Power cable taking-up and paying-off machine

A technology for take-up and pay-off machines and power cables, which is applied in the direction of overhead lines/cable equipment, etc., can solve the problems of poor versatility of pay-off barrels, reduce the difficulty of adjustment, increase the adjustment range, and reduce labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

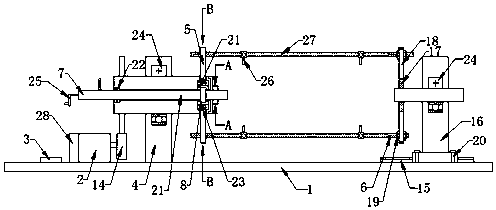

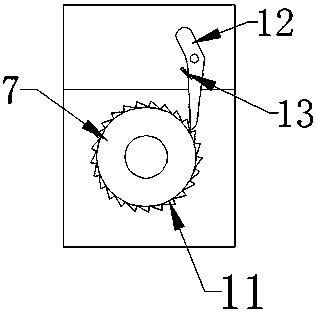

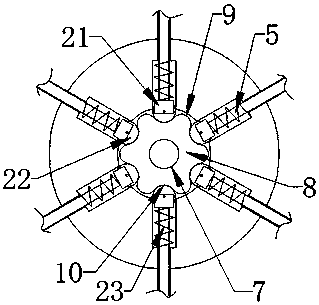

[0031] This embodiment, as the best embodiment of the present invention, discloses a power cable take-up and pay-off machine, the specific structure is as follows Figure 1 to Figure 3 As shown, it includes a frame 1, the frame 1 is provided with a connected motor 2 controller 3, and the motor 2 is provided with a motor brake 28; the frame 1 is provided with a left base 4 through rolling bearing 24 rotation, so One side of the left base 4 is provided with an end cover 30, and the left base 4 is slidably provided with an adjusting rod 7 and at least four sliding rods 5, and the adjusting rod 7 and the sliding rods 5 are respectively provided with an adjusting block 8 and a limit position. Block 21, the limit block 21 is rotated to be provided with roller 22, on the said adjusting fast 8, the supporting teeth 9 and the draw-in groove 10 are interlacedly arranged, and the said roller 22 is matched with the draw-in groove 10; The left base 4 is provided with a ratchet 11 and a paw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com