Tire building machine belt layer drum and radial expansion and contraction method thereof

A tire building machine and belt drum technology, applied in the field of rubber machinery, can solve problems such as complex internal structure of the drum, reduced air path sealing performance, hidden dangers of tire safety, etc., to achieve convenient installation, commissioning and maintenance, simple adjustment means, and guarantee consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

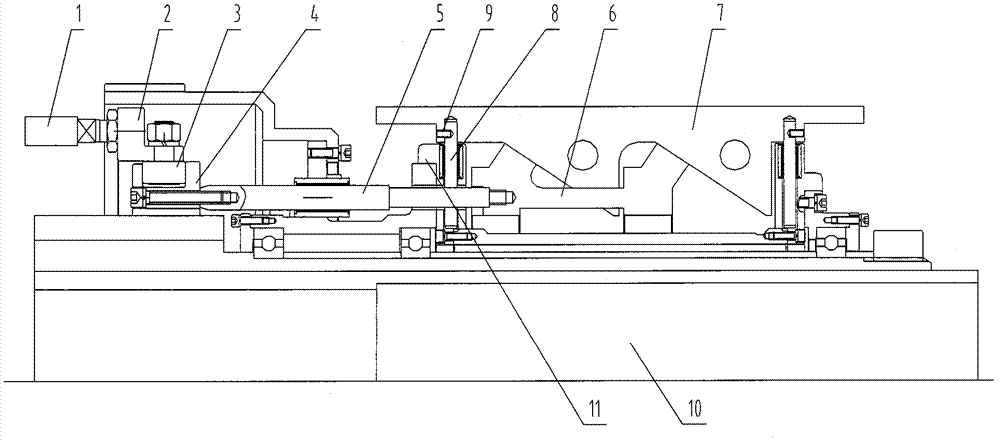

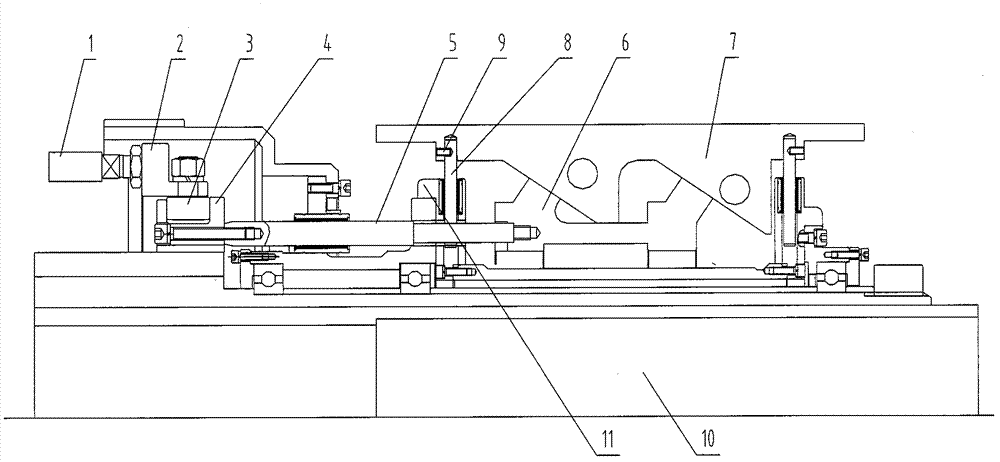

[0039] Example 1, such as figure 1 and figure 2 As shown, the belt drum of the tire building machine mainly includes:

[0040] a spindle 10;

[0041] Two sets of drum tiles 7 that can expand and contract radially and a tapered sleeve 6 that rotates axially synchronously with the drum tiles 7 are set radially along the main shaft 10;

[0042] A second push rod 1 driven by a servo motor (not shown) is arranged axially along the main shaft 10, and several rolling bearings 3 are installed on the inner side of the second push rod 1 through the connecting seat 2;

[0043] One end of the first push rod 5 is laterally fixed to the tapered sleeve 6 , and the other end is connected to a switch plate 4 which is sleeved on several rolling bearings 3 at the same time. That is to say, the transfer disc 4 drives the synchronous rotation between the first push rod 5 and the tapered sleeve 6 while rotating axially around several rolling bearings 3;

[0044] A support frame 11 is sheathed ...

Embodiment 2

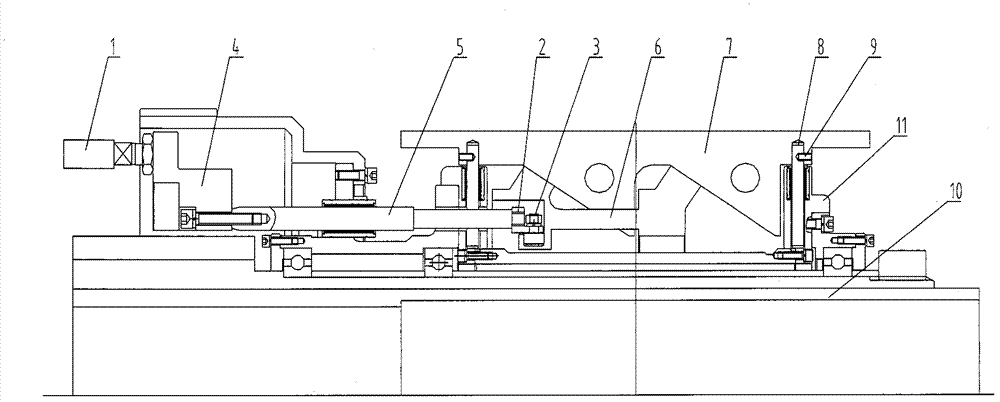

[0050] Example 2, such as image 3 As shown, the belt drum of the tire building machine mainly includes:

[0051] a spindle 10;

[0052] Two sets of drum tiles 7 that can expand and contract radially and a tapered sleeve 6 that rotates axially synchronously with the drum tiles 7 are set radially along the main shaft 10;

[0053] A servo motor (not shown) is arranged axially along the main shaft 10 to drive and connect the first push rod 5 through the switch plate 4, and the other end of the first push rod 5 is connected to an annular connecting seat 2 and a set of rolling bearings 3. The outer end of the tapered sleeve 6 is correspondingly suspended and fitted on the rolling bearing 3;

[0054] Then the outer end of the tapered sleeve 6 can rotate axially around the rolling bearing 3, while the first push rod 5, the switching disc 4, and the connecting seat 2 do not rotate axially, and only transmit the axial driving force of the servo motor To the tapered sleeve 6, the tap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com