectively carried out on the training samples in each classification for obtaining the training set data corresponding to each classification, and the weight of each sample point after the contraction is calculated; and the test samples are classified according to the weights of K sample points in the training set data with the nearest distance away from the test samples. The invention can ensure the accuracy of the classification at the same time of considering the computer calculation speed improvement and calculation complexity reduction.

Owner:TSINGHUA UNIV

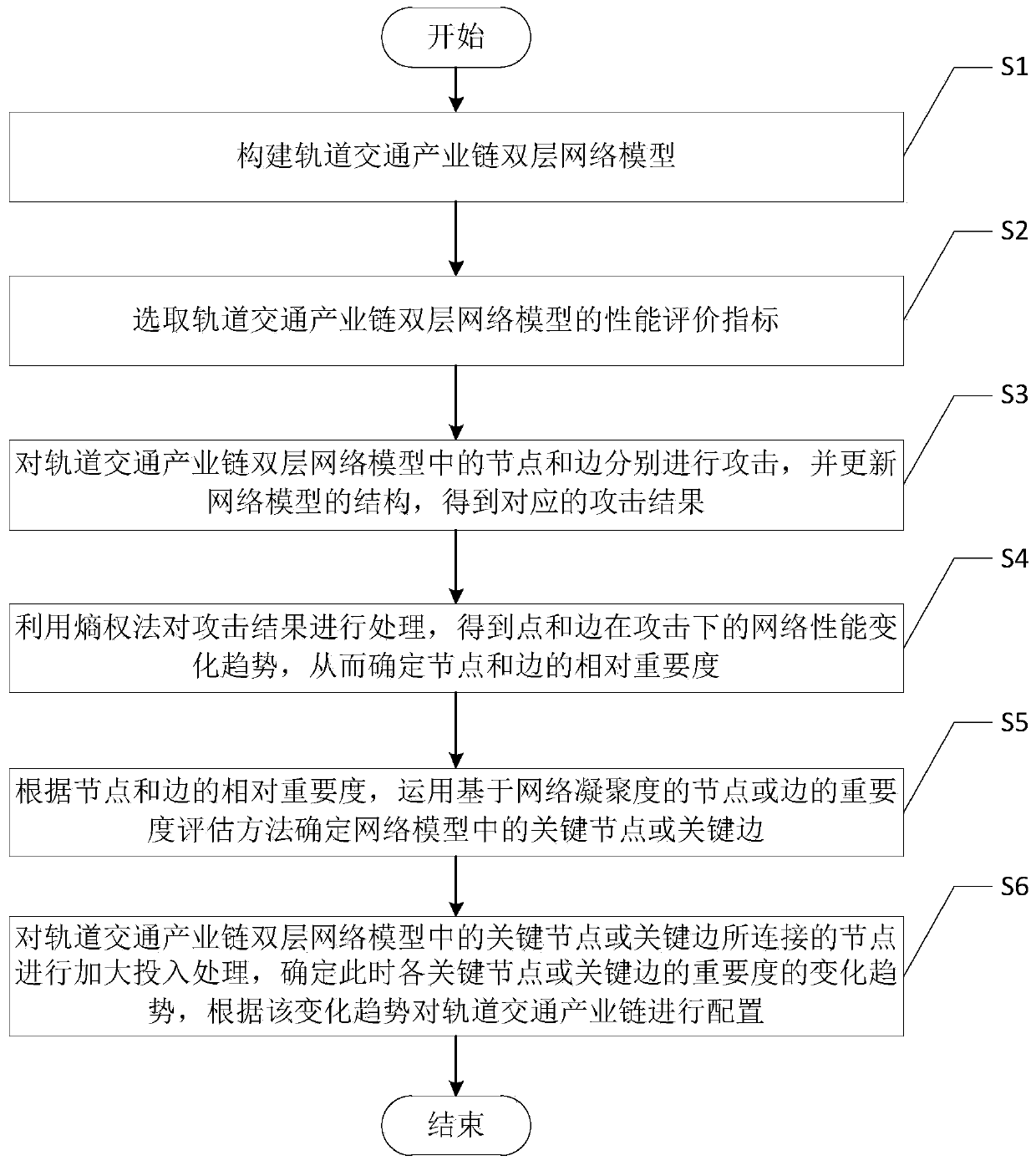

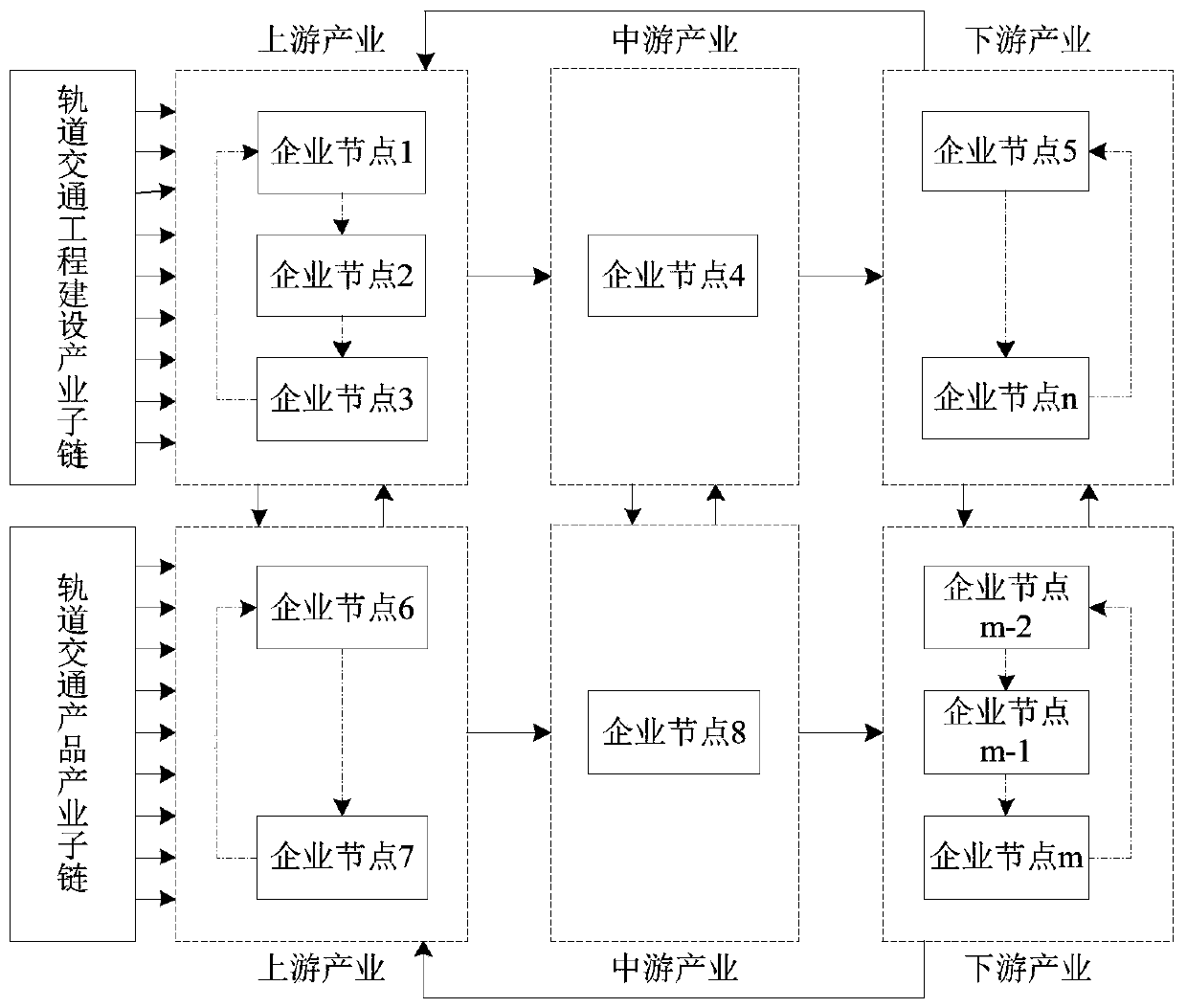

Rail transit industrial chain configuration method based on multilayer complex network

ActiveCN110046838AAccurately analyze network performanceAccurately reflect the real situationResourcesContraction methodEntropy weight method

The invention discloses a rail transit industrial chain configuration method based on a multilayer complex network. The method is based on a multilayer complex network theory. The method comprises: using a SpaceL method to establish a dependency type multilayer complex network topological structure of a rail transit industrial chain with weight, applying the modes of deliberate attack and random attack; respectively attacking nodes and edges in the network; corresponding evaluation indexes are selected; determining the weight of each index by using an entropy weight method; analyzing the change trend and related characteristic performance of the network performance under opposite edge and point attacks; analyzing and determining the relative importance of the nodes and the edges in the rail transit network, finally, using a node contraction method with weights for obtaining key nodes of the nodes, analyzing the change trend of the important nodes in the network under the continuous increase input condition, and therefore corresponding decision support is provided for reasonable configuration of the rail transit industry chain.

Owner:SOUTHWEST JIAOTONG UNIV

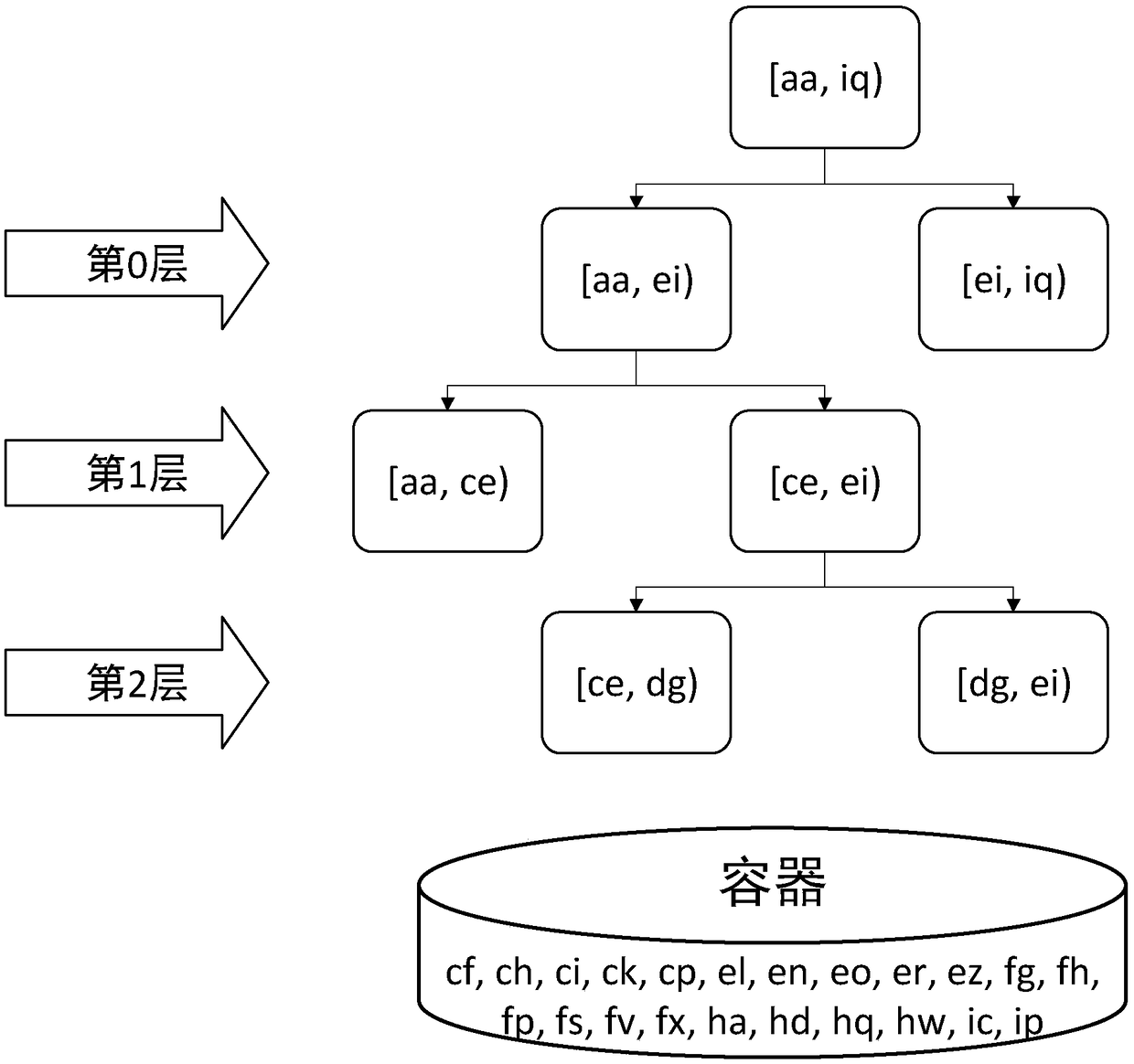

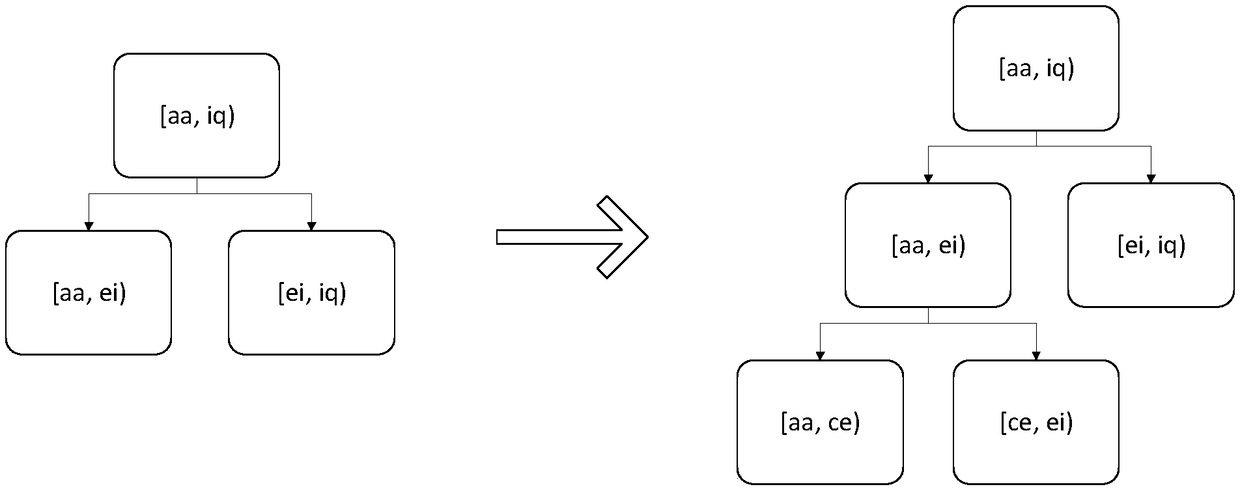

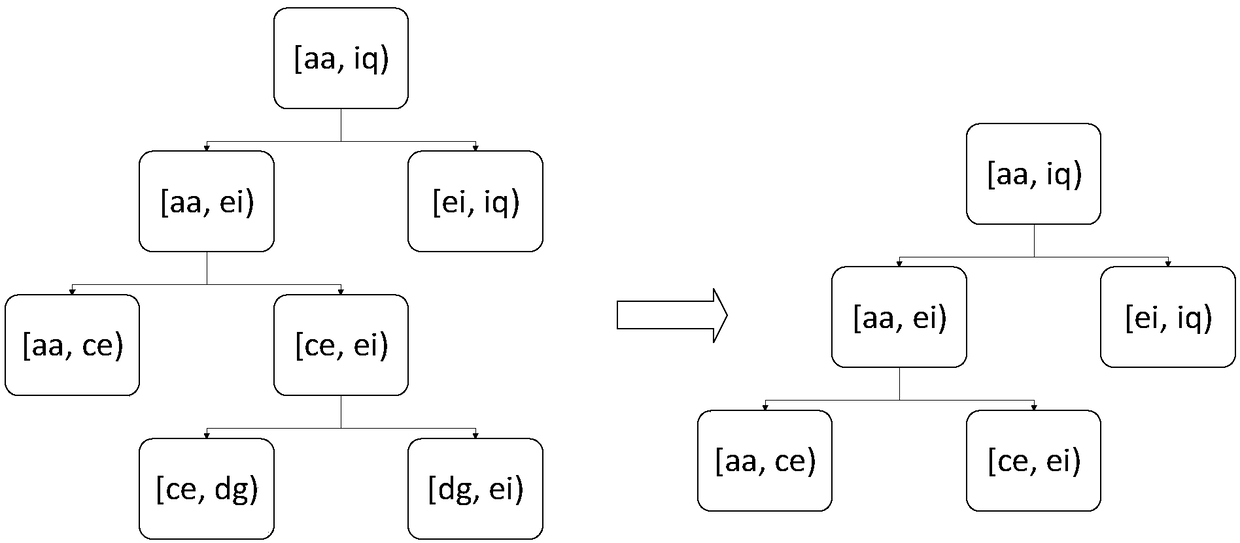

Range query filtering method for key value pair storage and key value pair storage system

ActiveCN108717448AReduce overheadMeeting Space Efficiency TargetsSpecial data processing applicationsContraction methodWorkload

The invention discloses a range query filtering method for key value pair storage and a key value pair storage system. According to the range query filtering method for key value pair storage, a growth and contraction method is used for index of key value pairs contained in each container in the key value pair storage system; and a range filter is generated according to a given space budget so asto filter the range query. The system workload is learned in the query process, and the range filter is adjusted. The false positive rate of the range filter can be effectively reduced through such dynamic adjustment; the filtering effect is improved; invalid disk IO of the key value pair storage system is greatly reduced; and the reading performance of the whole system is improved.

Owner:NANJING UNIV +2

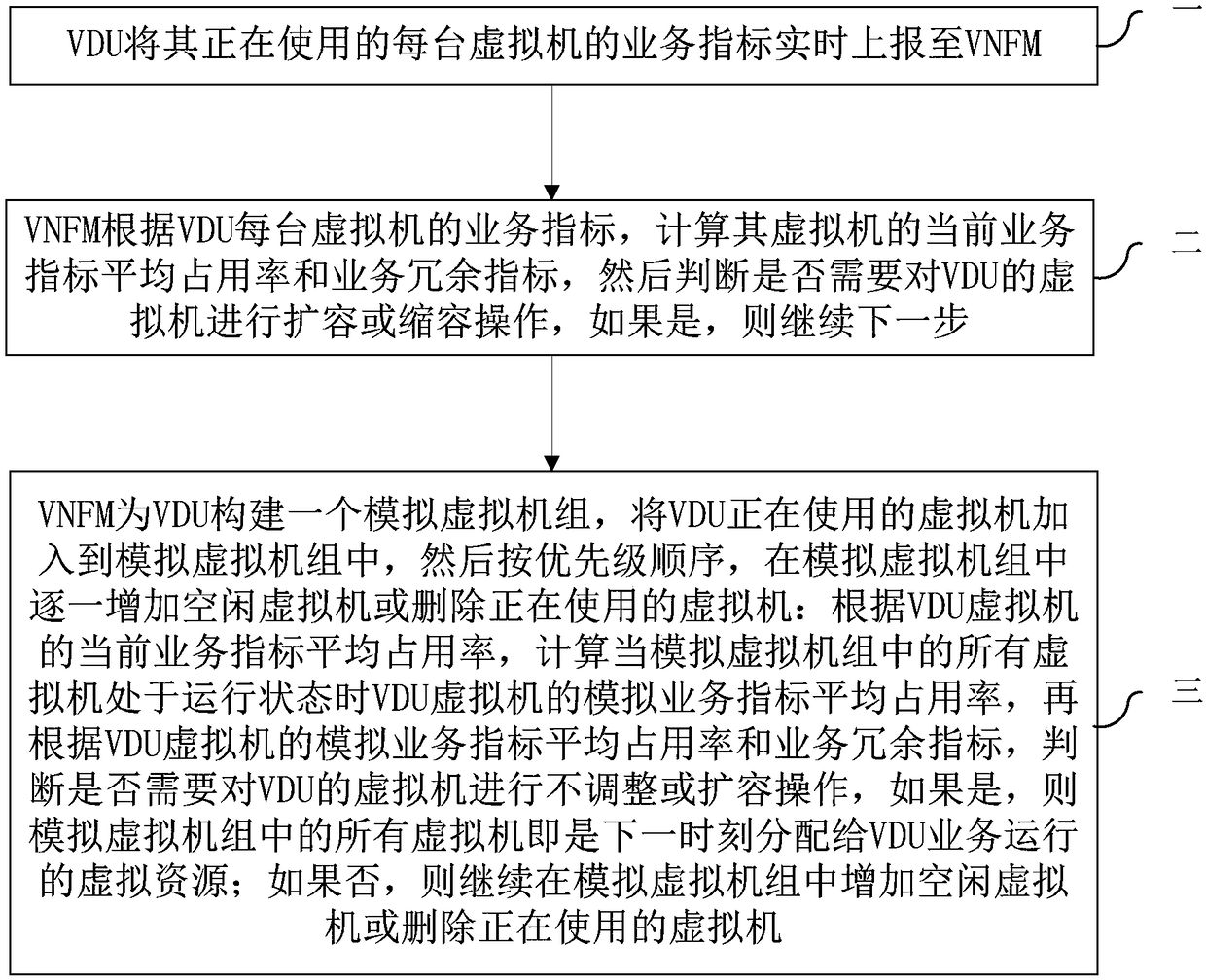

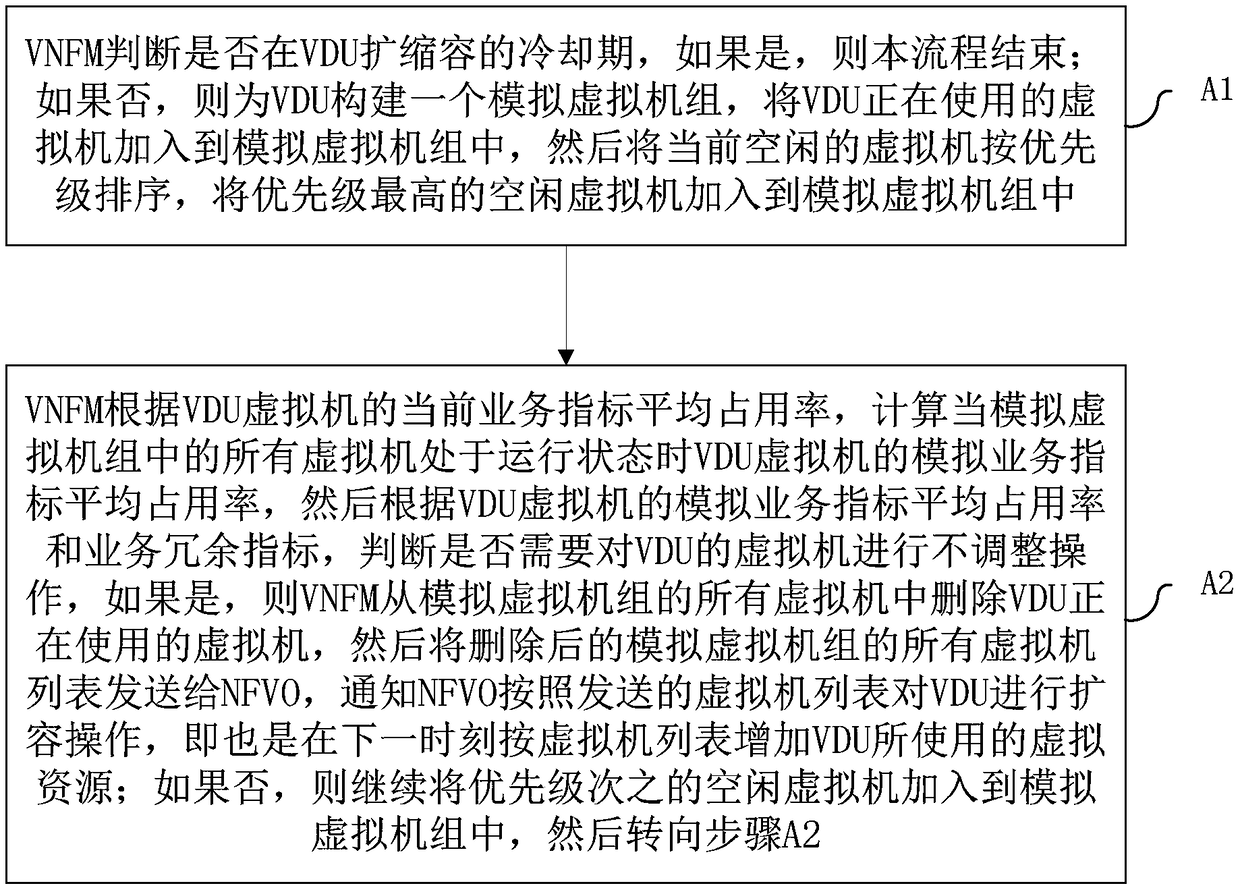

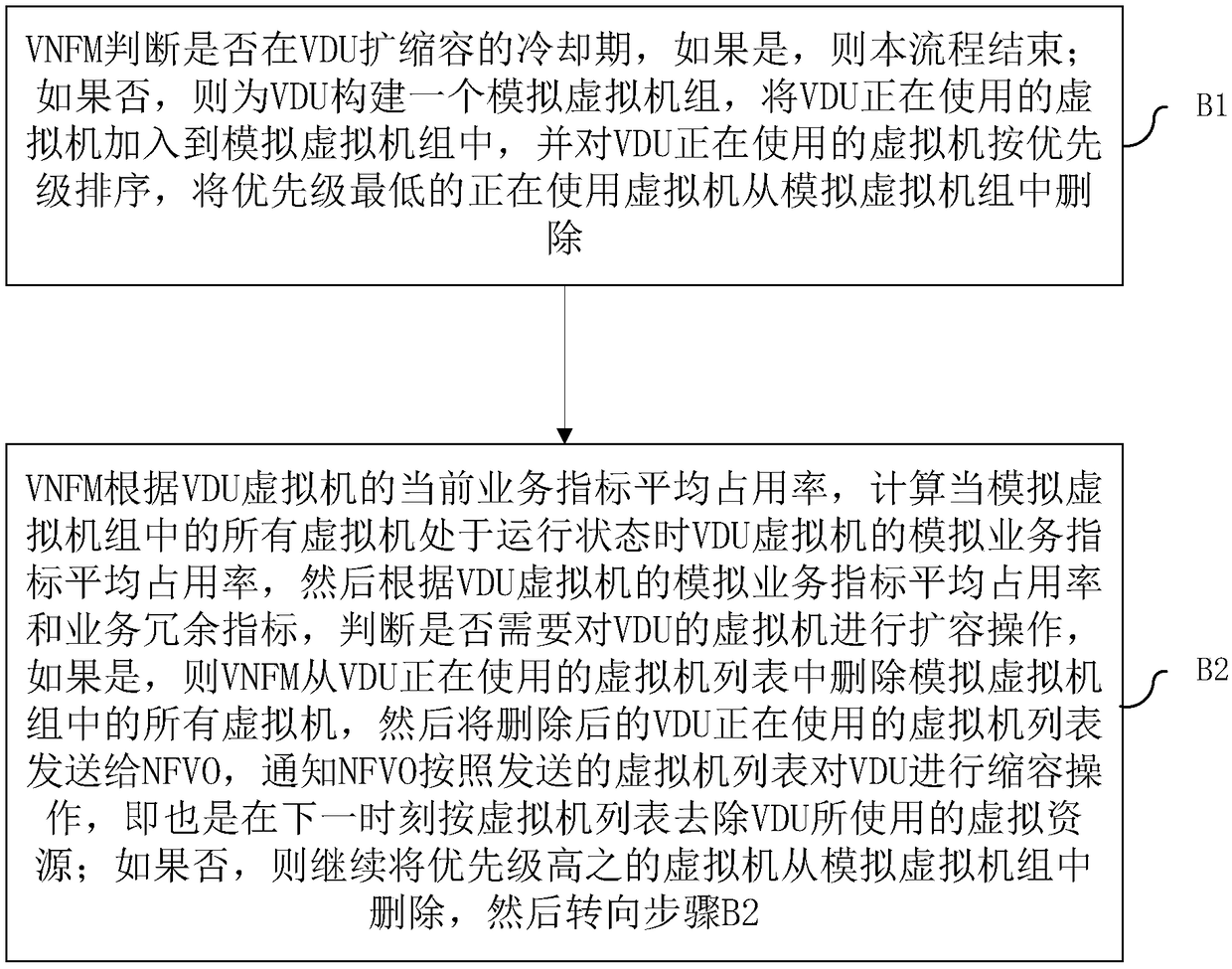

Multidimensional intelligent capacity expansion and contraction method and system of telecommunication network security service VNF

ActiveCN108847956AAvoid scaling up and downResource allocationData switching networksOccupancy rateTelecommunications network

The invention provides a multidimensional intelligent capacity expansion and contraction method and system of a telecommunication network security service VNF. The method comprises the following steps: a VDU reports a virtual machine service indicator that is being used to a VNFM; the VNFM calculates an average occupancy rate of a current service indicator and a service redundancy indicator of a VDU virtual machine, and judges whether a capacity expansion or a capacity contraction operation needs to be performed on the VDU virtual machine, and if yes, the next step is continued; and the VNFM builds an analog virtual machine group, joins the virtual machine that is being used by the VDU to the analog virtual machine group, and then increases idle virtual machines one by one or deletes the virtual machine that is being used in the analog virtual machine group: calculating the average occupancy rate of an analog service indicator of the VDU virtual machine, judging whether the non-adjustment or capacity expansion operation needs to be performed on the VDU virtual machine, if yes, the simulating the virtual machines in the virtual machine group, that is, virtual resources allocated tothe UDV at the next moment. The invention belongs to the field of communication, and the virtual resources meeting the operation demands can be accurately provided for all kinds of telecommunication network security services.

Owner:NAT COMP NETWORK & INFORMATION SECURITY MANAGEMENT CENT +2

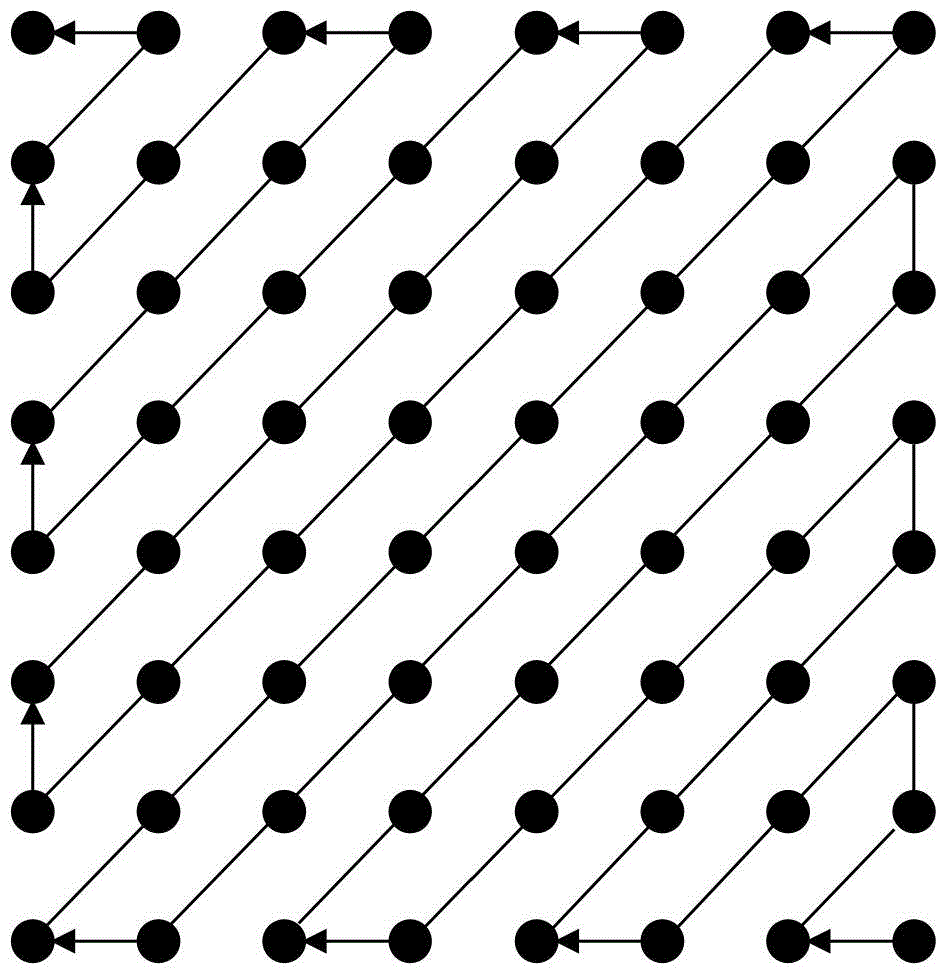

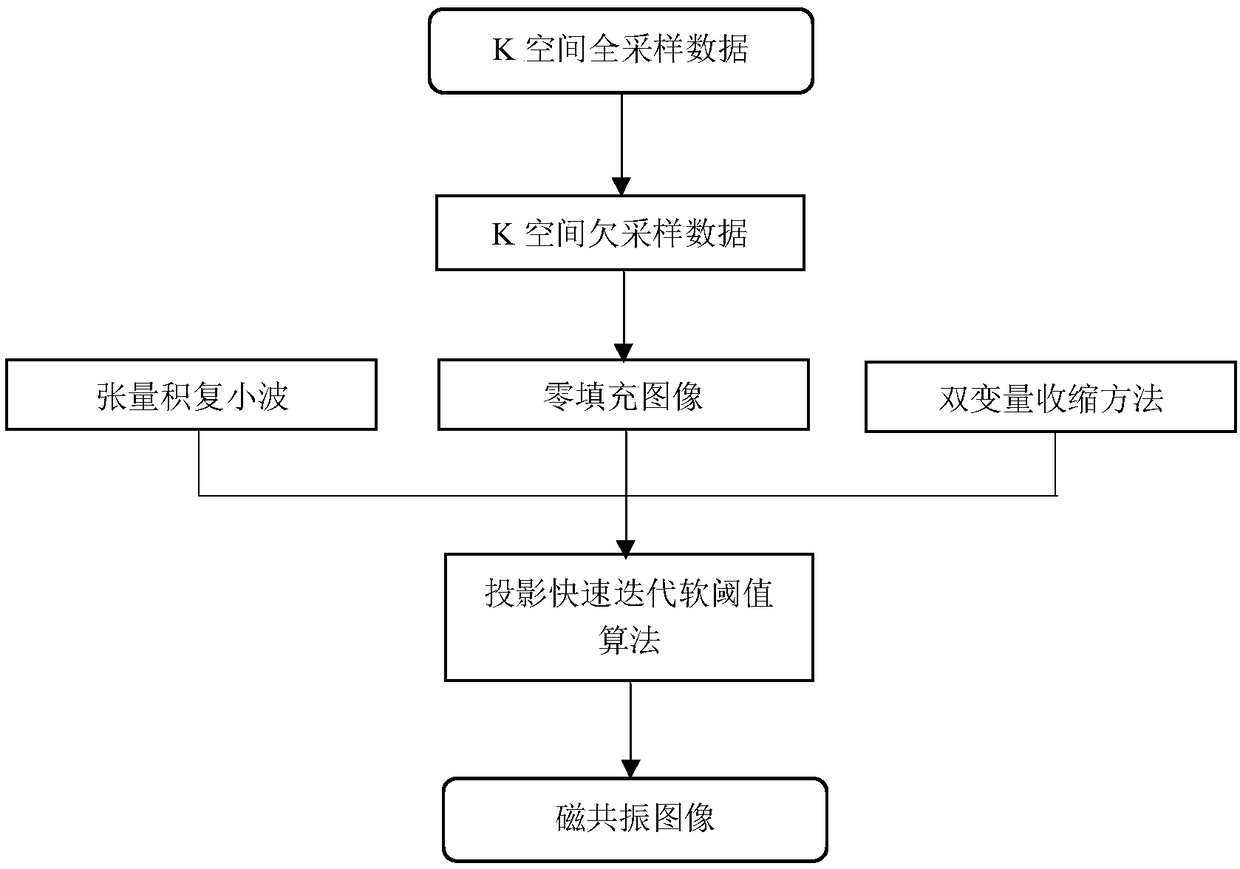

Method for rapidly reconstructing magnetic resonance imaging based on tensor product complex wavelet tight frame

ActiveCN109188327AHigh precisionImprove refactoring qualityMagnetic measurementsDiagnostic recording/measuringContraction methodTight frame

The invention discloses a method for rapidly reconstructing a magnetic resonance imaging based on a tensor product complex wavelet tight frame, and provides a new research method for rapid magnetic resonance imaging. According to the method for rapidly reconstructing the magnetic resonance imaging based on the tensor product complex wavelet tight frame, the K-space data is undersampled by using the Cartesian sampling trajectory mode, so that the scanning speed of a device is greatly improved; the imaging is decomposed from multiple directions based on the sparse transformation of the tensor product complex wavelet tight frame, so that the accuracy of magnetic resonance imaging is improved; the convex optimization problem in imaging reconstruction is solved by using the projection fast iterative soft threshold algorithm, so that the speed of magnetic resonance imaging reconstruction is accelerated; and a regularization parameter is adaptively calculated based on the bivariate contraction method in the projection fast iterative soft threshold algorithm, thus not only the process for blindly selecting parameters is omitted, but also the quality of imaging reconstruction is improved.

Owner:ZHEJIANG SCI-TECH UNIV

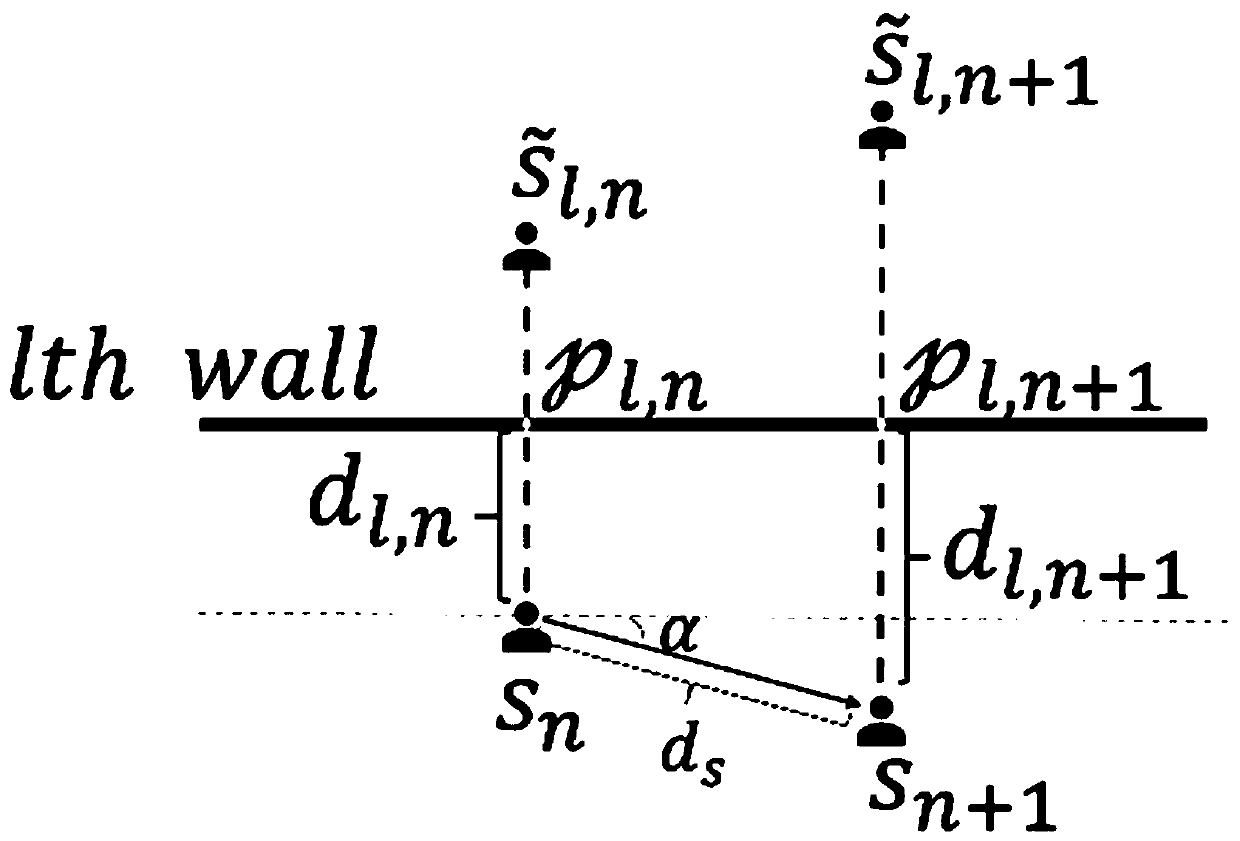

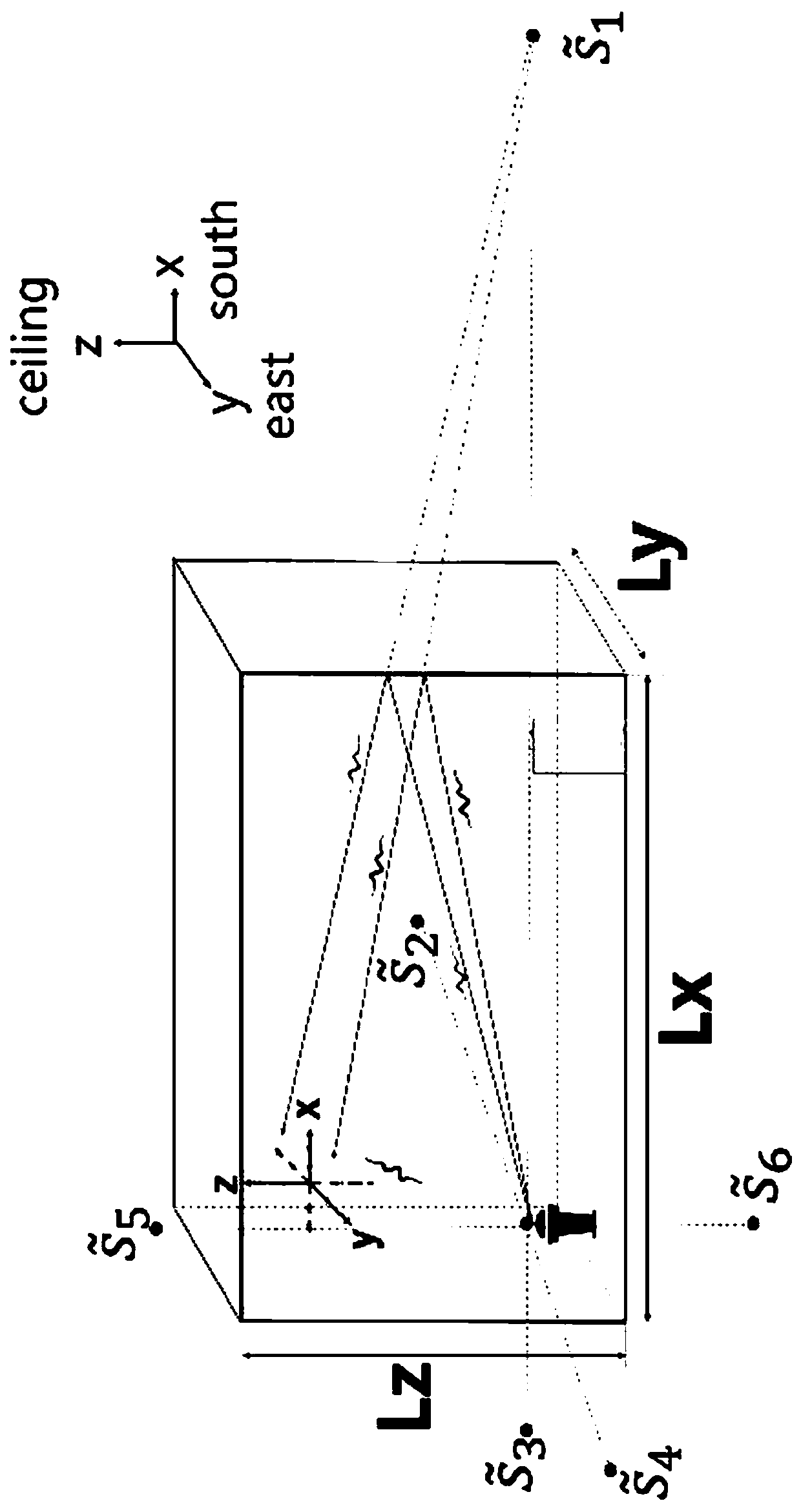

Indoor space geometric contour reconstruction method based on acoustic mirror image model

ActiveCN108872939AImprove accuracySolve the impact of delay estimation accuracyPosition fixationSound sourcesReconstruction method

The invention discloses an indoor space geometric contour reconstruction method based on an acoustic mirror image model; a sound receiver, a phase transformation generalized cross correlation analysismodule, a sound source positioning module, a plane parameter analysis module and the acoustic mirror image model are provided; the method uses sound signals as sound source signal, and uses a movableM array element star array as the sound receiver; the method comprises the following steps: locating the sound source according to a controllable response power phase transformation and area contraction method; using the acoustic mirror image model to obtain distance estimated values between the positions of a talker making single step movement and each indoor reflection surface before and afterthe single step is moved via the cross correlation analysis of sound transmit-receive signals; finally, combining with indoor space shape priors to convert the space geometric contour reconstruction problem into the sound source positioning problem, solving the mirror image sound source position, and realizing the indoor space geometric contour reconstruction. The method can improve the indoor space geometric contour reconstruction accuracy, and considers the sound source versatility, thus obtaining robust contour reconstruction effects.

Owner:GUILIN UNIV OF ELECTRONIC TECH

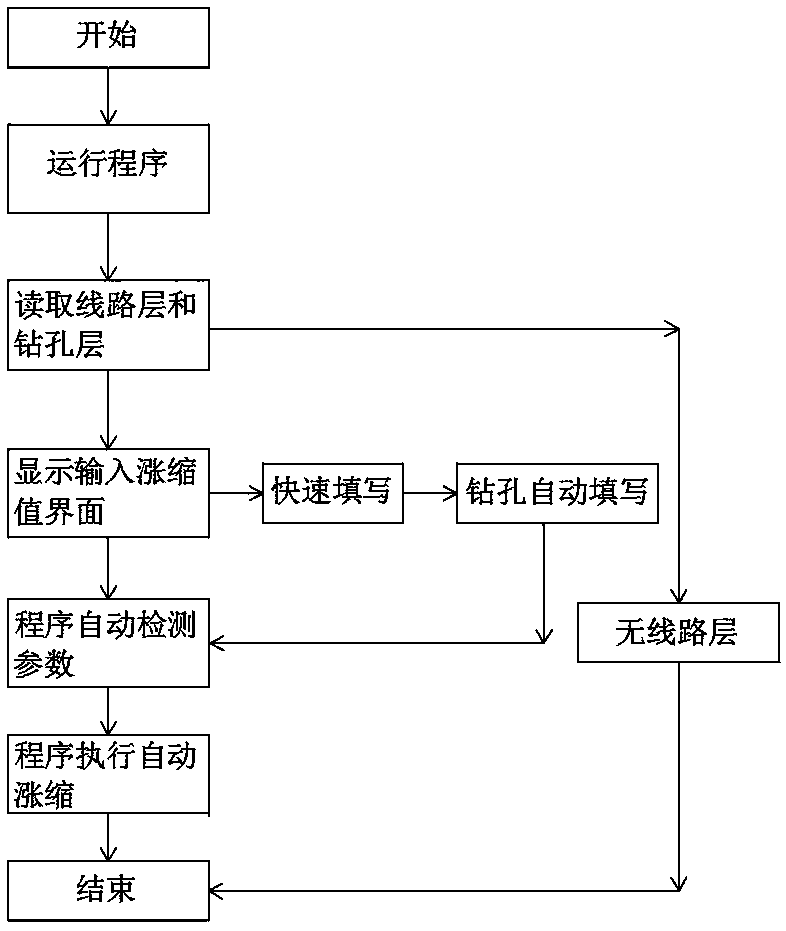

automatic expansion and contraction method for a PCB circuit and drill holes

ActiveCN109657265APrevent wrong expansion and contractionTimely modificationCAD circuit designSpecial data processing applicationsContraction methodContraction time

The invention provides a PCB (Printed Circuit Board) line and road drilling automatic expansion and contraction method, which comprises the following steps of: reading a line layer and a drilling layer in a PCB file lamination layer; Displaying the name, the expansion and contraction coefficient and the check box of each layer of the circuit layer in a row in a window, filling each row of data bya user, and selecting the expansion and contraction by the check box after check; filling Program inspection parameters; executing Expansion and contraction, ynamically filling an expansion and contraction instruction in the engineering manufacturing software into the engineering manufacturing software through a program, the engineering manufacturing software receives the instruction to execute expansion and contraction, displaying all expansion and contraction layer in a centralized mode, filling the parameters in a centralized mode, and preventing error expansion and contraction caused by too many layers; And performing automatic filling of the drilling parameters: combining the obtained line expansion and shrinkage parameters with the drilling data, automatically analyzing and calculating the expansion and shrinkage data of the drilling layer, and automatically filling the drilling expansion and shrinkage parameters.

Owner:HUIZHOU KING BROTHER CIRCUIT TECH +2

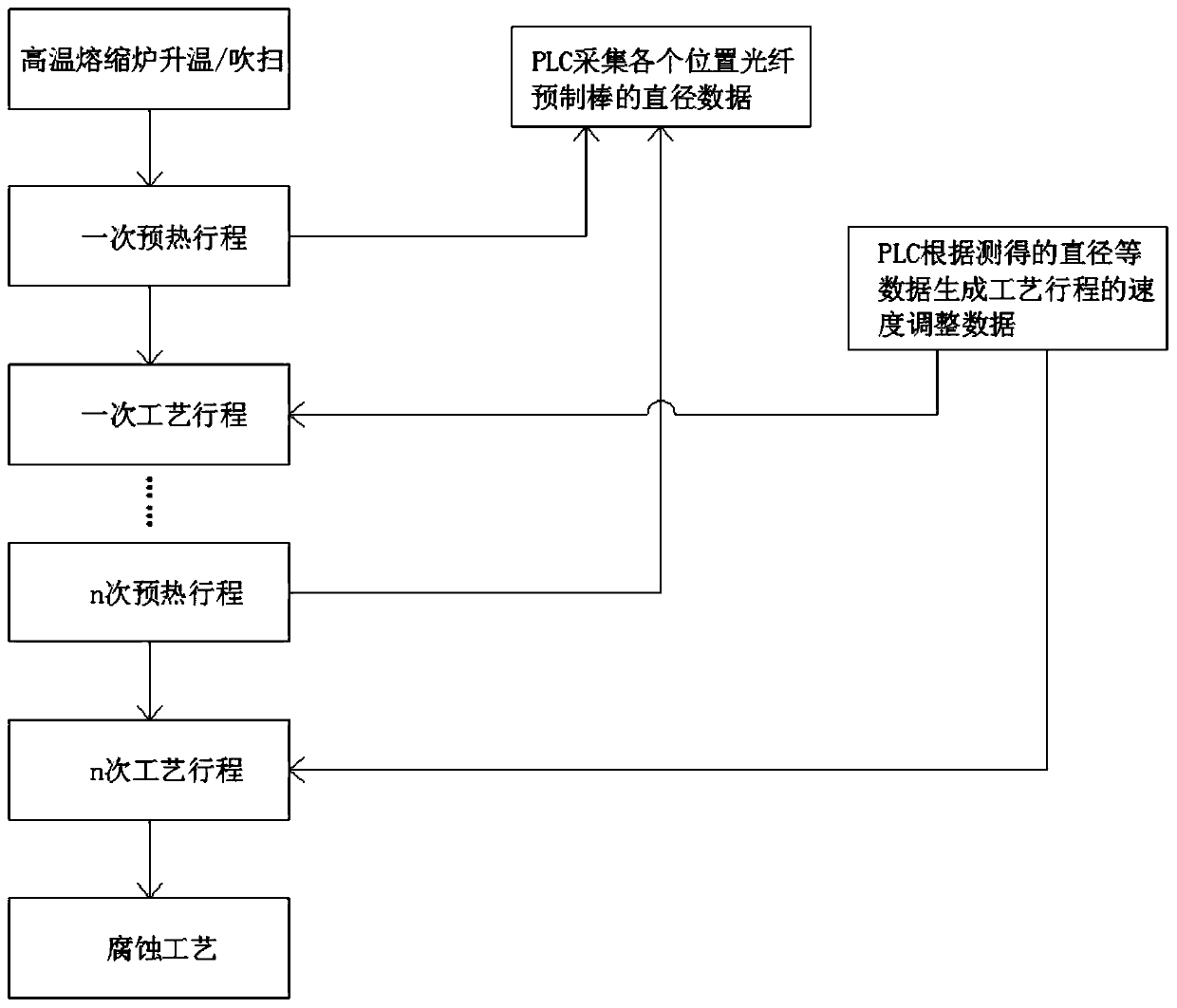

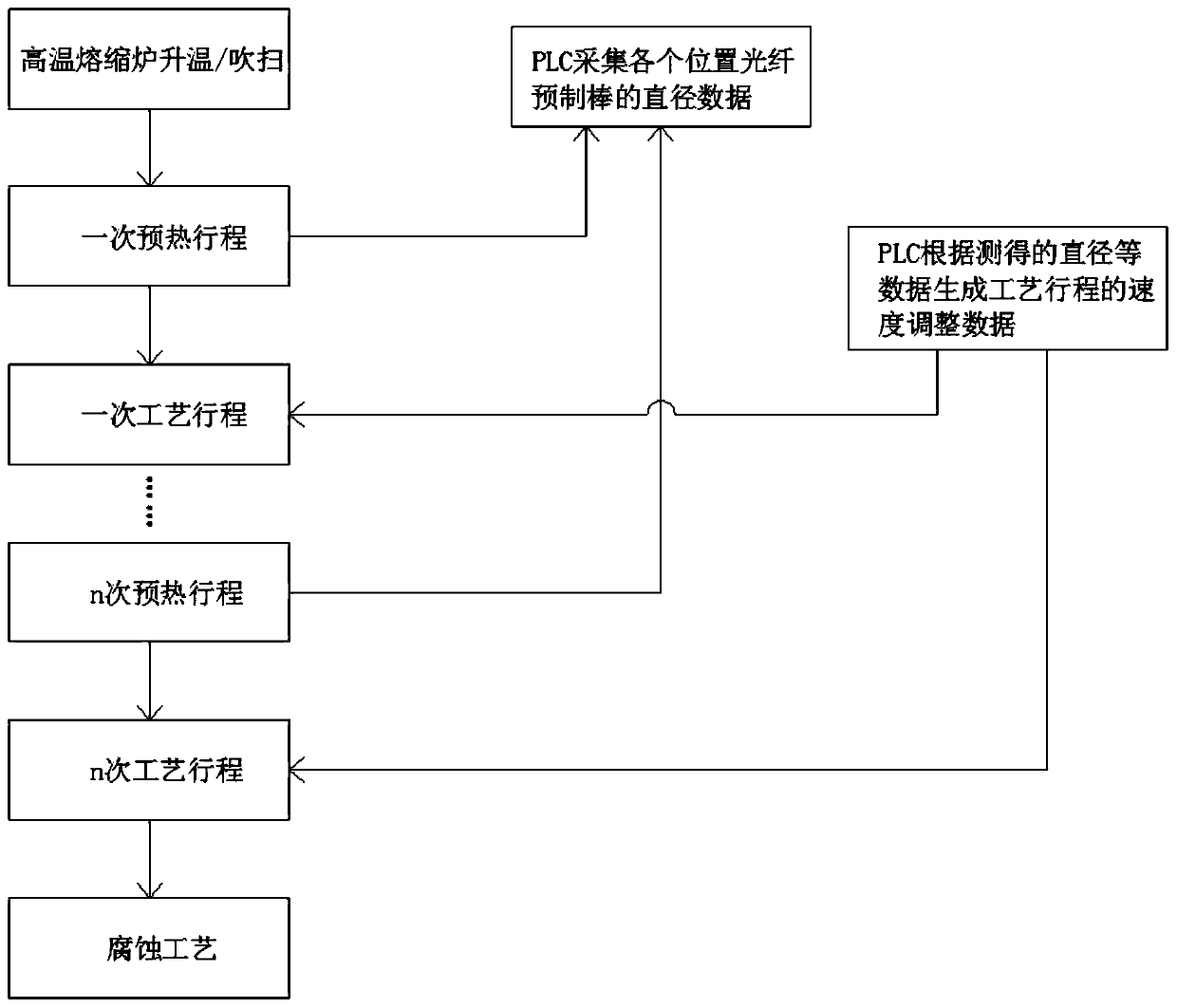

Melting contraction method for improving uniformity of preform mandril

PendingCN110002738AUniform corrosion amountImprove uniformityGlass making apparatusContraction methodMetallurgy

The invention discloses a melting contraction method for improving the uniformity of a preform mandril. A melting contraction lathe, a high-temperature melting contraction furnace, an outer diameter measuring instrument, a shuttling moving motor and an encoder are included. The melting contraction method for improving the uniformity of the preform mandril comprises the following steps: S1, a preparation process: the high-temperature melting contraction furnace is heated to clamp a deposited hollow optical fiber perform on the melting contraction lathe; and S2, a melting contraction process: heating the continuously rotating hollow perform to 2000-2300 DEG C under the action of a high temperature, wherein the preform is softened at the high temperature. According to the melting contractionmethod for improving uniformity of the preform mandril, by arranging the outer diameter measuring instrument on the high-temperature melting contraction furnace and fixing the outer diameter measuringinstrument together with the high-temperature melting contraction furnace, the outer diameter measuring instrument moves with the high-temperature melting contraction furnace synchronously. The diameter of the optical fiber preform in the melting contraction process is measured in real time by means of the outer diameter measuring instrument. Moreover, position information in the moving process of the high-temperature melting contraction furnace is positioned accurately by means of the high-temperature melting contraction furnace and the encoder on the shuttling moving motor.

Owner:PNC PROCESS SYSTEMS CO LTD

Self-cleaning member and coating composition

InactiveUS8512855B2Easily washing awayEasily washed awayFouling preventionOther chemical processesHysteresisSurface layer

A self-cleaning member comprising a member having a porous surface is disclosed. The member has a contact angle hysteresis Δθ (=θa−θr), which is a difference between an advancing contact angle θa and a receding contact angle θr measured by a dynamic contact angle measurement with an extension / contraction method, of 80 degree or more at the surface layer and a receding contact angle θr of 25 degree or less, is capable of forming a water film on the surface by water provided and of allowing an ionic or reactive contaminant to be washed away without fixation.

Owner:TOTO LTD

Folding cotton air-drying equipment

ActiveCN110440545AReduce space usageDrying cotton works wellDrying chambers/containersDrying solid materialsOmnidirectional antennaContraction method

The invention discloses folding cotton air-drying equipment. The folding cotton air-drying equipment structurally comprises a disc. A plurality of supporting feet are fixedly arranged on the lower endface of the disc. The support feet are abutted against the ground to support the equipment. An air-drying device which adopts a simultaneous expansion and contraction method to unfold the equipment and is used for storing air-dried cotton is arranged above a platform plate. A driving device for driving the air-drying device to rotate so that the cotton can be rotated when air-dried and omnidirectional air-drying can be facilitated is arranged on the lower side of the air-drying device. According to the equipment, the air-drying device capable of being folded freely and the driving device forrotating the cotton during the air-drying process so that omnidirectional air-drying can be facilitated are adopted, the method of setting different heights is adopted, the cotton is omnidirectionallyair-dried at multiple angles, the space is saved for use, and the air-drying effect of cotton of the equipment is better.

Owner:永春县产品质量检验所福建省香产品质量检验中心国家燃香类产品质量监督检验中心福建

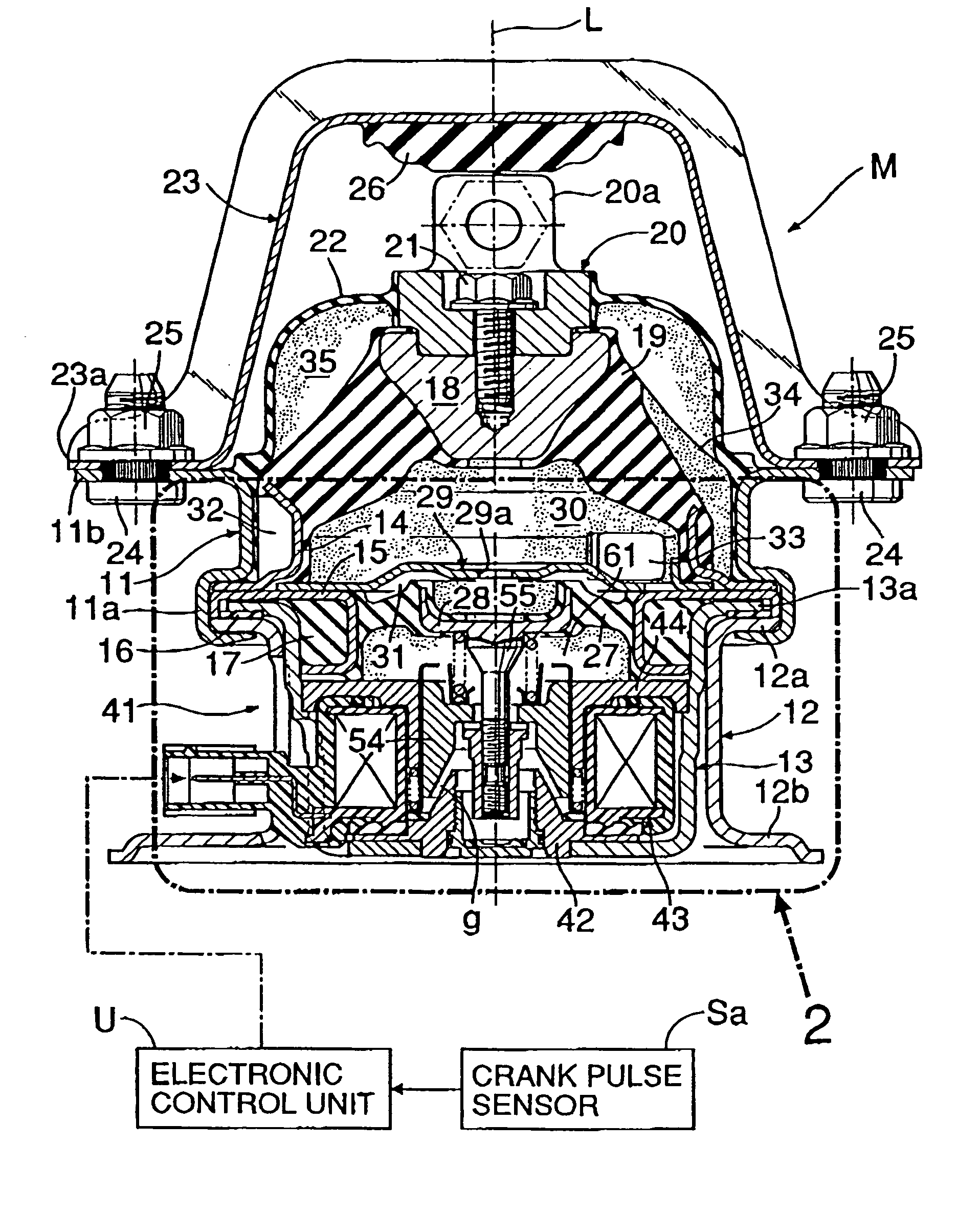

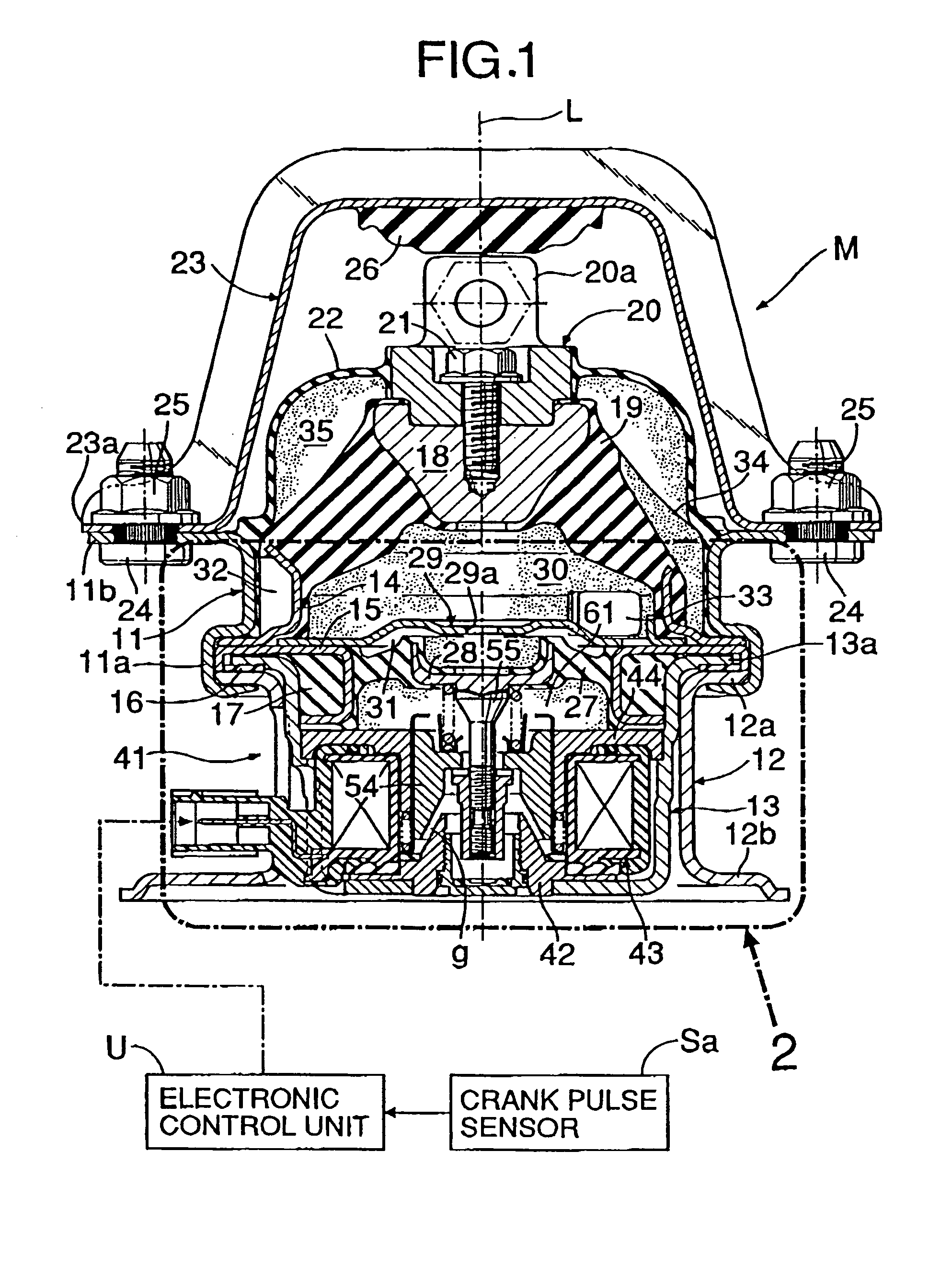

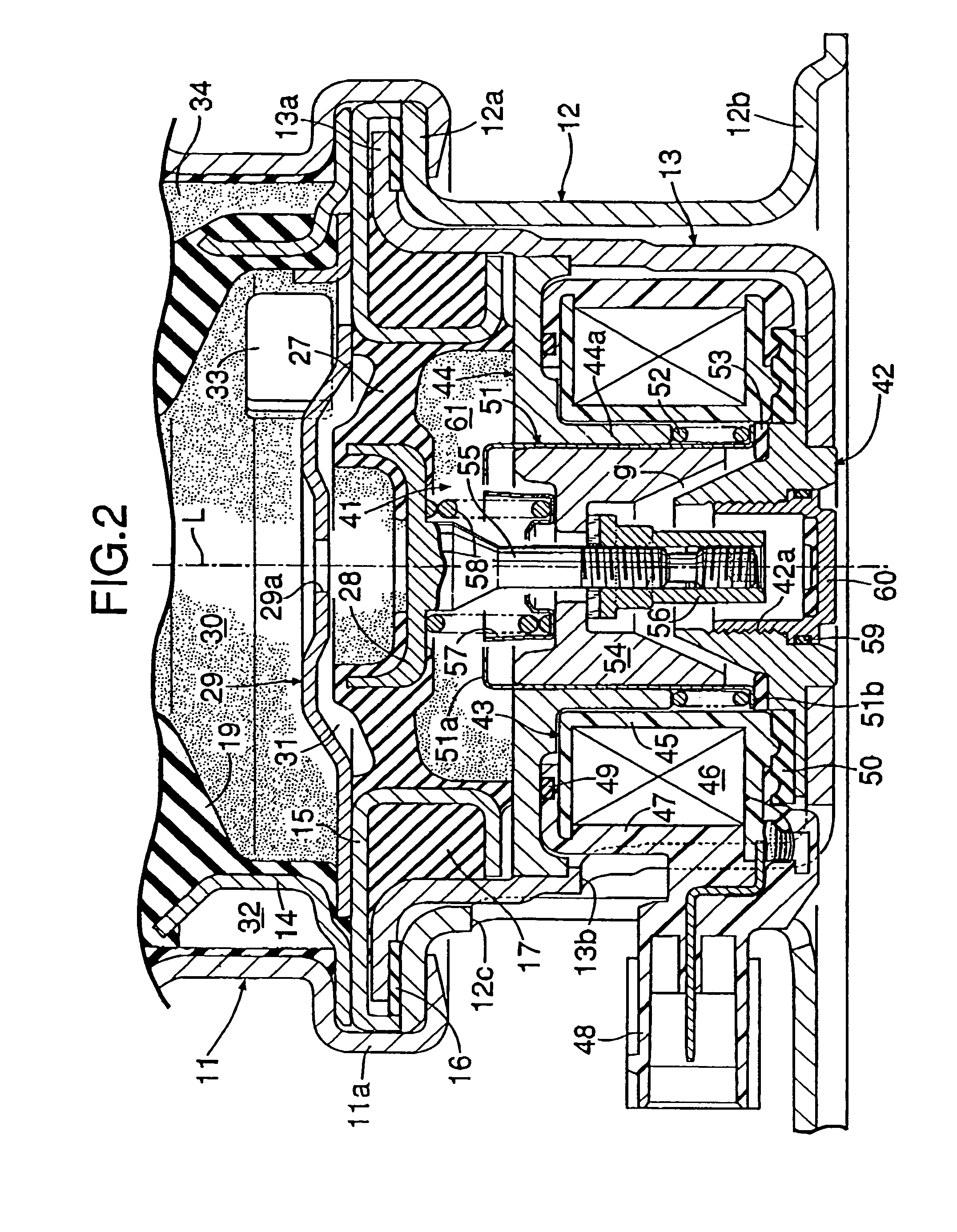

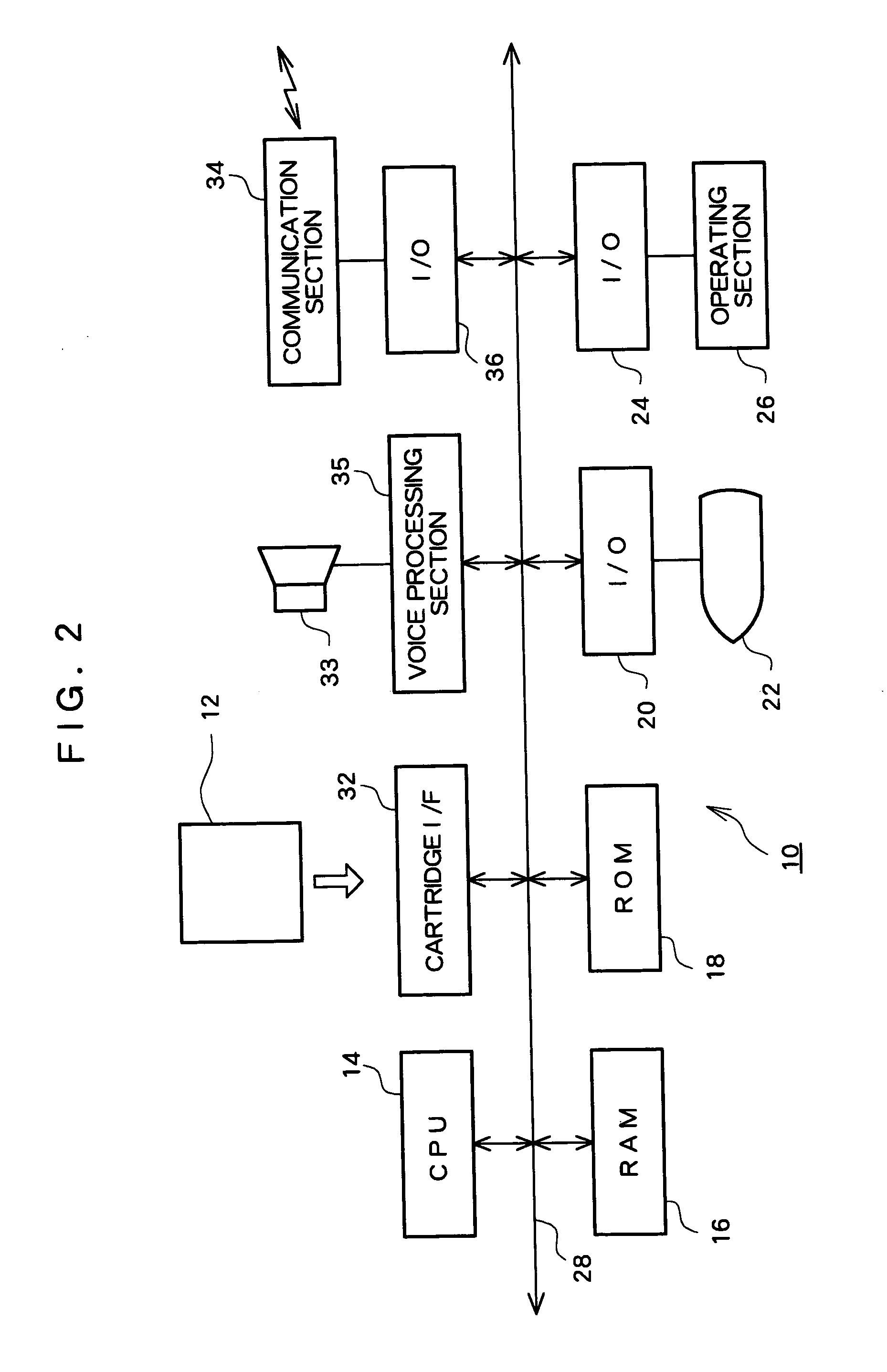

Actuator drive control device

InactiveUS7915842B2Improve accuracyComponent can be removedDC motor speed/torque controlStands/trestlesContraction methodWave shape

An active vibration isolation support system includes an electronic control unit which supplies a target electric current to an actuator to periodically drive the actuator in an expansion and contraction manner with a target vibration waveform. The controller sets the target electric current by synthesizing a driving primary electric current waveform corresponding to the target vibration waveform for the actuator with higher-order (driving secondary and / or tertiary) electric current waveforms which eliminate higher-order vibration components of the actuator corresponding to the driving primary electric current waveform. It is possible to alleviate a calculating load in the electronic control unit by ignoring the quaternary and still higher-order vibration components which less affect the target vibration waveform for the actuator.

Owner:HONDA MOTOR CO LTD

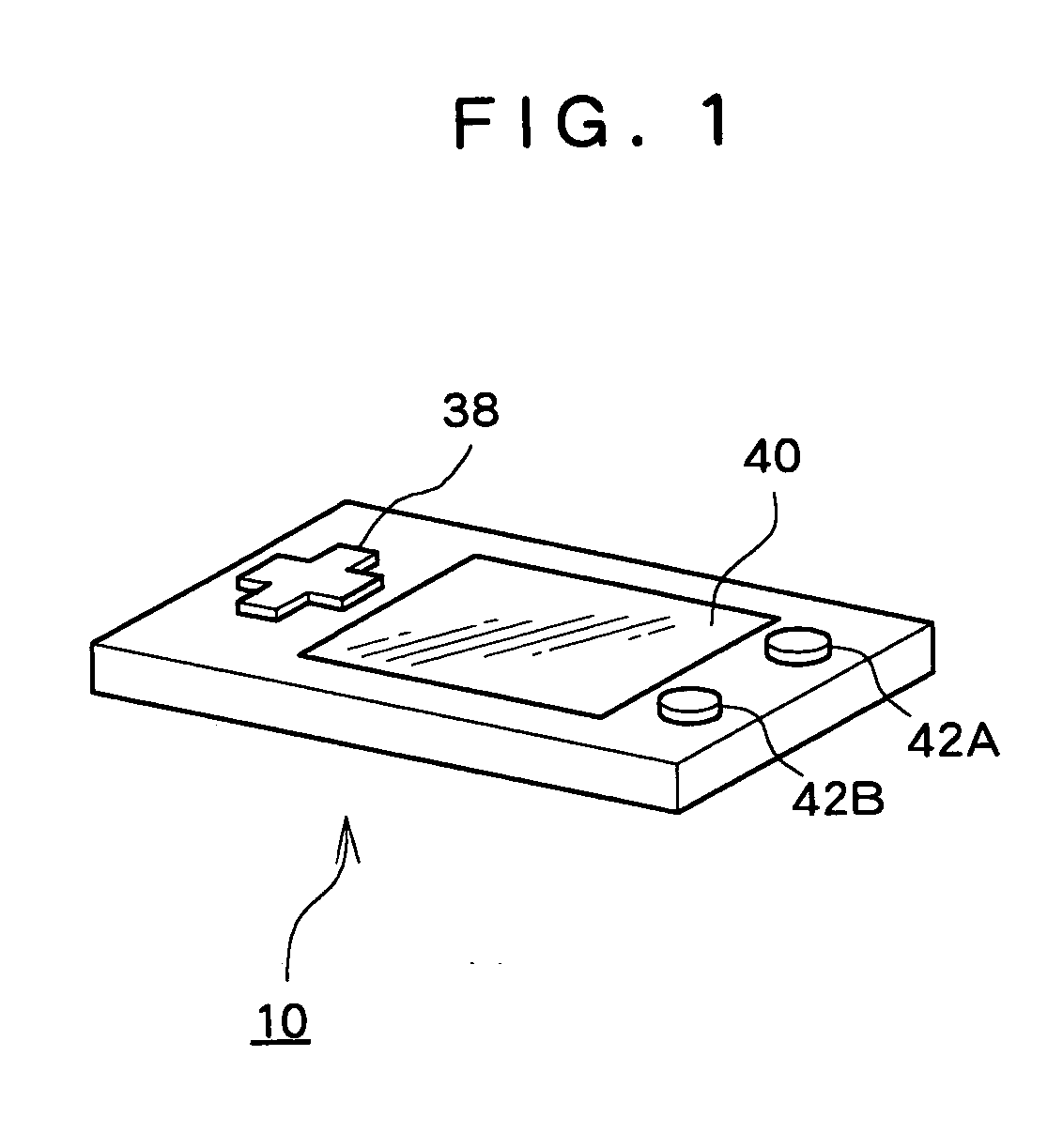

Elastic scaling method and system of virtual machine based on OpenStack

InactiveCN109032764ABind load balancingMonitor performance data in real timeResource allocationSoftware simulation/interpretation/emulationAutoscalingContraction method

The invention discloses a virtual machine elastic expansion and contraction method and system based on OpenStack. The method comprises the following steps: binding the virtual machine to load balanceand setting elastic expansion and contraction; monitoring and obtaining virtual machine performance data; when the performance data of the virtual machine satisfies the elastic scaling condition, thevirtual machine automatically scalling elastically. The invention automatically extends and contracts the virtual machine elastically by monitoring the performance data of the virtual machine, and effectively solves the problem of uneven distribution of virtual machine resources or waste of resources.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

Game device, game region expansion and contraction method, game program and information storage medium

InactiveUS20050107146A1Simple processEasy to operateGeometric image transformationAnimationContraction methodComputer graphics (images)

Owner:KONAMI DIGITAL ENTERTAINMENT CO LTD

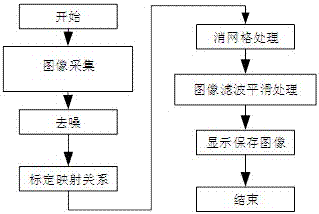

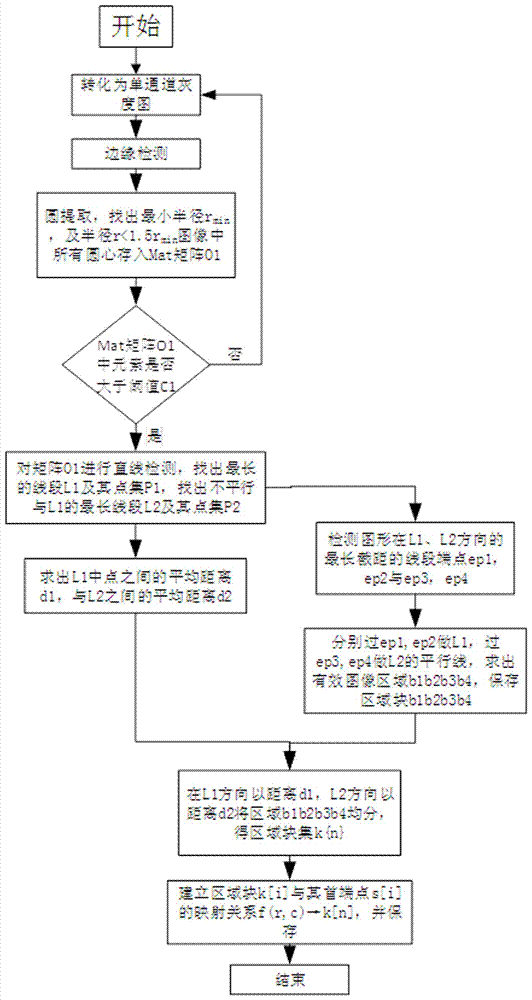

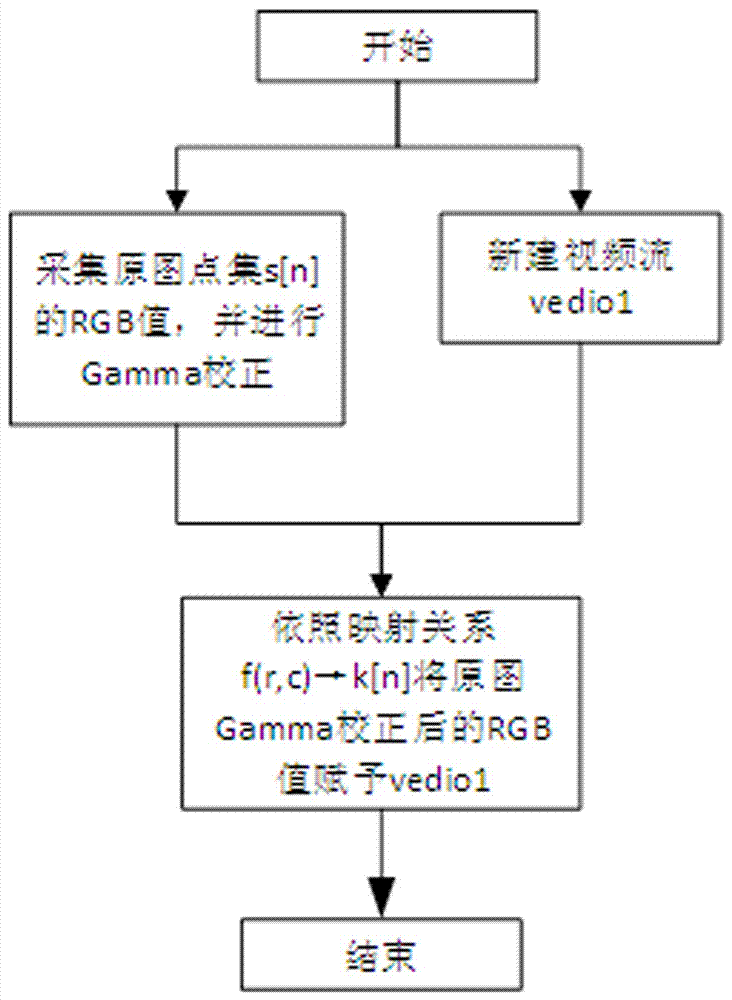

Endoscope image processing method

ActiveCN107516298AQuality improvementImage enhancementImage analysisContraction methodImaging processing

The invention discloses an endoscope image processing method. The method comprises the following steps of S1, using Gaussian filtering to remove a white noise generated during an image acquisition process; S2, calibrating a mapping relation f(r, c)-k{n} of an original image and a newly-constructed image so that a smallest circle bright spot circle center (r, c) in the original image is mapped to a rhomboid area (b1, b2, b3, b4) in the newly-constructed image, and acquiring an area block set k{n}; S3, according to a result of the step2, carrying out grid removing processing on subsequent images; S4, filtering the images acquired from the step3 again so that the images are smooth and continuous; and S5, storing and displaying the processed images. Wavelet transform and a threshold contraction method are used to preprocess collected image information, and through grid removing, gamma correction and filtering smooth processing, image quality is greatly increased.

Owner:安徽航天生物科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com