Automatic take-up machine of fishing-net weaving machine shuttle reel

A loom shuttle and wire take-up technology, applied in the field of fishing net line take-up, can solve the problems of wasting labor, increasing production costs, and low take-up efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below through specific examples.

[0033] The downstream and upstream mentioned in the present invention are determined by the running state of the fishing net line. The position that the fishing net line passes first is the upstream, and the position that passes through it later is the downstream.

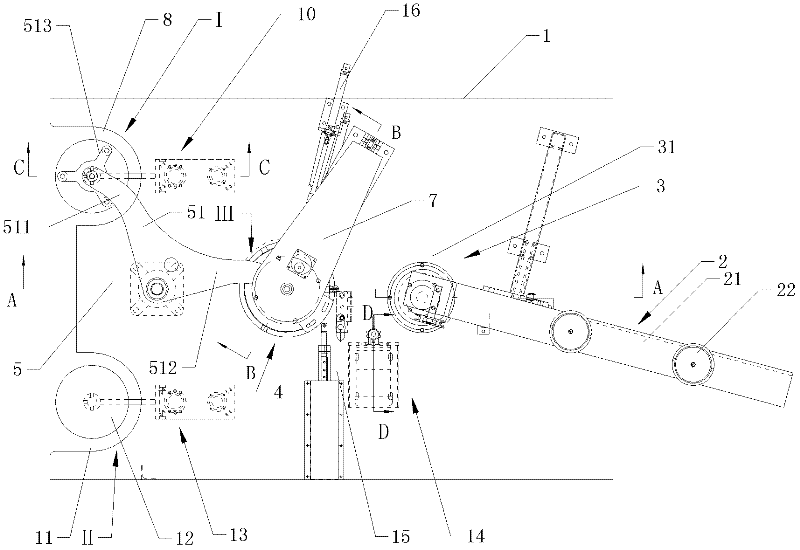

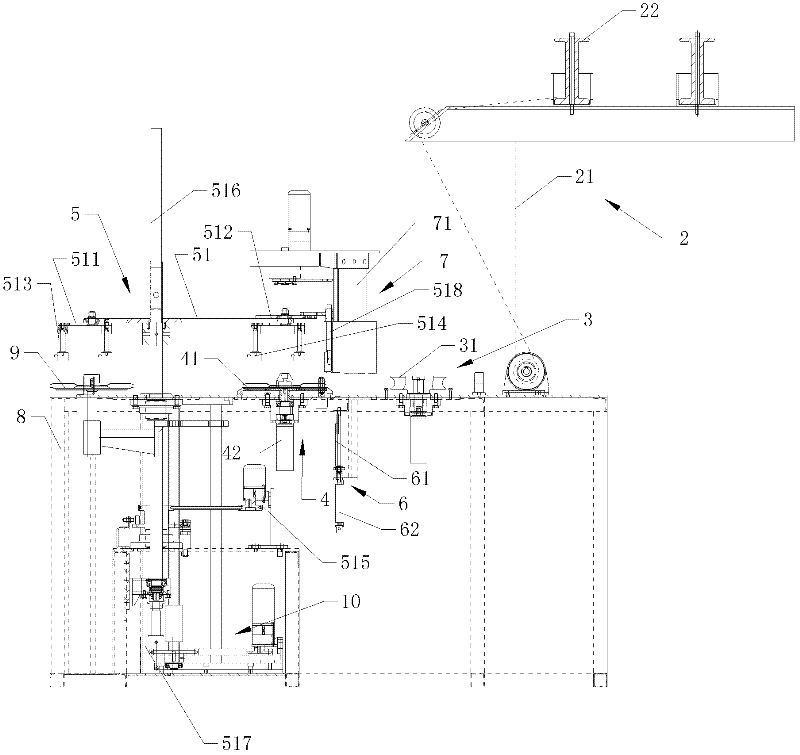

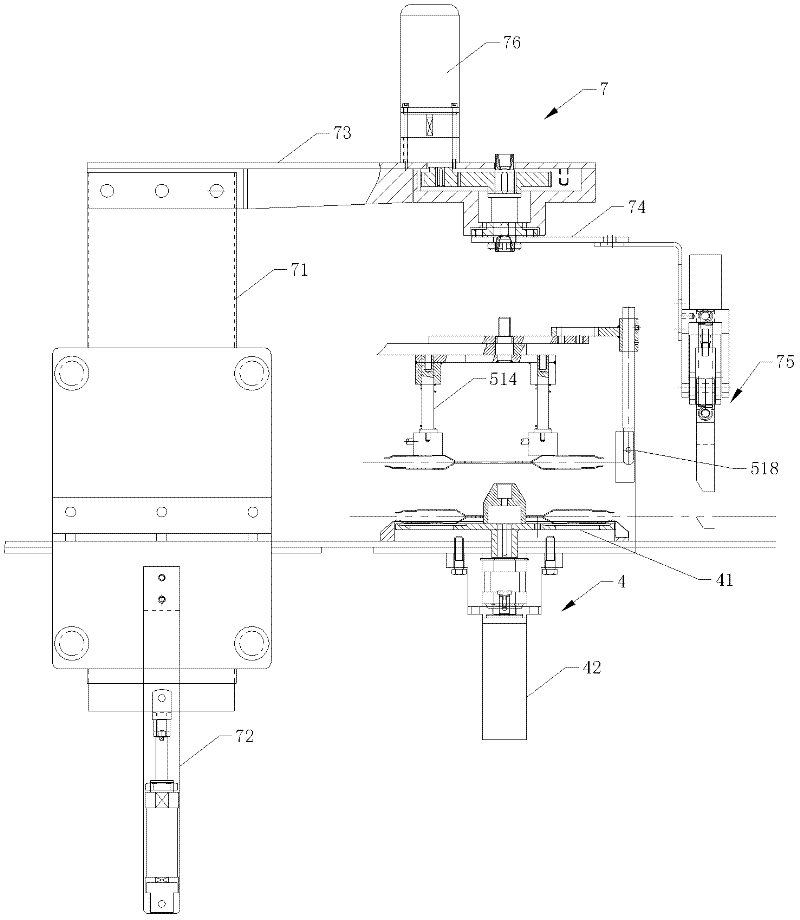

[0034] A fishing net loom shuttle automatic take-up machine, such as Figure 1 to Figure 6 As shown, including frame 1, said fishing net loom shuttle automatic take-up machine also includes

[0035] Lead wire device 2, described lead wire device 2 comprises the lead frame 21 that is fixed on the frame 1 and the pay-off reel 22 that is rotatably installed on the lead frame 21; Wherein in order to save operation, at least two pay-off reels are installed on the frame 1 22. In this way, the buffer can be replaced to ensure the smooth progress of production.

[0036] Traction device 3, described traction device 3 is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com