Pay-off device and method

A technology of a wire-laying device and a protection device, which is applied to measuring devices, active optical measuring devices, reference lines/planes/sectors, etc., can solve the problems of low efficiency and heavy measurement and wire-laying tasks, and achieve high efficiency, simple production, and Guarantee the effect of laying-out accuracy requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

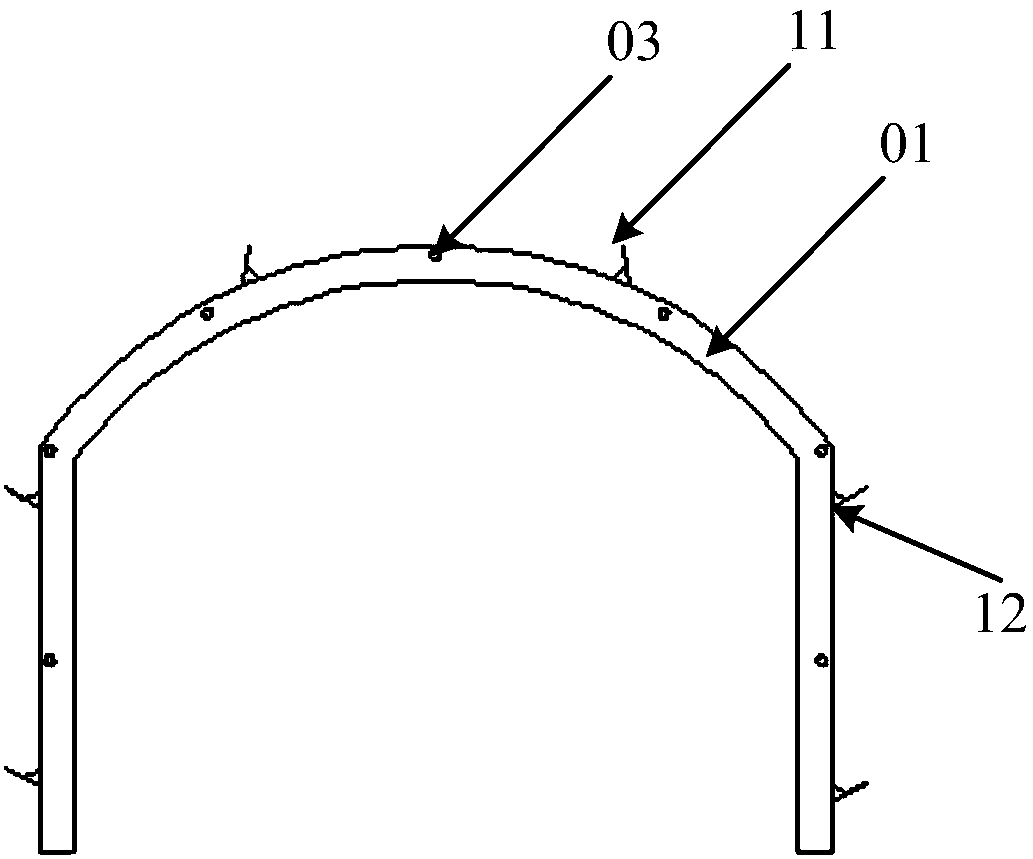

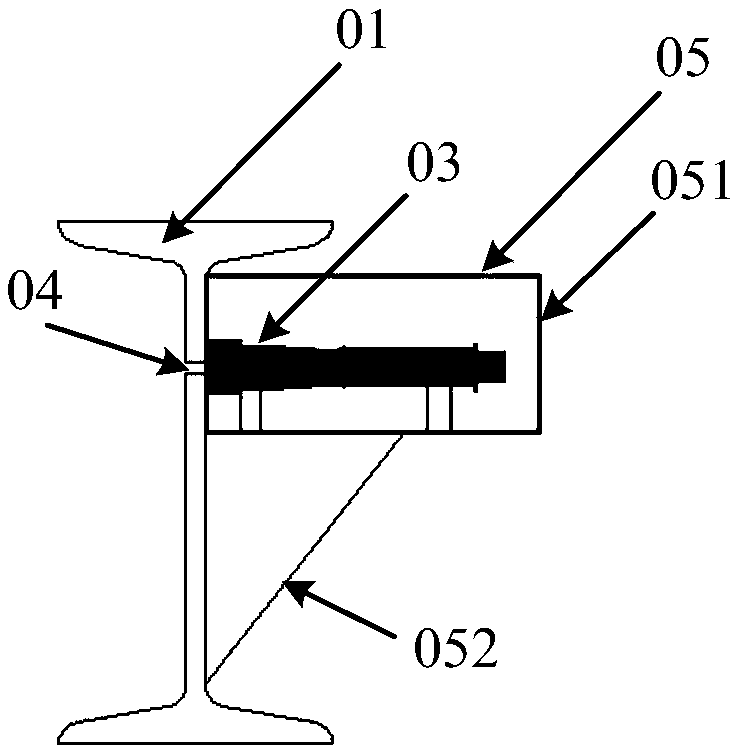

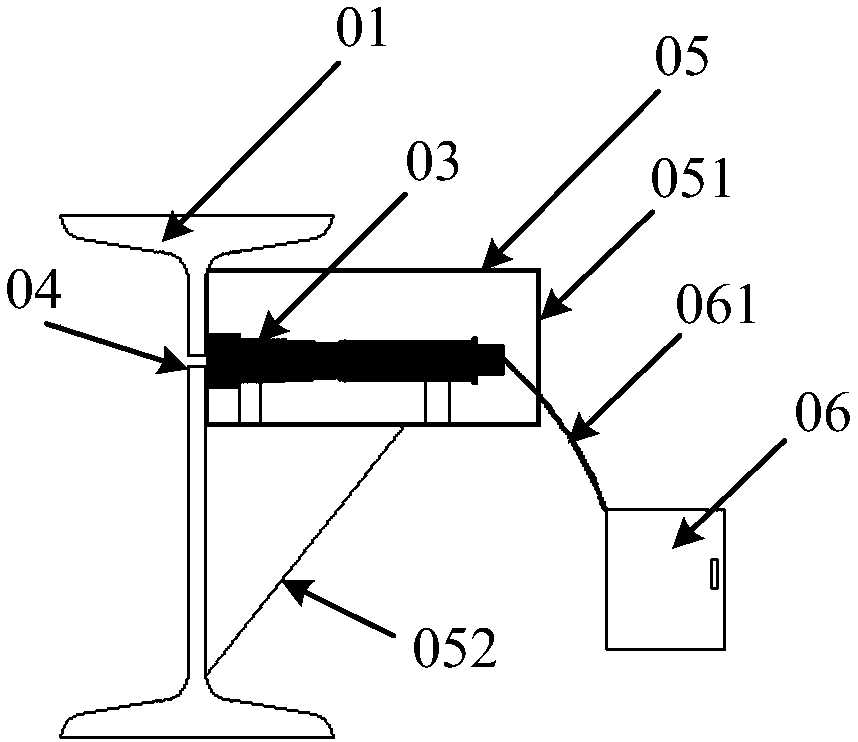

[0030] This embodiment provides a pay-off device, such as figure 1 As shown in the figure, it is used to set out the line during the tunnel construction process, that is, according to the design drawings of the tunnel, the designed tunnel is put into the excavation section according to 1:1, and then the construction is carried out according to the released line. The pay-off device in this embodiment includes:

[0031] The first arch 01 has the same outer contour as the target tunnel, where the target tunnel is the actual size of the tunnel set in the drawing, and the first arch 01 is set on the outside of the excavation section. According to the design parameters such as the slope ratio and length of the target tunnel, determine the installation position of the first arch. It is better to set the first arch 01 within the range of not less than 20m from the excavation section, and the preferred value is 30m. It is guaranteed to meet the lay-out requirements and avoid the dama...

Embodiment 2

[0041] This embodiment provides a pay-off method for using the pay-off device in Embodiment 1 to perform a pay-off operation, such as Figure 10 shown, including the following steps:

[0042] S01: Place the first arch 01 at a first distance from the excavation section 02. The first arch 01 is provided with a number of first laser transmitters 03 and first openings 10. It is better to set the first arch 01 within a range of not less than 20m from the excavation section, which can not only ensure that the requirements for laying out lines are met, but also avoid the damaging effects of blasting flying stones. In this embodiment, the first arch 01 is set at a distance of 30m from the excavation section, and is fixed by locking foot anchors 11. Seven first laser transmitters 03 are arranged on the first arch 01, and three are arranged on the top arch. , one arching point on both sides, one on each side wall 100cm away from the bottom plate, the position of the first laser transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com