Full-automatic dual-coil continuous take-up machine

A fully automatic, wire take-up technology, applied in the field of wire and cable manufacturing, can solve the problems of increasing labor intensity and unsafety of workers, reducing production line speed, reducing production efficiency, etc., to achieve low manufacturing costs, improve wire take-up efficiency, reduce The effect of manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

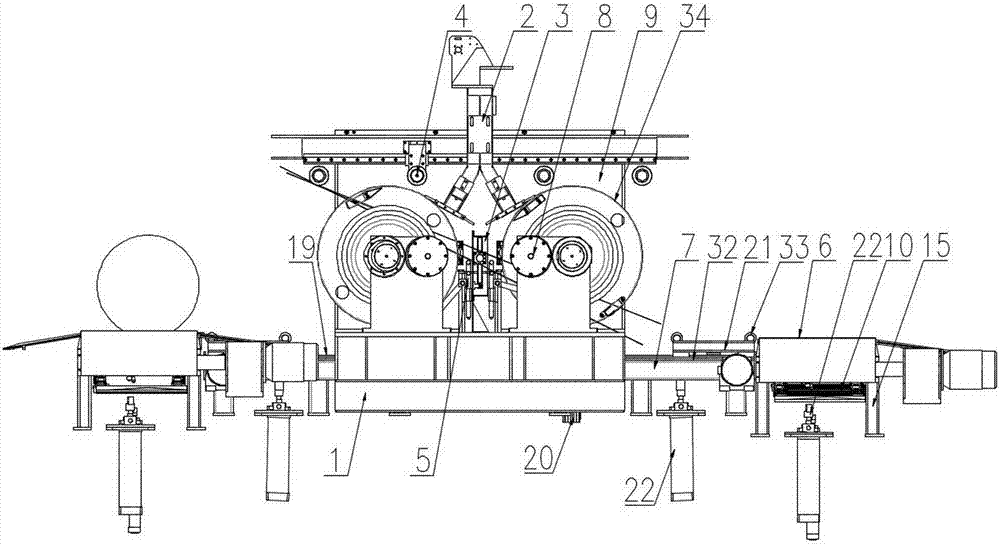

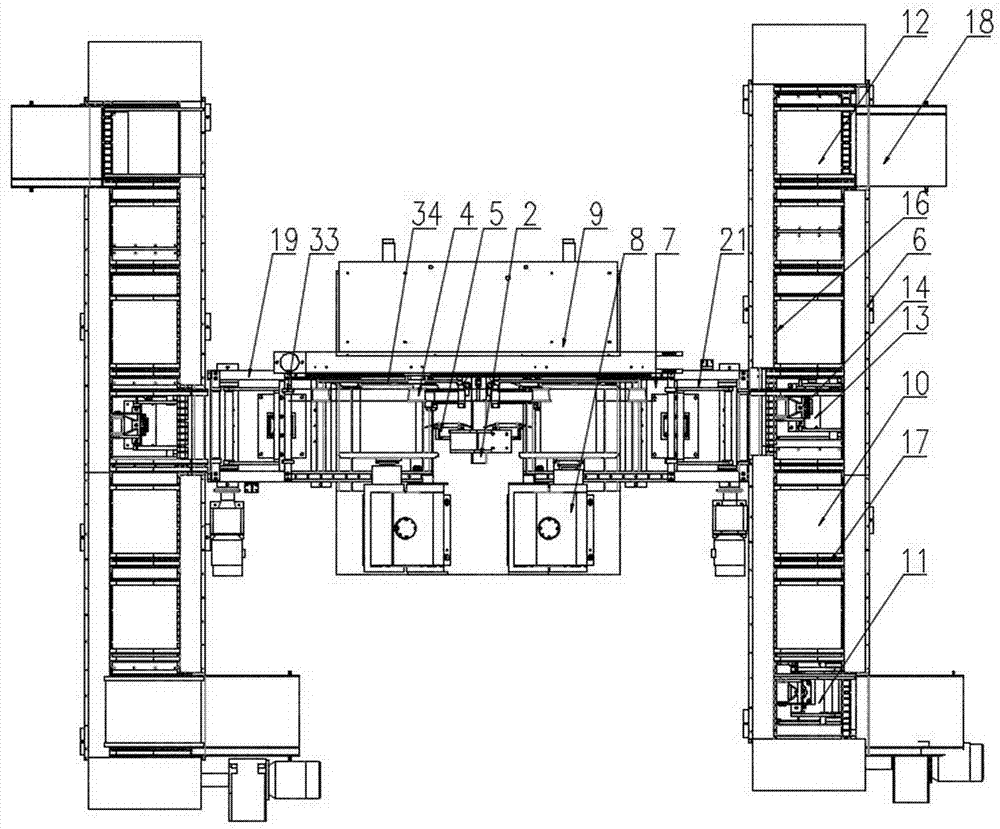

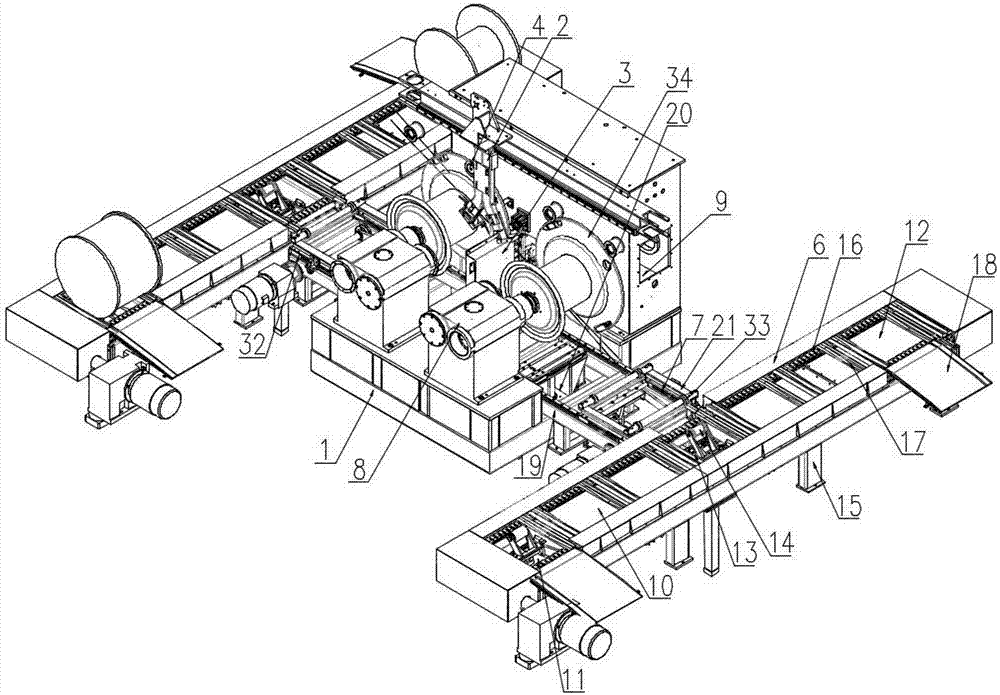

[0049] A fully automatic double-disc continuous wire take-up machine, comprising a frame 1, on which a cable reel automatic tightening device, an automatic wire arranging device 2, an automatic wire catching device 3, an automatic wire pulling device 4 and a cutting device are arranged. 5. There are two groups of automatic wire reel tightening devices, and the two groups of wire reel automatic tightening devices are symmetrically arranged on the frame 1, and the automatic wire arranging device 2 and the automatic wire pulling device 4 are both arranged on the frame 1, the automatic thread catcher 3 is arranged in the middle between the two groups of wire reel automatic tightening devices, and the cutting device 5 is arranged in the lower part between the two groups of wire reel automatic tightening devices; the frame Two sets of symmetrical automatic disk-transporting devices 6 and two symmetrical automatic disk-changing devices 7 are arranged on both sides of 1.

[0050] In t...

Embodiment 2

[0062] A fully automatic double-disc continuous wire take-up machine, comprising a frame 1, on which a cable reel automatic tightening device, an automatic wire arranging device 2, an automatic wire catching device 3, an automatic wire pulling device 4 and a cutting device are arranged. 5. There are two groups of automatic wire reel tightening devices, and the two groups of wire reel automatic tightening devices are symmetrically arranged on the frame 1, and the automatic wire arranging device 2 and the automatic wire pulling device 4 are both arranged on the frame 1, the automatic thread catcher 3 is arranged in the middle between the two groups of wire reel automatic tightening devices, and the cutting device 5 is arranged in the lower part between the two groups of wire reel automatic tightening devices; the frame Two sets of symmetrical automatic disk-transporting devices 6 and two symmetrical automatic disk-changing devices 7 are arranged on both sides of 1.

[0063] In t...

Embodiment 3

[0069]A fully automatic double-disc continuous wire take-up machine, comprising a frame 1, on which a cable reel automatic tightening device, an automatic wire arranging device 2, an automatic wire catching device 3, an automatic wire pulling device 4 and a cutting device are arranged. 5. There are two groups of automatic wire reel tightening devices, and the two groups of wire reel automatic tightening devices are symmetrically arranged on the frame 1, and the automatic wire arranging device 2 and the automatic wire pulling device 4 are both arranged on the frame 1, the automatic thread catcher 3 is arranged in the middle between the two groups of wire reel automatic tightening devices, and the cutting device 5 is arranged in the lower part between the two groups of wire reel automatic tightening devices; the frame Two sets of symmetrical automatic disk-transporting devices 6 and two symmetrical automatic disk-changing devices 7 are arranged on both sides of 1.

[0070] In th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com