Body wave resonator and processing method thereof

A technology for acoustic wave resonators and main parts, which is applied to electrical components, impedance networks, etc., and can solve problems such as deterioration of resonators, long dry etching time, complex processing, and increased production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

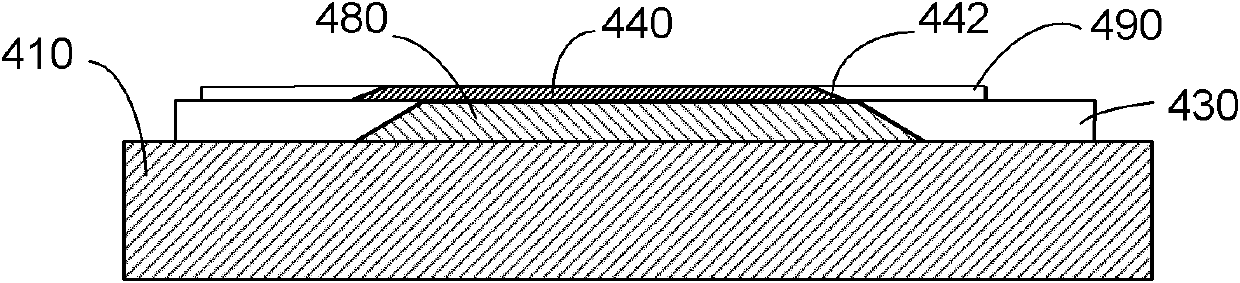

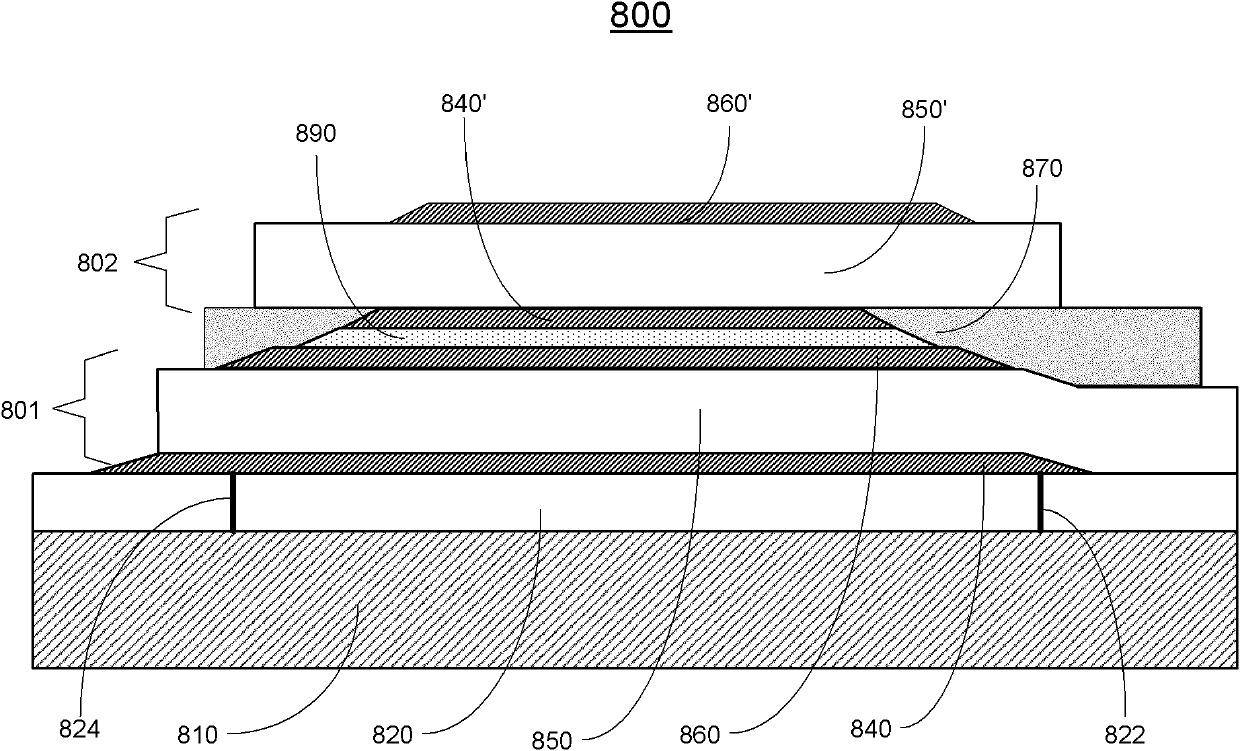

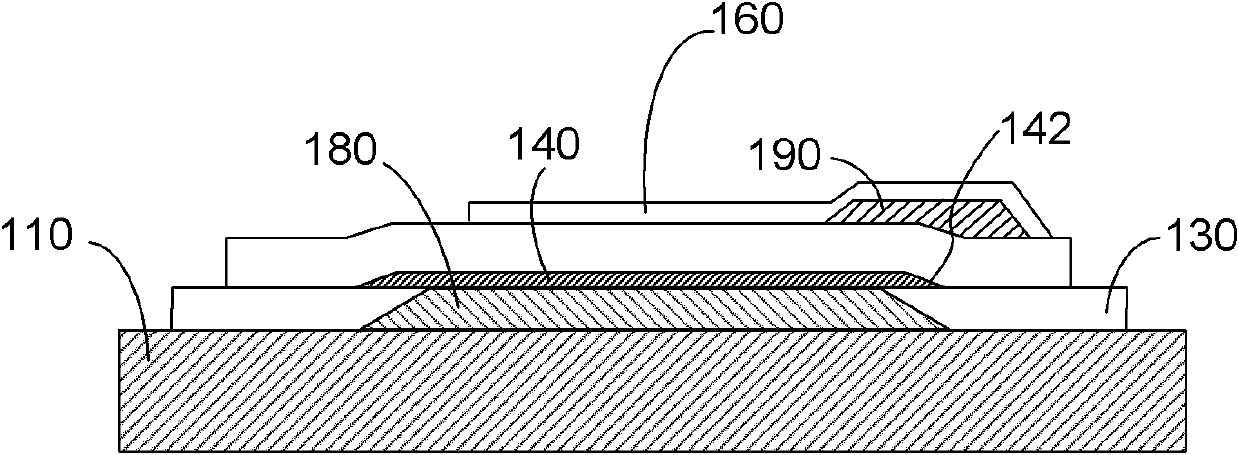

[0100] The bulk wave resonator and its processing method of the present invention will be described in detail below with reference to the embodiments and the accompanying drawings.

[0101] The bulk wave resonator and its processing method of the present invention relate to an improved and Q value of the bulk wave resonator, this resonator improves the and Q value, thereby improving the performance of the resonator and improving its processing method. with improved and Q values of the bulk wave resonator, at the sloped end face of the bottom electrode or the edge of the step, the resonant excitation part formed by the poor piezoelectric film with twisted columnar structure will contribute minimally to the electrical response of the entire resonator , and the lateral sound energy diffused into the connection will also be minimized. One form of the invention is to form an air gap between one of the two electrodes and the piezoelectric layer or fill it with a dielectric la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com