Bulk acoustic wave resonator with electrical isolation layer, manufacturing method of bulk acoustic wave resonator, filter and electronic equipment

A bulk acoustic wave resonator and isolation layer technology, applied in the field of bulk acoustic wave resonator and bulk acoustic wave resonator manufacturing, can solve the problem of increasing process difficulty, wafer-level device packaging complexity, reduction of electromechanical coupling coefficient, growth of single crystal materials, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

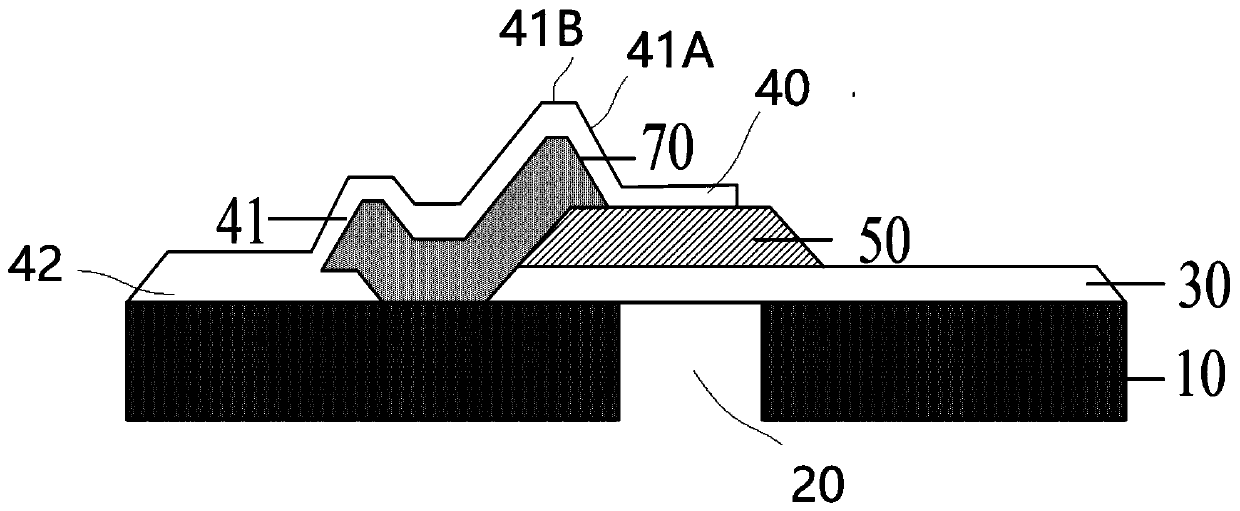

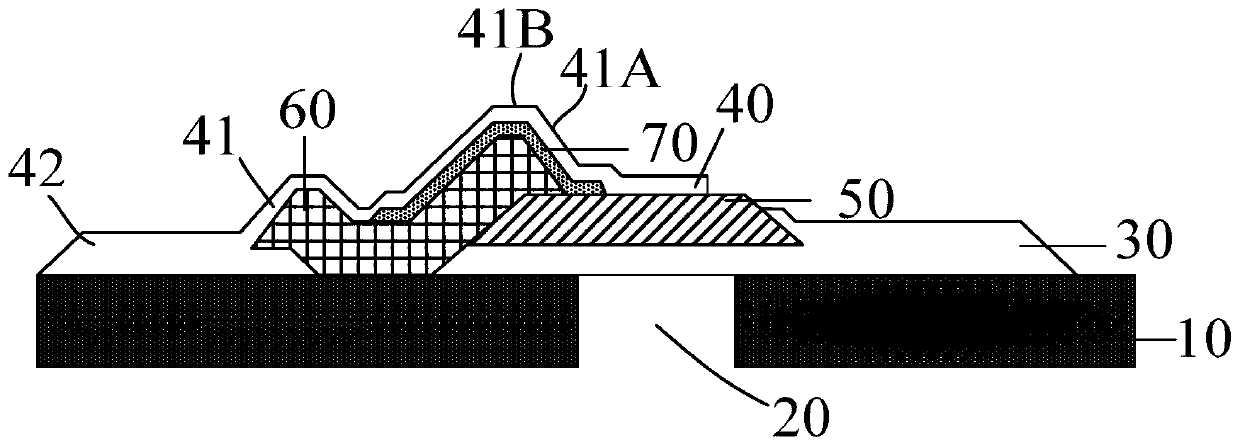

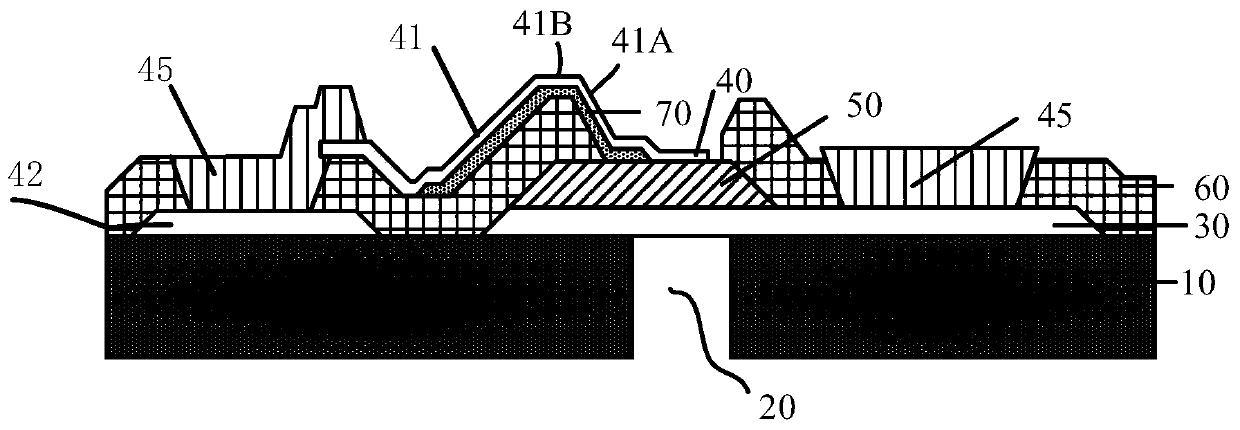

[0032] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings. In the specification, the same or similar reference numerals designate the same or similar components. The following description of the embodiments of the present invention with reference to the accompanying drawings is intended to explain the general inventive concept of the present invention, but should not be construed as a limitation of the present invention.

[0033] In the present invention, a bulk acoustic wave resonator is prepared on a single crystal piezoelectric layer with a bottom electrode obtained by directly growing a piezoelectric layer after growing the bottom electrode or by other methods (such as bonding) through a top-down processing method. , leading out the top electrode by adding an air or dielectric isolation layer. The invention can also minimize the parasitic capacitance betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com