Automatic wire take-up device for electric power industry

A wire take-up device and power technology, applied in the field of power equipment, can solve the problems of easy winding of cables, non-uniform winding, affecting the next use, etc., and achieve the effects of simple structure, convenient operation, and convenient movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

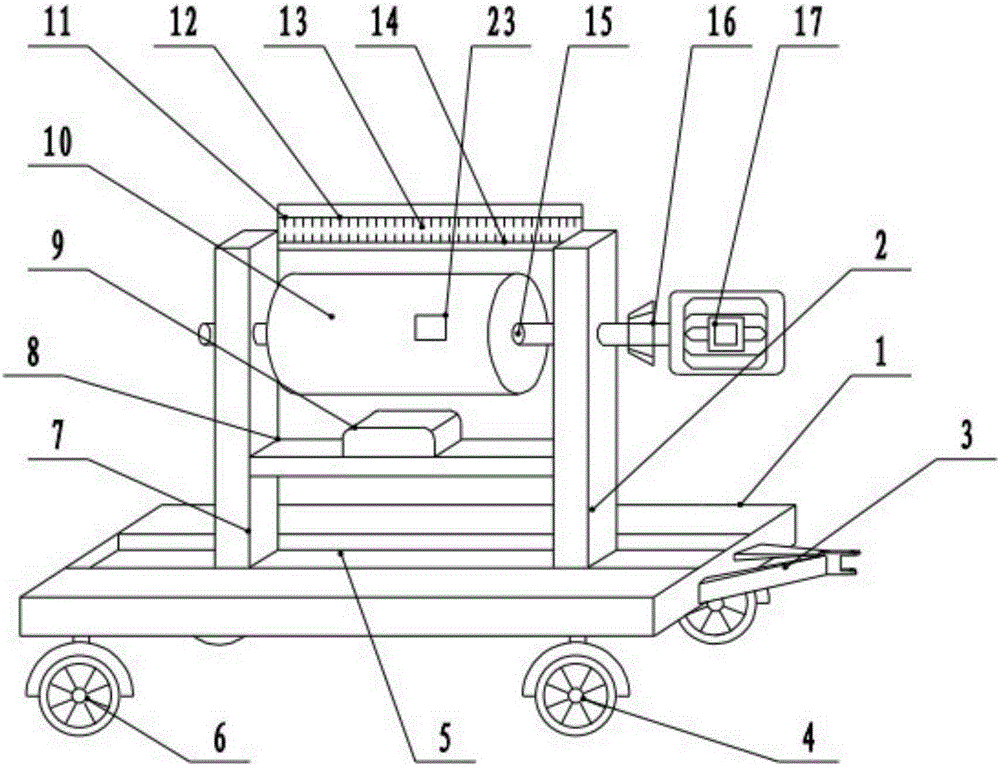

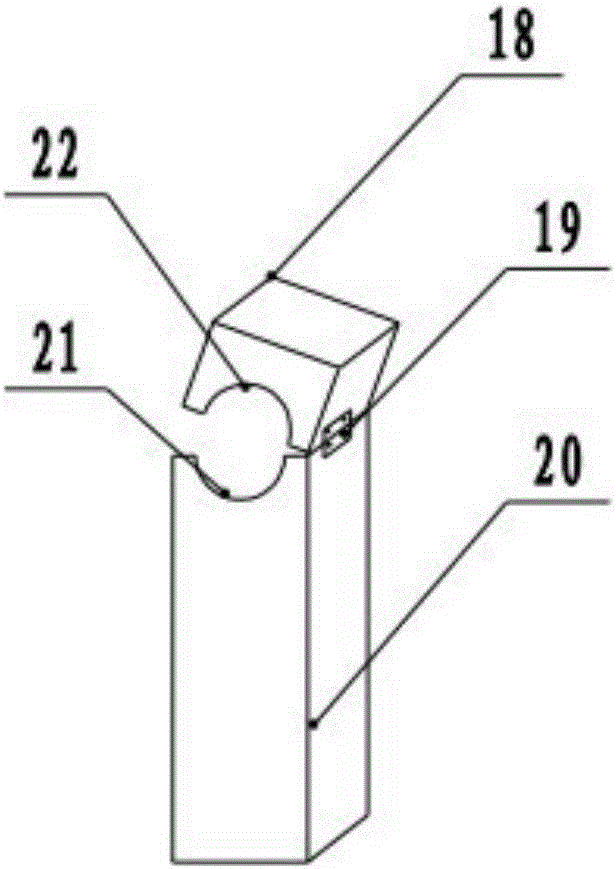

[0016] The specific implementation manner of the present invention will be described in further detail below through the description of the best embodiment with reference to the accompanying drawings.

[0017] Such as figure 1 and 2 As shown, the automatic take-up device for electric power includes a support device and a take-up device. The support device includes a support base 1 and a support frame 7. The support base 1 is provided with a slideway 5, and the bottom of the support frame 7 is embedded in the slideway 5. The support frame 7 includes a support column 2 and a support plate 8. The support plate 8 is provided with a motor I9; the take-up device includes a winding frame 10, a rotating shaft 15 and a motor II 17. Motor II17 at one end.

[0018] When in use, put one end of the cable on the winding frame 10, start the motor I9 and motor II17, the motor II17 drives the rotating shaft 15 to rotate, so that the cable is wound on the winding frame 10, and the motor I9 dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com