Patents

Literature

182 results about "Acoustic mirror" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An acoustic mirror is a passive device used to reflect and focus (concentrate) sound waves. Parabolic acoustic mirrors are widely used in parabolic microphones to pick up sound from great distances, employed in surveillance and reporting of outdoor sporting events. Pairs of large parabolic acoustic mirrors which function as "whisper galleries" are displayed in science museums to demonstrate sound focusing.

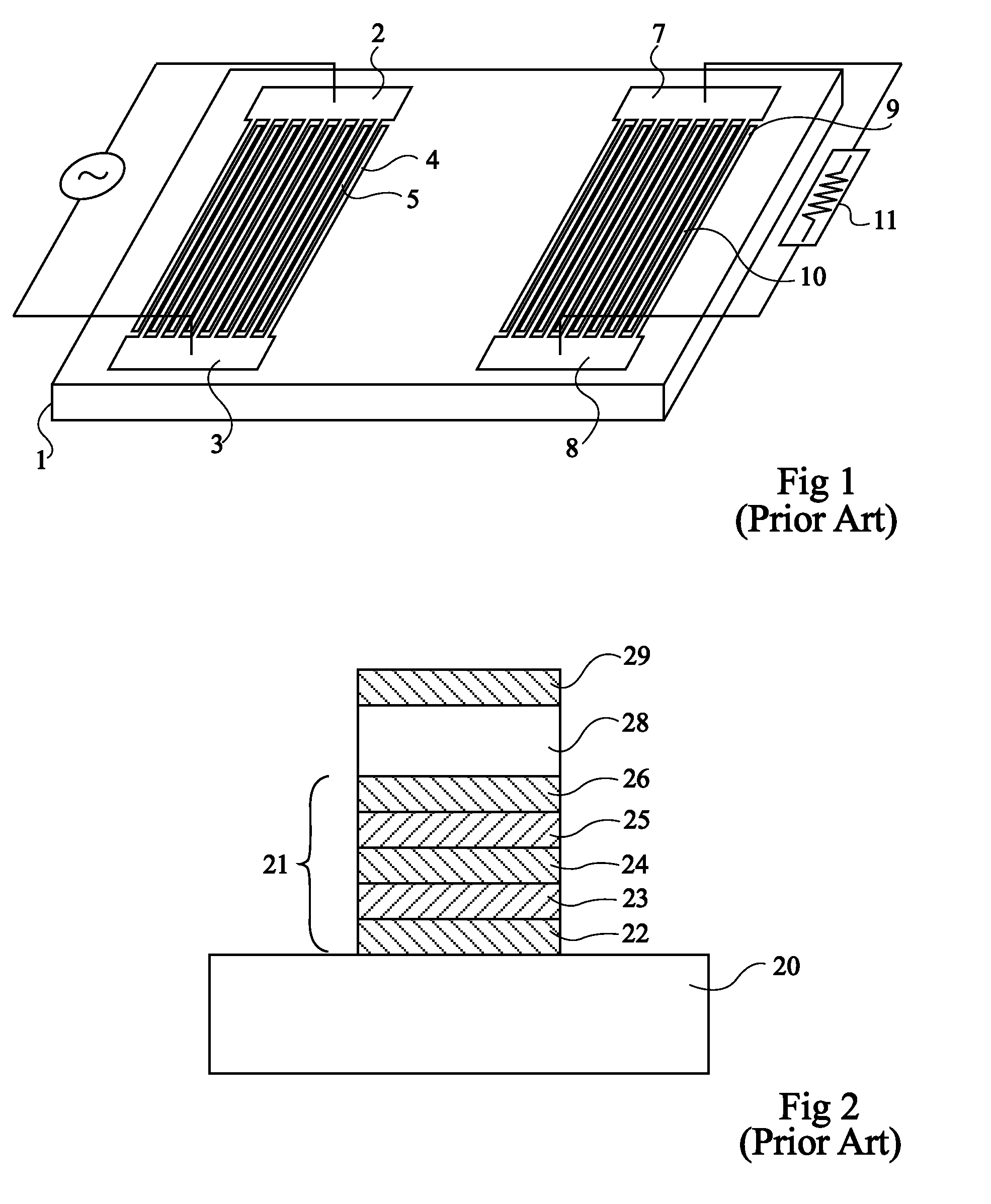

Component operating with bulk acoustic waves and a method for producing the component

ActiveUS6998940B2Contributed to reliabilityEasy to flattenPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksAcoustic waveAcoustic impedance

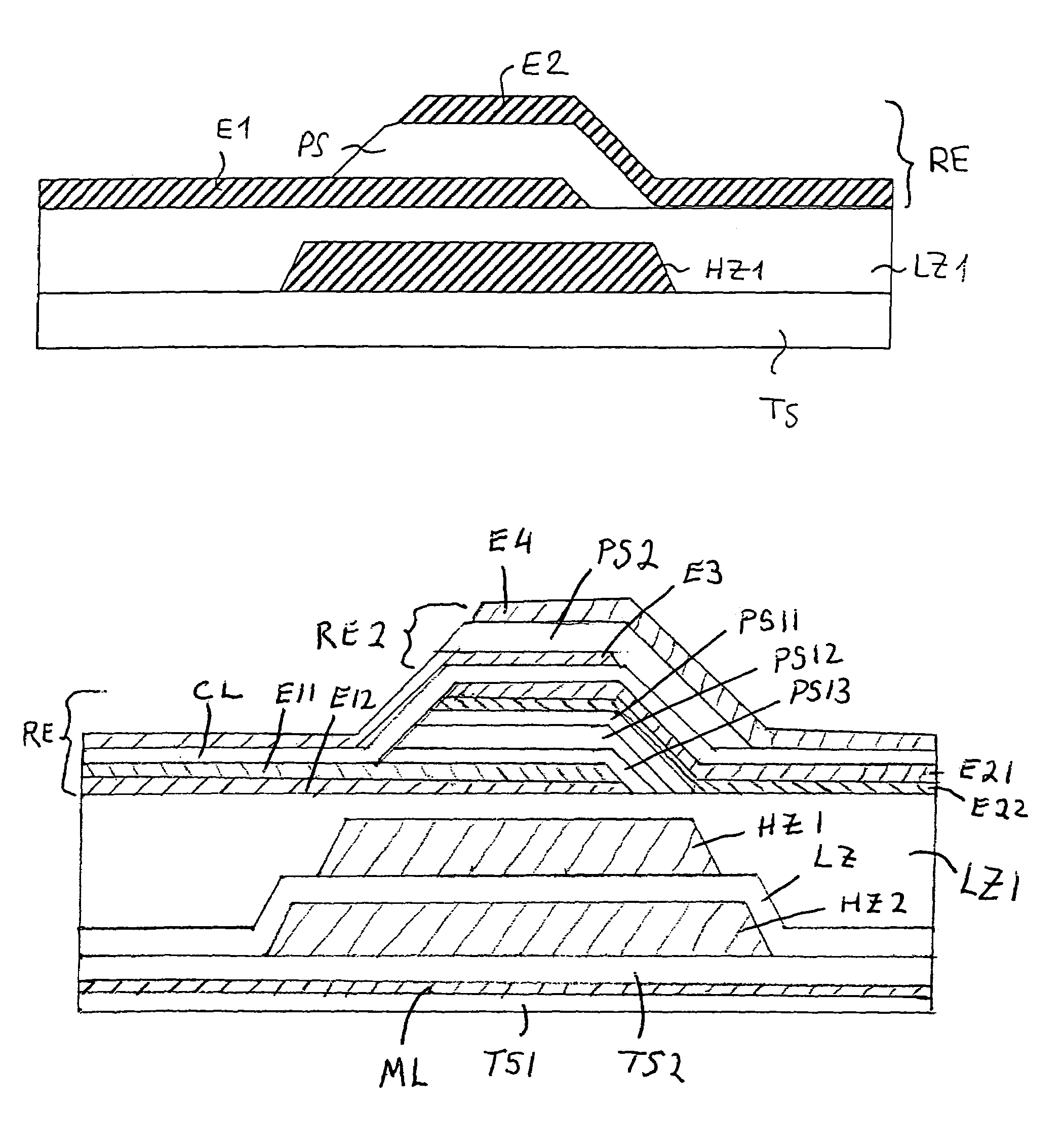

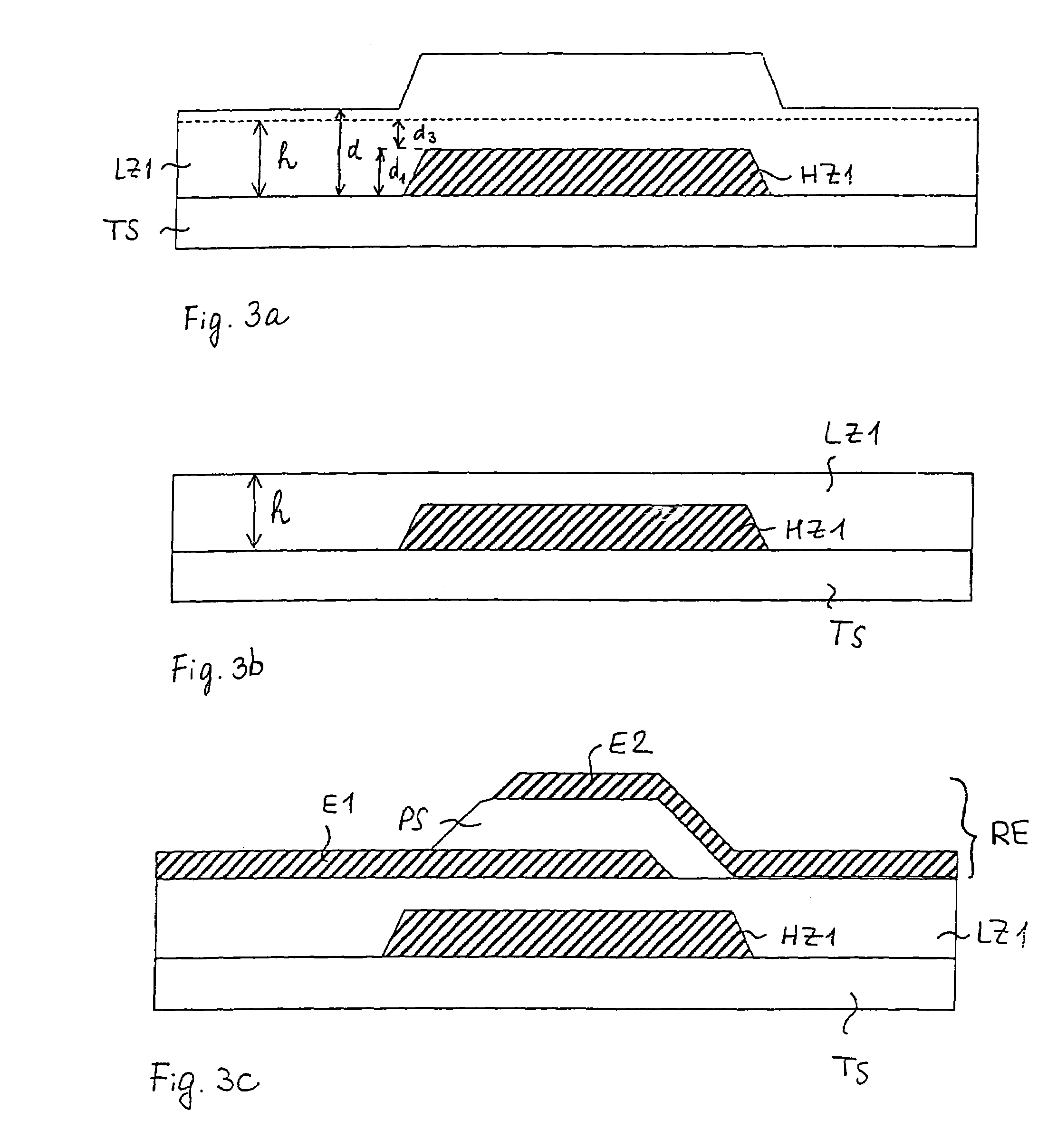

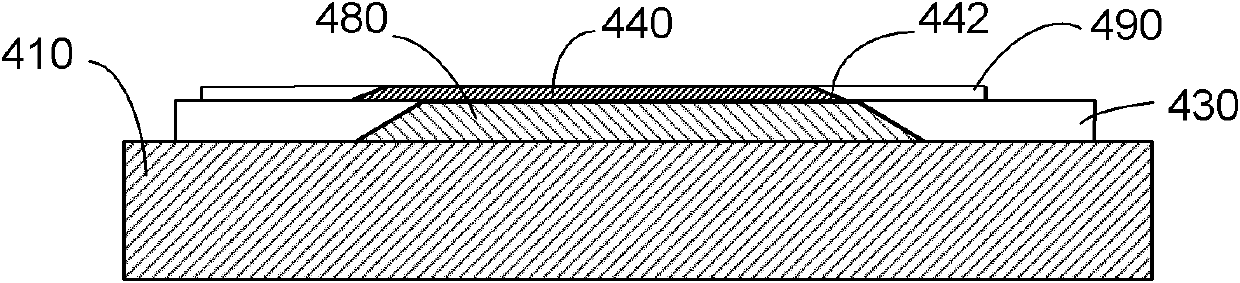

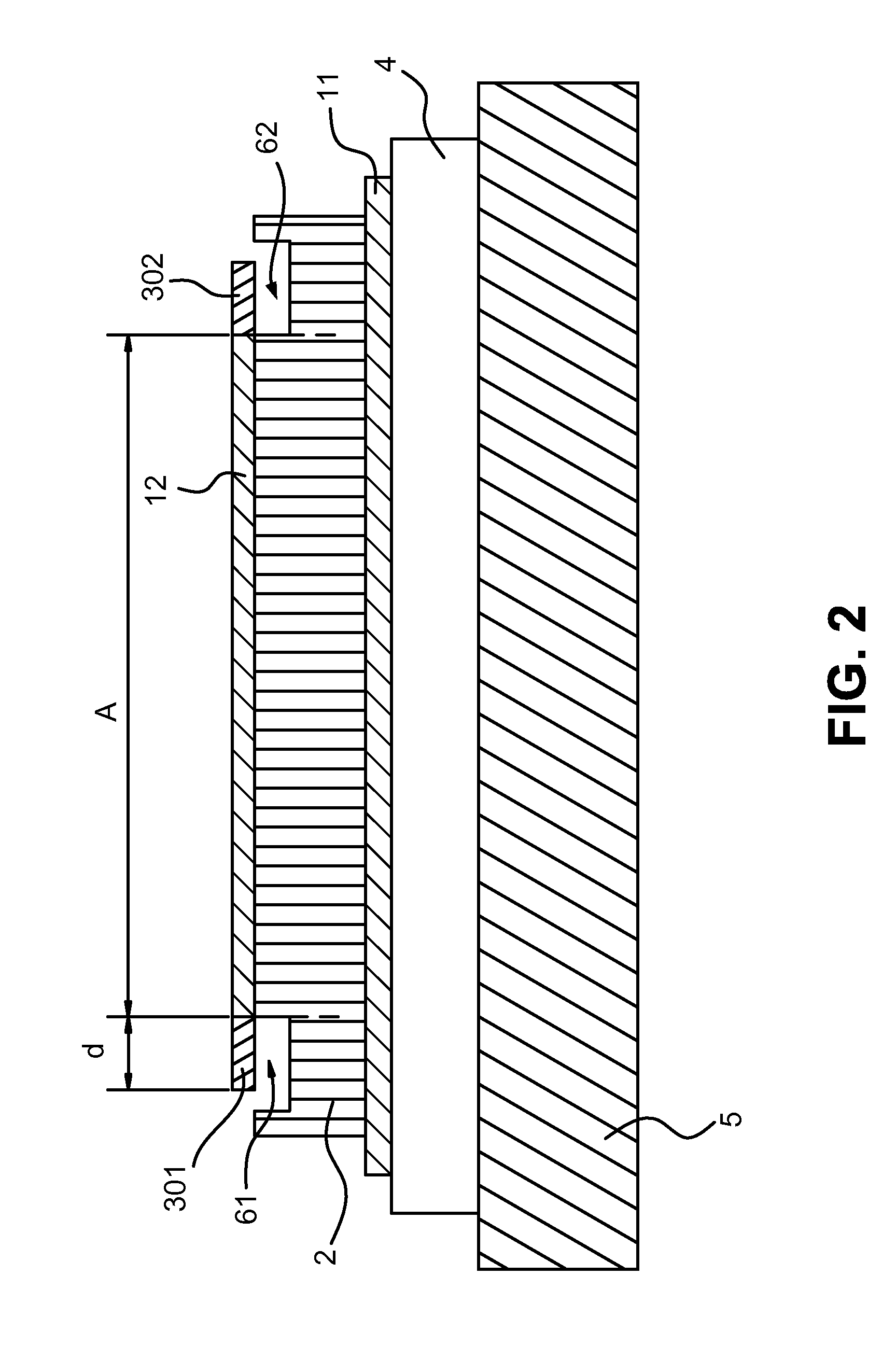

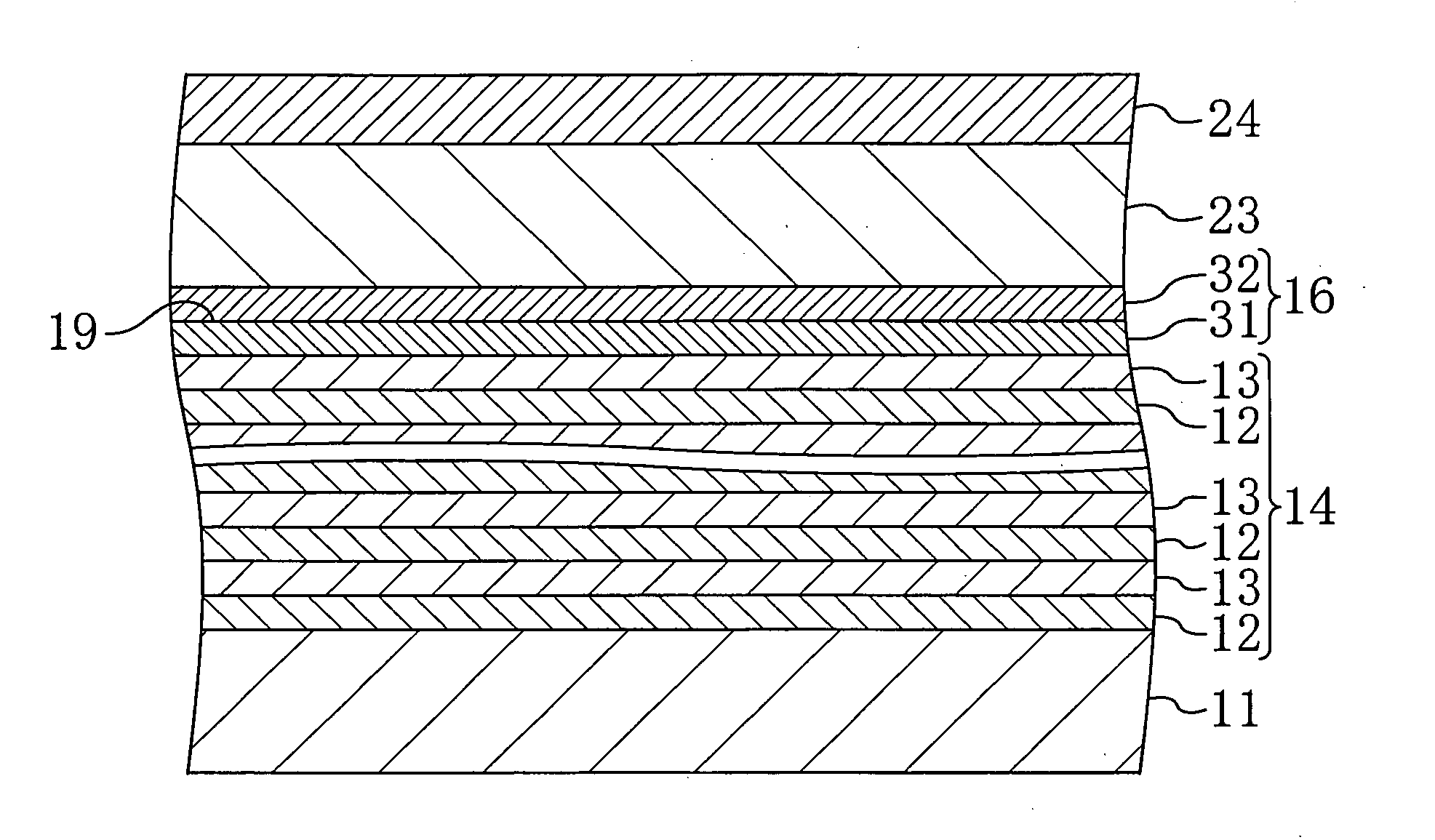

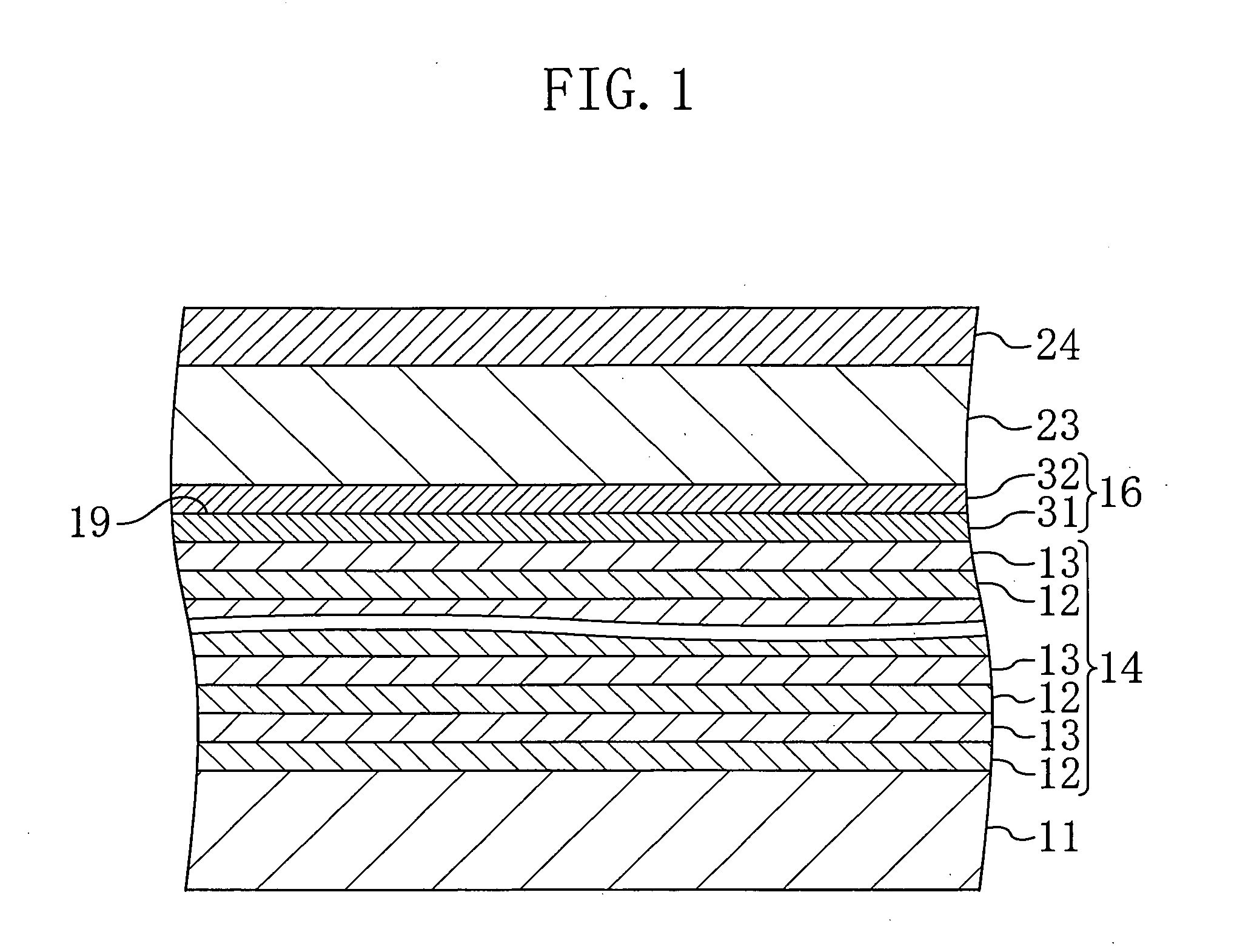

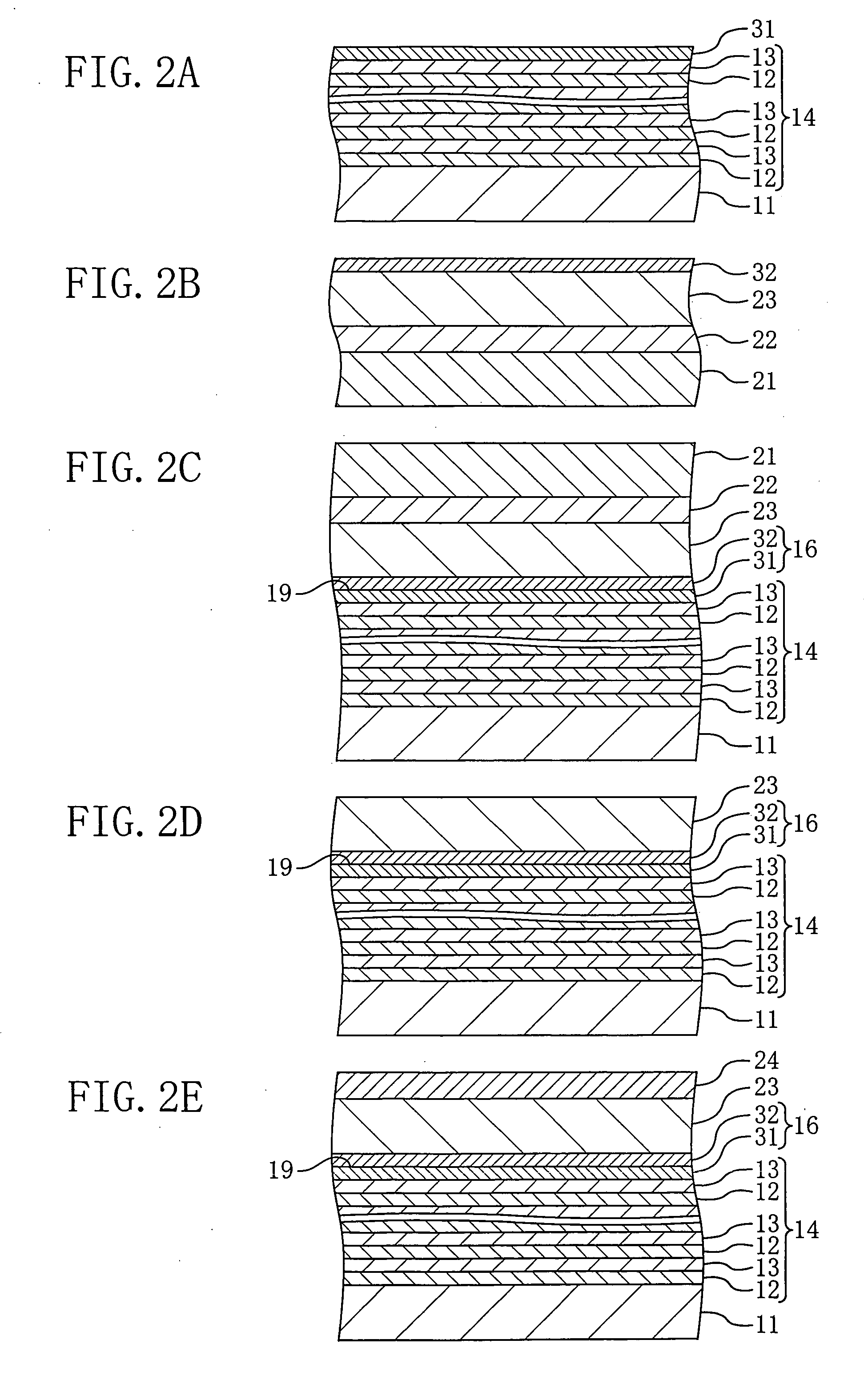

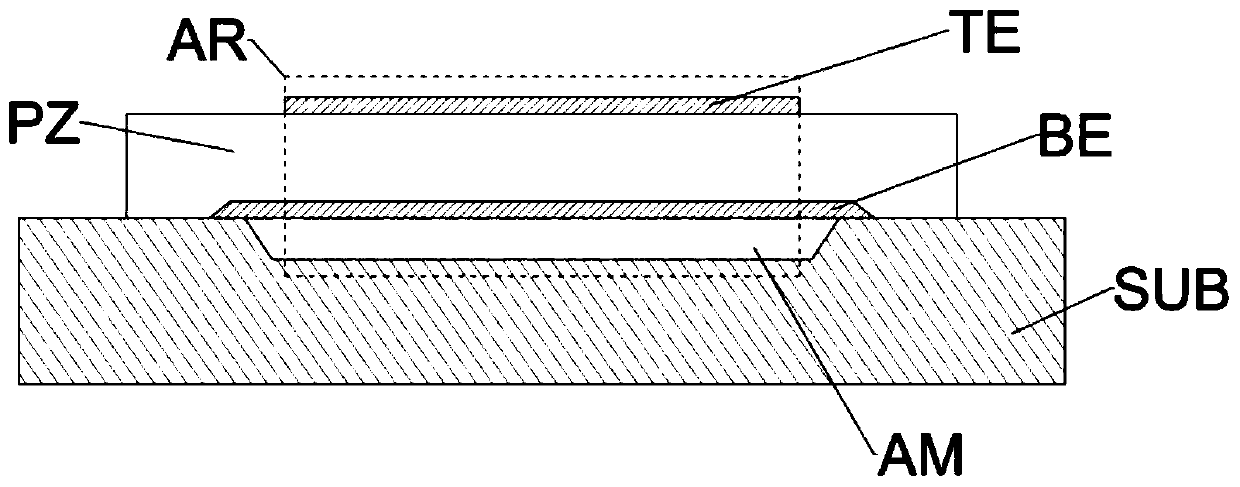

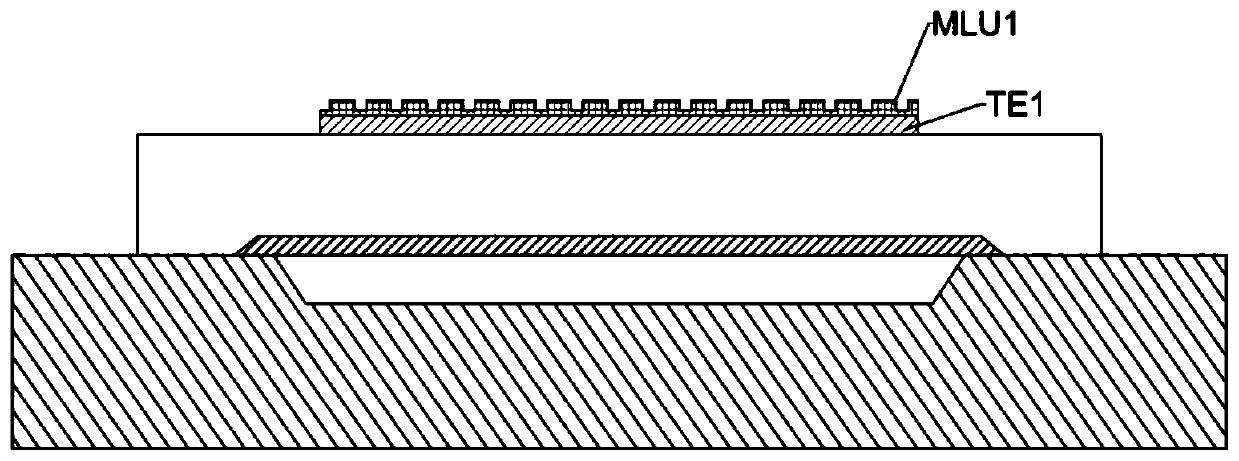

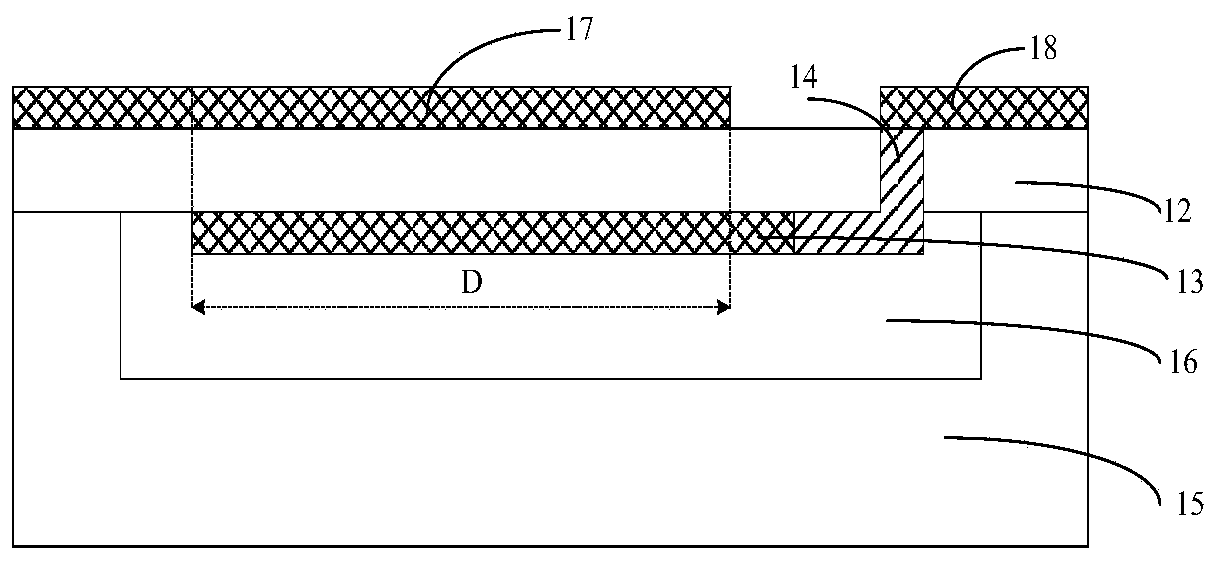

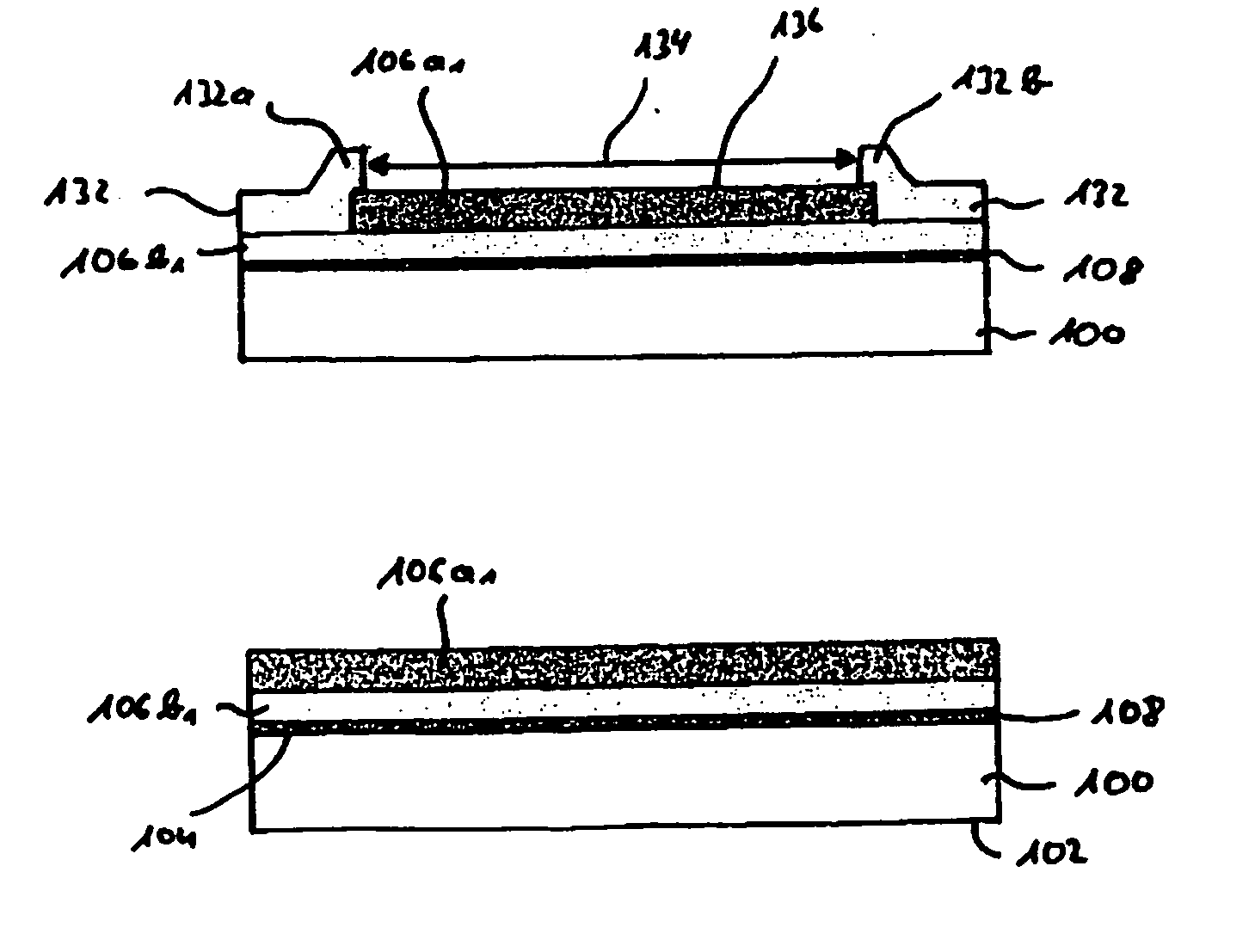

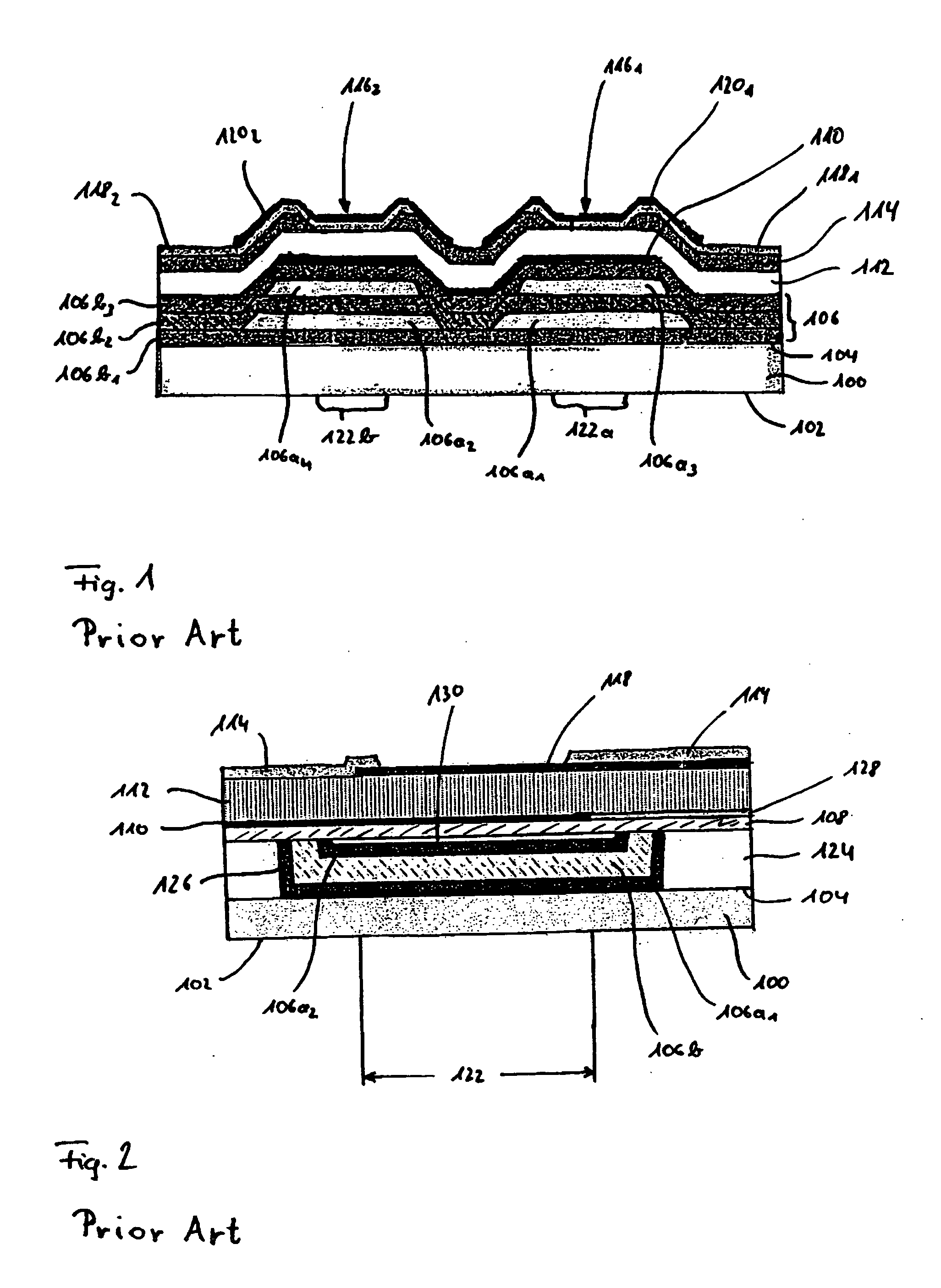

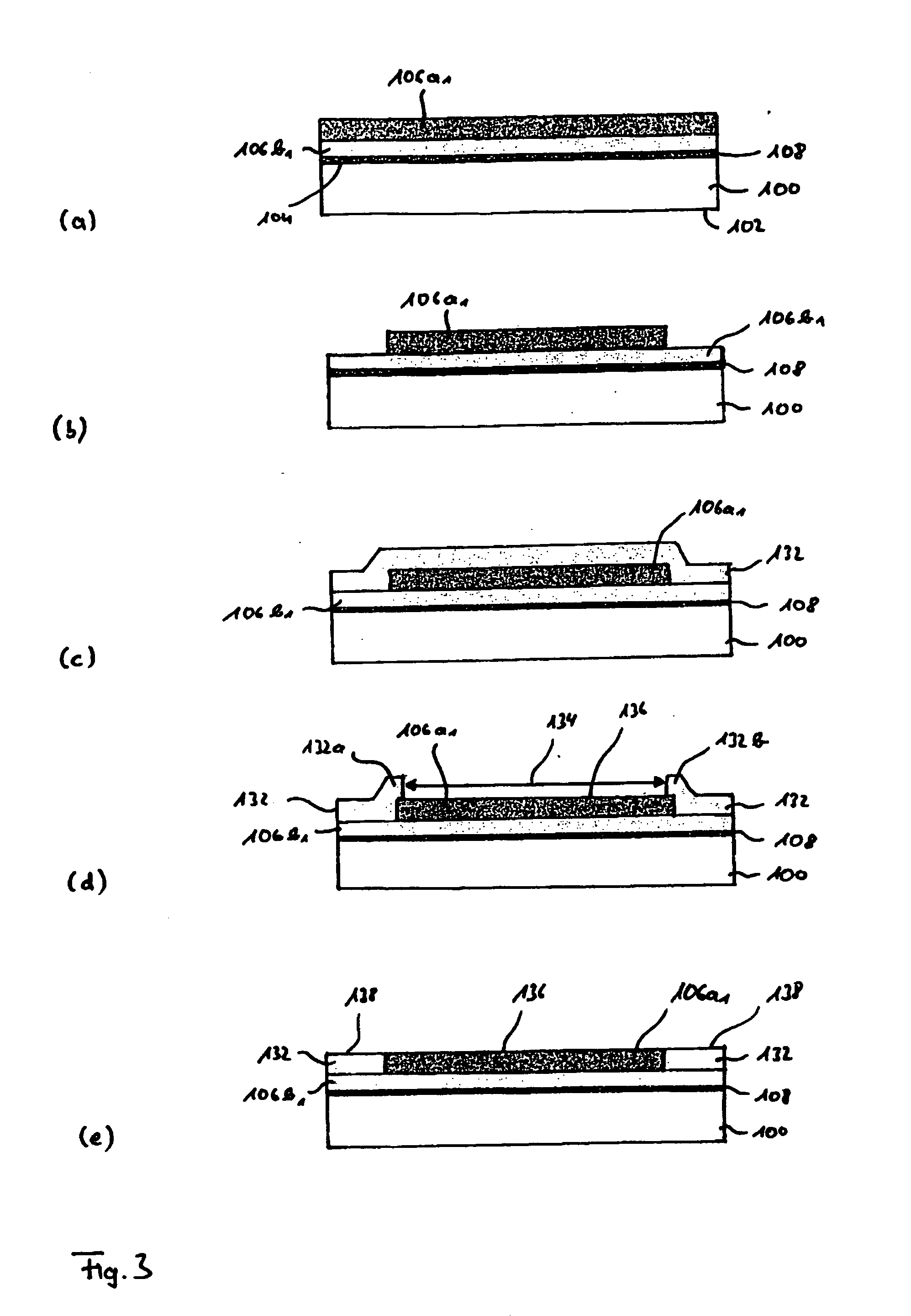

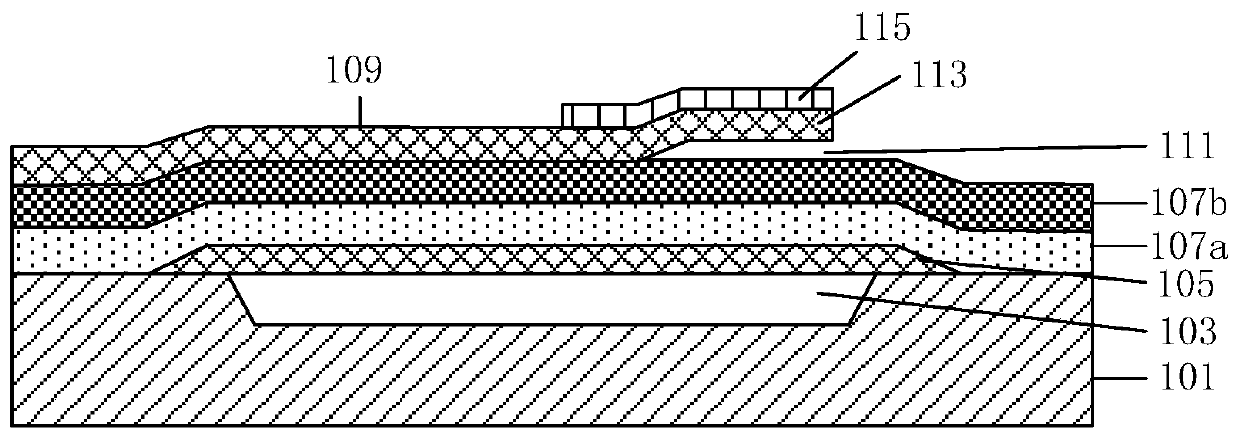

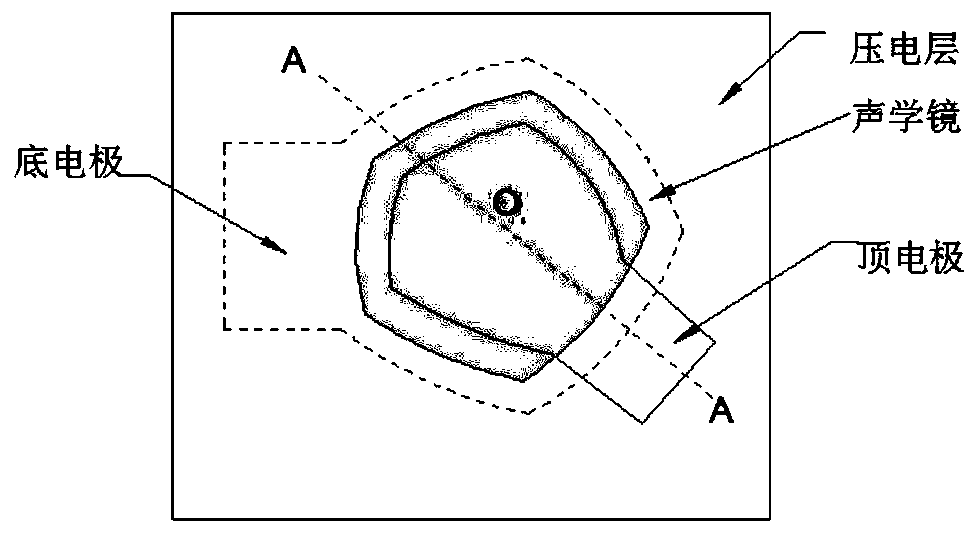

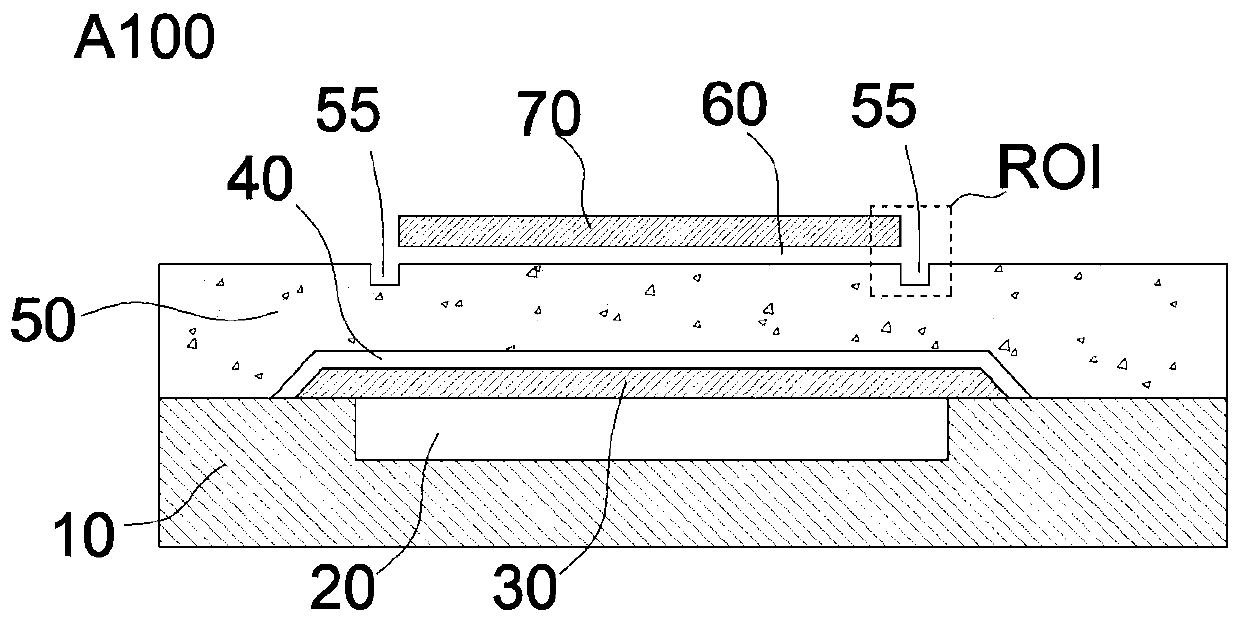

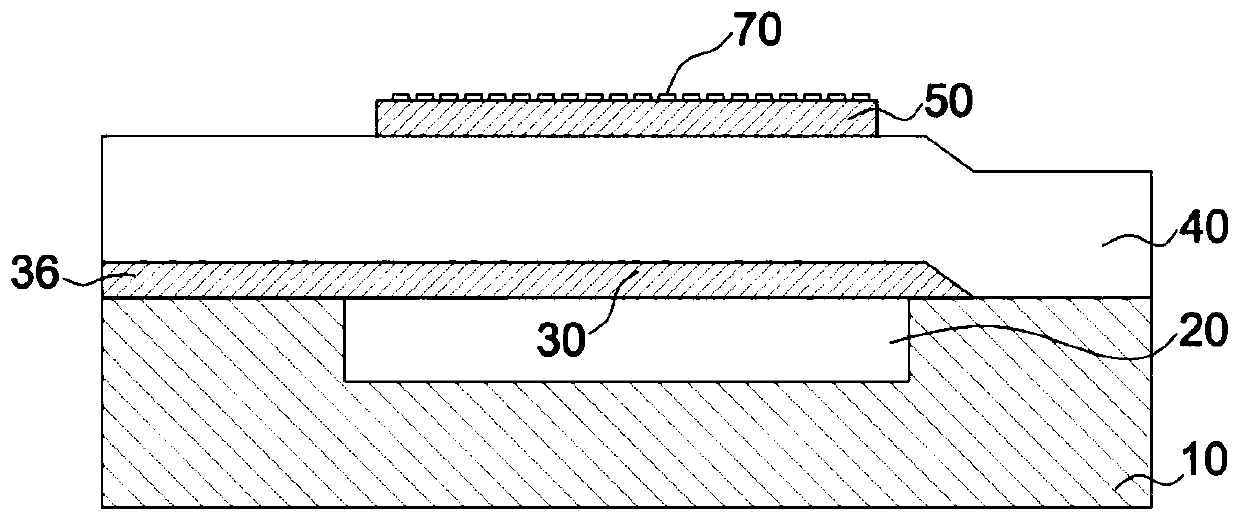

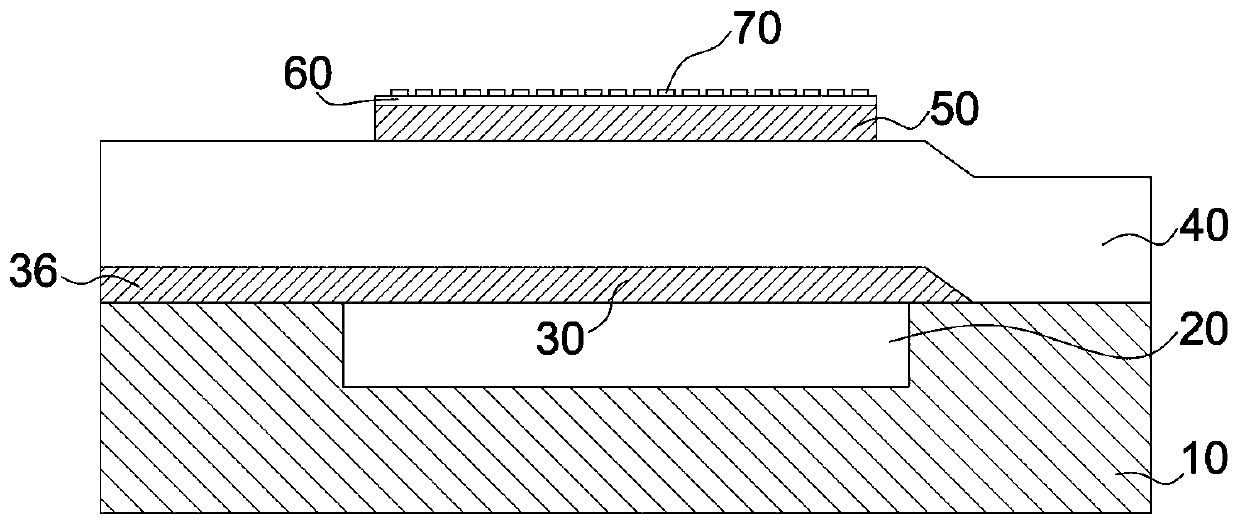

A component operating with bulk acoustic waves has a carrier substrate, a thin-film resonator and an acoustic mirror arranged between the resonator and carrier substrate. The acoustic mirror is formed by at least one high acoustic impedance layer, which is covered by a low acoustic impedance layer and the uppermost low impedance acoustic layer is planarized to form a flat planar surface on which the thin-film resonator is formed.

Owner:SNAPTRACK

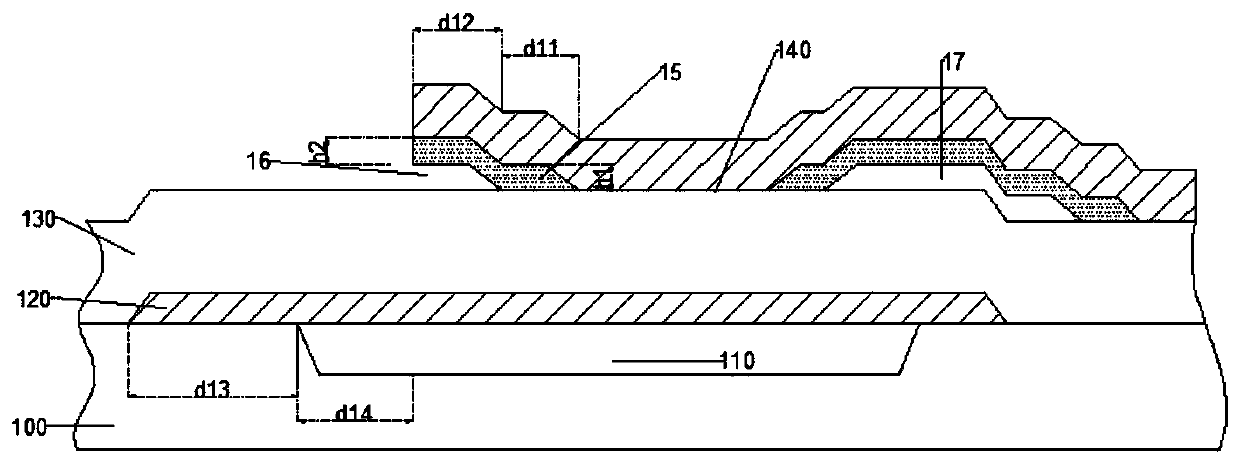

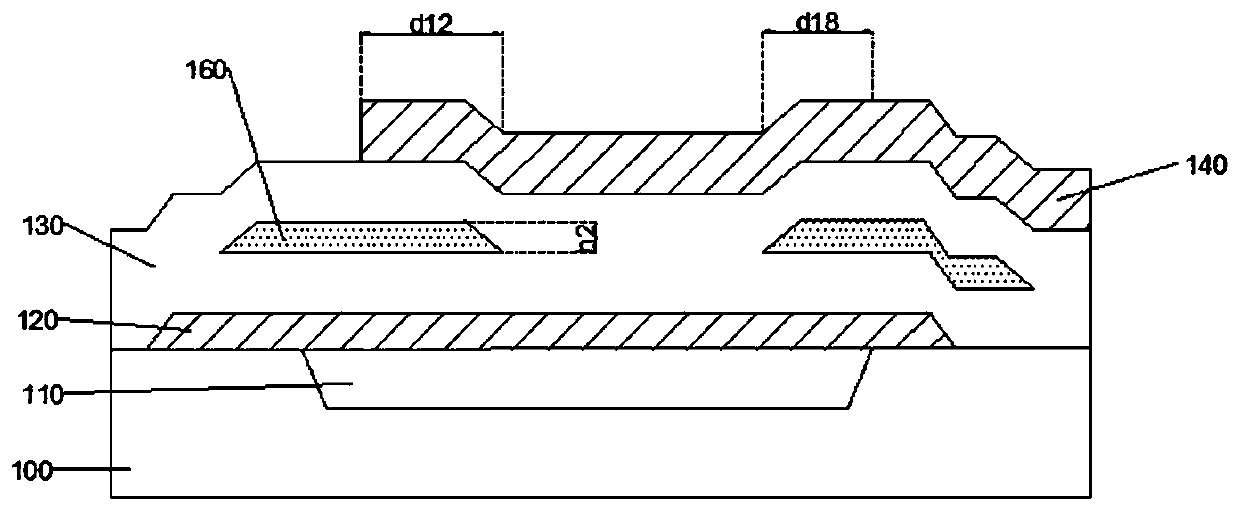

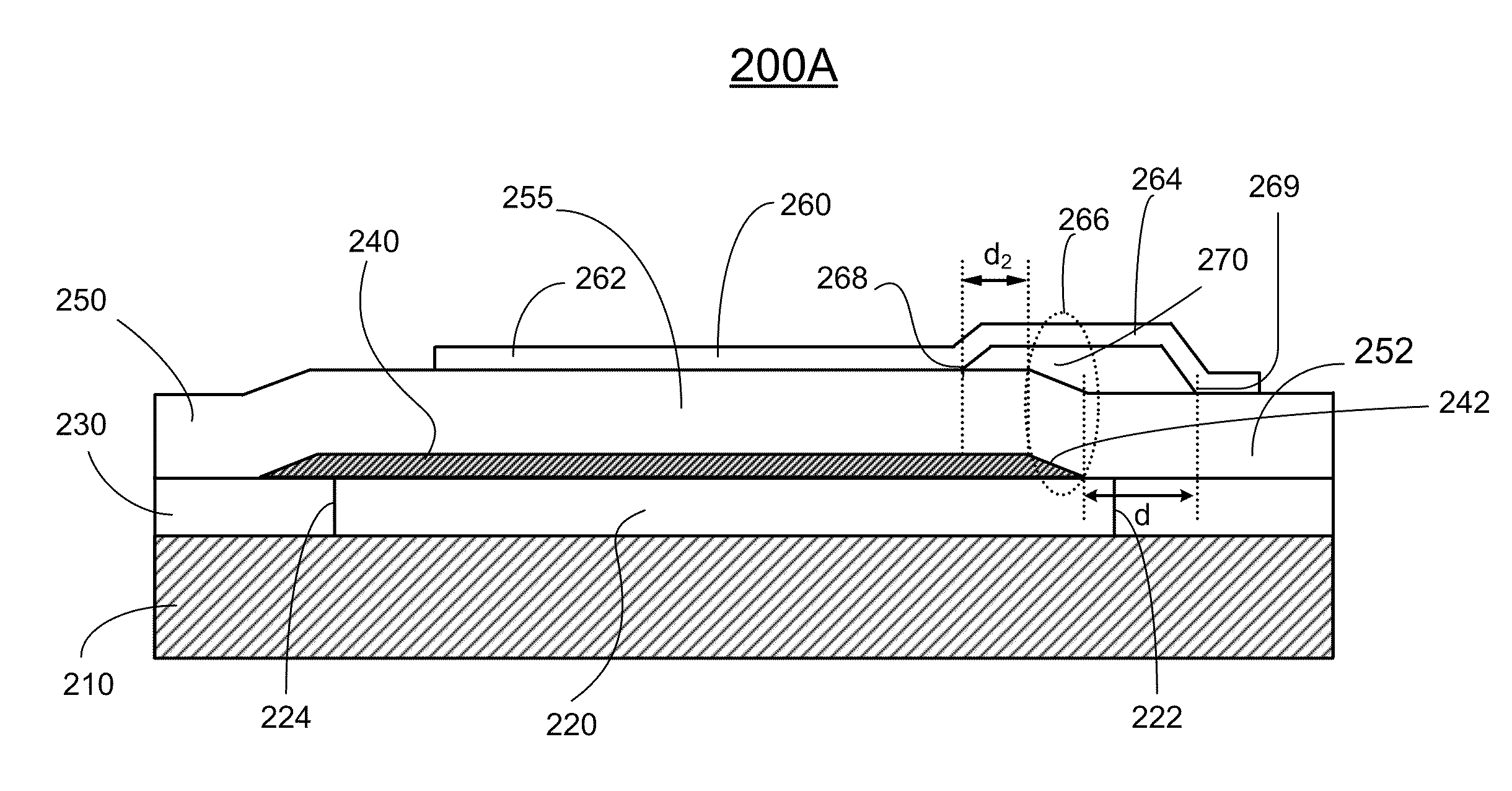

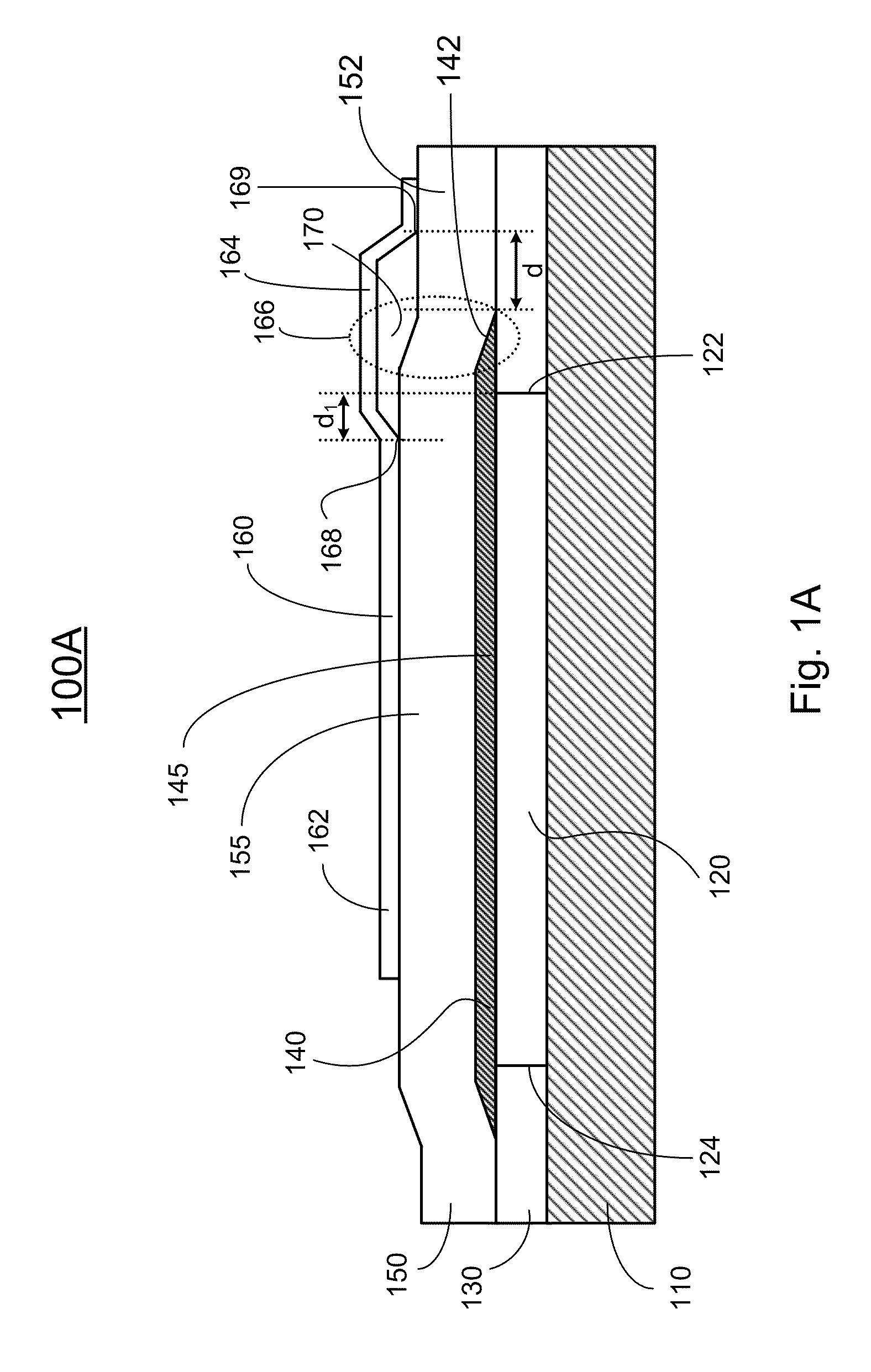

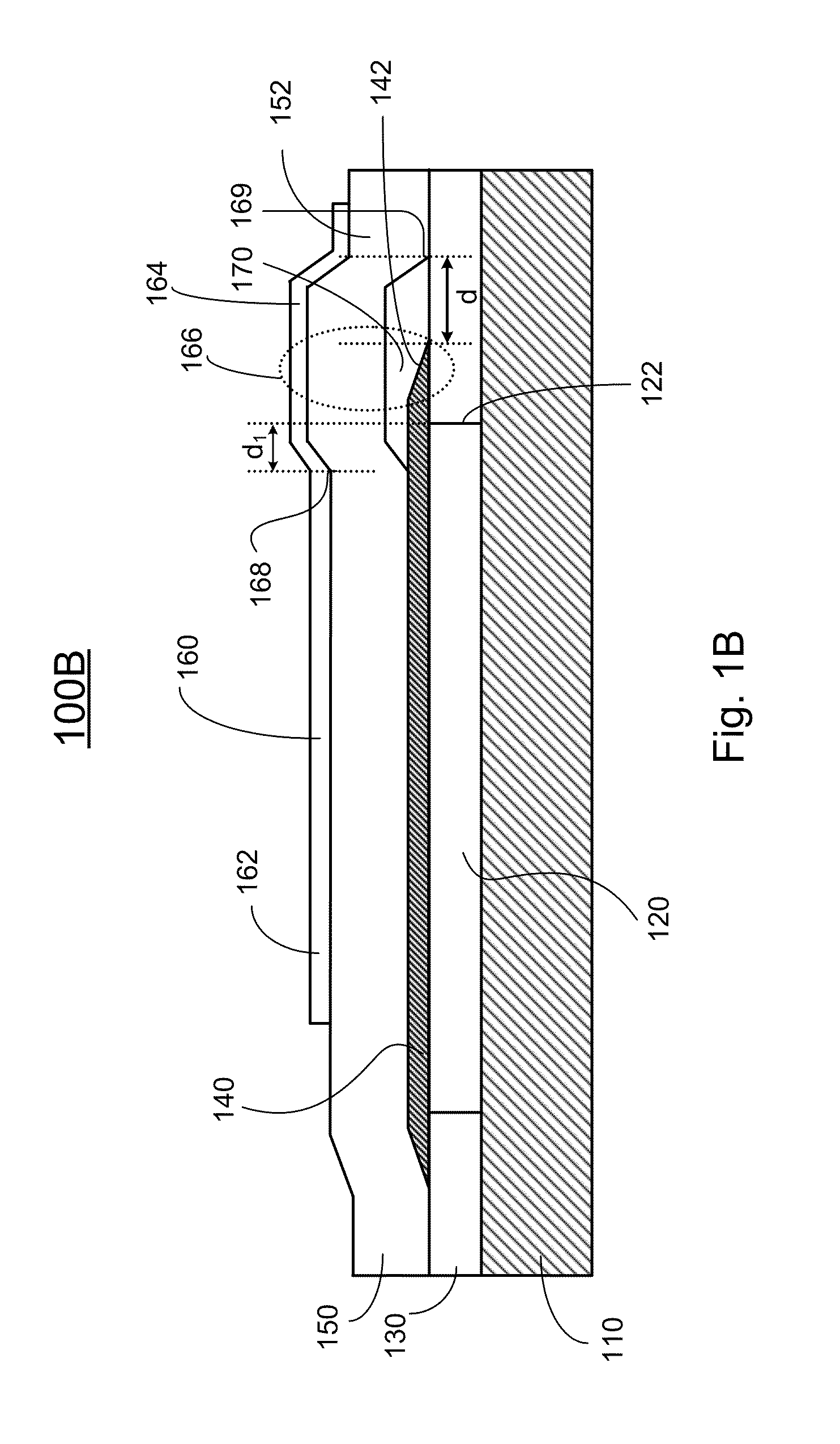

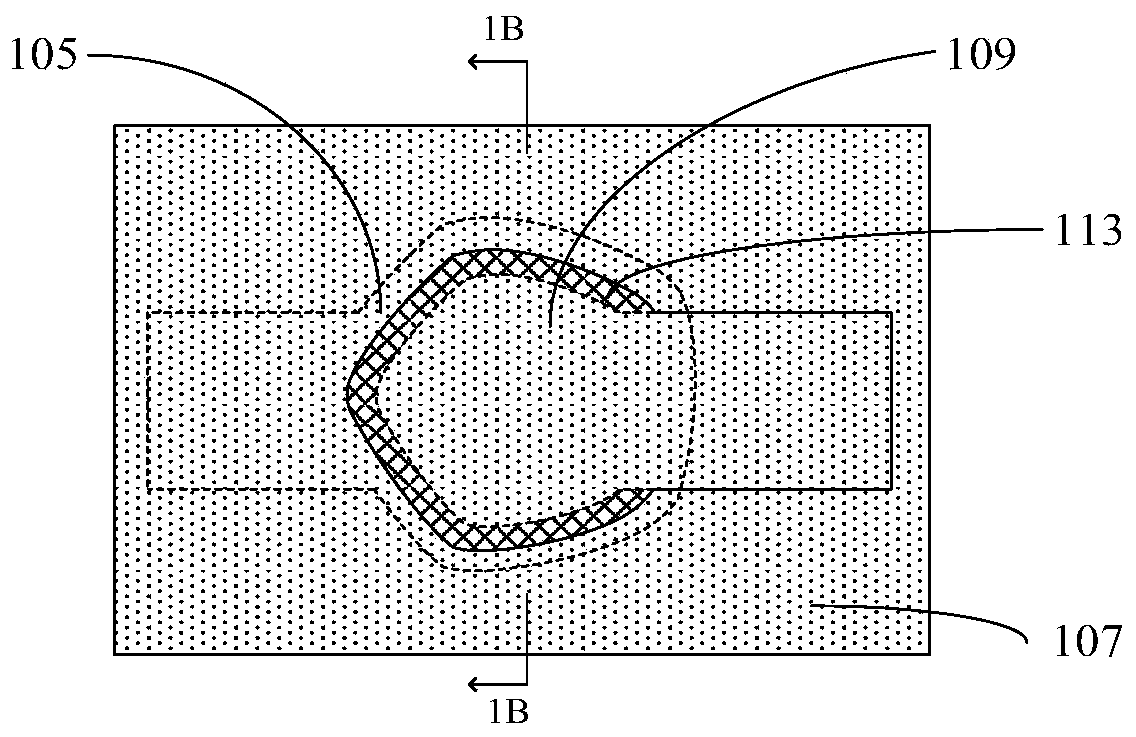

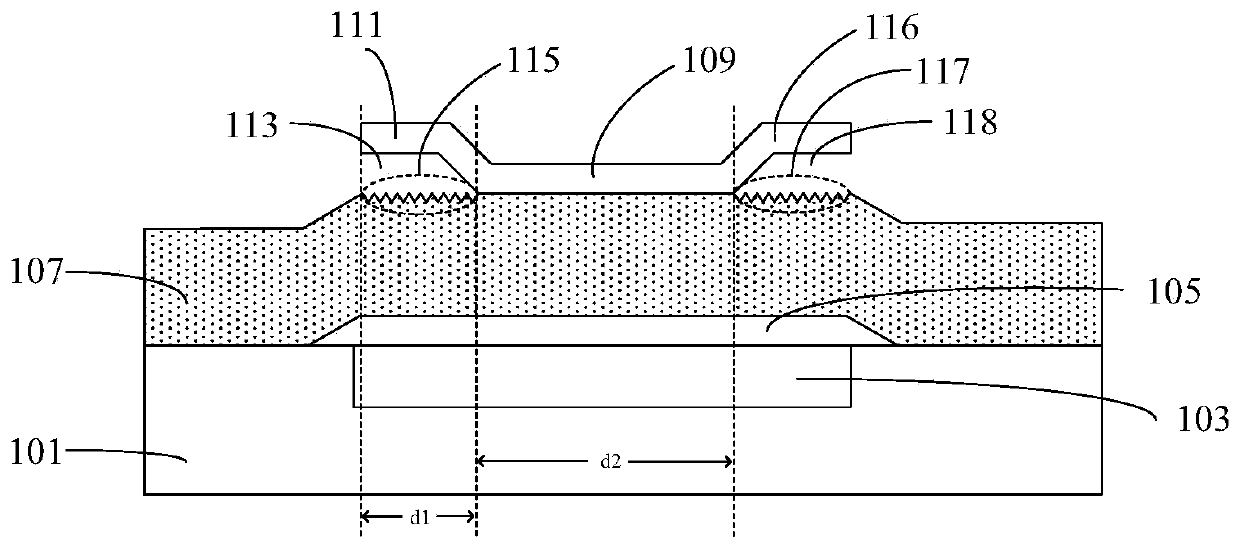

Bulk acoustic wave resonator and method of fabricating same

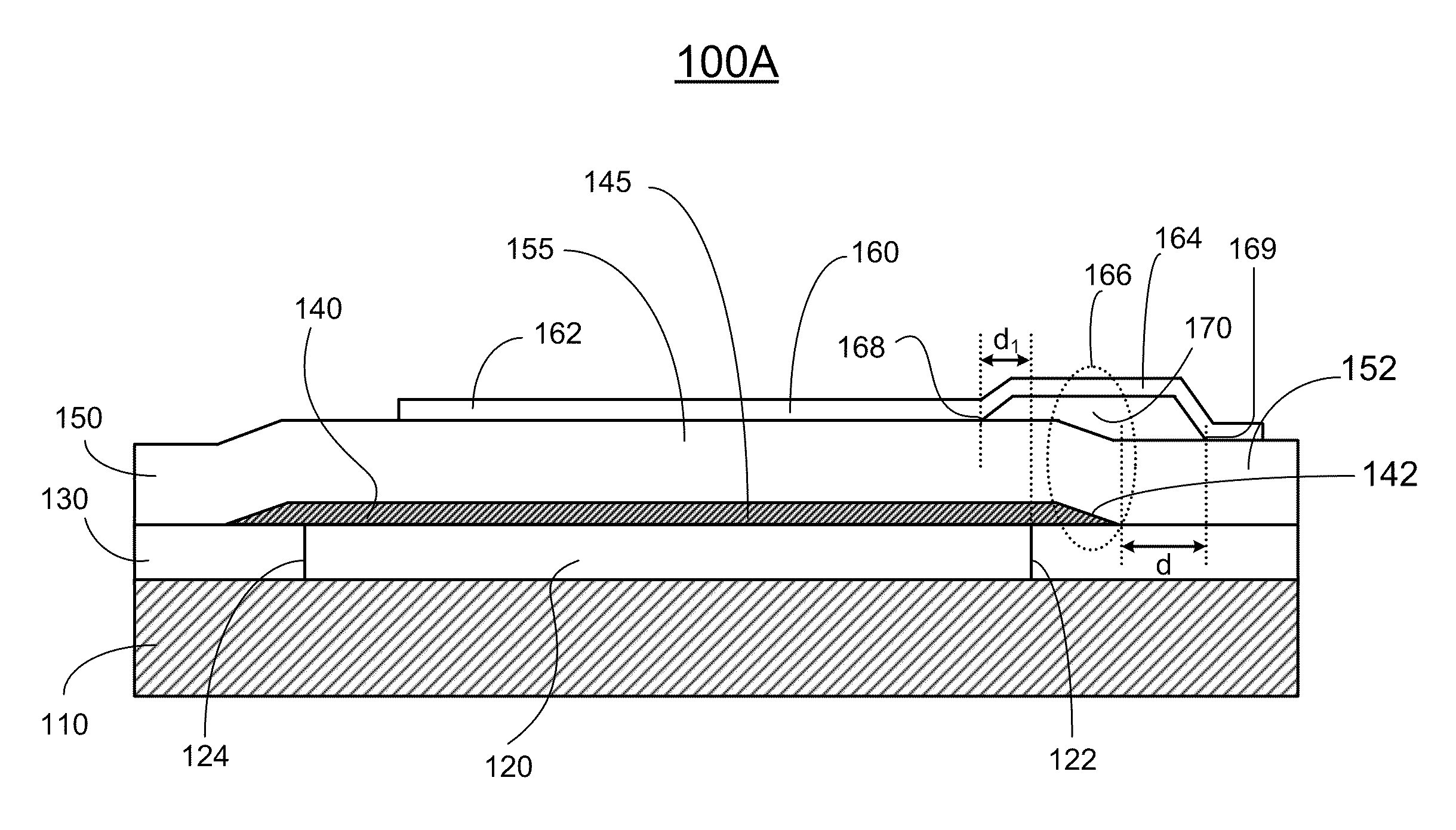

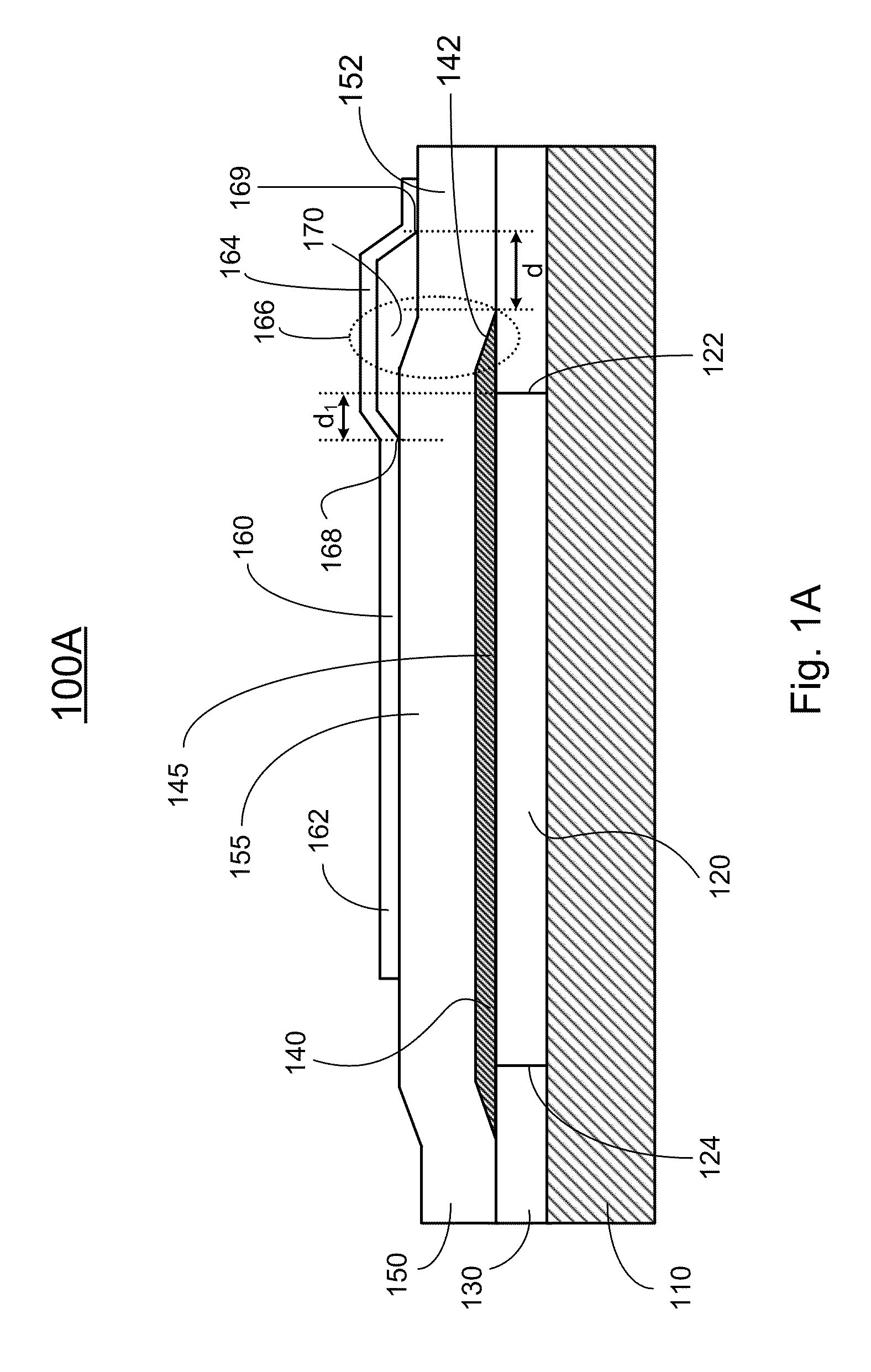

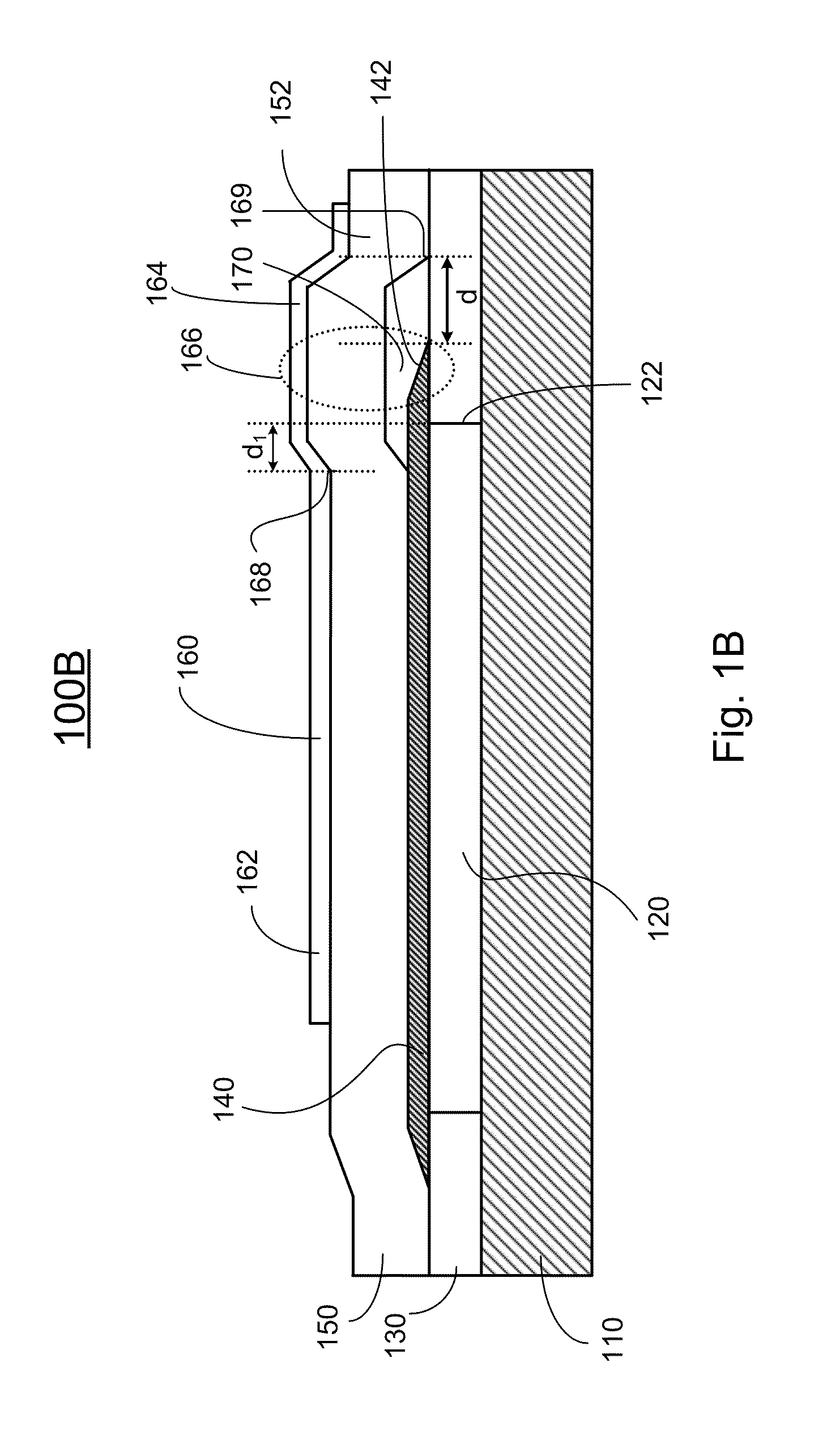

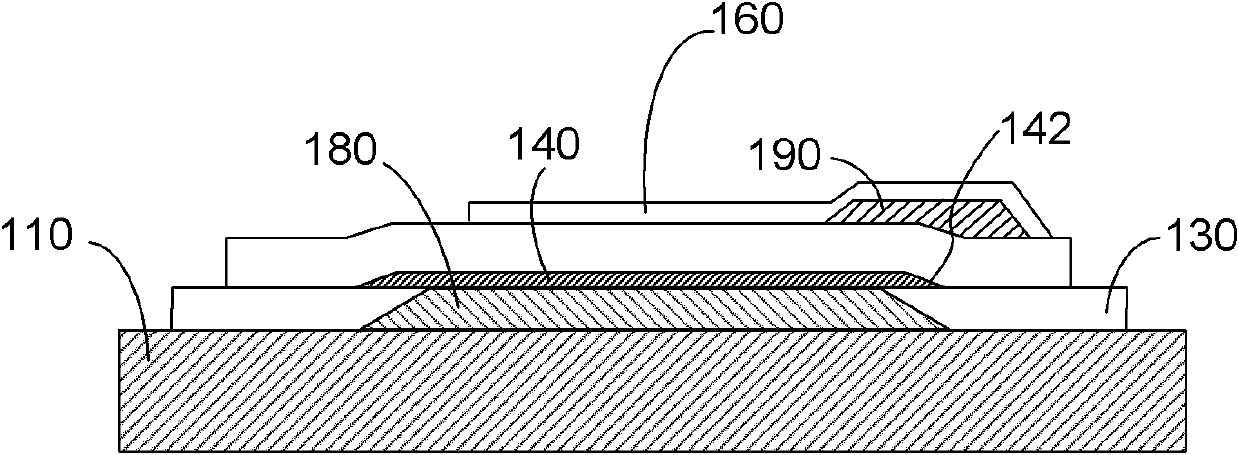

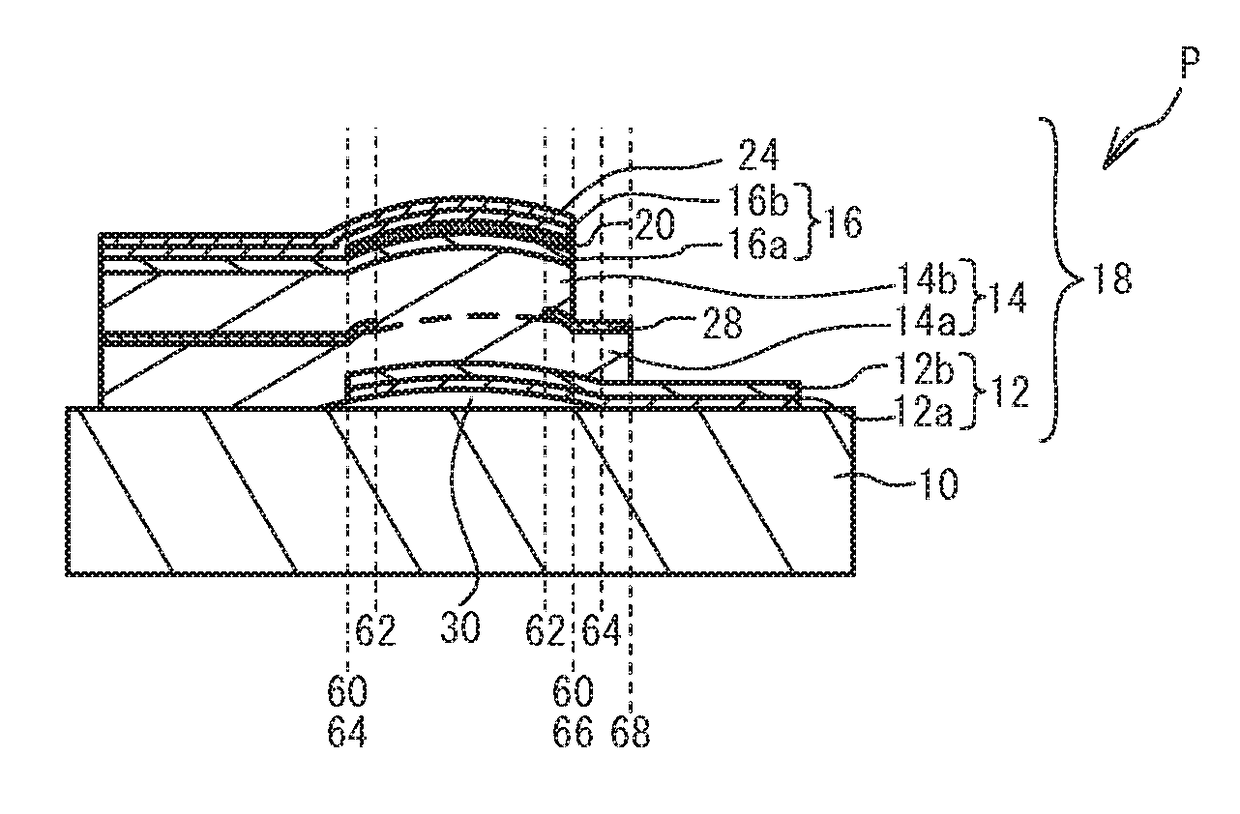

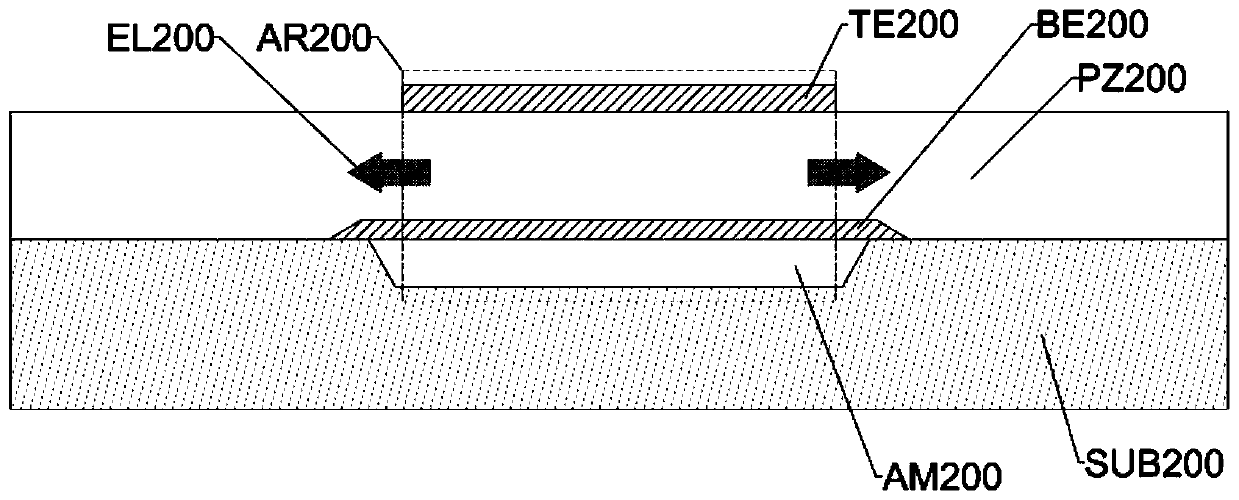

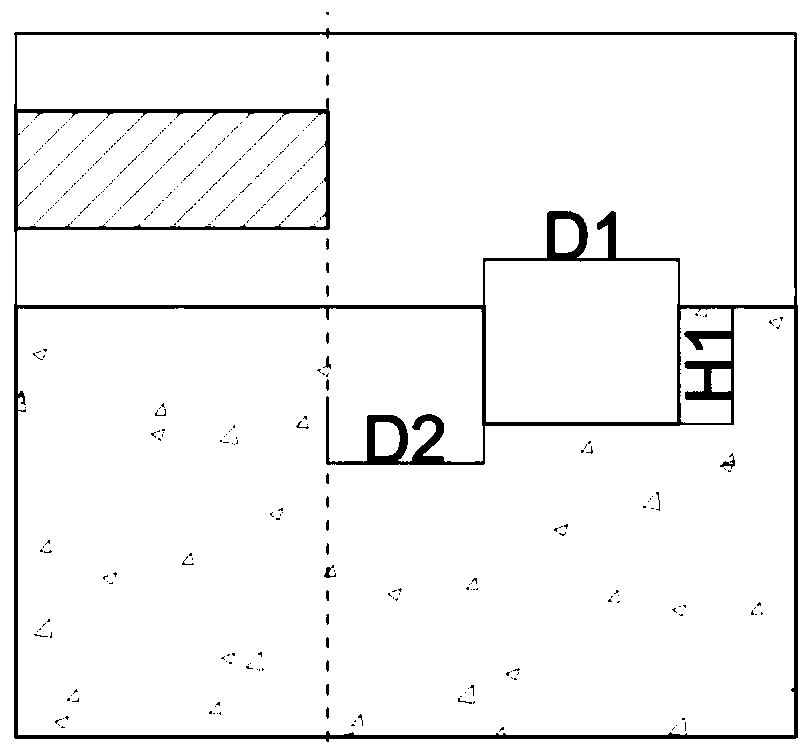

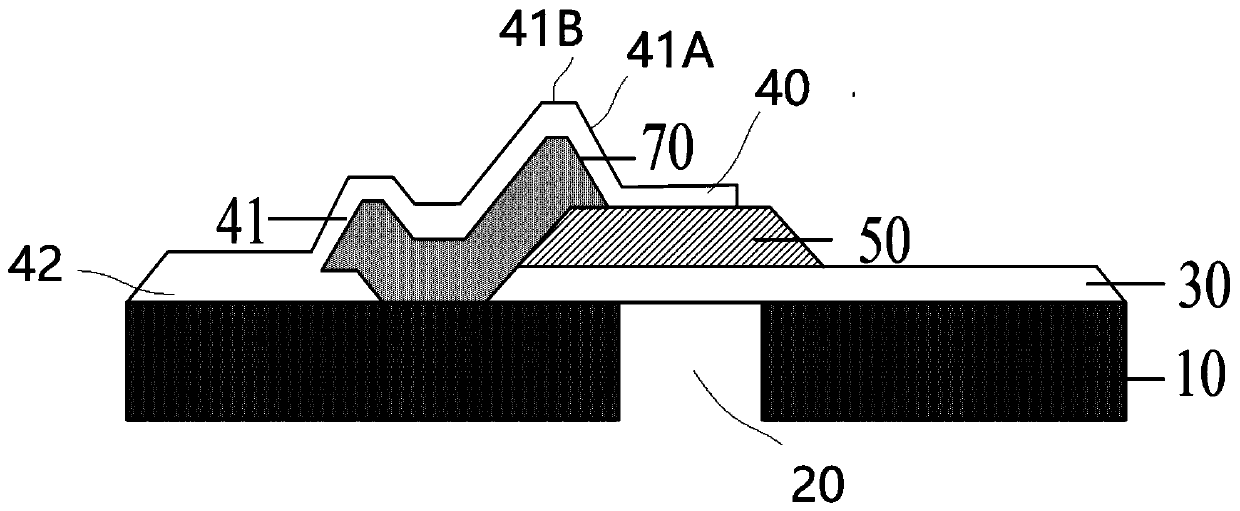

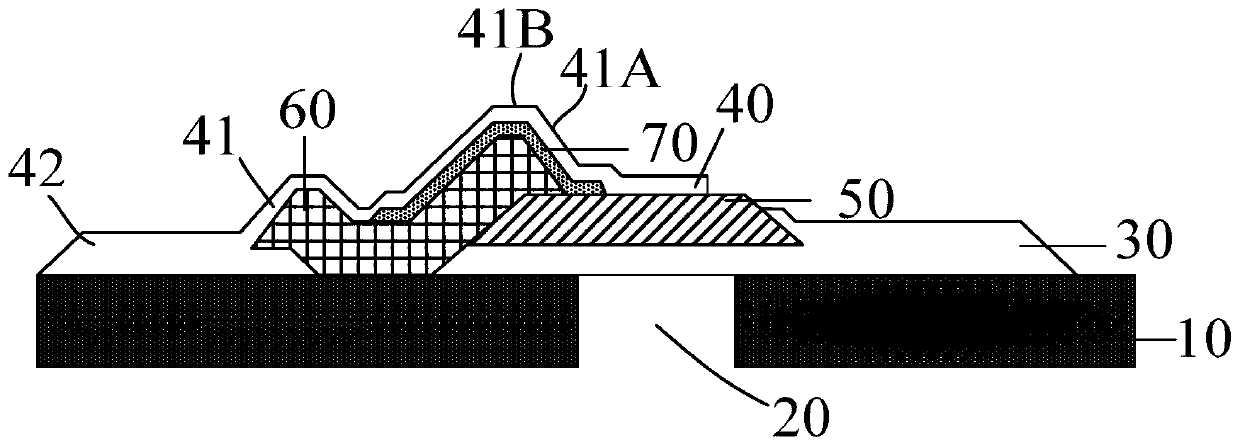

An acoustic resonator with improved quality factor and electro-mechanical coupling is disclosed. In one embodiment, the acoustic resonator includes an acoustic mirror formed on the top surface of a substrate or in the substrate, a first electrode having a end portion, formed on the acoustic mirror, a piezoelectric layer formed on the first electrode; and a second electrode formed on the piezoelectric layer, where at least one of the first electrode and the second electrode and the piezoelectric layer define an air gap in a region that overlaps the end portion of the first electrode. In one embodiment, a dielectric film is deposited on the surface of the end portion of the first electrode to form completely planarized surface before the piezoelectric layer deposition. In another embodiment, an air gap between the second electrode and the piezoelectric layer, so that the piezoelectric coupling in the end portion area of the first electrode is minimally contributed into the whole resonator.

Owner:AVAGO TECH INT SALES PTE LTD

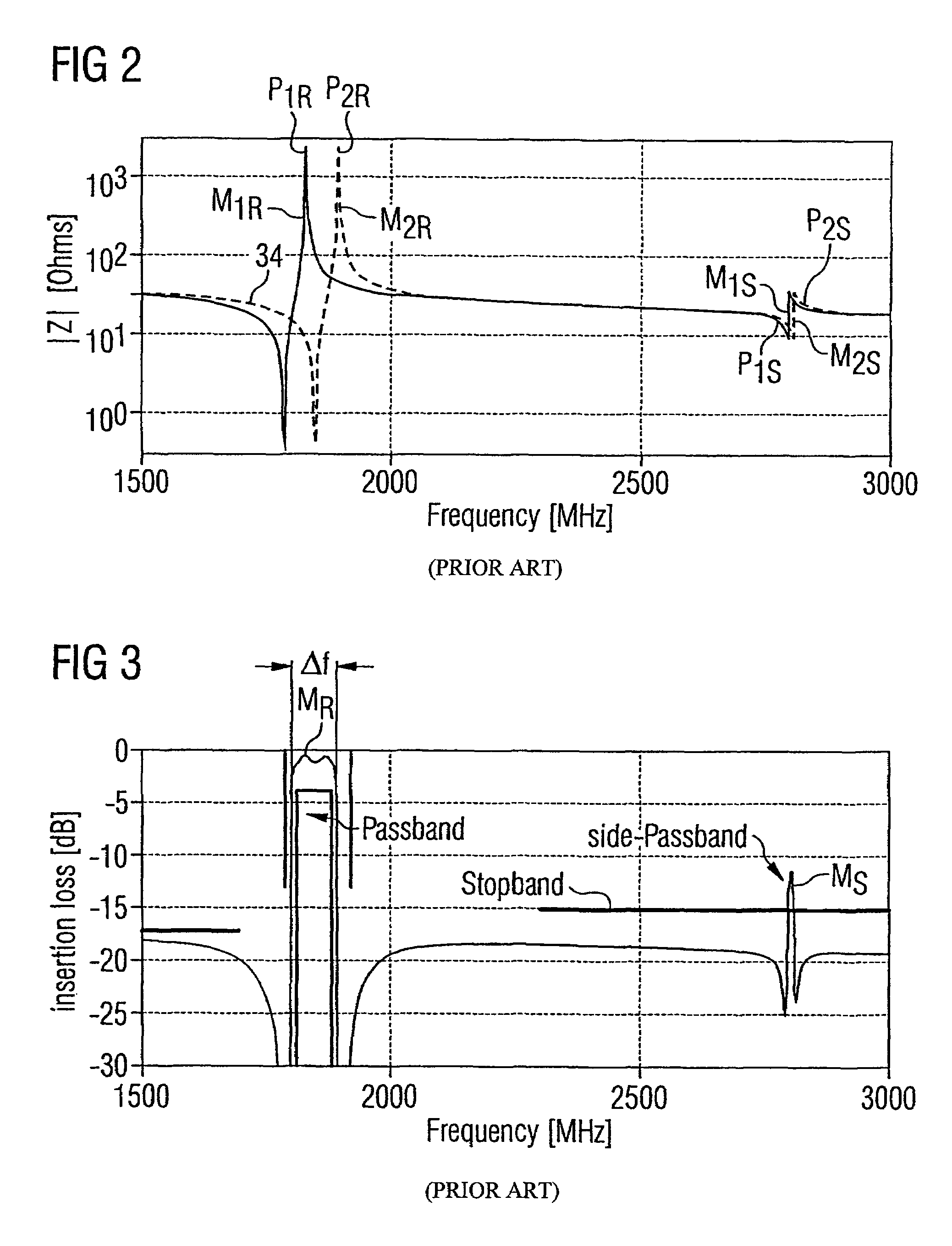

Bulk acoustic wave filter and method for eliminating unwanted side passbands

ActiveUS7439824B2Suppression frequencyImpedence networksPiezoelectric/electrostrictive devicesThin-film bulk acoustic resonatorAcoustic wave

Owner:AVAGO TECH INT SALES PTE LTD

Piezoelectric resonator structure

ActiveUS20110148547A1Impedence networksPiezoelectric/electrostriction/magnetostriction machinesAcousticsAcoustic mirror

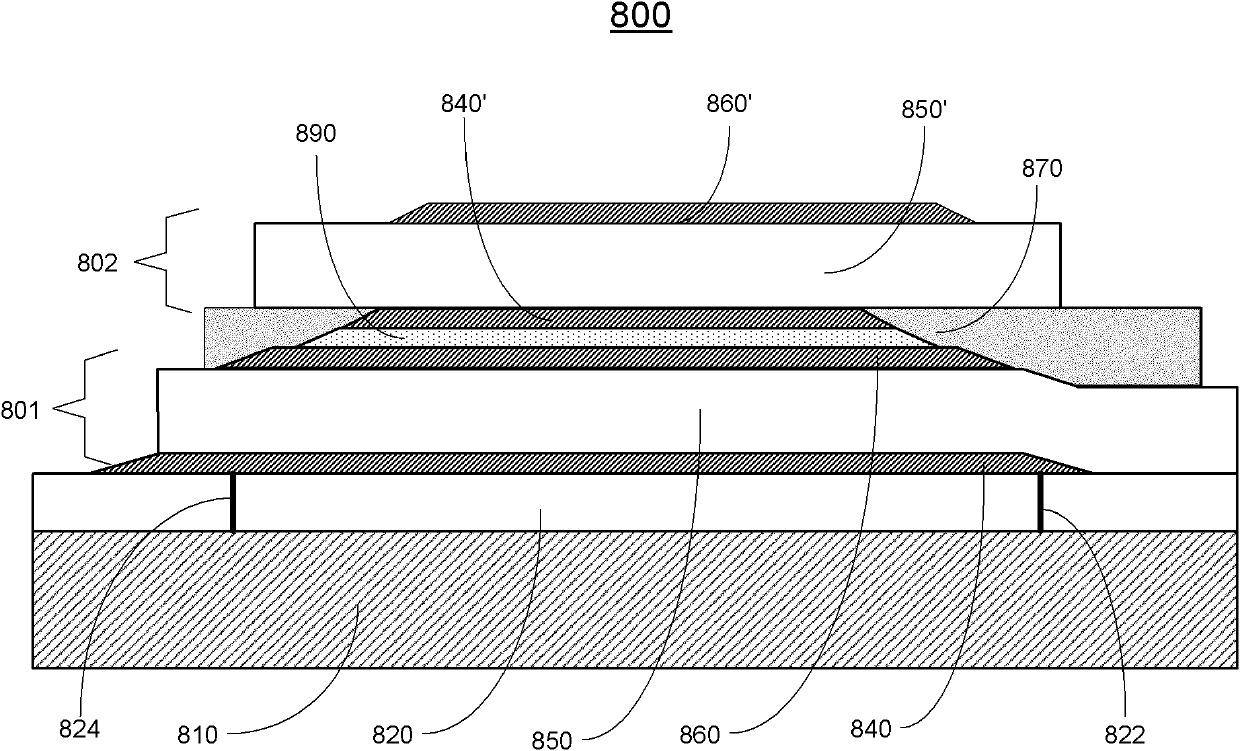

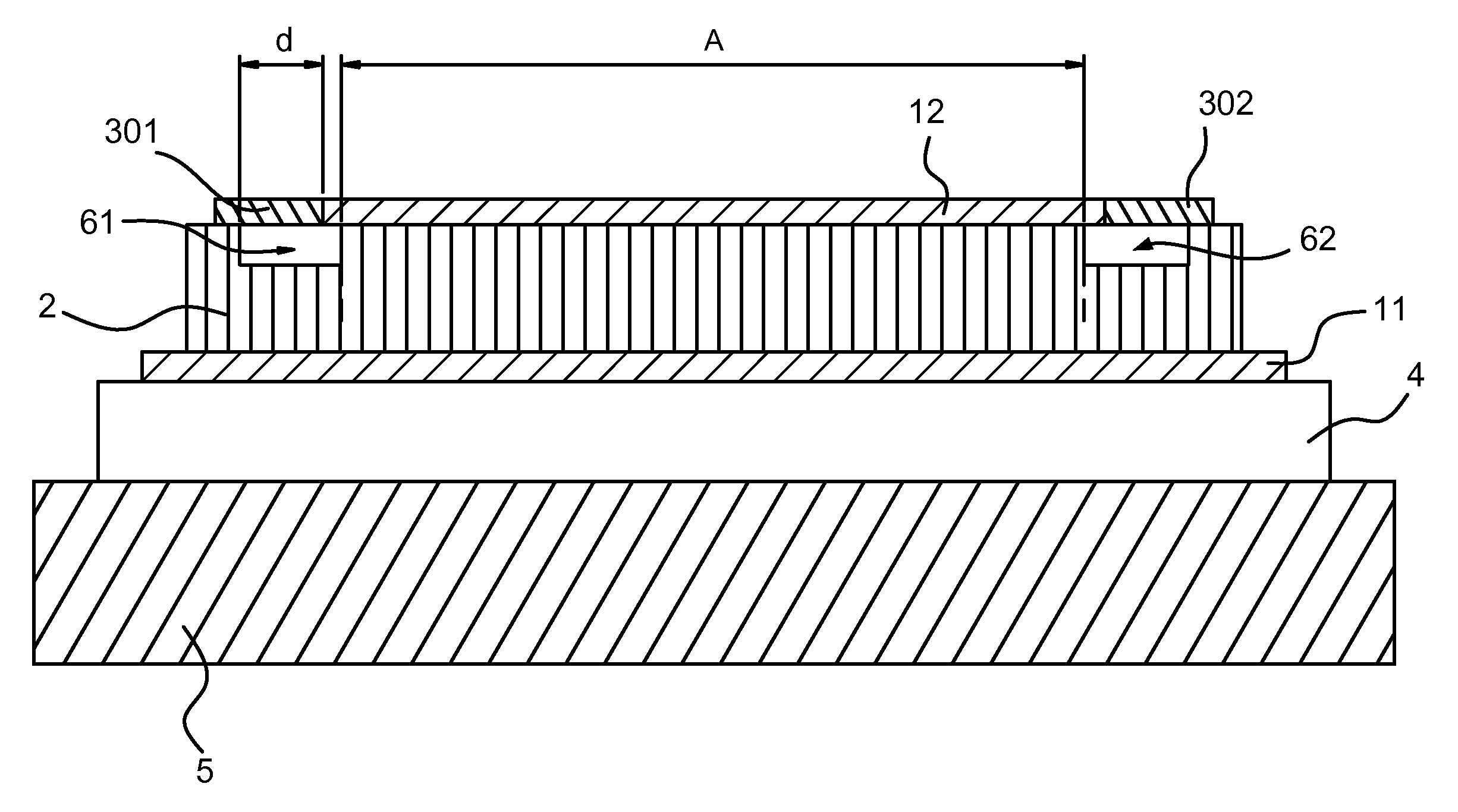

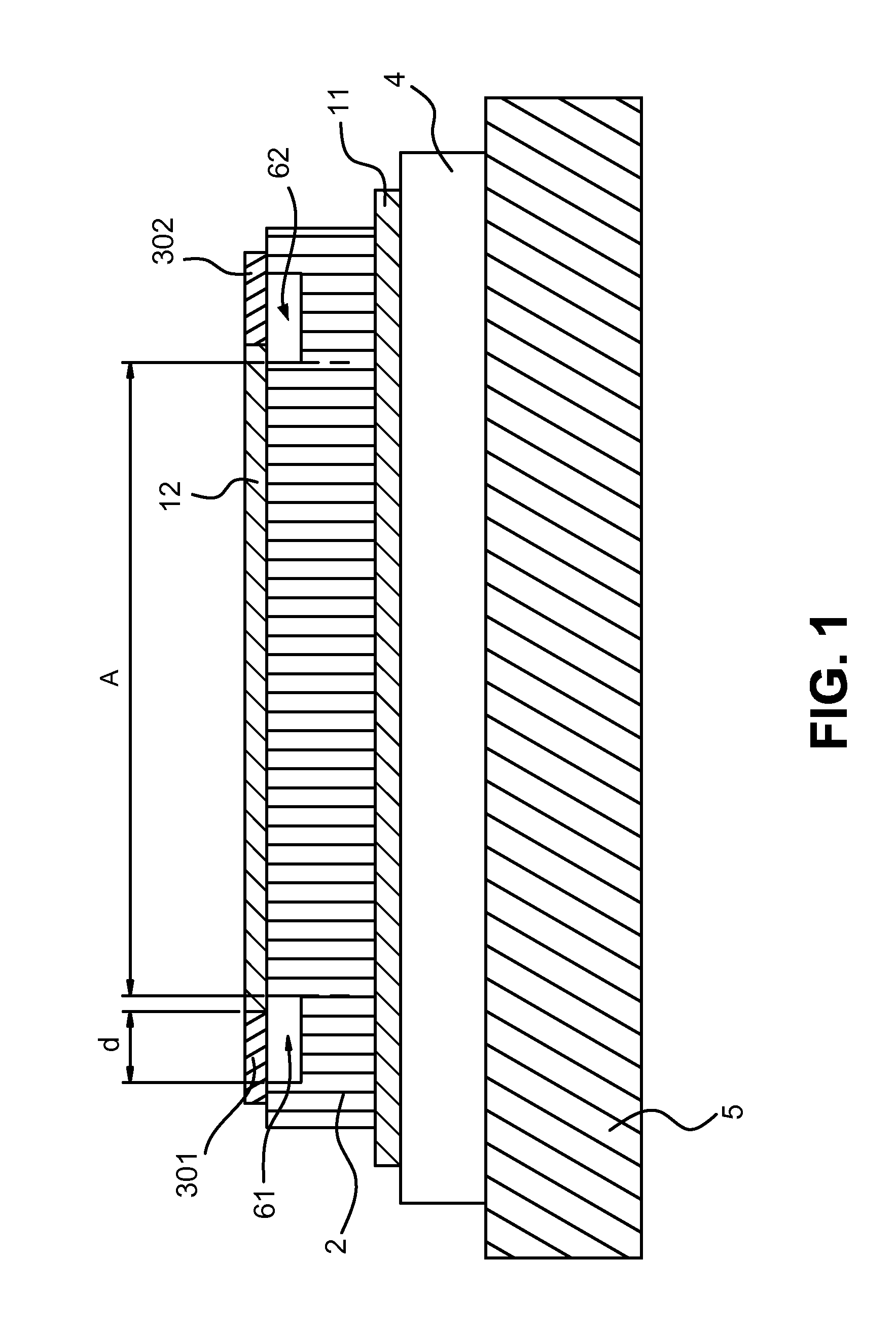

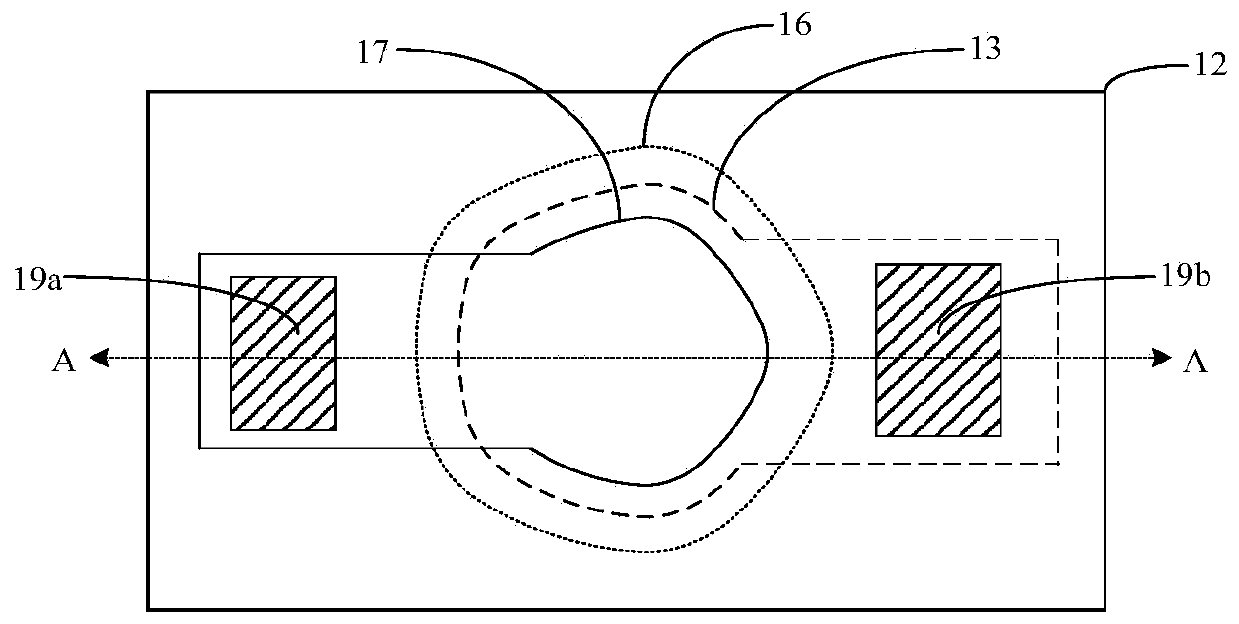

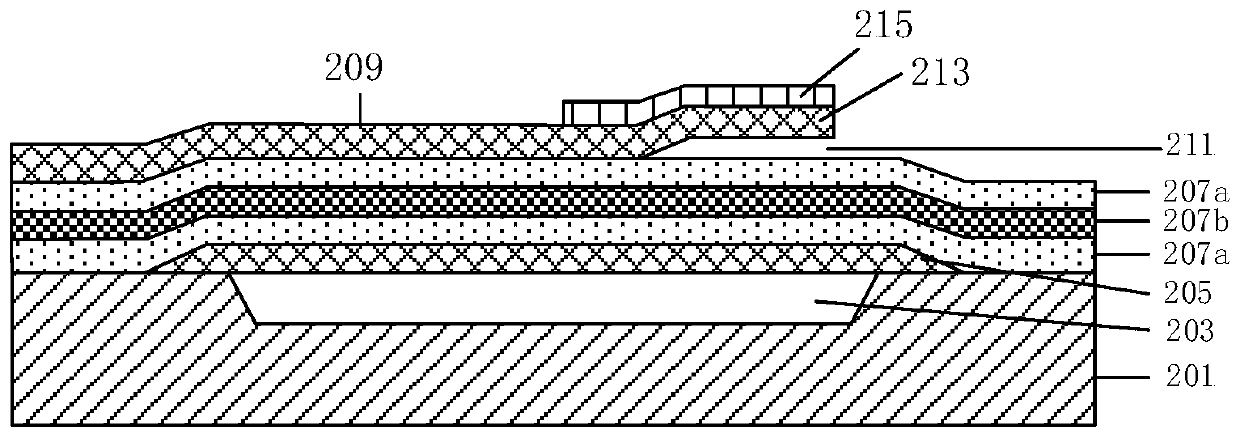

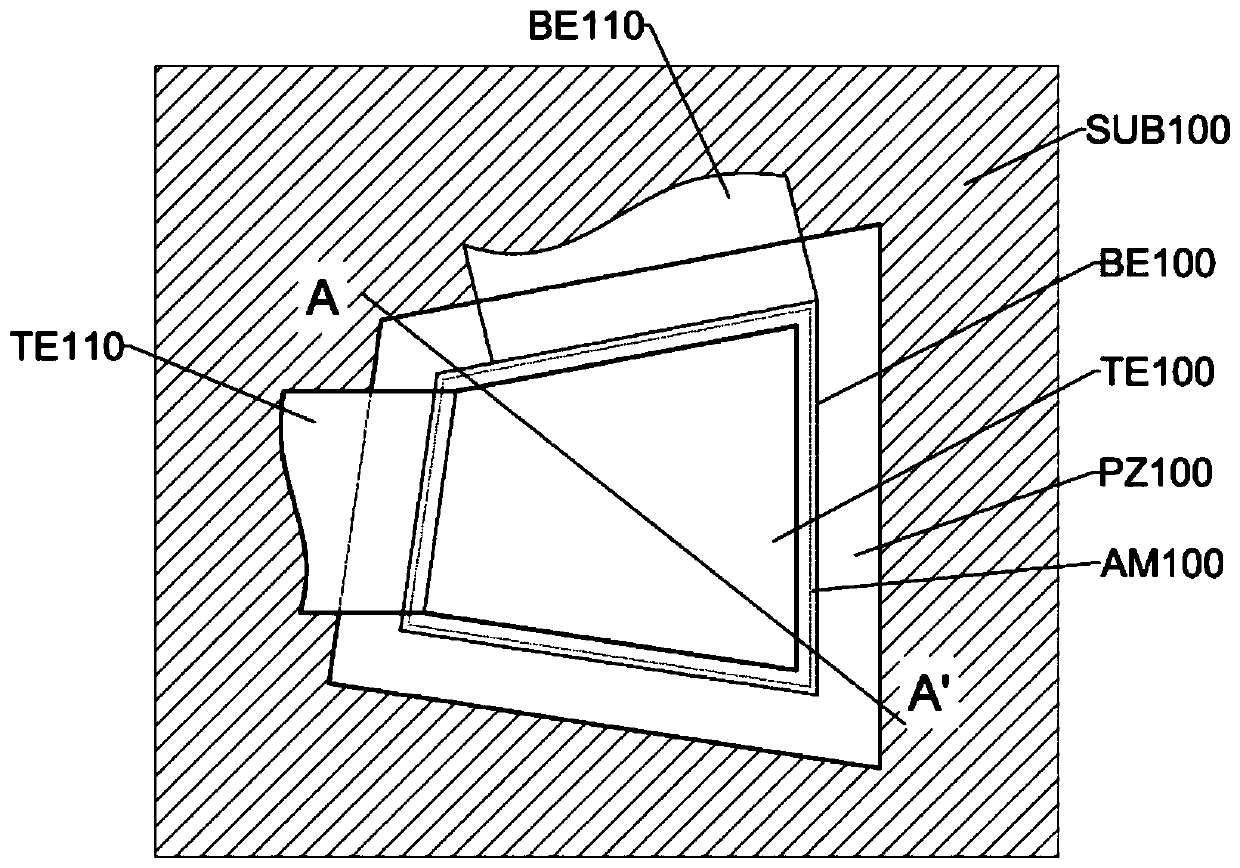

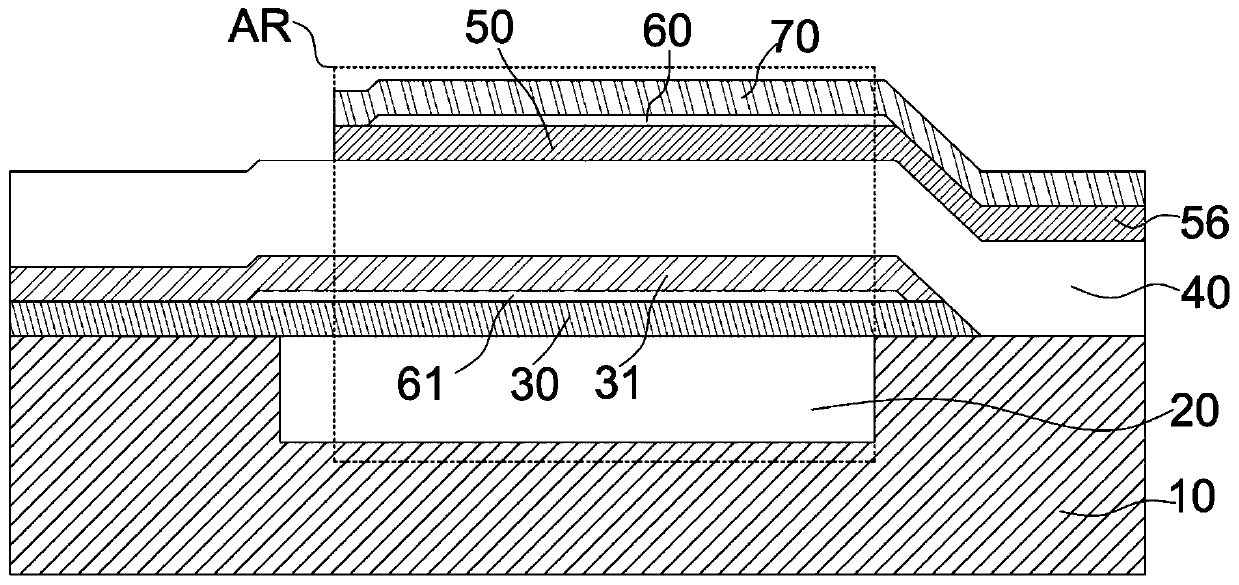

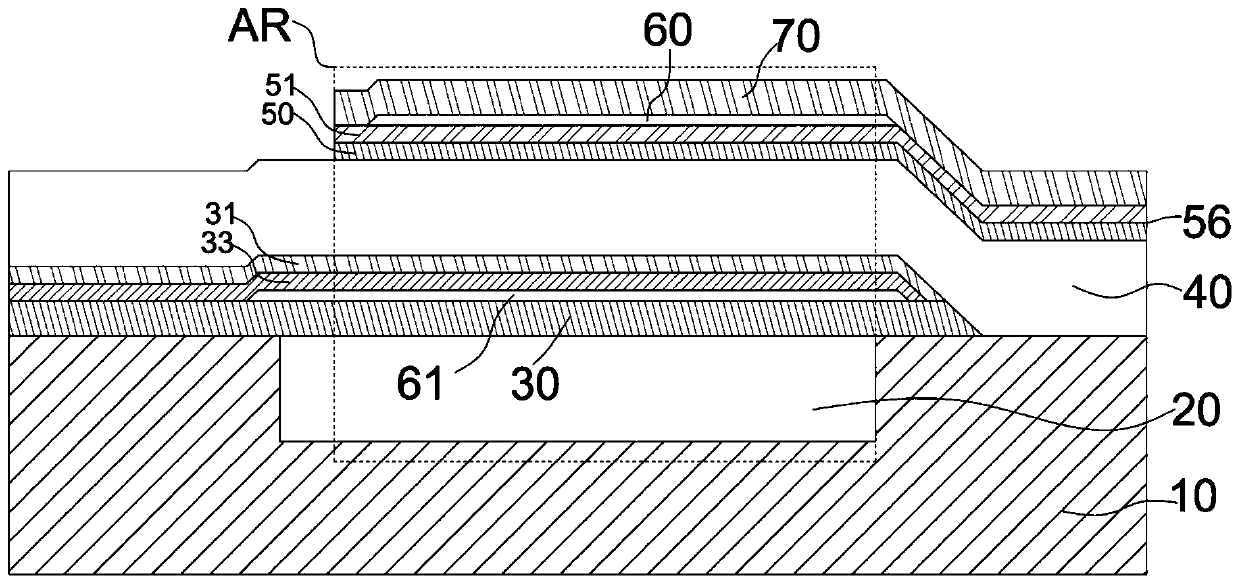

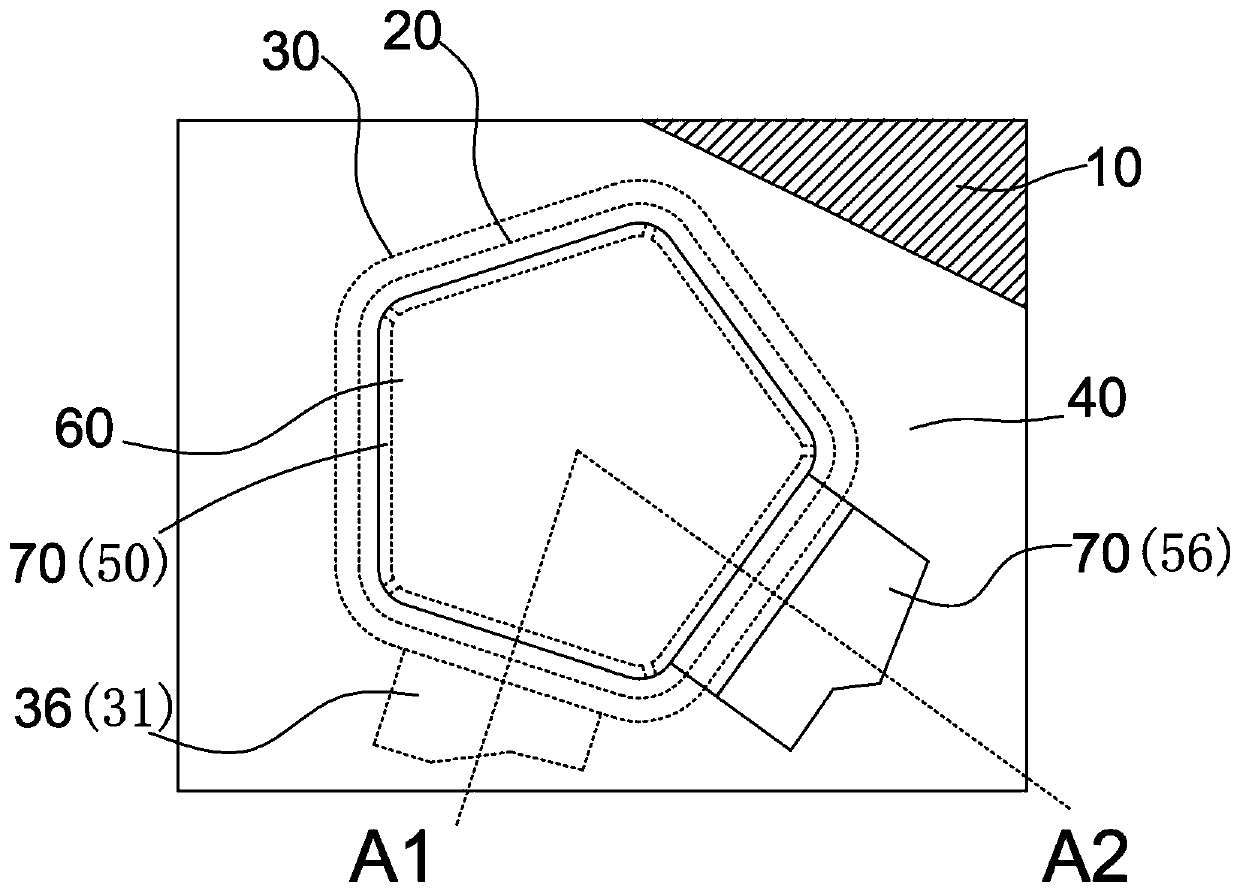

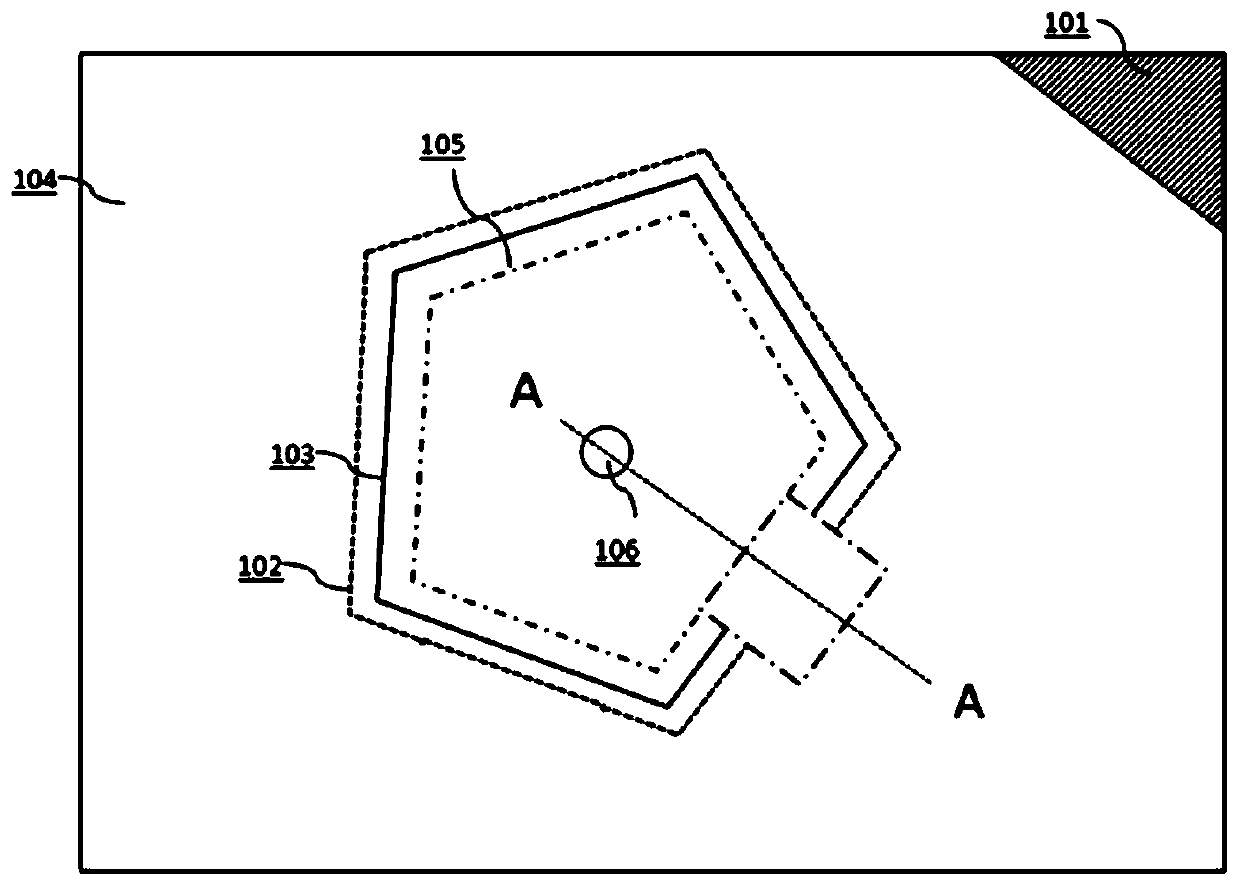

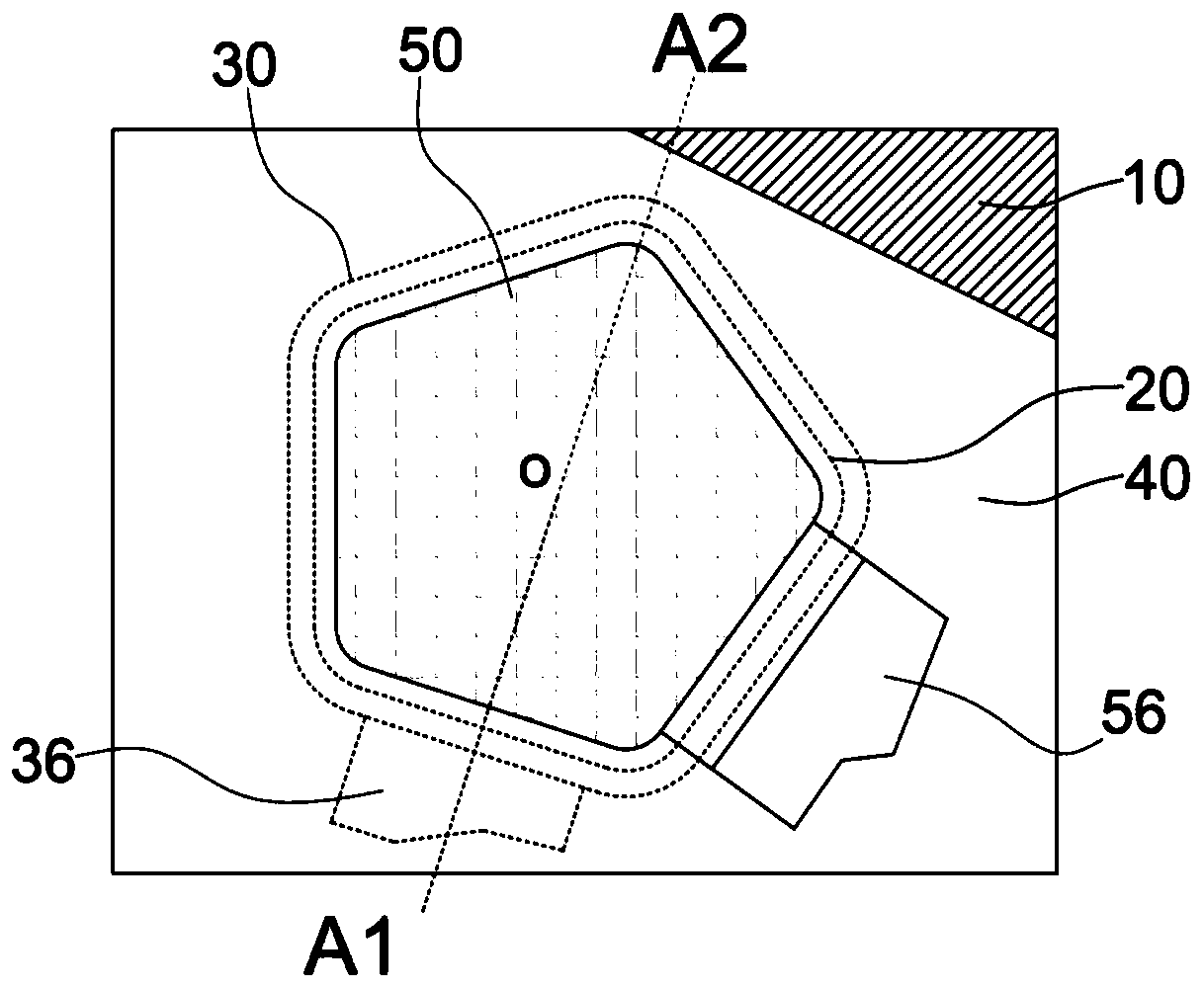

A piezoelectric resonator structure, comprising: (i) a substrate, (ii) an acoustic mirror, (iii) a first electrode, (iv) a piezoelectric layer, and (v) a second electrode, wherein each of the substrate, the acoustic mirror, the first electrode, the piezoelectric layer, and the second electrode has a top surface and a bottom surface, a first end portion and an opposite, second end portion, and a body portion defined therebetween, wherein the overlapped area of body portions of the substrate, the acoustic mirror, the first electrode, the piezoelectric layer and the second electrode is defined as an active area A. A plurality of air gaps and interference structures is formed at the first end portion of the piezoelectric layer and the second electrode, and the second end portion of the piezoelectric layer and the second electrode to enhance the performance of the piezoelectric resonator.

Owner:AVAGO TECH INT SALES PTE LTD

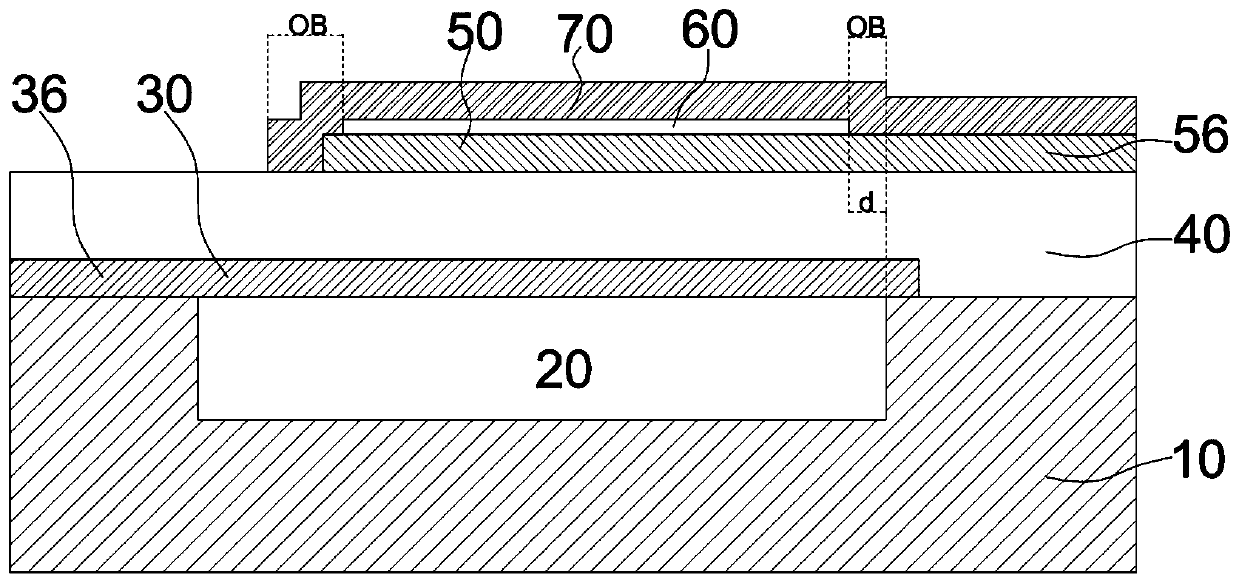

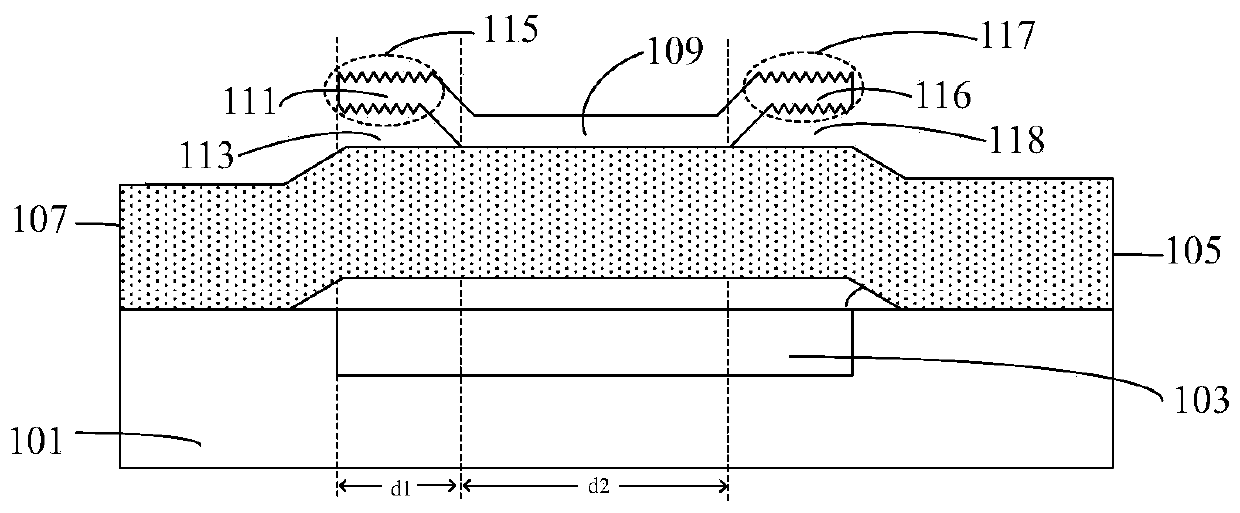

Body wave resonator and processing method thereof

ActiveCN101908865ASimple structureEasy to processImpedence networksElectromechanical coupling coefficientBody waves

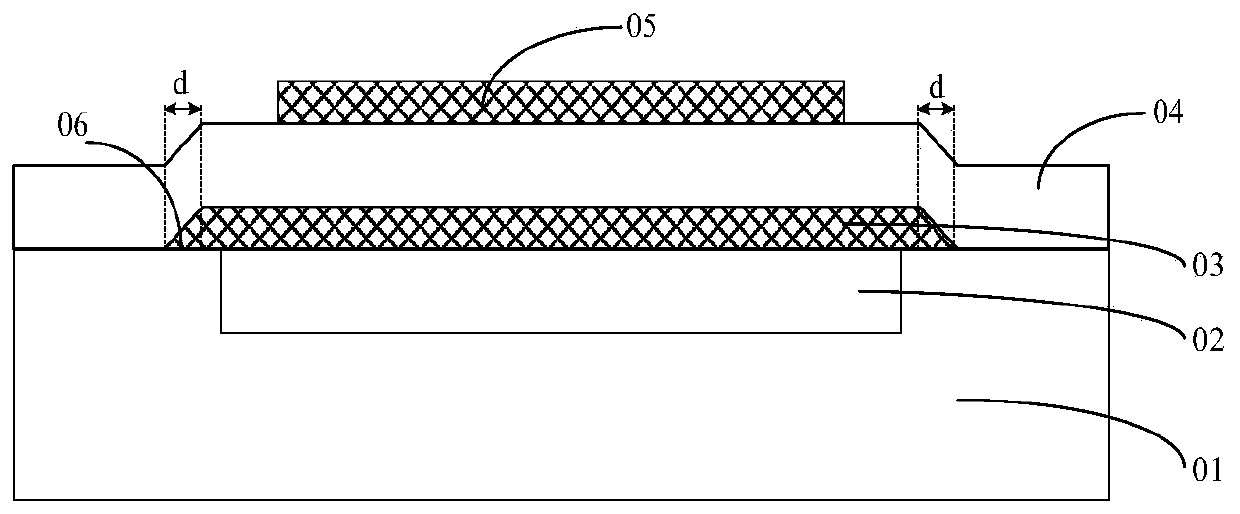

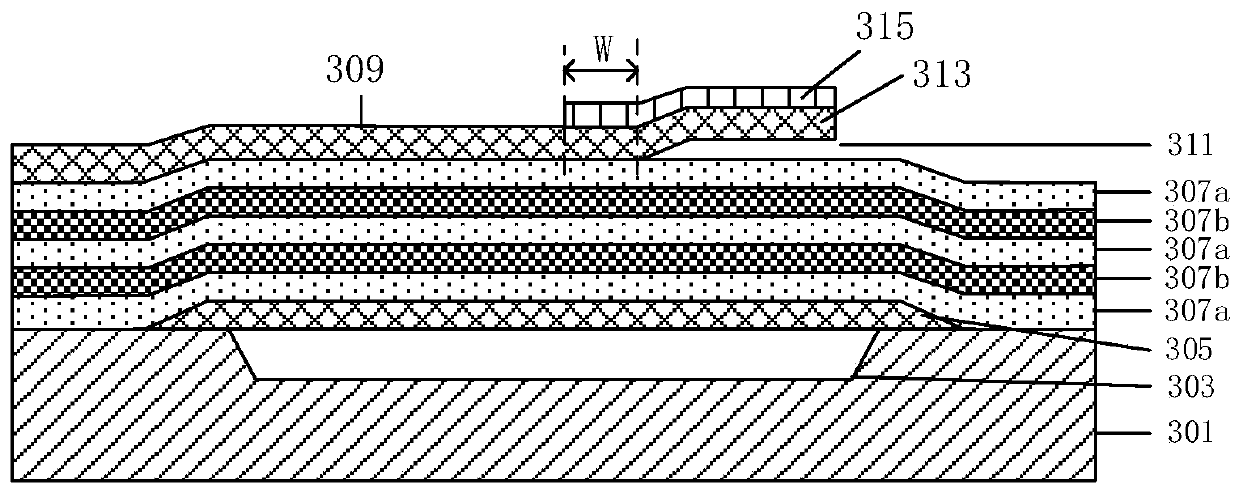

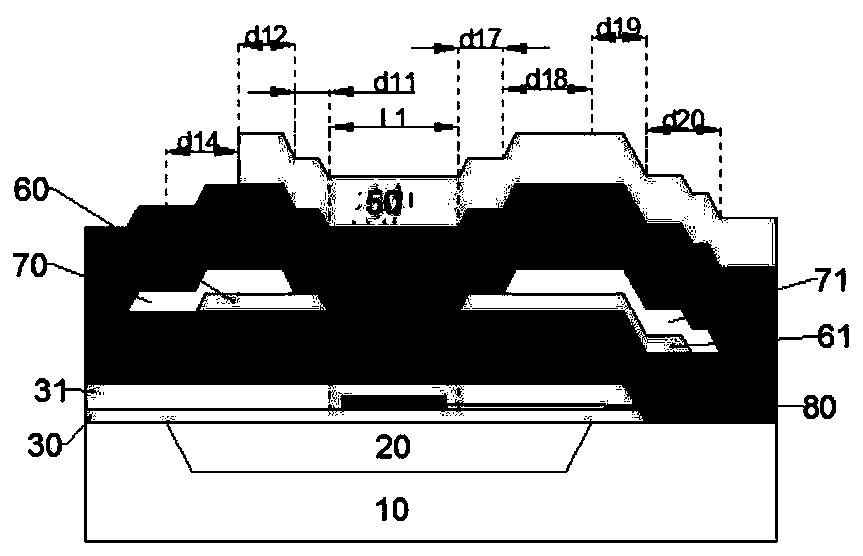

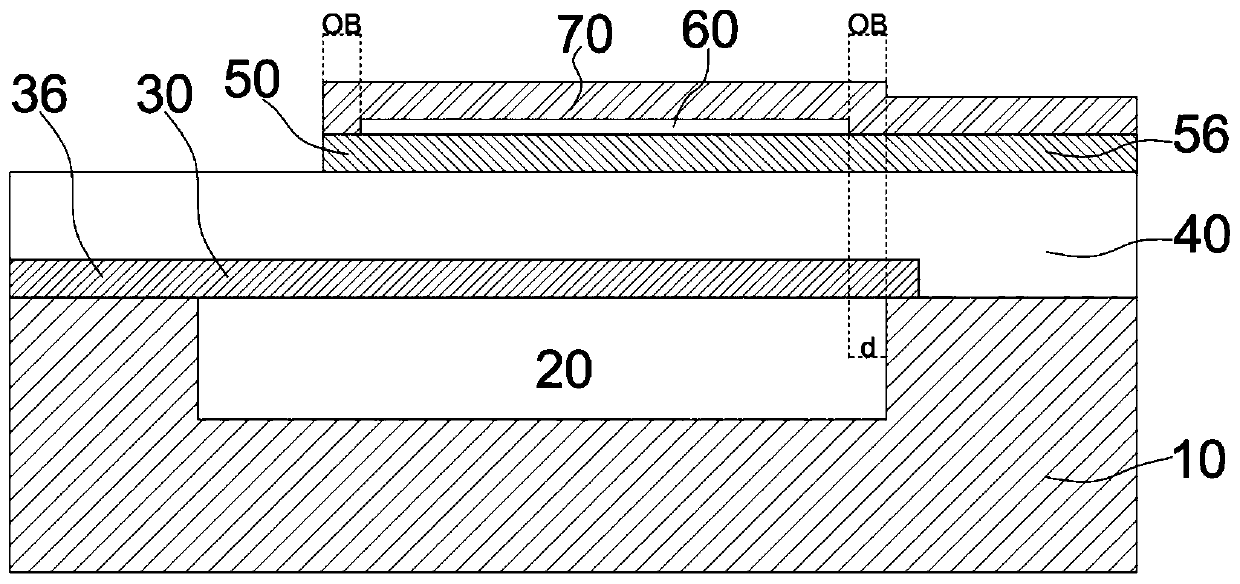

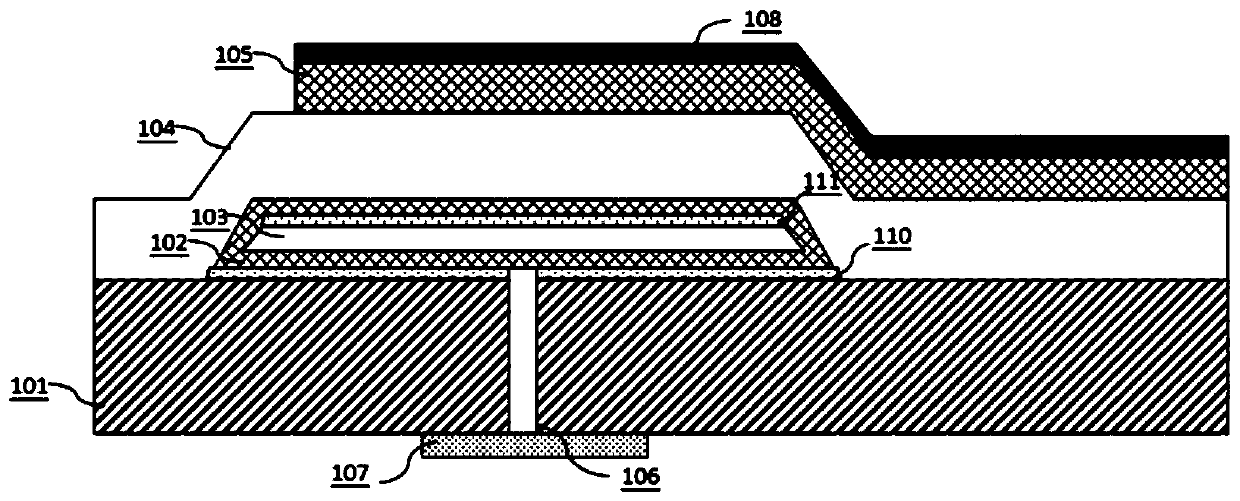

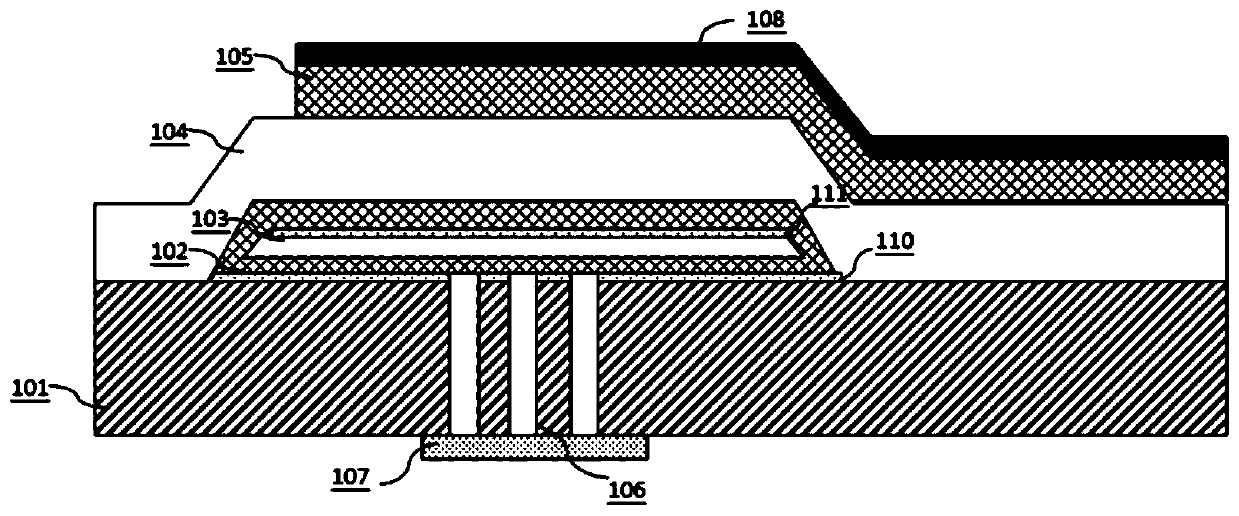

The invention relates to a body wave resonator and a processing method thereof. The body wave resonator comprises an acoustic mirror arranged on or embedded in a substrate and provided with a first edge and a second edge, a dielectric layer which is arranged on the substrate and in full contact with the two edges of the acoustic mirror, a first electrode which is arranged on the acoustic mirror and composed of a first terminal part, a second terminal part and a main part which is arranged between the first and the second terminal parts, a piezoelectric layer which is arranged on the first electrode and composed of a main part, a first terminal part and a second terminal part, and a second electrode which is arranged on the piezoelectric layer and consists of a main part and a second part, wherein the main part is located above the main part of the piezoelectric layer and connected with the second part, so that the connected joint of the main part and the second part is arranged between the first edge and the second edge of the acoustic mirror, and an air gap is formed between the second part of the second electrode and the first terminal part of the piezoelectric layer. The body wave resonator has simple structure and convenient processing, and can improve the quality factor, effective electro-mechanical coupling factor and static discharge resistance capacity.

Owner:ROFS MICROSYST TIANJIN CO LTD

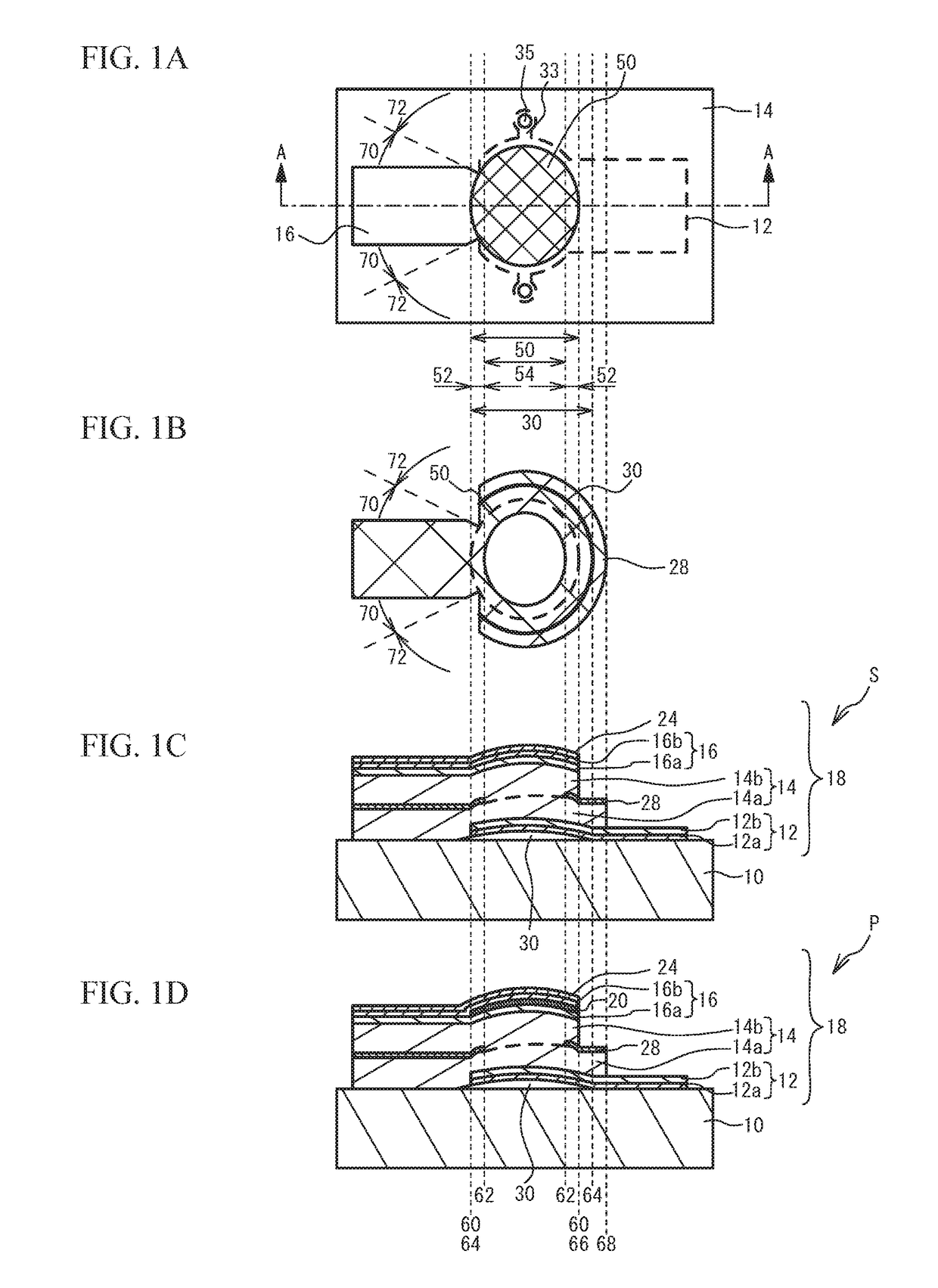

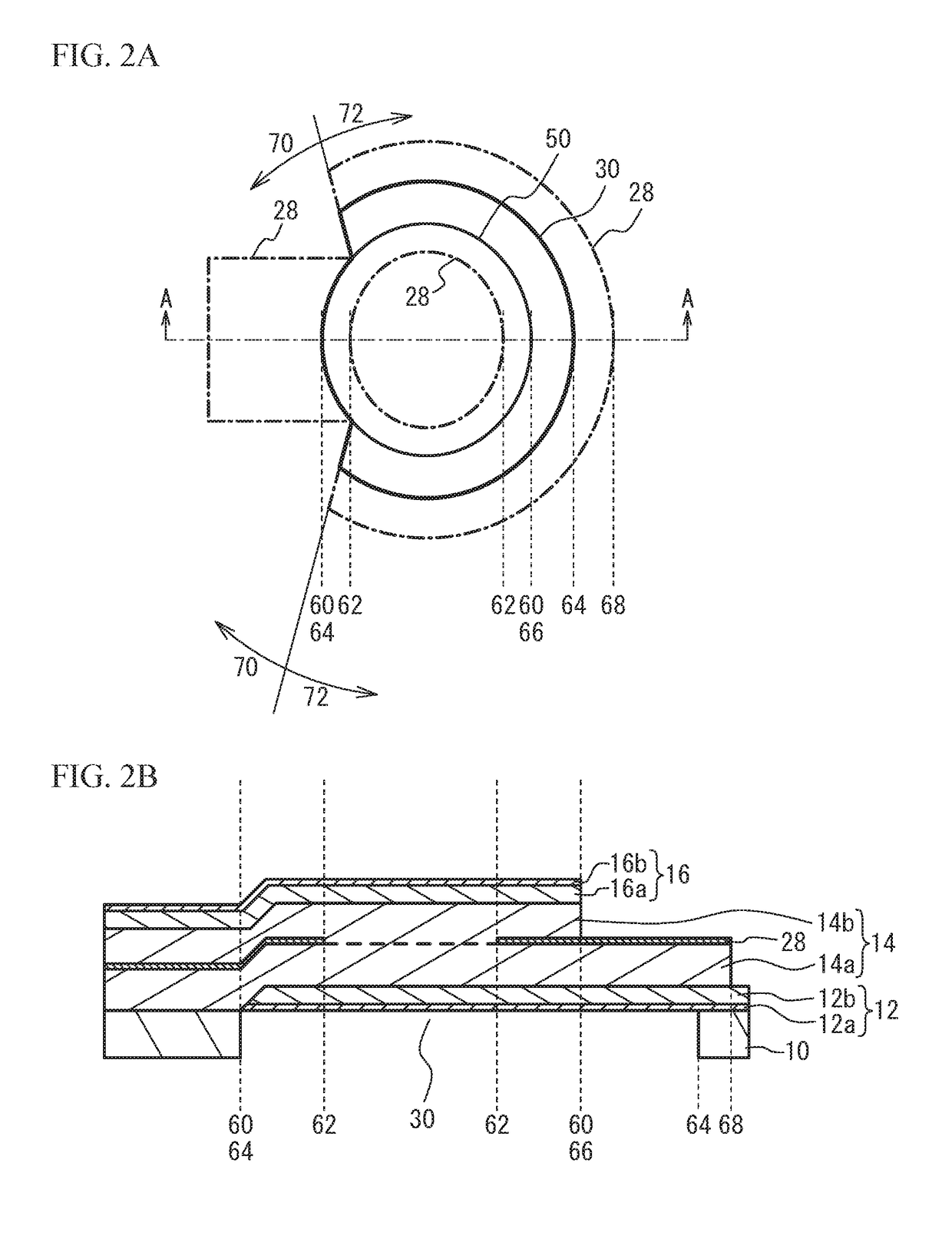

Contour mode resonators with acoustic reflectors

ActiveUS7385334B1Piezoelectric/electrostriction/magnetostriction machinesImpedence networksCMOSRf filters

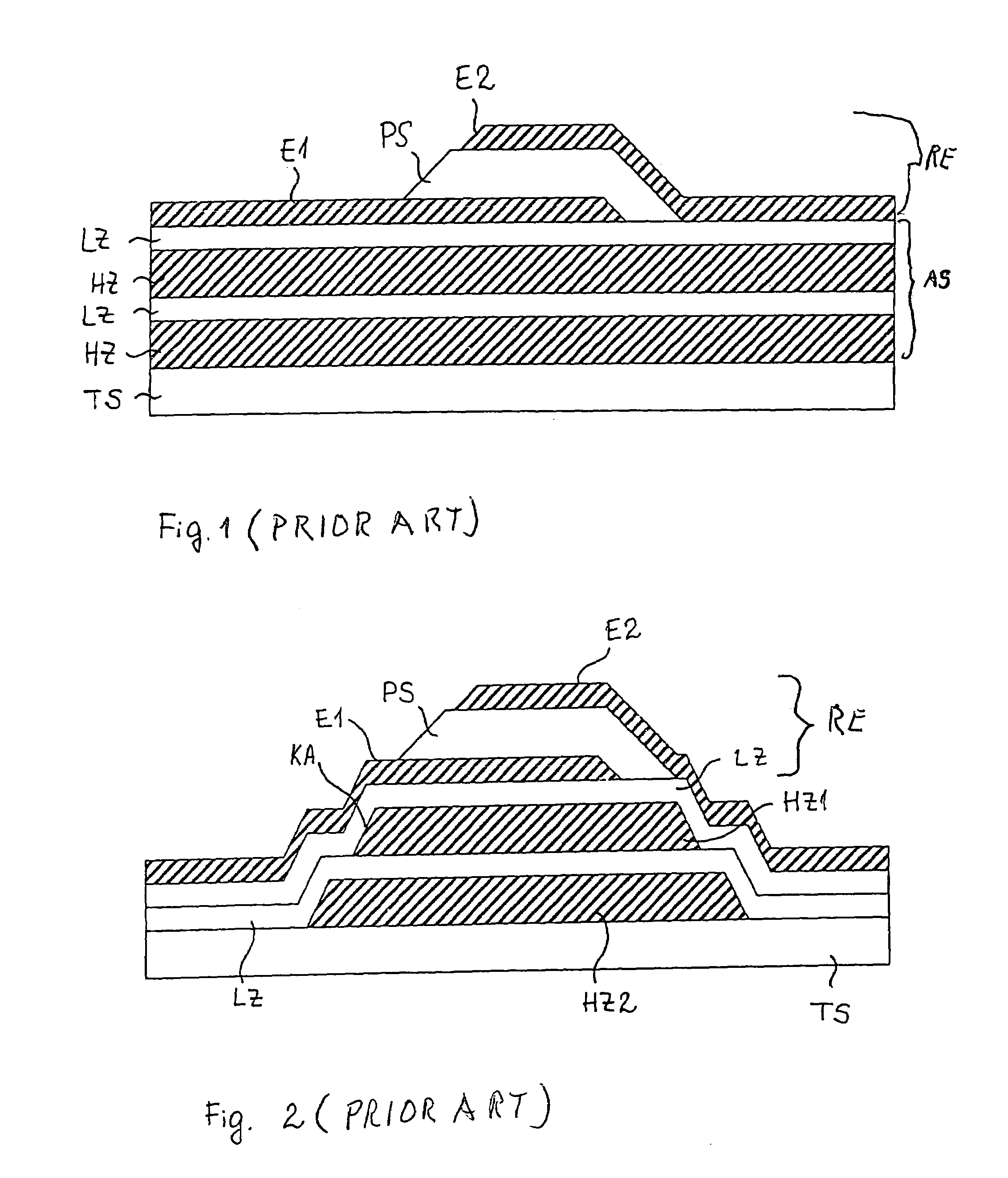

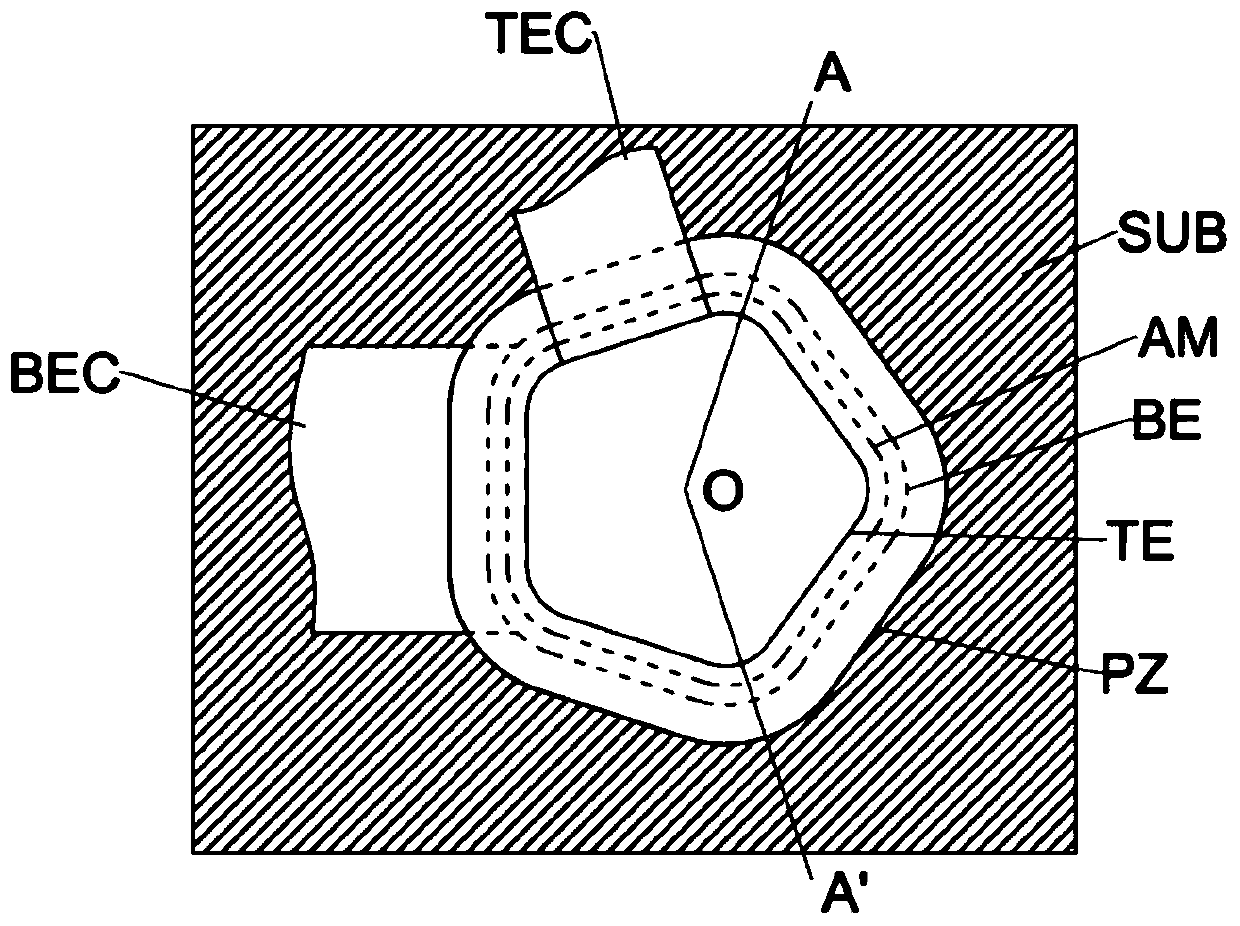

A microelectromechanical (MEM) resonator is disclosed which has a linear or ring-shaped acoustic resonator suspended above a substrate by an acoustic reflector. The acoustic resonator can be formed with a piezoelectric material (e.g. aluminum nitride, zinc oxide or PZT), or using an electrostatically-actuated material. The acoustic reflector (also termed an acoustic mirror) uses alternating sections of a relatively low acoustic impedance ZL material and a relatively high acoustic impedance ZH material to isolate the acoustic resonator from the substrate. The MEM resonator, which can be formed on a silicon substrate with conventional CMOS circuitry, has applications for forming oscillators, rf filters, and acoustic sensors.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

Piezoelectric resonator structure having an interference structure

ActiveUS8384497B2Piezoelectric/electrostriction/magnetostriction machinesImpedence networksAcousticsAcoustic mirror

Owner:AVAGO TECH INT SALES PTE LTD

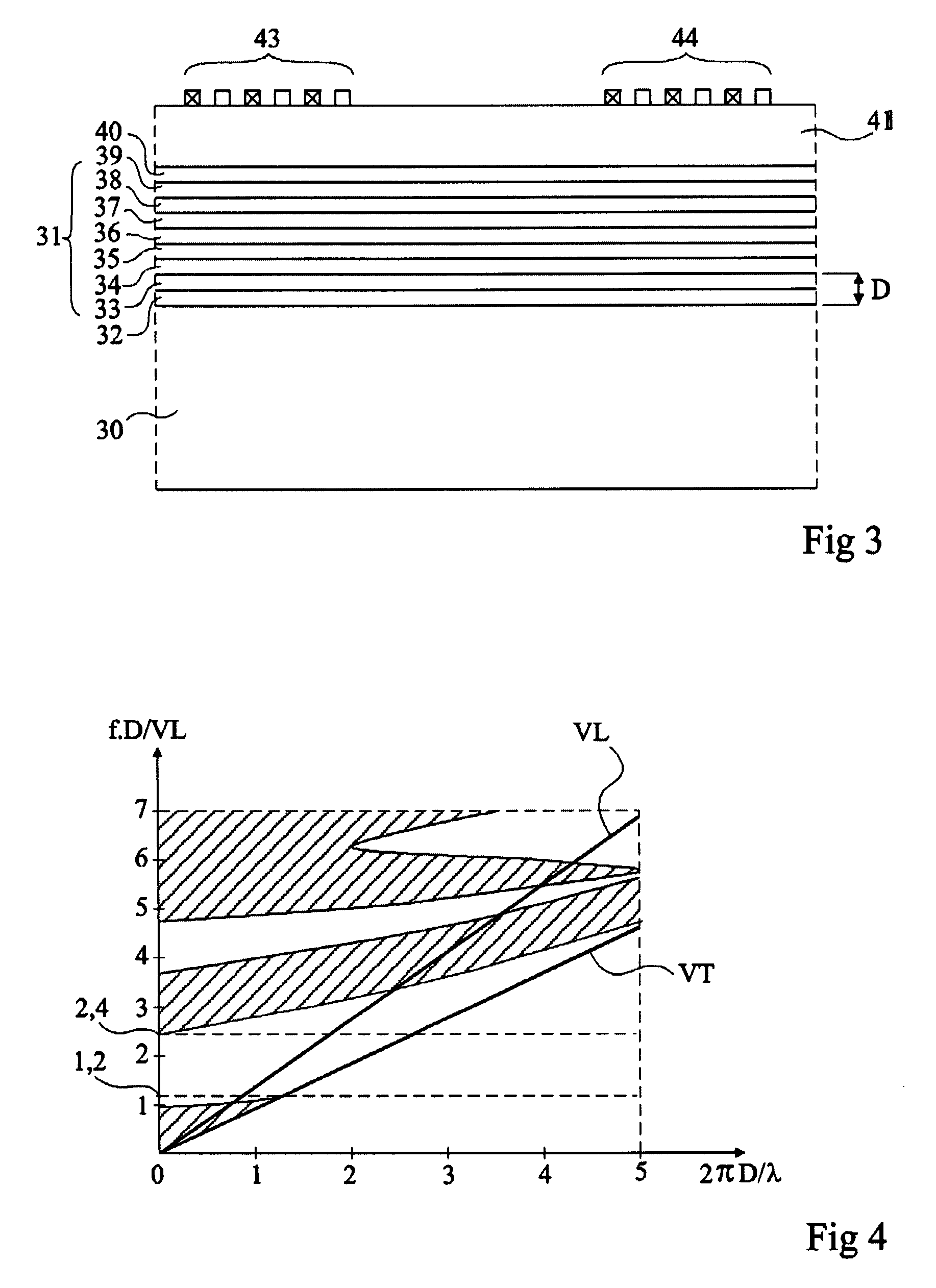

High-Frequency Acoustic Wave Device

ActiveUS20080211602A1Many applicationsPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksAcoustic waveAcoustic mirror

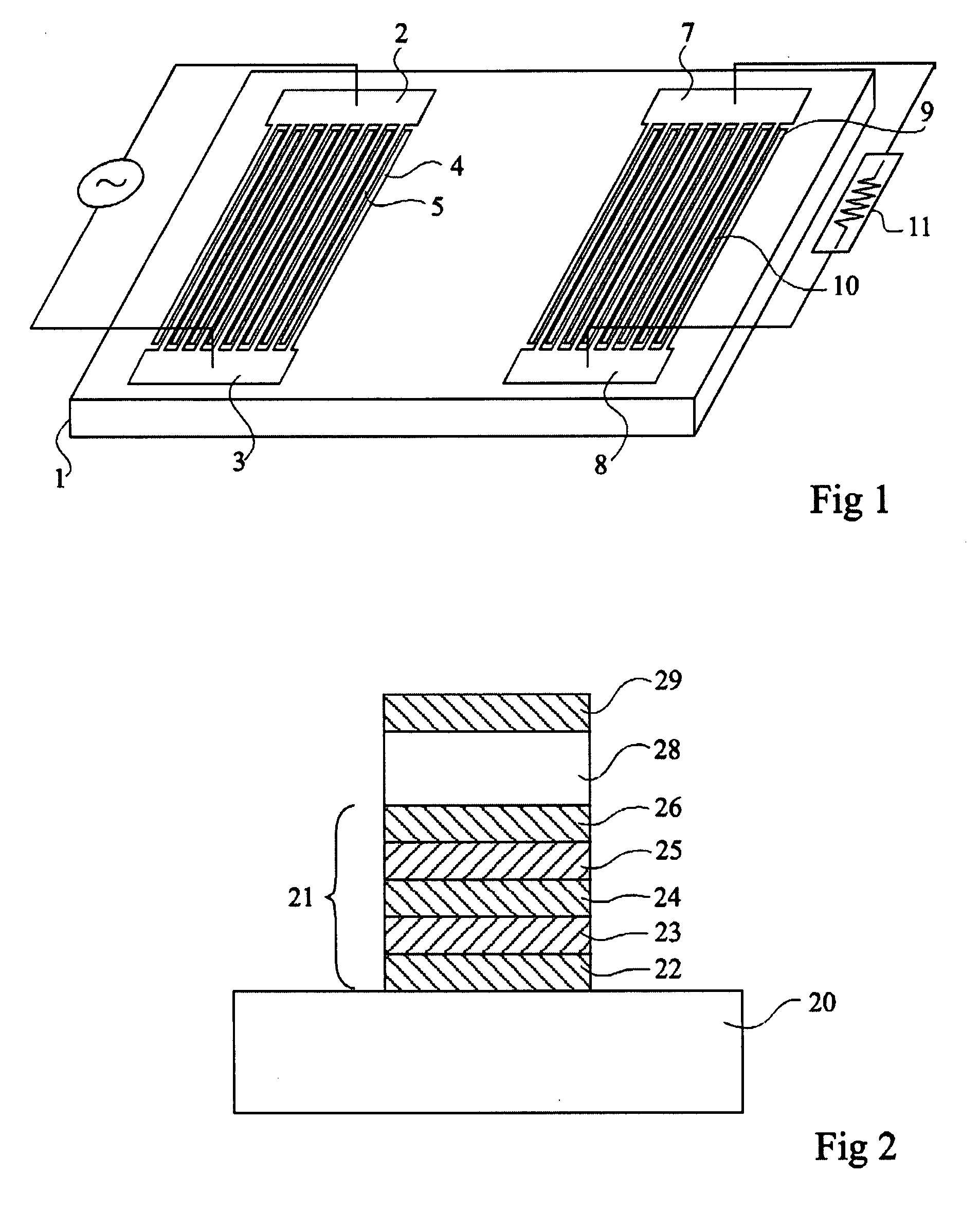

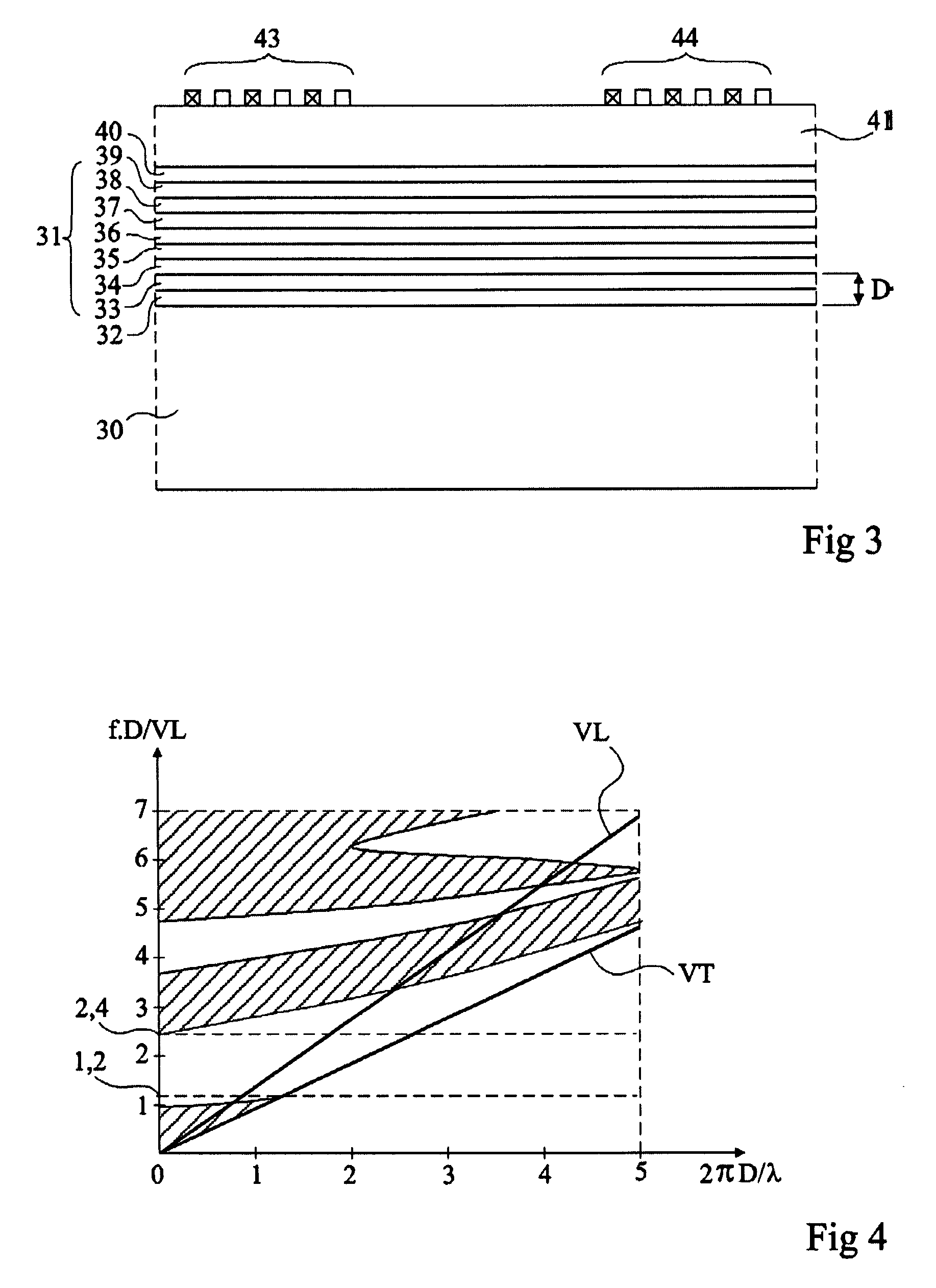

An acoustic wave device comprising a piezoelectric layer on an omnidirectional acoustic mirror and excitation and / or reception means on a surface of said piezoelectric layer, capable of exciting waves in a band gap of the acoustic mirror.

Owner:CENT NAT DE LA RECHERCHE SCI +1

Piezoelectric resonator and method for manufacturing the same

InactiveUS20060145785A1Prevent interdiffusionEliminate needPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksBond interfaceAcoustics

A piezoelectric resonator includes a substrate, an acoustic mirror formed on the substrate and includes alternately stacked first acoustic mirror material layers and second acoustic mirror material layers having higher acoustic impedance than that of the first acoustic mirror material layers, a piezoelectric film formed on the acoustic mirror, a top electrode formed on the piezoelectric film and a bottom electrode formed below the piezoelectric film. A bonding interface is provided between metal films bonded to each other between the substrate and the piezoelectric film.

Owner:PANASONIC CORP

Bulk acoustic wave resonator

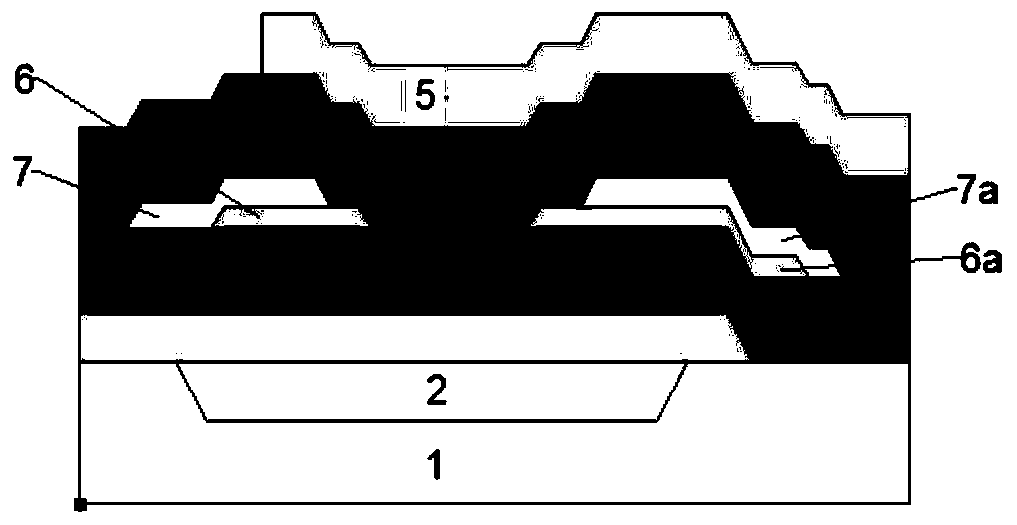

The invention provides a bulk acoustic wave resonator which comprises a substrate, an acoustic mirror structure, a lower electrode, a piezoelectric film structure and an upper electrode which are sequentially arranged from bottom to top. The upper surface and / or the lower surface of the upper electrode and / or the lower electrode are / is provided with an accessory structure, and the accessory structure is provided with protrusions or pits in the direction perpendicular to the surface of the upper electrode.

Owner:TIANJIN UNIV +1

Bulk acoustic wave resonator, method for manufacturing bulk acoustic wave resonator, bulk acoustic wave resonator unit, filter, and electronic device

The present invention relates to a single crystal thin film bulk acoustic resonator, comprising: a substrate; an acoustic mirror; a bottom electrode, connected with the bottom electrode pin; a top electrode, connected with the top electrode pin; a piezoelectric layer, arranged between the bottom electrode and the top electrode, wherein the piezoelectric layer is a single crystal film piezoelectriclayer, and an overlapping region of the acoustic mirror, the bottom electrode, the top electrode and the single crystal film piezoelectric layer in the thickness direction of the resonator forms an effective region of the resonator. The projections of the non-pin end of the top electrode and the non-pin end of the bottom electrode in the thickness direction of the resonator can be spaced apart from the edge of the acoustic mirror. The invention further relates to a manufacturing method of the single-crystal film bulk acoustic resonator, a single-crystal film bulk acoustic resonator unit withthe single-crystal film resonator and an electronic device.

Owner:TIANJIN UNIV +1

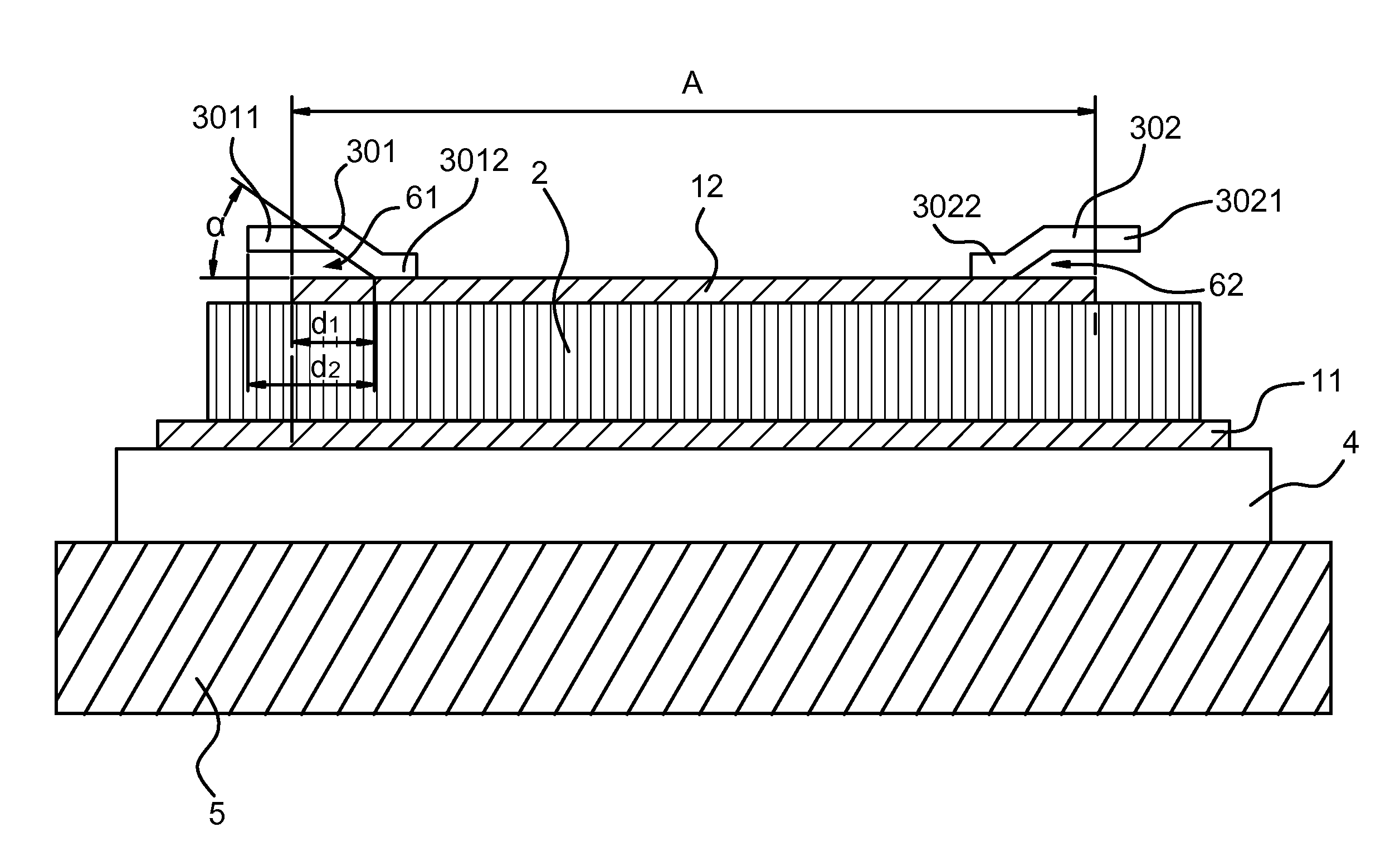

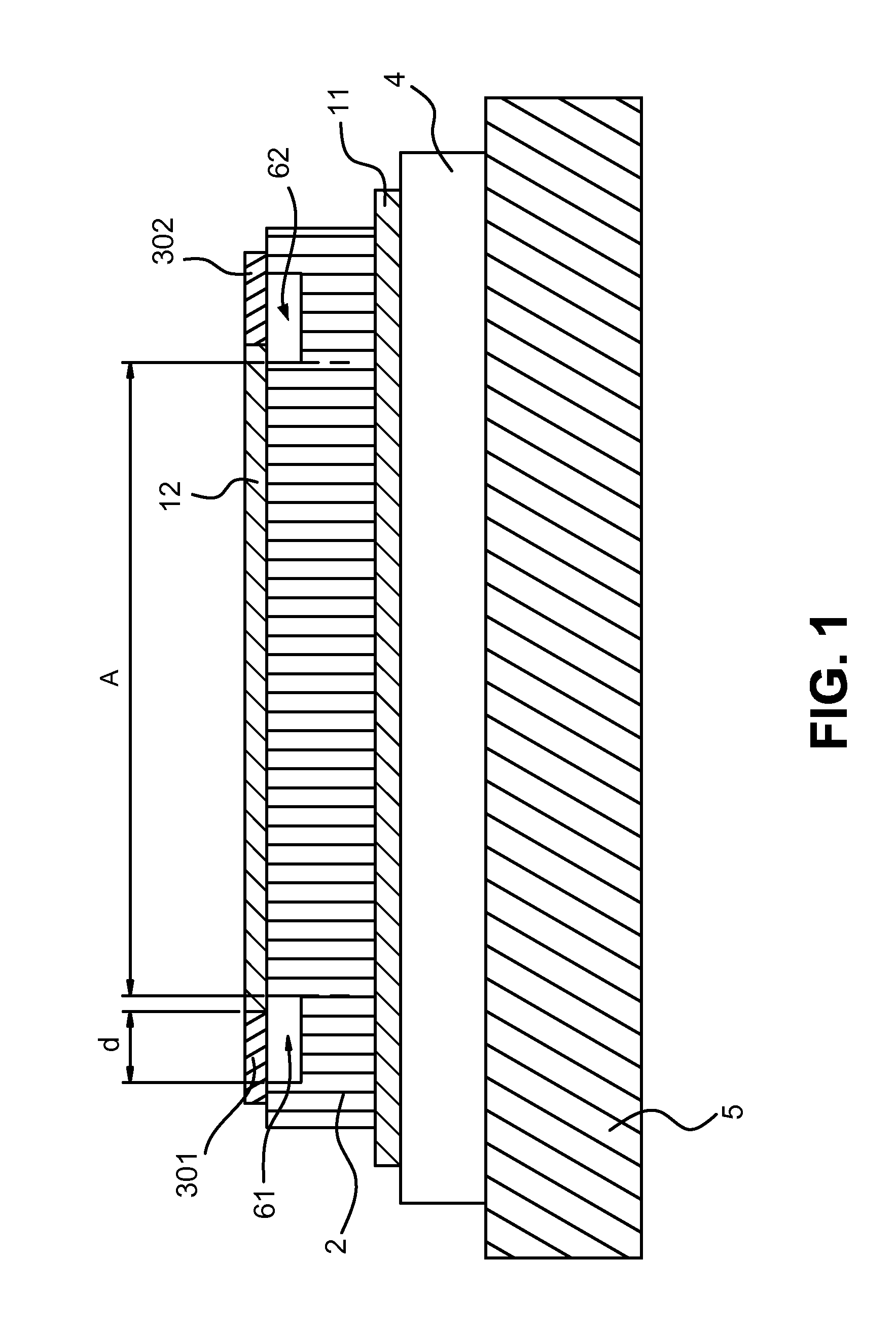

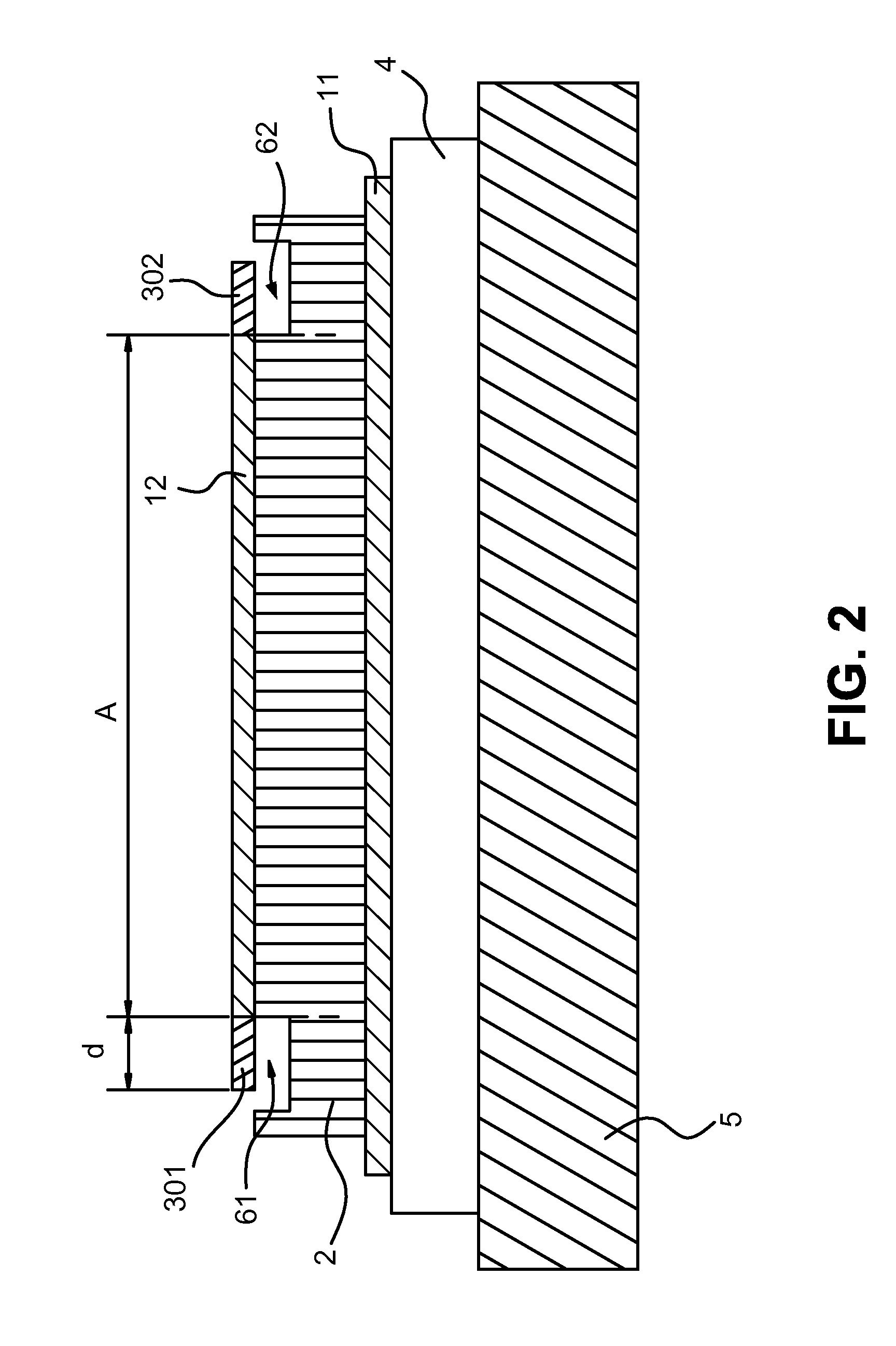

Bulk acoustic wave filter and method for eliminating unwanted side passbands

ActiveUS20050200433A1Suppression frequencyEasy to implementImpedence networksPiezoelectric/electrostrictive devicesThin-film bulk acoustic resonatorAcoustic wave

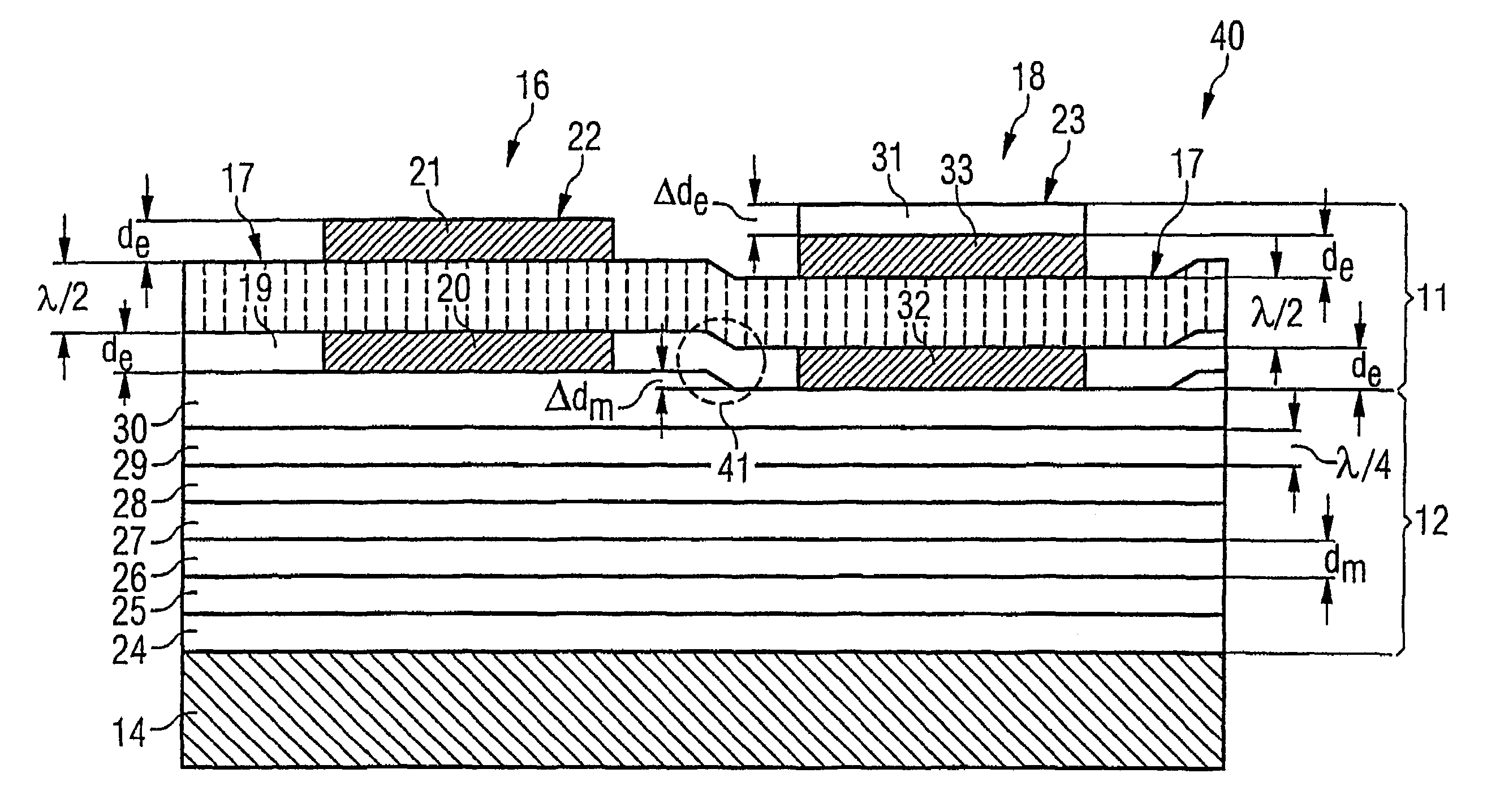

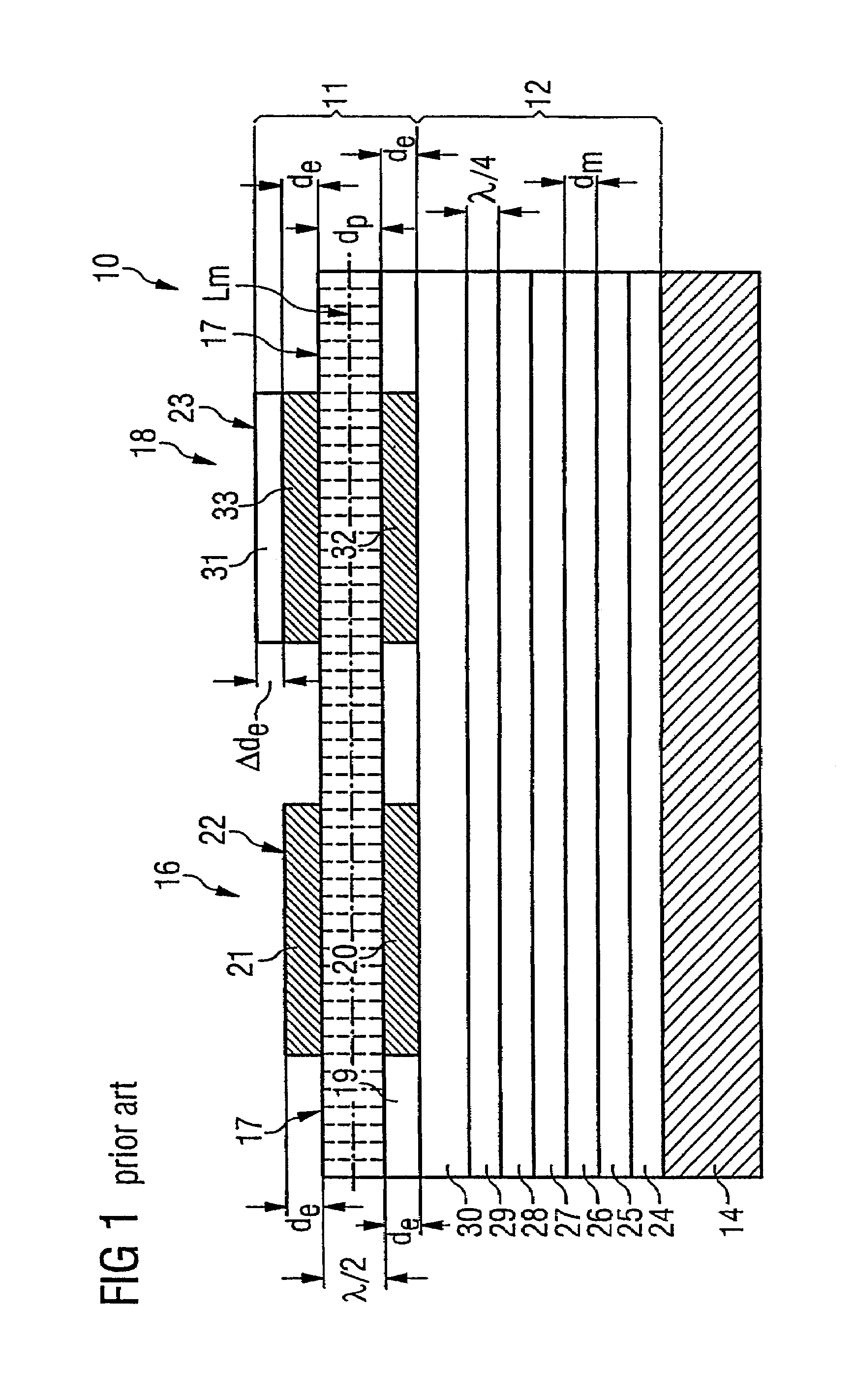

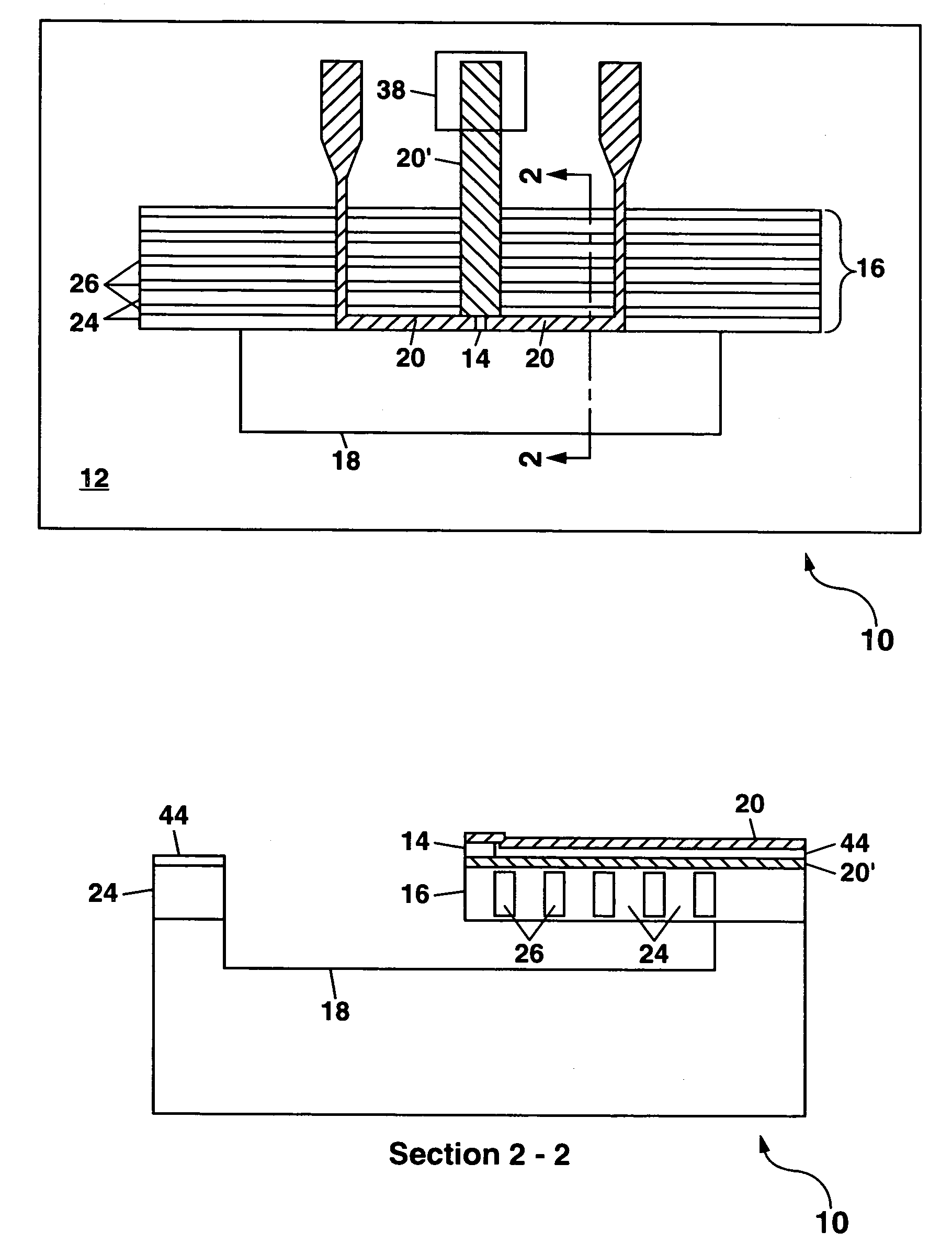

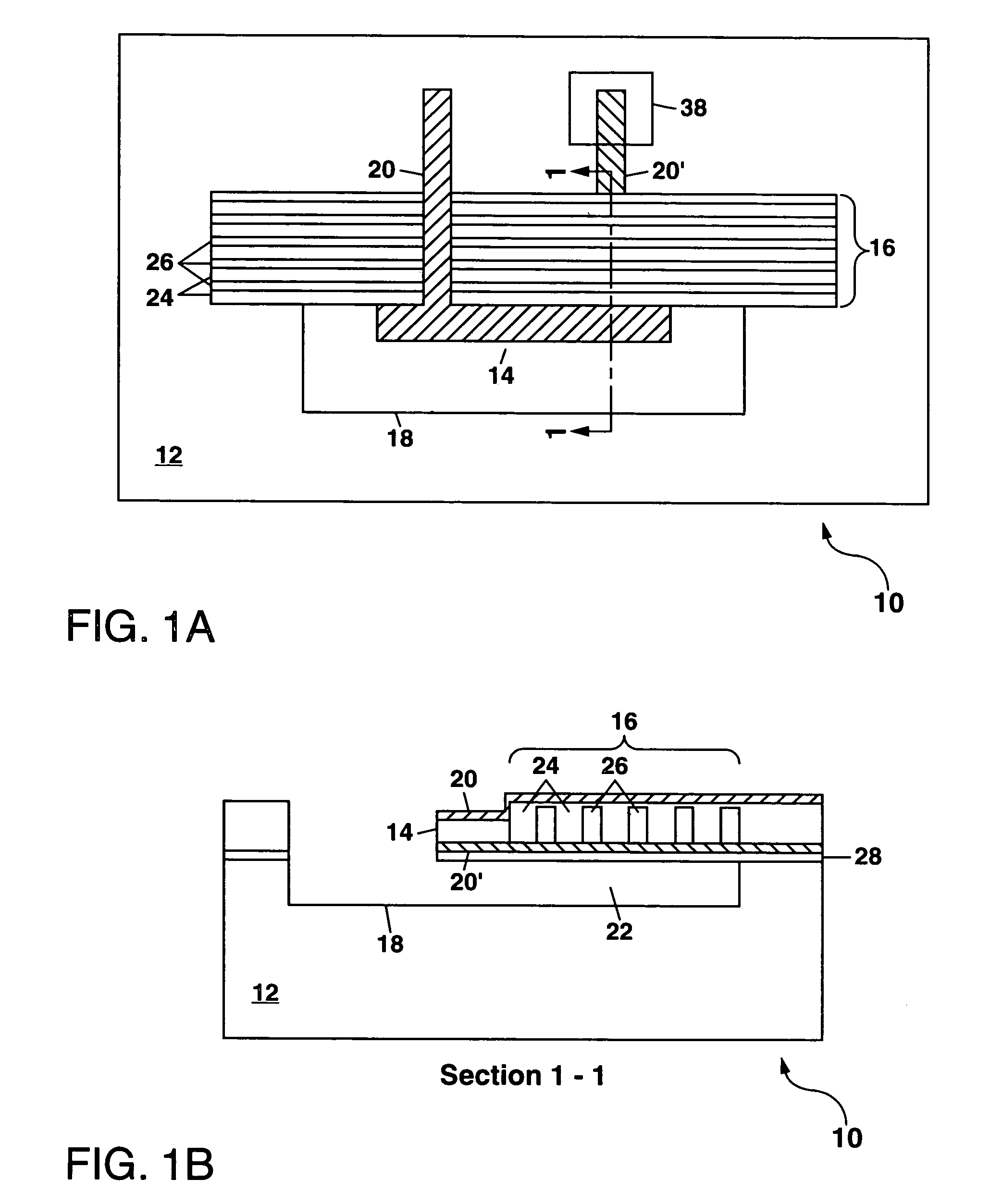

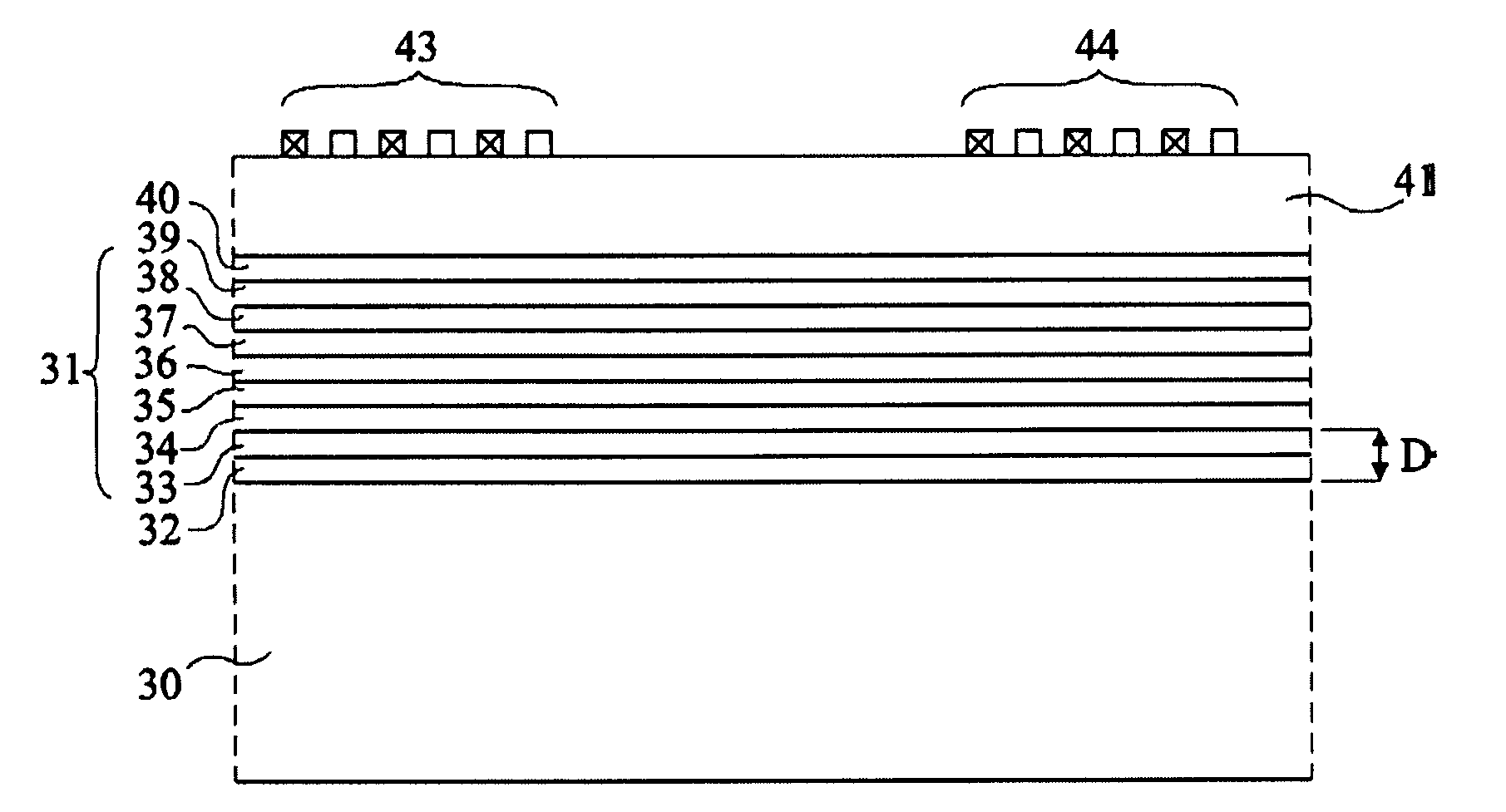

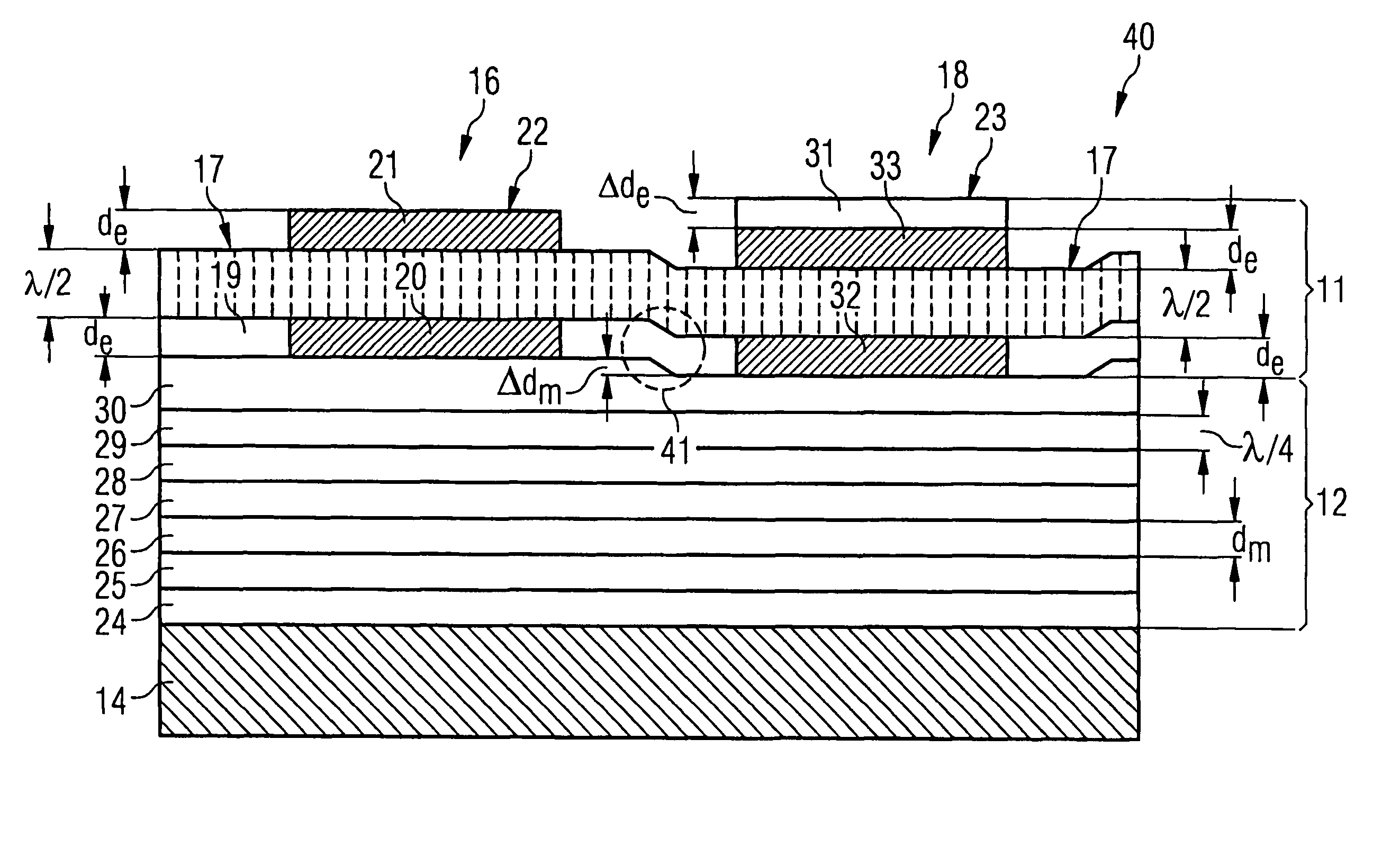

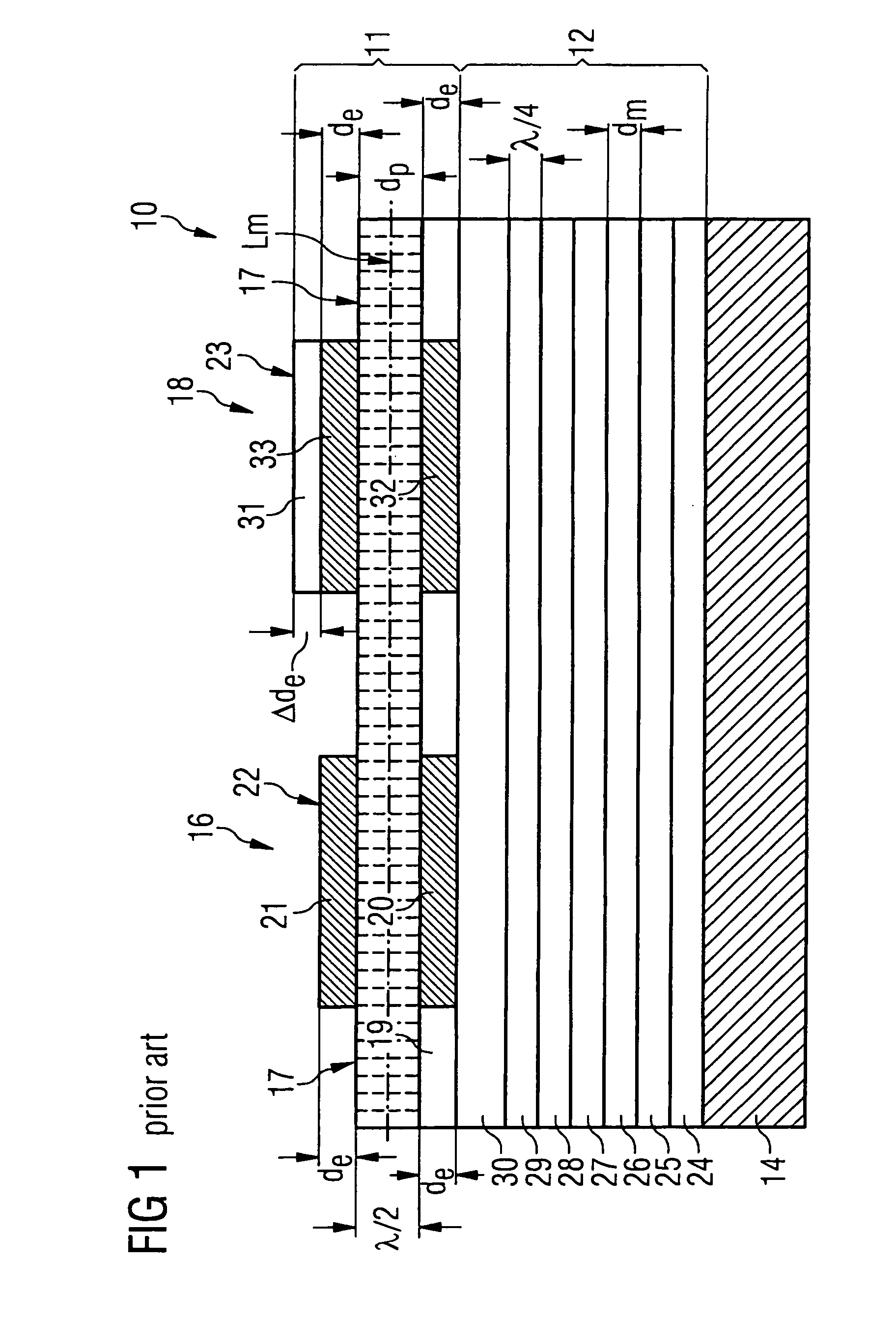

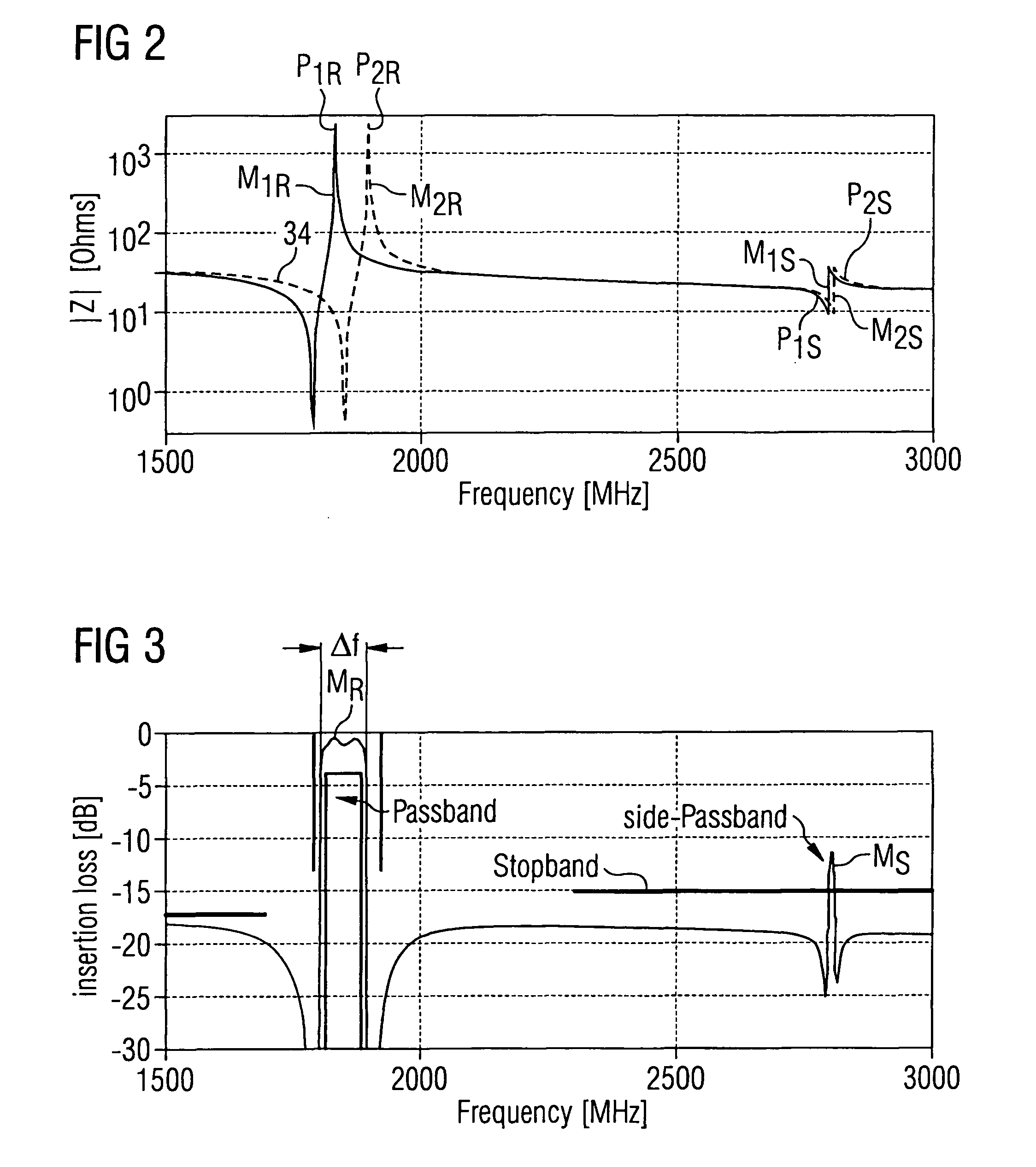

A bulk acoustic wave (BAW) filter (40) is fabricated from thin film bulk acoustic wave resonators and a method eliminates unwanted side passbands. This BAW filter comprises a substrate (14) a resonator section (11) and an acoustic mirror section (12). Further it comprises a detuning component (31) positioned in the resonator section (11) to provide precise passband characteristics and an additional detuning component (41) in the acoustic mirror section (12) to suppress unwanted side-passband characteristics.

Owner:AVAGO TECH INT SALES PTE LTD

Method of manufacturing an acoustic mirror for piezoelectric resonator and method of manufacturing a piezoelectric resonator

InactiveUS20070199185A1Improve uniformityEnhanced couplingPrinted circuit assemblingPiezoelectric/electrostrictive device manufacture/assemblyAcoustic impedanceAcoustic mirror

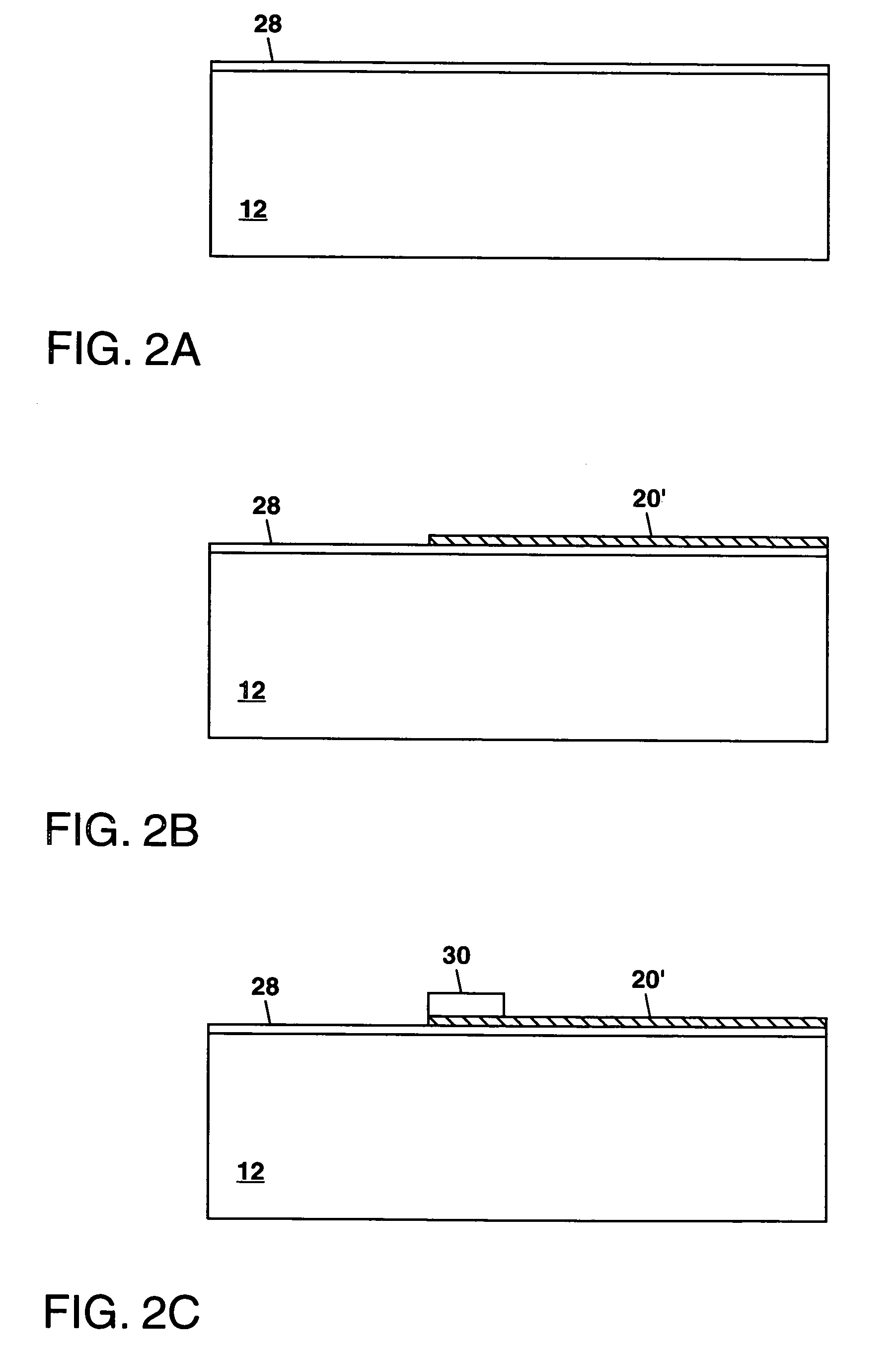

A mirror for a piezoelectric resonator consisting of alternately arranged layers of high and low acoustic impedance is manufactured by at first producing a first layer on which a second layer is produced, so that the second layer partially covers the first layer. Then, a planarization layer is applied on the first layer and on the second layer. Subsequently, a portion of the second layer is exposed by structuring the planarization layer, wherein the portion is associated with an active region of the piezoelectric resonator. Finally, the resulting structure is planarized by removing the portions of the planarization layer remaining outside the portion.

Owner:CONTRIA SAN LIABILITY

Piezoelectric thin film resonator, filter, and duplexer

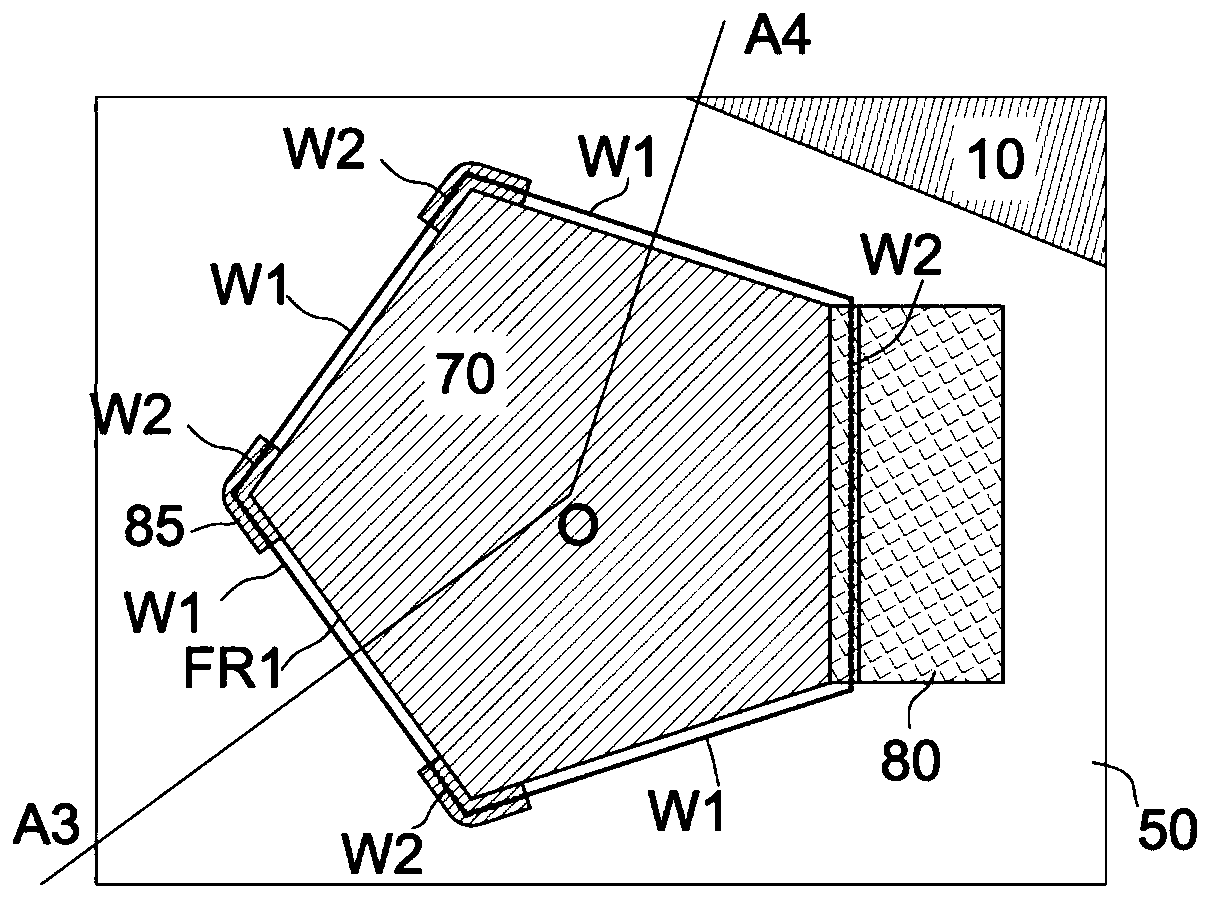

A piezoelectric thin film resonator includes: an acoustic reflection layer including an air gap or an acoustic mirror; lower and upper electrodes facing each other in a stacking direction, at least a part of each of the lower and upper electrodes being located on or above the acoustic reflection layer; a piezoelectric film sandwiched between the lower and upper electrodes and including lower and upper piezoelectric films, at least a part of an end face of the piezoelectric film in a film thickness direction being located between outer outlines of the resonance region and the acoustic reflection layer in at least a part of a region surrounding a resonance region; and an insertion film inserted between the lower and upper piezoelectric films, located in at least a part of an outer peripheral region within the resonance region, and not located in a center region of the resonance region.

Owner:TAIYO YUDEN KK

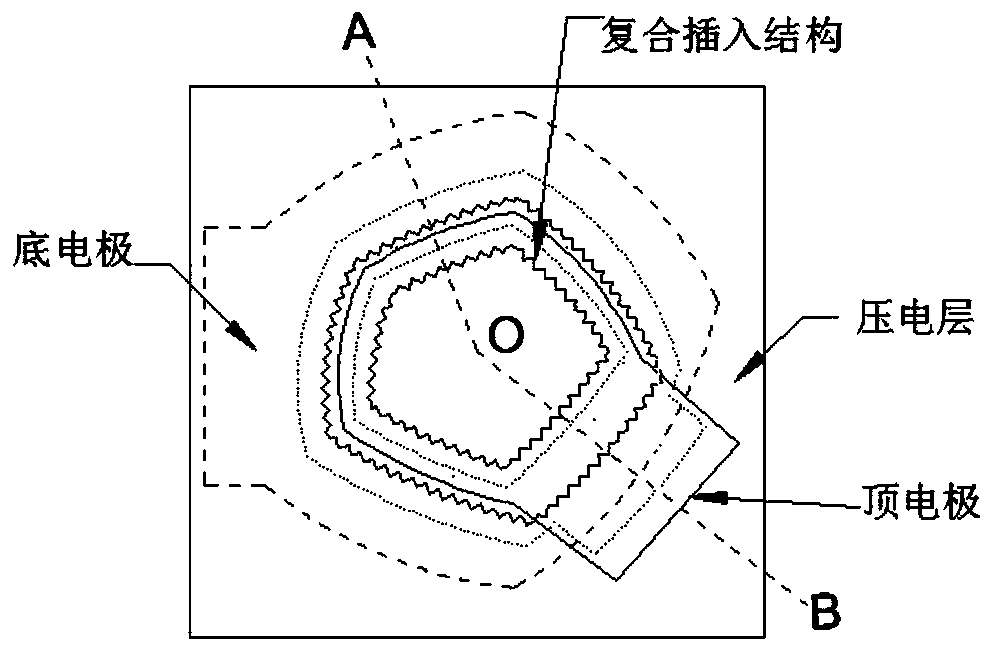

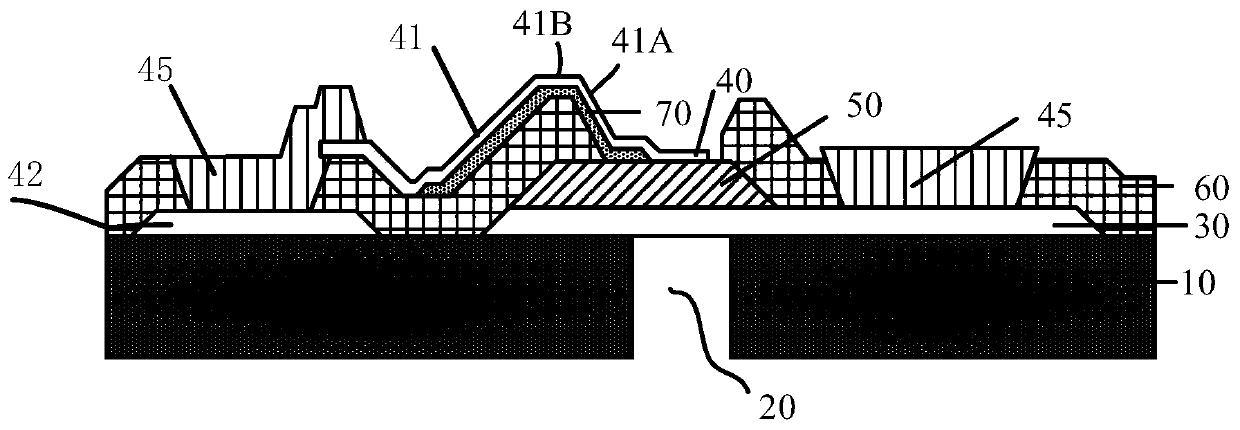

Bulk acoustic wave resonator having piezoelectric layer with insertion structure, filter, and electronic device

The present invention relates to a bulk acoustic wave resonator, and the resonator comprises a substrate; an acoustic mirror; a bottom electrode; a top electrode; and a piezoelectric layer, wherein anoverlapped area of the acoustic mirror, the bottom electrode, the piezoelectric layer and the top electrode in the thickness direction of the substrate is an effective area of the resonator; a composite insertion structure arranged along the edge of the effective area is arranged in the piezoelectric layer; a composite insertion structure including a first insertion layer and a second insertion layer, at least a portion of the first insertion layer overlapping the active region in a plan view of the resonator, and at least a portion of the first insertion layer overlapping the second insertion layer in a plan view of the resonator; the first insertion layer is made of a metal material and the second insertion layer is made of air or a dielectric material, or the first insertion layer is made of a dielectric material and the second insertion layer is made of air. The invention also relates to a filter and an electronic device.

Owner:TIANJIN UNIV +1

Bulk acoustic wave resonator and method of fabricating same

ActiveUS8692631B2Piezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesAcousticsAcoustic mirror

An acoustic resonator with improved quality factor and electro-mechanical coupling is disclosed. In one embodiment, the acoustic resonator includes an acoustic mirror formed on the top surface of a substrate or in the substrate, a first electrode having a end portion, formed on the acoustic mirror, a piezoelectric layer formed on the first electrode; and a second electrode formed on the piezoelectric layer, where at least one of the first electrode and the second electrode and the piezoelectric layer define a gap in a region that overlaps the end portion of the first electrode. In one embodiment, a dielectric film is deposited on the surface of the end portion of the first electrode to form completely planarized surface before the piezoelectric layer deposition. In another embodiment, a gap between the second electrode and the piezoelectric layer, so that the piezoelectric coupling in the end portion area of the first electrode is minimally contributed into the whole resonator.

Owner:AVAGO TECH INT SALES PTE LTD

Bulk acoustic wave resonator with variable doping concentration, filter and electronic equipment

The present invention relates to a bulk acoustic wave resonator, and the resonator comprises a substrate; an acoustic mirror; a bottom electrode disposed over the substrate; a top electrode facing thebottom electrode and having an electrode connection portion; and a piezoelectric layer which is arranged above the bottom electrode and between the bottom electrode and the top electrode, wherein thepiezoelectric layer comprises at least three piezoelectron layers, and the types of doped substances and / or the concentrations of the doped substances of the at least three piezoelectron layers havealternate changes and / or periodic changes in the thickness direction of the piezoelectric layer. The invention also relates to a filter having the bulk acoustic wave resonator, an electronic device having the filter, and a manufacturing method of the bulk acoustic wave resonator.

Owner:TIANJIN UNIV +1

Bulk acoustic wave resonator provided with insertion structure and temperature compensation layer, filter and electronic equipment

The present invention relates to a bulk acoustic wave resonator, and the resonator comprises a substrate; an acoustic mirror; a bottom electrode; a top electrode; wherein an overlapped area of the acoustic mirror, the bottom electrode, the piezoelectric layer and the top electrode in the thickness direction of the substrate is an effective area of the resonator; wherein a composite insertion structure arranged along the edge of the effective region is arranged in the piezoelectric layer, the composite insertion structure comprises a first insertion layer and a second insertion layer, at leastone part of the first insertion layer is overlapped with the effective region in a top view of the resonator, and the first insertion layer is at least partially overlapped with the second insertion layer in the top view of the resonator, wherein the first insertion layer is made of a metal material and the second insertion layer is made of air or a dielectric material, or the first insertion layer is made of a dielectric material and the second insertion layer is made of air, in a top view of the resonator, at least one part of the temperature compensation layer is located in the effective area, and the temperature compensation layer is made of a material opposite to the piezoelectric layer in frequency temperature coefficient. The invention also relates to a filter and an electronic device.

Owner:TIANJIN UNIV +1

Bulk acoustic wave resonator with doped isolation structure

The invention provides a bulk acoustic wave resonator with a doped isolation structure. The bulk acoustic wave resonator includes a substrate, an acoustic mirror embedded in substrate, a lower electrode positioned on the substrate and the acoustic mirror; a piezoelectric layer positioned on the lower electrode; and an upper electrode on the piezoelectric layer, an upper electrode and a piezoelectric layer. The lower electrode and the acoustic mirror form an effective region at the overlapped part in the thickness direction of the resonator, the peripheral region of the piezoelectric layer is provided with a doped isolation structure, the doped isolation structure is provided with a multi-layer structure in the transverse direction, each layer is provided with uniform element doping concentration, and the doping concentrations or doping elements in two adjacent layers are different from each other.

Owner:TIANJIN UNIV +1

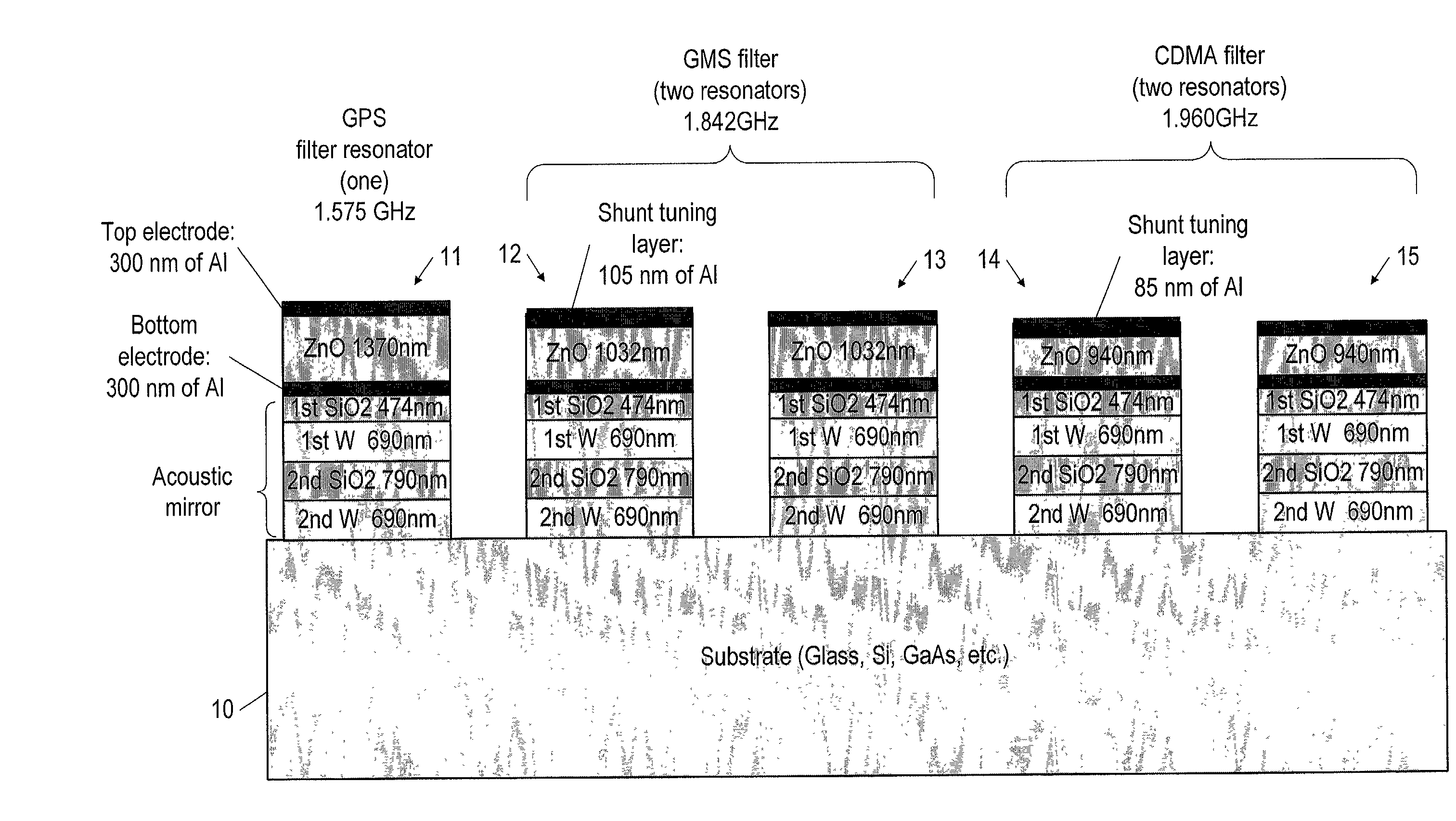

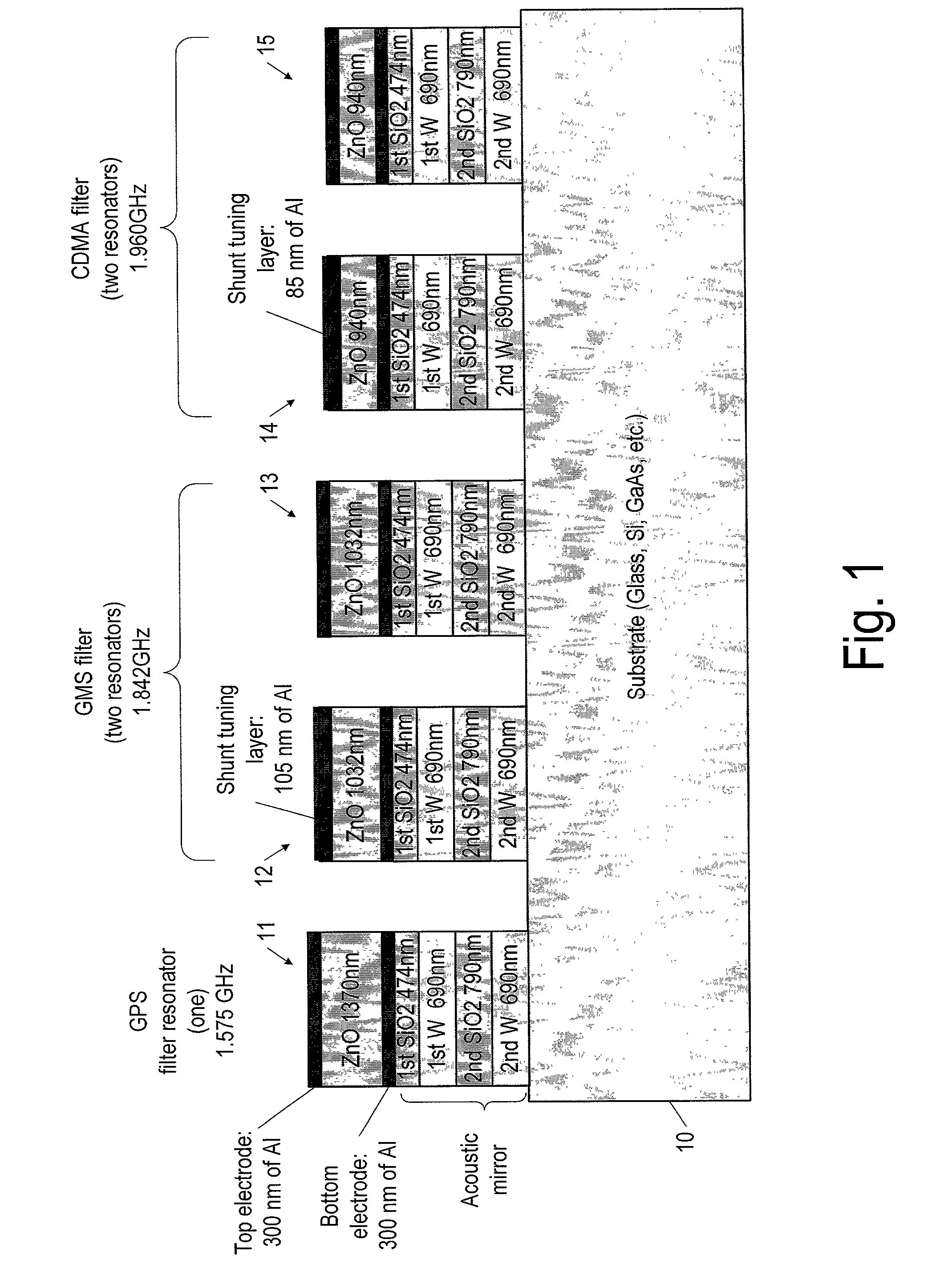

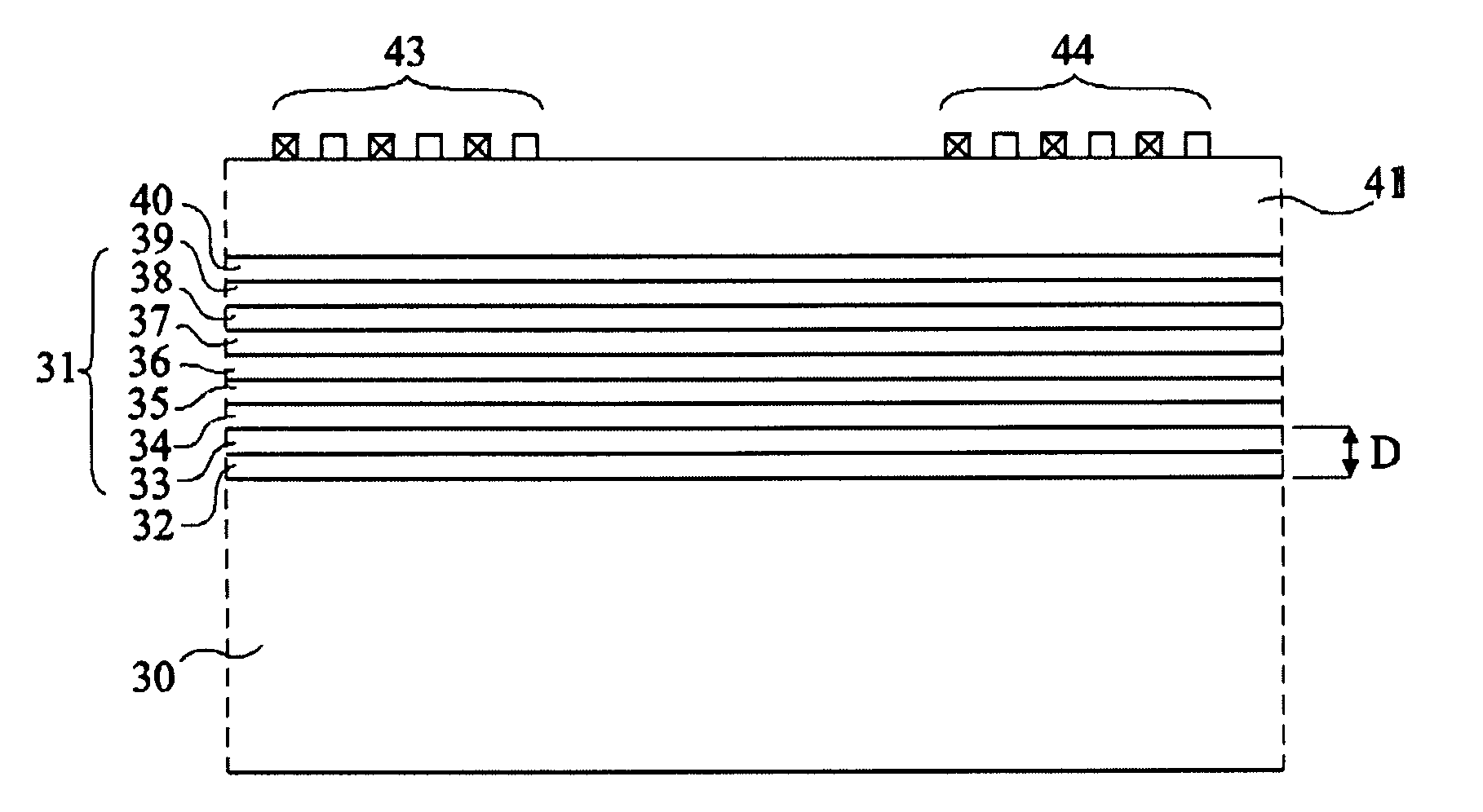

Baw filters having different center frequencies on a single substrate and a method for providing same

InactiveUS20020089395A1Piezoelectric/electrostrictive device manufacture/assemblyImpedence networksAcoustic waveCenter frequency

A method of fabricating a plurality of bulk acoustic wave (BAW) resonators on a single substrate, and the corresponding product, the BAW resonators having substantially different resonant frequencies, the method including the steps of: providing a substrate having an upper facing surface; depositing an isolation structure on the upper facing surface of the substrate; depositing a first metallic layer on the isolation structure, the first metallic layer serving as a bottom electrode; and depositing piezolayer material on the bottom electrode so as to have thicknesses corresponding to each of the different resonant frequencies, each different thickness located in a location where a resonator having a resonant frequency corresponding to the thickness is to be located. In one of several embodiments, the step of depositing piezolayer material on the bottom electrode itself includes the steps of: depositing piezolayer material to a thickness corresponding to the lowest frequency resonator; providing hard mask material over areas where the lowest frequency resonators are to be located; and removing the piezolayer material down to the thickness of the next higher frequency resonators. In some applications of the method, the isolation structure is an acoustic mirror, and the method further includes the step of providing the acoustic mirror, interposed between the substrate and the bottom electrode, according to a design that imparts to the acoustic mirror a desired reflection coefficient over a predetermined range of frequency including the substantially different resonant frequencies.

Owner:AVAGO TECH WIRELESS IP SINGAPORE PTE

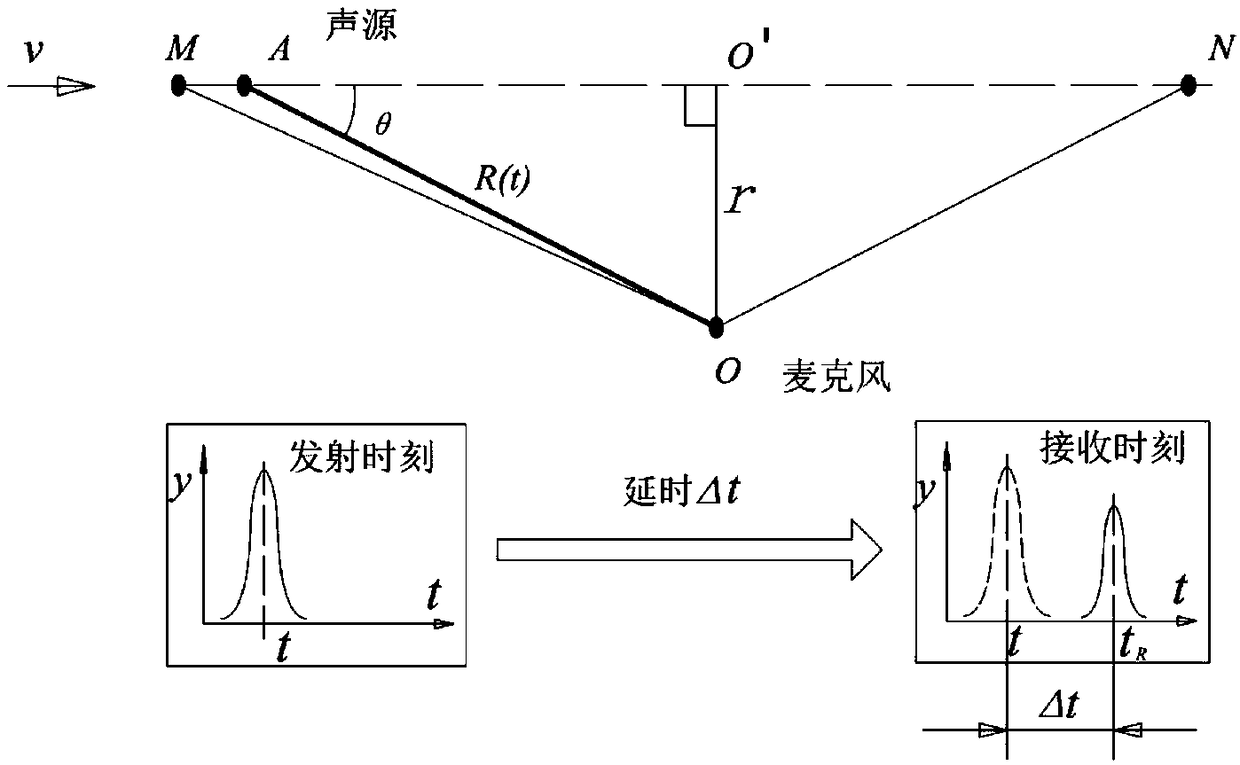

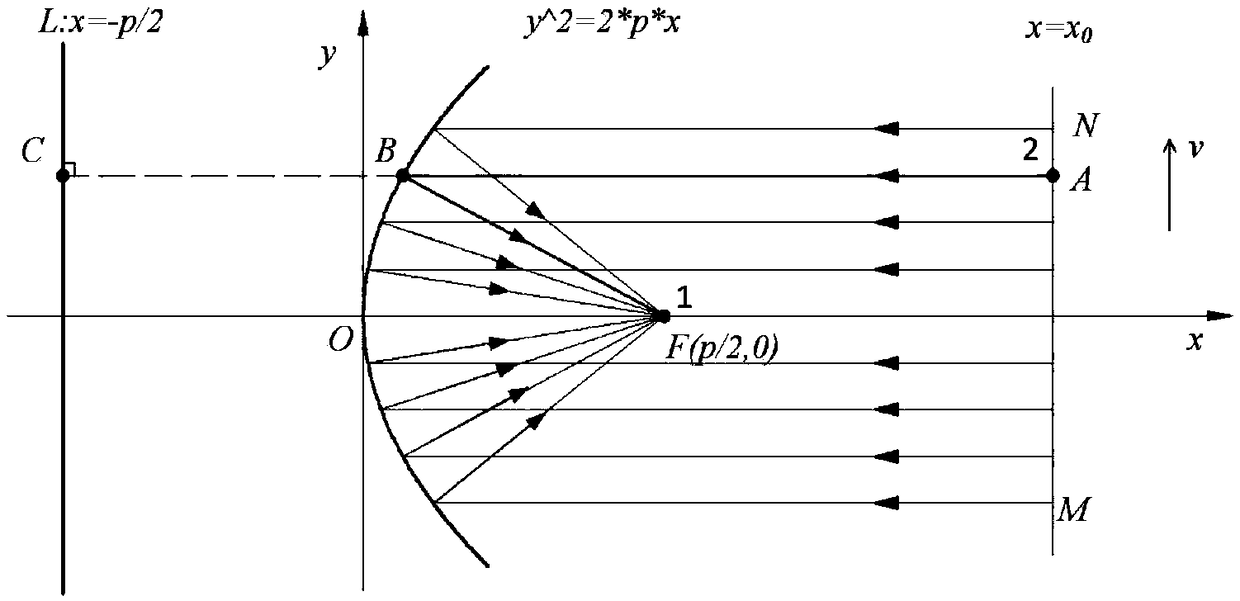

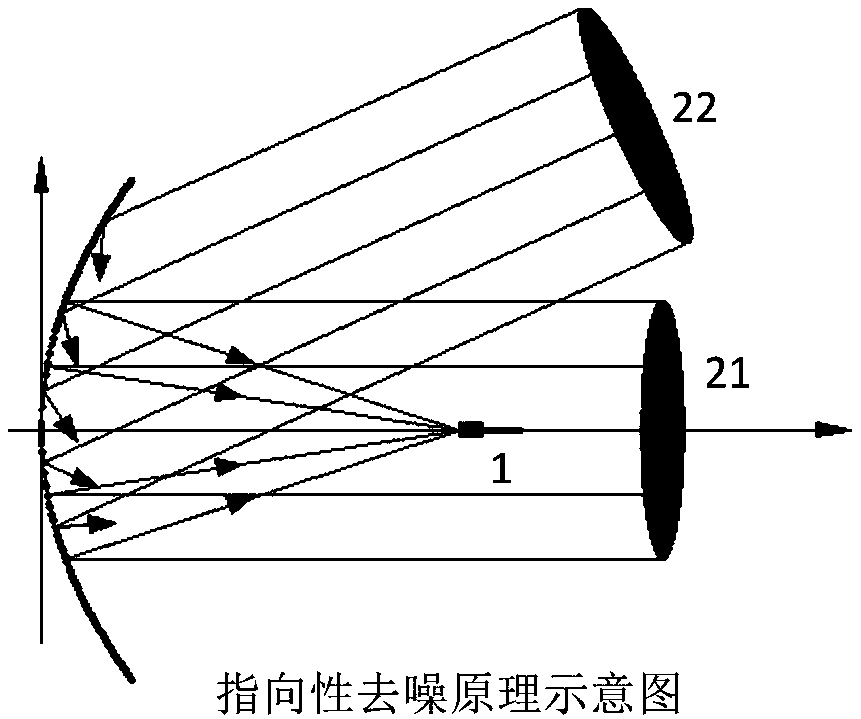

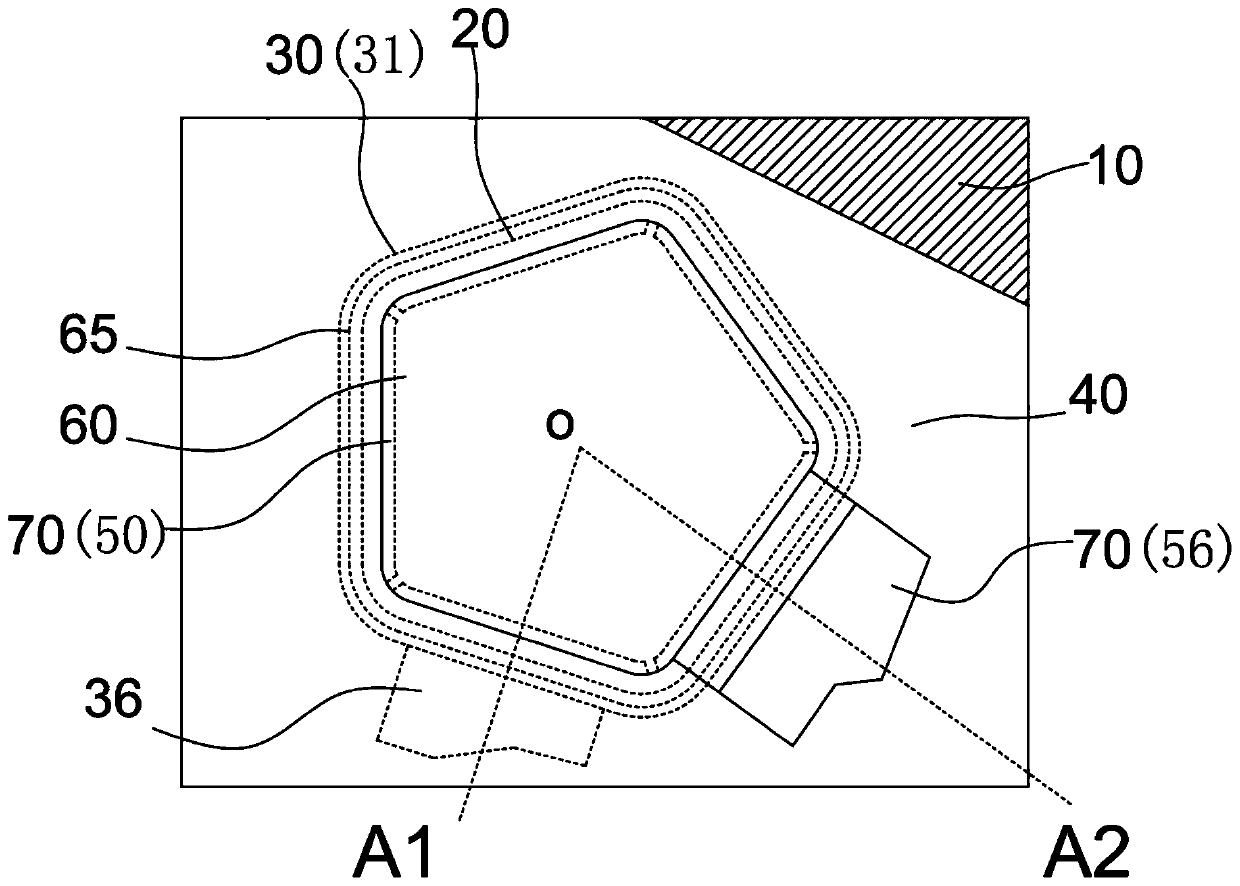

Paraboloidal acoustic mirror array collection device used for wayside acoustic detection of train bearings

ActiveCN108801637AOvercoming the Doppler Distortion ProblemImprove accuracySubsonic/sonic/ultrasonic wave measurementMachine bearings testingFocal positionParaboloid

The invention provides a paraboloidal acoustic mirror array collection device used for wayside acoustic detection of train bearings. The paraboloidal acoustic mirror array collection device comprisesa plurality of same acoustic mirror units which are arranged along rails horizontally, straightly and uniformly, each of the acoustic mirror units comprises a microphone, an acoustic reflector and a support, reflection surfaces of acoustic mirrors are paraboloids, curves of horizontal cross-sections of the reflection surfaces of the acoustic mirrors are parabolas, and the microphones are respectively placed at focal positions of the acoustic mirror paraboloids. The paraboloidal acoustic mirror array collection device has the advantages that in principle, the acoustic mirrors can avoid dopplerdistortion and can eliminate noise directionally, by arranging the acoustic mirrors in an array mode, length of a collected signal can be increased, and accuracy in train bearing fault diagnosis can be improved effectively.

Owner:ANHUI UNIVERSITY

Bulk acoustic wave resonator having void layer on electrode, filter, and electronic device

The present invention relates to a bulk acoustic wave resonator, and the bulk acoustic wave resonator comprises a substrate; an acoustic mirror; a bottom electrode; a top electrode; and a piezoelectric layer which is arranged between the bottom electrode and the top electrode; the bottom electrode and / or the top electrode are / is a gap electrode; the gap electrode is provided with a gap layer; a first electrode layer is arranged on the side, close to the piezoelectric layer, of the gap layer, a second electrode layer is arranged on the side, away from the piezoelectric layer, of the gap layer,the gap layer is arranged between the first electrode layer and the second electrode layer in the thickness direction of the resonator, and the corresponding first electrode layer and second electrodelayer are electrically connected with each other; the resistivity of the first electrode layer is greater than that of the second electrode layer; and / or the acoustic impedance of the first electrodelayer is greater than that of the second electrode layer. The invention further relates to a filter with the resonator and electronic equipment with the filter or the resonator.

Owner:ROFS MICROSYST TIANJIN CO LTD

Bulk acoustic wave resonator with electrode having gap layer and protruding structure, filter and electronic device

The present invention relates to a bulk acoustic wave resonator, and the resonator comprises a substrate; an acoustic mirror; a bottom electrode; a top electrode; and a piezoelectric layer disposed between the bottom electrode and the top electrode, wherein an overlapping region of the top electrode, the bottom electrode, the acoustic mirror, and the piezoelectric layer in a thickness direction ofthe resonator defines an effective region of the resonator; the top electrode comprises a gap layer, a first top electrode and a second top electrode, wherein the gap layer is formed between the first top electrode and the second top electrode in the thickness direction of the resonator, and the first top electrode is in surface contact with the piezoelectric layer; the first top electrode is provided with a protruding structure at the edge of the effective area in the effective area, and the top surface of the protruding structure is higher than the upper surface of the first top electrode in the effective area. The invention further relates to a filter with the resonator and electronic equipment with the filter or the resonator.

Owner:ROFS MICROSYST TIANJIN CO LTD

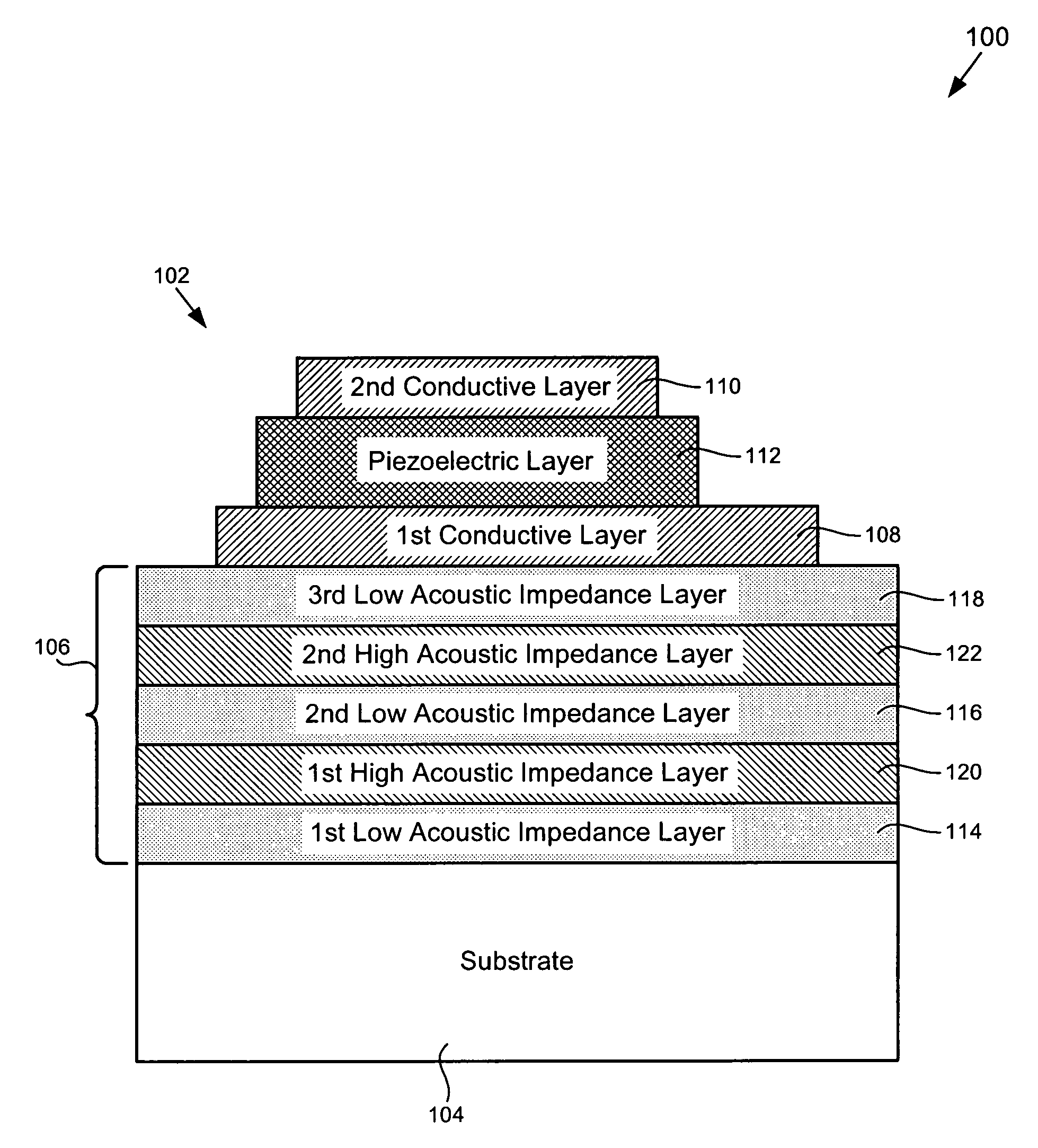

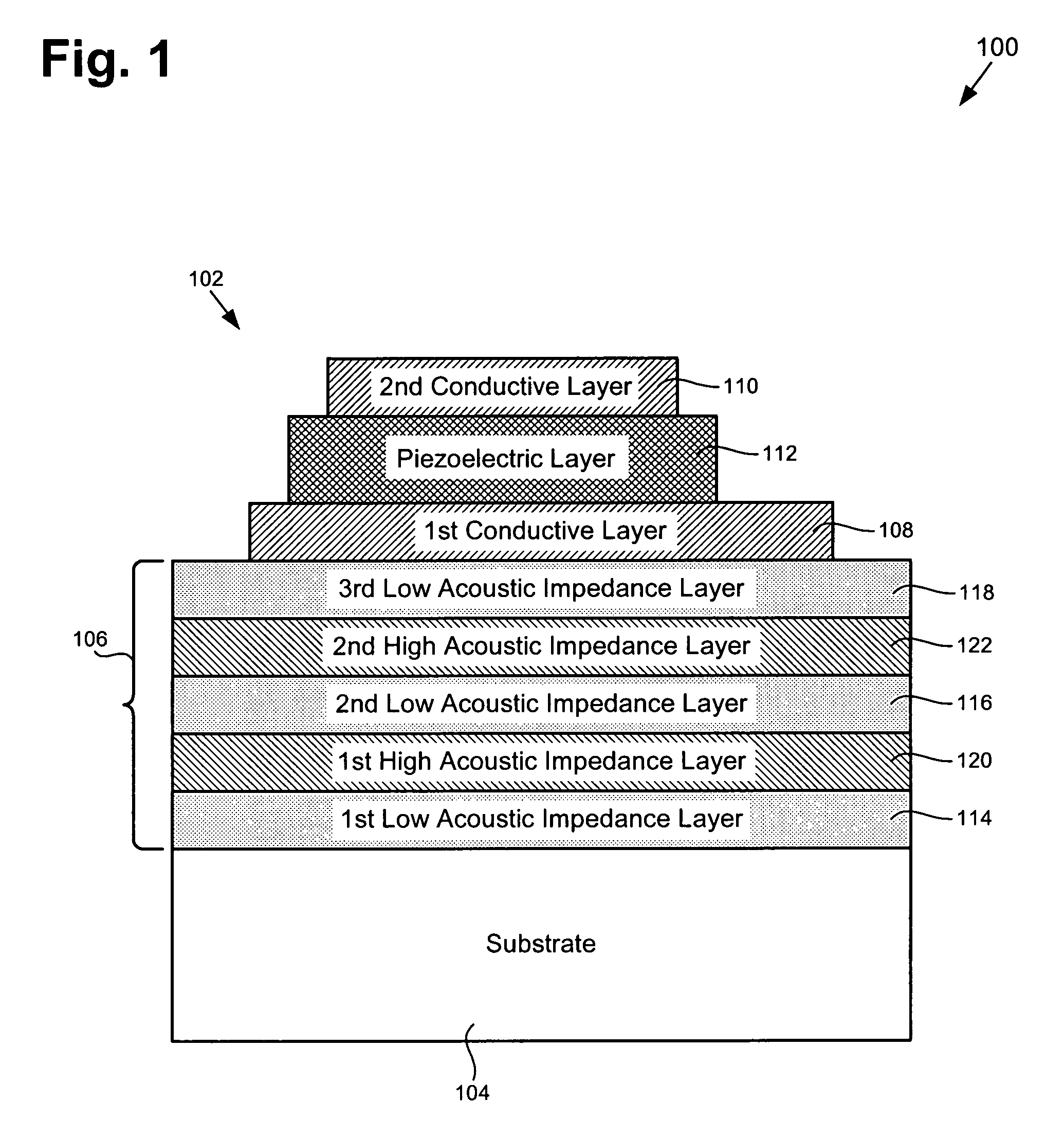

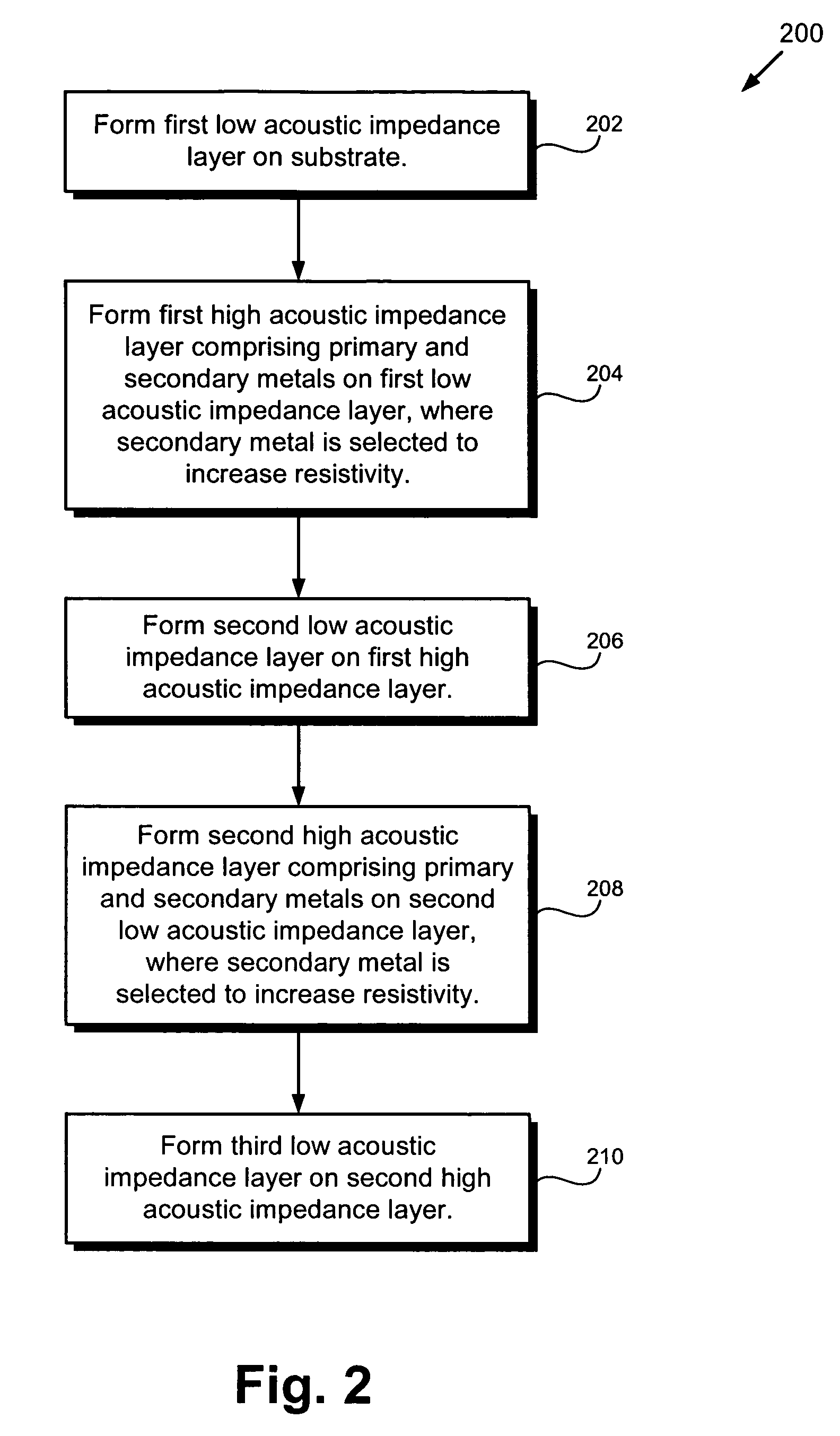

Acoustic mirror structure for a bulk acoustic wave structure and method for fabricating same

InactiveUS7414350B1Impedence networksPiezoelectric/electrostriction/magnetostriction machinesAcousticsAcoustic impedance

According to one embodiment of the invention, an acoustic mirror structure situated in a bulk acoustic wave structure includes a number of alternating low acoustic impedance and high acoustic impedance layers situated on a substrate. Each high acoustic impedance layer includes a first mole percent of a primary metal and a second mole percent of a secondary metal, where the first mole percent of the primary metal is greater than the second mole percent of the secondary metal, and where the secondary metal causes each high acoustic impedance layer to have increased resistivity. According to this exemplary embodiment, the second mole percent of the secondary metal can cause only a minimal decrease in density of each high acoustic impedance layer. The increased resistivity of each high acoustic impedance layer can cause a reduction in electrical loss in the bulk acoustic wave structure.

Owner:AVAGO TECH WIRELESS IP SINGAPORE PTE

Bulk acoustic wave resonator having void layer on electrode, method of manufacturing same, filter, and electronic apparatus

PendingCN111130490ASmall sizeIncreased power capacityImpedence networksElectrical connectionAcoustic wave

The invention relates to a bulk acoustic wave resonator and a manufacturing method thereof. The resonator includes: a substrate; a bottom electrode; a top electrode; and a piezoelectric layer, the electrode is arranged between the bottom electrode and the top electrode; wherein the bottom electrode is a gap electrode, the gap electrode is provided with a gap layer, distances exist between the gaplayer and the top surface and the bottom surface of the gap electrode in the thickness direction of the gap electrode, the gap layer forms an acoustic mirror cavity of the resonator, or an acoustic mirror structure is arranged in the gap layer; the substrate is provided with at least one electric connection through hole, one end of the through hole is connected to the bottom electrode, and the other end of the through hole is suitable for being connected to a bonding pad located on the lower side of the substrate. The invention further relates to a filter with the resonator and electronic apparatus with the filter or the resonator.

Owner:ROFS MICROSYST TIANJIN CO LTD

Bulk acoustic wave resonator with acoustic impedance mismatch structure, filter and electronic equipment

The invention relates to a bulk acoustic wave resonator. The bulk acoustic wave resonator comprises a substrate, an acoustic mirror, a bottom electrode disposed over the substrate, a top electrode, apiezoelectric layers arranged above the bottom electrode and between the bottom electrode and the top electrode, and an electrode support portion forming a gap at least between the piezoelectric layerand the top electrode. An overlapping region of the acoustic mirror, the bottom electrode, the piezoelectric layer, and the top electrode in the thickness direction of the resonator constitutes an effective region of the resonator. Along at least a portion of a free edge of the top electrode, the resonator is provided with an acoustic impedance mismatch structure. The invention further relates toa filter and electronic equipment with the filter.

Owner:TIANJIN UNIV +1

Bulk acoustic wave resonator with composite array quality charge, filter and electronic equipment

The invention discloses a bulk acoustic wave resonator. The bulk acoustic wave resonator comprises a substrate, an acoustic mirror, a bottom electrode, a top electrode, and a piezoelectric layer arranged between the bottom electrode and the top electrode. A mass load is arranged on the top electrode, the mass load comprises at least two array structures, and the at least two array structures comprise a first array structure and a second array structure; a first dot array is formed in the center of a first array element of the first array structure; the centers of the second array elements of the second array structure form a second dot array, the second dot array is obtained by planar rotation or planar translation relative to the first dot array, the adjacent array elements of the two array structures are spaced apart from each other, and the size of the first array element is different from the size of the second array element. The invention further discloses a filter with the resonator and electronic equipment with the filter or the resonator.

Owner:ROFS MICROSYST TIANJIN CO LTD

Bulk acoustic wave resonator with electrical isolation layer, manufacturing method of bulk acoustic wave resonator, filter and electronic equipment

The invention discloses a bulk acoustic wave resonator. The bulk acoustic wave resonator comprises a substrate, a bottom electrode, a top electrode, a piezoelectric layer disposed between the bottom electrode and the top electrode and an acoustic mirror. The resonator further comprises an electrode connecting part, an electrical isolation layer and an electrode pin; the electrode connecting part covers the electrical isolation layer, one end of the electrode connecting part is electrically connected with the top electrode, and the other end of the electrode connecting part is suitable for being electrically connected with the electrode pin; one part of the electrical isolation layer forms electrical isolation between the electrode connecting part of the resonator and the bottom electrode;and at least one part of the electrical isolation layer covers at least one part of the end surface of the piezoelectric layer and the end surface of the bottom electrode so as to form electrical isolation between the electrode connecting part and the bottom electrode. The invention further discloses a manufacturing method of the bulk acoustic wave resonator, a filter with the resonator and electronic equipment with the filter or the resonator.

Owner:ROFS MICROSYST TIANJIN CO LTD

Bulk acoustic wave resonator with rough surface, filter, and electronic device

The present invention relates to a bulk acoustic wave resonator, and the resonator comprises a substrate; an acoustic mirror; a bottom electrode disposed over the substrate; a top electrode opposed tothe bottom electrode; and a piezoelectric layer which is arranged above the bottom electrode and between the bottom electrode and the top electrode, wherein the overlapped area of the acoustic mirror, the bottom electrode, the piezoelectric layer and the top electrode in the thickness direction of the substrate is the effective area of the resonator; the resonator is adjacent to the boundary of the effective area, and an air gap is formed outside the boundary; at least one surface in the surfaces corresponding to the air gaps is a rough surface, and the roughness of the rough surface is greater than that of part of the surface around the rough surface of the part where the rough surface is located; and rare earth elements are doped in the piezoelectric layer. The invention further relatesto a filter with the resonator and electronic equipment with the filter.

Owner:TIANJIN UNIV +1

High-frequency acoustic wave device

ActiveUS7880563B2Piezoelectric/electrostrictive device manufacture/assemblyImpedence networksAcoustic waveAcoustic mirror

An acoustic wave device comprising a piezoelectric layer on an omnidirectional acoustic mirror and excitation and / or reception means on a surface of said piezoelectric layer, capable of exciting waves in a band gap of the acoustic mirror.

Owner:CENT NAT DE LA RECHERCHE SCI +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com